Plasma tracking ruled fly-saw

A plasma and flying saw technology, which is applied to the equipment field of dynamic tracking and fixed-length cutting of metal pipes and profiles, can solve the problems of high noise, dangerous saw blades, and high consumption cost of sawing flying saws, so as to achieve low consumption cost, Good development prospects and good incision quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

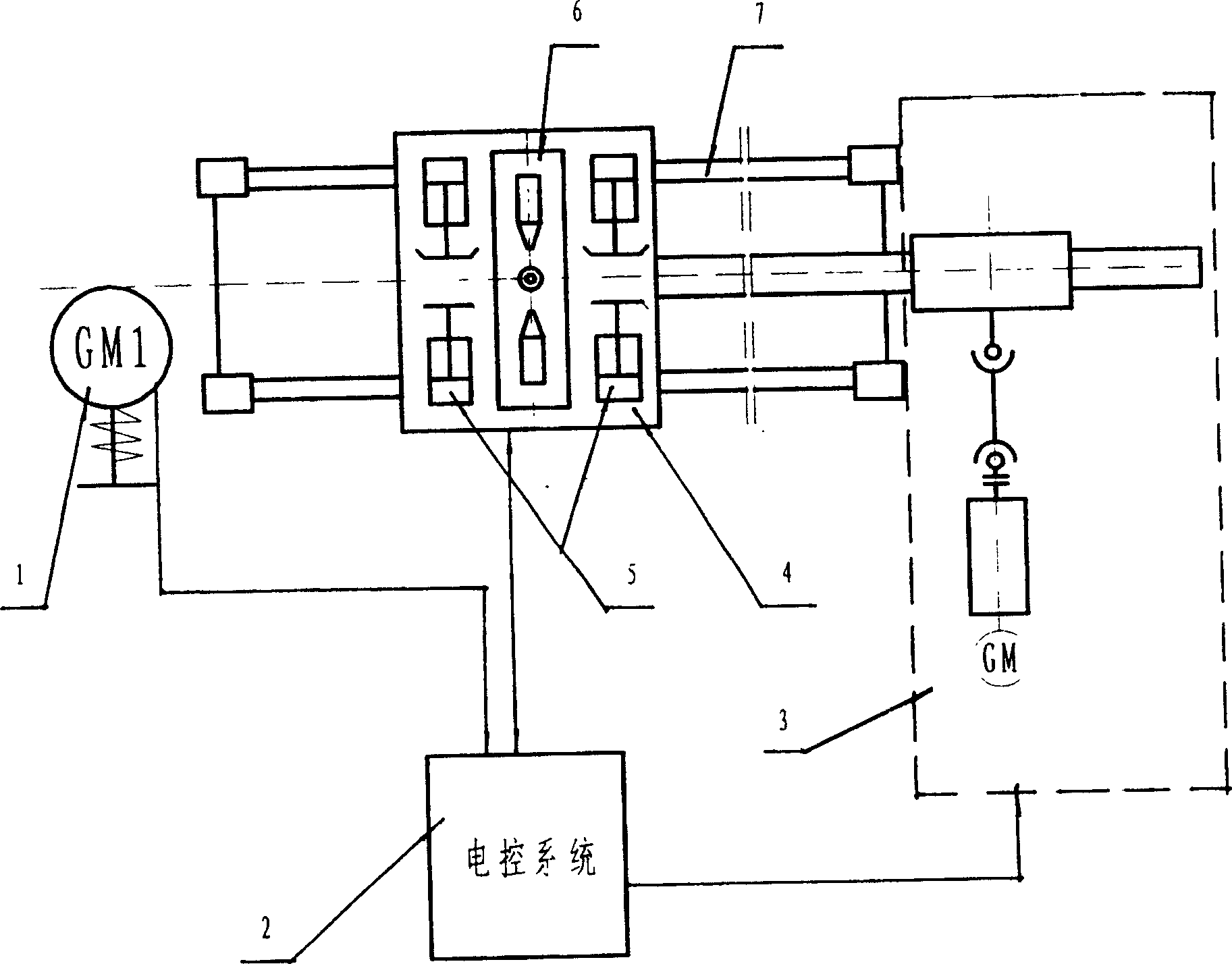

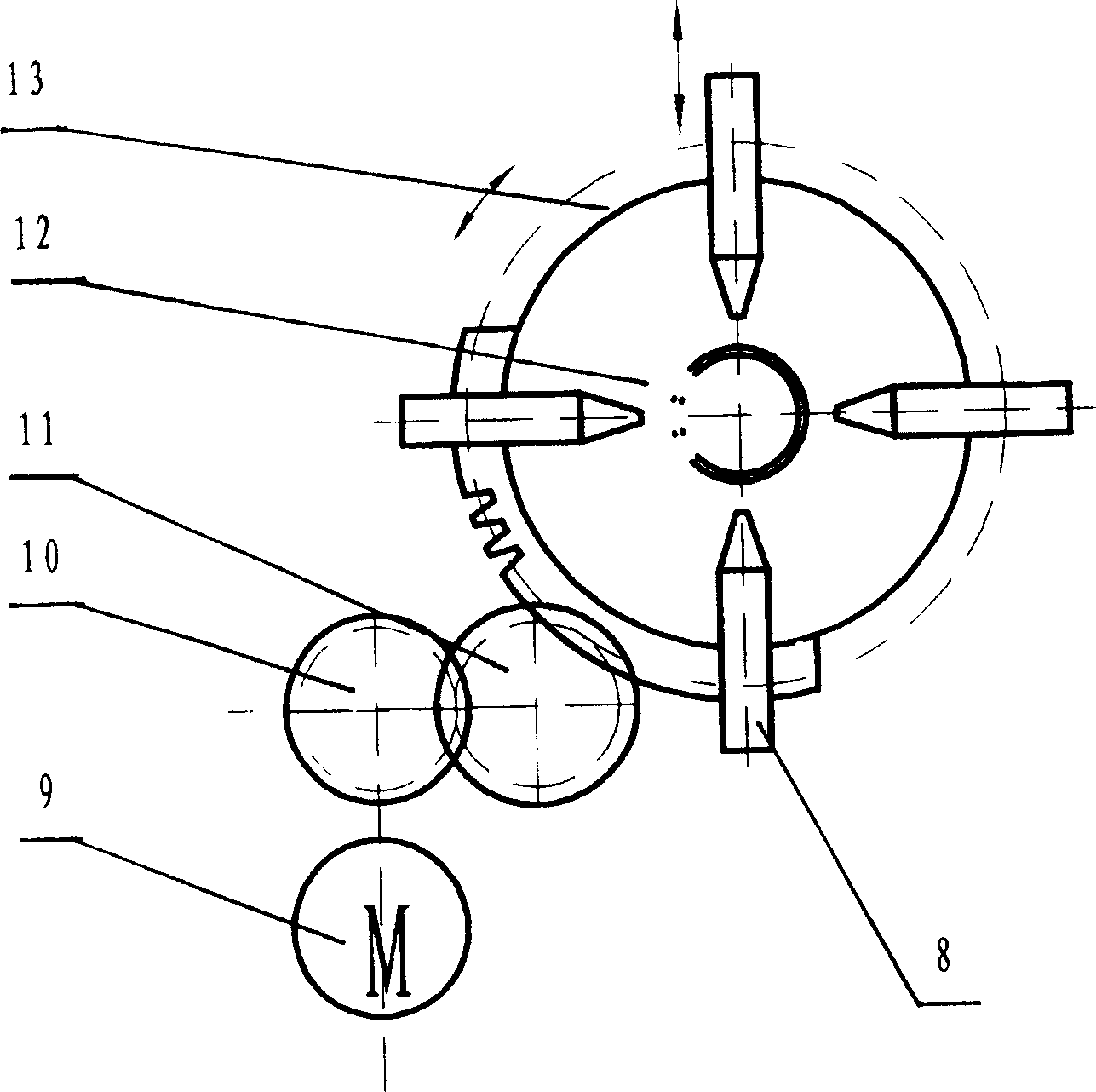

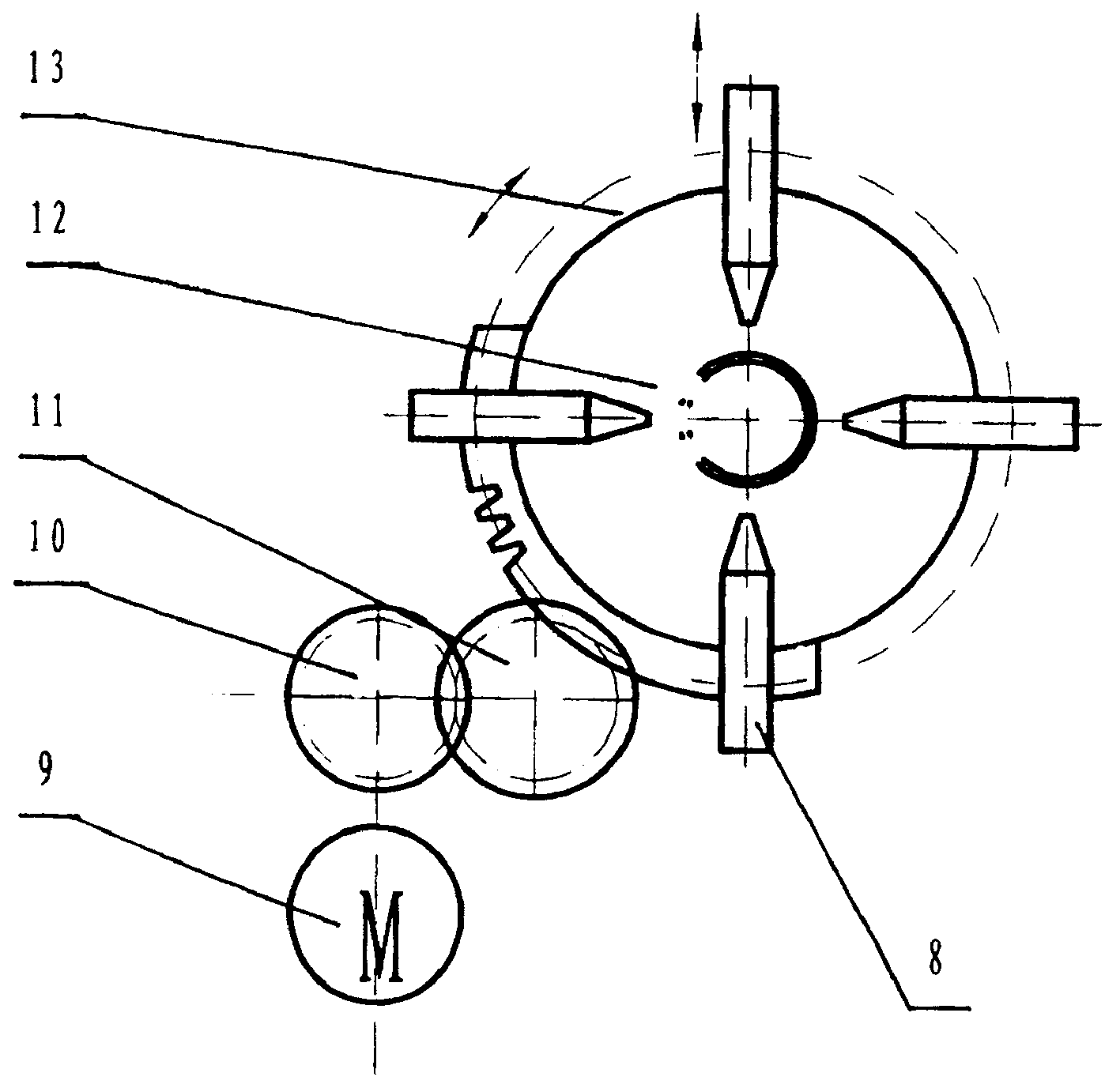

[0015] Embodiment: a flying saw with plasma tracking and fixed length (take the round pipe as an example, see Figures 1 and 2), including a flying saw trolley 4, a speed measuring device 1, an electrical control system 2, a drive system 3, a clamp 5 and a guide rail base 7. The drive system 3 is connected to the flying saw trolley 4 sitting on the guide rail base 7, and the speed measuring device 1 is connected to the electrical control system 2. It is characterized in that a plasma cutting device 6 is installed on the flying saw trolley 4. The plasma cutting device 6 It is composed of a plasma gun 8 installed on a profiling frame 13, and the outer edge of the profiling frame 13 is connected with a rotating motor 9 according to a transmission device.

[0016] The above-mentioned plasma gun 8 that is installed on the profiling frame 13 can adopt four installations (see figure 2) .

[0017] The above-mentioned transmission device connecting the outer edge of the profiling fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com