Laser ranging optical axis consistency dynamic calibration method and system

A technology of laser ranging and dynamic calibration, applied in the field of laser measurement, it can solve the problems such as the decrease of the measurement range and accuracy of the ranging system, the poor consistency of the optical axis parallelism and the optical axis, so as to avoid the need for regular return to the factory for adjustment and realize distance measurement. system, the effect of improving continuous working time and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings.

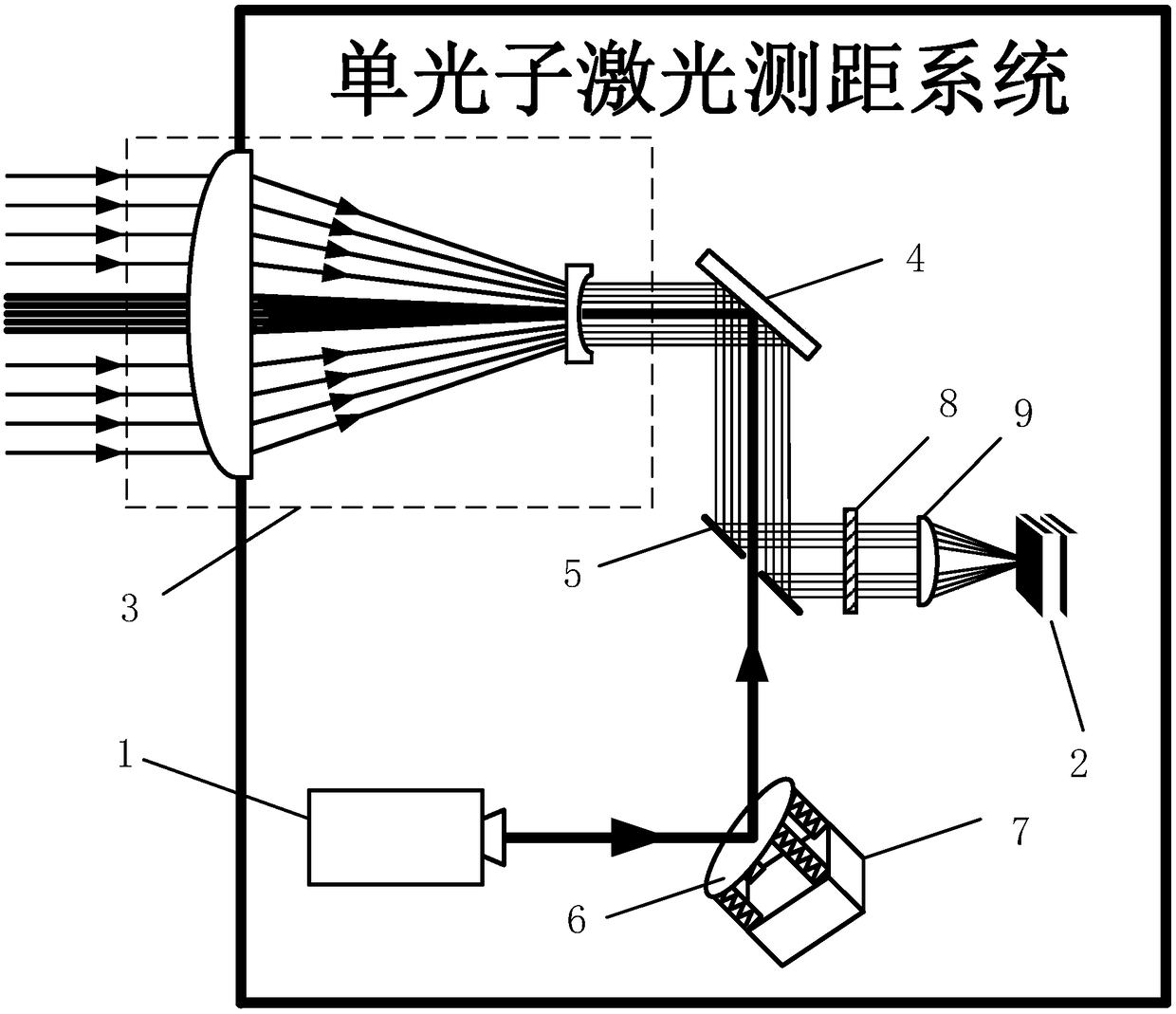

[0026] The present invention provides a laser ranging system, such as figure 1 As shown, it includes a laser 1, a transmitting optical path, a receiving optical path, and a signal receiving and processing device 2. The optical path is provided with a laser transceiver lens 3, a first fixed mirror 4, a second fixed mirror, an FSM mirror 6, a piezoelectric deflection pendulum Stage 7, narrow band filter 8, and receiving optical assembly 9.

[0027] Among them, the second fixed reflector is a hollow reflector 5; the emitted light of the emission light path is emitted from the laser 1 and reflected by the FSM reflector 6, passes through the hollow part of the hollow reflector 5, is reflected by the first fixed reflector 4, and is transmitted and received from the laser Lens 3 is sent out.

[0028] The reflected light of the receiving optical path passes through the laser transceive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com