Wafer cutting method

A cutting method and wafer technology, which can be used in electrical components, fine working devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as chipping at the top edge of deep reactive ion etching trenches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

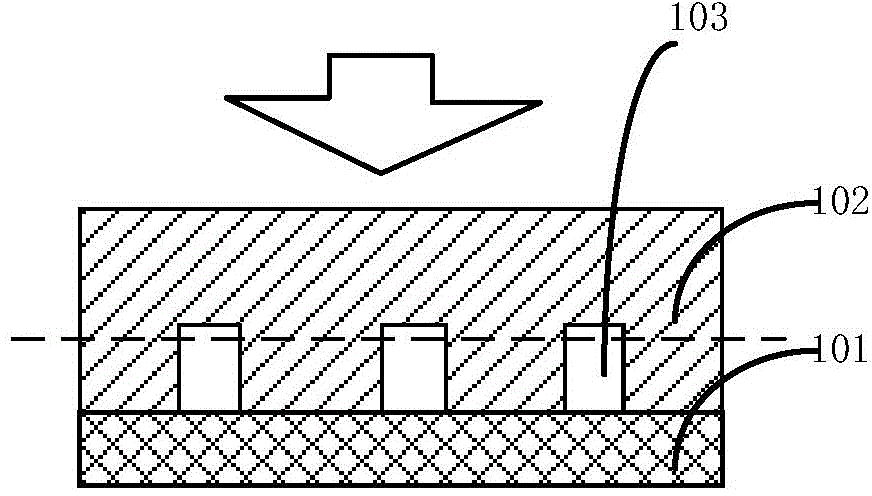

[0043] Current methods for dicing wafers with high-aspect-ratio trenches are figure 1 As shown, a semiconductor substrate 102 is firstly provided, and several trenches 103 with a high aspect ratio are formed in the semiconductor substrate 102 by means of deep reactive ion etching (DRIE), and then the front surface of the semiconductor substrate is bonded. Put a layer of tape (tape) 101 on it, and reverse the semiconductor substrate 102 for back grinding, so as to expose the trench 103 with high aspect ratio, so as to achieve the purpose of cutting (Dicing), such as figure 1 shown.

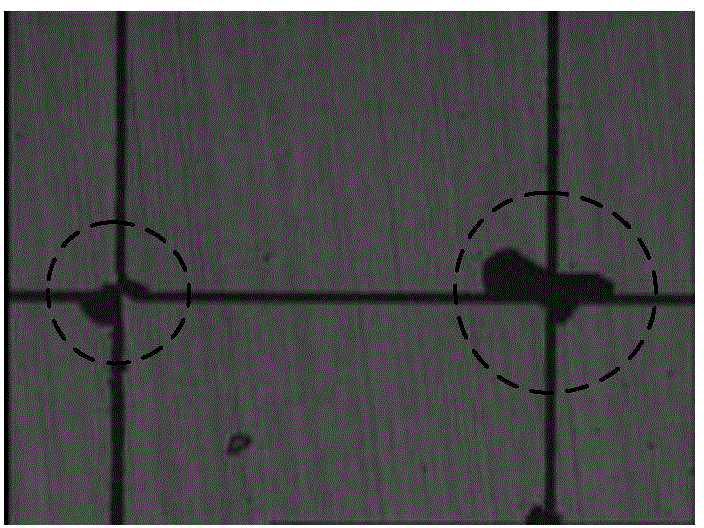

[0044] In DRIE cutting, the cutting and pressure of the grinding wheel on the wafer when approaching the groove 103 and the grinding trench (grinding trench) can easily cause severe chipping (chipping) on the top of the groove 103, such as figure 2 shown.

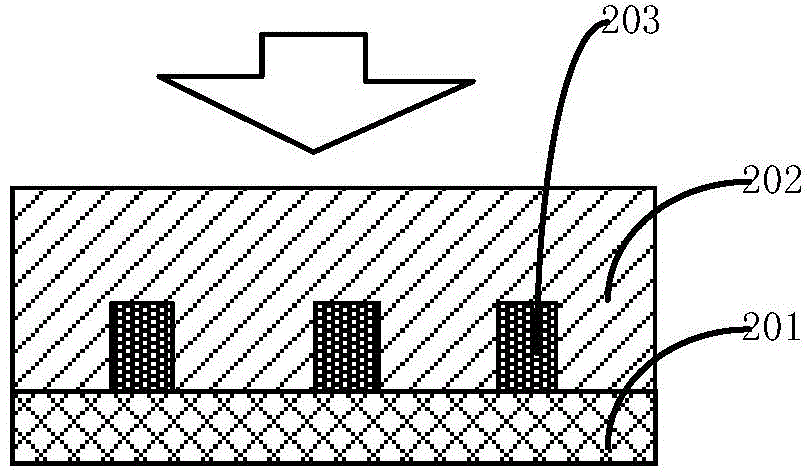

[0045] In order to solve the problems existing in the prior art, the present invention provides a new wafer cutting method, the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com