Coating attaching method, display panel and manufacturing method of display device

A technology for display panels and manufacturing methods, applied in lamination devices, lamination auxiliary operations, chemical instruments and methods, etc., can solve the problems that the film layer cannot be cut, the lead wire in the binding area is cut, etc., to improve the cutting yield and the effect of automated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order for those skilled in the art to better understand the technical solution of the present invention, the method for attaching the film layer, the method for manufacturing the display panel and the display device provided by the present invention will be described in detail below with reference to the accompanying drawings.

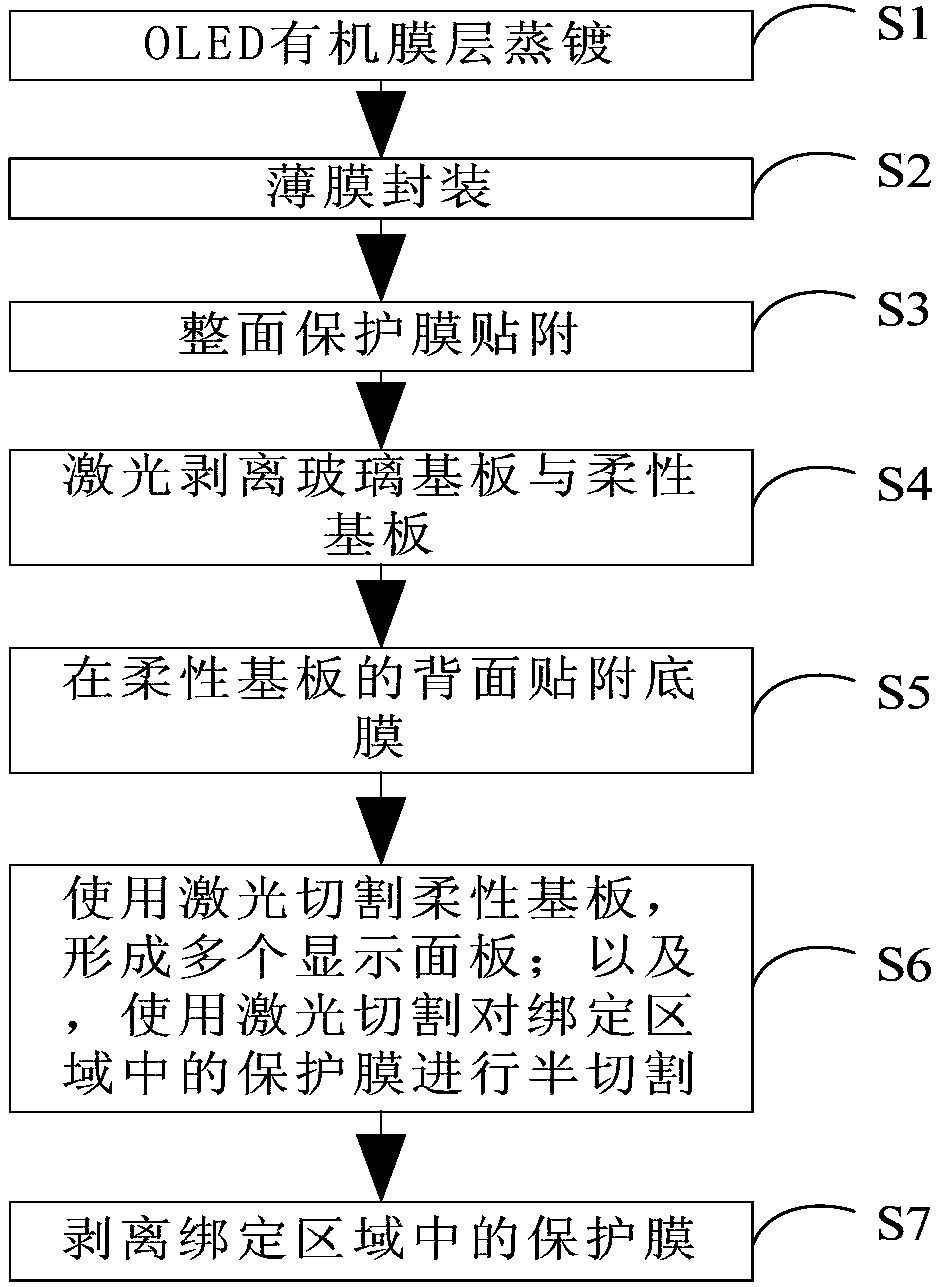

[0068] figure 1 For the process flow chart of the existing flexible display panel, please refer to figure 1 , the process includes:

[0069] S1, OLED organic film evaporation;

[0070] S2, film encapsulation;

[0071] S3, the whole surface protective film is attached;

[0072] S4, laser lift off transparent substrate and flexible substrate;

[0073] S5, attaching a base film on the back of the flexible substrate;

[0074] S6, cutting the flexible substrate using a laser to form a plurality of display panels; and half-cutting the protective film in the bonding area using laser cutting;

[0075] S7, peeling off the protective film in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com