A kind of super-yellowing-resistant high-hardness UV full-bright transparent topcoat and preparation method thereof

A transparent topcoat and high hardness technology, applied in the field of UV paint, can solve the problems of poor yellowing resistance, affecting the decorative effect of 3D printing patterns, and being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

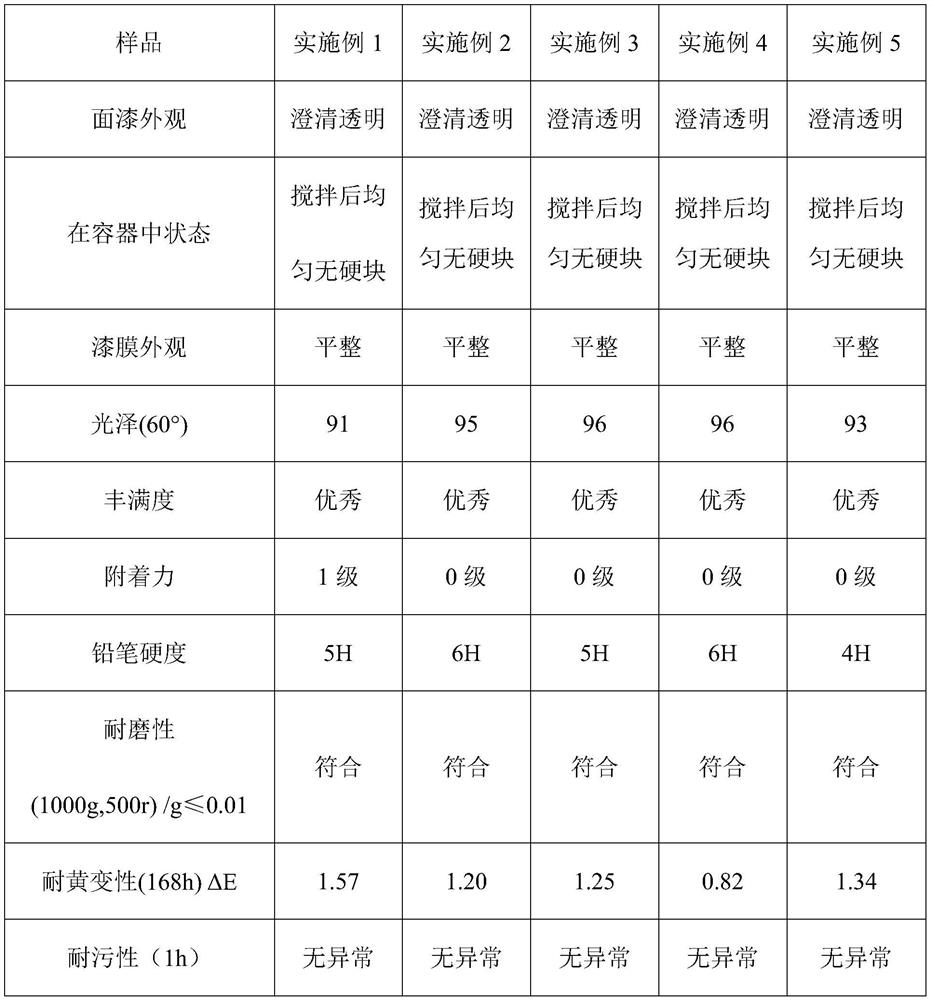

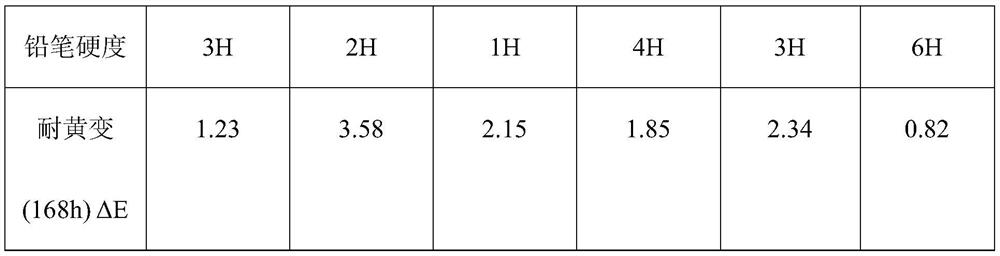

Examples

Embodiment 1

[0041] A kind of super-yellowing-resistant high-hardness UV full-bright transparent topcoat of the present embodiment is made up of the following raw materials in parts by weight:

[0042] 20 parts of bisphenol A epoxy acrylate;

[0043] 10 parts of amino-modified epoxy acrylate;

[0044] 0.65 parts of isobornyl acrylate;

[0045] 6.5 parts of neopentyl glycol diacrylate;

[0046] 13 parts of three (2-hydroxyethyl) isocyanuric acid triacrylates;

[0047] 3 parts of photoinitiator;

[0048] 0.2 part of defoamer;

[0049] 0.3 parts of anti-settling agent;

[0050] Among them, the amino-modified epoxy acrylate is 6100D-80 produced by Jiangmen Hengguang New Material Co., Ltd.;

[0051] Wherein, the photoinitiator is 2-hydroxyl-methylphenylpropane-1-one.

[0052] The preparation method of the super-yellowing-resistant high-hardness UV full-bright transparent topcoat of the present embodiment comprises the following steps:

[0053] Step 1: adding the bisphenol A epoxy acryla...

Embodiment 2

[0057] A kind of super-yellowing-resistant high-hardness UV full-bright transparent topcoat of the present embodiment is made up of the following raw materials in parts by weight:

[0058] 25 parts of bisphenol A epoxy acrylate;

[0059]16 parts of amino-modified epoxy acrylate;

[0060] 3.6 parts of isobornyl acrylate;

[0061] 9 parts of neopentyl glycol diacrylate;

[0062] 13.4 parts of three (2-hydroxyethyl) isocyanuric acid triacrylates;

[0063] 3.6 parts of photoinitiator;

[0064] 0.3 part of defoamer;

[0065] Wetting agent 0.4 parts;

[0066] Dispersant 0.5 parts.

[0067] Among them, the amino-modified epoxy acrylate is 6100D-80 produced by Jiangmen Hengguang New Material Co., Ltd.;

[0068] Wherein, the photoinitiator is composed of 2-hydroxy-methylphenylpropan-1-one and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide in a mass ratio of 1:0.2.

[0069] Refer to Example 1 for the preparation method of the super-yellowing-resistant high-hardness UV full-brigh...

Embodiment 3

[0071] A kind of super-yellowing-resistant high-hardness UV full-bright transparent topcoat of the present embodiment is made up of the following raw materials in parts by weight:

[0072] 30 parts of bisphenol A epoxy acrylate;

[0073] 18 parts of amino-modified epoxy acrylate;

[0074] 2.7 parts of isobornyl acrylate;

[0075] 13.5 parts of neopentyl glycol diacrylate;

[0076] 13.8 parts of three (2-hydroxyethyl) isocyanuric acid triacrylates;

[0077] 4 parts of photoinitiator;

[0078] 0.3 part of defoamer;

[0079] Wetting agent 0.4 parts;

[0080] Dispersant 0.8 parts.

[0081] Among them, the amine-modified epoxy acrylate is Yatumei YTM2087 produced by Guangdong Libang Changrunfa Technology Materials Co., Ltd.;

[0082] Wherein, the photoinitiator is composed of 2-hydroxy-methylphenylpropane-1-one and 1-hydroxy-cyclohexyl-phenyl ketone in a mass ratio of 1:0.5.

[0083] Refer to Example 1 for the preparation method of the super-yellowing-resistant high-hardnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com