Pulse modulation temperature sensor calibration system and calibration method

A temperature sensor and pulse modulation technology, applied in the field of calibration system of pulse modulation temperature sensor, can solve the problems of inability to real-time automatic calibration, complex circuit structure, digital output deviation, etc., to facilitate CMOS process integration, simplify system structure, improve measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

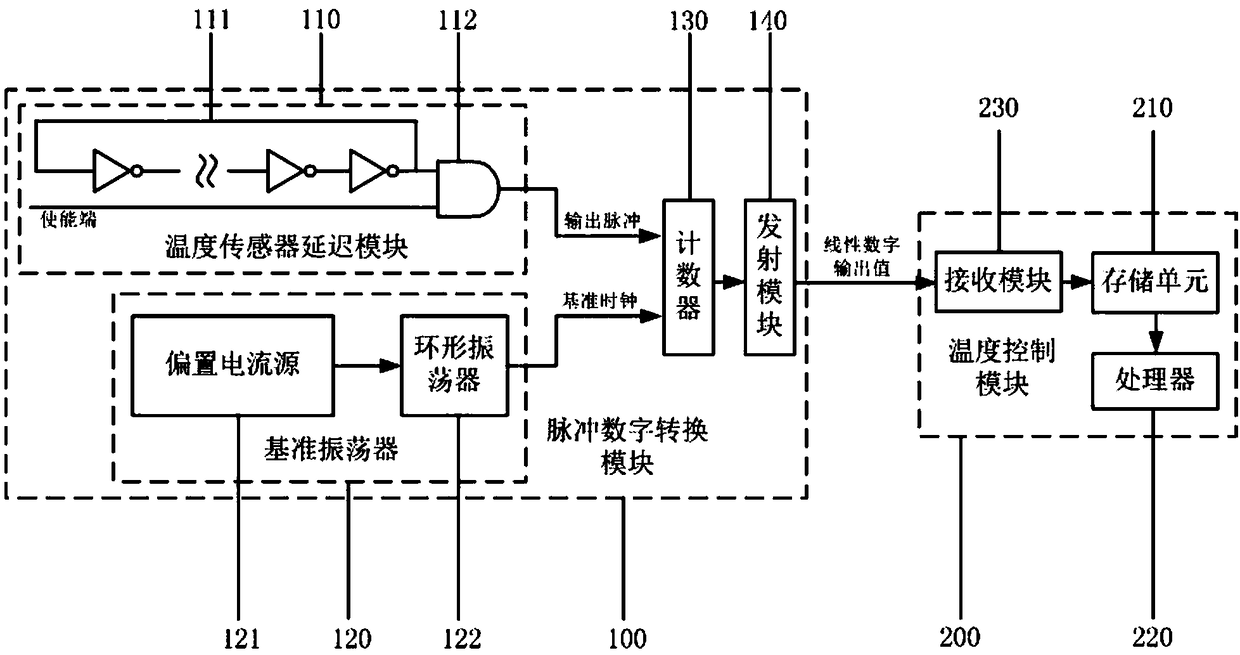

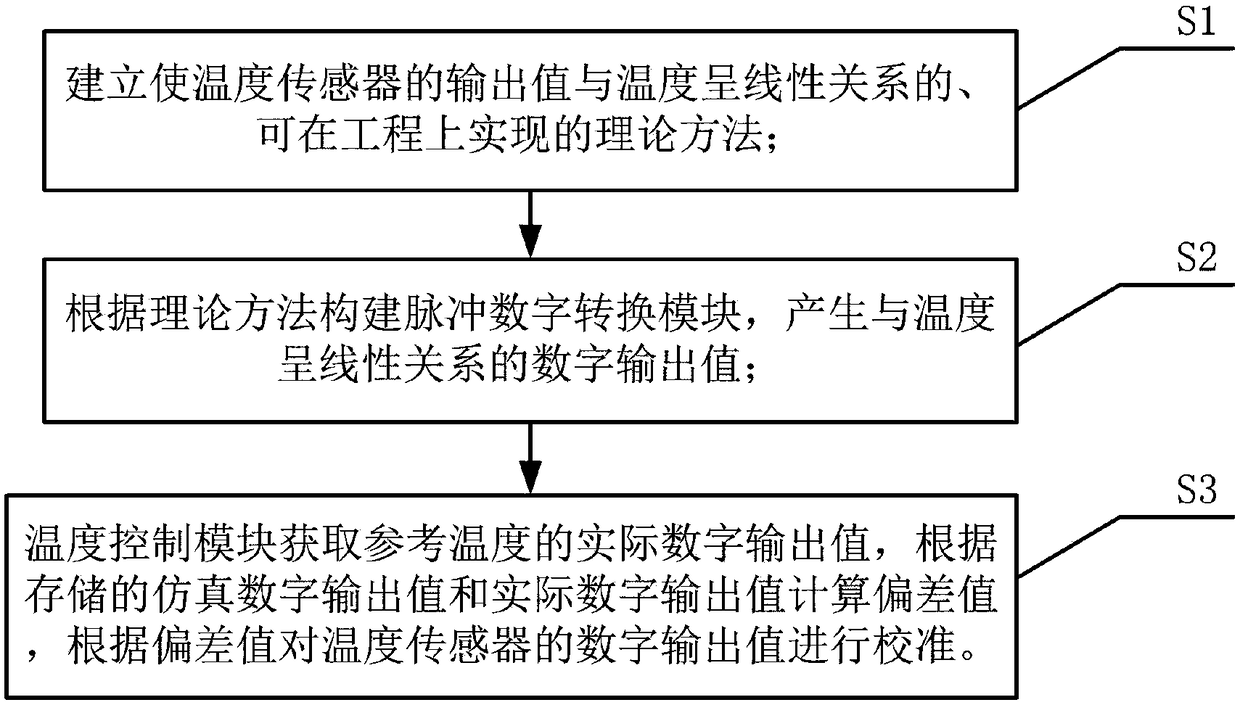

[0062] The invention provides a calibration system for a pulse modulation temperature sensor, specifically as figure 1 and figure 2 As shown, including a pulse digital conversion module 100 and a temperature control module 200;

[0063] The pulse-to-digital conversion module 100 is used to convert the output pulse into a digital output value linearly related to temperature according to the reference clock, and specifically includes a temperature sensor delay module 110, a reference oscillator 120, a counter 130 and a transmission module 140:

[0064] The temperature sensor delay module 110 is used to generate temperature-related output pulses; the reference oscillator 120 is used to generate a reference clock; the counter 130 is used to count the output pulses under the control of the reference clock to generate a digital value that is linearly related to the temperature output value; a transmitting module 140 , configured to transmit the digital output value generated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com