Design method for ultraviolet laser machining apparatus for cutting wafer

An ultraviolet laser and processing equipment technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of slow processing speed, cutting groove line width, high cost, high anti-vibration stability and positioning accuracy, high cutting The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

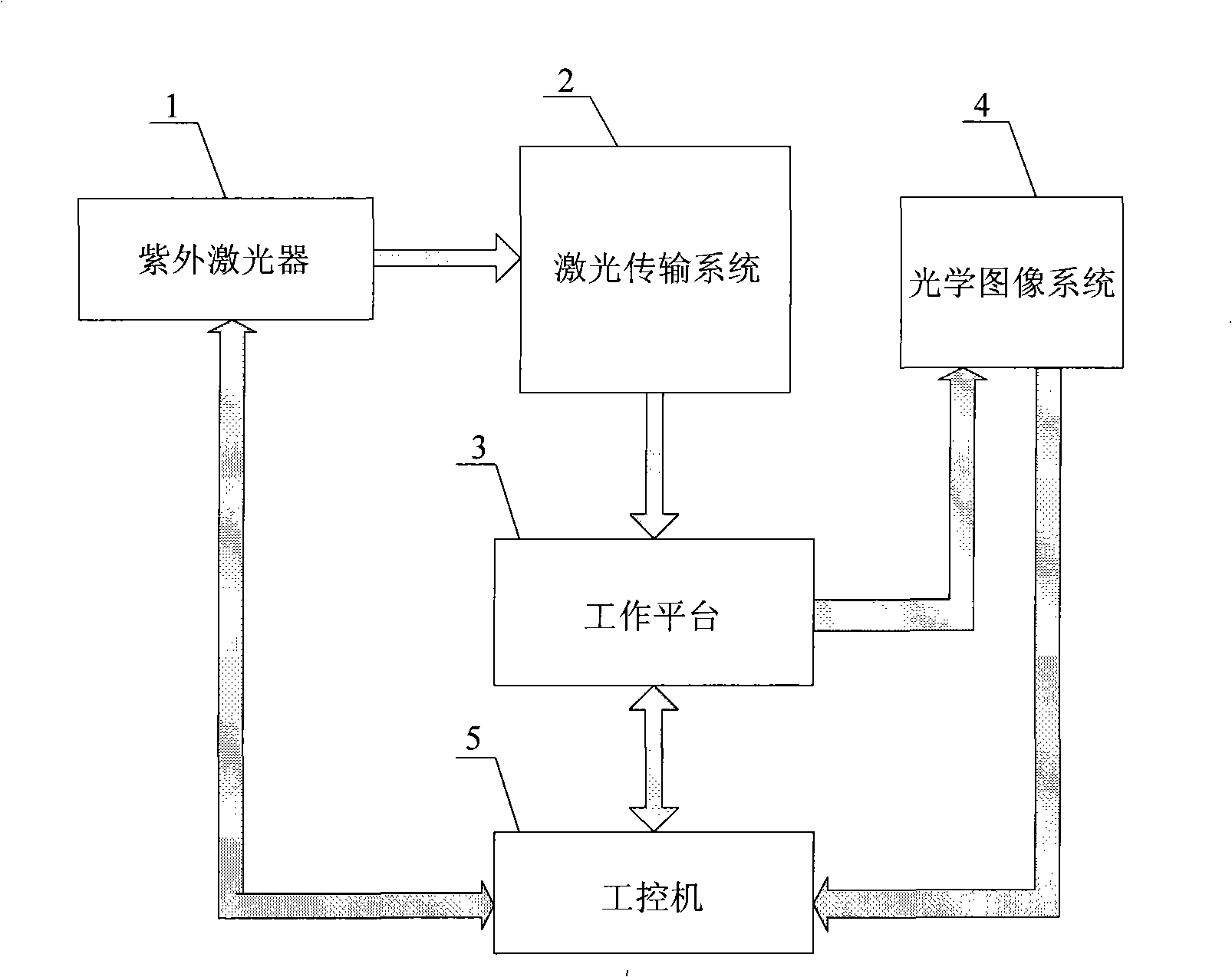

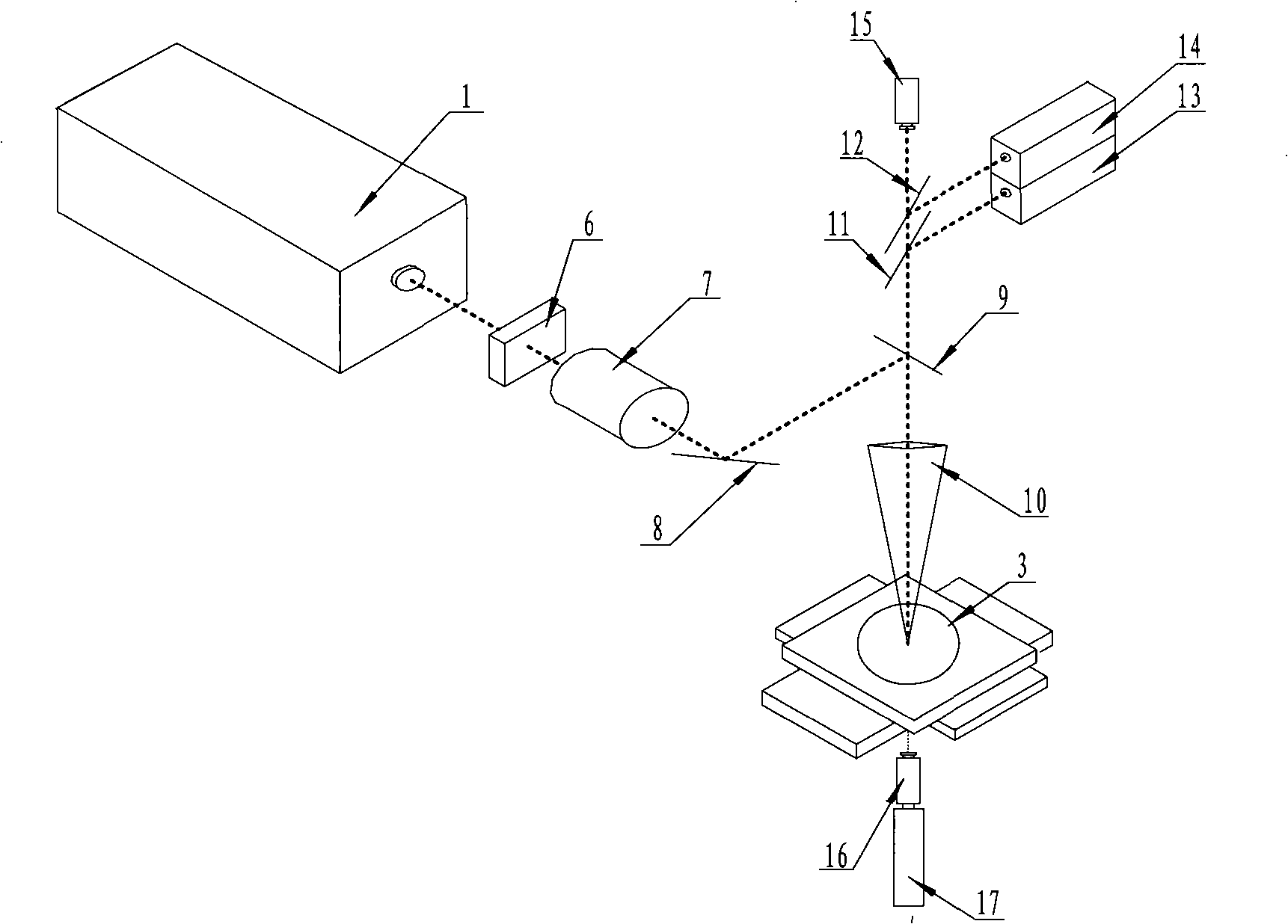

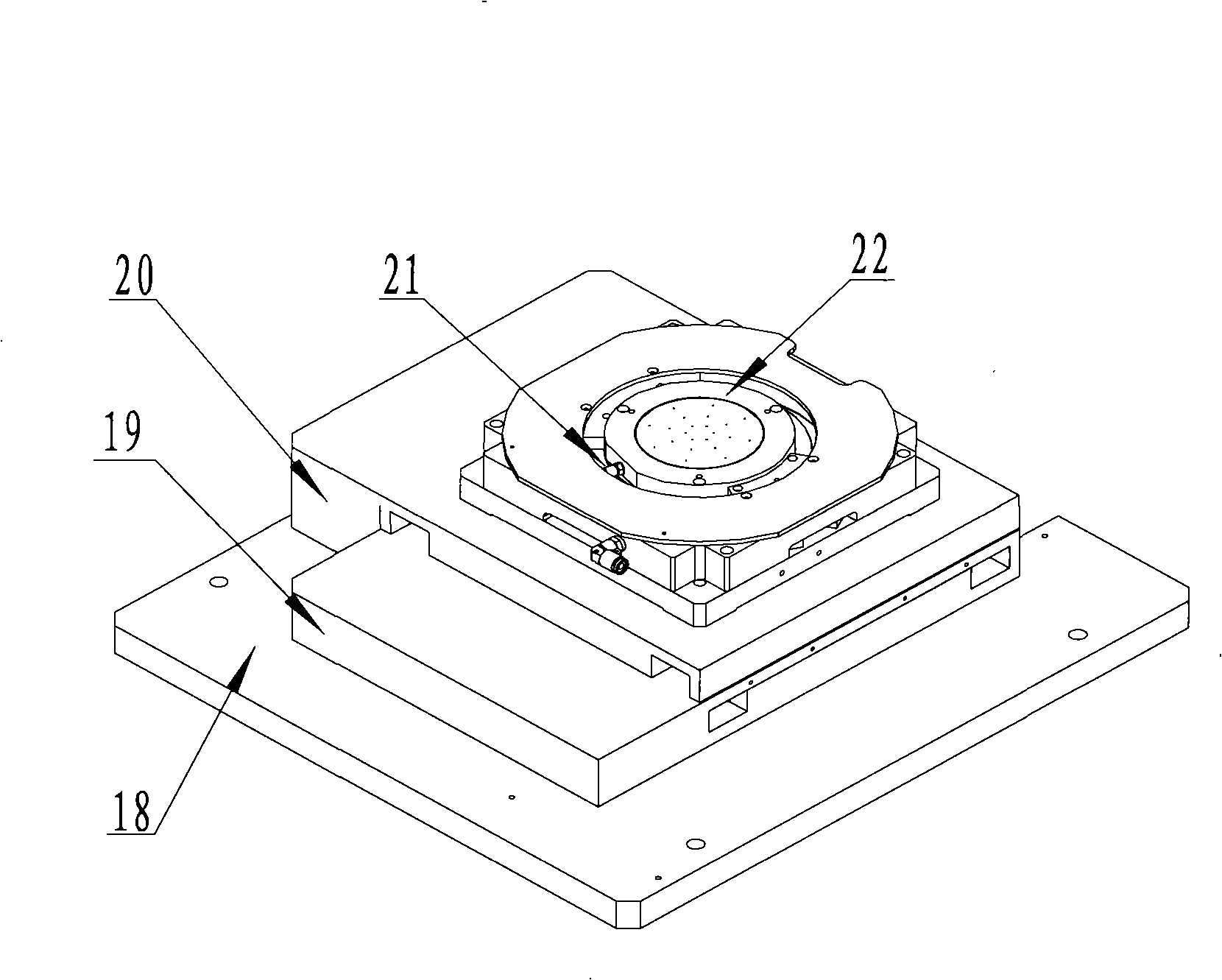

[0029] Such as figure 1 As shown, the wafer ultraviolet laser cutting equipment includes an ultraviolet laser 1, a laser transmission system 2, a processing platform 3, an optical image system 4 and an industrial computer 5. The laser emitted by the ultraviolet laser 1 is incident on the laser transmission system 2, and the laser transmission system 2. The focused spot of high energy density is vertically incident on the processing platform 3, and the laser energy distribution focused on the surface of the processing platform is controlled by adjusting the optical components in the laser transmission system 2. Before laser cutting, the crystal to be processed is controlled by the optical image system 4 The circle is used for positioning and planning of the cutting trajectory. During laser cutting, the laser optical axis remains stationary while the processing platform 3 moves linearly in the X and Y axes relative to the optical axis; the ultraviolet laser 1 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com