Display substrate, preparation method thereof and display device

A technology for display substrates and display areas, which is applied in the photoplate-making process of patterned surfaces, optical mechanical equipment, transportation and packaging, etc., can solve problems such as cracks, cracks, and performance impact of display devices, and achieve the best display effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Aiming at the present situation that cracks are easily caused in the non-display area and the cracks are transmitted to the display area to affect the display performance of the display area, the present invention provides a display substrate, which has better impact resistance, so it can effectively improve the performance of the display substrate. Overall performance for a better display.

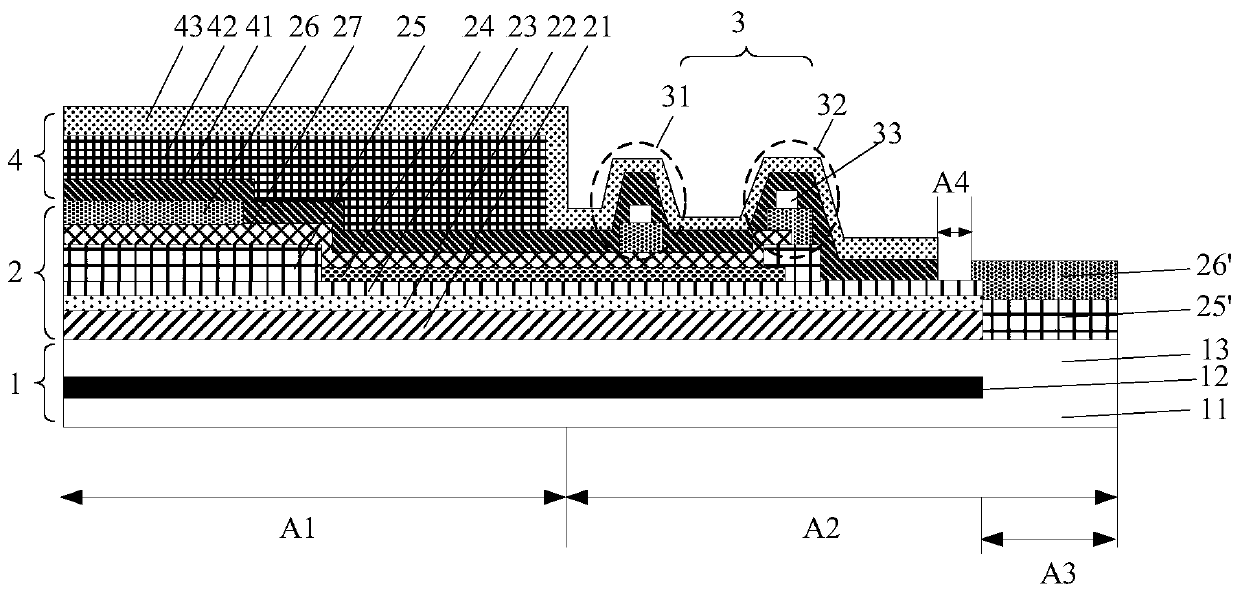

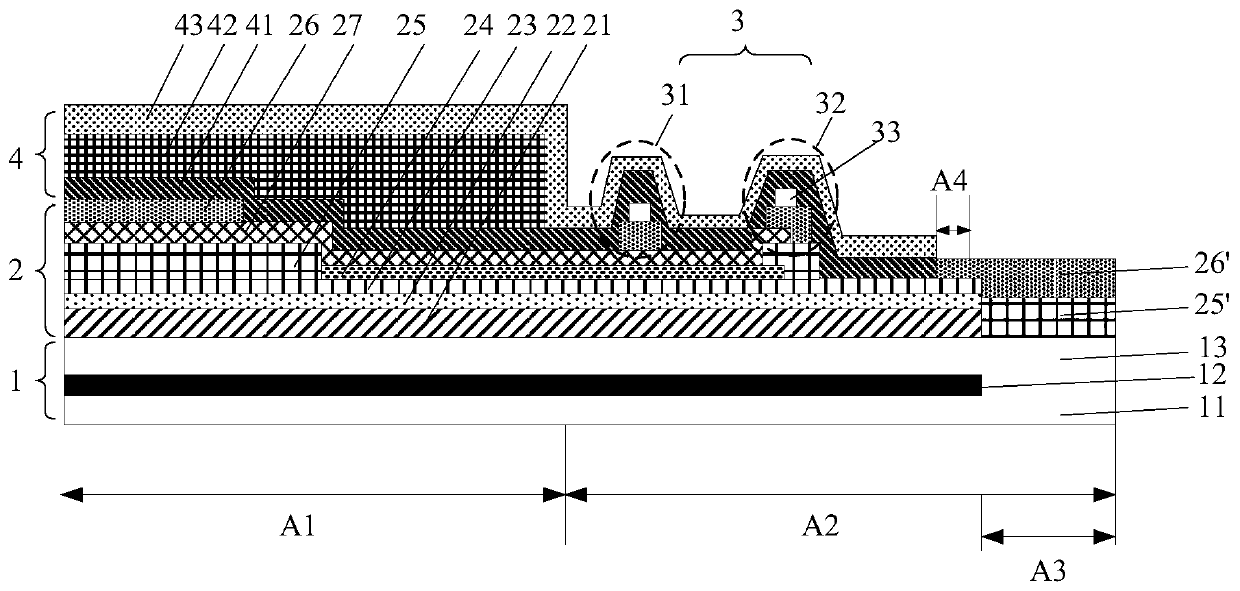

[0049] Such as figure 1 As shown, the display substrate includes a substrate 1. The display substrate is divided into a display area A1 and a non-display area A2 located on the periphery of the display area A1. The display area A1 has a plurality of pixel areas, and each pixel area is provided with a pixel structure 2. ( figure 1Only a part of the pixel structure 2 close to the non-display area A2 is shown in the figure), the pixel structure 2 includes a plurality of stacked organic film layers and inorganic film layers, and the area near the edge of the non-display area A2 is the...

Embodiment 2

[0067] This embodiment provides a method for preparing a display substrate, which can be used to form the display substrate of Embodiment 1. As mentioned above, the display substrate includes a substrate 1, and the display substrate is divided into a display area A1 and a non-display area A2 located on the periphery of the display area A1. The display area A1 has a plurality of pixel areas, and each pixel area is provided with a pixel structure 2. The pixel structure 2 includes a plurality of stacked organic film layers and inorganic film layers.

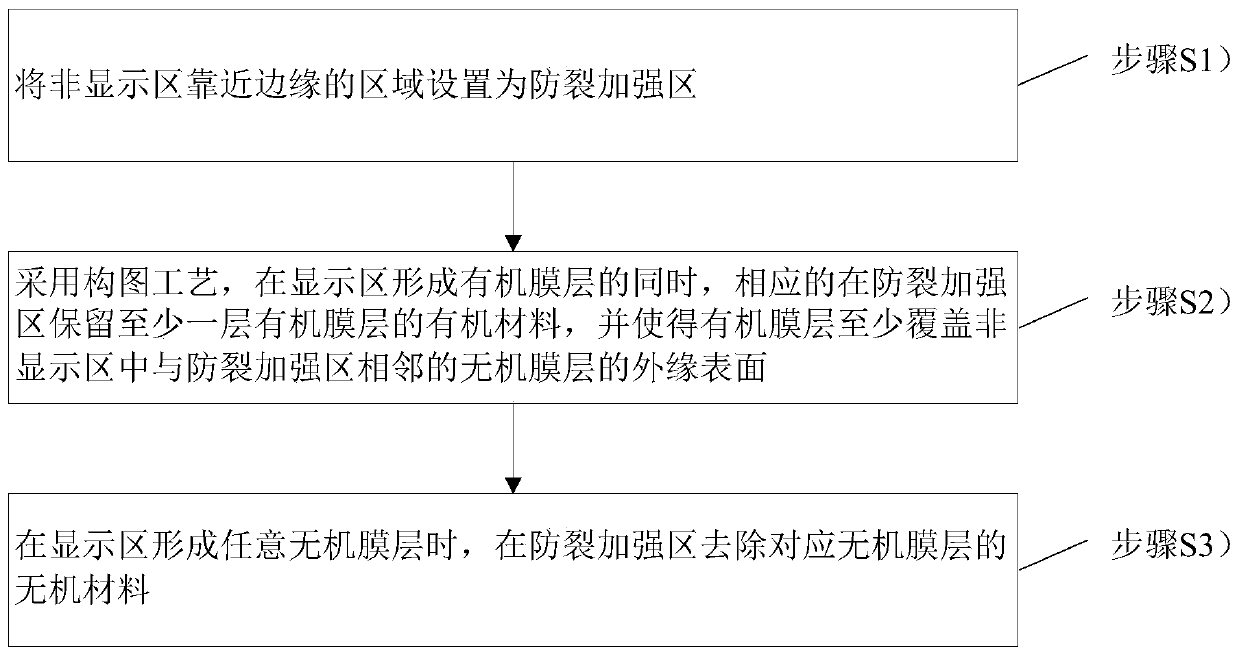

[0068] Such as image 3 As shown, the preparation method of the display substrate includes steps:

[0069] Step S1): Set the area near the edge of the non-display area A2 as the anti-crack reinforcement area A3.

[0070] In this step, the pixel structure 2 includes the control element and the light emitting device. According to the anti-crack strengthening area A3, the control element and the light emitting device are pre-planned ...

Embodiment 3

[0084] This embodiment provides a display device, which includes the display substrate in Embodiment 1.

[0085] The display device can be: desktop computer, tablet computer, notebook computer, mobile phone, PDA, GPS, vehicle display, projection display, video camera, digital camera, electronic watch, calculator, electronic instrument, instrument, liquid crystal panel, electronic paper, TV Computers, monitors, digital photo frames, navigators and other products or components with display functions can be applied to multiple fields such as public display and virtual display.

[0086] The display device can obtain better display effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com