Crystal bar slicing device

A technology of slicing device and crystal rod, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of decreased electrochemical reaction efficiency, decreased reaction activity, and inability to cut crystal rods, so as to avoid local electrolytes. The effect of uneven concentration, enhanced flow, reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

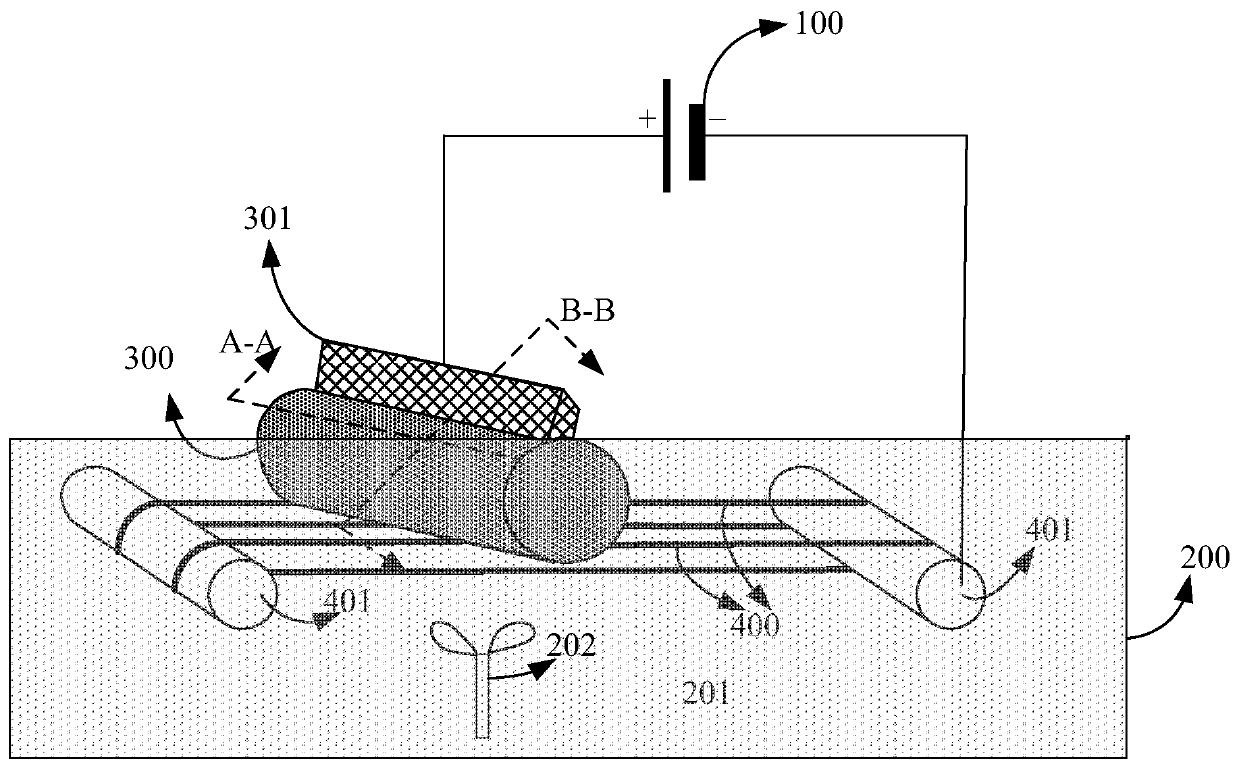

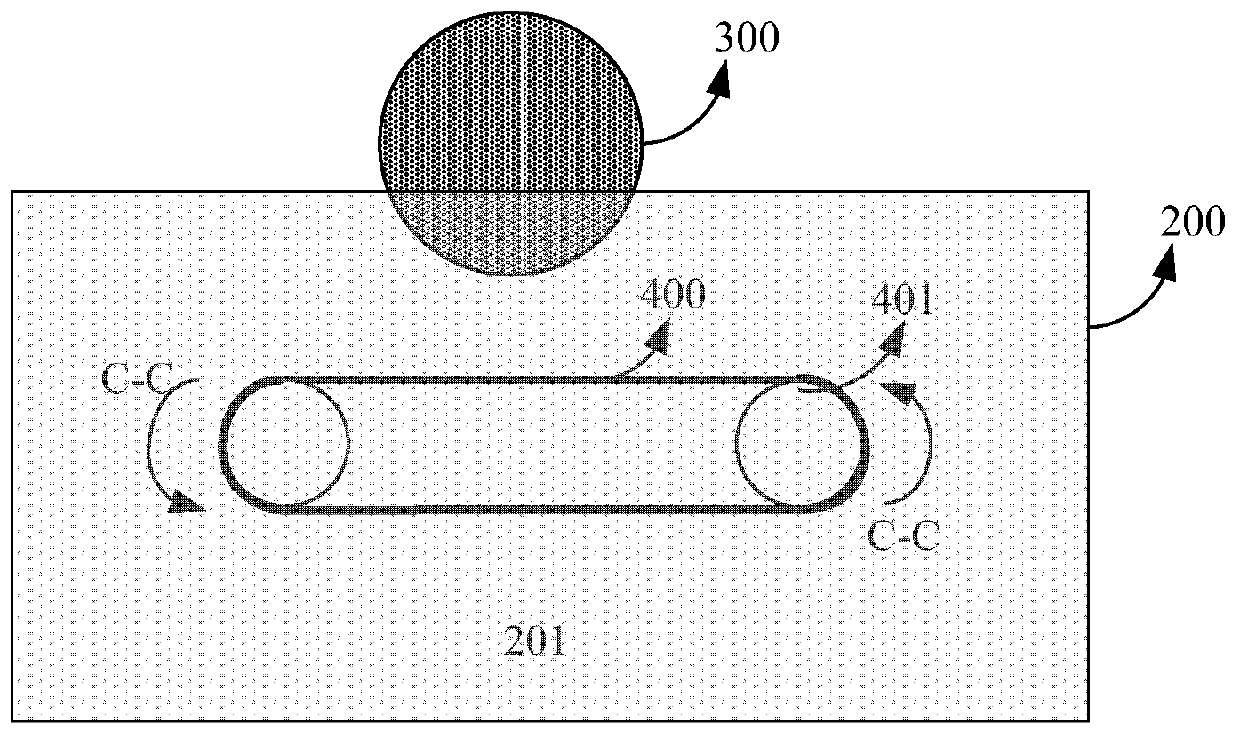

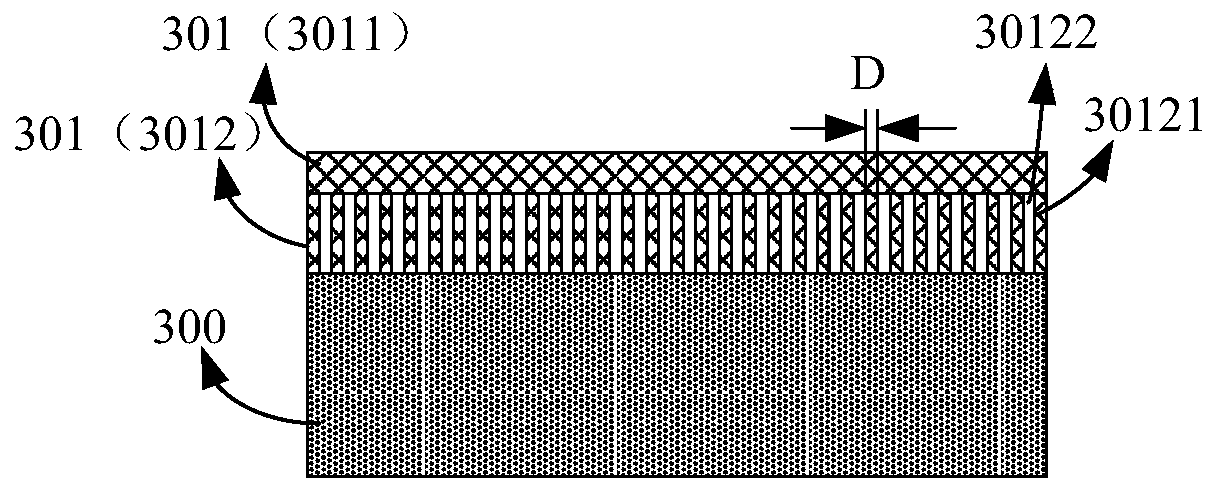

[0037] see below figure 1 and figure 2 An exemplary description is given to a crystal rod slicing device proposed by the present invention, figure 1 It is a structural schematic diagram of an ingot slicing device according to an embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the front view of the arrangement of the middle ingot relative to the wire electrode.

[0038] First, see figure 1 , according to an embodiment of the present invention, the crystal rod slicing device includes a power source 100 , an electrolytic cell 200 , and an anode and a cathode electrically connected to the power source 100 , respectively.

[0039] The power supply 100 can be any device that can provide DC voltage or current, such as an AC power supply that cooperates with an AC-to-DC device to provide DC voltage or current, a DC power supply, etc., and is not limited here.

[0040] The electrolytic cell 200 includes an electrolyte 201 for reacting with a silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com