Method for cutting sapphire substrate LED chip through lasers

A sapphire substrate and LED chip technology, applied in laser welding equipment, electrical components, circuits, etc., can solve problems such as low cutting yield, poor appearance, and prone to double crystals, so as to improve cutting yield and improve appearance rate, to avoid the effect of twin crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for cutting a sapphire substrate LED chip by laser, comprising:

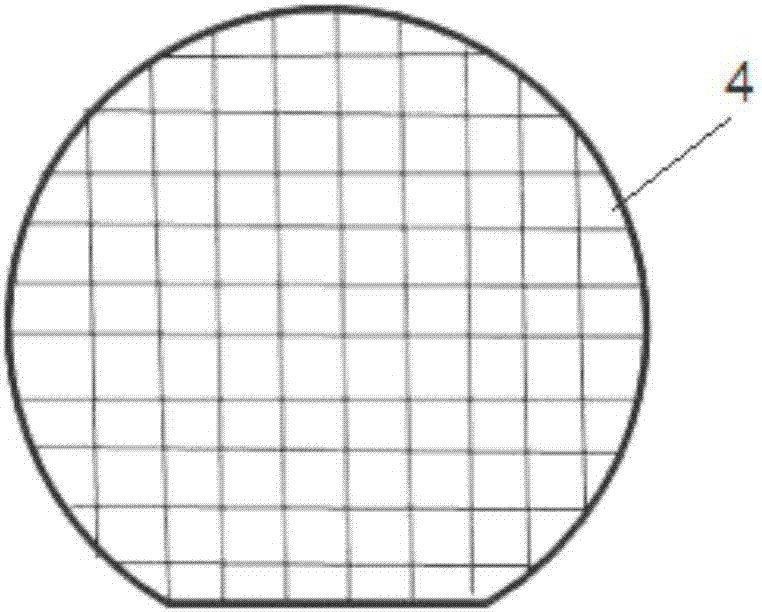

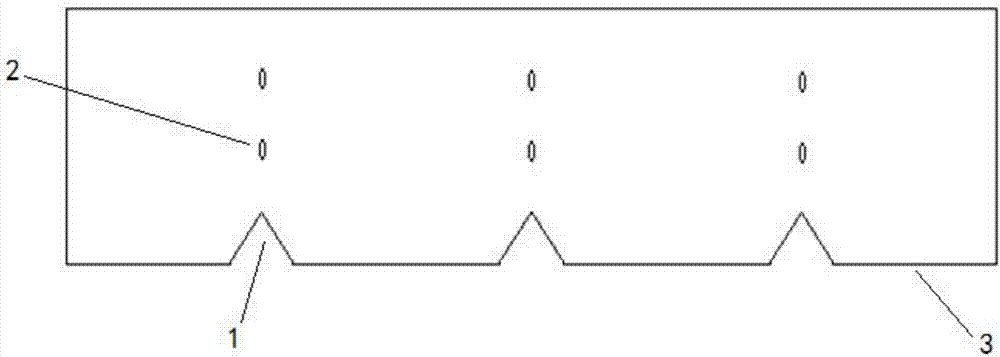

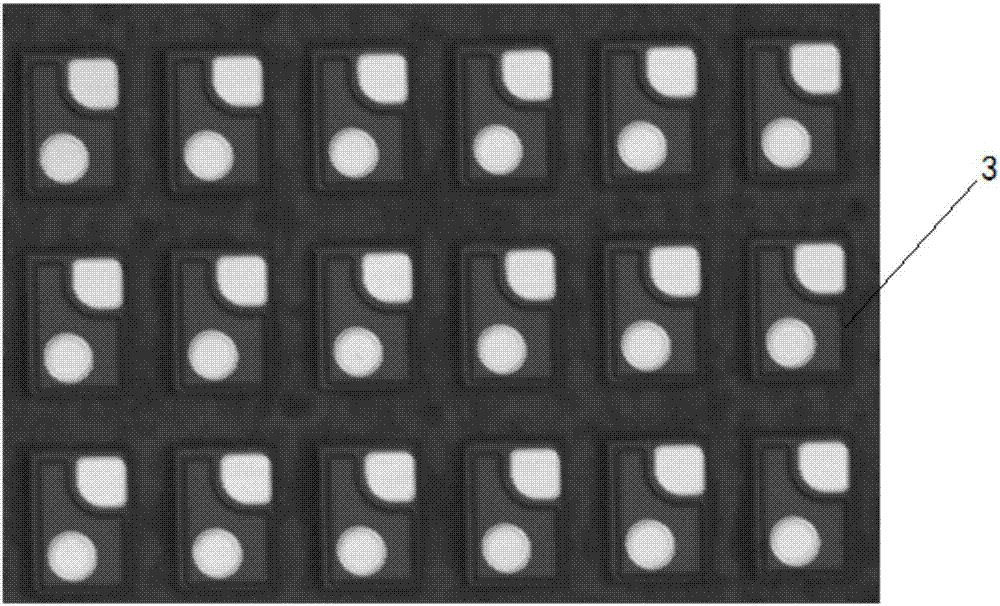

[0042] (1) Utilize the ultraviolet laser dicing machine to ablate and cut the groove 1 on the electrode surface 3 of the sapphire substrate wafer; the wafer refers to the LED chip that has completed the electrode but not cut; Refers to the thinned sapphire substrate wafer 4; the laser frequency in the Y direction of the wafer is 120-150KHz, the moving speed of the ultraviolet laser dicing machine is 110-130mm / s, and the laser frequency in the X direction of the wafer is 120-150KHz. It is 120-150KHz, and the moving speed of the ultraviolet laser scribing machine is 110-130mm / s;

[0043] (2) Invert the wafer so that the electrode surface is in contact with the white film, and the substrate is facing up, and placed on the platform of the invisible laser dicing machine, and the laser is applied to the sapphire substrate wafer by using the invisible laser dicing machine Inside: at least two parallel ...

Embodiment 2

[0048] A method for cutting a sapphire substrate LED chip by laser as described in Embodiment 1, the difference is that the thickness of the sapphire substrate wafer is 150-200 μm. When the thickness of the sapphire substrate wafer is 150-200 μm, it is sequentially cut out from the electrode surface: the first modified layer and the second modified layer, and the distance between the first modified layer and the electrode is The surface is 20-100 μm; the distance between the second modified layer and the first modified layer is 20-50 μm.

Embodiment 3

[0050] A kind of method utilizing laser cutting sapphire substrate LED chip as described in embodiment 1, its difference is, when the thickness of described sapphire substrate wafer is greater than or equal to 200 μm, at distance from described electrode surface (1 / 3) Cut ~(2 / 5) sapphire substrate wafer thickness position to form the first modified layer, and then prepare modified layers at intervals of 20-25 μm along the first modified layer to form parallel modified layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com