Manufacturing method of monolithic touch control screen

一种触控屏、单片式的技术,应用在玻璃制造设备、制造工具、玻璃的钢化等方向,达到工艺步骤简单、提高生产效率、提高切割良率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation process of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

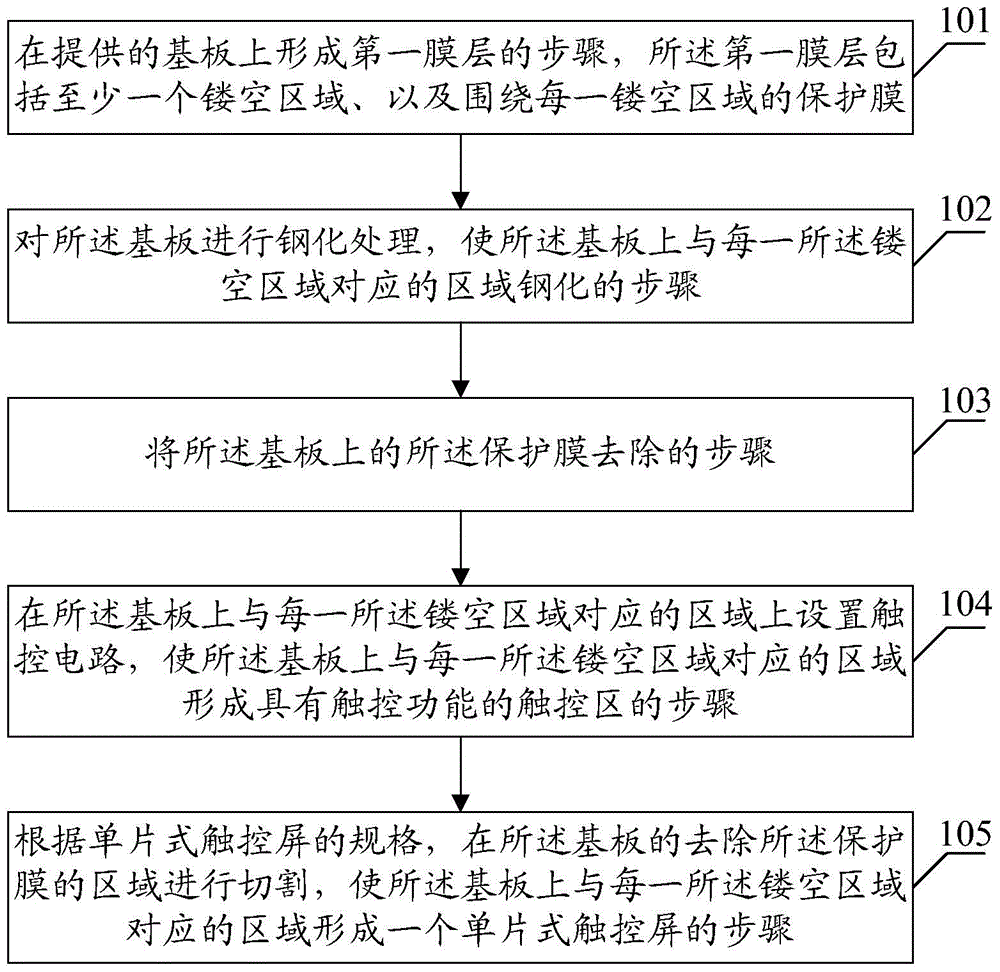

[0019] see figure 1 , an embodiment of the present invention provides a method for manufacturing a single-chip touch screen, including:

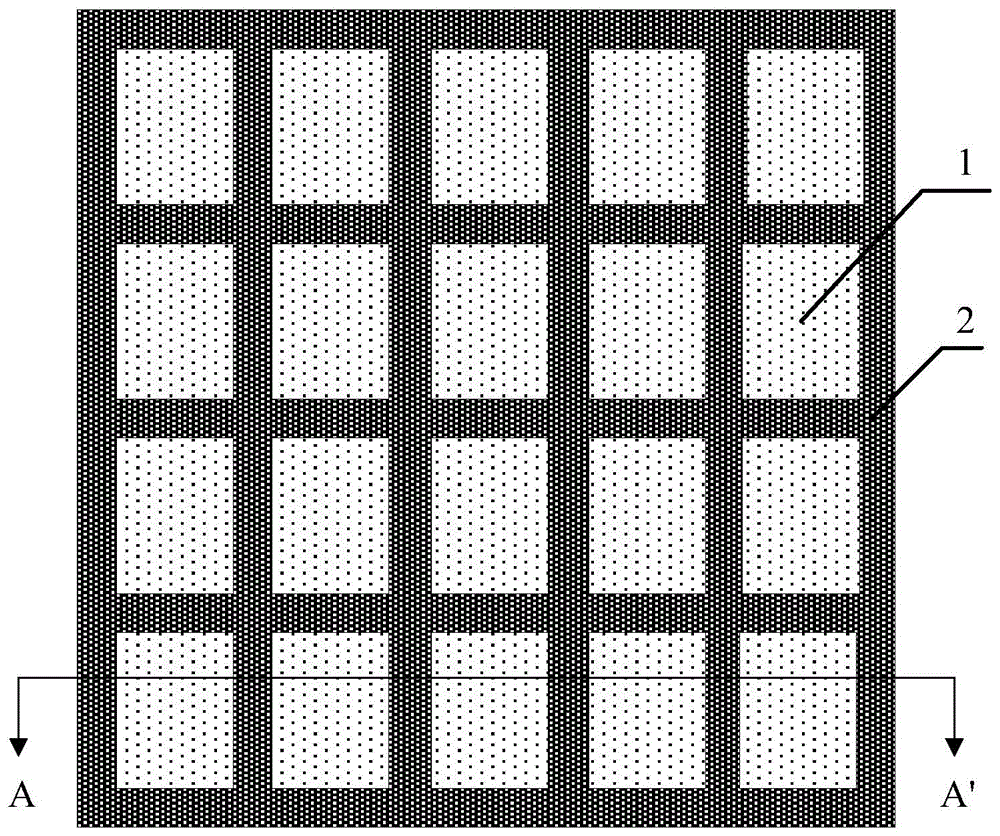

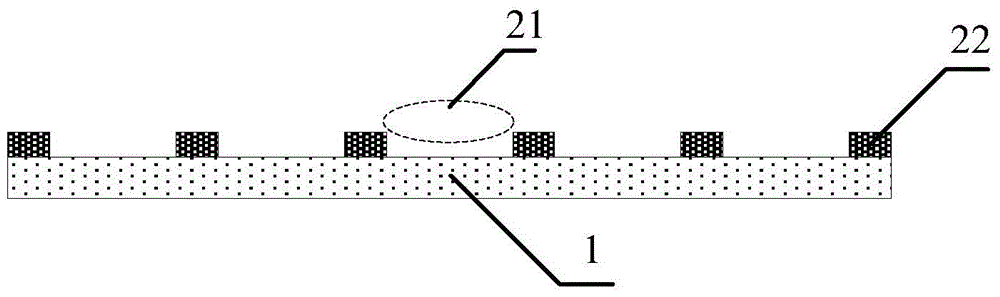

[0020] 101 , a step of forming a first film layer 2 on the provided substrate 1 , the first film layer 2 includes at least one hollowed out area 21 and a protective film 22 surrounding each hollowed out area 21 .

[0021] There are many ways to form the first film layer 2 on the substrate 1 . For example, by coating a thin film for protecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com