Hydraulic high-speed free piston linear generator

A linear generator and hydraulic piston technology, applied in free piston engines, machines/engines, mechanical equipment, etc., can solve the problem of low speed of generator movers, achieve low cost, convenient manufacturing and processing, and increase work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

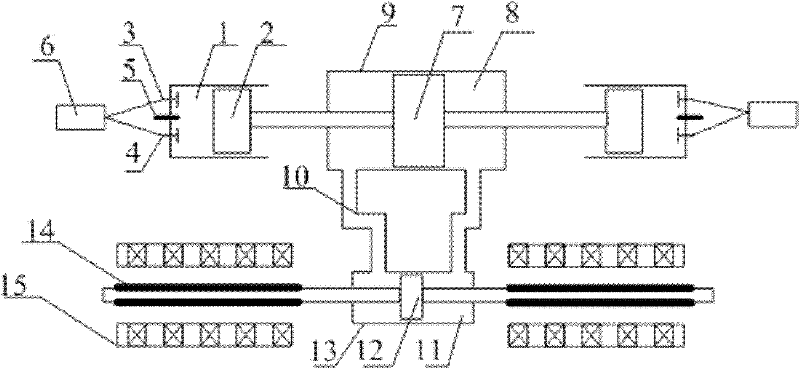

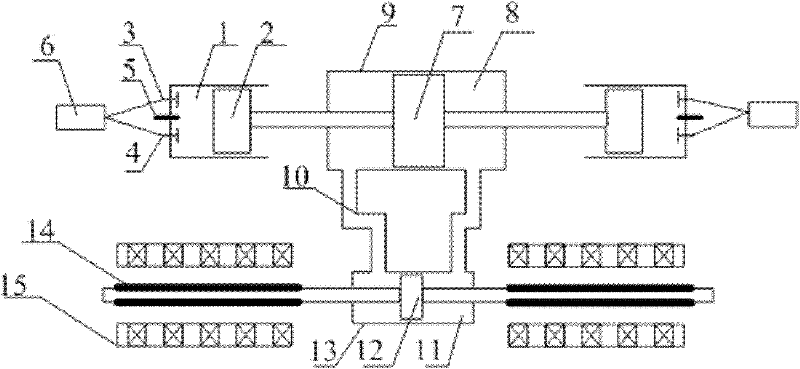

[0018] A hydraulic high-speed free-piston internal-combustion linear generator of the present invention mainly includes a free-piston internal-combustion engine, a hydraulic transmission mechanism and a linear generator. The free piston internal combustion engine includes: engine cylinder 1, piston 2, intake valve 3, exhaust valve 4, fuel injector 5, intake and exhaust controller 6; hydraulic transmission mechanism includes: first hydraulic piston 7, first hydraulic chamber 8 , the first hydraulic pump 9, the high-pressure oil pipe 10, the second hydraulic chamber 11, the second hydraulic piston 12, the second hydraulic pump 13; the linear generator includes: a motor mover 14, a motor stator 15;

[0019] The first hydraulic piston 7 is placed in the first hydraulic pump 9; the second hydraulic piston 12 is placed in the second hydraulic pump 13; the first hydraulic pump 9 communicates with the second hydraulic pump 13 through a high-pressure oil pipe 10 to form a hydraulic tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com