Electrothermal composite material with three-dimensional filling structure

A composite material and electric heating technology, applied in the field of textile processing, can solve the problems of slowing down the heating speed, emission, poor impact resistance of the electric heating sheet, etc., and achieve the effects of fast weaving speed, good integrity and high impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

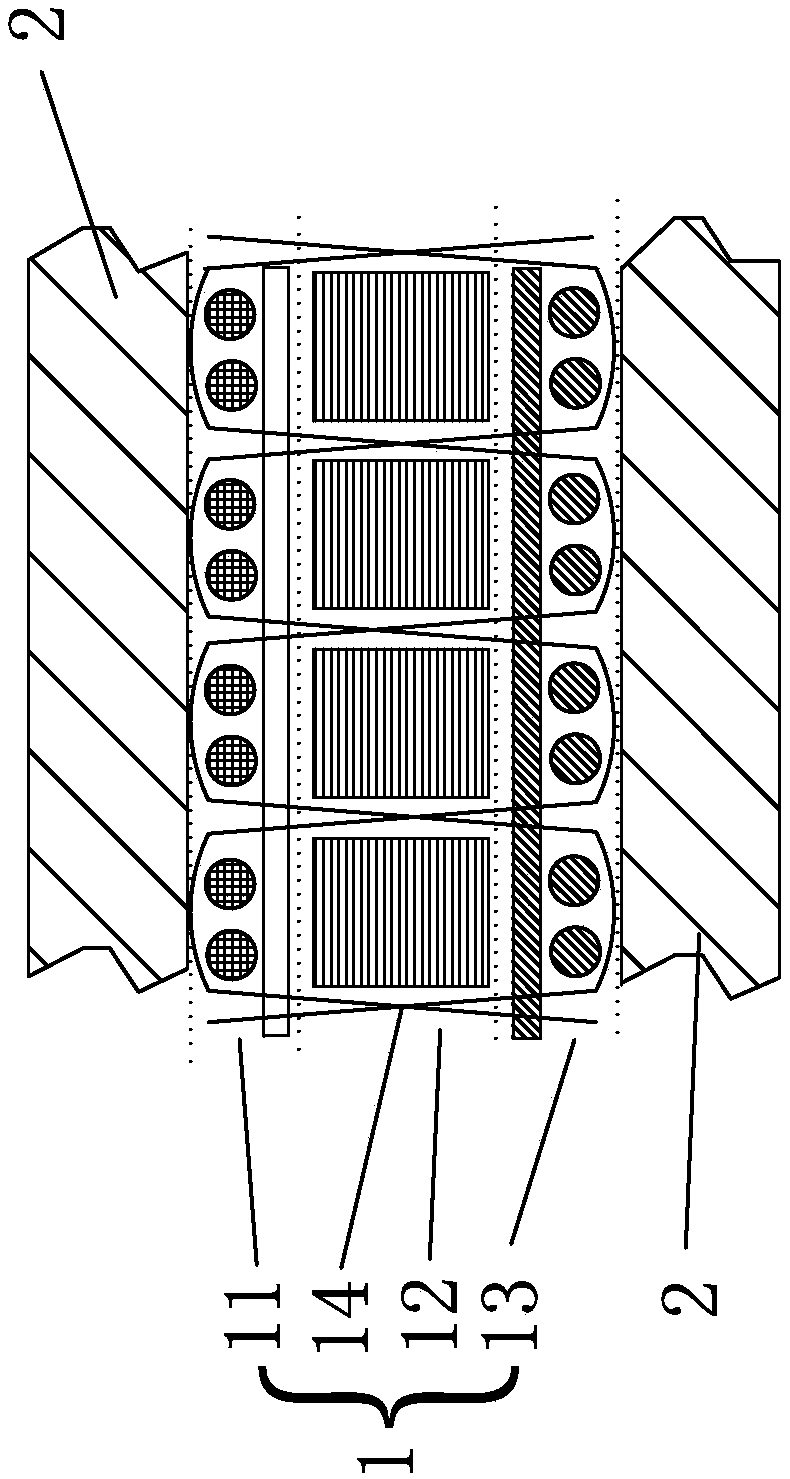

[0029] Such as figure 1 The three-dimensional filling structure electrothermal composite material shown includes a fabric layer 1 with a three-dimensional fabric structure and a resin layer 2 compounded on the above fabric layer, and the fabric layer 1 faces the ground when it is placed flat on the ground under normal use. One side is the lower side, and the side of the fabric layer 1 facing away from the ground is the upper side. The fabric layer 1 includes an electric heating layer 11, a heat insulating layer 12, a support layer 13 and a binding yarn 14, and the electric heating layer 11, heat insulation layer 12 and support The layers 13 are stacked in parallel in the vertical direction, the heat insulation layer 12 is located below the electric heating layer 11, the supporting layer 13 is arranged below the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com