A casting electrode material and preparation method thereof

A technology for electrode materials and raw materials, applied in the field of casting electrode materials and preparation, can solve the problems of low negative working potential of aluminum alloy anode materials, and achieve the effects of facilitating industrial production, improving electrochemical performance, and negative working potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

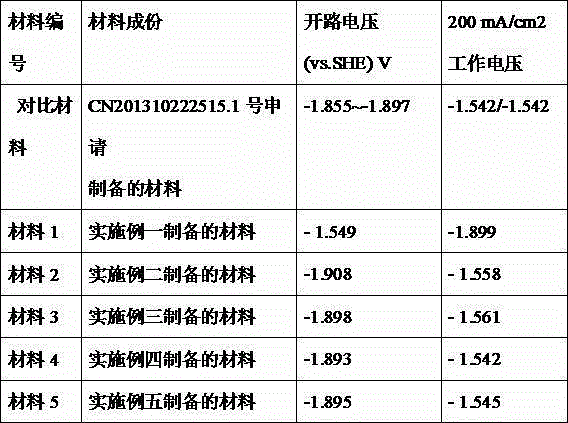

Embodiment 1

[0026] In the cast electrode material of the present invention, the weight percentage of each component is: Sc0.1%, Th0.03%, As0.04%, Fe0.3%, Os0.02%, Se1%, and the rest is Mg.

[0027] The preparation method of the cast electrode material of the present invention includes the following steps:

[0028] 1) First, carry out the ingredients according to the above ingredients, the raw materials Sc, Th, As, Fe, Os, Se, Mg are added in the form of pure substances, and the purity is greater than 99.9%;

[0029] 2) Use a crucible resistance furnace to smelt the alloy raw materials. First heat the crucible to 450°C, then evenly sprinkle 3% of the alloy raw material weight on the crucible wall and bottom with magnesium flux; then put the alloy raw materials into the crucible, and then Sprinkle magnesium flux accounting for 0.8% of the alloy raw material weight on the raw material, and then heat the crucible. After the alloy raw materials in the crucible are all melted, remove the slag on the l...

Embodiment 2

[0032] In the cast electrode material of the present invention, the weight percentage of each component is: Sc0.3%, Th0.05%, As0.08%, Fe0.5%, Os0.04%, Se2%, and the rest is Mg.

[0033] The preparation method of the cast electrode material of the present invention includes the following steps:

[0034] 1) First, carry out the ingredients according to the above ingredients, the raw materials Sc, Th, As, Fe, Os, Se, Mg are added in the form of pure substances, and the purity is greater than 99.9%;

[0035] 2) Use a crucible resistance furnace to smelt the alloy raw materials. First heat the crucible to 500°C, and then evenly sprinkle 5% of the alloy raw material weight on the wall and bottom of the crucible with magnesium flux; then put the alloy raw materials into the crucible, and then Sprinkle magnesium flux accounting for 1.5% of the alloy raw material weight on the raw material, and then heat the crucible. After the alloy raw materials in the crucible are all melted, remove the sl...

Embodiment 3

[0038] In the cast electrode material of the present invention, the weight percentage of each component is: Sc0.2%, Th0.04%, As0.06%, Fe0.4%, Os0.03%, Se1.5%, and the rest is Mg.

[0039] The preparation method of the cast electrode material of the present invention includes the following steps:

[0040] 1) First, carry out the ingredients according to the above ingredients, the raw materials Sc, Th, As, Fe, Os, Se, Mg are added in the form of pure substances, and the purity is greater than 99.9%;

[0041] 2) Use a crucible resistance furnace to smelt the alloy raw materials, first heat the crucible to 475°C, and then evenly sprinkle 4% of the alloy raw material weight on the wall and bottom of the crucible with magnesium flux; then put the alloy raw materials into the crucible, and then Sprinkle 1.1% of the alloy raw material weight with magnesium flux on the raw material, and then heat the crucible. After the alloy raw materials in the crucible are all melted, remove the slag on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com