Laser cutting method

A laser cutting, laser beam technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

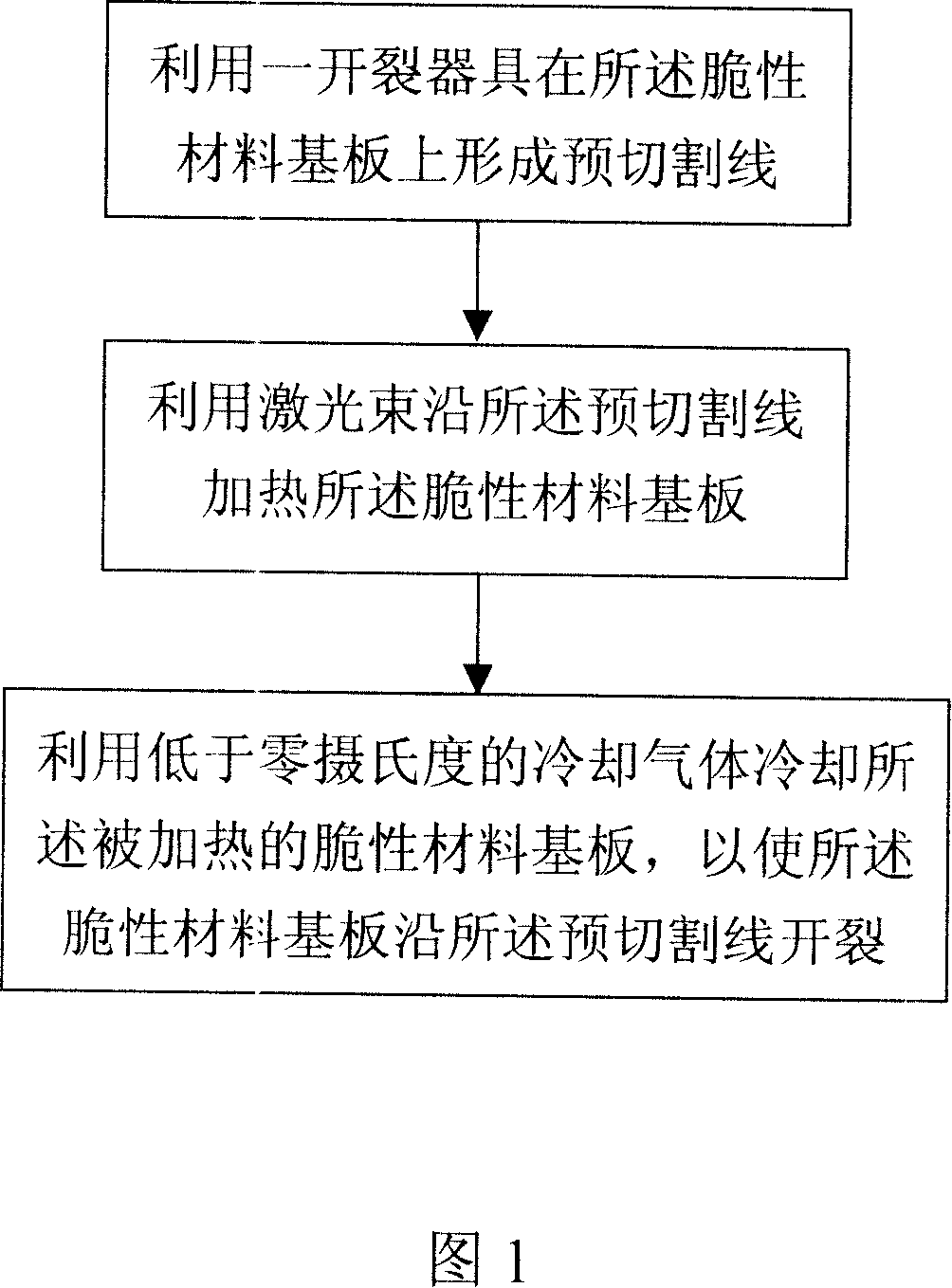

[0011] Referring to FIG. 1, a laser cutting method for cutting a brittle material substrate provided by an embodiment of the present invention includes the following steps:

[0012] (1) Using a cracking tool to form pre-cut lines on the brittle material substrate. The brittle material substrate can be made of brittle materials such as ceramics, glass or quartz. The cracking tool can be a diamond knife or a knife wheel or the like.

[0013] (2) Using a laser beam to heat the brittle material substrate along the pre-cut line. The wavelength of the laser beam is related to the material of the brittle material substrate. When the brittle material substrate is made of ceramic, glass or quartz, the wavelength of the laser beam is usually 10.6 microns. Preferably, the brittle material substrate is heated to a temperature greater than 100 degrees Celsius, which is less than the vaporization temperature of the brittle material substrate.

[0014] (3) Cooling the heated brittle mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com