Cutting method of Z-shaped notch of H-shaped steel

A cutting method, H-beam technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

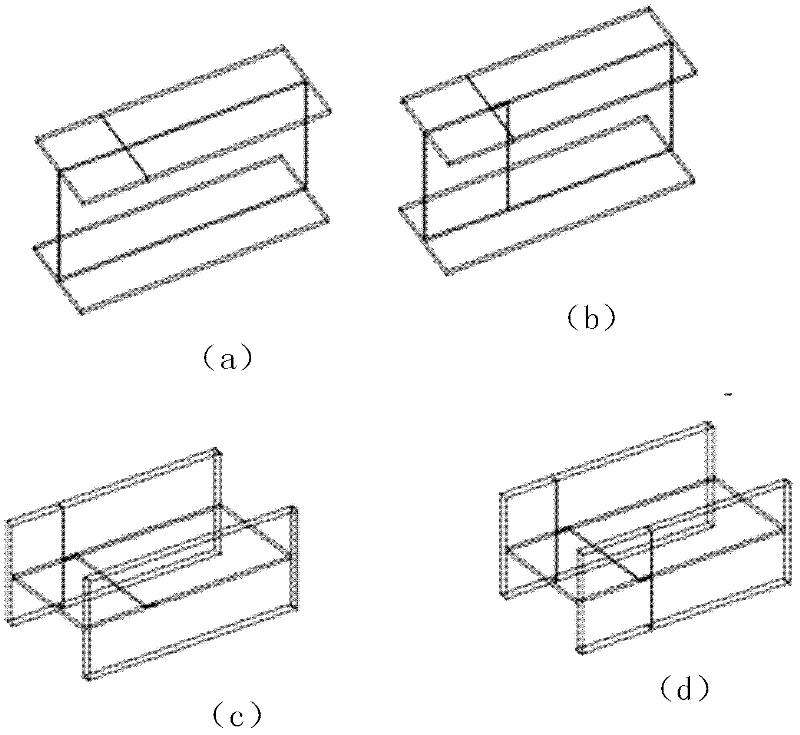

[0029] Embodiment 1. Cutting method 1 of Z-shaped incision of H-shaped steel. The cutting method is attached figure 2 (a)- figure 2 (d) shown.

[0030] Step 1, as attached figure 2 As shown in (a), for the H-shaped steel placed in the horizontal direction of the web, cut the web of the H-shaped steel according to the middle trimming edge of the Z-shaped incision (that is, the vertical in the Z stroke).

[0031] Specifically, the present invention should determine the specific position of the middle trimming edge of the Z-shaped slit according to the length of the actual required H-shaped steel, such as for a 12-meter-long H-shaped steel, it needs to be cut into 7 meters long according to actual construction requirements and two sections of 5-meter-long H-shaped steel with Z-shaped cuts, so that the intersection of 7 meters and 5 meters of the web of the 12-meter-long H-shaped steel is the specific position of the middle trimming.

[0032] The present invention can be cu...

Embodiment 2

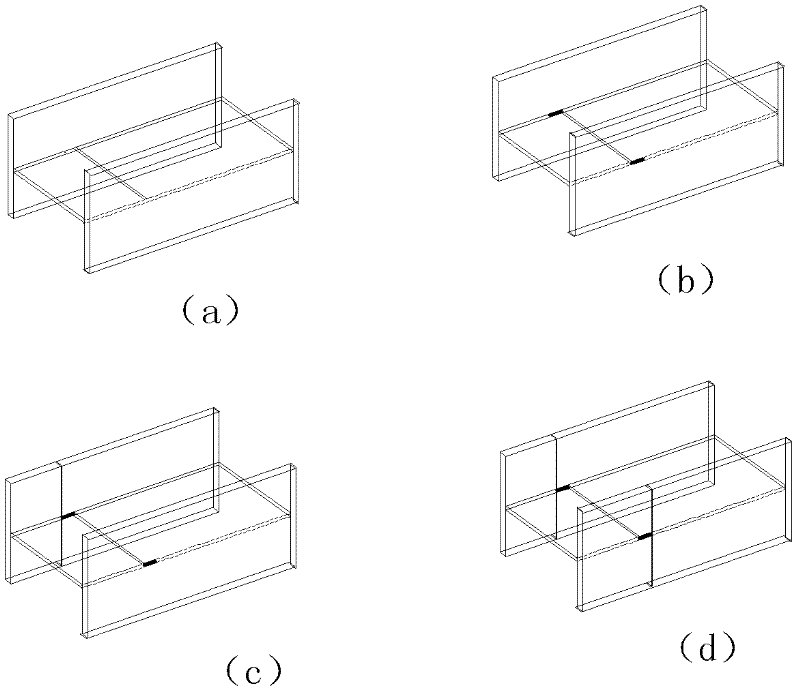

[0039] Embodiment 2, the cutting method 2 of the Z-shaped incision of the H-shaped steel.

[0040] This embodiment is basically the same as the first embodiment above, and the difference includes that the execution order of the steps in this embodiment is different from that in the first embodiment, that is, in this embodiment, the part of the connection between the web and the wing is peeled off first, Then cut through the web, and finally cut the flanges on both sides, specifically:

[0041] Step 1. For the H-shaped steel placed in the horizontal direction of the web, cut the joints between the web of the H-shaped steel and the flanges on both sides according to the two sides of the Z-shaped incision (that is, the two horizontal lines in the Z stroke) to peel off Partial connection of the web and side flanges.

[0042] Specifically, for one of the trimming edges on both sides, the joint between the web and the flange of the H-shaped steel is cut from the pre-cutting point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com