Method and device for background digital calibration of production line ADC (analog-to-digital converter)

A technology of calibration device and calibration method, applied in the direction of analog/digital conversion calibration/test, etc., can solve the problems of limited application range and difficult synchronization of output signals, achieve small calibration error, overcome accuracy drop and large error, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

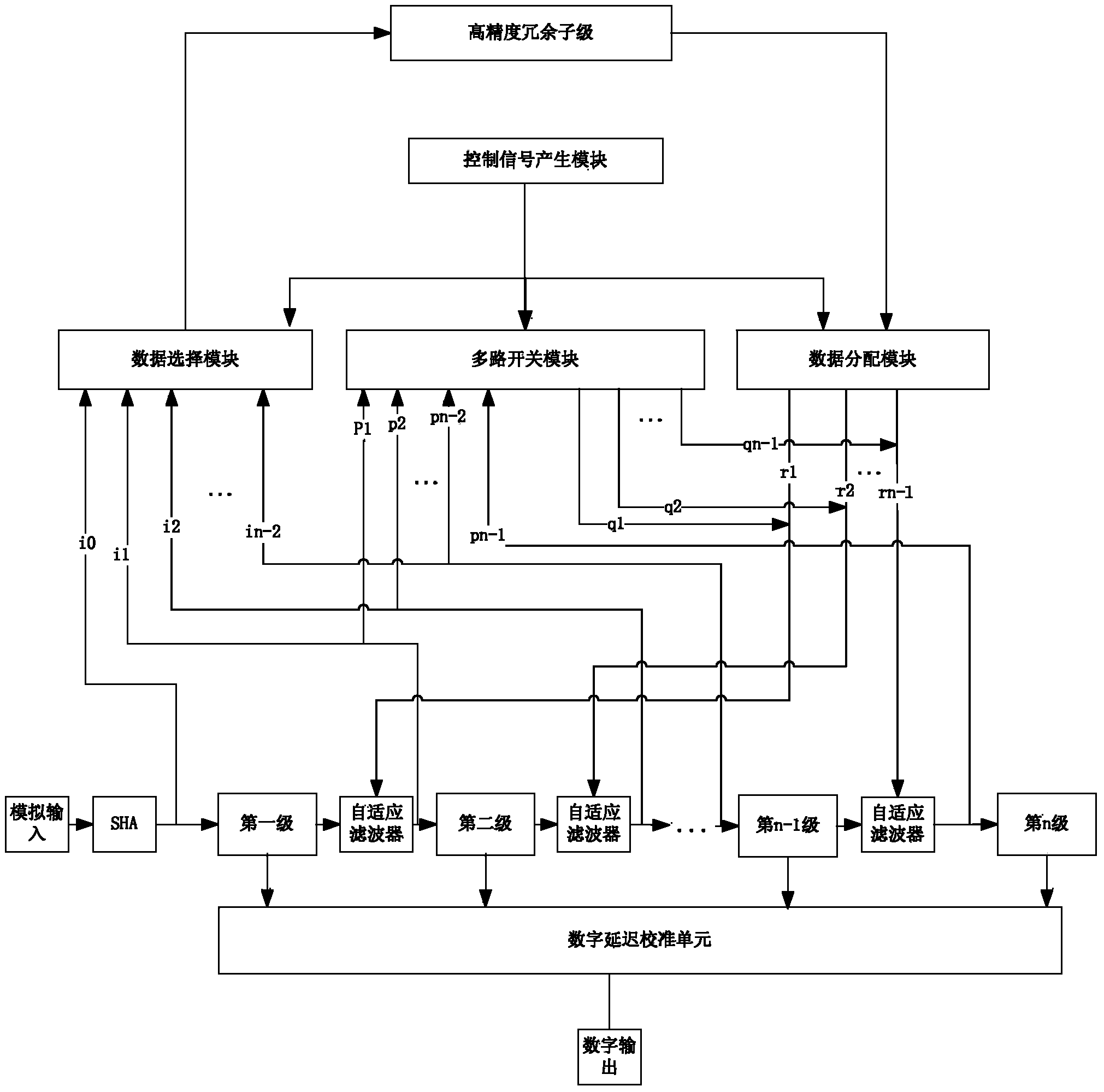

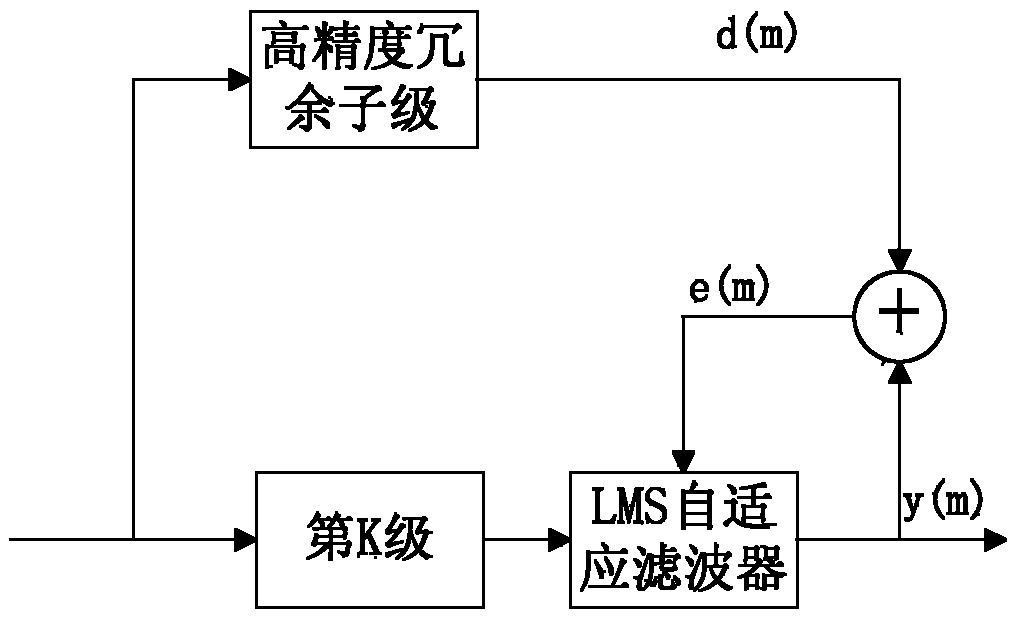

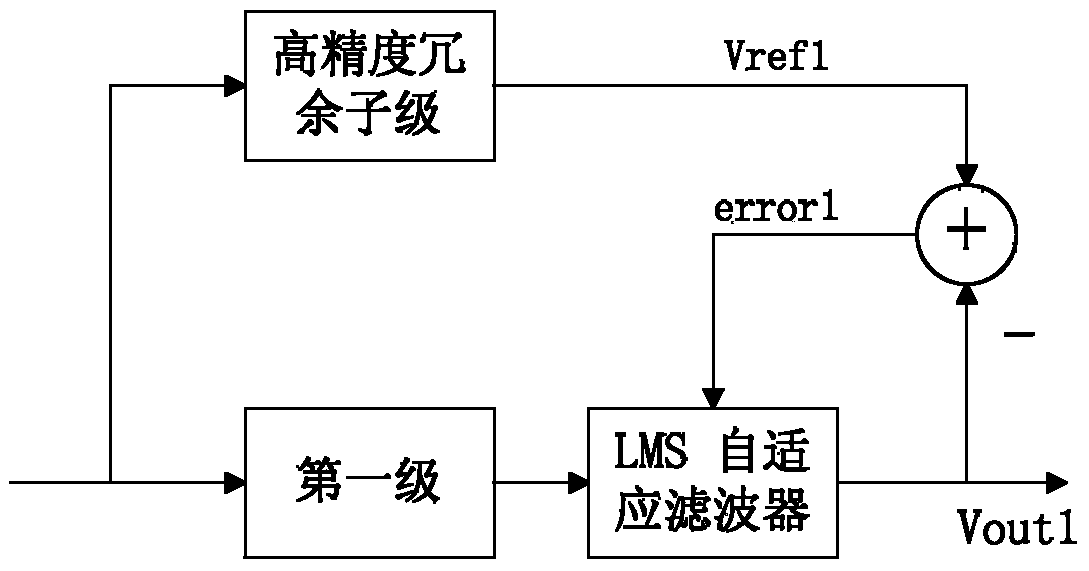

[0044] Such as figure 1 As shown, this embodiment discloses a background digital calibration device of a pipeline ADC, including an adaptive filter, a high-precision ADC redundant sub-stage, a data selection module, a data distribution module, a multi-way switch module and a control signal generation module; The precision of the high-precision ADC redundant sub-stage used in this embodiment is higher than that of each ADC sub-stage in the pipeline. All components of the calibration device in this embodiment are realized by CMOS technology. The adaptive filter used in this embodiment is an LMS adaptive filter, and of course other adaptive filters such as RLS may also be used. The pipeline ADC includes n-level ADC sub-stages, which are respectively the first stage to the n-th stage; the analog signal is input to the first-stage ADC sub-stage after passing through the sample-and-hold amplifier SHA. In this embodiment, the channels of the data selection module are respectively m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com