Automatic wall polishing facility

A kind of equipment and wall technology, which is applied in the field of automatic wall grinding equipment, can solve the problems of low automation degree, low grinding precision and quality, and unreasonable structural design of wall grinding equipment, so as to speed up grinding efficiency, liberate manpower, and ensure safety. The effect of operating distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

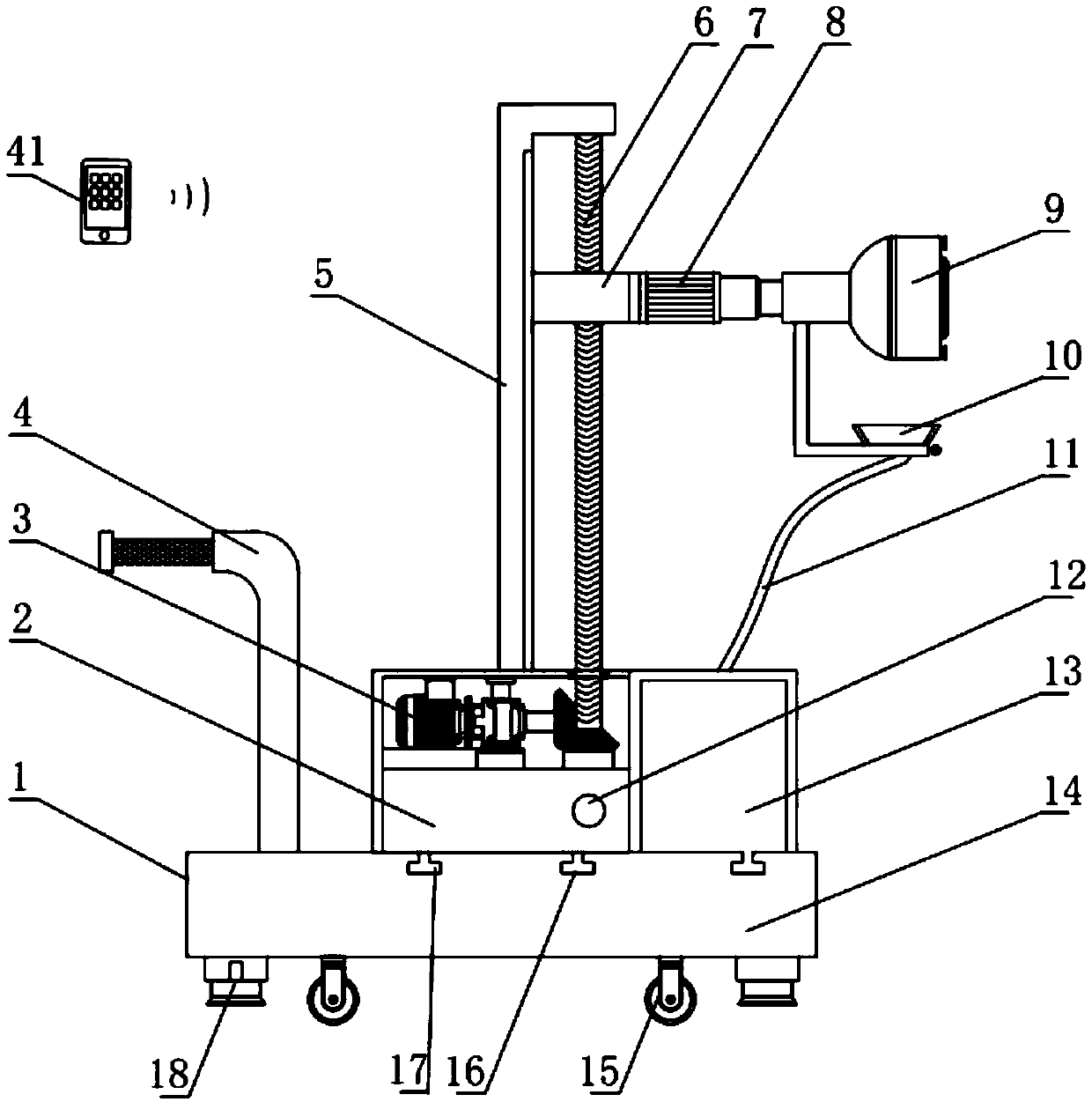

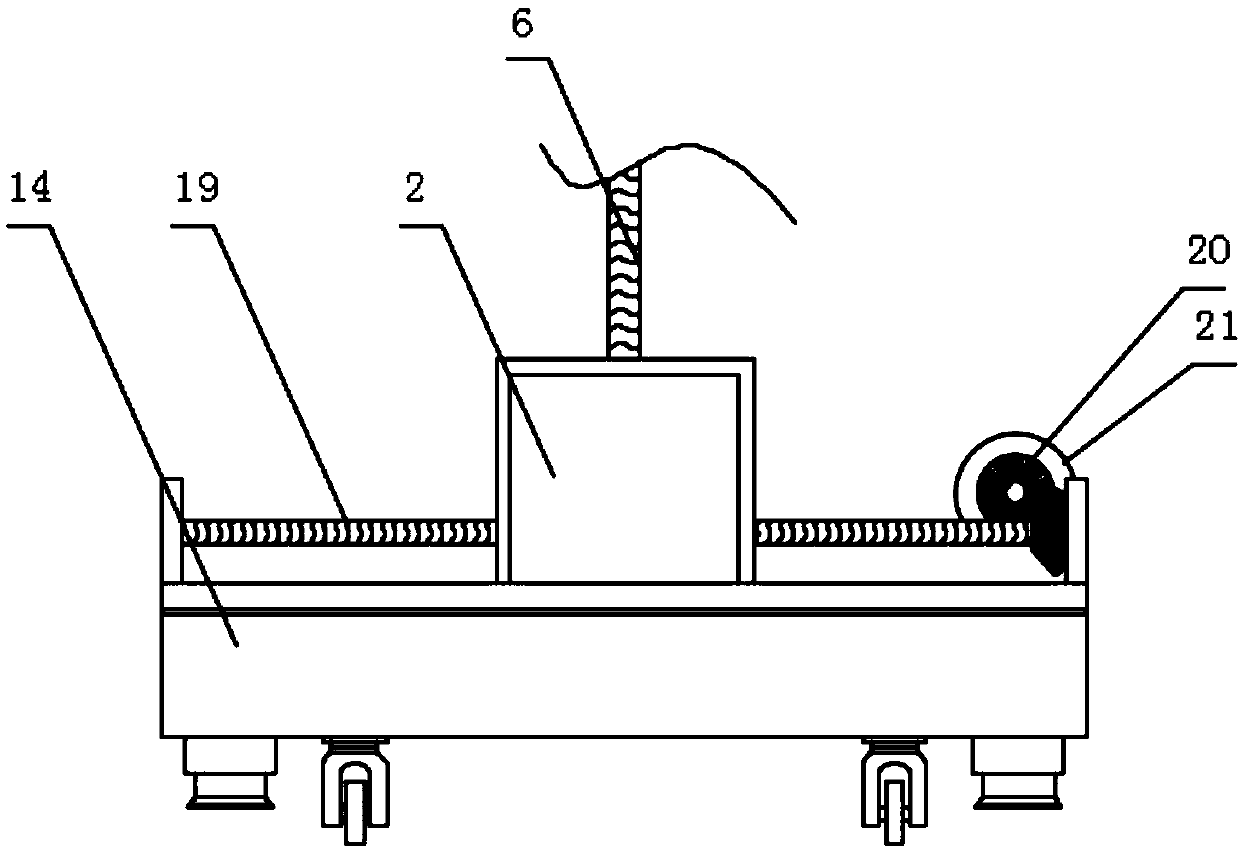

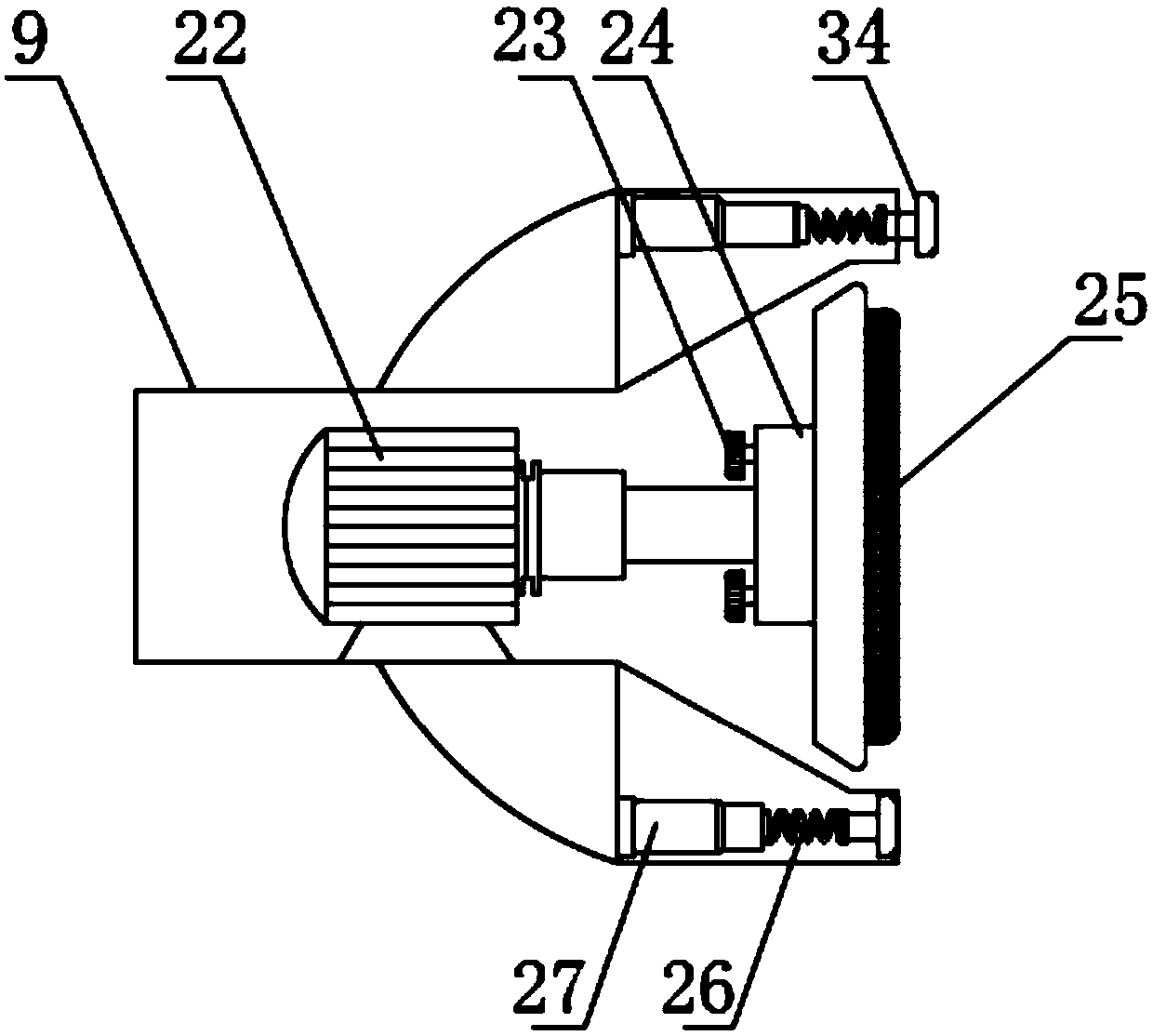

[0032] refer to Figure 1-2, a kind of automatic wall polishing equipment, comprises support and traveling mechanism 1 and polishing mechanism 9, and support and traveling mechanism 1 comprises a chassis 14, and the top surface of chassis 14 is provided with chassis 2, and first servomotor 3 is installed inside chassis 2 , and the output end of the first servo motor 3 is rotationally connected with the first threaded rod 6 through the bevel gear 20, the first threaded rod 6 is installed vertically on the top of the chassis 2, and the top surface of the chassis 2 is fixed on one side of the first threaded rod 6 L-shaped fixed plate 5, the surface of the first threaded rod 6 is connected with the grinding mechanism 9 through the adjustment block 7, the second threaded rod 19 is installed horizontally on the top surface of the chassis 14, and the second threaded rod 19 passes through the first threaded hole inside the chassis 2 12 is rotationally connected with the chassis 2, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com