Ink droplet ejection state adjusting system and method for piezoelectric printing nozzle

A printing nozzle and state adjustment technology, which is applied in printing and other directions, can solve the problems of difficult long-term maintenance of the nozzle state, time-consuming and laborious, and limited application of inkjet printing technology, so as to avoid manual experience adjustment, ensure printing quality, and reduce labor costs. Effects of Operations and Invalid Operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing, the present invention is described in further detail:

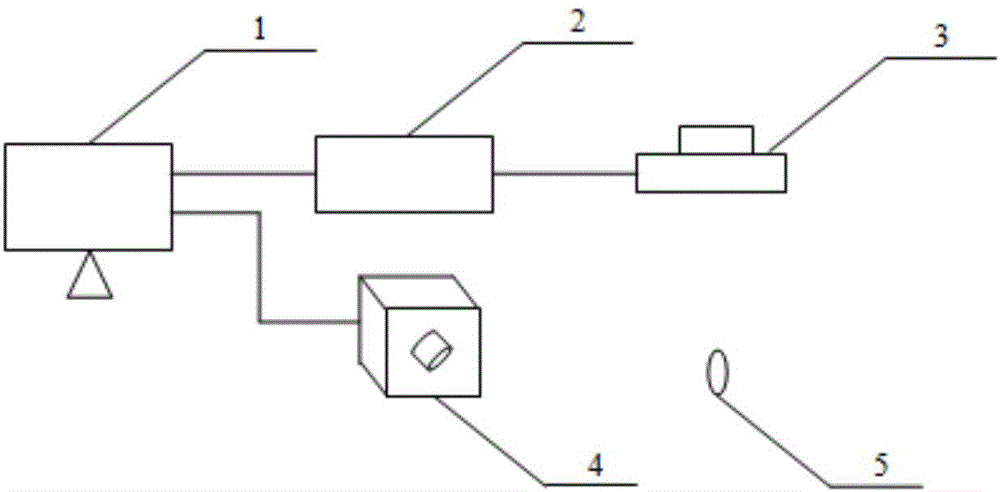

[0063] See figure 1 , the ink drop ejection state adjustment system for the piezoelectric printing nozzle of the present invention includes a CCD camera 4 , a computer computing platform 1 , a nozzle driving controller 2 , and a piezoelectric printing nozzle 3 .

[0064] The computer computing platform 1 uses a CCD camera to capture the state of the ink drop ejected by the piezoelectric printing nozzle, obtains the state parameters of the ink drop through image processing, and extracts the corresponding characterization parameters of the ink drop according to the working principle of the piezoelectric printing nozzle. According to the gap between the current ink drop characterization parameters and the expected ink drop characterization parameters, the artificial bee colony algorithm is used to optimize, and an expected driving waveform driving parameter is obtained, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com