Silicon slice cutting fluid and preparation method thereof

A silicon wafer cutting fluid and anti-oxidant technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problem of poor dispersion and redispersion of silicon carbide powder, deposition and agglomeration of silicon carbide powder, inability to disperse silicon carbide powder, etc. Problems, achieve the effect of improving cutting yield, easy operation, ensuring stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

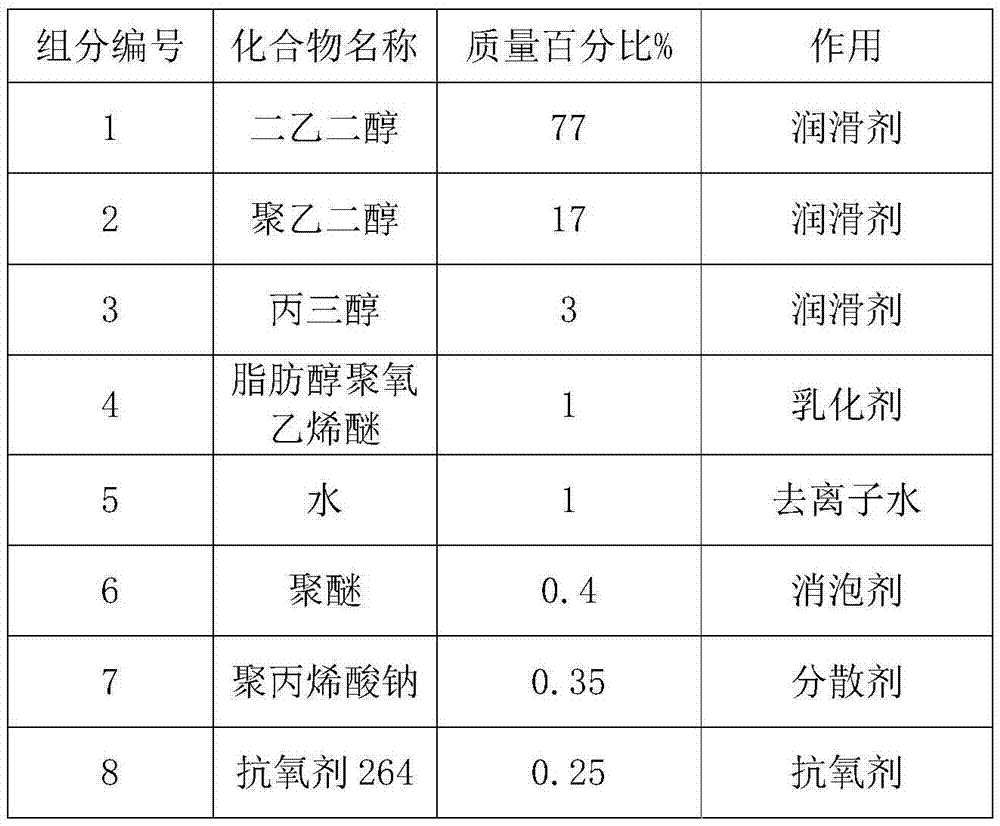

[0023] In the silicon wafer cutting fluid in this example, the defoamer is polyether, the dispersant is sodium polyacrylate, and the antioxidant is antioxidant 264. The components are shown in Table 1:

[0024] The component table of table 1 embodiment 1

[0025]

[0026] Among them, diethylene glycol, polyethylene glycol and glycerin are used as lubricants, and fatty alcohol polyoxyethylene ethers are used as emulsifiers.

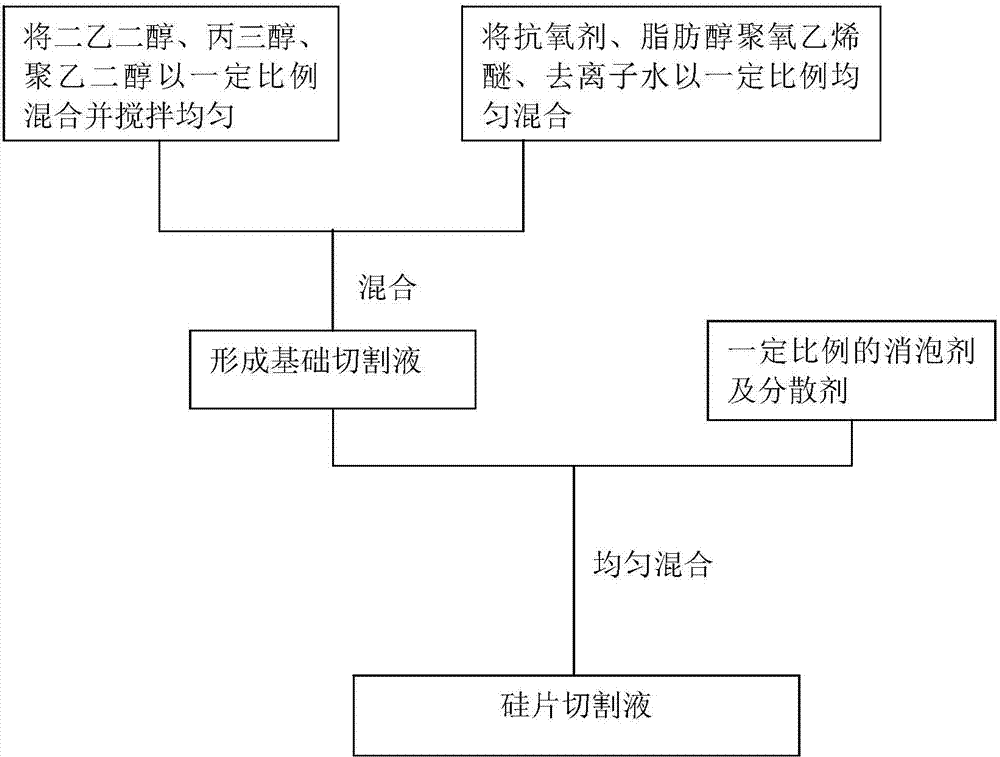

[0027] Its preparation method is as figure 1 As shown, the above three lubricants are mixed according to the above mass percentages, and stirred at room temperature to form a uniform mixed solution 1; the antioxidant, emulsifier and deionized water are mixed according to the above mass percentages and stirred evenly , added to the mixed solution 1 to form a basic cutting fluid; the dispersant and defoamer were added to the basic cutting fluid according to the mass percentage, and fully stirred to form a uniform silicon wafer cutting fluid.

Embodiment 2

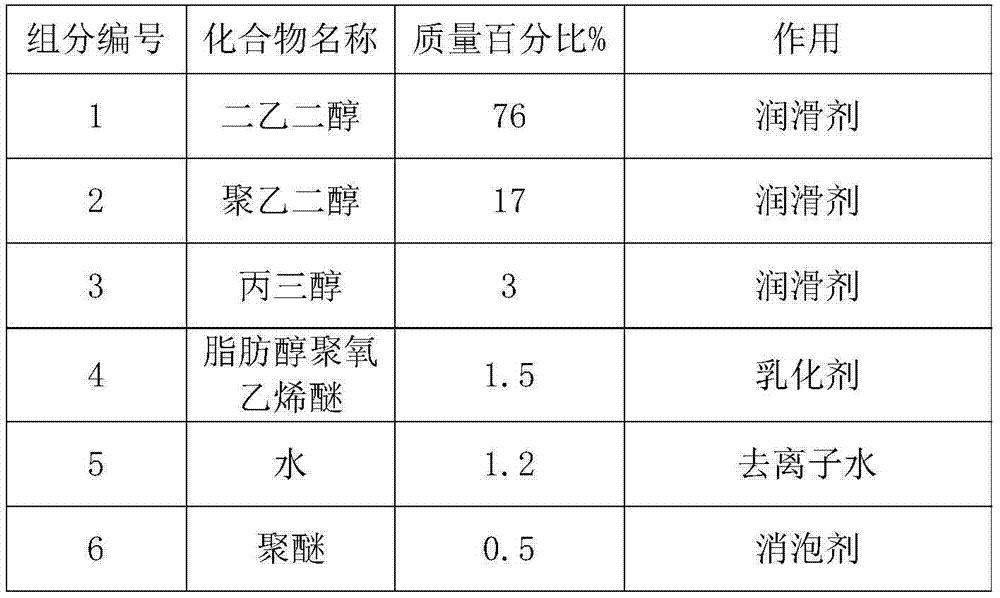

[0029] In the silicon chip cutting fluid in this example, its defoamer is polyether, its dispersant is sodium polyacrylate, its antioxidant is antioxidant 264, and its components are as follows:

[0030] The component table of table 2 embodiment 2

[0031]

[0032]

[0033] Its preparation method is to mix diethylene glycol, polyethylene glycol and glycerin according to the mass percentage, and stir at room temperature to form a uniform mixed solution 1; mix antioxidant 264, fatty alcohol polyoxyethylene ether and deionized water are mixed according to the above mass percentage and stirred evenly, then added to the mixed solution 1 to form a basic cutting fluid; sodium polyacrylate and polyether are added to the basic cutting fluid according to the above mass percentage, and fully stirred to form Uniform wafer cutting fluid.

Embodiment 3

[0035] Silicon chip cutting fluid in this example, its antifoaming agent adopts polyether, dispersant adopts sodium polyacrylate, antioxidant adopts antioxidant 264, and lubricant includes diethylene glycol, polyethylene glycol and glycerol, the composition The points are shown in Table 3:

[0036] The component table of table 3 embodiment 3

[0037]

[0038] Its preparation method is to mix the lubricant according to the mass percentage, and stir at room temperature to form a uniform mixed solution 1; mix the antioxidant 264, fatty alcohol polyoxyethylene ether and deionized water according to the above mass percentage and After stirring evenly, add it to the mixed solution 1 to form a basic cutting fluid; add sodium polyacrylate and polyether to the basic cutting fluid according to the mass percentage, and fully stir to form a uniform silicon wafer cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com