Display panel manufacturing method, display panel and display device

A display panel and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, electrical components, etc., can solve problems such as easy cracks, packaging reliability test failure, difficult control of display panel cutting yield, etc., to achieve The effect of improving the cutting yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

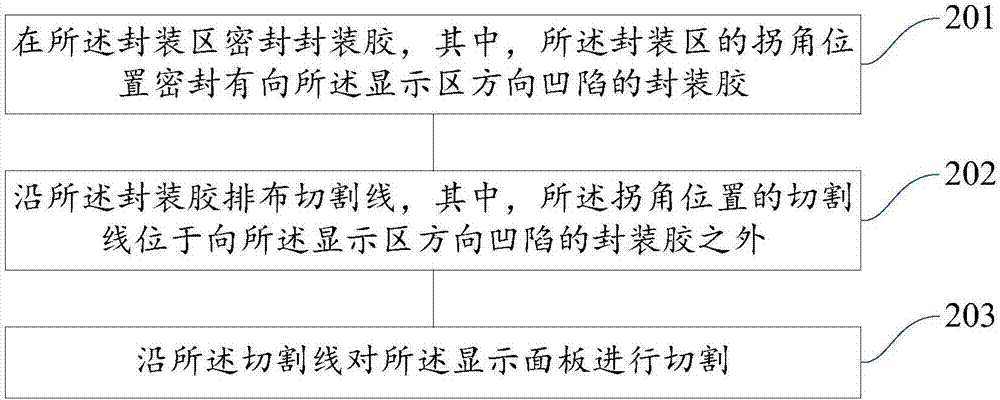

[0028] refer to figure 2 , which shows a flow chart of a method for manufacturing a display panel according to Embodiment 1 of the present invention, which may specifically include the following steps:

[0029] Step 201 , sealing the encapsulation area with an encapsulation glue, wherein the corners of the encapsulation area are sealed with an encapsulant recessed toward the display area.

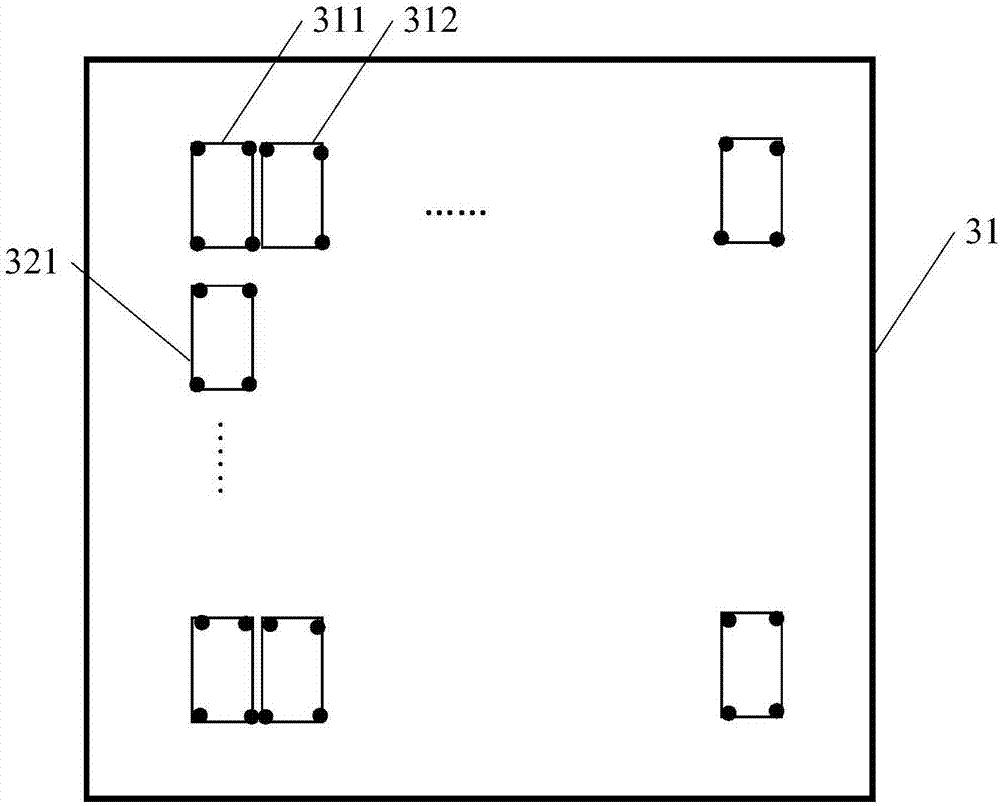

[0030] In an embodiment of the present invention, the display motherboard includes at least one display panel, and each display panel has a display area and a packaging area surrounding the display area. Firstly, a silk screen with corners recessed inward is made, wherein the pattern of the screen corresponds to the size and position of each display panel in the display motherboard. Wherein, the display panel is an OLED panel, and the OLED panel includes an AMOLED (Active Matrix / Organic Light Emitting Diode, Active Matrix Organic Light Emitting Diode) panel

[0031] refer to image 3 As...

Embodiment 2

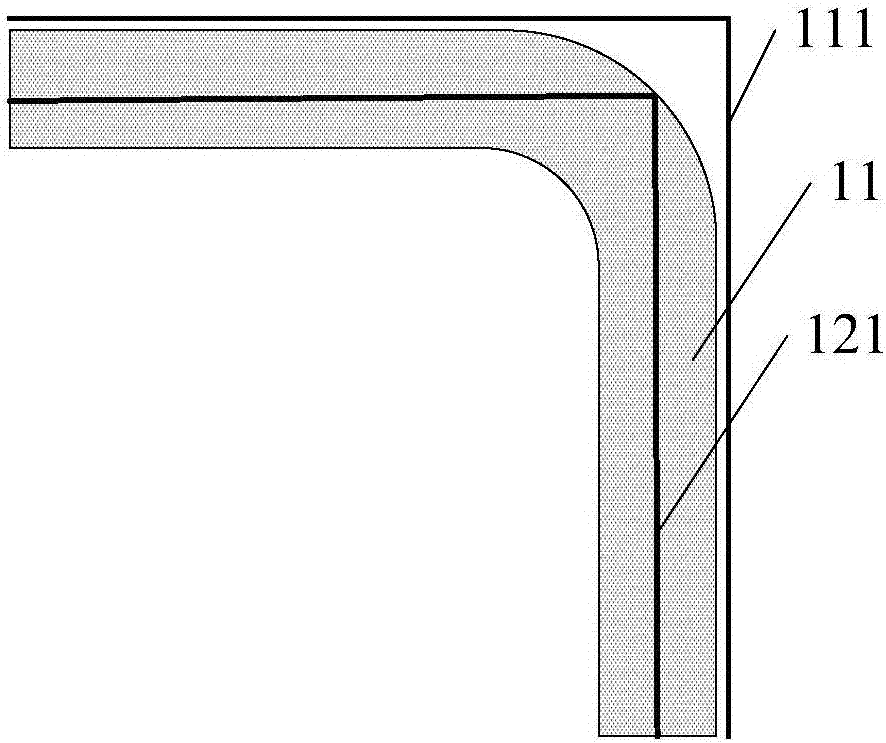

[0052] An embodiment of the present invention provides a display panel, which has a display area and an encapsulation area surrounding the display area, and an encapsulant recessed toward the display area is formed at a corner of the encapsulation area.

[0053] Specifically, the display motherboard includes at least one display panel, and each display panel has a display area and a packaging area surrounding the display area.

[0054] Firstly, a silk screen with corners recessed inward is made, wherein the pattern of the screen corresponds to the size and position of each display panel in the display motherboard.

[0055] Then, seal the encapsulation glue in the encapsulation area by screen printing according to the inwardly recessed screen corners. Since the inwardly recessed corners of the encapsulation area form a directional display area The encapsulant with concave direction. Wherein, the display panel is an OLED panel, and the packaging glue includes glass glue, which ...

Embodiment 3

[0063] A display device is provided in an embodiment of the present invention, and the display device includes the above-mentioned display panel.

[0064] The display panel has a display area and an encapsulation area surrounding the display area, and an encapsulant recessed toward the display area is formed at a corner of the encapsulation area.

[0065] Arranging cutting lines along the encapsulation, wherein the cutting lines at the corners are located outside the encapsulation recessed toward the display area; according to the arranged cutting lines, each display panel is cut along the cutting lines to obtain a separated Multiple display panels.

[0066] The display panel is an OLED panel, the height of the encapsulant is 4-10 μm, and the width of the non-depression in the encapsulant is greater than 300 μm.

[0067] In a preferred embodiment of the present invention, the width of the non-depression in the encapsulant is 300-700 μm.

[0068] The display device may be any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com