Patents

Literature

98results about How to "Real-time calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

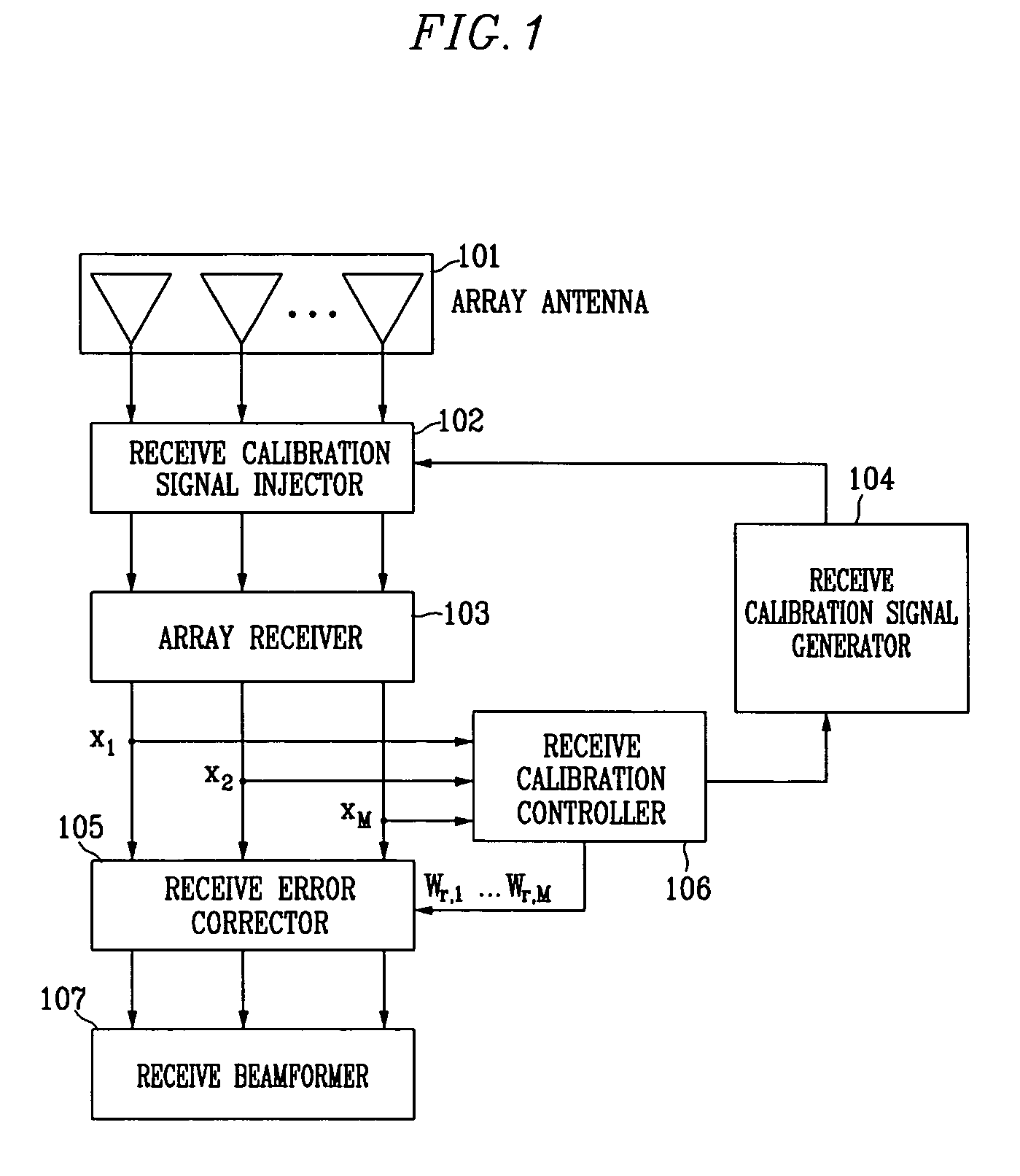

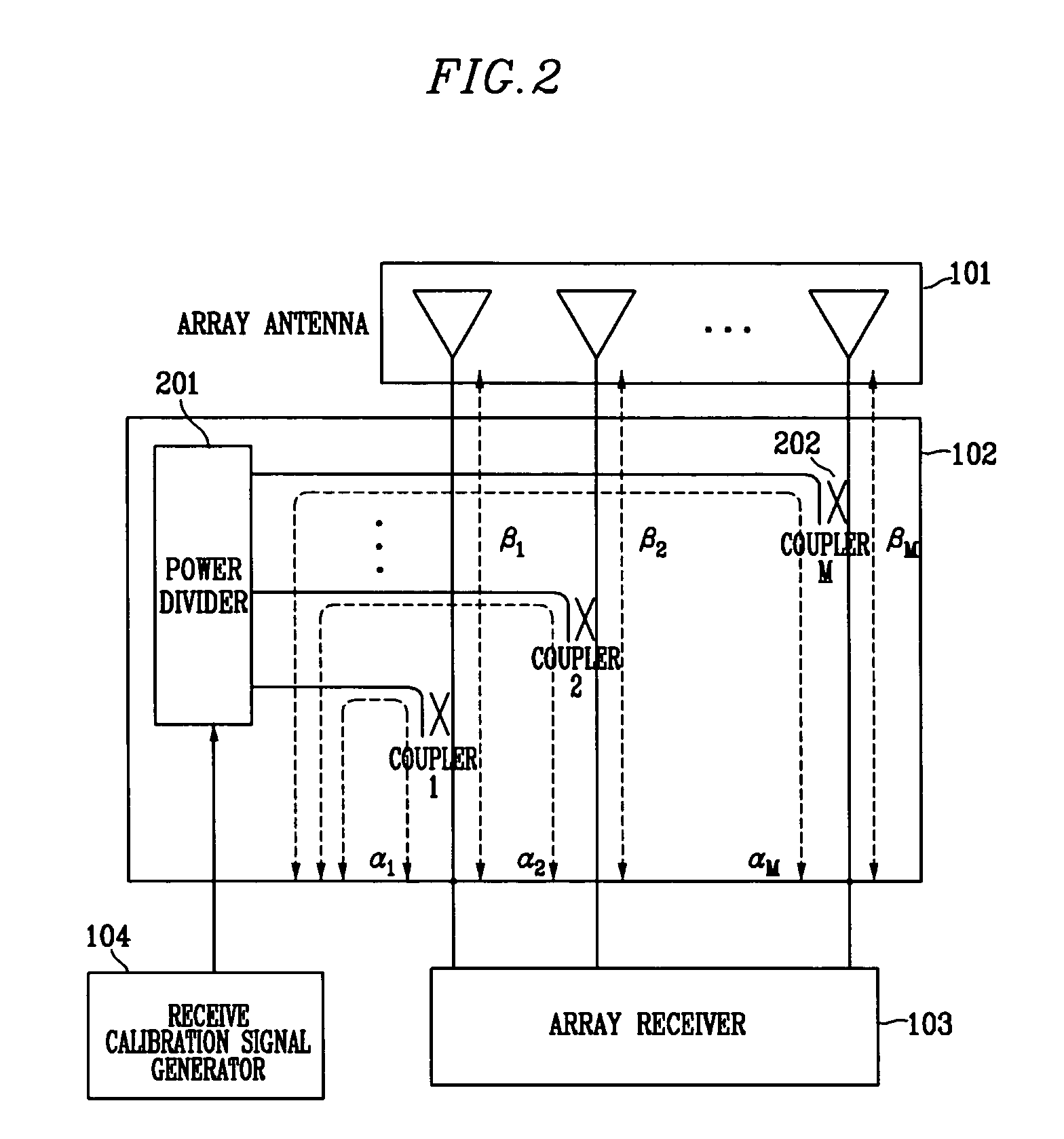

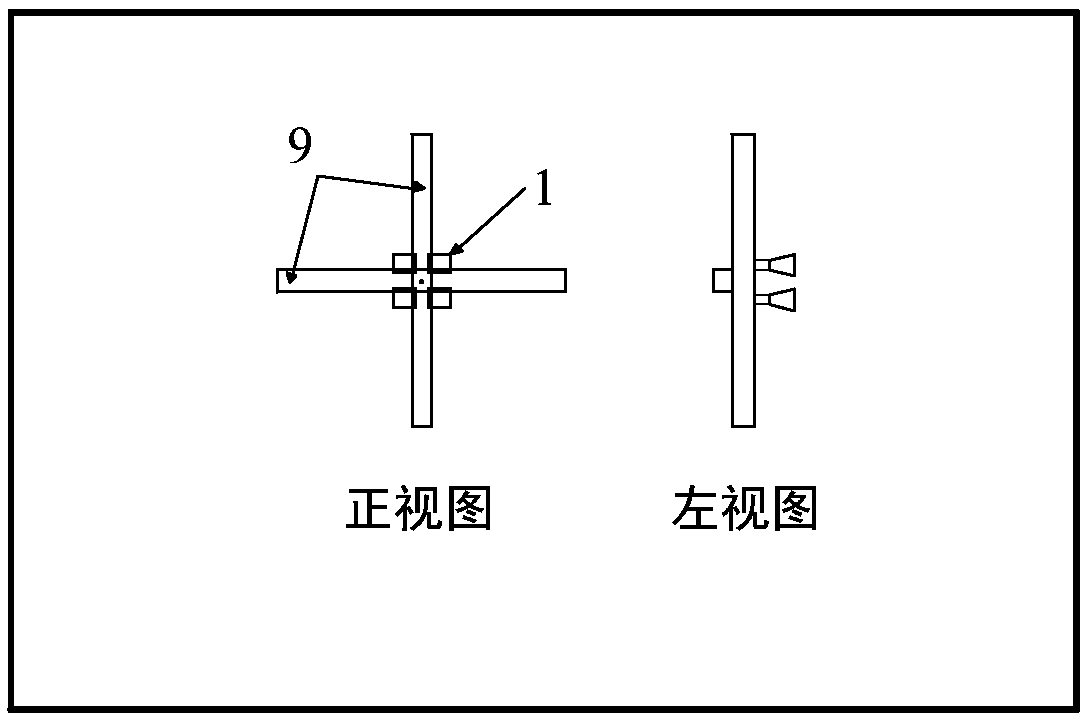

Transmitting and receiving apparatus and method in adaptive array antenna system capable of real-time error calibration

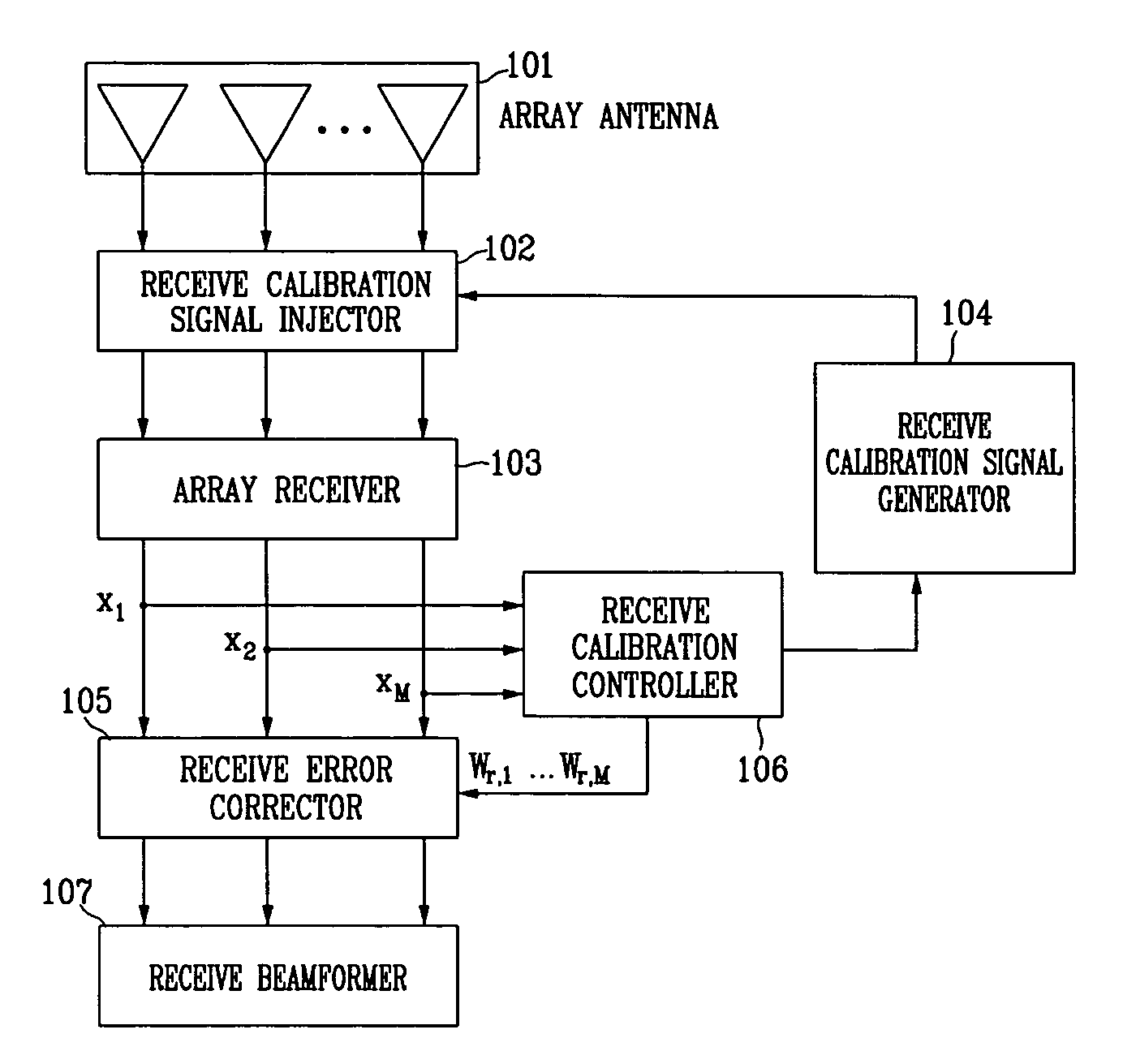

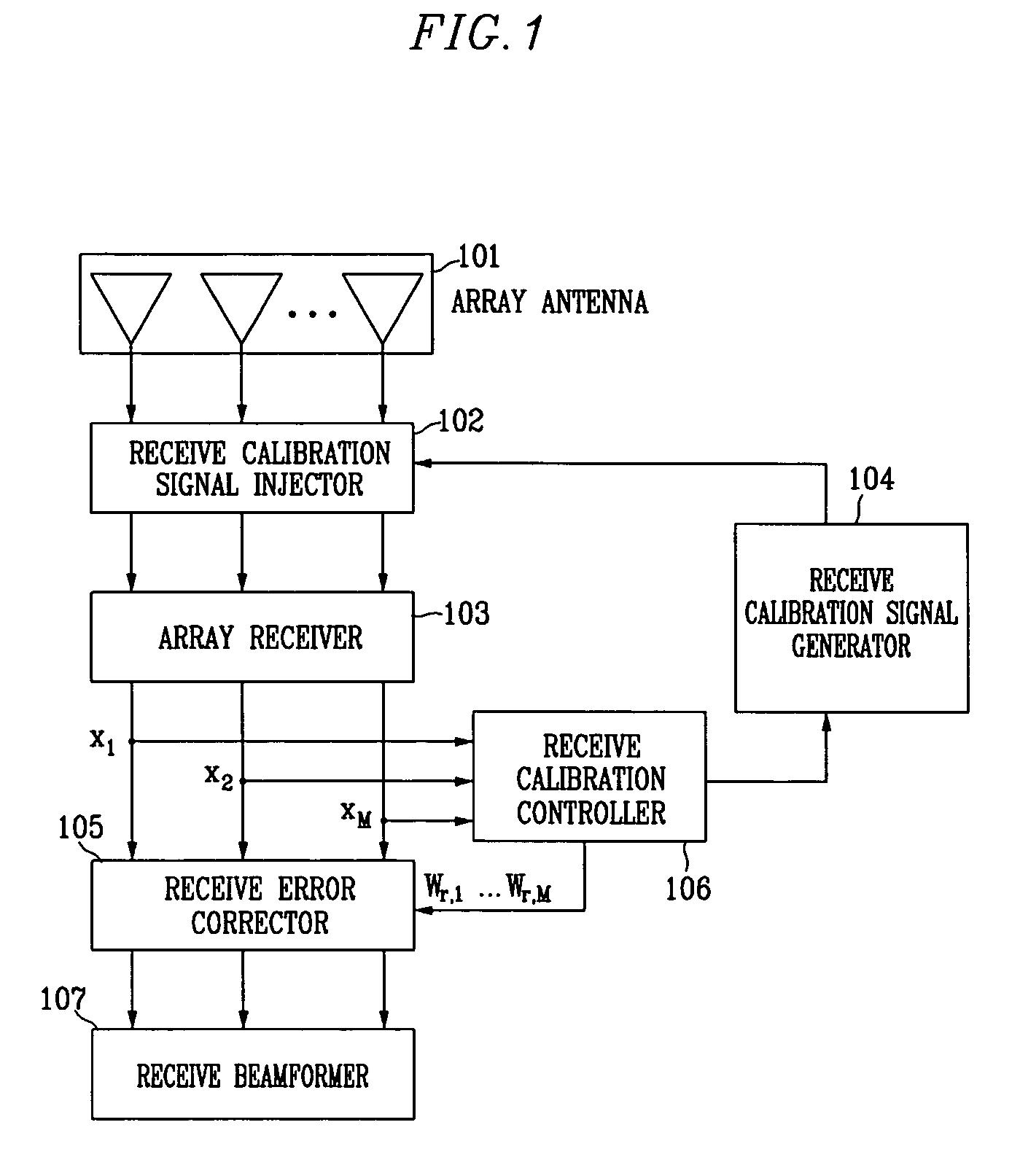

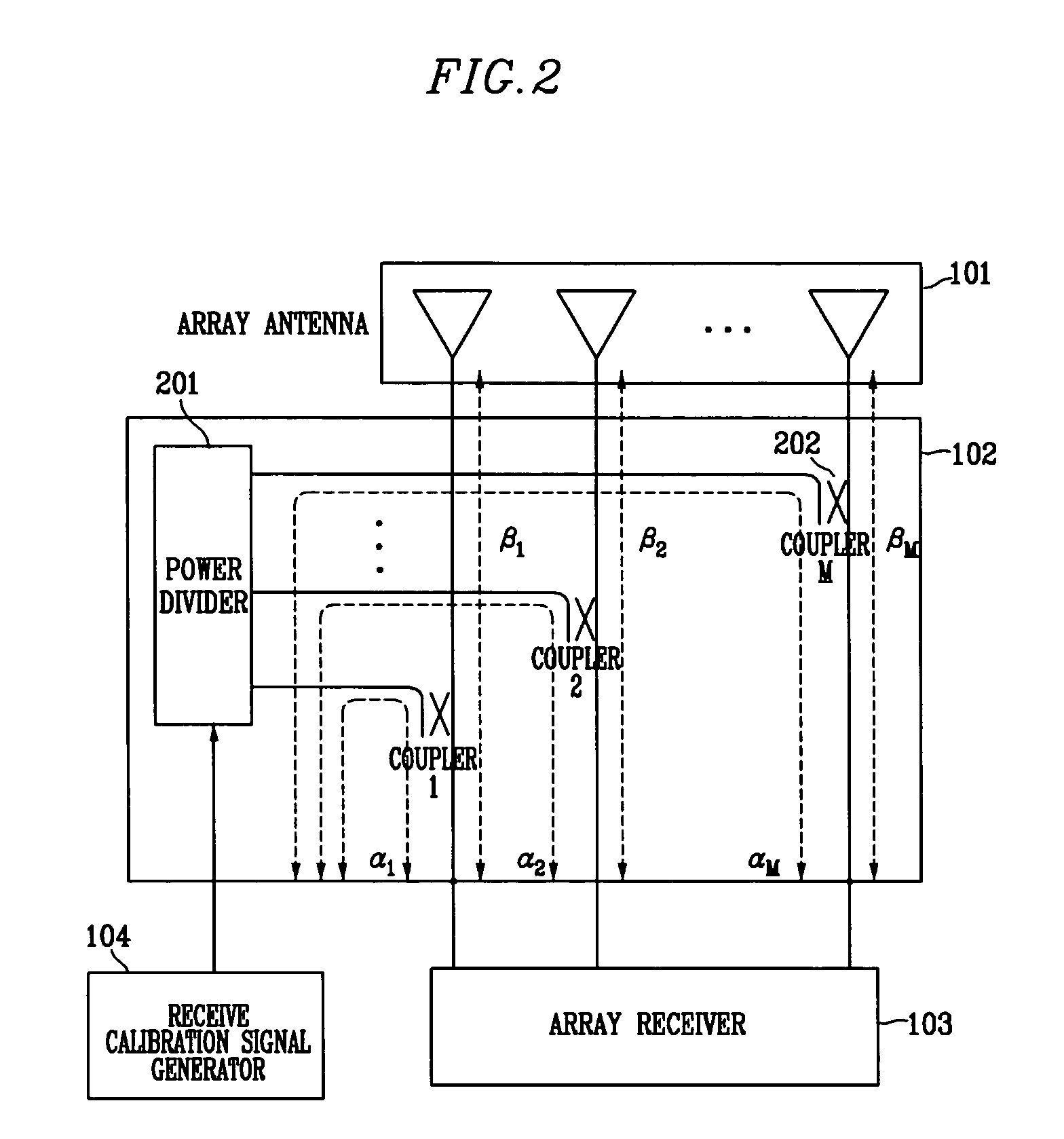

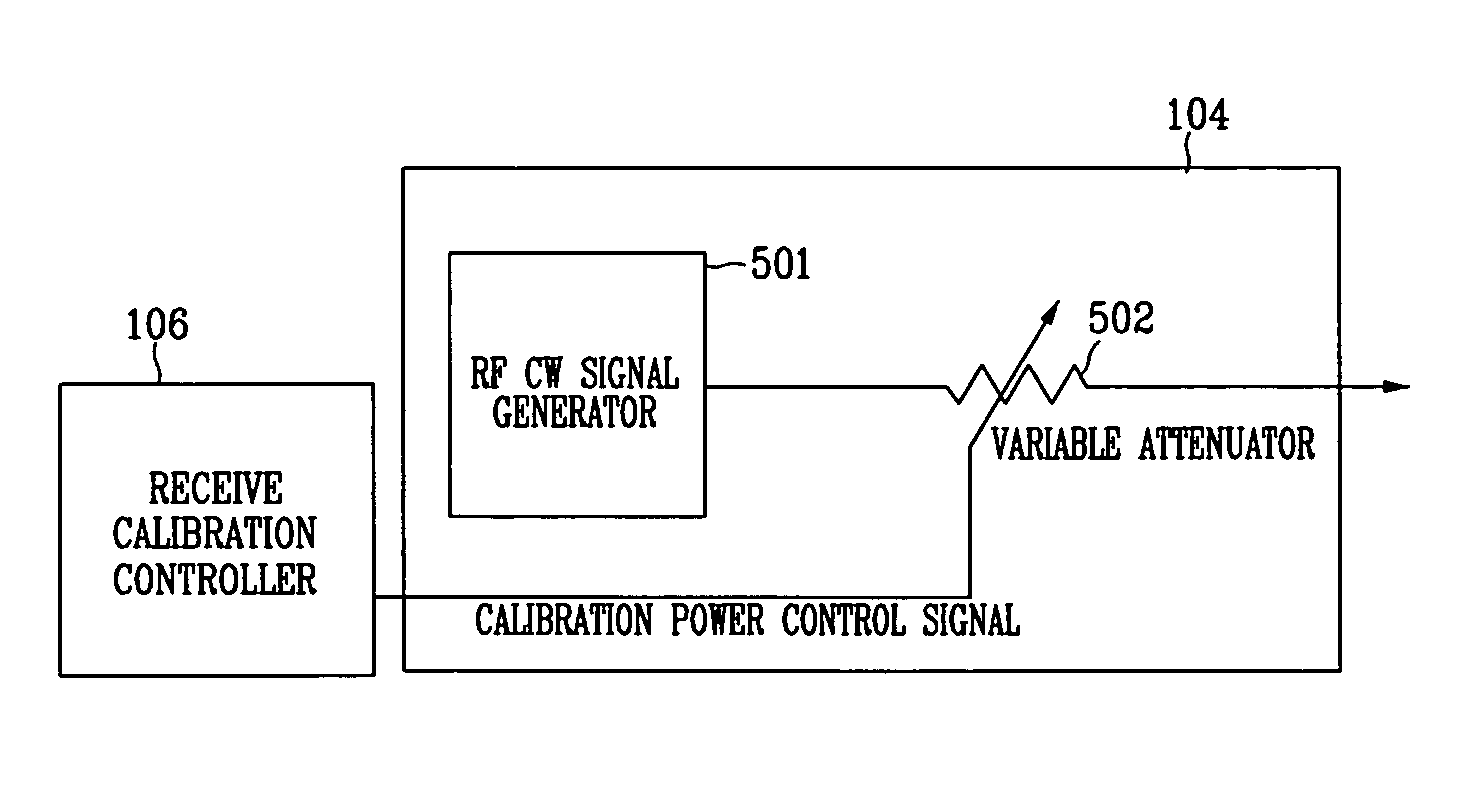

ActiveUS20050140546A1Shorten the time intervalReduce distractionsWave based measurement systemsAntenna arraysTime errorRelative transfer function

Disclosed are a transmitting and receiving apparatus and method in an adaptive array antenna system capable of real-time calibration. Transfer functions in the transmitting and receiving apparatus are estimated by injecting a calibration signal to each of transmit and receive channels and analyzing the signals that has passed through the transmit and receive channels. An RF CW sinusoidal signal of a single frequency can be used as the calibration signal to simplify a process of signal processing in a baseband. In addition, in the calibration of the receiving apparatus, gains of all receive channels are controlled using an identical signal. Thus, a relative transfer function characteristic of the receive channels is constant irrespective of the gains of the receivers.

Owner:ELECTRONICS & TELECOMM RES INST

Transmitting and receiving apparatus and method in adaptive array antenna system capable of real-time error calibration

ActiveUS7205936B2Reduce distractionsShorten the time intervalWave based measurement systemsAntenna arraysRelative transfer functionComputer science

Disclosed are a transmitting and receiving apparatus and method in an adaptive array antenna system capable of real-time calibration. Transfer functions in the transmitting and receiving apparatus are estimated by injecting a calibration signal to each of transmit and receive channels and analyzing the signals that has passed through the transmit and receive channels. An RF CW sinusoidal signal of a single frequency can be used as the calibration signal to simplify a process of signal processing in a baseband. In addition, in the calibration of the receiving apparatus, gains of all receive channels are controlled using an identical signal. Thus, a relative transfer function characteristic of the receive channels is constant irrespective of the gains of the receivers.

Owner:ELECTRONICS & TELECOMM RES INST

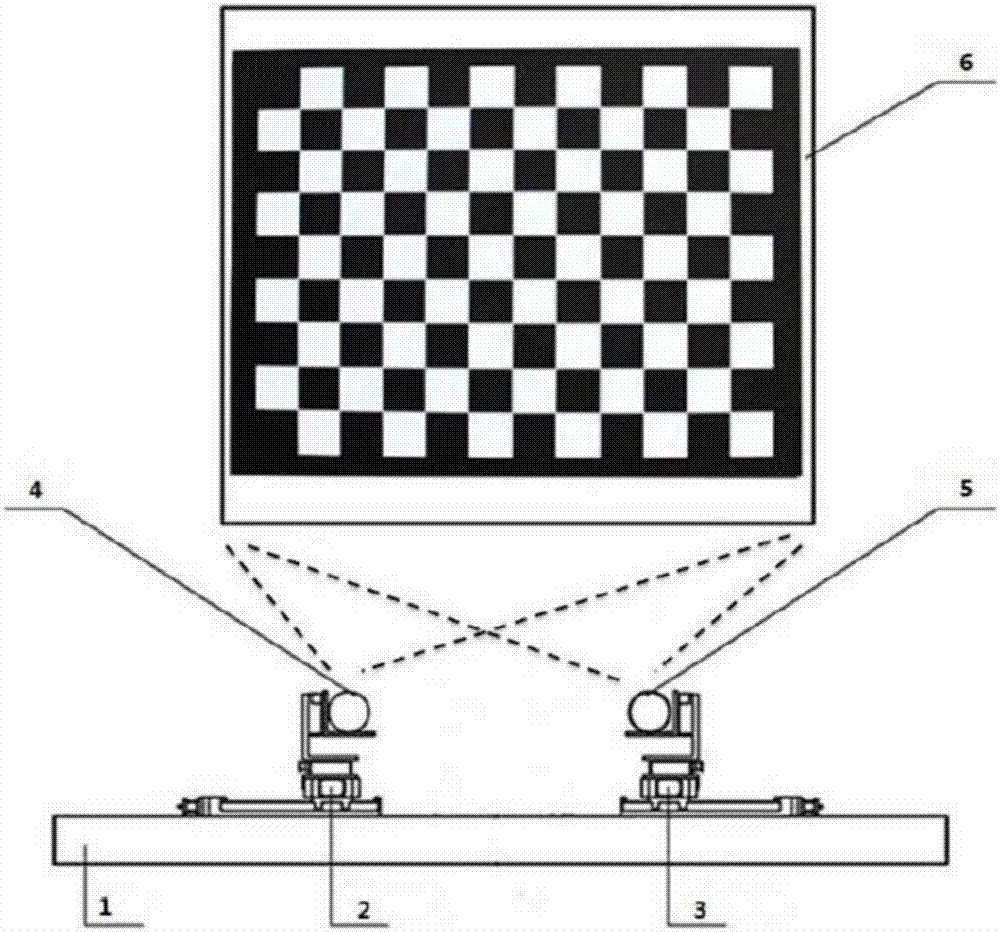

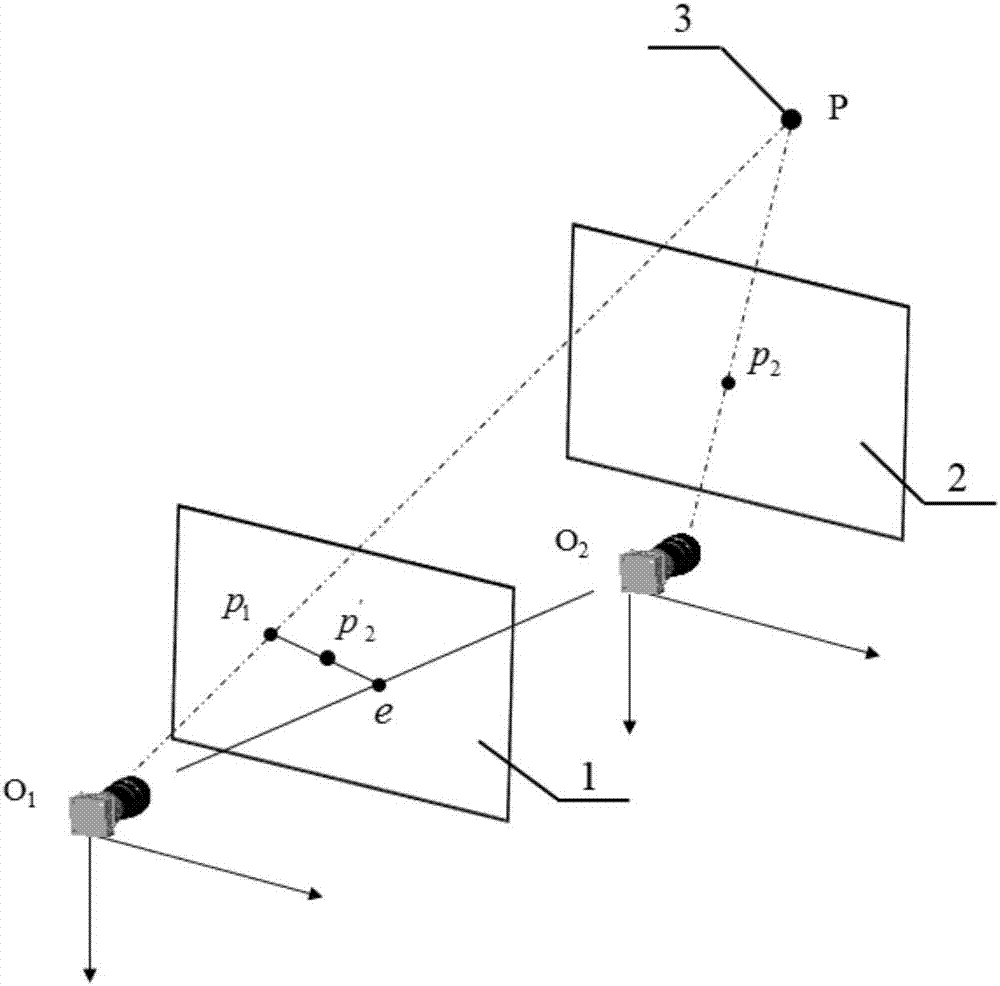

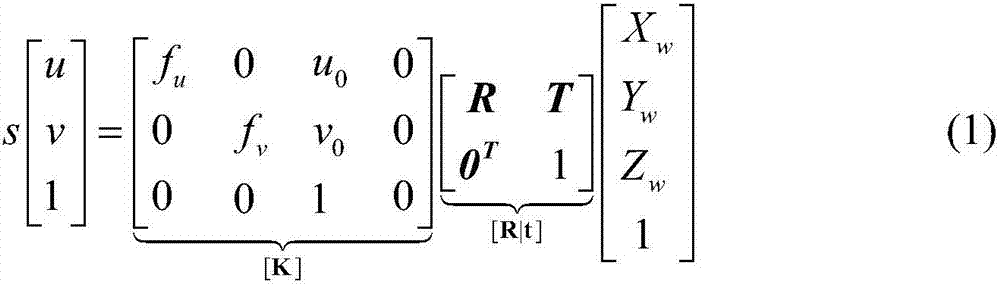

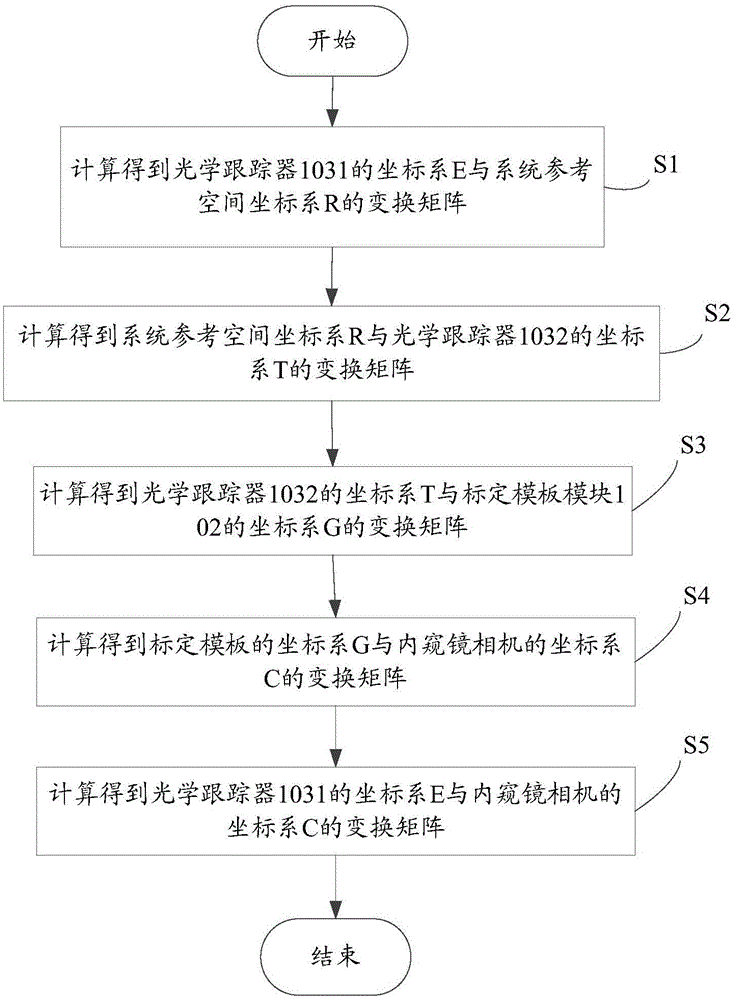

Step-by-step calibration method for camera parameters of binocular stereoscopic vision system

ActiveCN106981083AReal-time calibrationApplicable calibration requirementsImage analysisDimension measurementElectric control

The invention relates to a step-by-step calibration method for the camera parameters of a binocular stereoscopic vision system and belongs to the field of image processing and computer vision detection, which relates to a step-by-step calibration method for the camera intrinsic and external parameters of a dimension measurement system for large-scale forgings. According to the calibration method, firstly, the intrinsic parameter matrix of a camera is calibrated in the off-line manner in a laboratory, and the camera is driven to conduct two sets of mutually independent triorthogonal motions by a high-precision electric control platform. Secondly, based on the properties of FOD points, the intrinsic parameters of the camera are listed through the unique solution of a linear equation. At a forging experiment site, a basic matrix between two images is figured out through the 8-point method, and the method of decomposing of an essential matrix is conducted. In this way, the real-time on-line calibration for the external parameters of the camera is realized. Finally, based on the image information, the length of a high-precision three-dimensional scale is reconstructed, so that the solution of a camera scale factor is realized. The above method is simple and convenient in calibration process, short in calibration time and high in precision. The calibration of the camera of the binocular vision measurement system at the forging site can be precisely realized by adopting fewer images.

Owner:DALIAN UNIV OF TECH

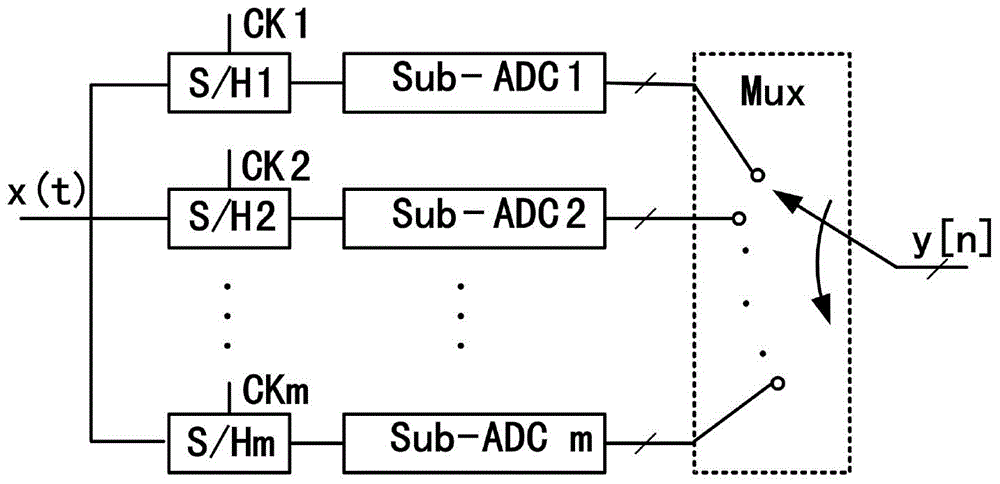

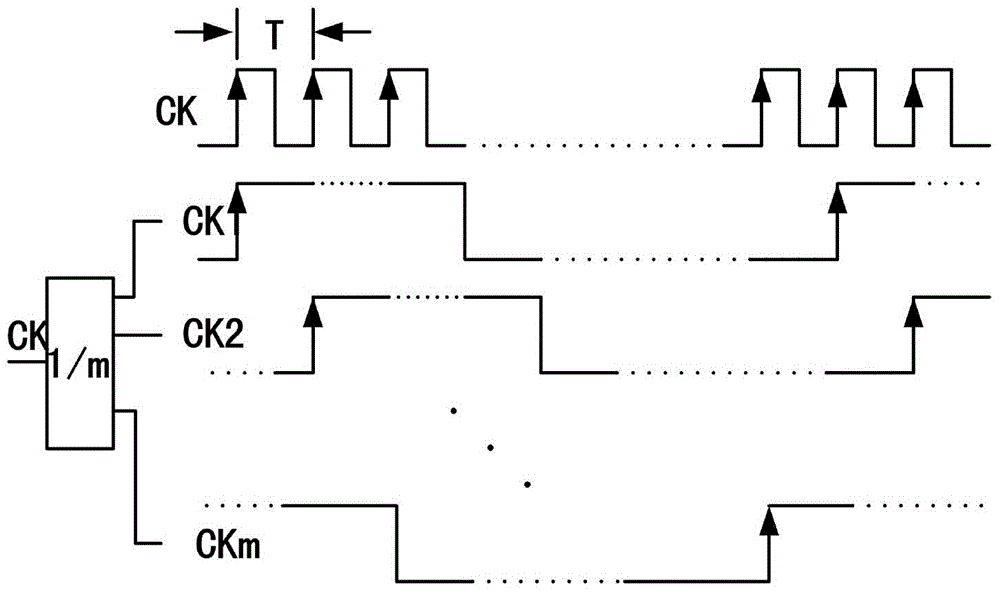

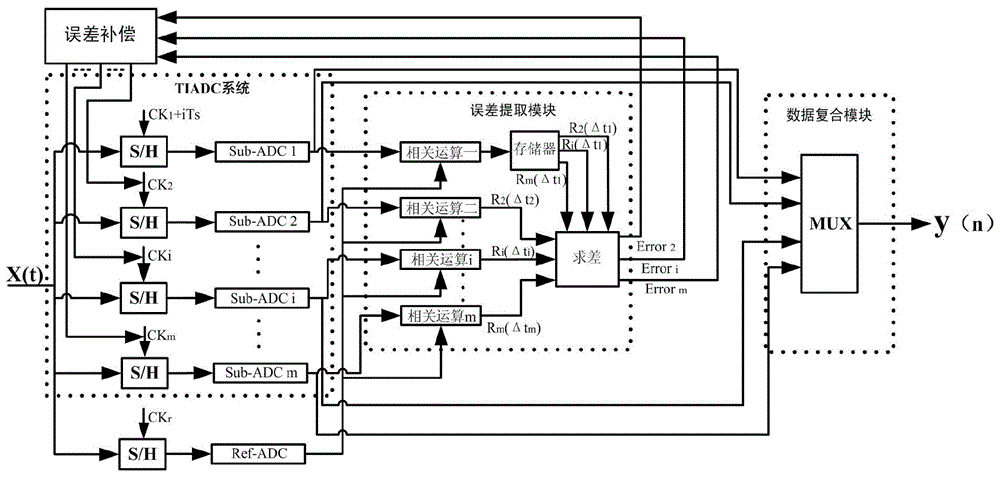

Calibrating module for sampling time error of TIADC (Time-interleaved Analog To Digital Converter) and calculating method for calibrating module

ActiveCN104901695AReduce consumptionImprove reliabilityAnalogue/digital conversion calibration/testingTime errorTime interleaved

The invention discloses a calibrating module for the sampling time error of a TIADC (Time-interleaved Analog To Digital Converter). The TIADC comprises a data conversion module and a data composition module, wherein the data conversion module consists of M channels comprising M sample hold circuits and M sub channel ADCs (Analog To Digital Converter); a reference channel is arranged on the data conversion module in parallel, so that a data conversion module with the reference channel is formed; the reference channel is formed by connecting one sample hold circuit with one single-bit reference channel ADC in series; the calibrating module is arranged between the data conversion module with the reference channel and the data composition module and consists of M auto-correlation operation modules, a memory, (M-1) differential modules and (M-1) error compensation modules. The calibrating module disclosed by the invention is suitable for calibrating TIADC systems of any channel and signals within the whole Nyquist sampling frequency, simply acquiring relative sampling time error among all the channels and efficiently compensating the relative sampling error, so that the calibration of the time error among the channels can be quickly and accurately realized at lower hardware overhead.

Owner:HEFEI UNIV OF TECH +1

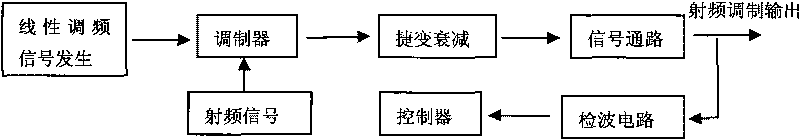

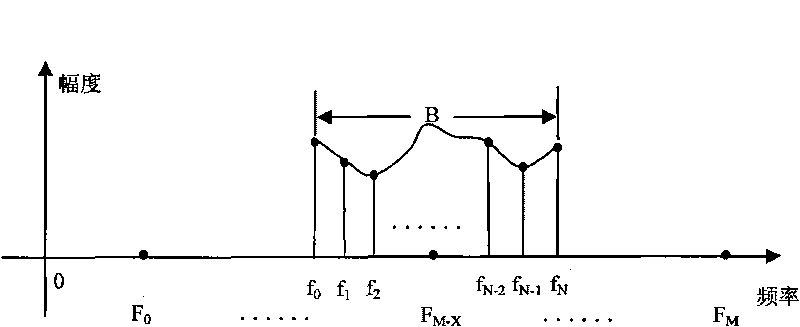

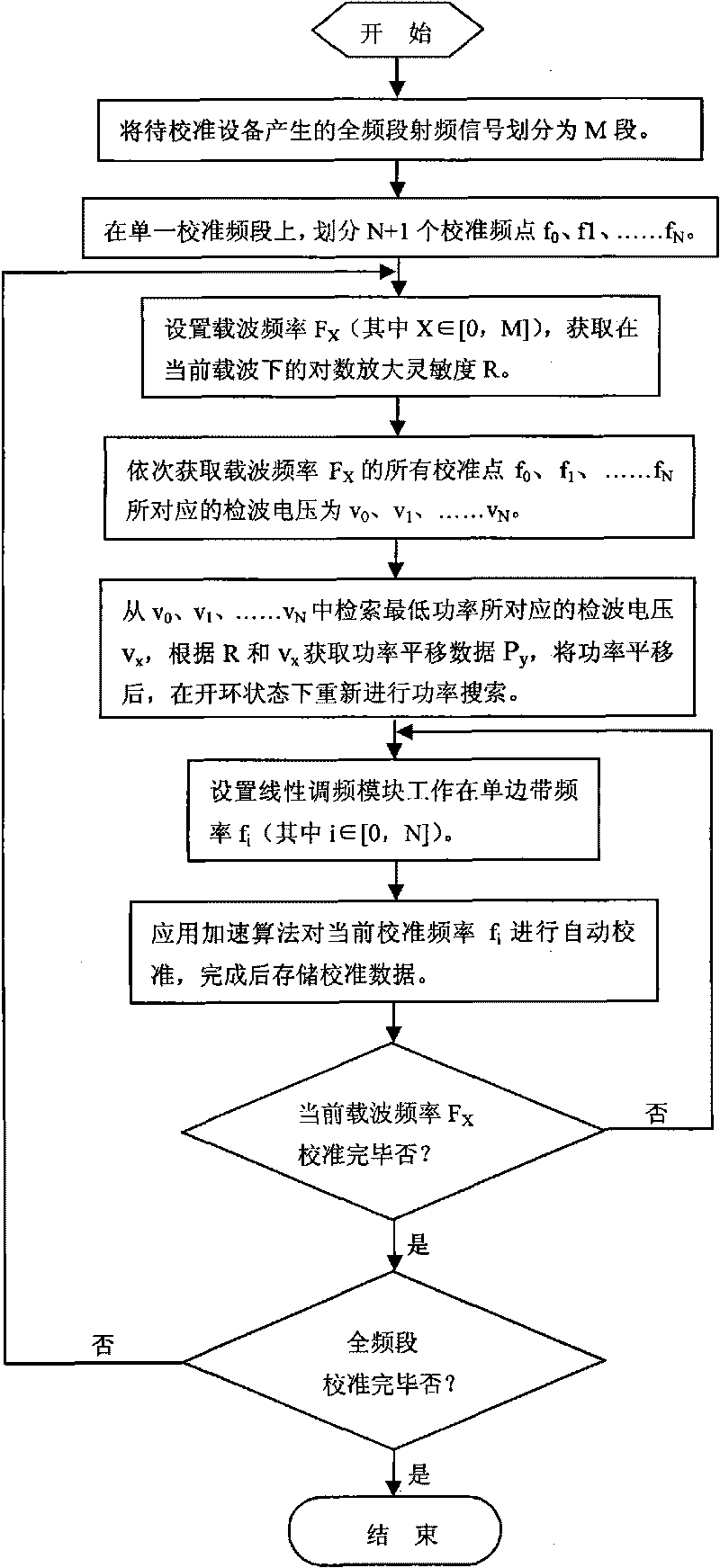

Calibrating method for big modulation bandwidth linear FM signal frequency response

ActiveCN101702018AReal-time calibrationWave based measurement systemsModulation bandwidthRadio frequency signal

A calibrating method for big modulation bandwidth linear FM signal frequency response relates to the technical field of testing, comprising the steps of: 1) dividing a radio frequency signal in a complete frequency range generated by a calibrating device into a plurality of frequency sections F0 to F1, F1 to F2,..., FM-2 to FM-1 and FM-1 to FM, for calibrating section by section, 2) confirming N+1 calibrating points on a single calibrating frequency section, 3) dynamically acquiring a log amplifying sensitivity R, 4) translating and searching the smallest carrier power, and 5) automatically calibrating frequency points FM one by one. The method of the invention automatically calibrates and compensates basing on the linear FM signal frequency response of an interior detection circuit and an agility damping circuit in the calibrating device and the frequency response calibration can be automatically performed without an additional testing and calibrating device for user to perform real time calibration on site. The detection circuit and the agility damping circuit are both located in a modulating channel, so not only the frequency response of linear FM signal generating module is calibrated but also the whole passage is calibrated.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Array antenna channel calibration system for plane wave simulator

ActiveCN109541330ACalibration is flexible and applicableSave calibration timeElectromagentic field characteristicsAntenna radiation diagramsPhase differenceTransmission coefficient

The invention discloses an array antenna channel calibration system for a plane wave simulator, which comprises a plane wave simulator array antenna comprising multiple sub units, a regulating networkfor controlling the amplitude and the phase of each sub unit, a calibration probe antenna or probe array with a fixed and known position, a vector network analyzer, a connector cable and other accessories. The calibration system adopts a vector superposition principle, through control on the phase of the tested array antenna channel, in a far field area of the antenna from the two-dimensional array antenna aperture unit channel, a transmission coefficient (S21) value when the phase of the tested array antenna channel changes is acquired, and thus, the channel amplitude and phase difference isanalyzed. The channel calibration system has a wide application range and can be used for consistency calibration on the unit channels of the array antenna, especially for the unit channel calibration of the planar wave generator array antenna.

Owner:BEIHANG UNIV

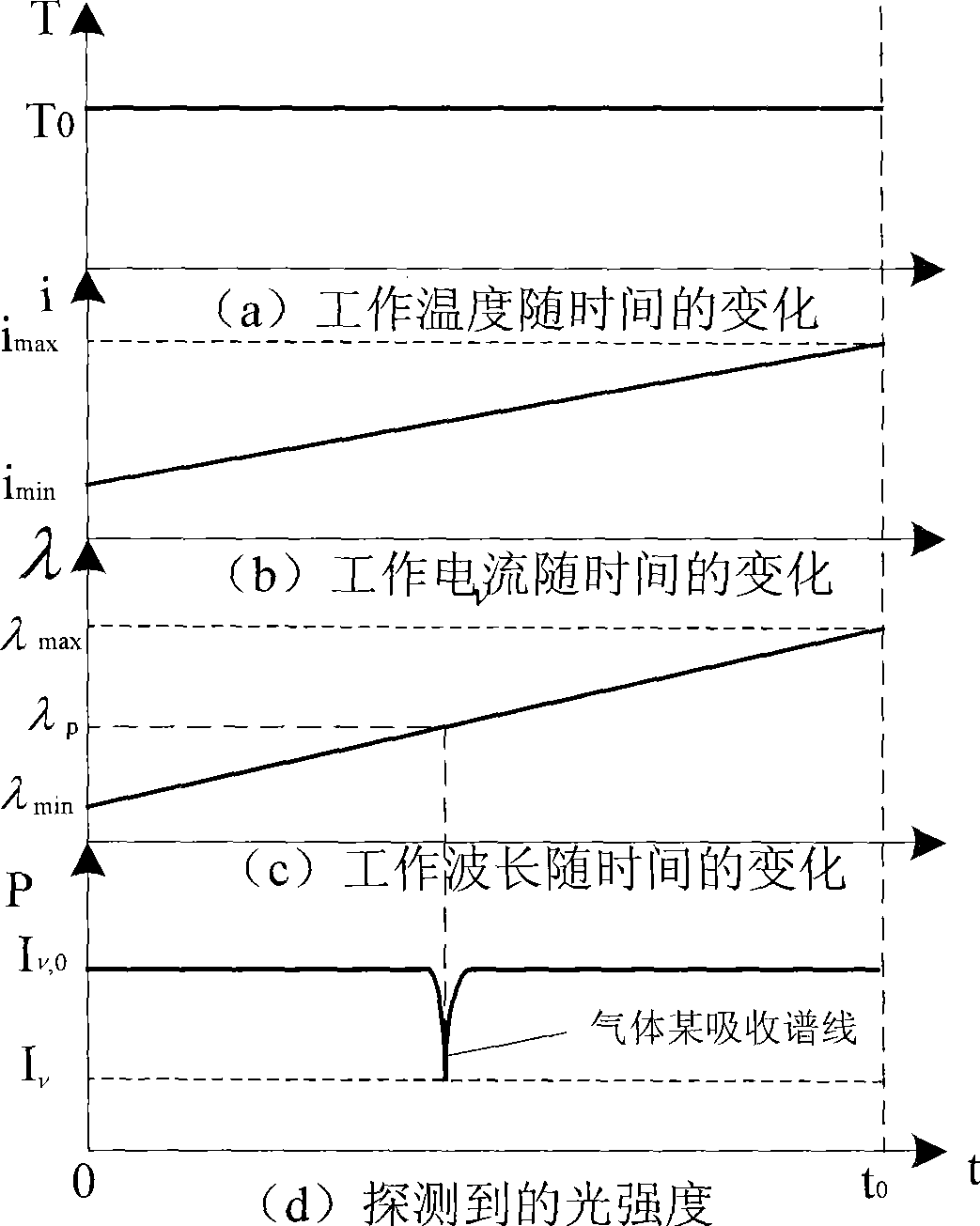

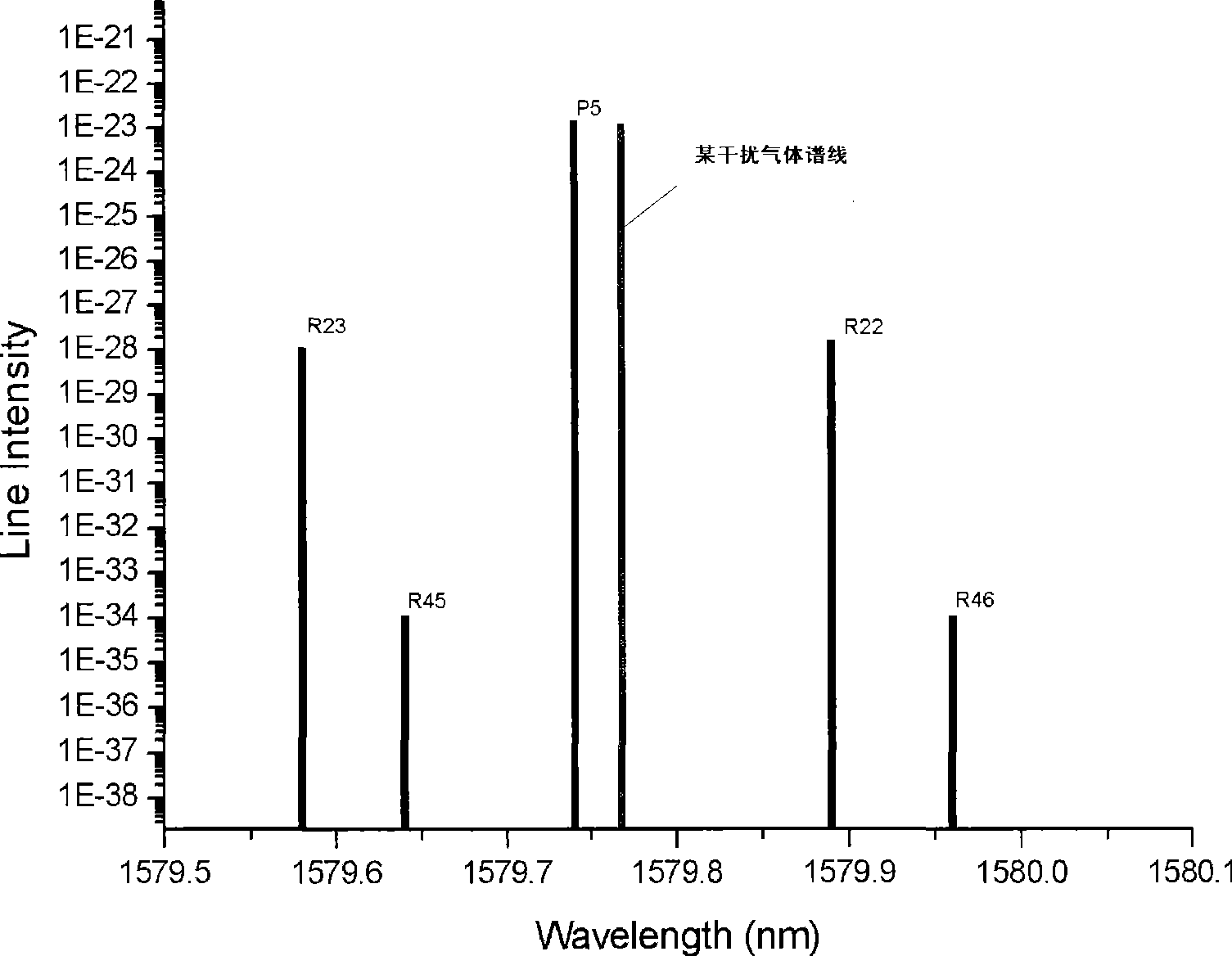

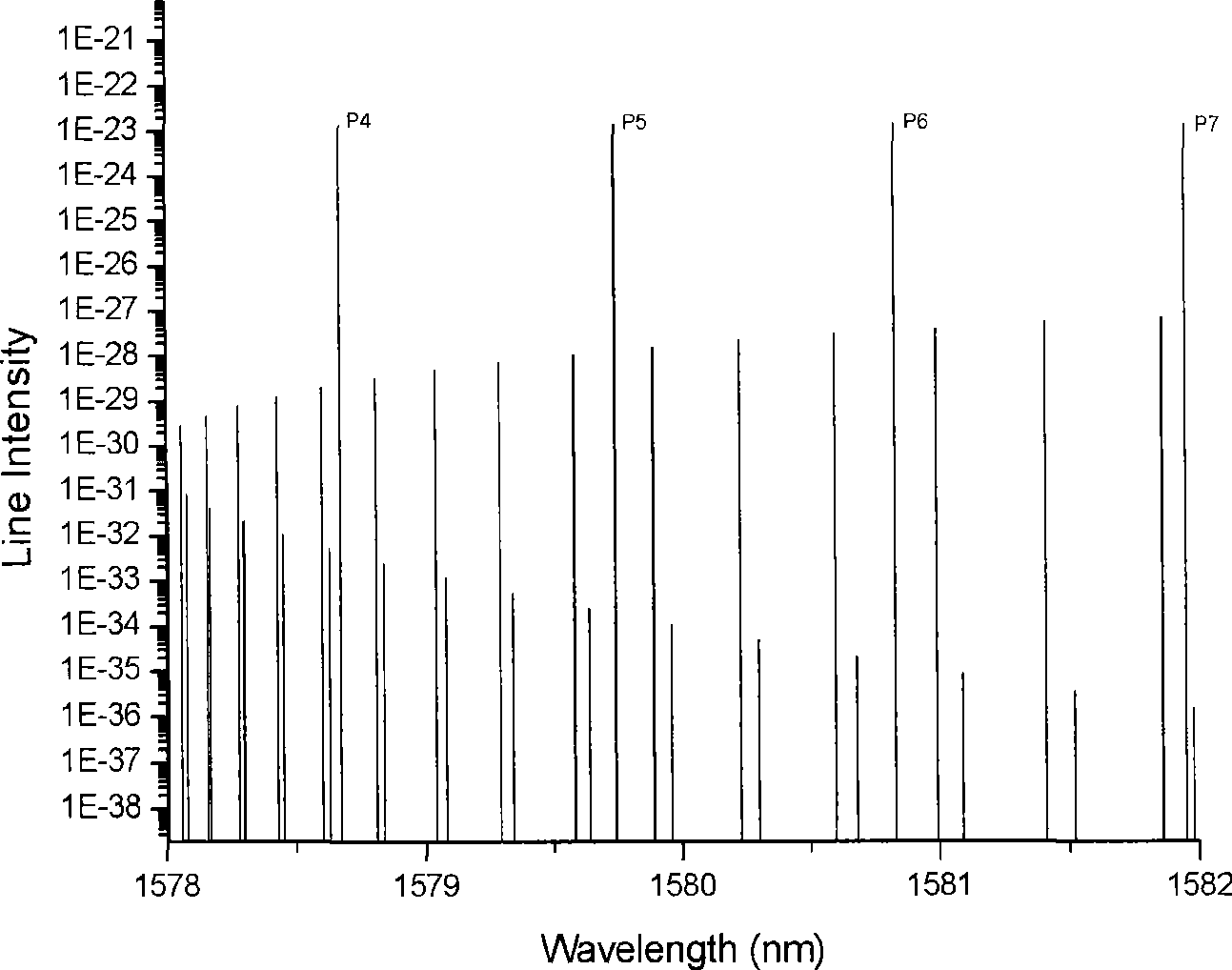

Laser absorption spectrum trace amount gas analysis method and apparatus using the same

ActiveCN101441173AReal-time measurementReal-time calibrationColor/spectral properties measurementsSpecial data processing applicationsGas analysisMeasurement device

The invention relates to an on-line self-calibration laser-adsorption-spectrum trace gas analysis method and the laser-adsorption-spectrum trace gas analysis device employing the method. The method comprises establishing a calibration gas chamber in the measuring light path, adding the standard gas the same as the gas to be measured in the calibration chamber, and calculating the concentration of the gas to be measured by detecting the original light intensity and the line intensity of the measuring light path and the calibration light path irrespective of the gas temperature and the pressure. The method for measuring the concentration of the gas to be measured is simple and accurate, and the device employing the method is also simplified remarkably and can realize real-time self-calibration.

Owner:CHONGQING CHUANYI AUTOMATION +1

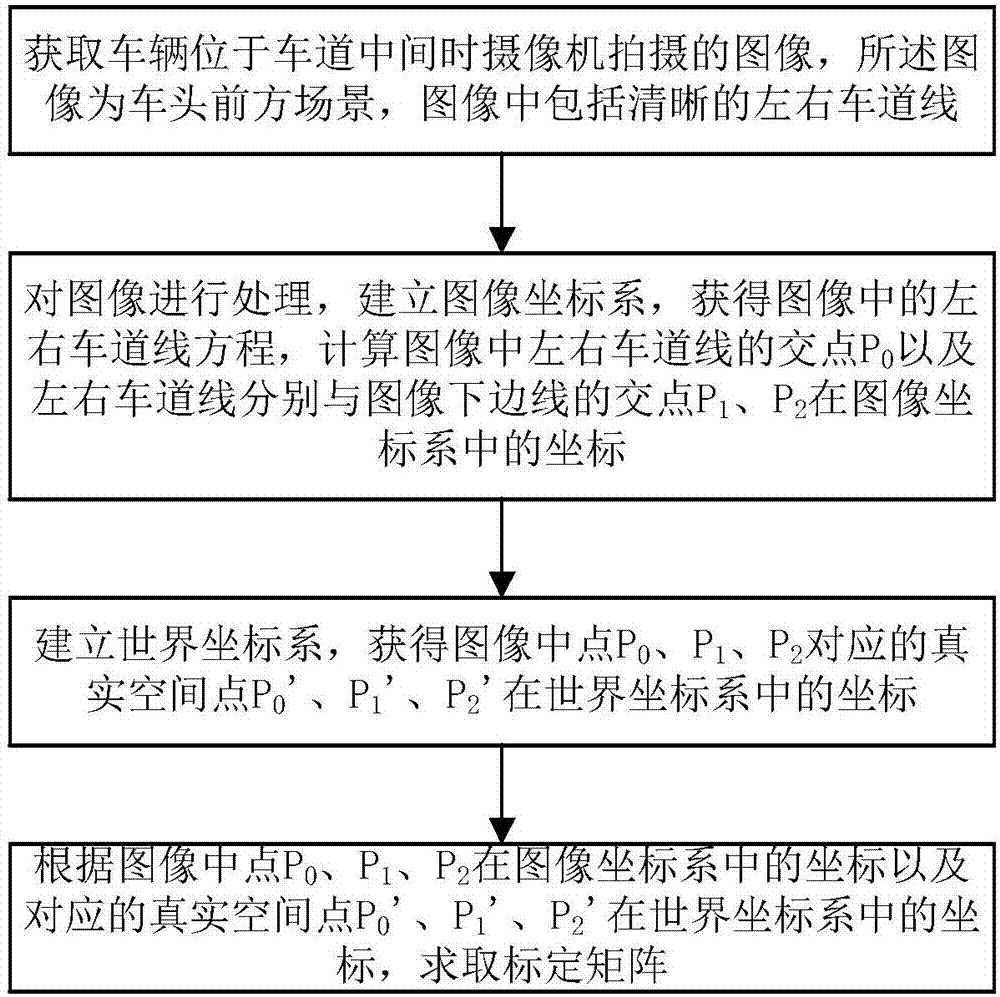

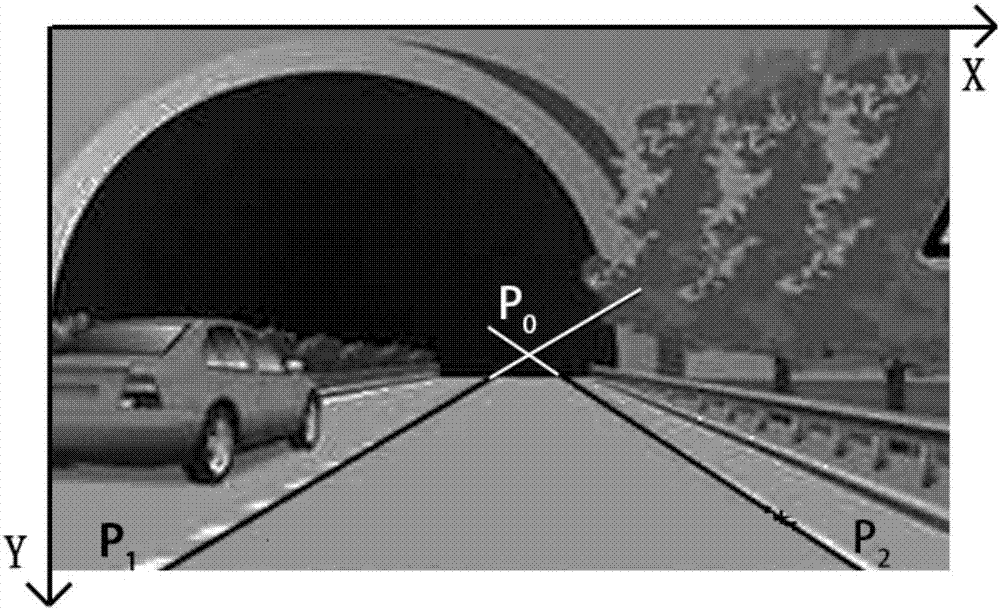

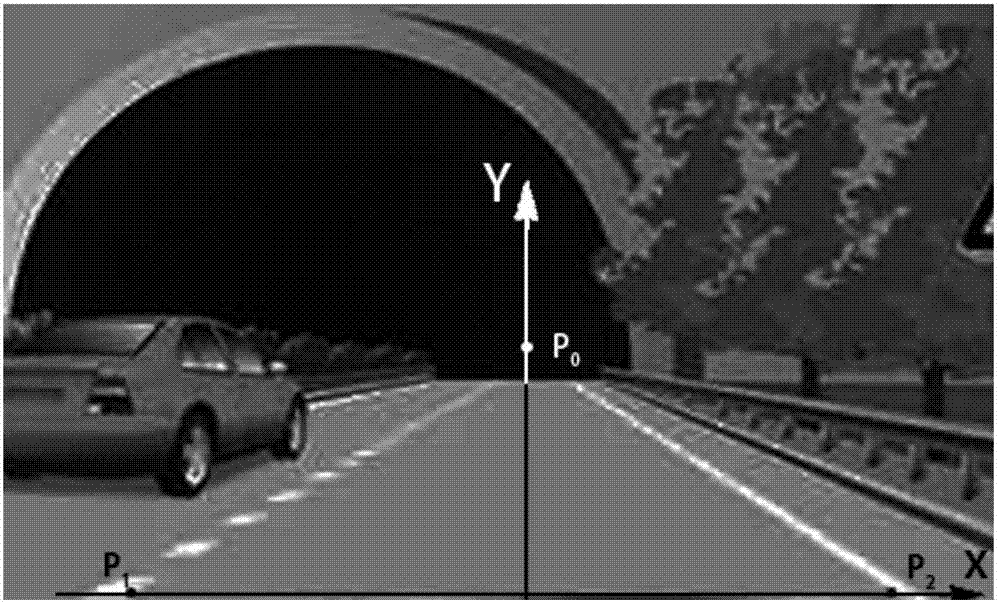

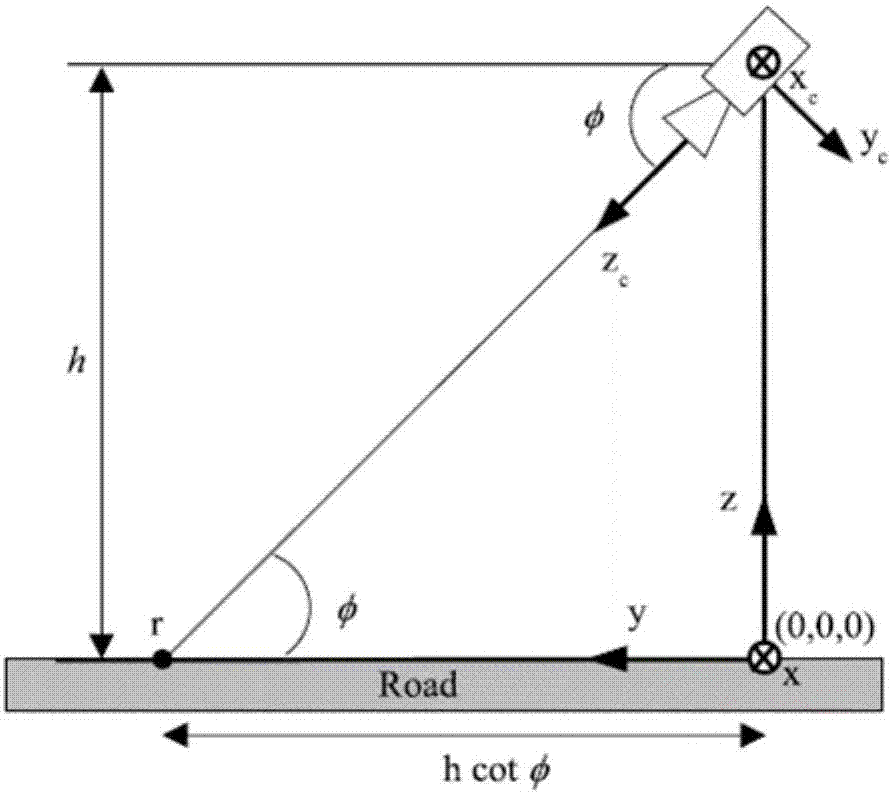

Vehicle-mounted camera automatic calibration method based on lane line vanishing points

ActiveCN107133985AImprove calibration accuracyEasy to operateImage analysisVanishing pointCalibration matrix

The invention provides a vehicle-mounted camera automatic calibration method based on lane line vanishing points. The method comprises the steps that an image photographed by a camera when the vehicle is in the middle of the lane is acquired, wherein the image includes clear left and right lane lines; the image is processed, a left and right lane line equation is acquired, and the coordinates of the intersection point P0 of the left and right lane lines and the intersection points P1 and P2 of the left and right lane lines and the lower side line of the image in an image coordinate system are calculated; a world coordinate system is established, and the coordinates of the real space points P0', P1' and P2' corresponding to the points P0, P1 and P2 in the image in the world coordinate system are acquired; and a calibration matrix is obtained according to the coordinates of the points P0, P1 and P2 in the image in the image coordinate system and the coordinates of the corresponding real space points P0', P1' and P2' in the world coordinate system. According to the method, the vehicle only requires to be driven in the middle of the lane or parked in the middle of the lane and then the photographed image can be automatically processed, and the calibration matrix can be obtained by inquiring the width of the current lane so that the calibration accuracy is high, operation is easy and convenient without artificial intervention and real-time calibration can be performed.

Owner:常州智行科技有限公司

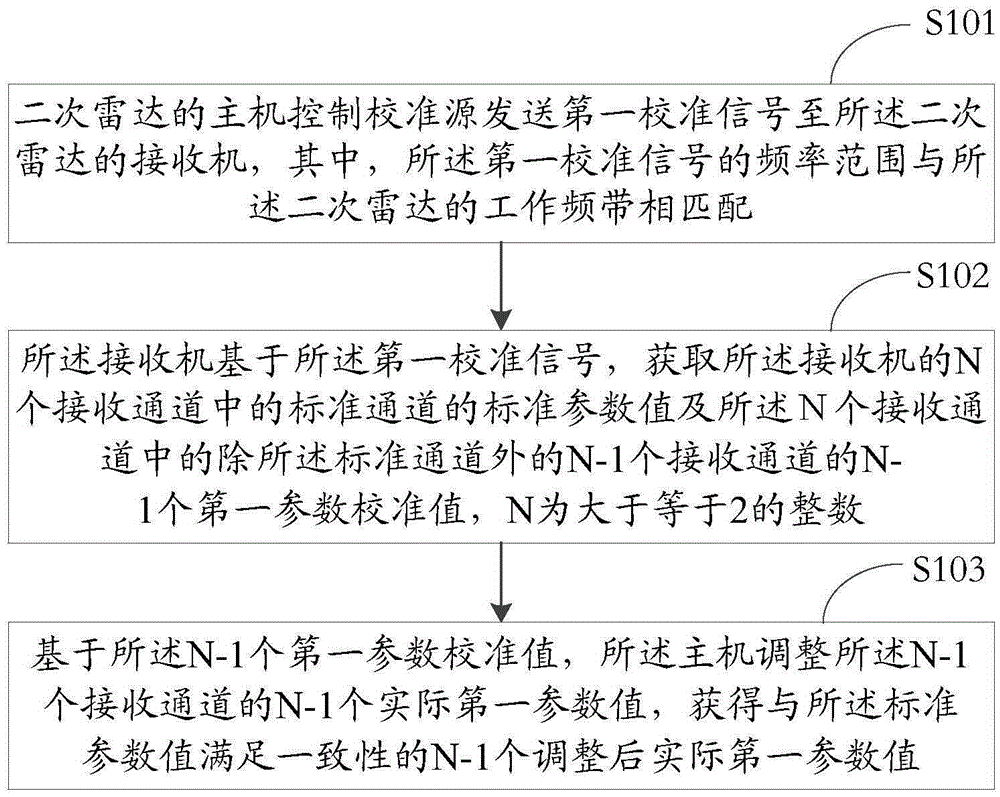

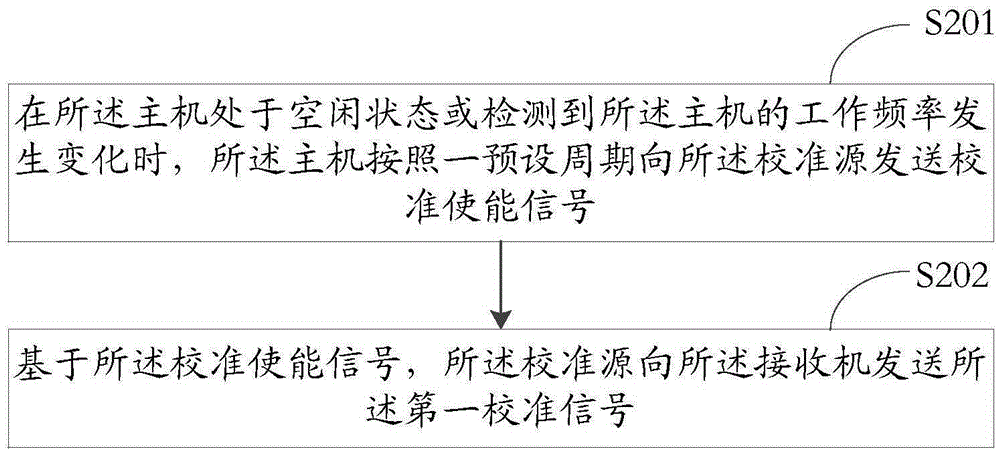

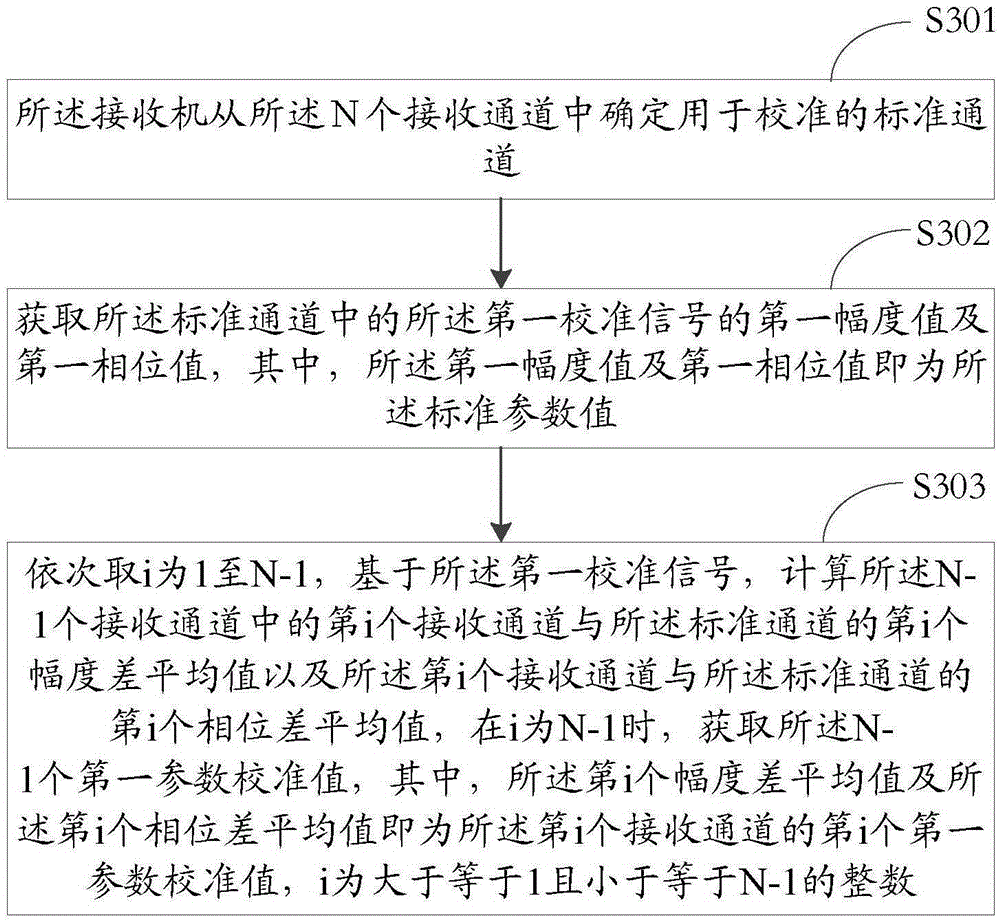

Radio frequency channel real-time calibration method and secondary radar

InactiveCN105425221AReduce maintenance costsReal-time calibrationRadio wave reradiation/reflectionRadarRadio frequency

The invention discloses a radio frequency channel real-time calibration method and a secondary radar. The method comprises the steps that the main unit of the secondary radar controls a calibration source to transmit a first calibration signal to a receiver of the secondary radar, wherein the frequency range of the first calibration signal is matched with the working band of the secondary radar; the receiver obtains a standard parameter value of a standard channel of N receiving channels and (N-1) first parameter values of (N-1) receiving channels, except the standard channel, of the receiver based on the first calibration signal, wherein N is an integer which is greater than or equal to 2; the main unit adjusts the (N-1) actual first parameter values of the (N-1) receiving channels based on the (N-1) first parameter values, and obtains (N-1) adjusted actual first parameter values which are consistent with the standard parameter value.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

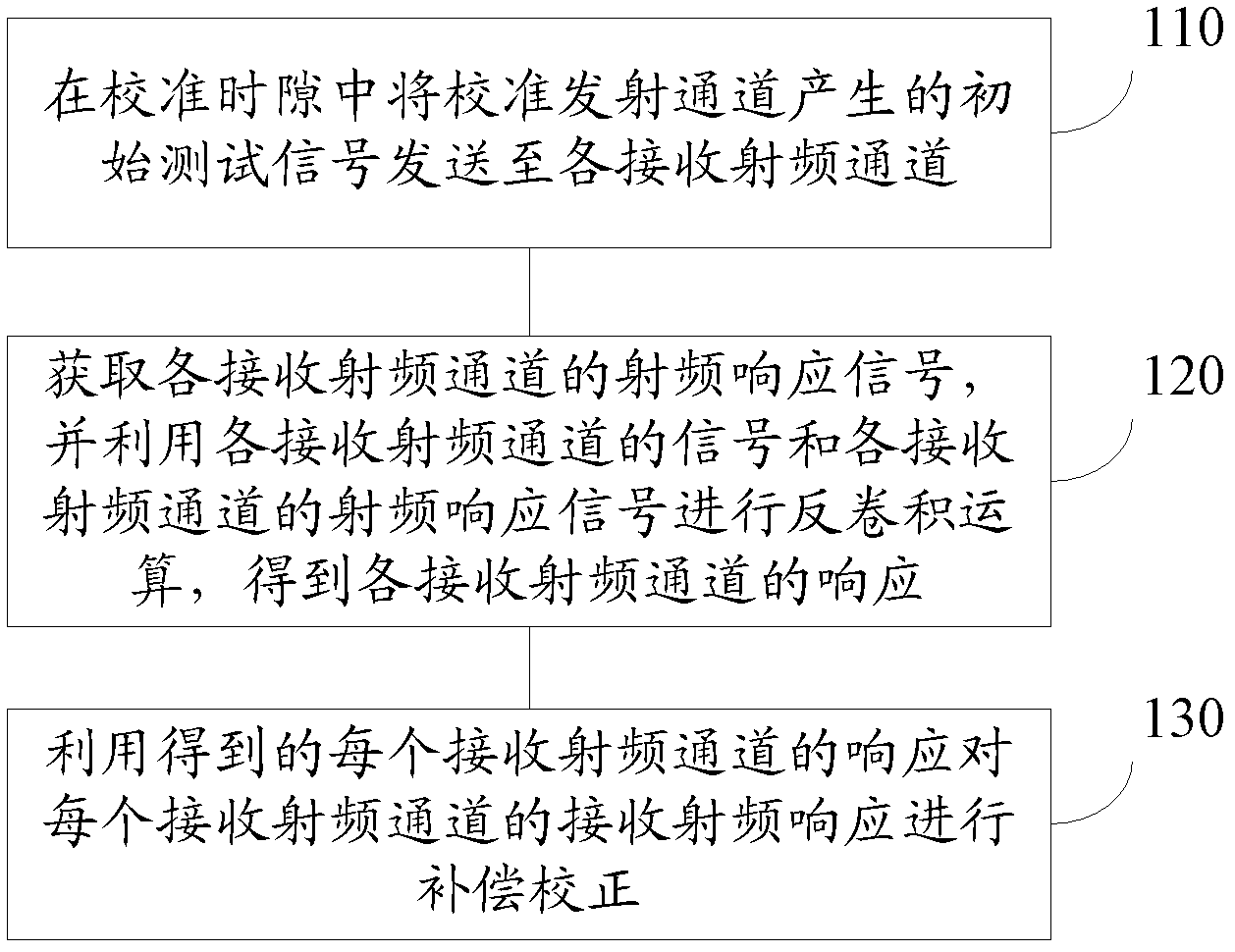

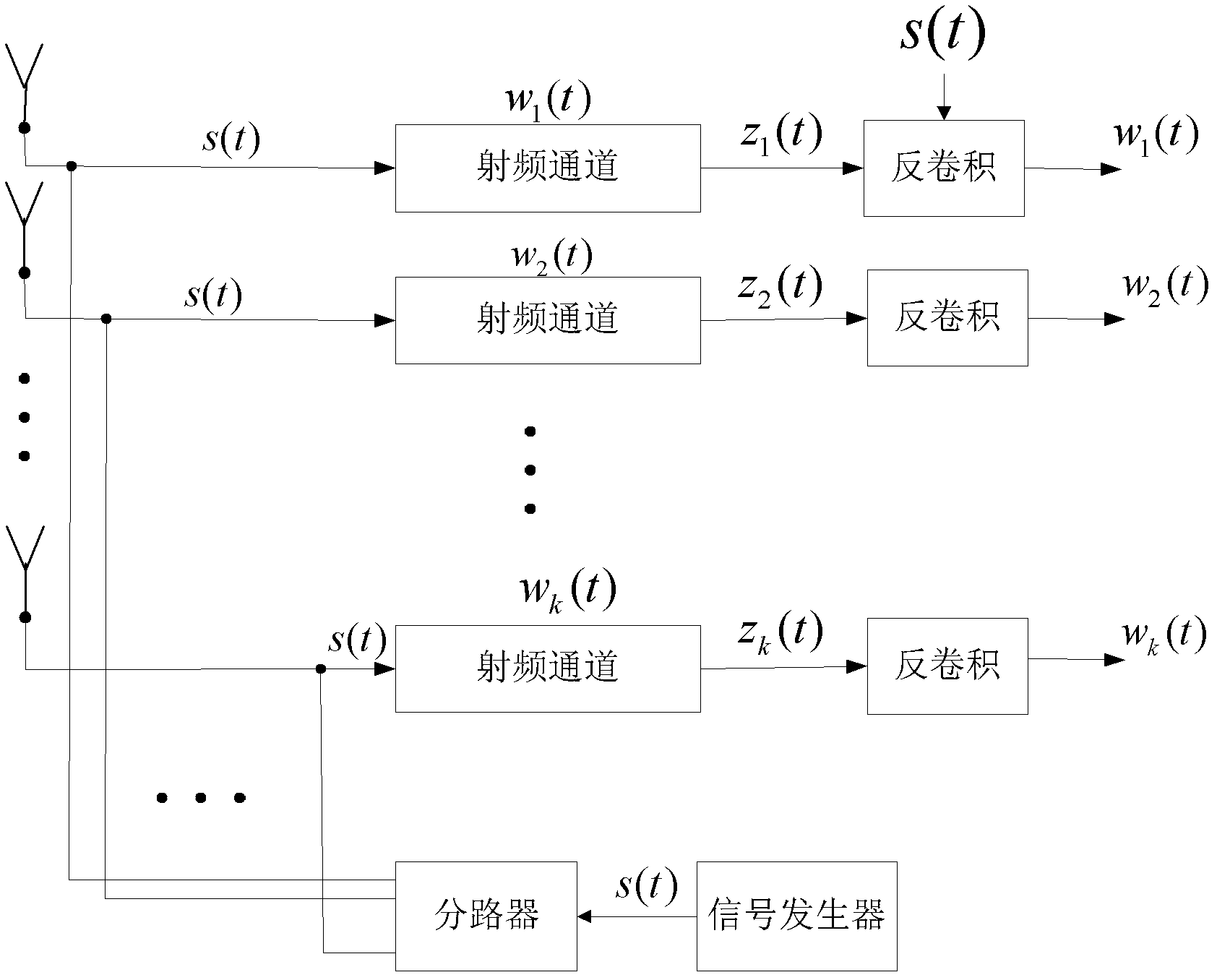

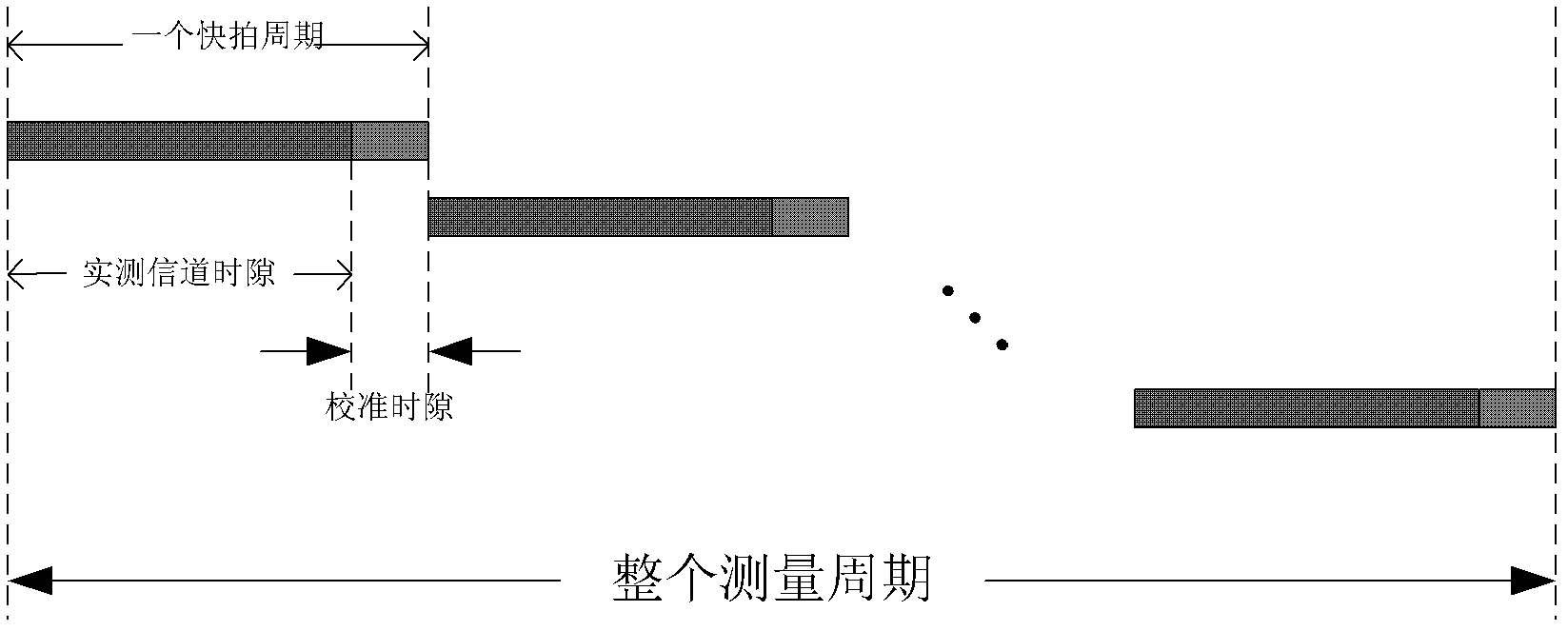

Method and device for carrying out real-time calibration on radio frequency responses of multi-channel receiver

InactiveCN102594430AReal-time calibrationThe calibration slot will calibrate the real-timeSpatial transmit diversityReceivers monitoringEngineeringRadio frequency

This invention provides a method and a device for carrying out real-time calibration on radio-frequency responses of a multi-channel receiver, and relates to the technical field of wireless communication. The method provided by the invention comprises the following steps of: sending an initial test signal generated by a calibrating transmitting channel to each receiving radio-frequency channel during a calibrating timeslot; acquiring a radio-frequency response signal of each receiving radio-frequency channel, and carrying out a deconvolution operation by using the signal and radio-frequency response signal of each receiving radio-frequency channel so as to obtain a response of each receiving radio-frequency channel; and carrying out compensation calibration on the receiving radio-frequency response of each receiving radio-frequency channel by using the response of each receiving radio-frequency channel. In the process, the acquisition of responses of each receiving radio-frequency channel can be realized in the multi-channel receiver, therefore, in actual applications, each receiving radio-frequency response of the multi-channel receiver can be accurately and conveniently calibrated in real time in various application scenes.

Owner:TSINGHUA UNIV

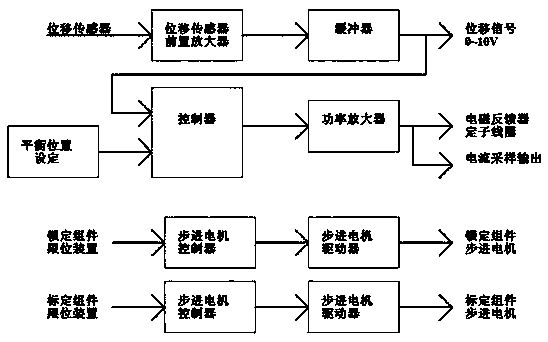

Micro-thrust measuring device with on-line calibration and locking functions

InactiveCN110146208AReal-time calibrationGuaranteed multiple working conditionsElectrical testingApparatus for force/torque/work measurementForce methodPower flow

The invention relates to a micro-thrust measuring device with on-line calibration and locking functions. The micro-thrust measuring device is used for the parameter testing of the ground long-life test of a Hall effect thruster. In order to measure the real-time thrust value of the Hall effect thruster under a plurality of working conditions in the long-life test process of the Hall effect thruster, a thruster to be tested is installed on a movable frame; the movable frame swings with low amplitude under the action of the thrust of the Hall thruster; the displacement sensor of an electromagnetic feedback assembly performs detection; swing displacement signals are inputted into a PID feedback control circuit; and an electromagnetic feedback force is in linear relation with coil current outputted by the PID circuit; the static characteristic of a thrust frame is calibrated through a standard mass weight in advance, so that the magnitude of the thrust can be obtained. According to the device of the invention, the electromagnetic feedback force method is adopted to carry out multi-times and multi-working-condition real-time on-line measurement on the Hall effect thruster; an on-line calibration and locking device is adopted to lock and unlock the micro-thrust measuring device a plurality of times, so that the static characteristic of the micro-thrust measuring device is obtained inreal time, and the accuracy and reliability of a thrust test are ensured.

Owner:BEIHANG UNIV

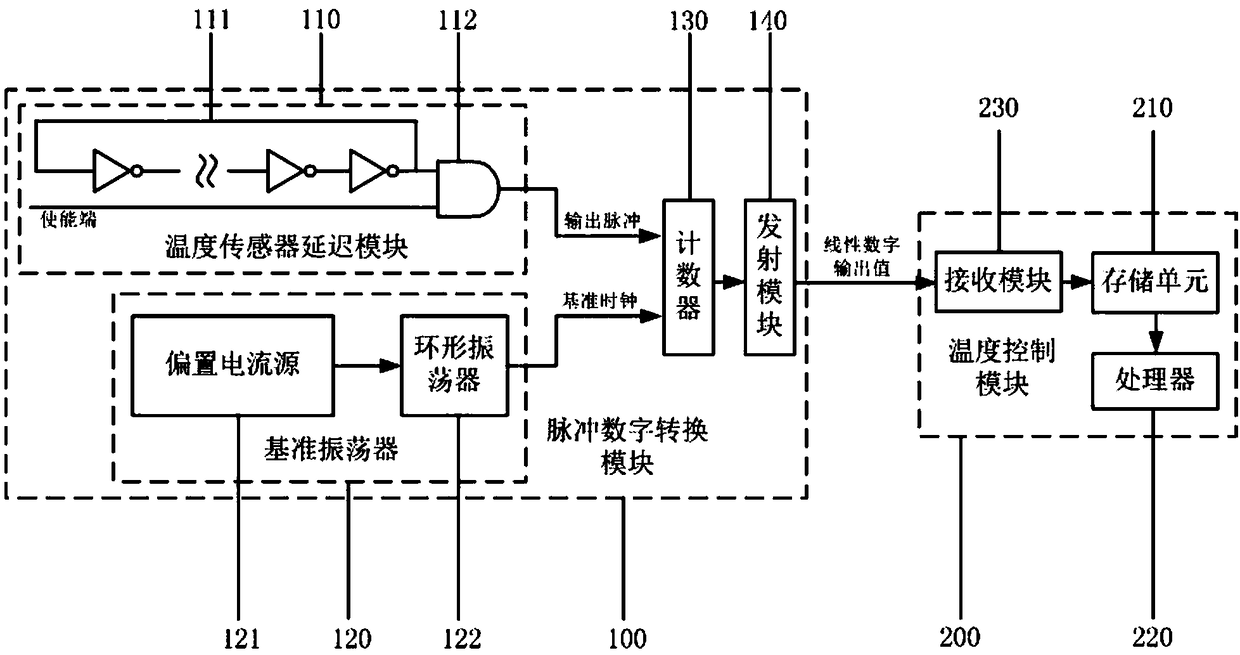

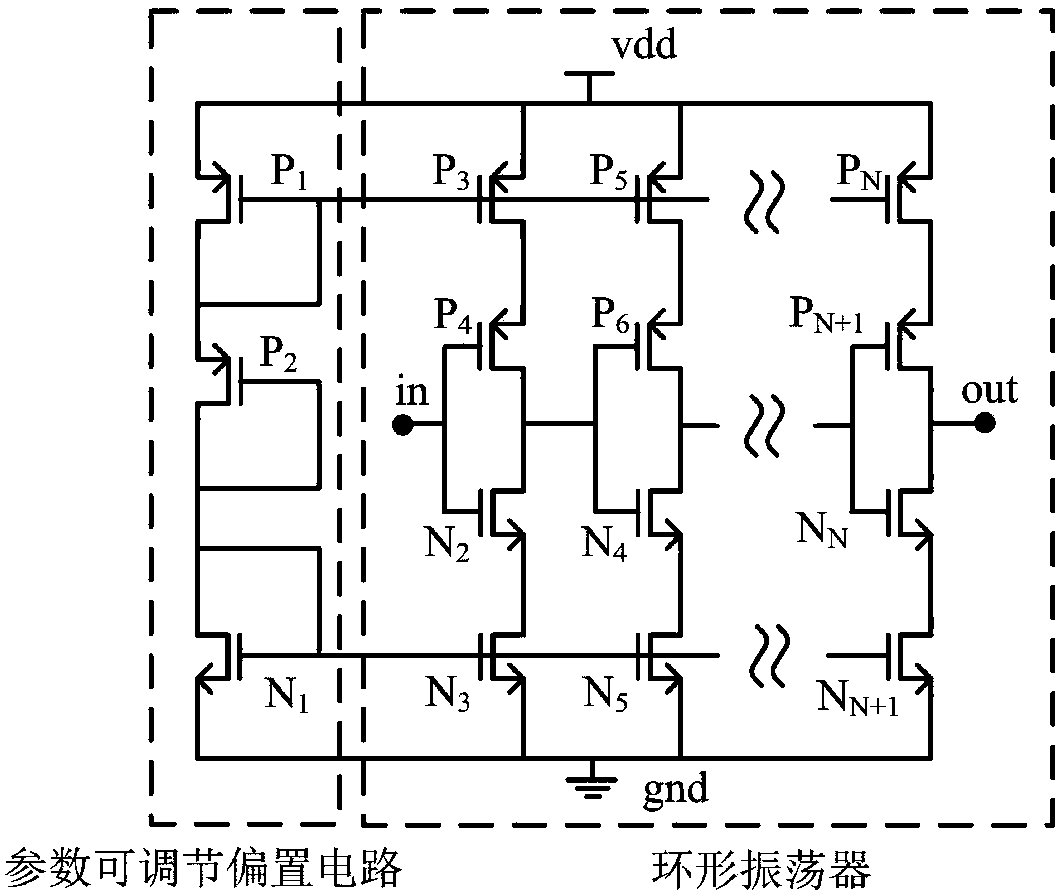

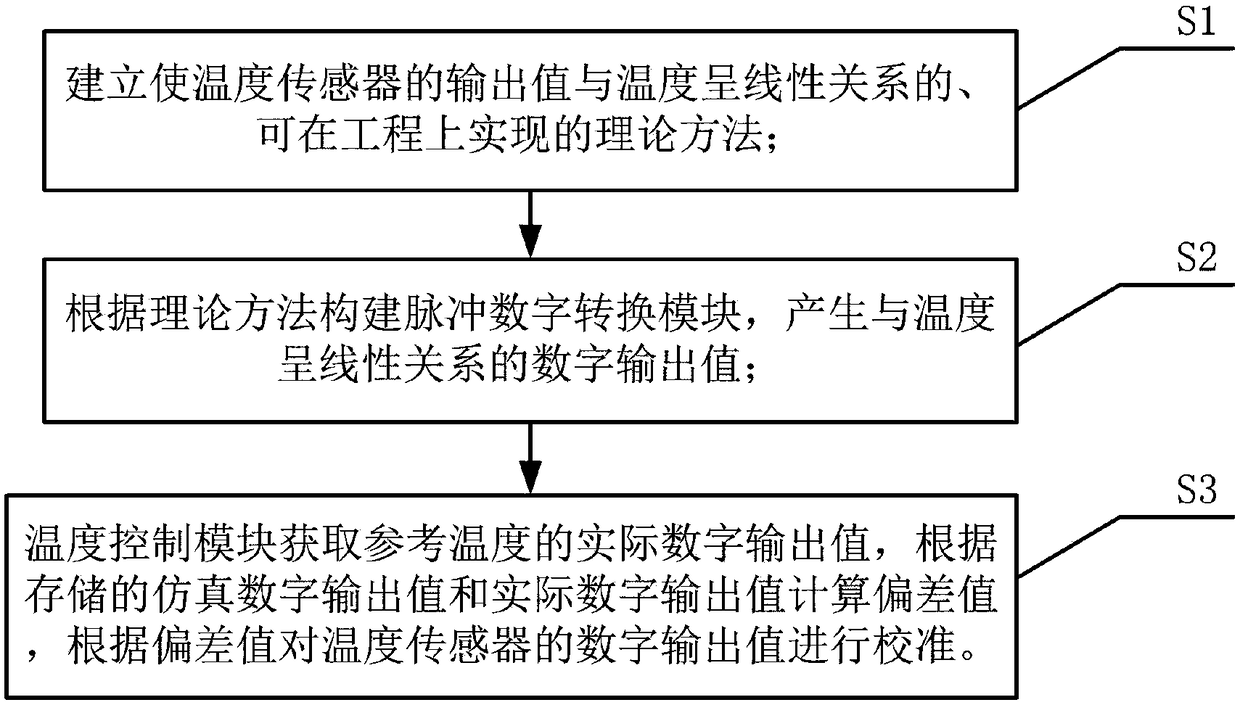

Pulse modulation temperature sensor calibration system and calibration method

ActiveCN108344527AHigh measurement accuracyAchieve calibrationThermometer testing/calibrationTemperature controlTheoretical methods

The invention provides a pulse modulation temperature sensor calibration system and calibration method, and belongs to the technical field of integrated circuit design. The system comprises a pulse digital conversion module and a temperature control module. The method comprises the steps that a theoretical method which enables the digital output value of the temperature sensor to have a linear relation with the temperature and can be implemented in engineering is established; the pulse digital conversion module is constructed according to the theoretical method so as to generate the digital output value having the linear relation with the temperature; and the temperature control module acquires the actual digital output value of the reference temperature, calculates the deviation value according to the stored simulation digital output value and the actual digital output value and calibrates the digital output value of the temperature sensor according to the deviation value. According to the system and the method, the measurement accuracy of the sensor can be enhanced, the calibration process can be simplified, real-time automatic calibration can be performed and the circuit structure can be simplified.

Owner:LIAONING TECHNICAL UNIVERSITY

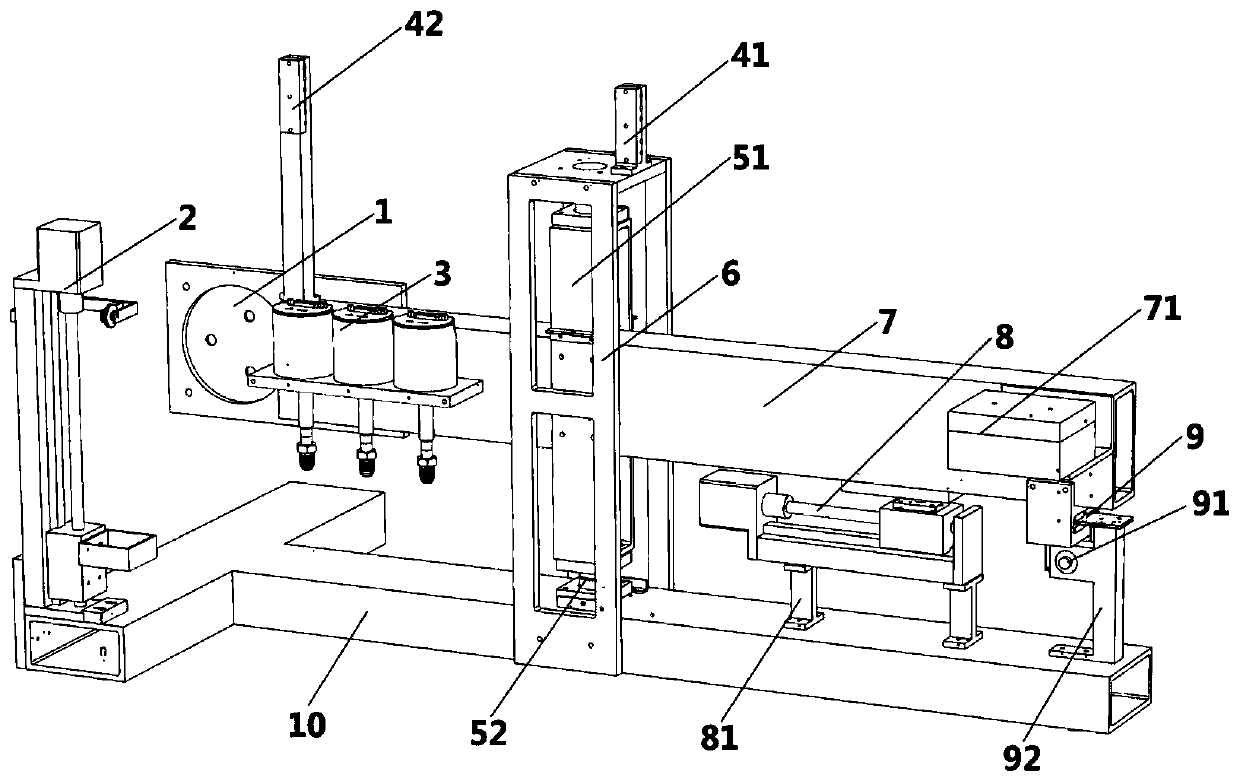

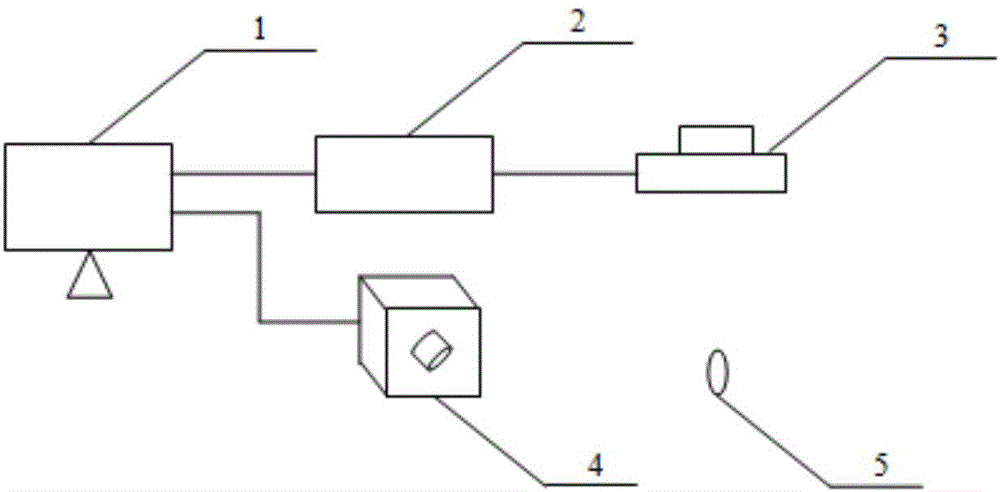

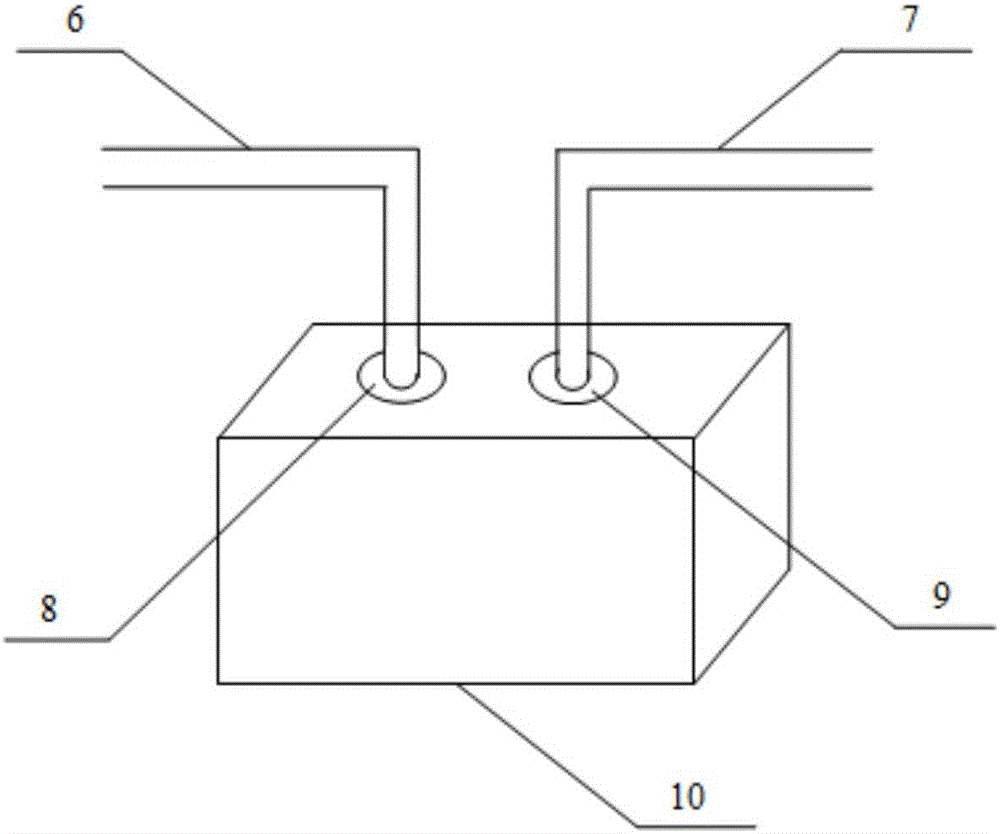

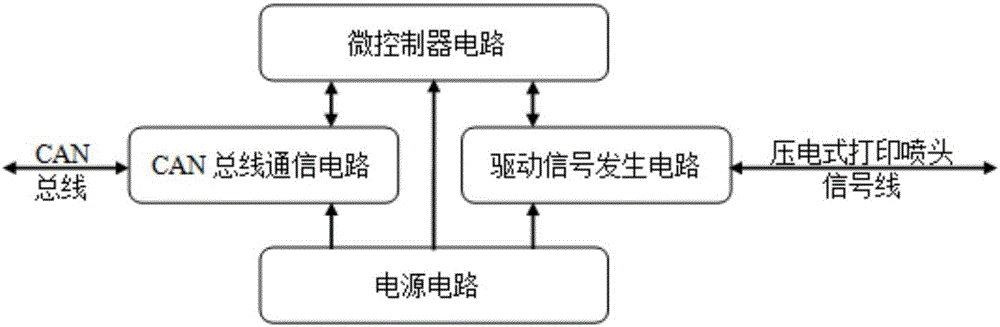

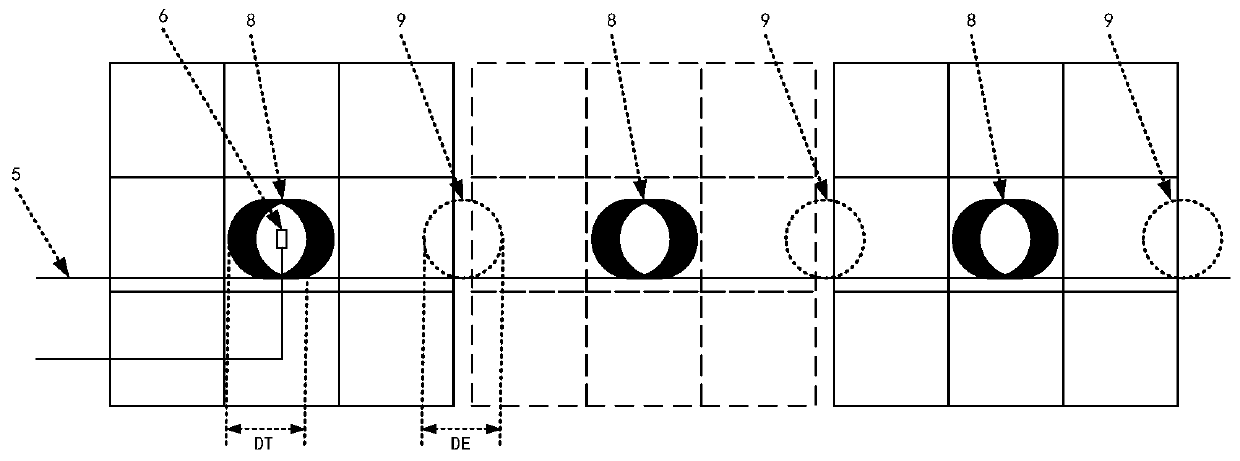

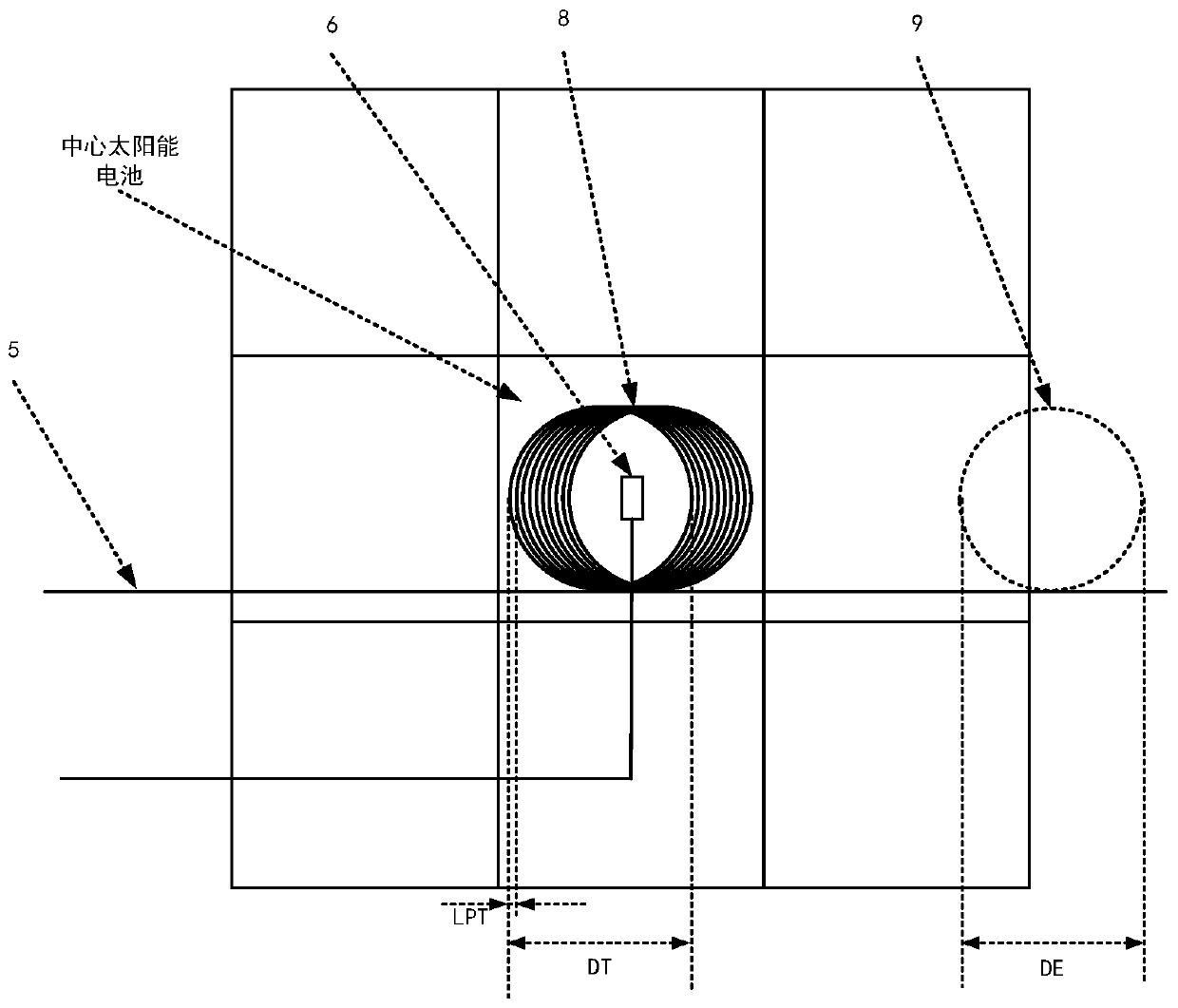

Ink droplet ejection state adjusting system and method for piezoelectric printing nozzle

The invention, which belongs to the technical field of ink-jet printing, provides an ink droplet ejection state adjusting system and method for a piezoelectric printing nozzle. The system is composed of a computer computing platform, a nozzle drive controller, a piezoelectric printing nozzle and a CCD camera. One end of the nozzle drive controller is connected with the computer computing platform and the other end is connected with the piezoelectric printing nozzle; and the CCD camera is connected with the computer computing platform. The nozzle drive controller generates a drive signal for the piezoelectric printing nozzle and simultaneously carries out time sequence controlling on the drive signal; the piezoelectric printing nozzle fluctuates in an ink cavity under the drive signal provided by the nozzle drive controller and the fluctuation is spread to spraying holes to form ink droplets; and the CCD camera captures states of ink droplets ejected by the piezoelectric printing nozzle.

Owner:天津斯沃姆科技发展有限公司

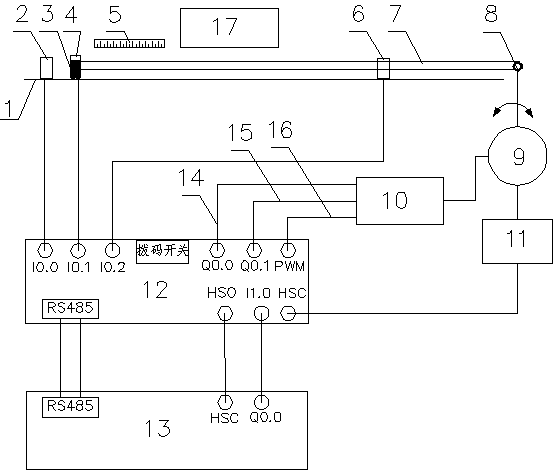

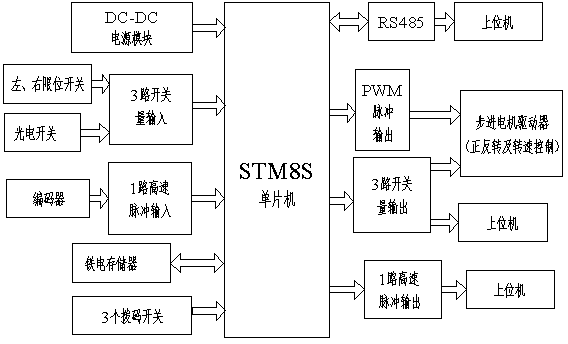

Workpiece length measurement device

InactiveCN103913122AEasy to installLow costUsing optical meansElectrical and Electronics engineering

A workpiece length measurement device comprises a left limit switch, a transmission mechanism, a sliding body, a photoelectric switch, a right limit switch, a stepper motor, a calibration scaleplate, an encoder, a controller and an industrial personal computer, wherein the transmission mechanism comprises a conveying belt and a transmission device. By shielding or reflecting light beams emitted by the photoelectric switch through a measured object, whether the object exists or not is detected; the length or the width of the measured object is detected through the photoelectric switch sliding along with the sliding body. The moving distance of the photoelectric switch can be conveniently acquired through the number of pulses of the encoder, and therefore the length of the measured object can be measured. In order to solve the problem that the length of the measured object is irrelevant to the photoelectric switch, the stepper motor and other parameters and make the measurement device be popularized and adapt to the measured object easily, real-time calibration is achieved by adding the calibration scaleplate, and the workpiece length measurement device can be accurately used permanently. The workpiece length measurement device not only is convenient to install and low in cost but also is high in measurement accuracy, stable and reliable in running, and convenient to popularize for use.

Owner:UNIV OF JINAN

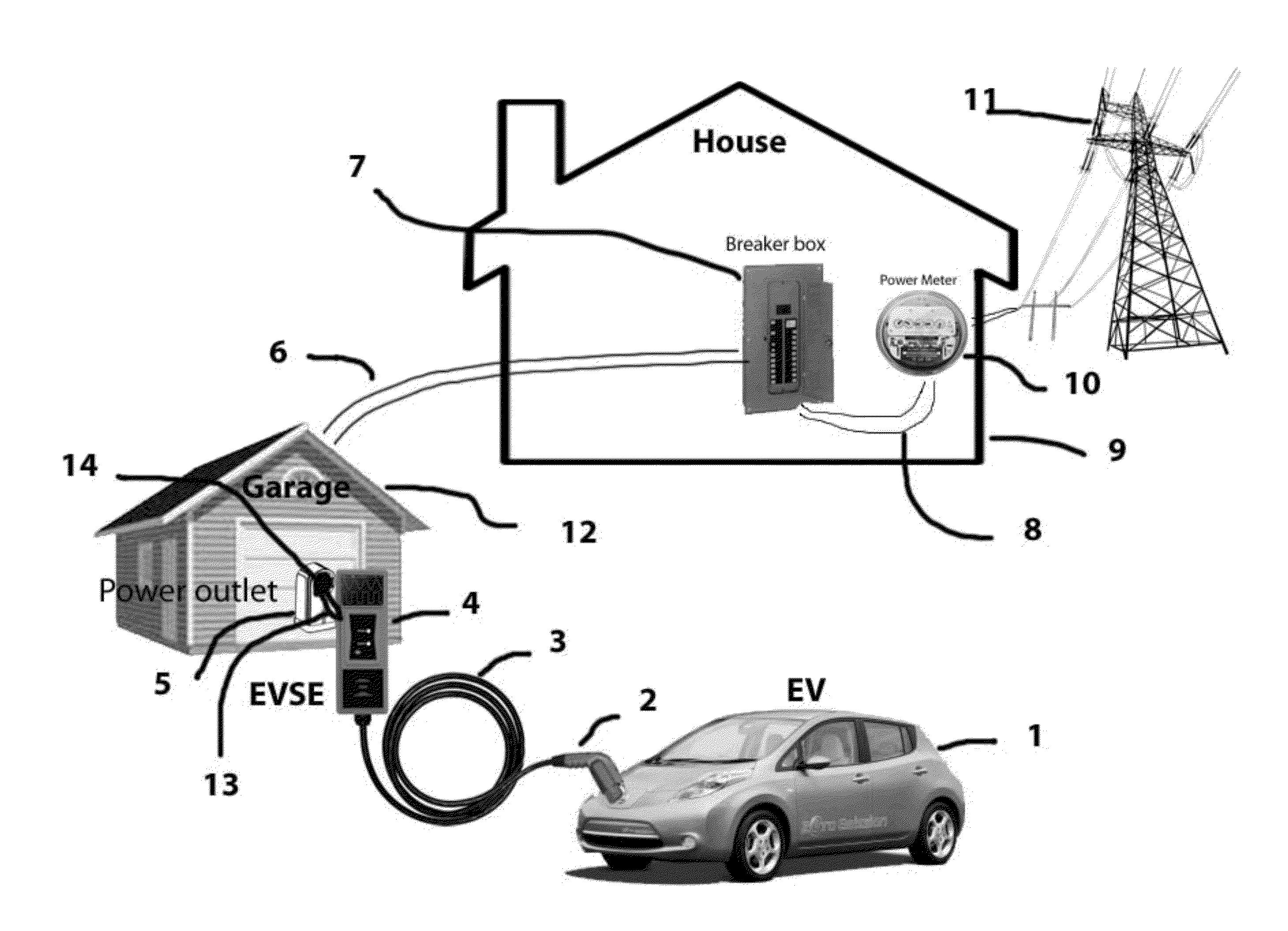

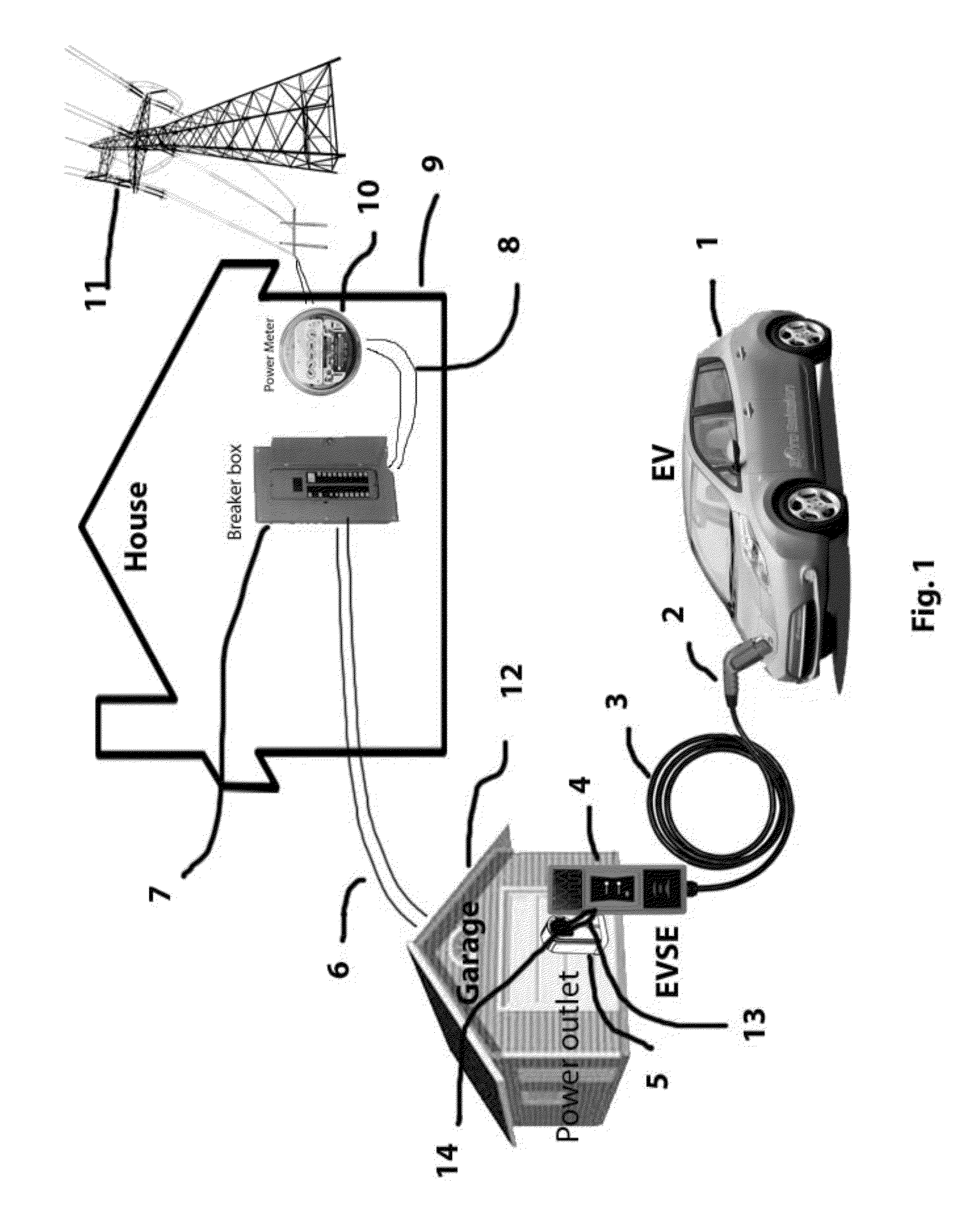

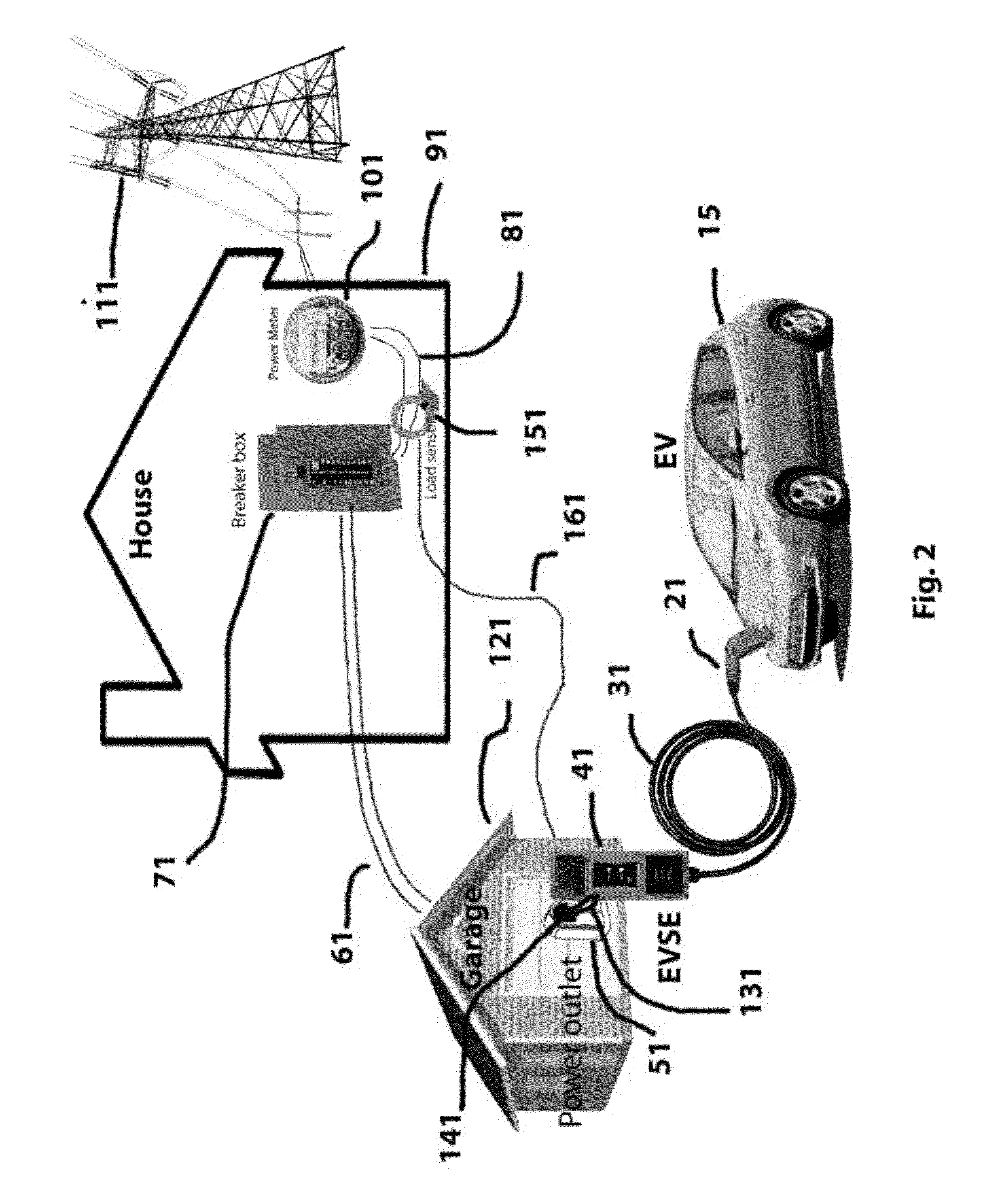

System and method for electric vehicle (EV) charging

InactiveUS20140077762A1High strength materialReal-time calibrationBatteries circuit arrangementsCharging stationsResidenceElectrical battery

A smart Electric Vehicle Supply Equipment (“EVSE”) that will accept input from different sources to determine the max rate of charge an Electric Vehicle (EV) can be safely charged at without overloading the electrical system of the residence. The system will also communication signals from the power company, fire department and police to reduce or eliminate the charging of the battery in the EV if the situation requires. The smart EVSE further comprises a non-invasive current and / or load sensing unit coupled to the power source for recharging the battery or batteries in the EV, cables to connect the load sensing unit to the EVSE, and optional wireless communication transmitter (sensor to EVSE), EVSE unit with compensating ability.

Owner:SPANOS MIKE

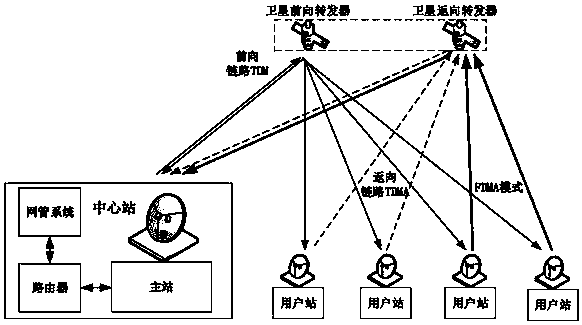

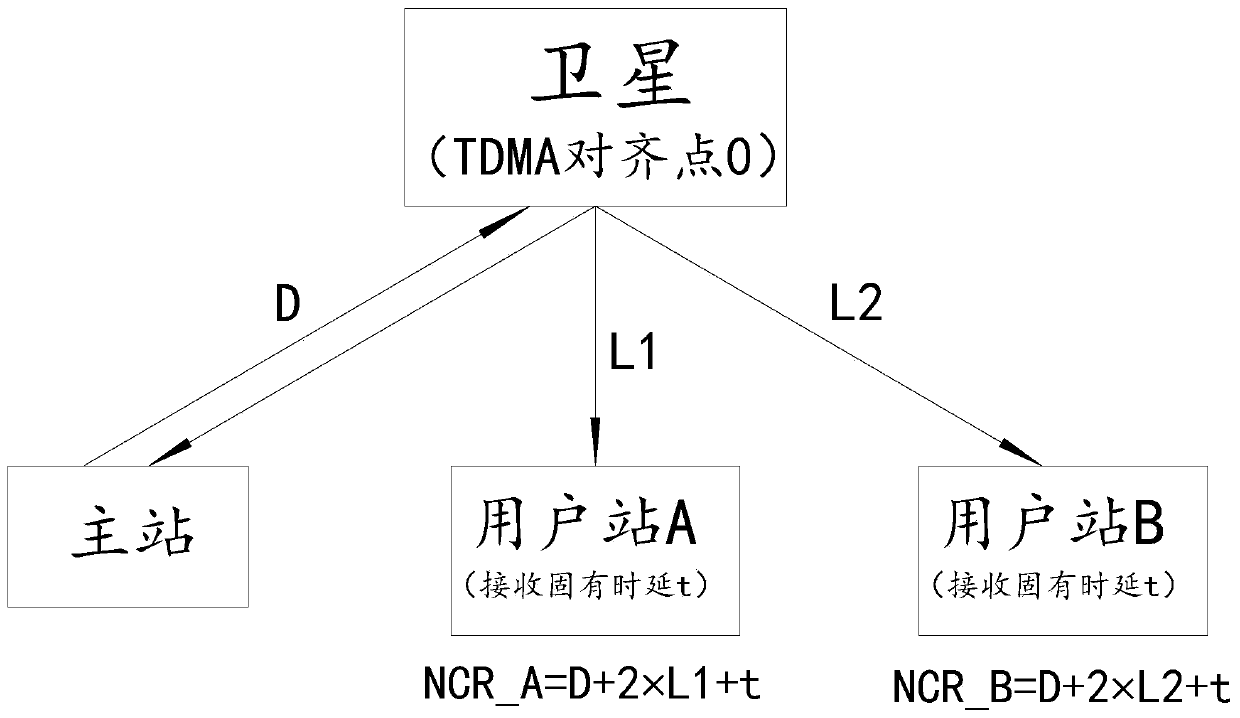

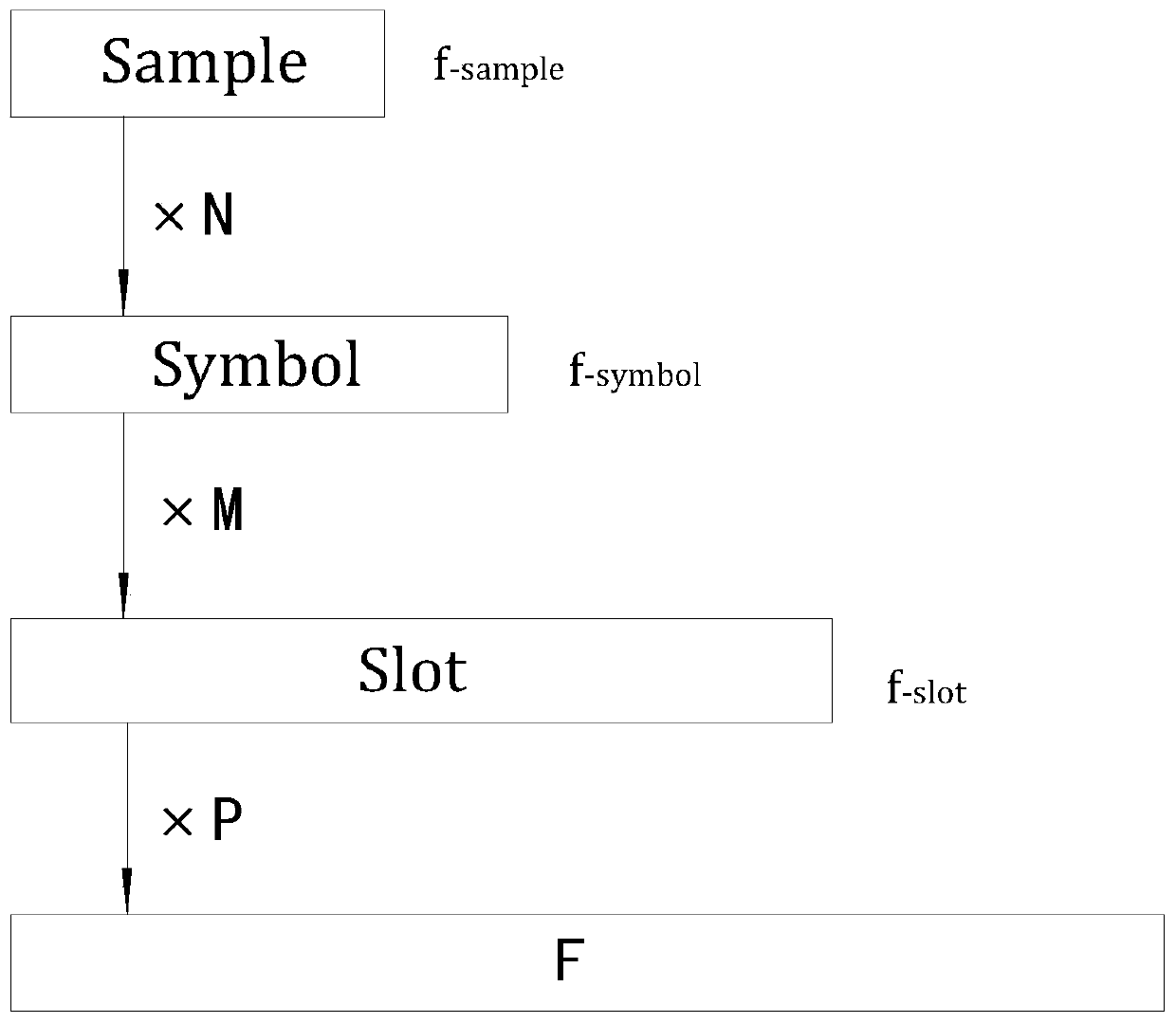

Satellite communication system time synchronization method based on TDMA

ActiveCN110401504ASimple methodReal-time calibrationTime-division multiplexRadio transmissionTimestampSystem time

A satellite communication system time synchronization method based on a TDMA comprises: arranging a clock with the frequency of fx at a sending station end to serve as a network reference clock NCR, each clock period counter of the network reference clock NCR being + 1, and performing zero clearing every 24 hours; taking a clock count value NCR_Value of a sending station end as a timestamp and inserting the timestamp into the forward link signal sequence at regular time; the user station calculating to obtain a link total time count value NCR _ X according to the received NCR_Value and a preset NCR_offset of the geographical location information of the terminal; calculating offsets of the frame F, the time slot Slot and the symbol Symbol according to the NCR_X, and performing continuous accumulation by taking f_symbol as a reference clock to serve as a time slot adjustment parameter to perform time slot adjustment on the user station. The method does not depend on whether the demodulation chip supports a standard NCR analysis function or not, belongs to open-loop calibration, and is real-time in calibration and high in precision.

Owner:广州天链通信科技有限公司

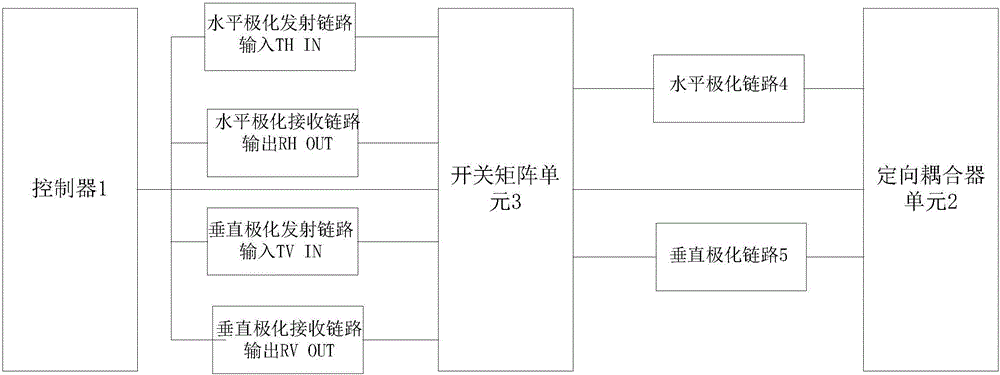

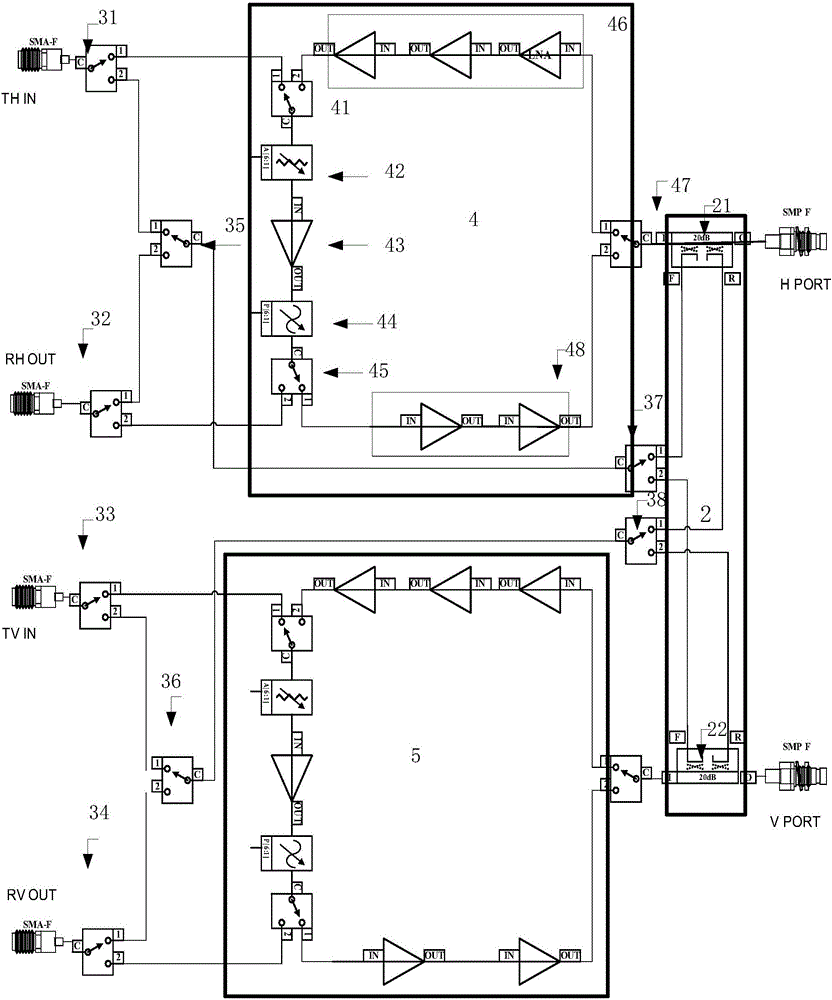

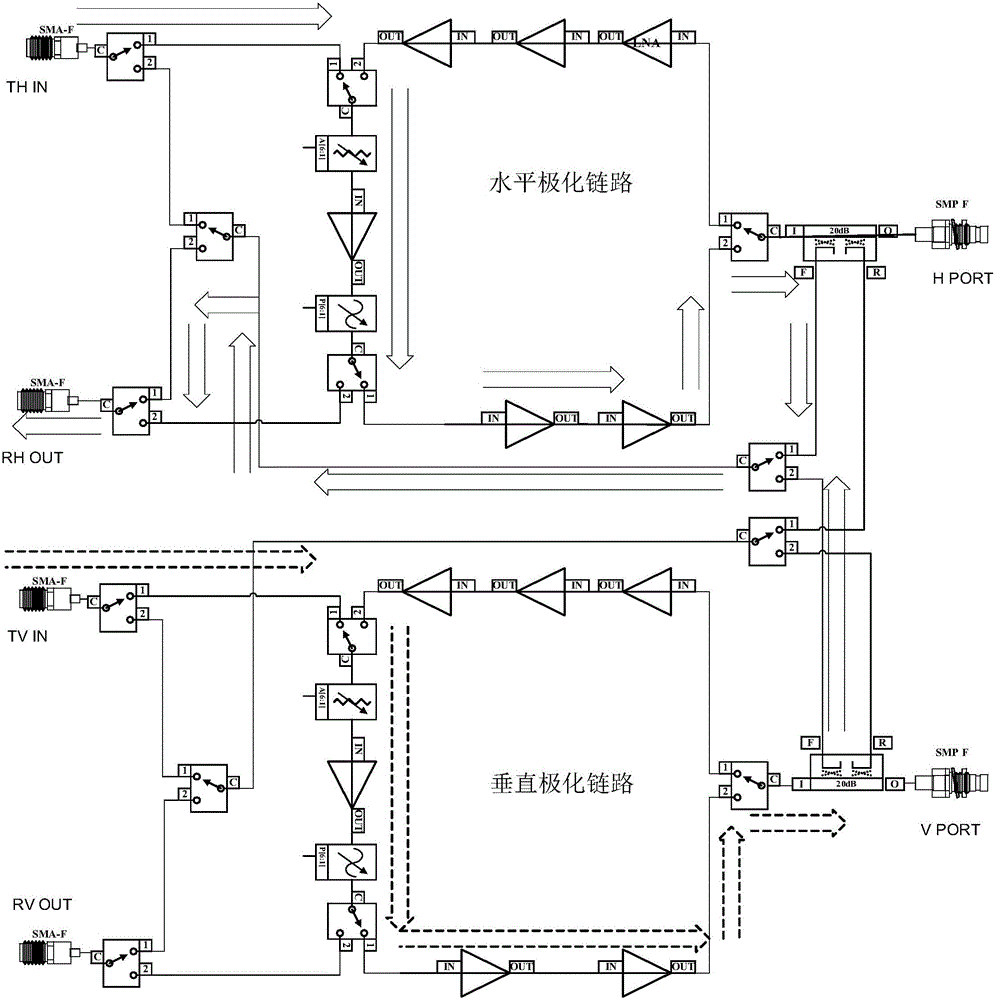

Phased array radar system transceiver unit and error calibration method thereof

ActiveCN105974383AFully automatedReal-time calibrationWave based measurement systemsTransceiverRadar systems

The invention discloses a phased array radar system transceiver unit and an error calibration method thereof. The phased array radar system transceiver unit comprises a horizontal polarized link and a vertical polarized link and is characterized by further comprising a controller, a directional coupler and a switch matrix unit, wherein the directional coupler is used for sampling radar emission signals and receiving calibration signals, the switch matrix is used for providing a common return for the horizontal polarized link and the vertical polarized link so as to realize automatic and real-time calibration of relative errors of the horizontal polarized link and the vertical polarized link of a radar system, and the phased array radar system transceiver unit is additionally provided with the directional coupler and the open matrix unit on the basis of a traditional phased array radar system transceiver unit.

Owner:XTR SOLUTIONS

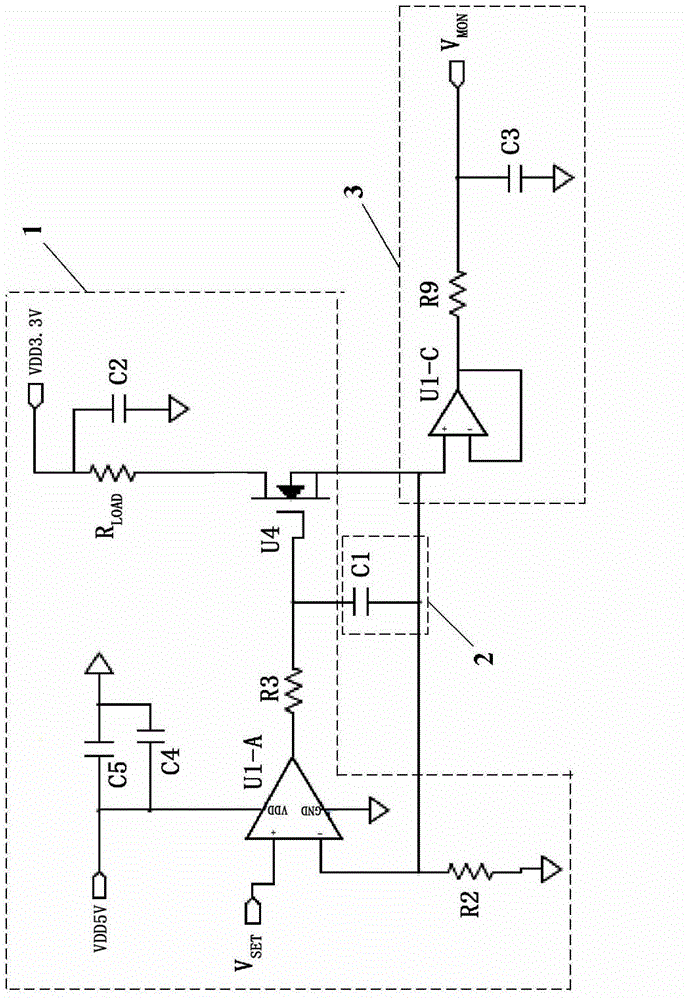

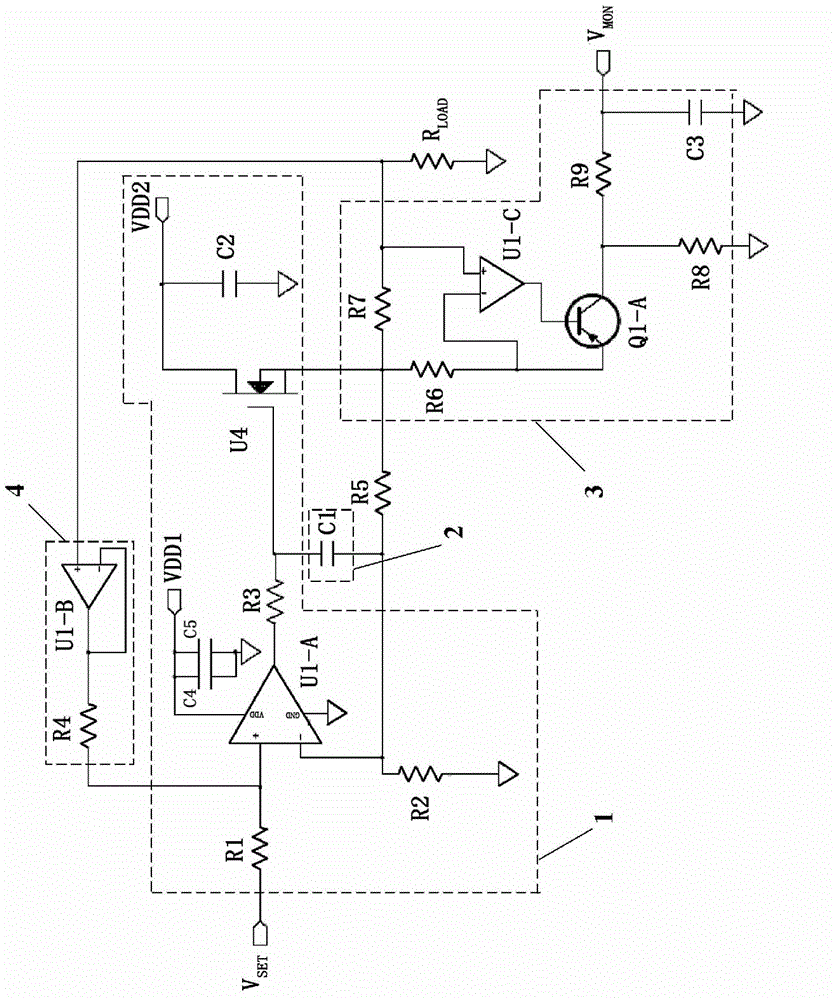

Constant current source power supplying circuit of laser

InactiveCN102723658AAchieve calibrationReal-time calibrationExcitation process/apparatusSemiconductor lasersNegative feedbackAudio power amplifier

The invention discloses a constant current source power supplying circuit of a laser, which is mainly used in the field of tunable laser and is capable of providing a highly stable power supplying current of a laser. The constant current source power supplying circuit comprises a voltage controlled input end, a voltage controlled constant current source circuit, a current output end, and a positive feedback circuit, wherein the positive feedback circuit includes a voltage follower, an input end of the voltage follower is connected with the current output end, an output end of the voltage follower is connected with a non-inverting input end of a first operational amplifier. A control voltage is inputted from the voltage controlled input end, the magnitude of the power supplying current of the laser outputted by the current output end is controlled through the voltage controlled constant current source circuit, when the control voltage jumps, the voltage of the non-inverting input end of the first operational amplifier is controlled by the power supplying current through the positive feedback circuit for a smooth transition in the direction of the control voltage. Under the action that a negative feedback speed of the voltage controlled constant current source circuit is faster than a positive feedback speed of the same, the power supplying current changes to a current value setby the control voltage smoothly.

Owner:SICHUAN MARS TECH

Multi-spectral radiation temperature measuring system and multi-spectral radiation temperature measuring method

ActiveCN103644972AOvercoming Model ErrorsImprove measurement uncertaintyRadiation pyrometryRadiation temperatureMulti spectral

The invention discloses a multi-spectral radiation temperature measuring system and a multi-spectral radiation temperature measuring method. The multi-spectral radiation temperature measuring system comprises a wide-spectrum light source, and an incident collimating lens group, an emergent collimating lens group and a spectrograph which are sequentially arranged on an emergent light path of the wide-spectrum light source. A to-be-measured flame is arranged between the incident collimating lens group and the emergent collimating lens group. According to the multi-spectral radiation temperature measuring system, an emissivity coefficient self-calibration system is arranged on the same path as the measured flame. Flame emissivity coefficients under different wavelengths are obtained by recording spectral parameters of the wide-spectrum light source, the flame and the wide-spectrum light source plus the flame. The method is used for correcting parameters of the multi-spectral radiation temperature measuring system, overcomes model error in traditional theory calculation correction and improves the measurement uncertainty.

Owner:NORTHWEST INST OF NUCLEAR TECH

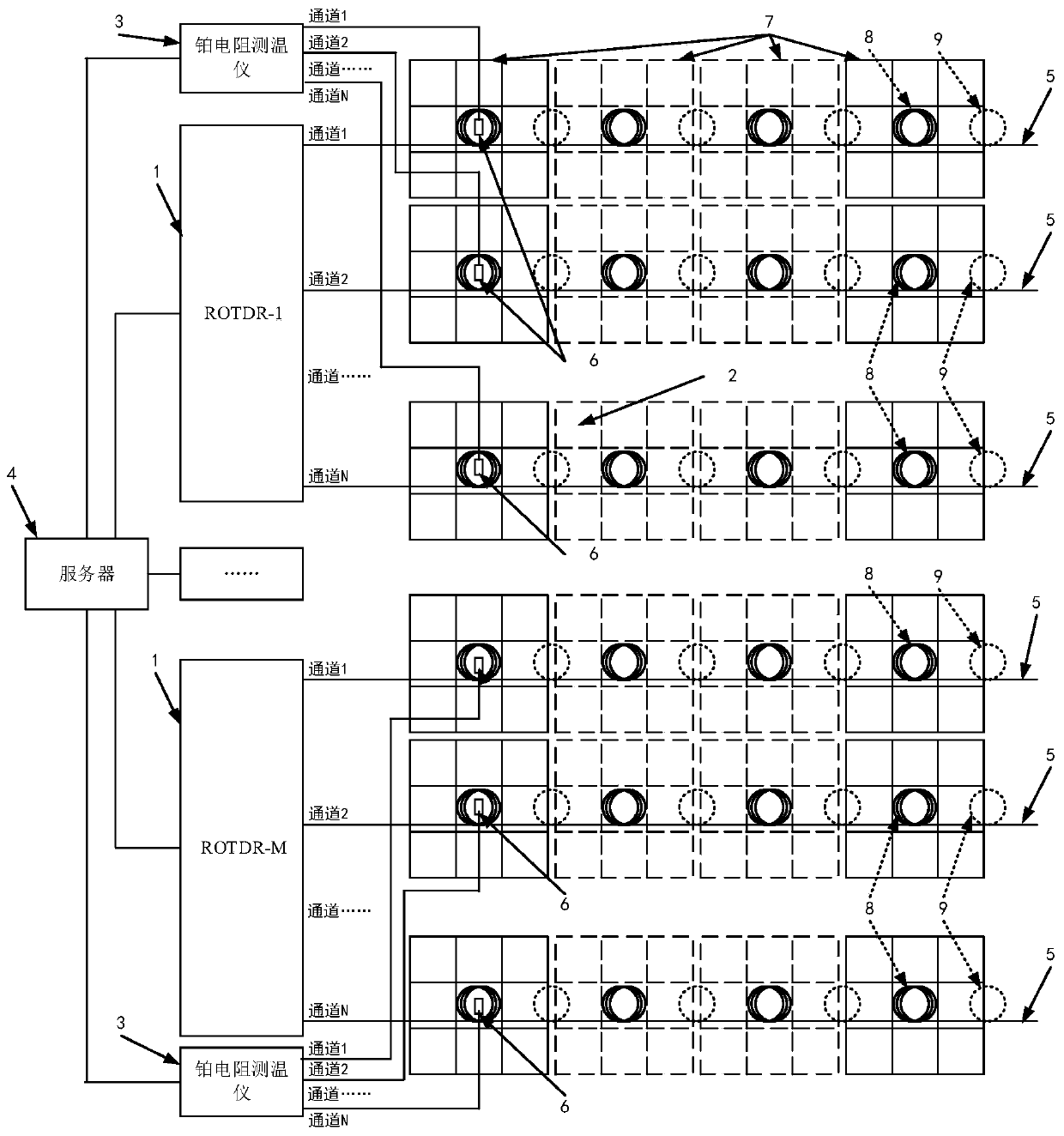

Solar panel temperature monitoring system based on optical fiber temperature distribution tester, and distribution monitoring method

InactiveCN110455437AImprove reliabilityReduce complexityPhotovoltaic monitoringThermometers using physical/chemical changesElectrical resistance and conductanceEngineering

The invention discloses a solar panel temperature monitoring system based on an optical fiber temperature distribution tester, and a distribution monitoring method. The system comprises an optical fiber temperature distribution tester, a solar panel component, a platinum resistance thermometer, and a server, wherein the optical fiber temperature distribution tester is provided with a temperature sensing cable that is bonded on a back panel of the solar panel component, the platinum resistance thermometer is connected with a platinum resistance probe which is fixed at a position where the temperature sensing cable is bonded on the back panel of the solar panel component, and both the platinum resistance thermometer and the optical fiber temperature distribution tester are connected with theserver. With distributed temperature test by the optical fiber temperature distribution tester as the core, the invention provides a method of distributing large-scale solar panel distributed temperature monitoring system, realizing temperature monitor of large-scale solar panel. The system has characteristics of lower complexity, high reliability, simple distribution, convenience in maintenance,real-time calibration during operating, and low cost.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

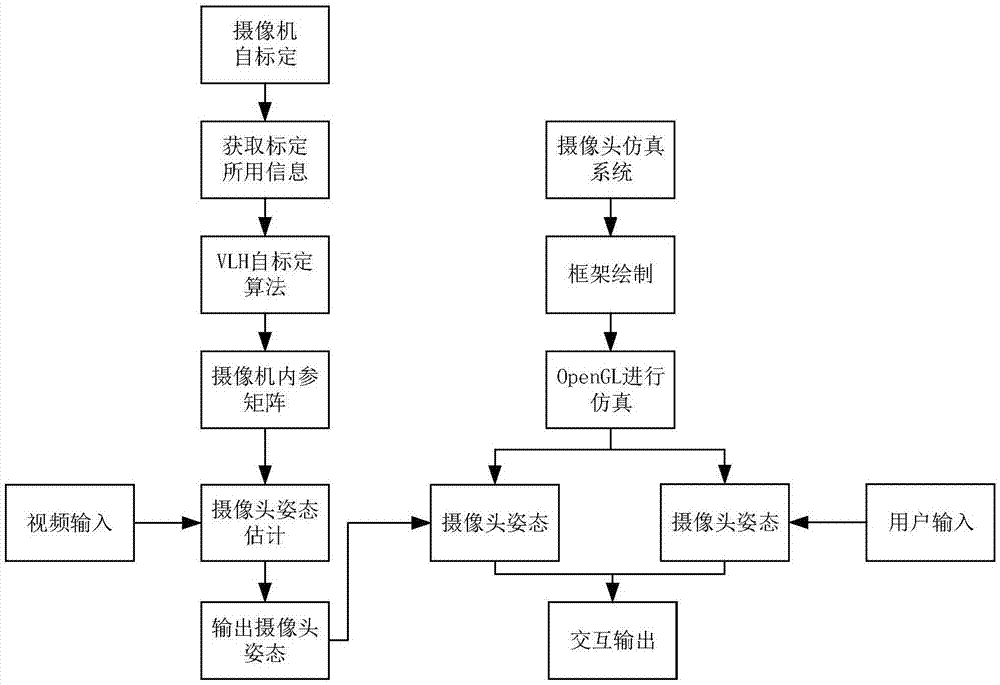

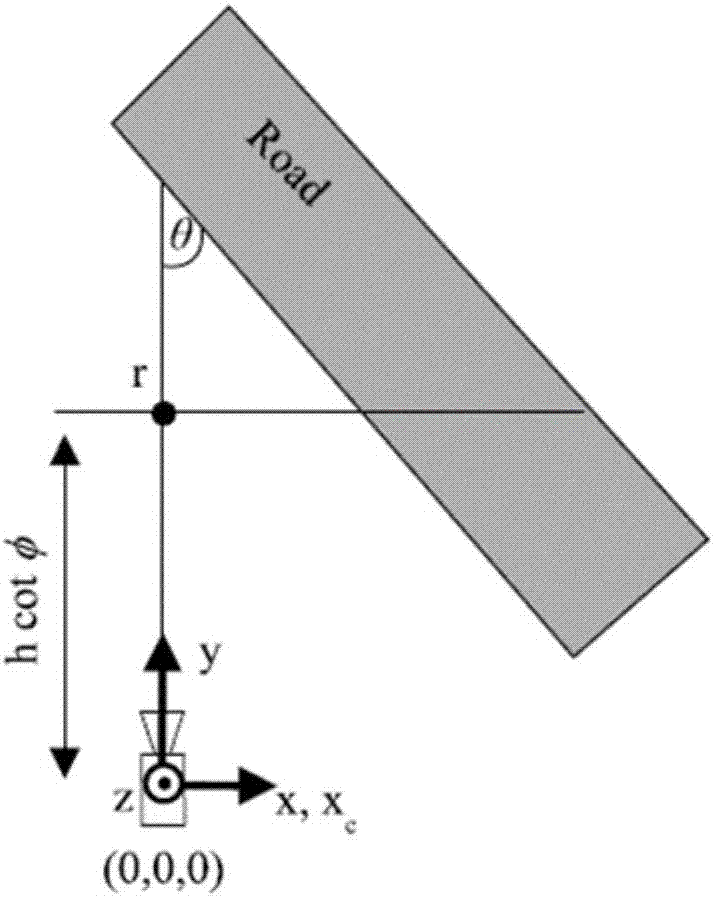

Traffic monitoring model calibration method and system based on physical coordinates of marking dotted line

InactiveCN107481291AEfficient identificationImprove robustnessImage enhancementImage analysisSimulationRoad traffic

The invention provides a traffic monitoring model calibration method and system based on physical coordinates of a marking dotted line, and the method comprises the following steps: 1), determining an internal parameter matrix of a road monitoring camera through a VLH self-calibration algorithm; 2), solving the posture parameters of a camera through the internal parameter matrix determined at step 1) and the coordinates of the marking dotted line in a traffic video; 2), obtaining the posture parameters of the camera after the execution of step 2), transmitting the posture parameters to a traffic monitoring model, carrying out the corresponding analysis calculation of the posture of the camera through the traffic monitoring model, and obtaining an accurate road monitoring result. The calculation speed of the traffic monitoring module is higher than the speed of a conventional camera calibration method. The method achieves the real-time calibration, is high in robustness, and is convenient in obtaining based on the coordinates of the marking dotted line. The method can achieve the quick calibration of traffic monitoring facilities through an actual road traffic video, and can achieve the real-time and accurate simulation of traffic video conditions.

Owner:CHANGAN UNIV

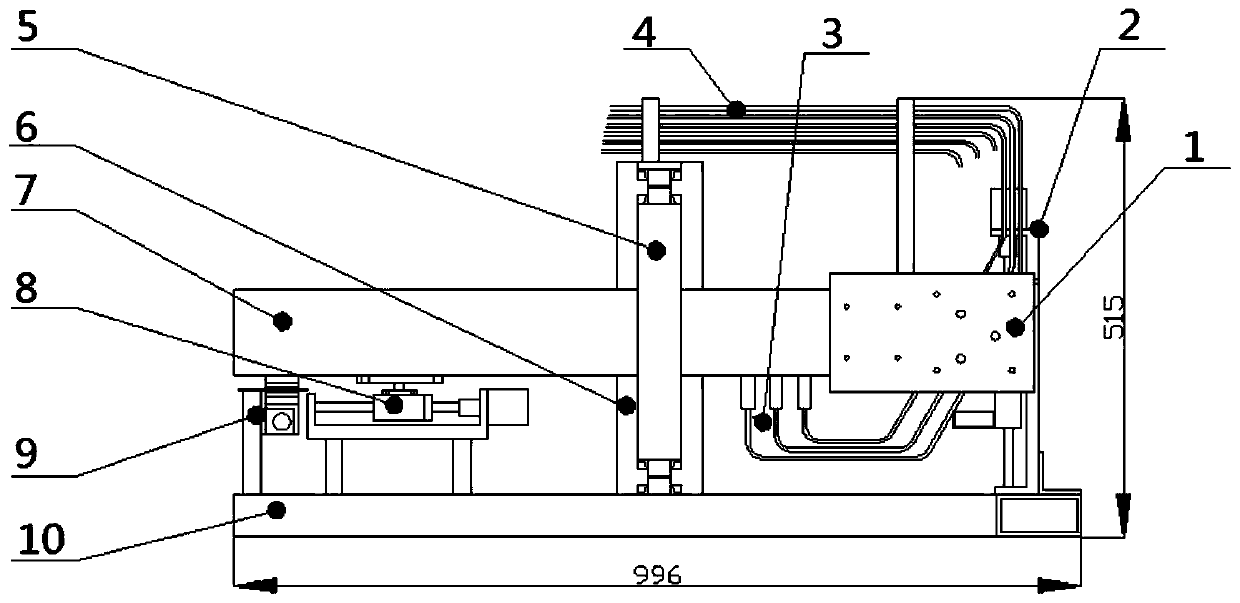

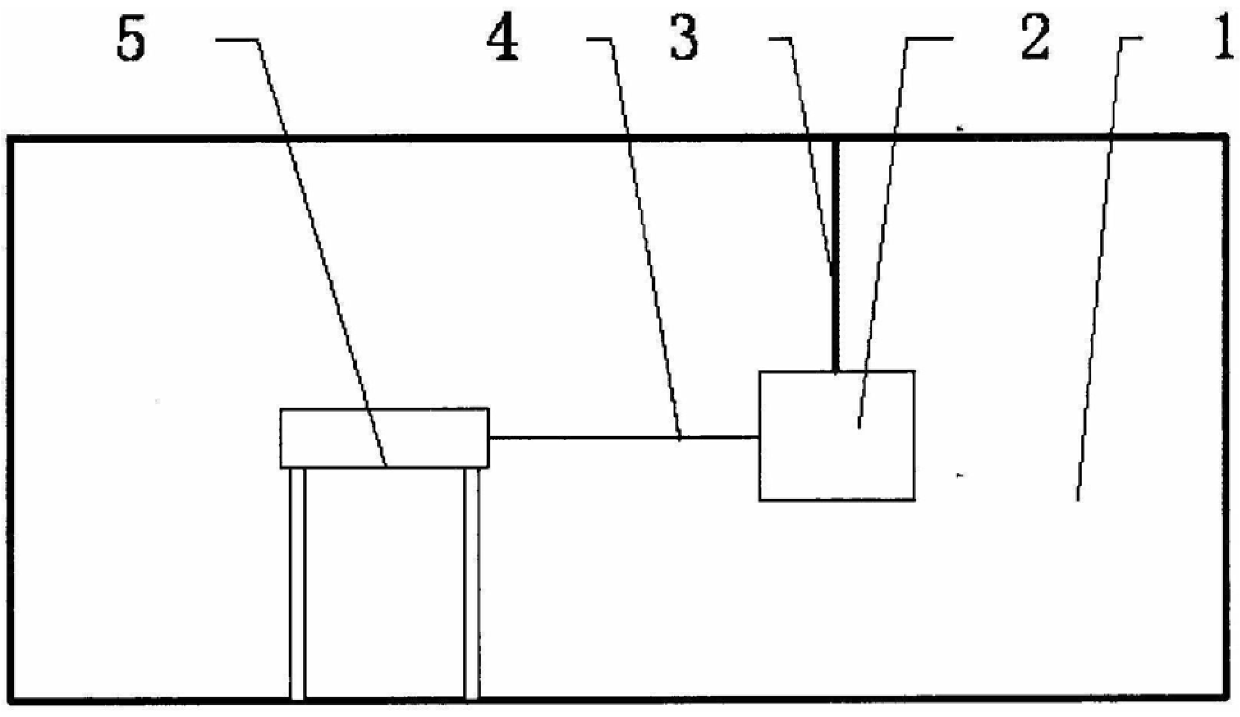

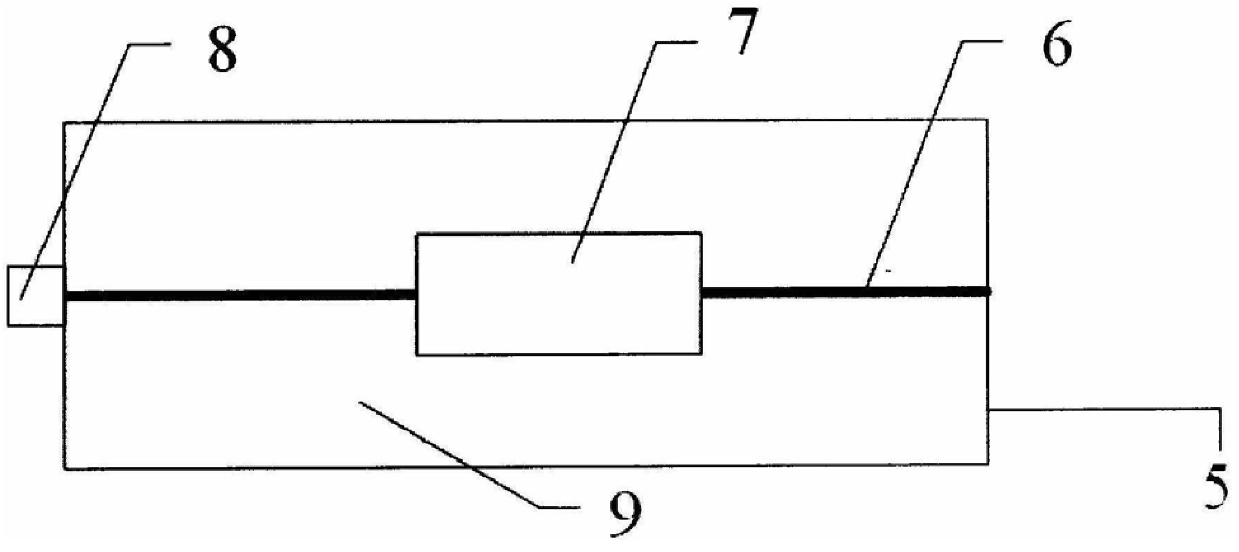

Calibration device and method for a micro-thrust measurement system

ActiveCN107182257BNo need to evaluate the effects of frictionReal-time calibrationApparatus for force/torque/work measurementEngineeringFriction force

The invention relates to a calibration device and method for a micro-thrust measurement system, belonging to the technical field of micro-thrust measurement of electric thrusters. The calibration device is mainly composed of a thruster, elastic parts, filaments and a calibration system; the calibration system is mainly composed of a lead screw, an electronic tension gauge, a stepping motor and a platform; one end of the elastic part is hoisted in a vacuum environment, and the other end is connected to the thrust connected to the thruster, perpendicular to the transverse centerline of the thruster; one end of the thruster is connected to one end of the electronic tension gauge through a filament, and the straightening direction of the filament in the straightened state is consistent with the direction of the transverse centerline of the thruster; the stepping motor The lead screw is fixed on the platform, the stepper motor is connected with the lead screw, the axis direction of the lead screw is parallel to the straightening direction of the filament, the electronic tension gauge is fixed on the lead screw, and the stepper motor, electronic tension gauge and filament are arranged in sequence. The calibration accuracy of the calibration device does not require evaluation of the effects of friction; real-time calibration of the thrust measurement system is possible.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

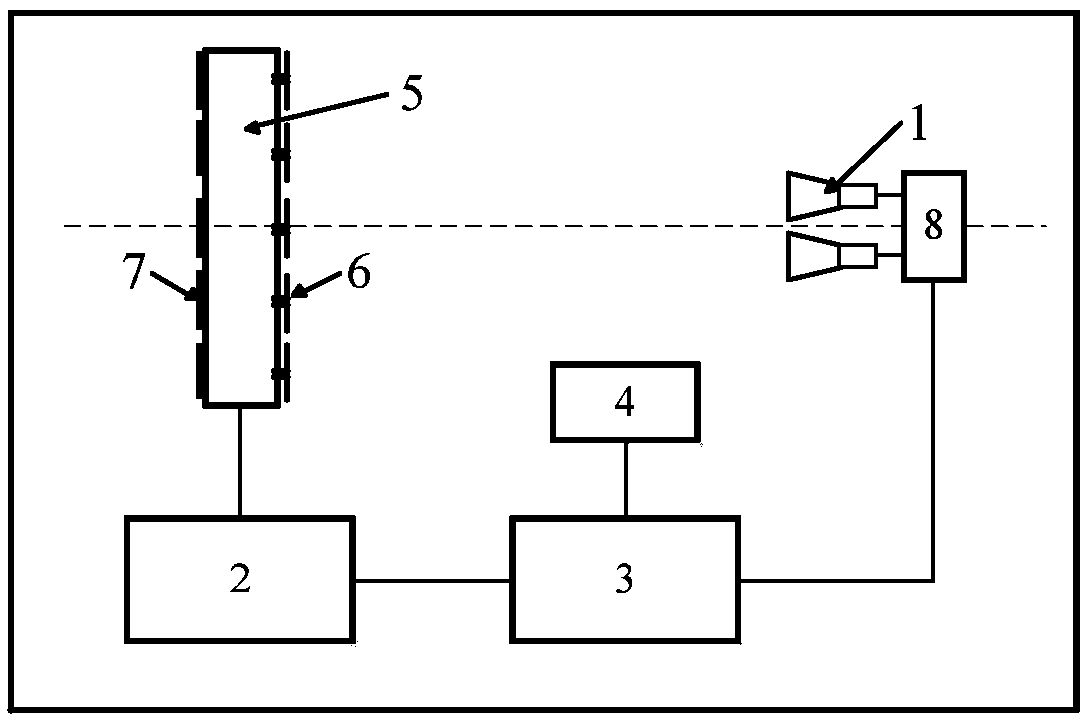

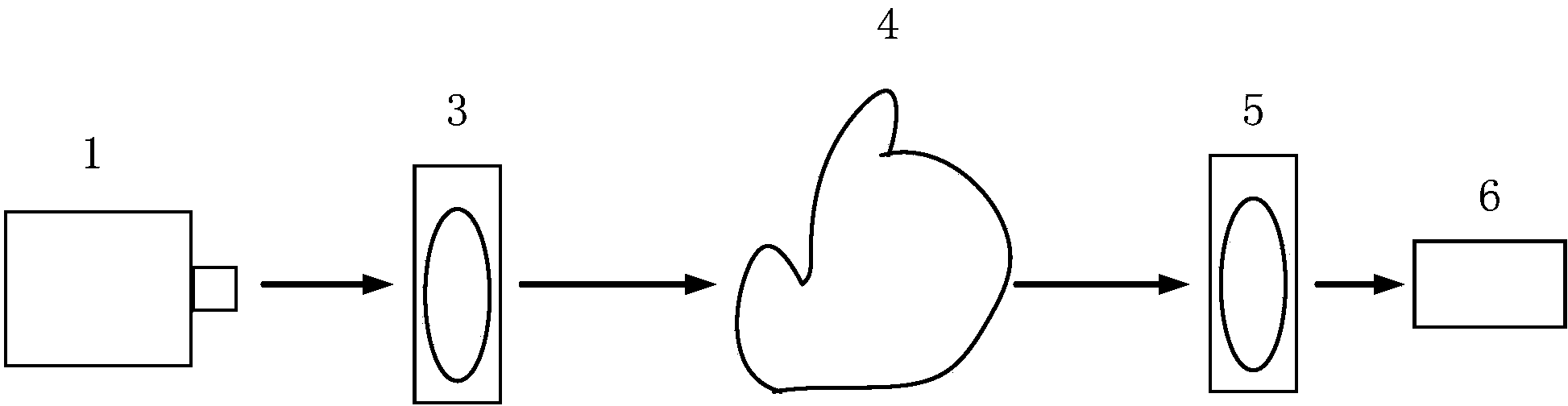

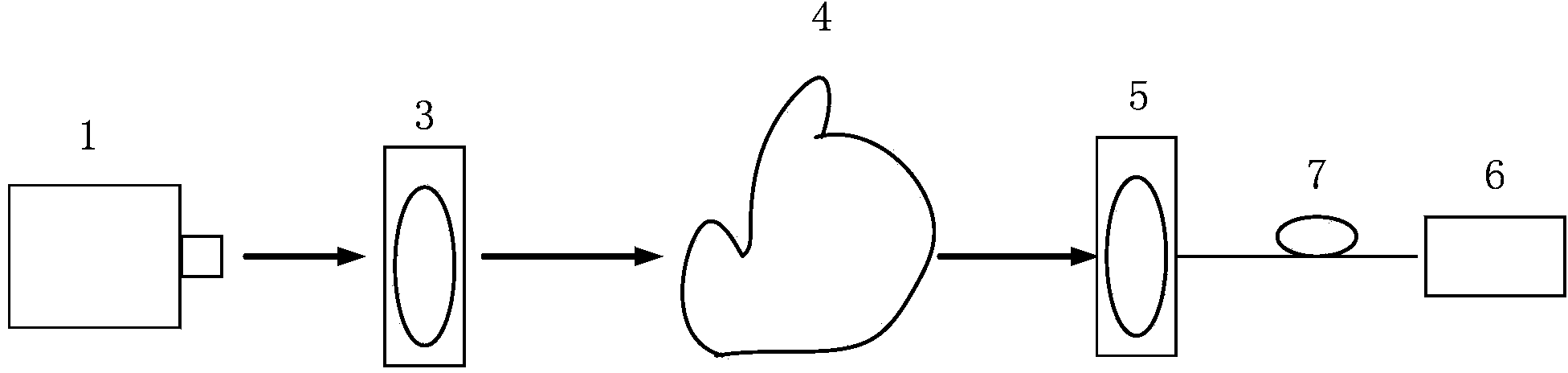

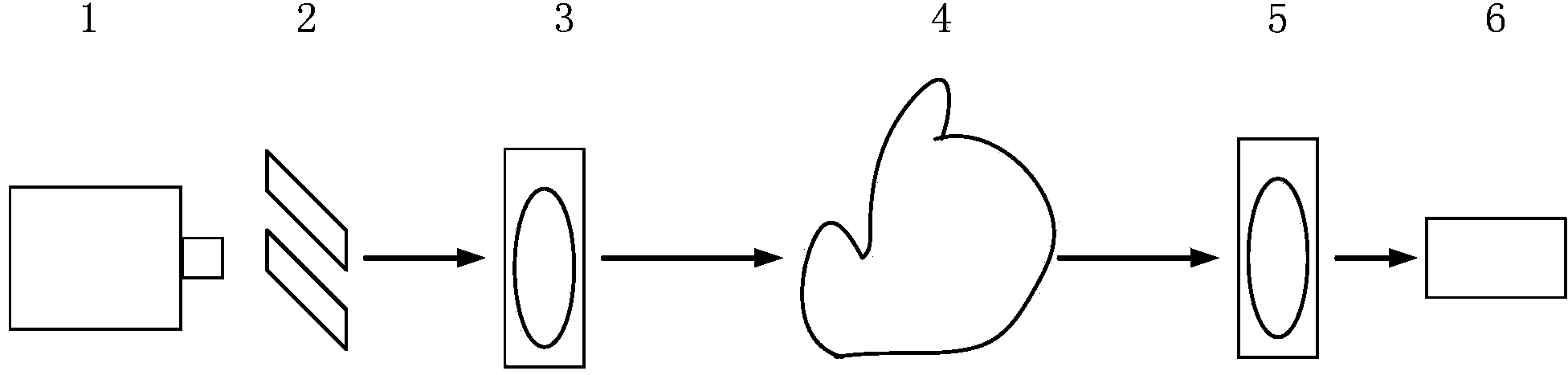

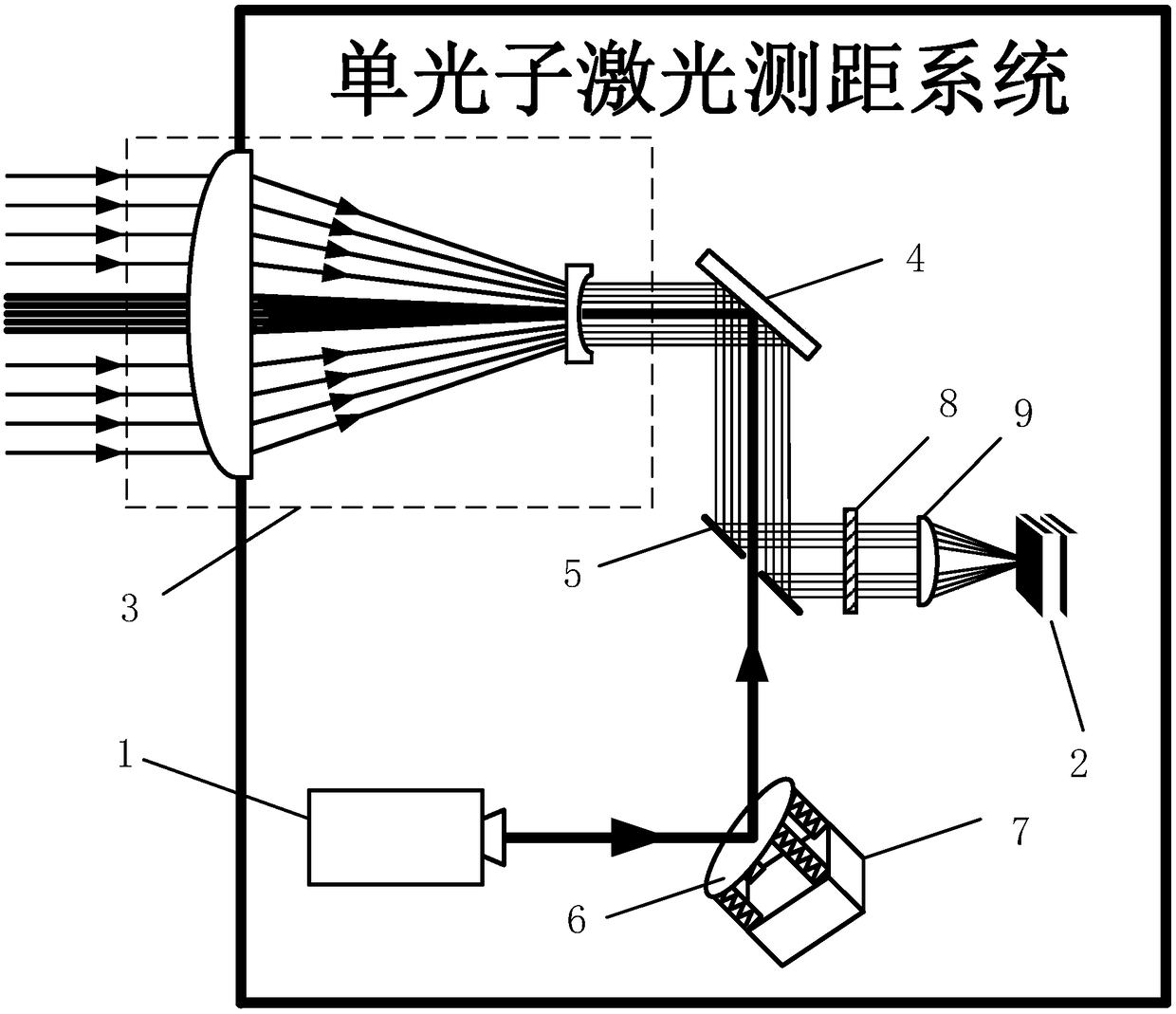

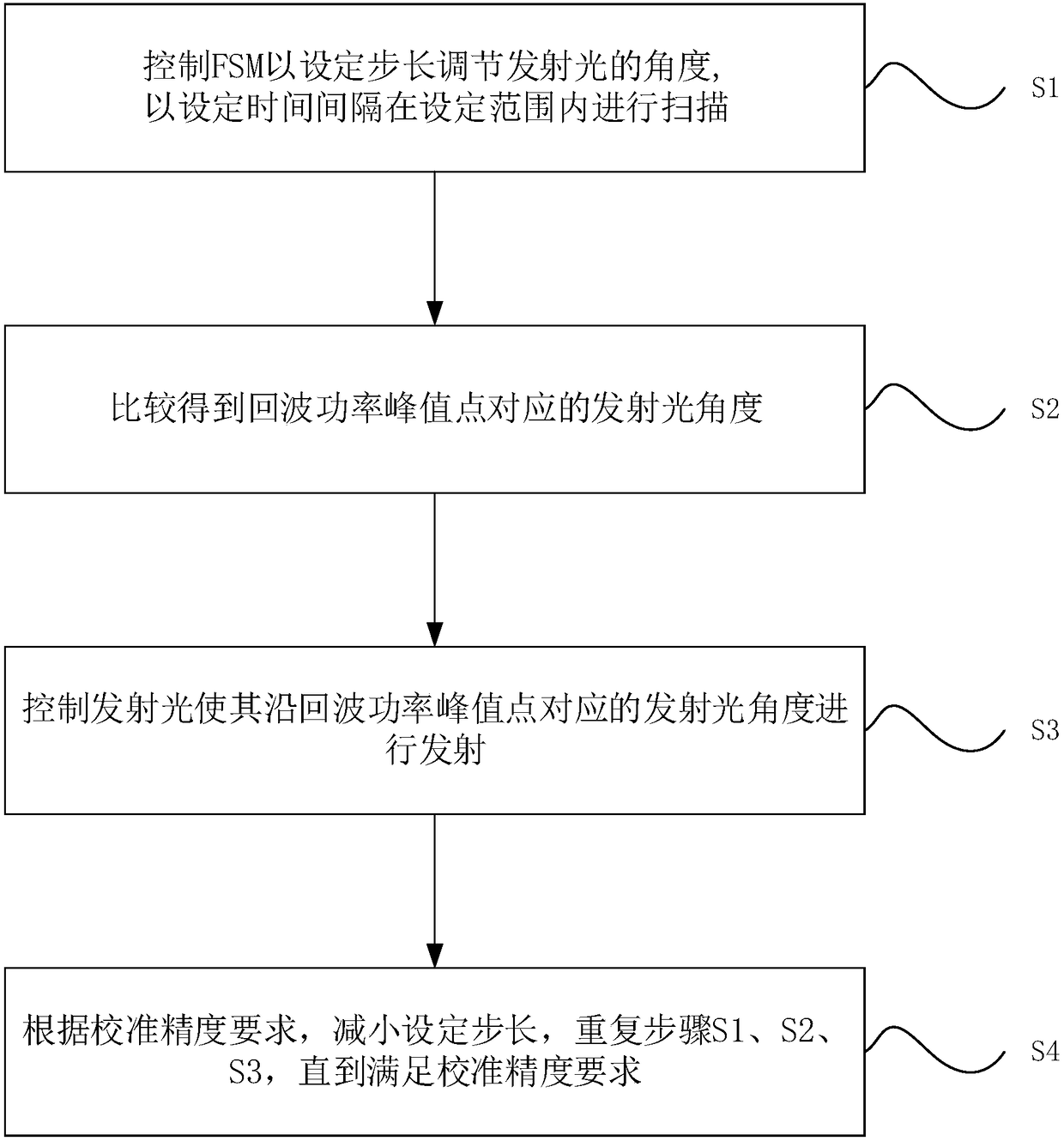

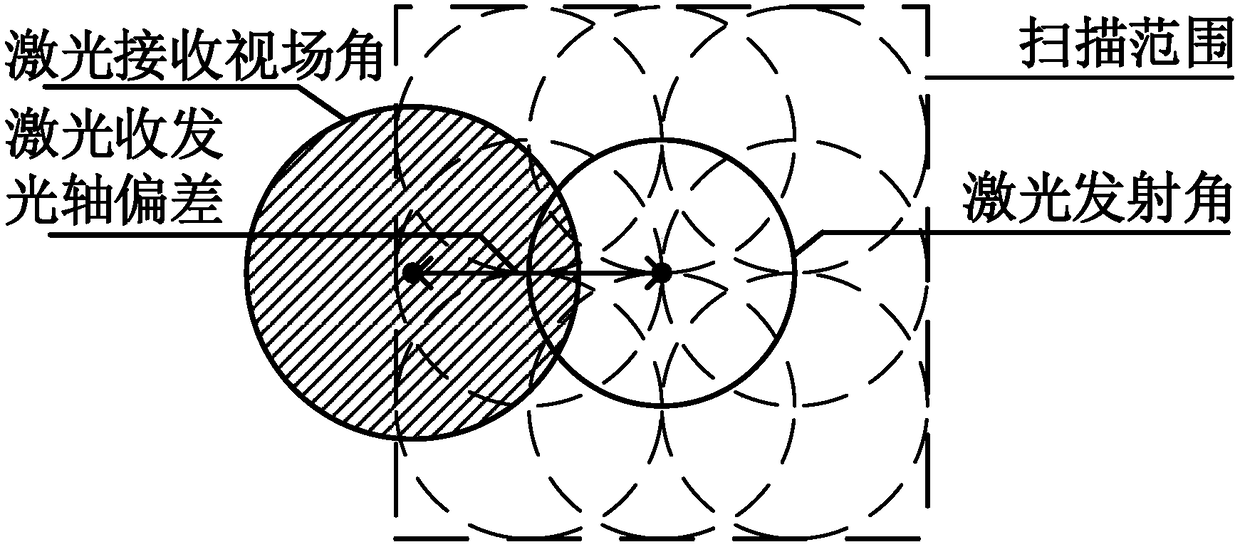

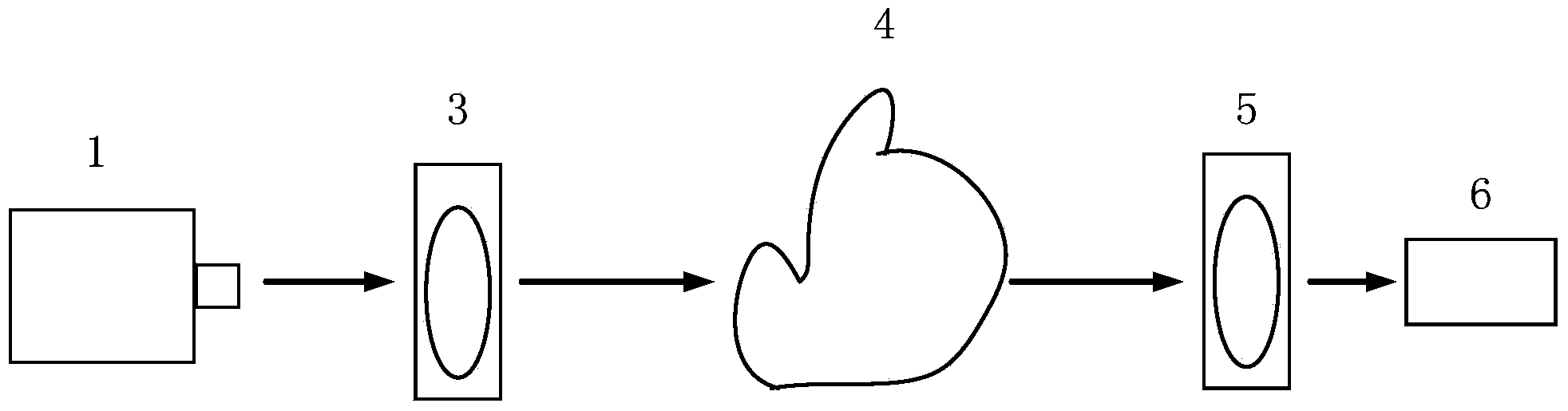

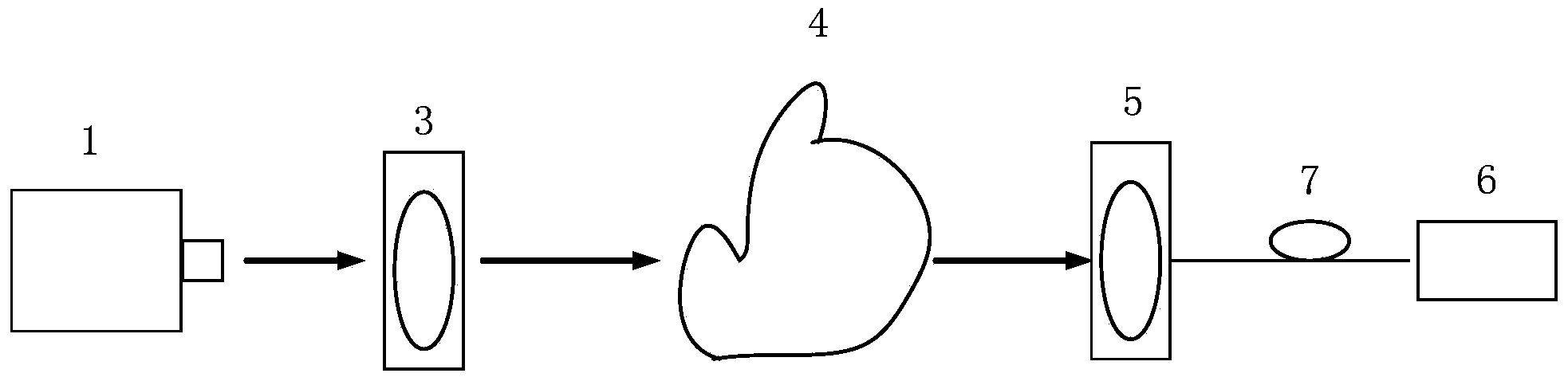

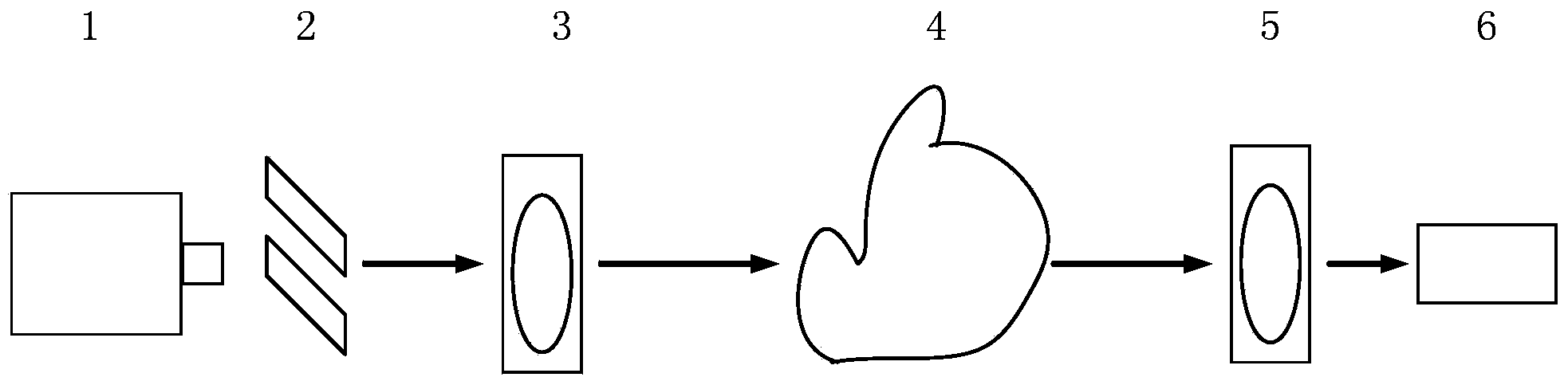

Laser ranging optical axis consistency dynamic calibration method and system

PendingCN108594209AExemption from regular factory recalibrationImprove continuous working time and environmental adaptabilityElectromagnetic wave reradiationOptical pathPeak value

The invention relates to the technical field of laser measurement, in particular to a laser ranging optical axis consistency dynamic calibration method and system. The laser ranging system comprises alaser 1, an emission light path, a receiving light path and a signal receiving and processing device 2, the light path is provided with a laser receiving and transmitting lens 3, a first fixed reflecting mirror 4, a hollow reflecting mirror 5, an FSM reflecting mirror 6, a piezoelectric deflection table 7, a narrow-band light filter 8 and a receiving optical assembly 9. The transmitting light path is adjusted for preset manner scanning, and the emission angle corresponding to the echo power peak value point meeting the system receiving-emitting optical axis error range requirement can be obtained through analysis and comparison, the piezoelectric deflection table is used for driving the FSM reflecting mirror to deflect, the emission light path is controlled to emit laser along the angle corresponding to the power peak value point, and therefore the consistency of the laser receiving-emitting optical axis is guaranteed, and the problem that the measurement range and precision of the ranging system are sharply reduced due to the fact that the parallelism of the laser receiving-emitting optical axis is degraded is solved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

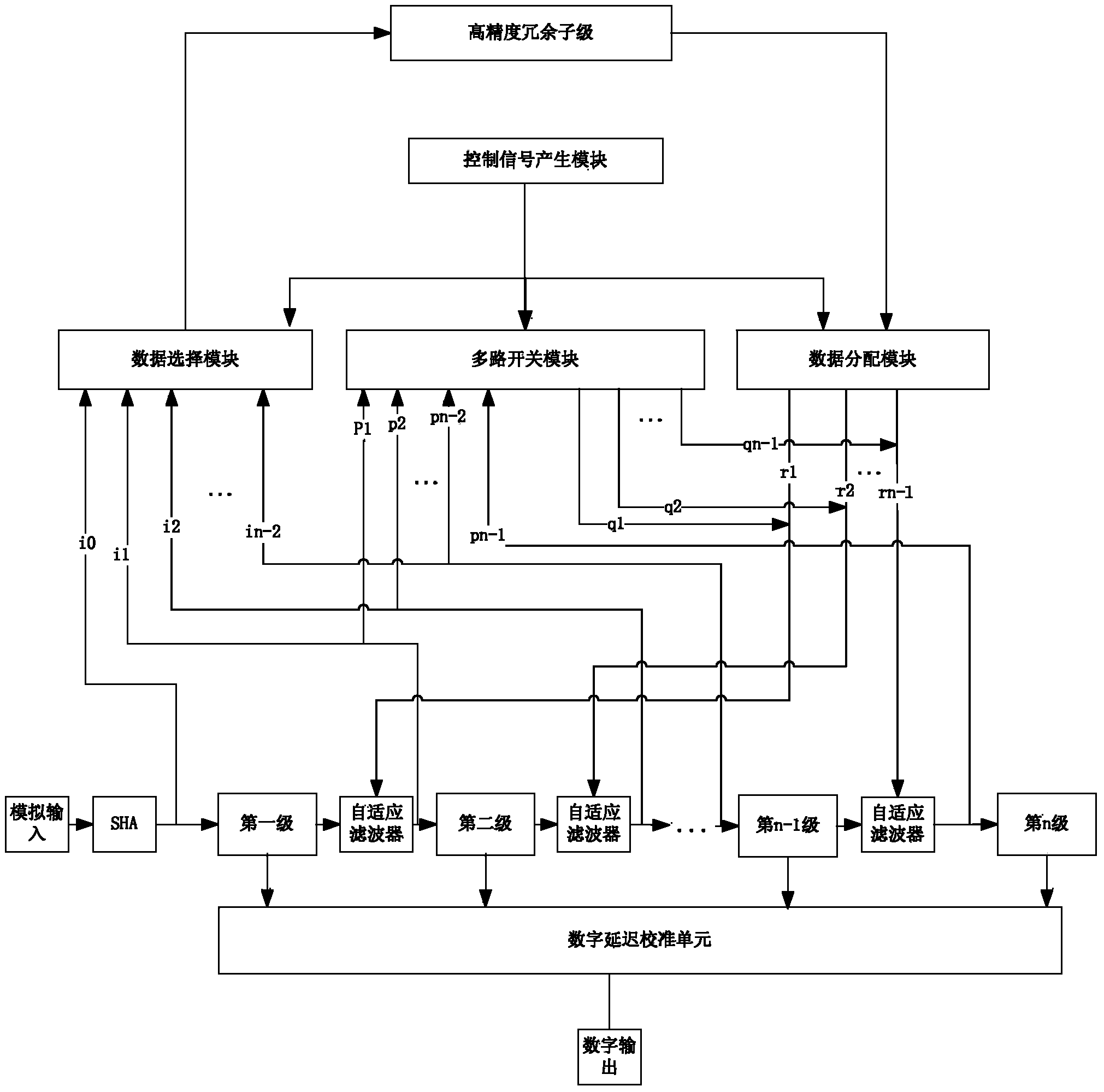

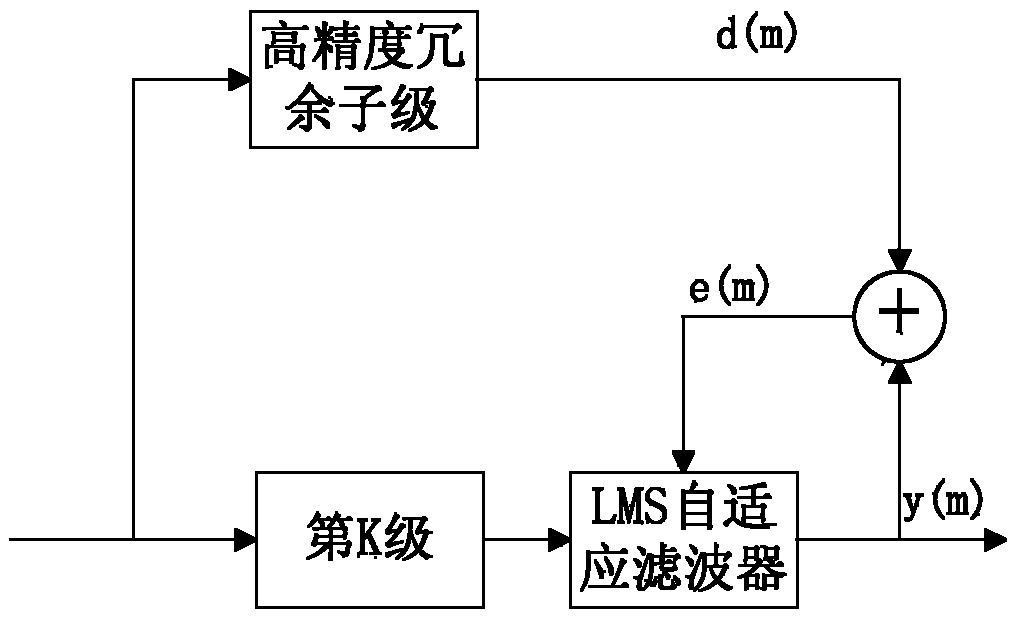

Method and device for background digital calibration of production line ADC (analog-to-digital converter)

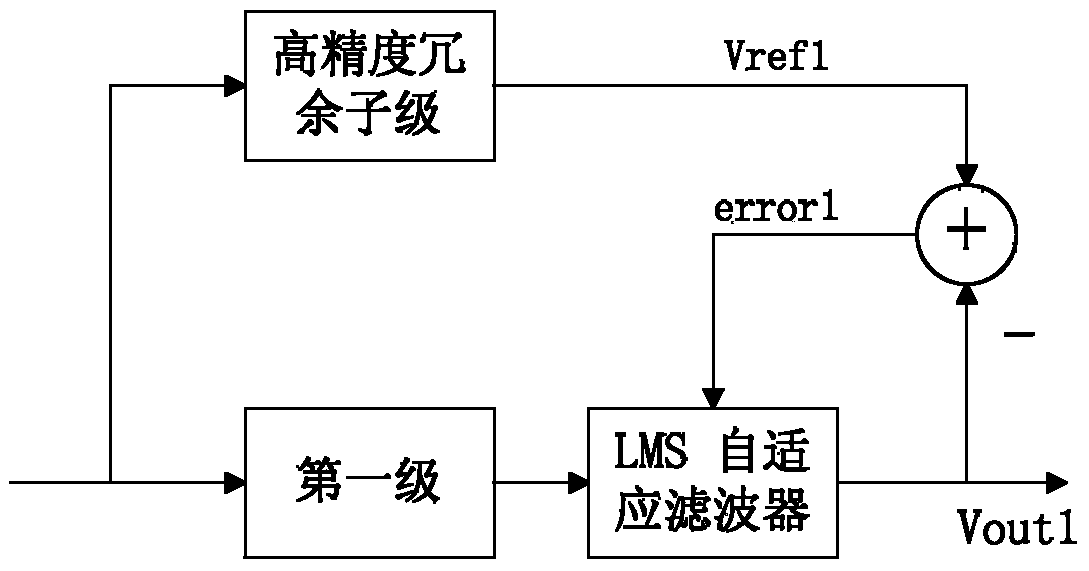

ActiveCN103973306AHigh precisionReduce calibration errorAnalogue/digital conversion calibration/testingProduction lineAdaptive filter

The invention discloses a method and a device for background digital calibration of a production line ADC (analog-to-digital converter). The device comprises an adaptive filter, a high-precision ADC redundancy sublevel, a data selection module, a data distribution module, a multiway switch module and a control signal generation module. The method includes: firstly, the control signal generation module controls the data selection module, the data distribution module and the multiway switch module, and the high-precision ADC redundancy sublevel and the adaptive filter perform initialization calibration sequentially from the first level to the j level of the production line ADC to enable the production line ADC to operate in a high-precision output state; secondly, during normal operation of the production line ADC, the control signal generation module controls each module to perform random calibration from the first level to the j level of the production line ADC so as to prevent ADC performance reduction resulted from an external environment and an internal environment of a chip. The method and the device for background digital calibration of the production line ADC have the advantages of small calibration errors and high calibration precision.

Owner:SOUTH CHINA UNIV OF TECH

Self-calibration device and method for emission rate coefficient of multi-spectrum radiation temperature measuring system

ActiveCN103630249AOvercoming Model ErrorsImprove measurement uncertaintyRadiation pyrometryColor/spectral properties measurementsEmissivityRadiation temperature

The invention discloses a self-calibration device and method for an emission rate coefficient of a multi-spectrum radiation temperature measuring system. The device comprises a wide spectrum optical source as well as an incidence collimating lens group and an outgoing collimating lens group which are arranged at the outgoing optical path of the wide spectrum optical source in sequence; a flame to be measured is arranged between the incidence collimating lens group and outgoing collimating lens group. The emission rate coefficient self-calibration system is arranged on the same path, penetrating through the measured flame, of the multi-spectrum radiation temperature measuring system, the emission rate coefficients of the flame under different wavelengths are obtained by recording the spectrum parameters of the wide spectrum optical source, the flame and the combination of the wind spectrum optical source and the flame, and the self-calibration device is used for the parameter calibrating of the multi-spectrum radiation temperature measuring system and overcomes the model error in the traditional theoretical calculation correction, so the measuring uncertainty is reduced.

Owner:NORTHWEST INST OF NUCLEAR TECH

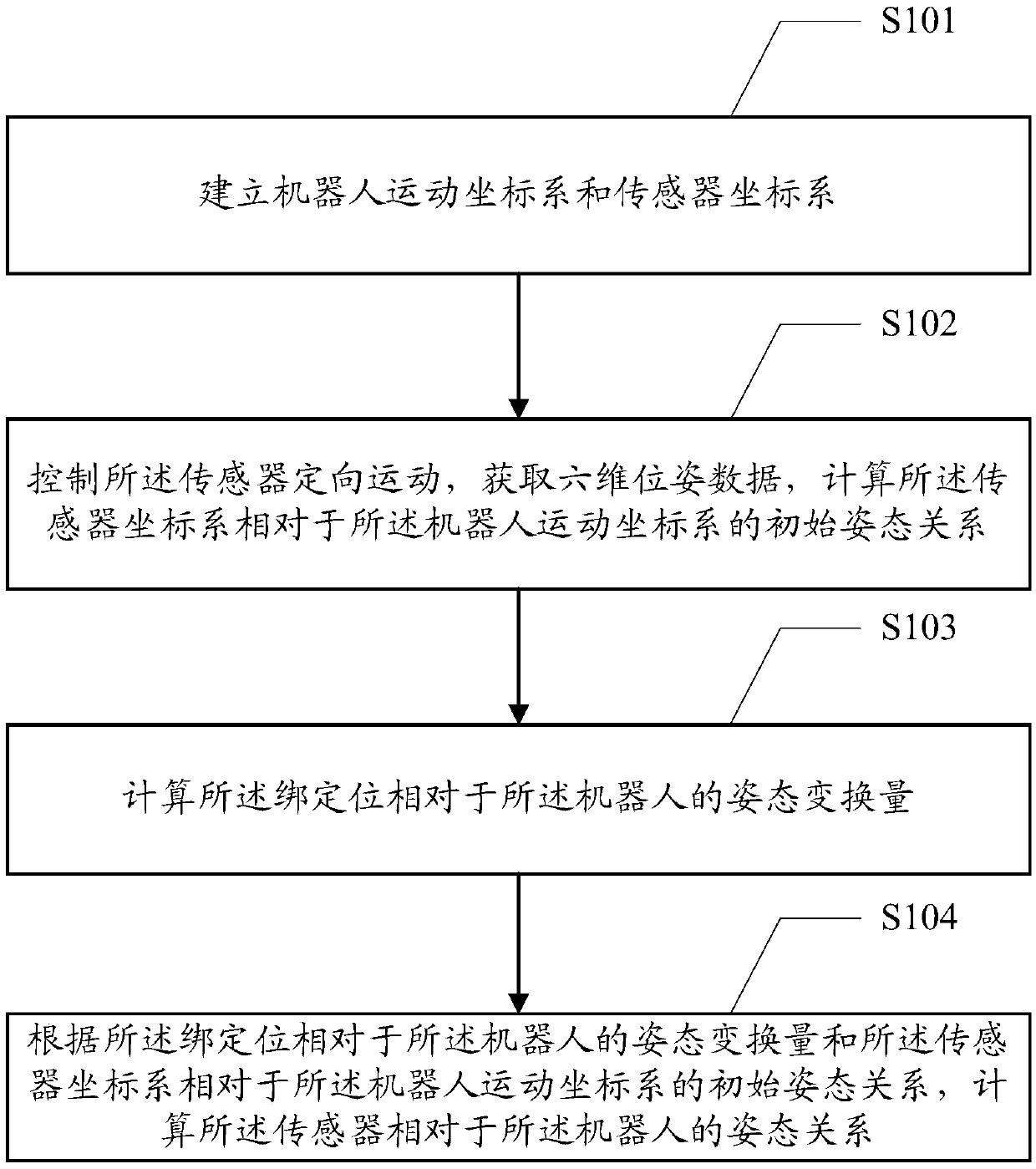

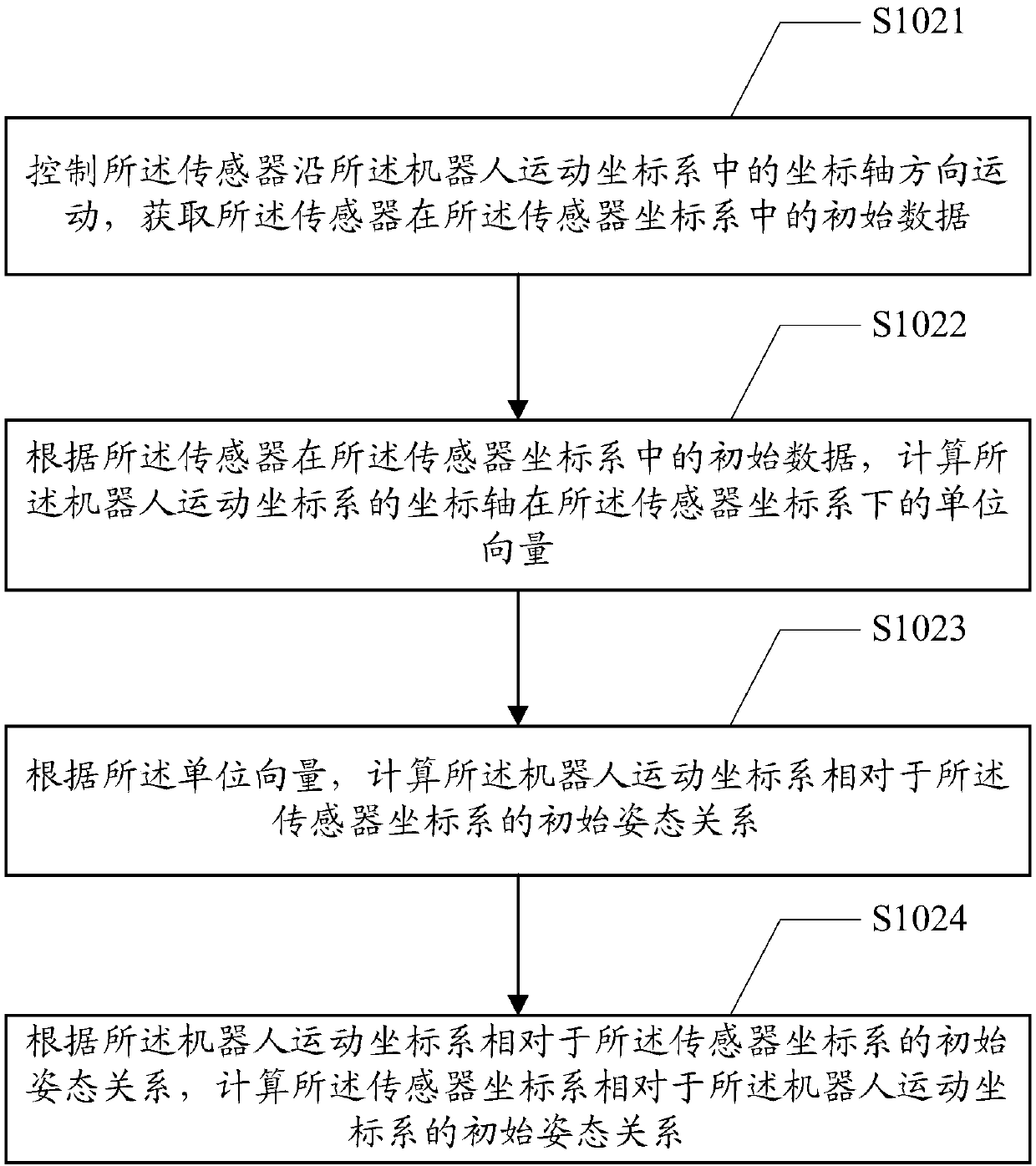

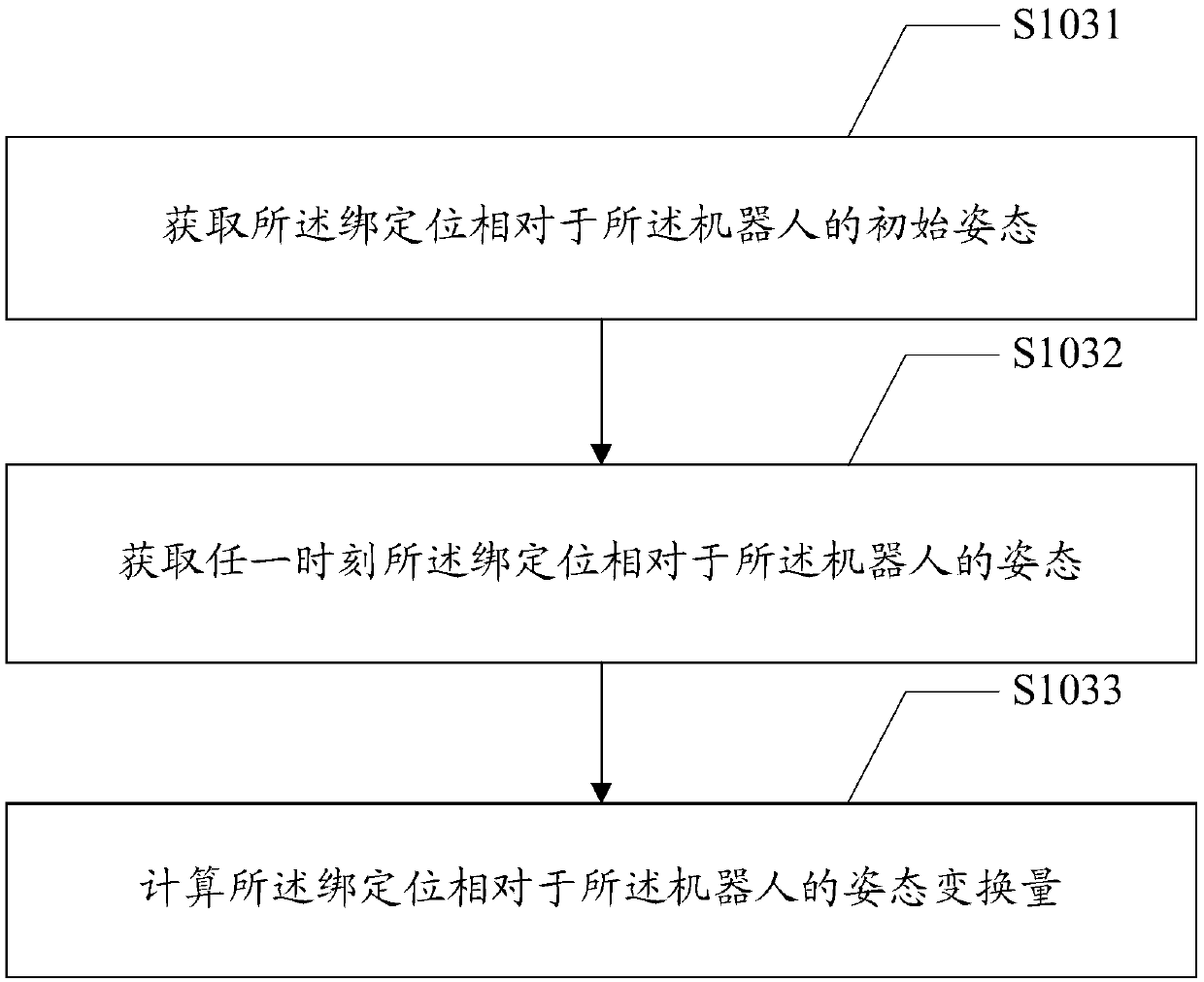

Method and device for calibrating sensor postures of robot in real time and terminal equipment

InactiveCN108818538AReal-time calibrationAvoid control errorProgramme-controlled manipulatorNavigation instrumentsSimulationTerminal equipment

The invention is applied to the technical fields of sensing control of industrial robots, and provides a method and device for calibrating sensor postures of a robot in real time and terminal equipment. A binding position of a sensor is arranged on the robot; and the sensor is arranged on the binding position. The method for calibrating sensor postures of the robot comprises the following steps: building a robot motion coordinate system and a sensor coordinate system; controlling orientated motion of the sensor; acquiring six-dimensional posture data; calculating an initial posture relation ofthe sensor coordinate system relative to the robot motion coordinate system; calculating posture converted quantity of the binding position relative to the robot; and calculating the posture relationof the sensor relative to the robot according to the posture converted quantity of the binding position relative to the robot and the initial posture relation of the sensor coordinate system relativeto the robot motion coordinate system. According to the method and device for calibrating sensor postures of the robot in real time disclosed by the invention, the phenomenon that control errors caused by the change of the sensor postures during control of the positions and the postures of the robot is avoided.

Owner:崧智智能科技(苏州)有限公司

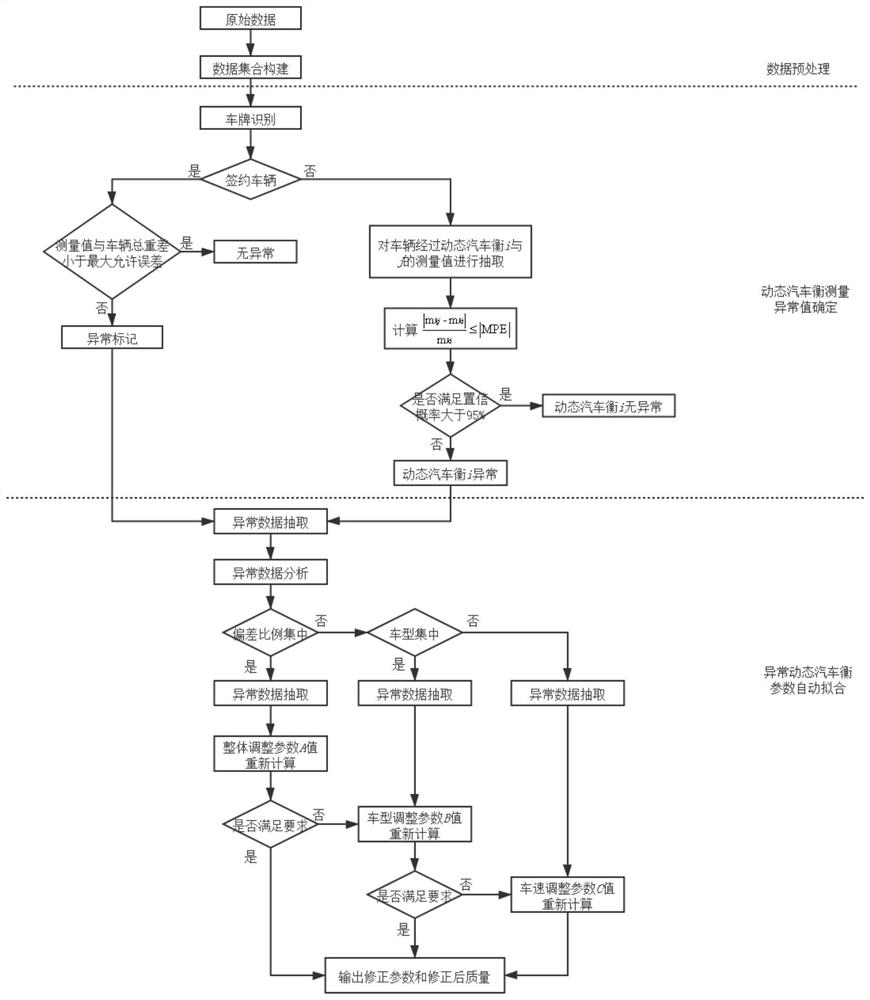

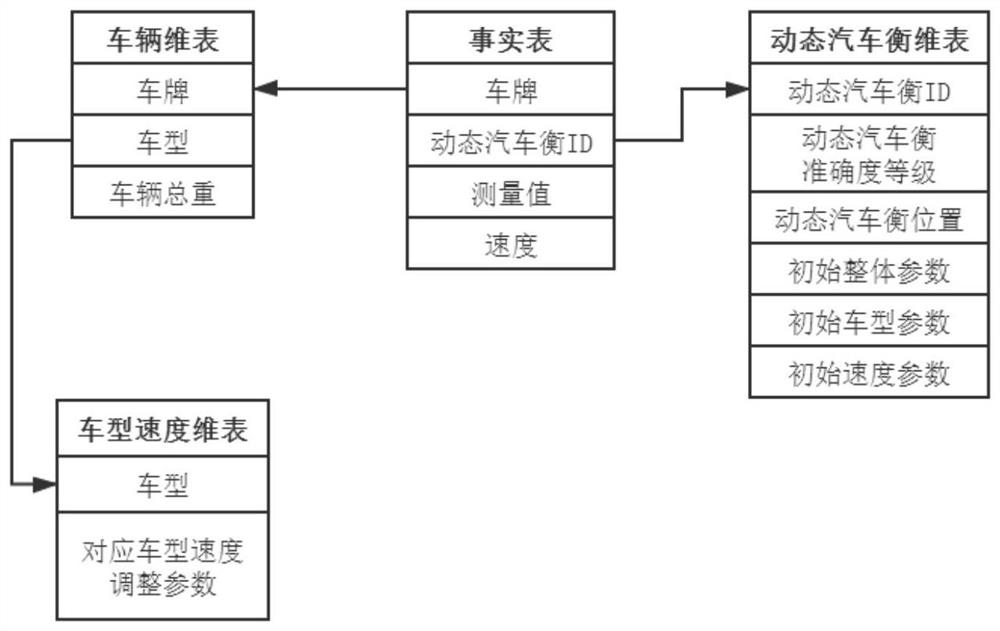

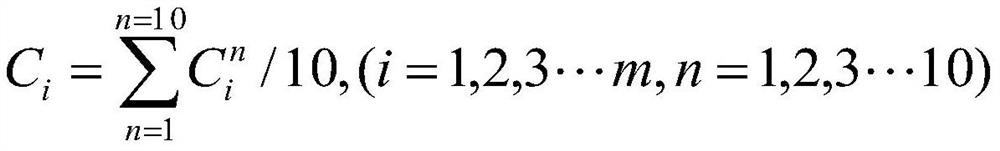

Dynamic truck scale metering method capable of automatically fitting parameters

PendingCN111625752AImprove efficiencyReduce labor costsWeighing apparatus testing/calibrationComplex mathematical operationsTruckData point

The invention discloses a dynamic truck scale metering method capable of automatically fitting parameters. The method includes sample data preprocessing, processing the collected redundant data; determining speed adjustment parameters and final data storage forms of different speed intervals; determining a measurement abnormal value of the dynamic truck scale; when a non-verification vehicle withunknown vehicle total weight passes through the dynamic truck scale, calibrating the dynamic truck scale. Through different dynamic truck scale measurement values, the vehicle is compared and an abnormal condition is determined. When a verification vehicle with known total weight of the vehicle passes through the dynamic truck scale, the abnormal condition of the verification vehicle is judged through comparison of a measured value and an agreed true value, abnormal dynamic truck scale parameters are automatically fitted, abnormal data points are extracted, the distribution condition of the abnormal data points is analyzed, and parameters needing to be adjusted and parameter values suggested to be adjusted are determined. The method is not limited by the type of the dynamic truck scale, does not need manual intervention, can achieve the full-automatic metering of the dynamic truck scale in time, greatly reduces the labor cost, can guarantee the metering performance, and improves the metering efficiency.

Owner:HENAN PROVINCE INST OF METROLOGY

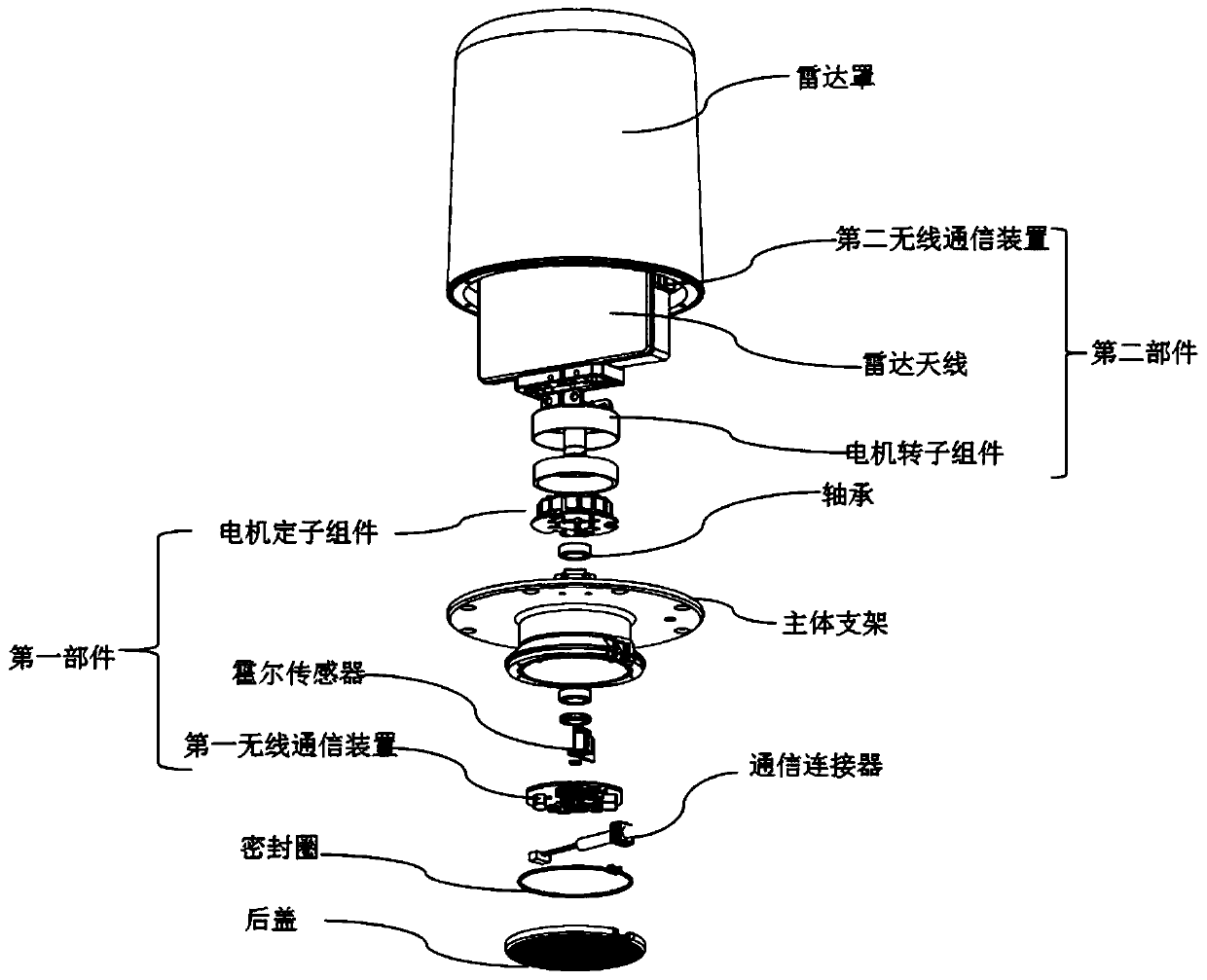

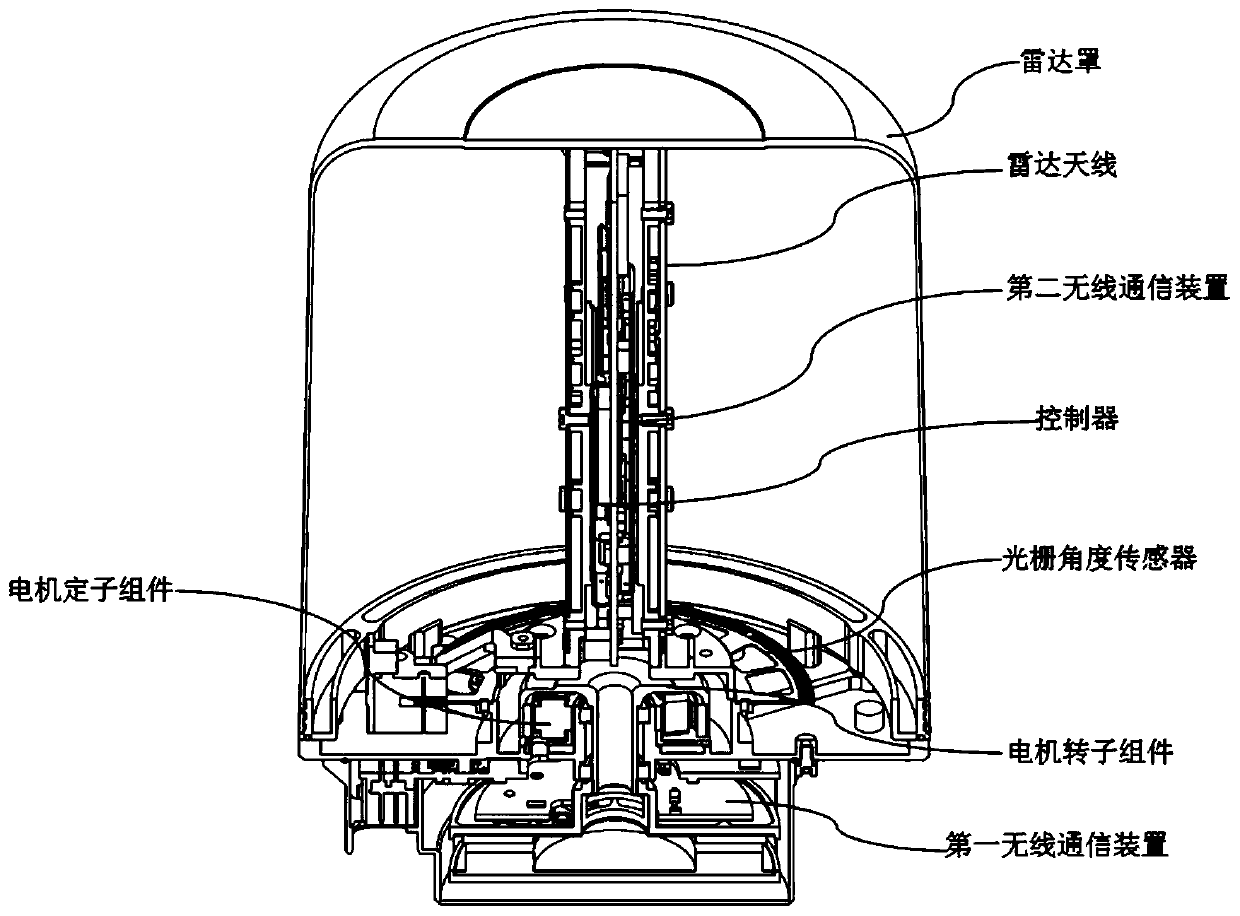

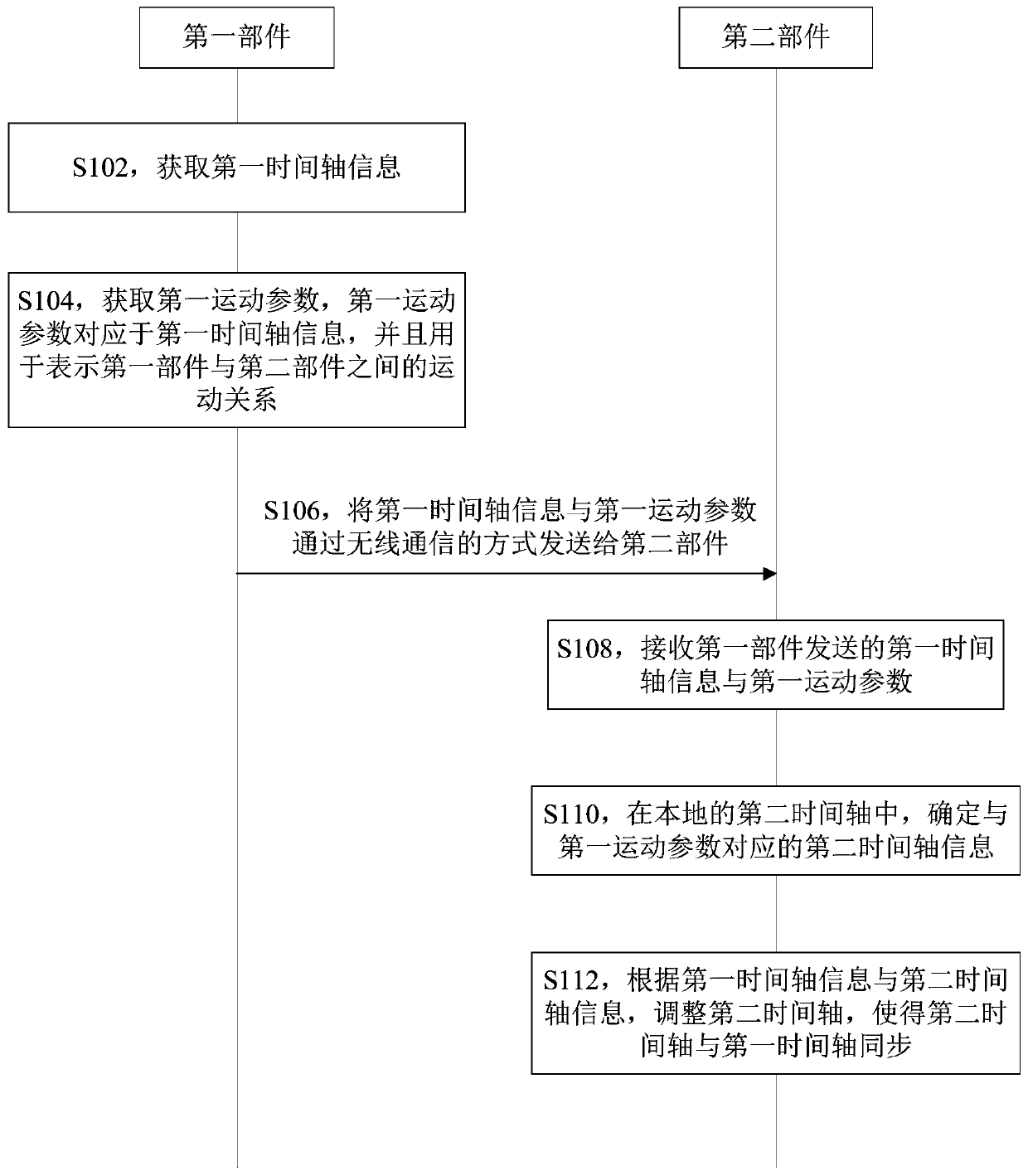

Time synchronization method, device and system and a storage medium

ActiveCN110785950AResolve delayReal-time adjustmentVector control systemsWireless architecture usageMotion parameterEngineering

The invention provides a time synchronization method, device and system and a storage medium. The time synchronization system comprises a first part and a second part, the first part and the second part are mechanically coupled, the first part and the second part can move relatively, and the first part and the second part are in wireless communication connection. The method comprises the steps that the second part receives first time axis information and first motion parameters sent by the first part, wherein the first motion parameters correspond to the first time axis information and are used for representing the motion relation between the first part and the second part; the second part determines second time axis information corresponding to the first motion parameter in a local secondtime axis; and the second part adjusts the second time axis according to the first time axis information and the second time axis information, so that the second time axis is synchronized with the first time axis. According to the method, the influence of wireless communication delay on time axis synchronization can be relieved to a certain extent, and the synchronization efficiency is improved.

Owner:SZ DJI TECH CO LTD

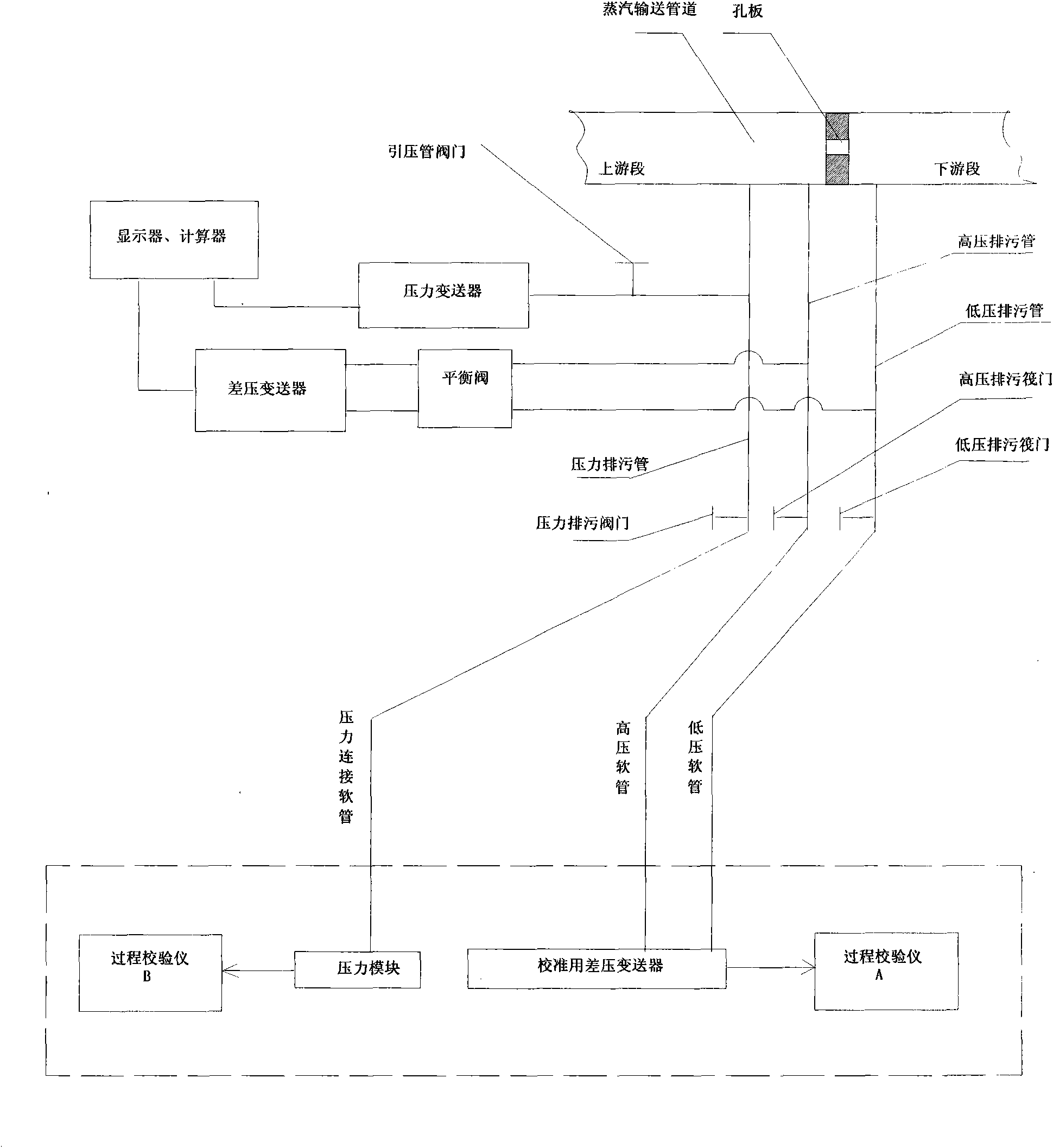

Method for online calibrating perforated plate-type steam flow measurement system

ActiveCN101672683ASolve the problem of accurate measurementImprove accuracyTesting/calibration apparatusDifferential pressureEngineering

The invention discloses a method for online calibrating perforated plate-type steam flow measurement system, comprising the following steps: equalizing the pressure at the high pressure end and the low pressure end of the perforated plate-type steam flow measurement system, closing a high-pressure end valve and a low-pressure end valve on a balance valve, subsequently draining sewage; connecting ahigh-pressure soft pipe of the online calibrating device of the perforated plate-type steam flow measurement system and a high-pressure sewage-drainage outlet of the high-pressure sewage-drainage pipe of the steam flow measurement system, connecting a low-pressure soft pipe with a low-pressure sewage-drainage outlet of the low-pressure sewage-drainage pipe of the steam flow measurement system, connecting a pressure connecting soft pipe with a pressure sewage-drainage outlet of the pressure sewage-drainage pipe of the steam flow measurement system; and opening exhaust ports on a differential pressure transmitter used for calibration after filling the condensed water in each sewage-drainage pipe, draining water of the exhaust ports of the differential pressure transmitter, subsequently leading the balance valve to recover to the working state, waiting the system for stabilization and subsequently reading the differential pressure value, the pressure value, the display flow value, calculating the practical flow value and correcting the display flow value according to the practical flow value. The method can realize online calibration of the steam flow measurement system, improve theproduction efficiency and reduce the equipment investment cost.

Owner:CHINA TOBACCO GUIZHOU IND +1

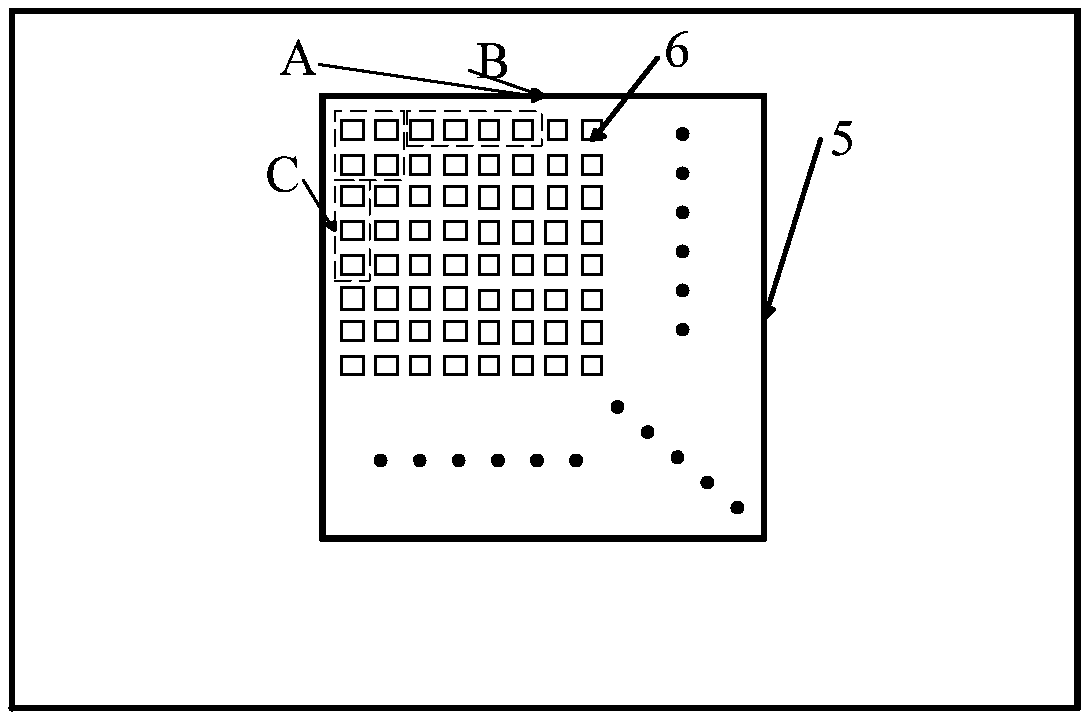

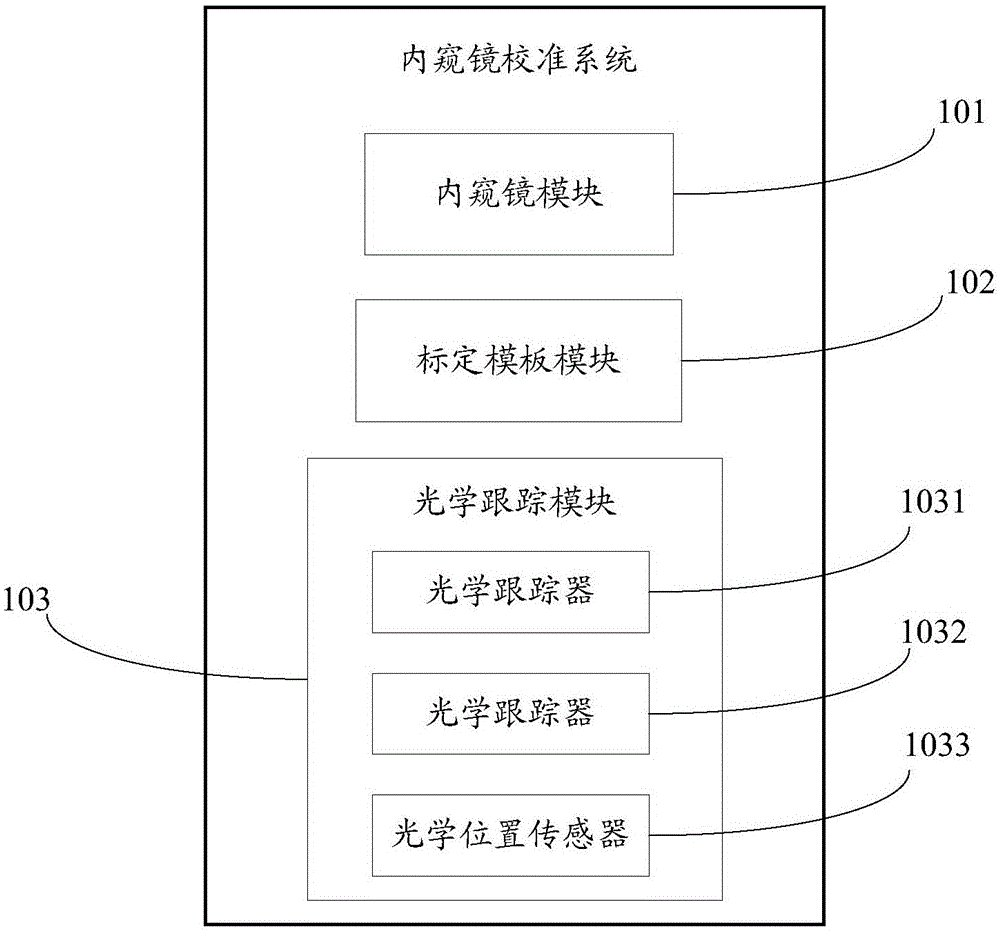

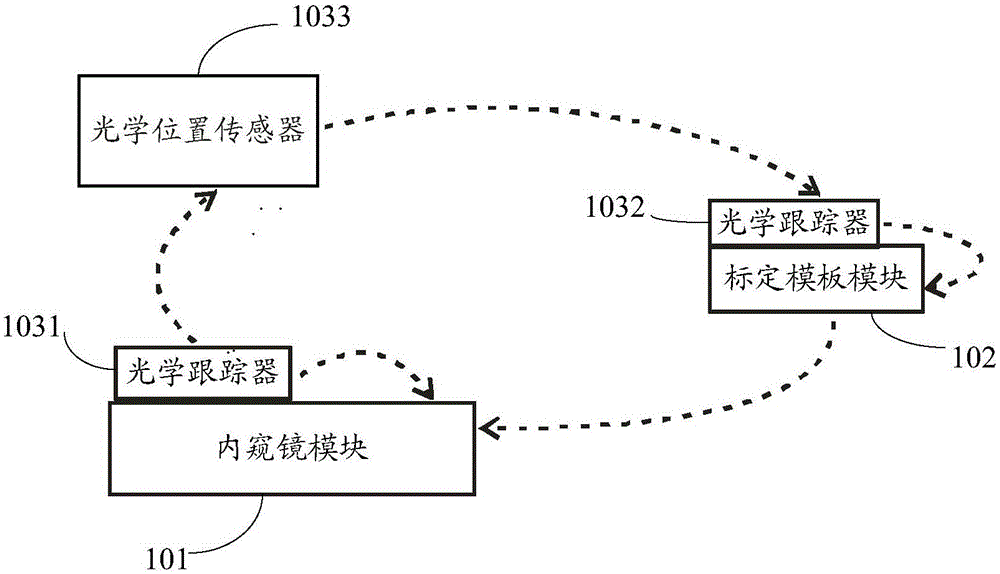

Endoscope calibration system and method

InactiveCN105105698AAvoid long-term occupationSimple calculationSurgeryEndoscopesCheckerboard patternComputer science

The invention relates to an endoscope calibration system and method. The endoscope calibration system includes an endoscope module, a calibration target module, and an optical tracking module, wherein the endoscope module includes a front end of the endoscope module, and an endoscope camera located in an endoscope camera channel; the calibration target module is a calibration plate such as a flat plate with an equally-spaced solid circle array pattern or a flat plate with a checkerboard pattern; the optical tracking module includes an optical tracker positioned at the front end of the endoscope, an optical tracker attached to a calibration target, and an optical position sensor. The invention also relates to an endoscope calibration method. According to the invention, the endoscope calibration can be carried out effectively, conveniently and accurately, and the working channels of the endoscope cannot be occupied additionally. The endoscope calibration system and method can be used for the real-time surgical navigation.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com