Numerical control cutting method for preventing inner hole notch of thick plate part

A cutting method and inner hole technology, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory cutting quality improvement effect, consumption of manpower and material resources, cutting notch damage to parts, etc., to reduce artificial The effect of modifying workload, reducing manpower and material resources, and improving cutting quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

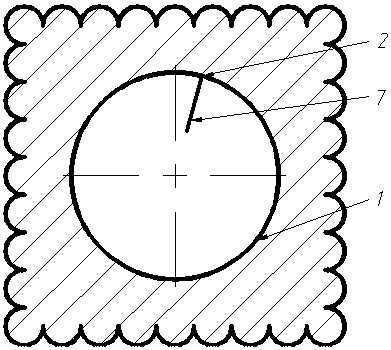

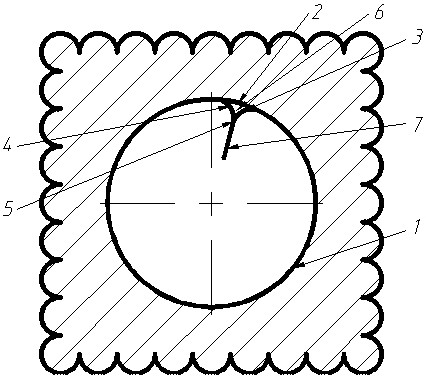

[0023] As shown in the figure, taking a part with a thickness of 55mm and an inner hole diameter of 100mm as an example, the cutting steps and process are specifically explained for the modification of the inner hole contour and the setting of cutting parameters.

[0024] (1) First, modify the parts library file, identify a part in the parts library whose thickness is 55 mm and the diameter of the inner hole is 100 mm, modify the identified part inner hole geometry in AutoCAD software, and decompose the part geometry into straight line segments and Arc line: select the midpoint 2 of the inner hole contour line 1 of the part, and make a right inscribed arc line 3 with a radius of 10 mm on the inner side of the part inner hole and the left and right sides of the midpoint respectively. The intersection of the side inscribed arc line 4, the right inscribed arc line 3 and the left inscribed arc line 4 is the arc extinguishing point 5 during CNC flame cutting, and the distance betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com