Air input system, annular air duct and annular fluid bath of circular cooler

A technology of annular air duct and air inlet system, applied in the field of iron and steel smelting, can solve problems such as affecting the static sealing of the trolley and affecting the ventilation of the grate plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

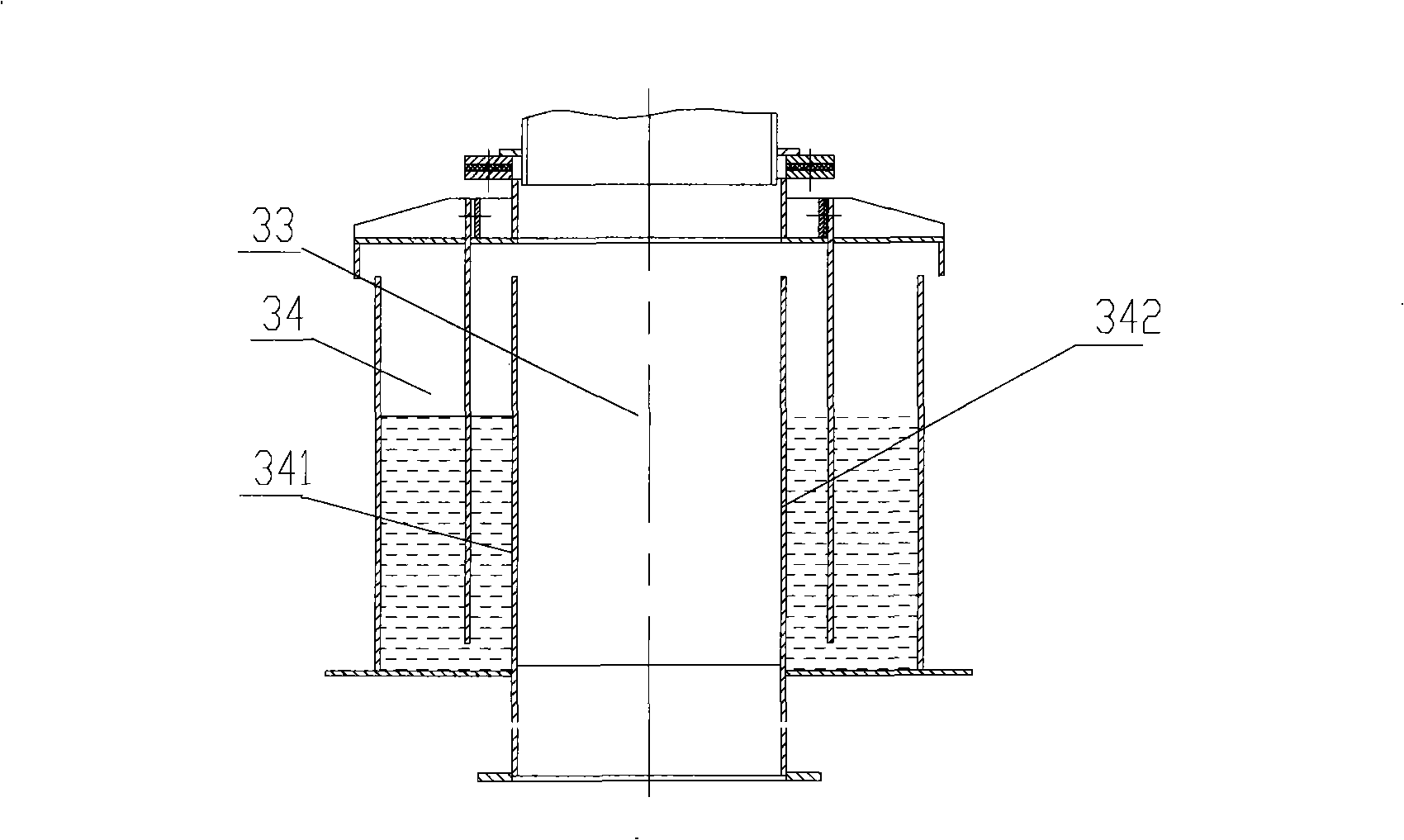

[0030] The invention improves the air intake system in the high temperature zone of the annular cooler, and sets the inner ring plate of the annular air duct liquid tank and the outer ring plate of the annular air duct liquid tank of the annular liquid tank in the air intake system as double-layer wall sleeves to avoid passing through the air duct The hot flue gas directly heats the liquid in the annular liquid tank, effectively preventing the liquid from heating up and vaporizing, which will affect the normal operation of other equipment of the annular cooler.

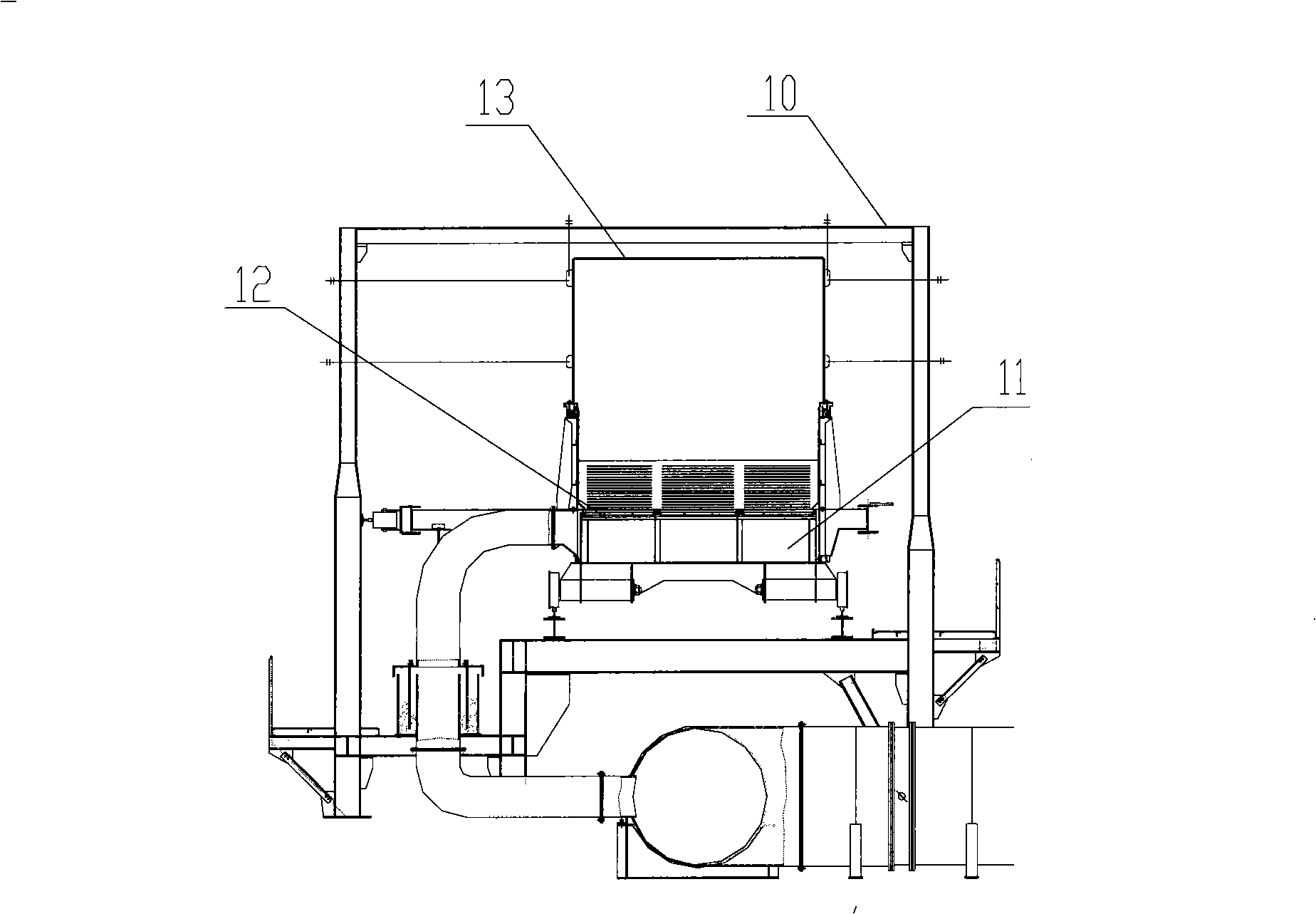

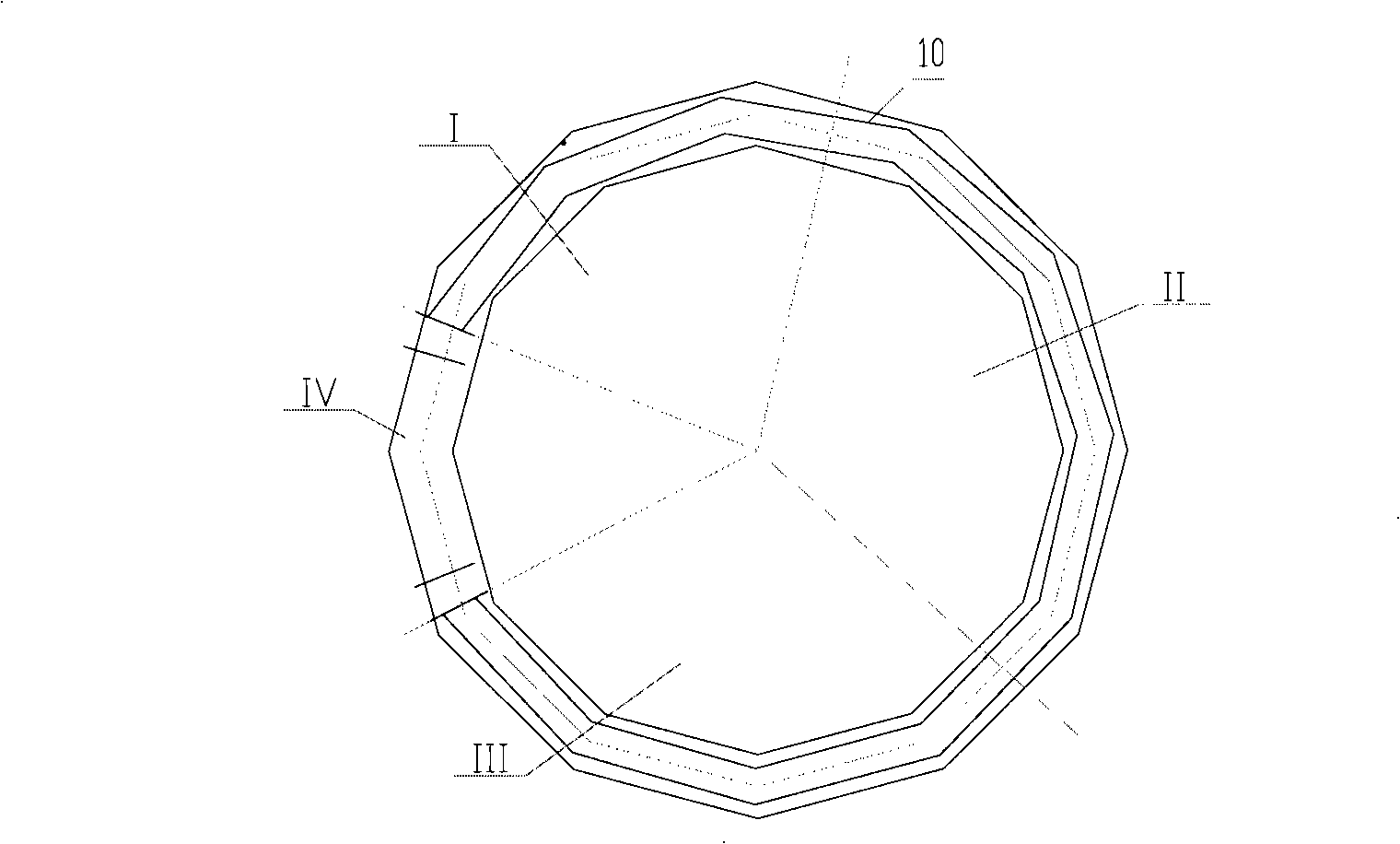

[0031] see Figure 4 , Figure 4 It is a radial cross-sectional view of the annular cooler 30 in the high temperature area. The annular air duct 31 is provided with a branch air duct 32 , and the branch air duct 32 is connected to the inlet of the annular air duct 33 . Each outlet of the annular air channel 33 is connected to each trolley air inlet pipe 36 respectively, and the trolley air inlet pipe 36 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com