A High Temperature Resistant Glass Fiber Reinforced Polypropylene Composite Material

A composite material, polypropylene technology, applied in the field of glass fiber reinforced polypropylene composite materials, can solve the problems of poor impact performance, poor effect, easy cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

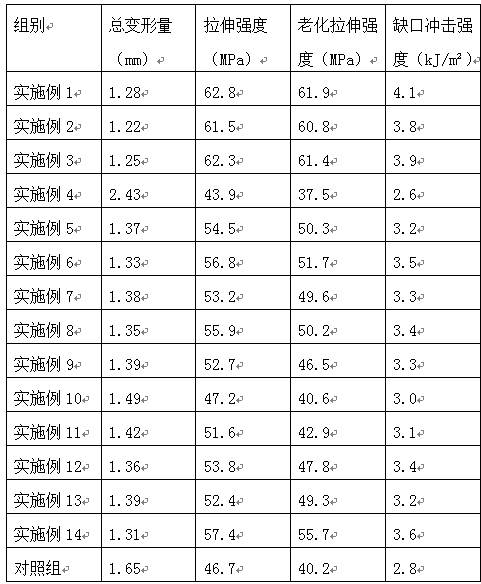

Examples

Embodiment 1

[0023] A high temperature-resistant glass fiber reinforced polypropylene composite material, which includes the following raw materials in parts by weight: 70 parts of polypropylene, 15 parts of high-density low-pressure polyethylene, 8 parts of alkali-free glass fiber, 18 parts of modified basalt fiber, polypropylene 5 parts of grafted maleic anhydride, 1.5 parts of sodium stearate, 1.2 parts of wollastonite powder, 2.5 parts of silane coupling agent;

[0024] The preparation method of the modified basalt modified fiber comprises the following steps:

[0025] (1) Soak basalt fibers in a nitric acid solution with a mass concentration of 7% for 15 minutes, then rinse with deionized water until neutral, and dry until the water content is lower than 15% for later use;

[0026] (2) In parts by weight, put 25 parts of the above-mentioned dried basalt fiber, 2 parts of ginger essential oil, 6.5 parts of 2,3-diamino-2-butenedinitrile, and 2 parts of sulfonated polyacrylamide in a bal...

Embodiment 2

[0035]A high temperature-resistant glass fiber reinforced polypropylene composite material, which includes the following raw materials in parts by weight: 65 parts of polypropylene, 12 parts of high-density low-pressure polyethylene, 6 parts of alkali-free glass fiber, 20 parts of modified basalt fiber, polypropylene 4 parts of grafted maleic anhydride, 2 parts of sodium stearate, 0.8 parts of wollastonite powder, 3 parts of silane coupling agent;

[0036] The preparation method of the modified basalt modified fiber comprises the following steps:

[0037] (1) Soak the basalt fibers in a nitric acid solution with a mass concentration of 8% for 20 minutes, then rinse with deionized water until neutral, and dry until the water content is lower than 15% for later use;

[0038] (2) In parts by weight, put 22 parts of the above dried basalt fiber, 3 parts of ginger essential oil, 6.8 parts of 2,3-diamino-2-butenedinitrile, and 1.5 parts of sulfonated polyacrylamide in a ball mill ta...

Embodiment 3

[0047] A high-temperature-resistant glass fiber reinforced polypropylene composite material, which includes the following raw materials in parts by weight: 75 parts of polypropylene, 18 parts of high-density low-pressure polyethylene, 10 parts of alkali-free glass fiber, 16 parts of modified basalt fiber, polypropylene 6 parts of grafted maleic anhydride, 1 part of sodium stearate, 1.6 parts of wollastonite powder, 2 parts of silane coupling agent;

[0048] The preparation method of the modified basalt modified fiber comprises the following steps:

[0049] (1) Soak the basalt fibers in a nitric acid solution with a mass concentration of 6% for 10 minutes, then rinse with deionized water until neutral, and dry until the water content is lower than 15% for later use;

[0050] (2) In parts by weight, put 28 parts of the above-mentioned dried basalt fiber, 1 part of ginger essential oil, 6.2 parts of 2,3-diamino-2-butenedinitrile, and 2.5 parts of sulfonated polyacrylamide in a ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com