Patents

Literature

43results about How to "Play the role of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

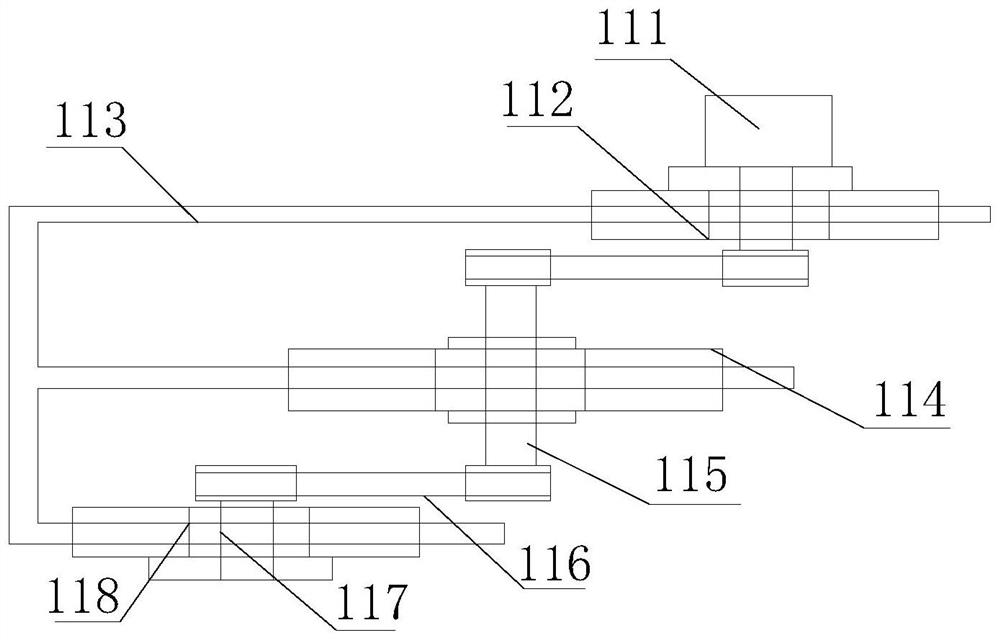

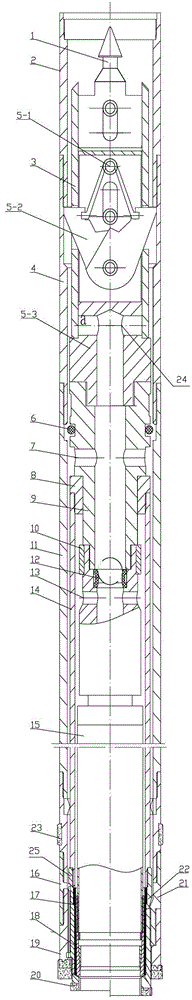

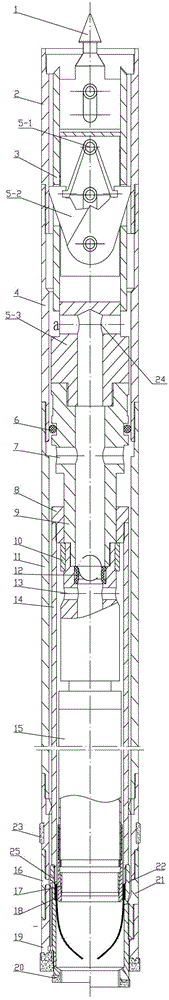

Rope core taking drill

InactiveCN103352671AImprove working conditionsPlay the role of cuttingCore removalStructural engineeringReamer

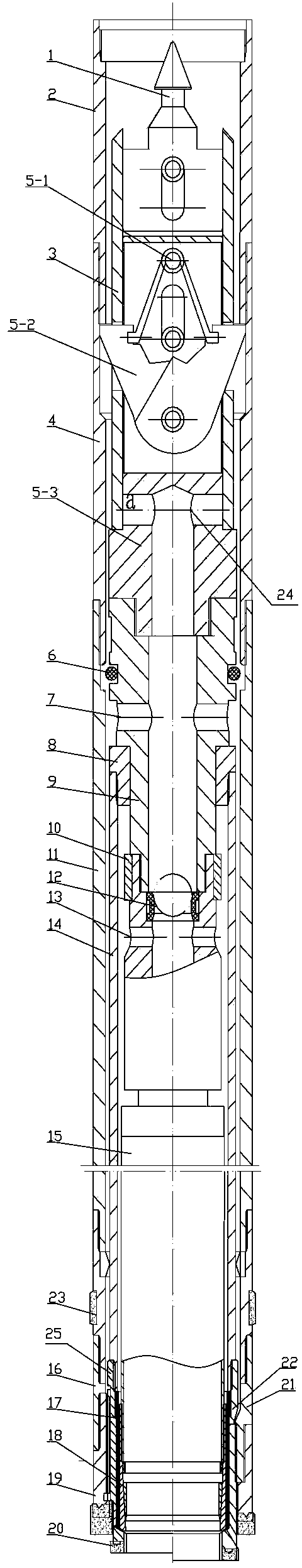

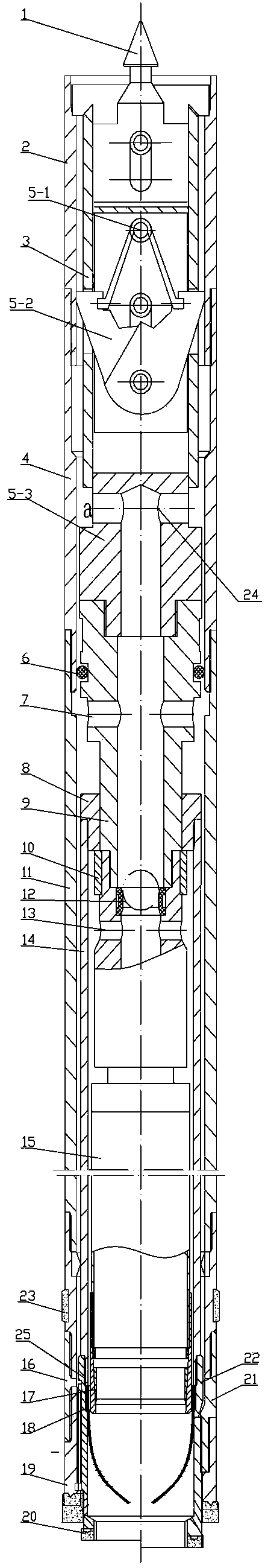

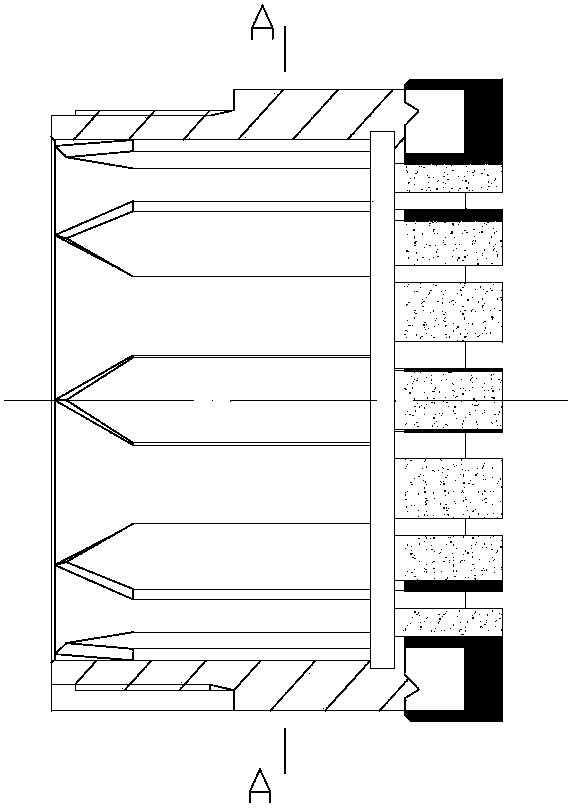

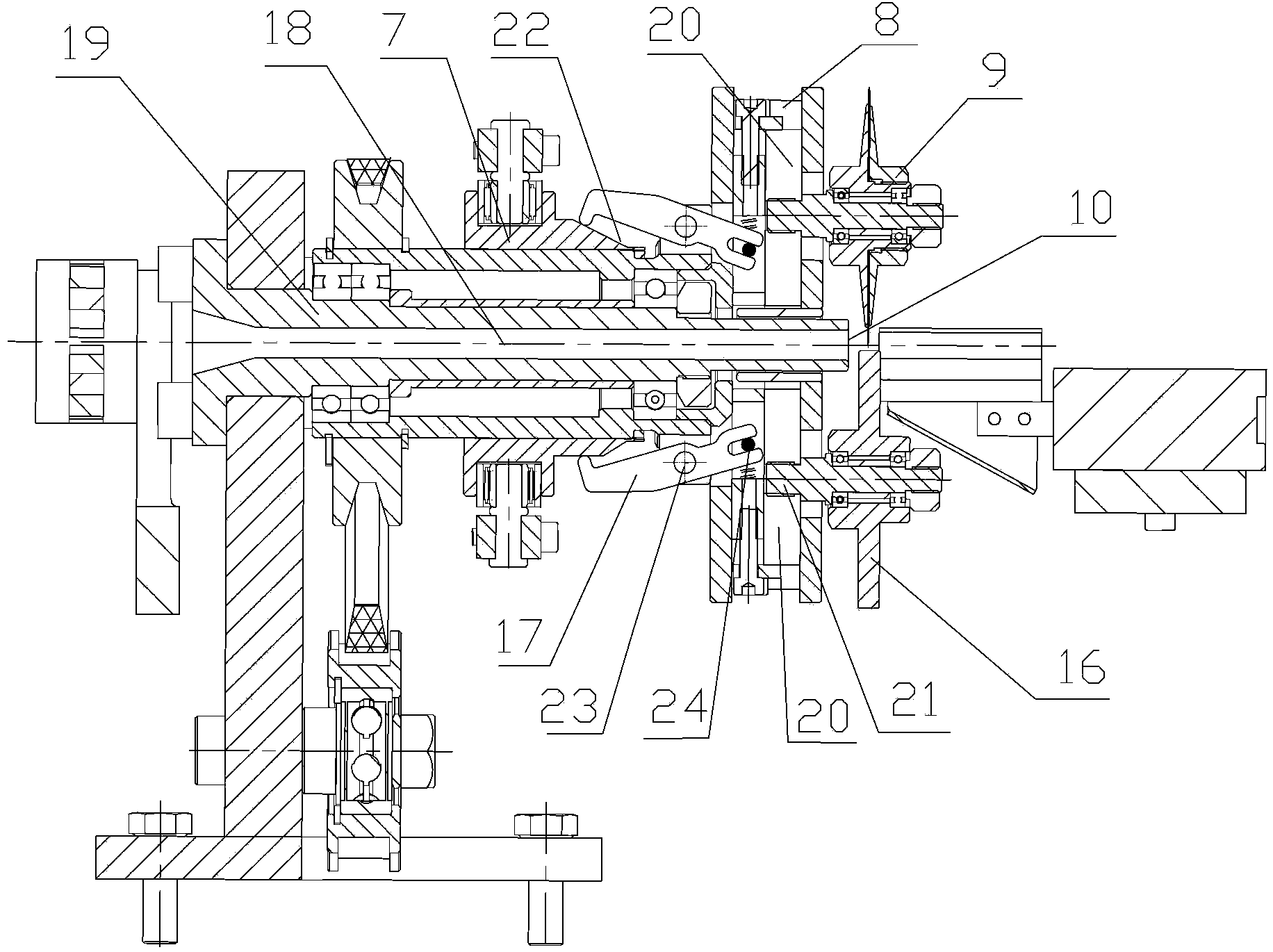

The invention discloses a rope core taking drill which comprises an outer pipe assembly and an inner pipe assembly. A reamer (23) is arranged in the outer wall assembly, and an inner pipe (14) and a third layer core pipe (15) are arranged in the inner pipe assembly. The rope core taking drill is characterized in that the lower end of the reamer (23) in the outer pipe assembly is connected with an external connector (16), and the lower end of the external connector (16) is connected with an external drill head (19). The lower end of the inner pipe (14) of the inner pipe assembly is connected with an inner drill head (20), and the inner drill head (20) protrudes forwards relative to the external drill head (19). The inner drill head is inserted into the outer drill head in a spline mode, and the inner drill head can be fished out together with the inner pipe, a clamping spring seat (18) and a clamping spring are arranged at the lower portion of the inner side of the third layer core pipe (15), and a blocking spring (17) is arranged on the outer side of the third layer core pipe (15). Regarding complex formation of fracture development, hard brittle fracture, soft and hard interbedding and the like, the drill has the advantages of prolonging the service life to the largest extent, increasing drill lifting intervals, improving the core recovery rate and the like.

Owner:李国民 +1

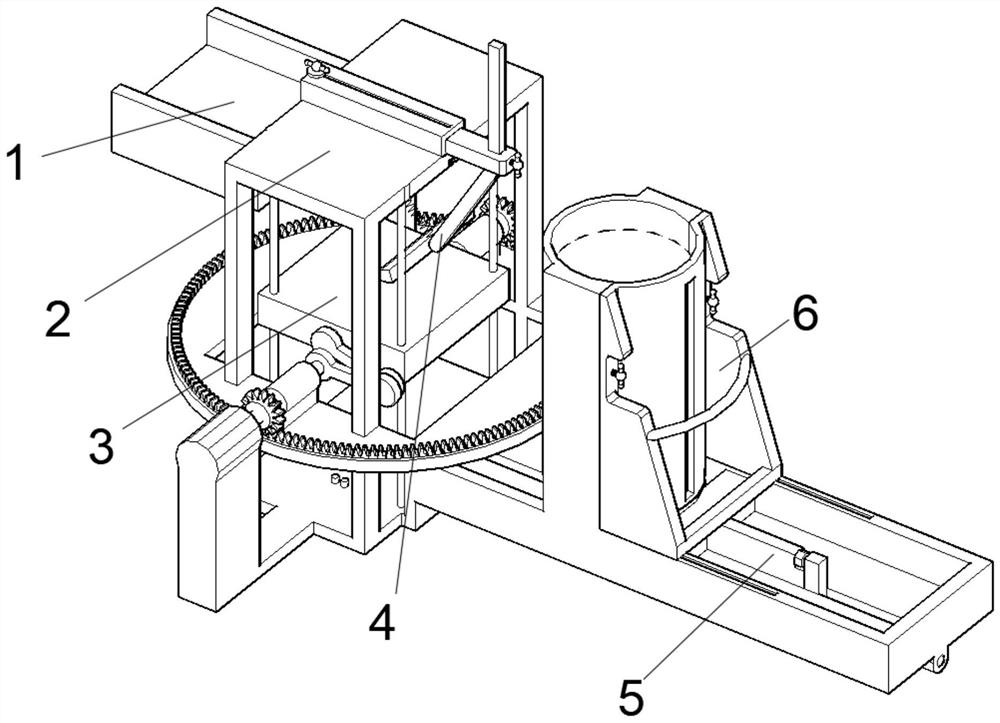

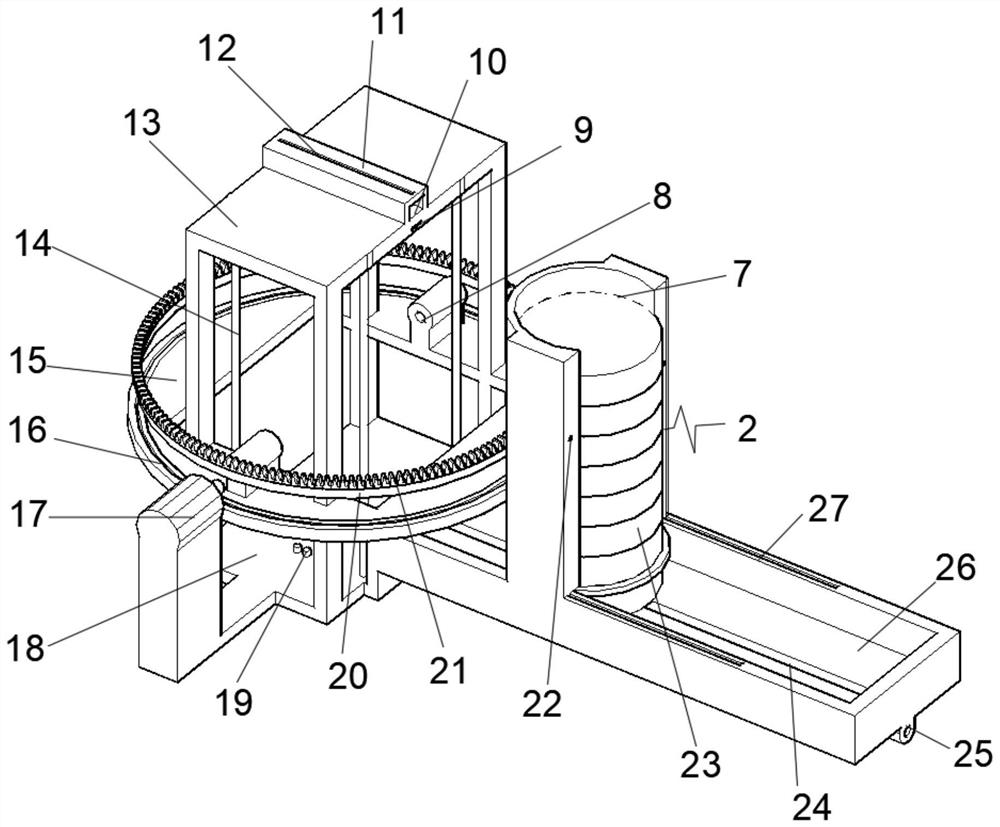

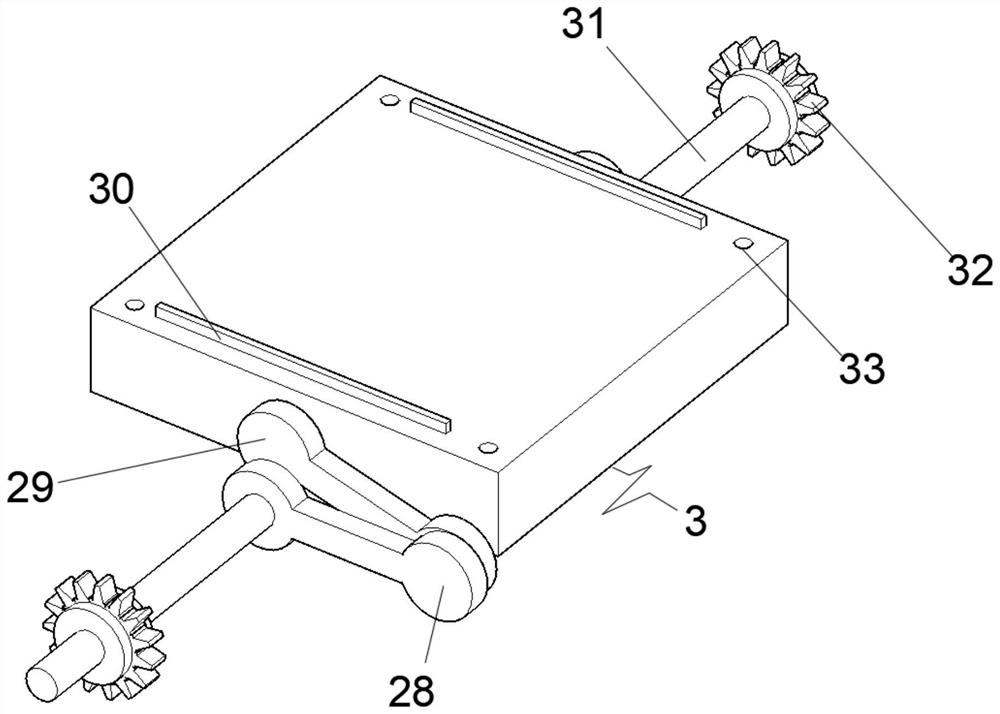

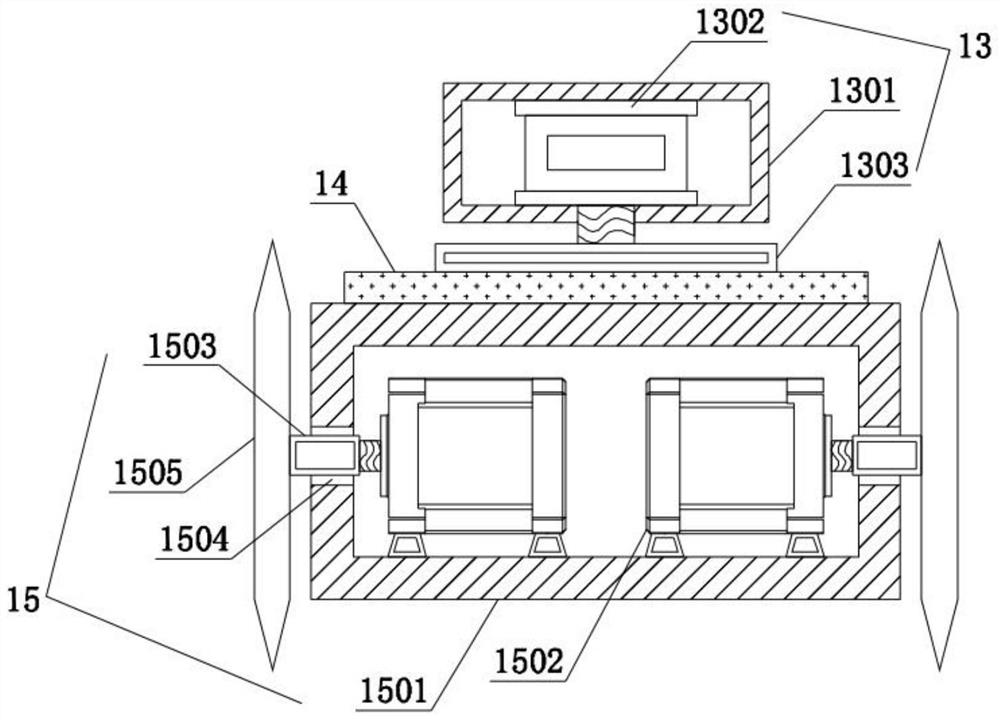

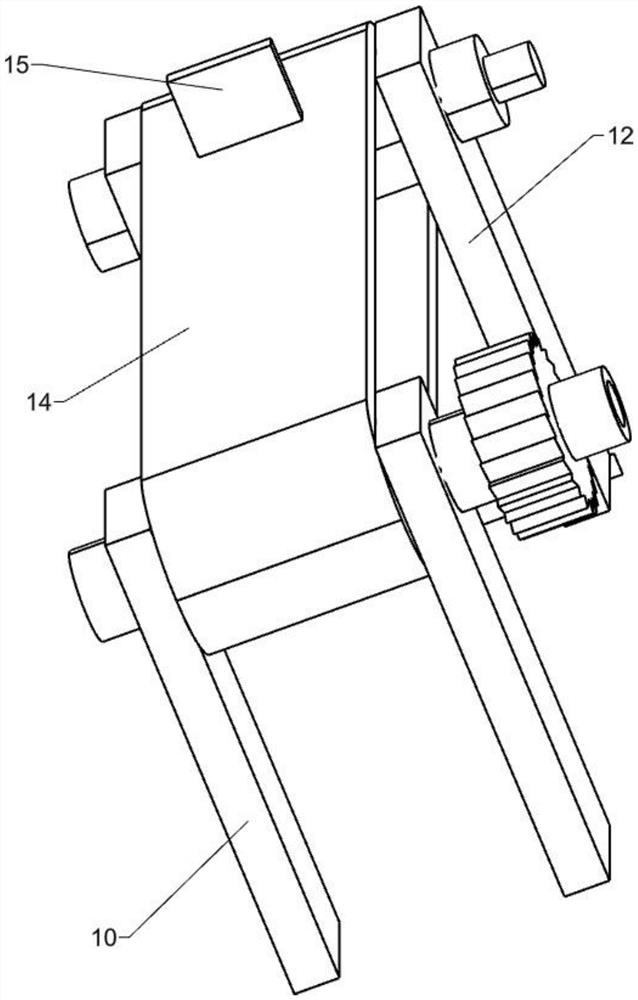

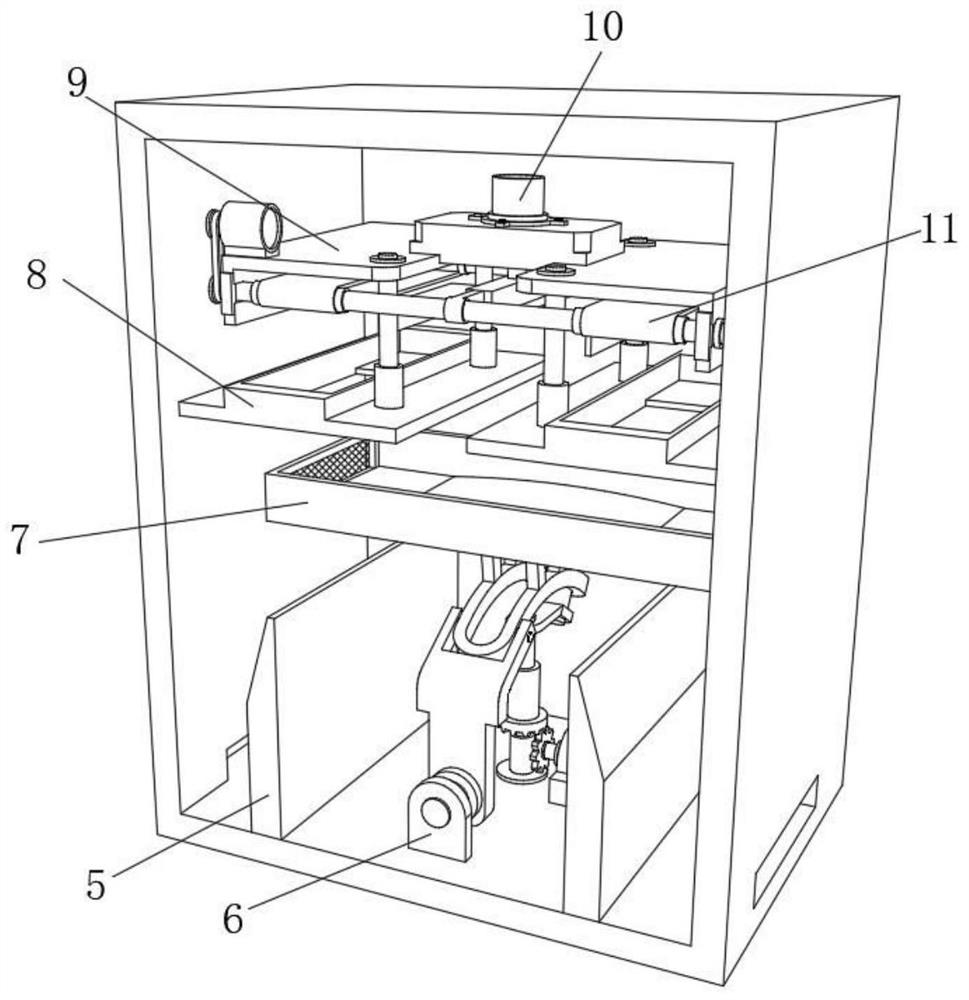

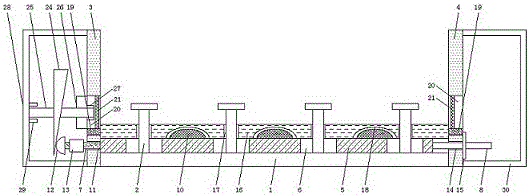

Up-and-down conveying device for metal circular plates with different thicknesses

ActiveCN112141608AGood up and downPlay the role of cuttingConveyorsConveyor partsGear wheelElectric machinery

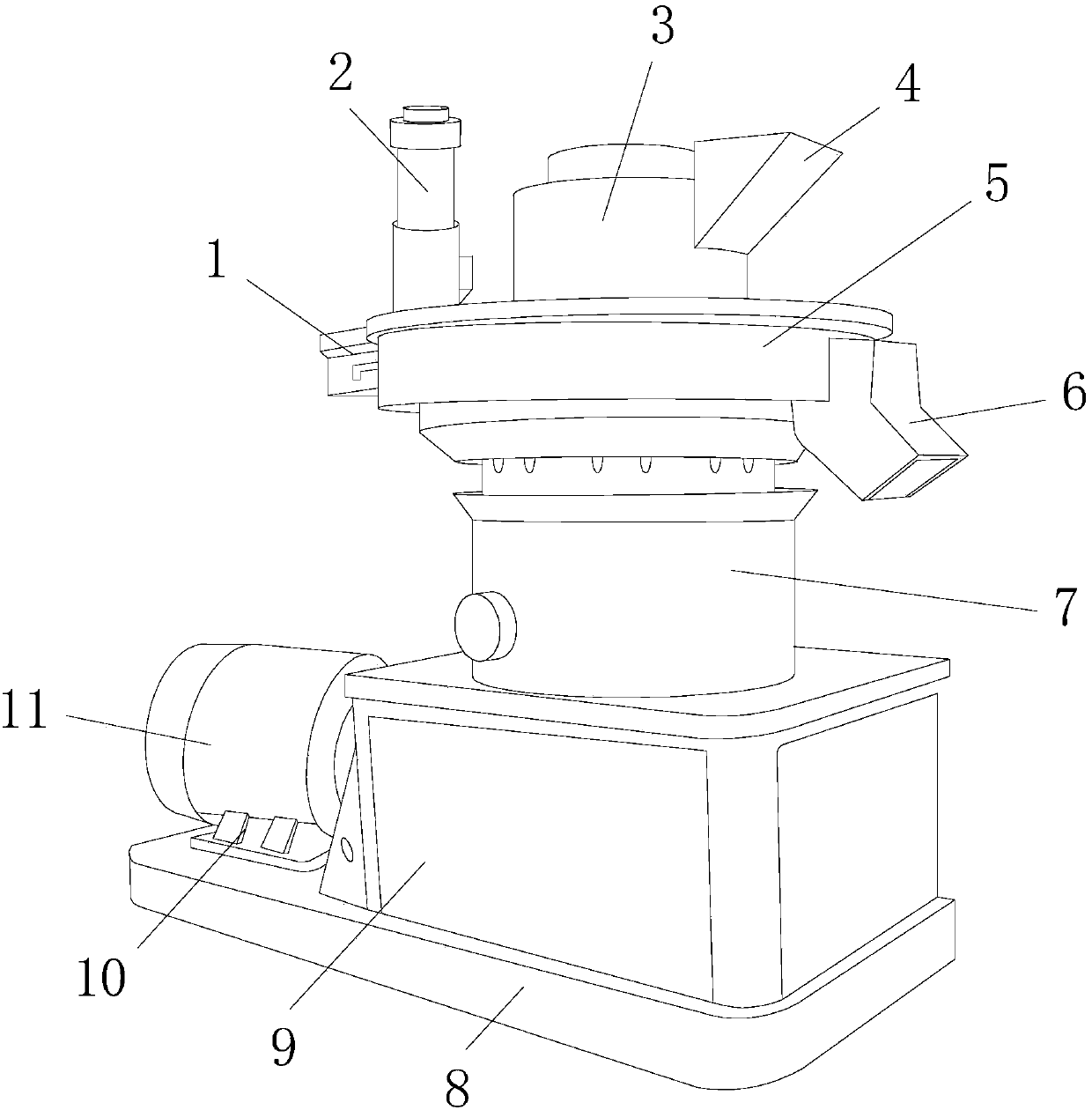

The invention discloses an up-and-down conveying device for metal circular plates with different thicknesses, which comprises a support frame, a driving device and a connecting device, wherein the driving device is rotatably mounted in the center of the top surface of the edge of one end of the support frame, the connecting device is movably mounted on the top surface of the driving device, a baseis fixedly mounted in the support frame, tooth-shaped clamping blocks are welded to the edge of the upper surface of the boss, supporting rods are symmetrically welded to the outer surface of the base, a first limiting sleeve is welded to the outer surface of the second limiting sleeve, a rotary disc is fixedly installed in the driving device, a driving motor is movably installed in the center ofthe bottom face of the rotary disc, and a connecting groove is formed in the center edge of the top surface of the rotary disc. through intermittent meshed clamping of a gear disc and the tooth-shaped clamping blocks, a limiting clamping block can discontinuously drive one end of a connecting rod to move in a limiting sliding groove, and the position of a production machine at the other end of the connecting rod can be automatically adjusted.

Owner:绍兴柯桥尼希纺织科技有限公司

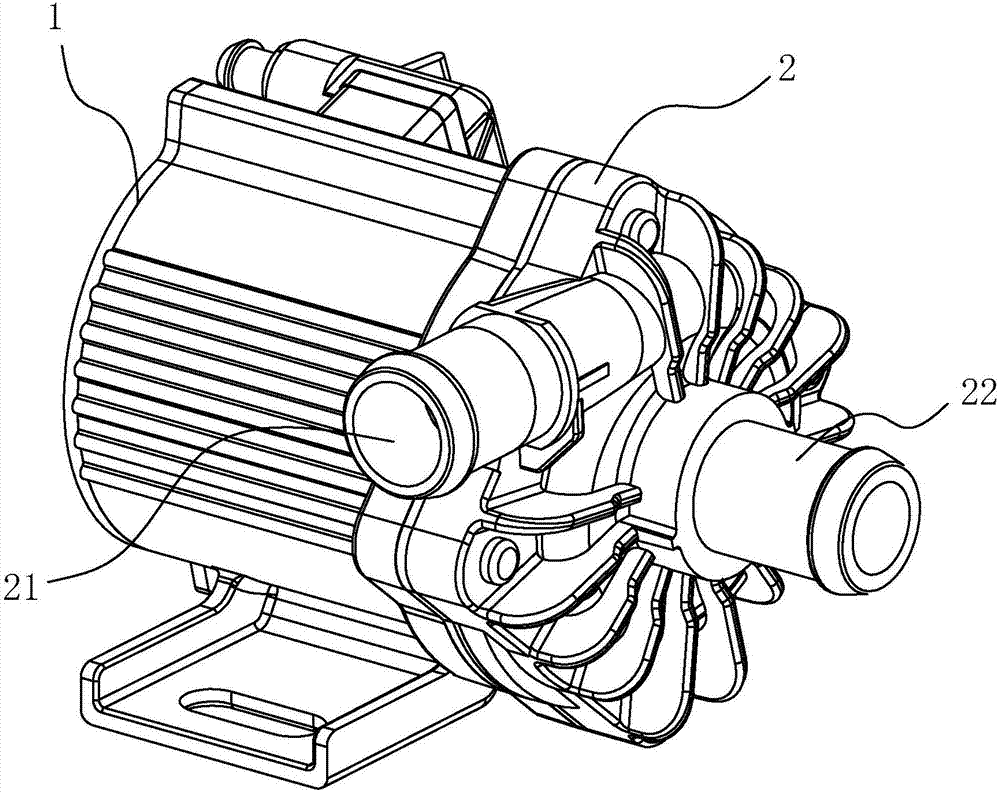

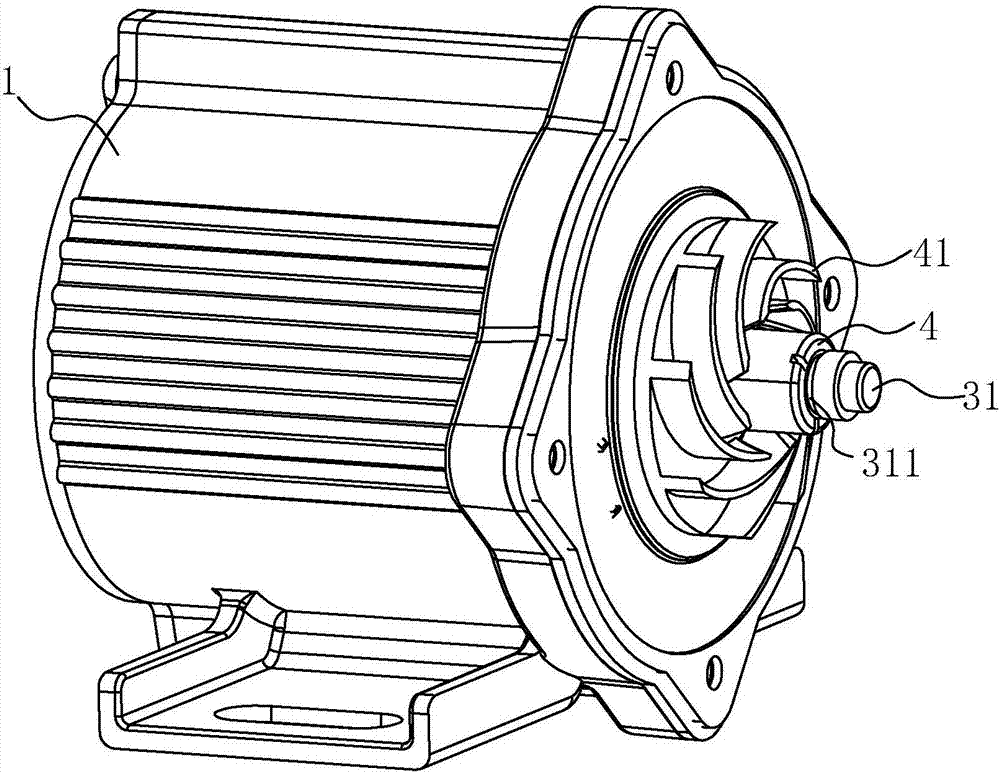

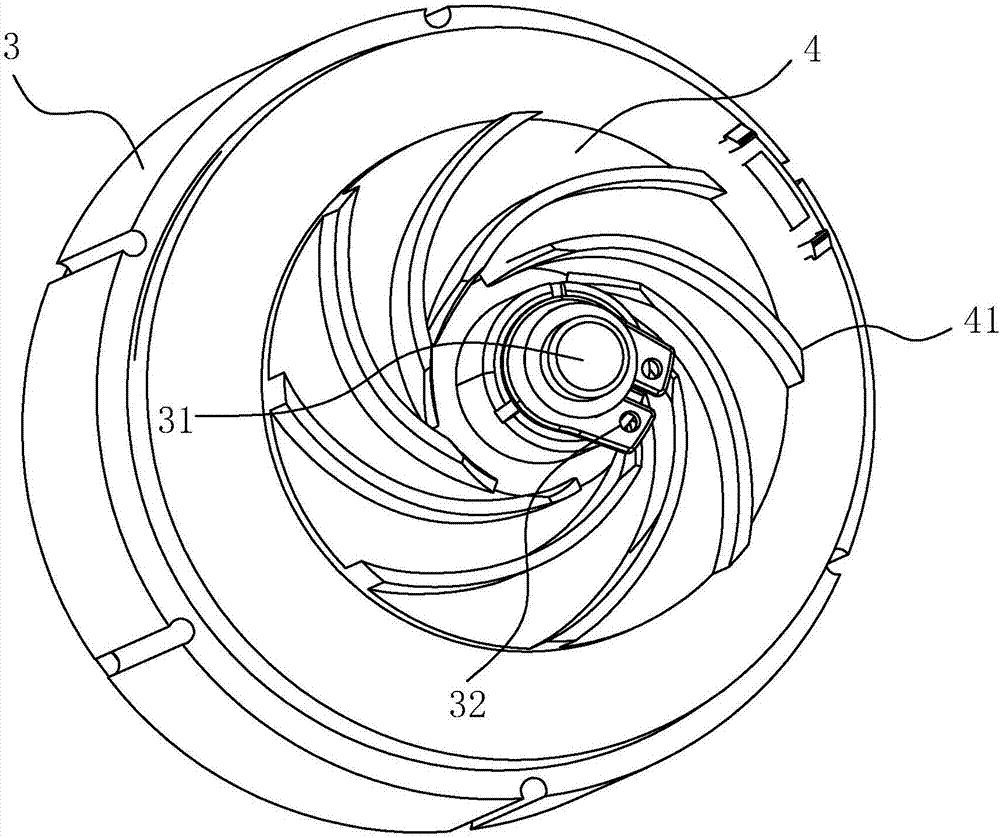

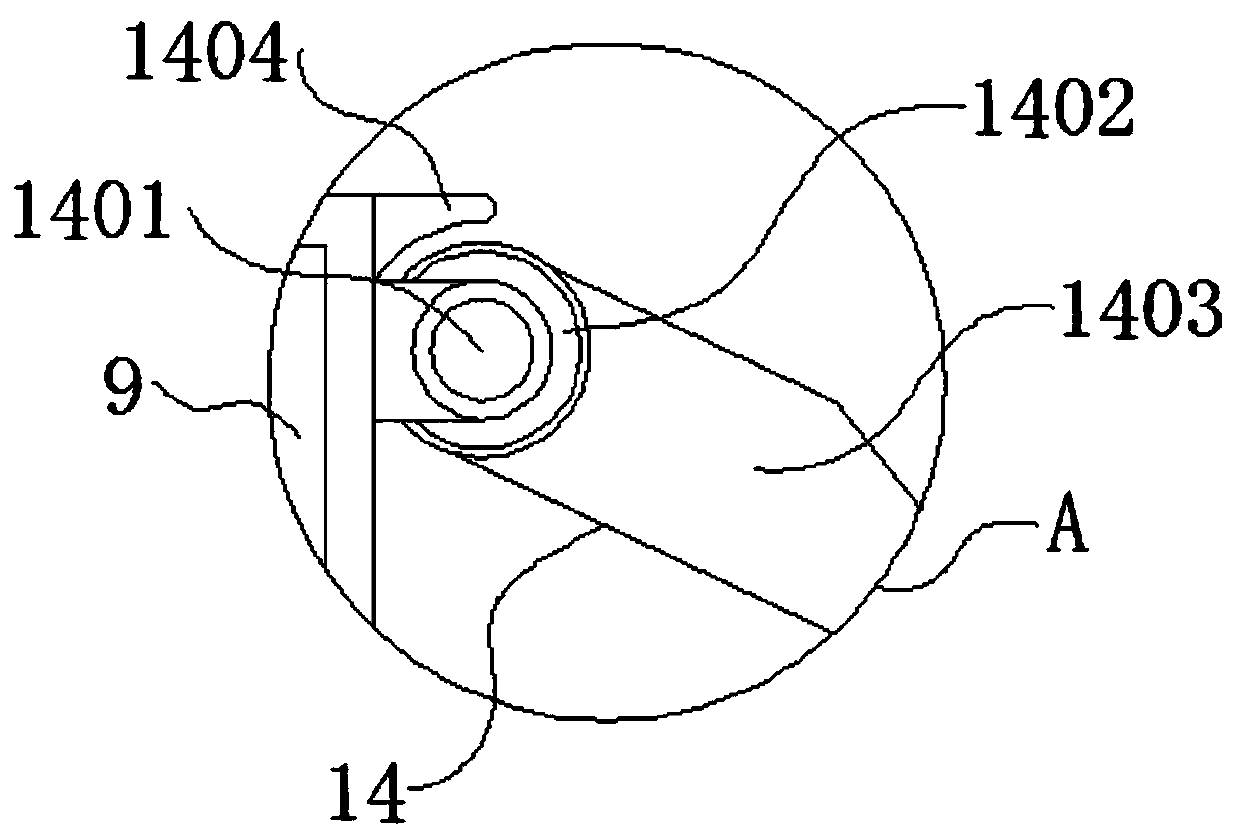

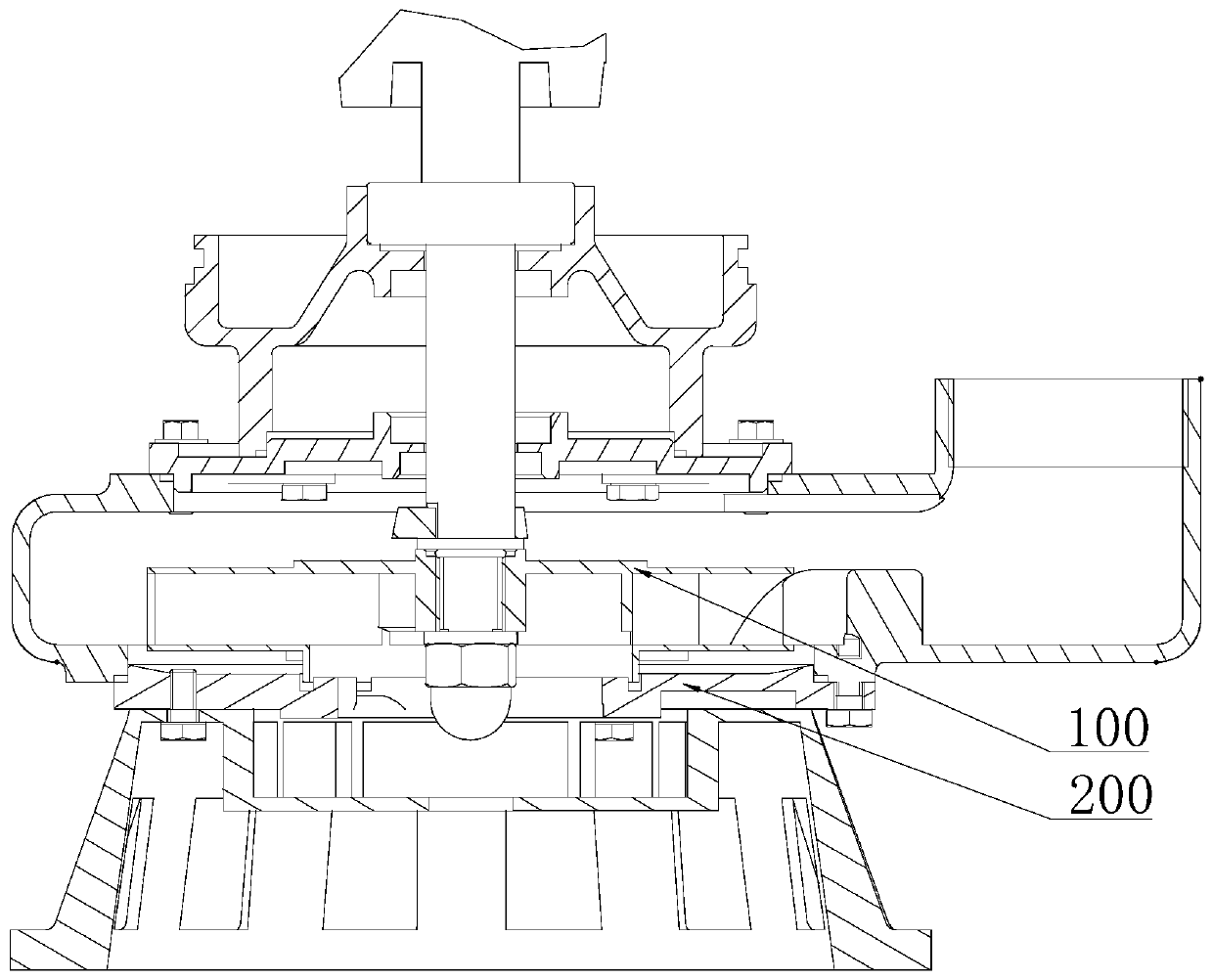

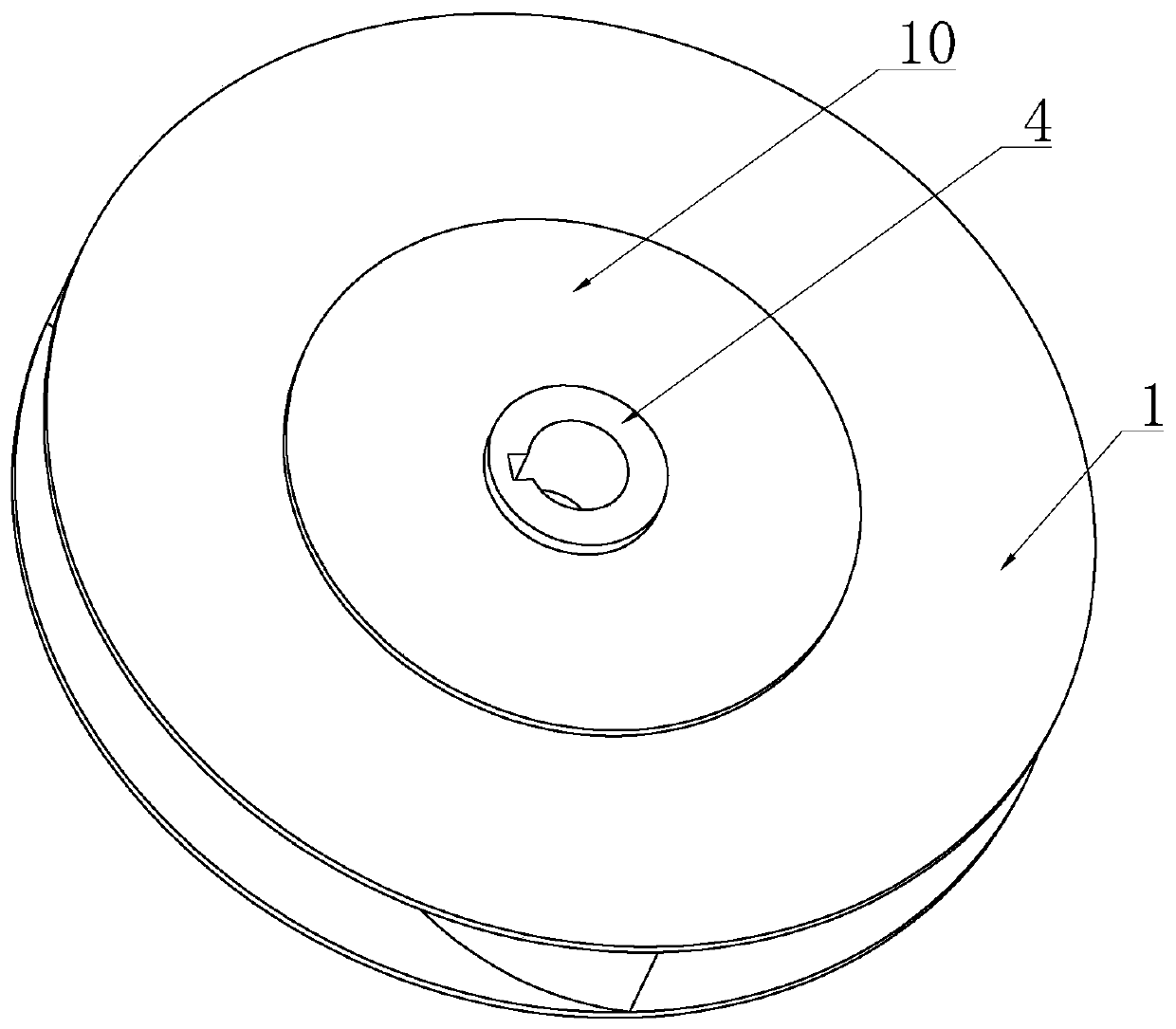

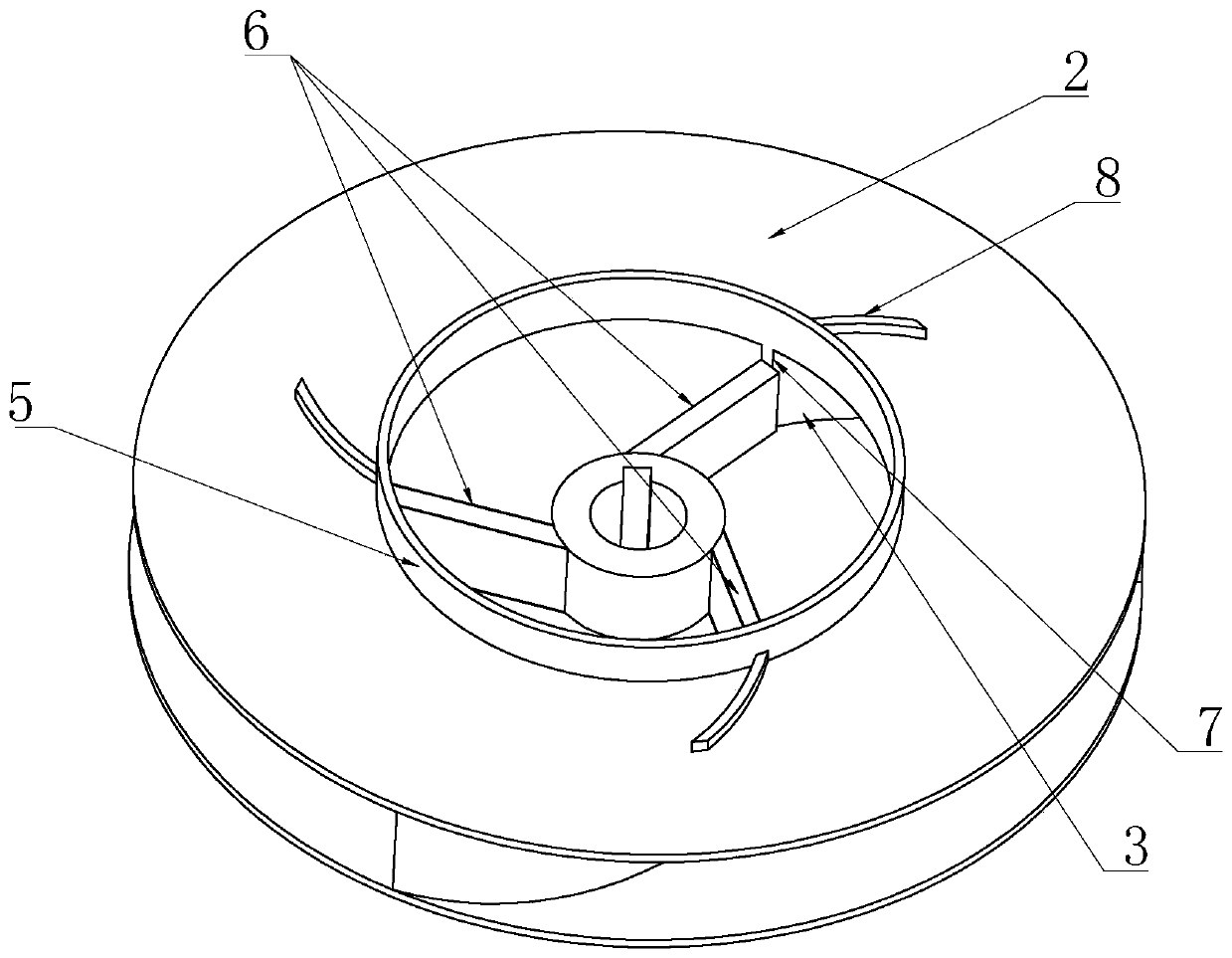

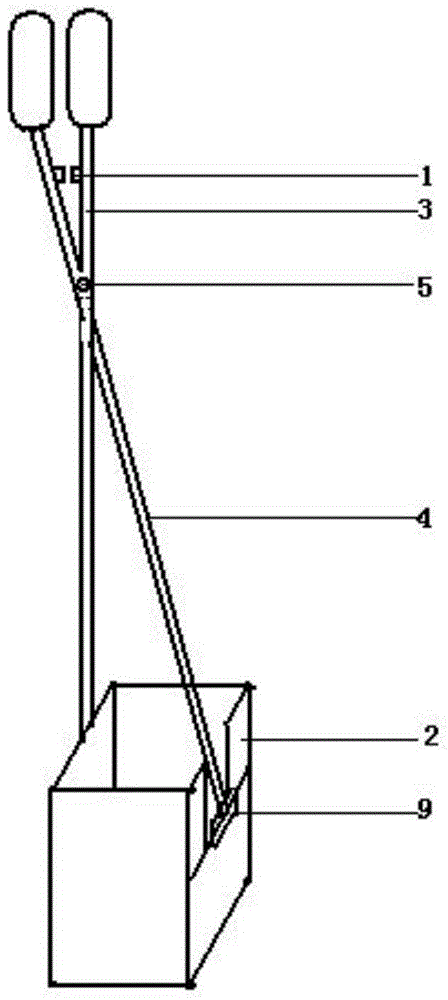

Water pump

ActiveCN107191386ARelieve pressureFirmly connectedPump componentsPump installationsImpellerElectric machinery

A water pump comprises a pump body and a pump cover arranged on the pump body in a covering manner. A water inlet is formed at the center of the pump cover. A water outlet is formed in the circumferential face of the pump cover. A motor is arranged in the pump body. An output shaft of the motor is sleeved with an impeller located in the pump cover. The impeller is provided with a plurality of blades. The impeller is provided with a circular-truncated-cone-shaped shade body. The center of the shade body is provided with a through hole. The through hole corresponds to the water inlet. The edge of the side, where the impeller is located, of the shade body is turnup towards the side where the pump cover is located, and cooling water not entering the shade body here flows along the surface of the shade body. Hereby, due to the fact that the edge of the side, close to the impeller, of the shade body is turnup towards the side where the pump cover is located, the cooling water which is thrown away along the surface of the shade body can move along the side far away from the pump body, and a water film is formed between the shade body and the pump cover; and in this way, the situation that the cooling water not entering the space between the shade body and the impeller enters an output flow channel to be mixed with pressurized cooling water, and then the lift of the finally conveyed cooling water is lowered is prevented beneficially.

Owner:宁波天安汽车零部件有限公司

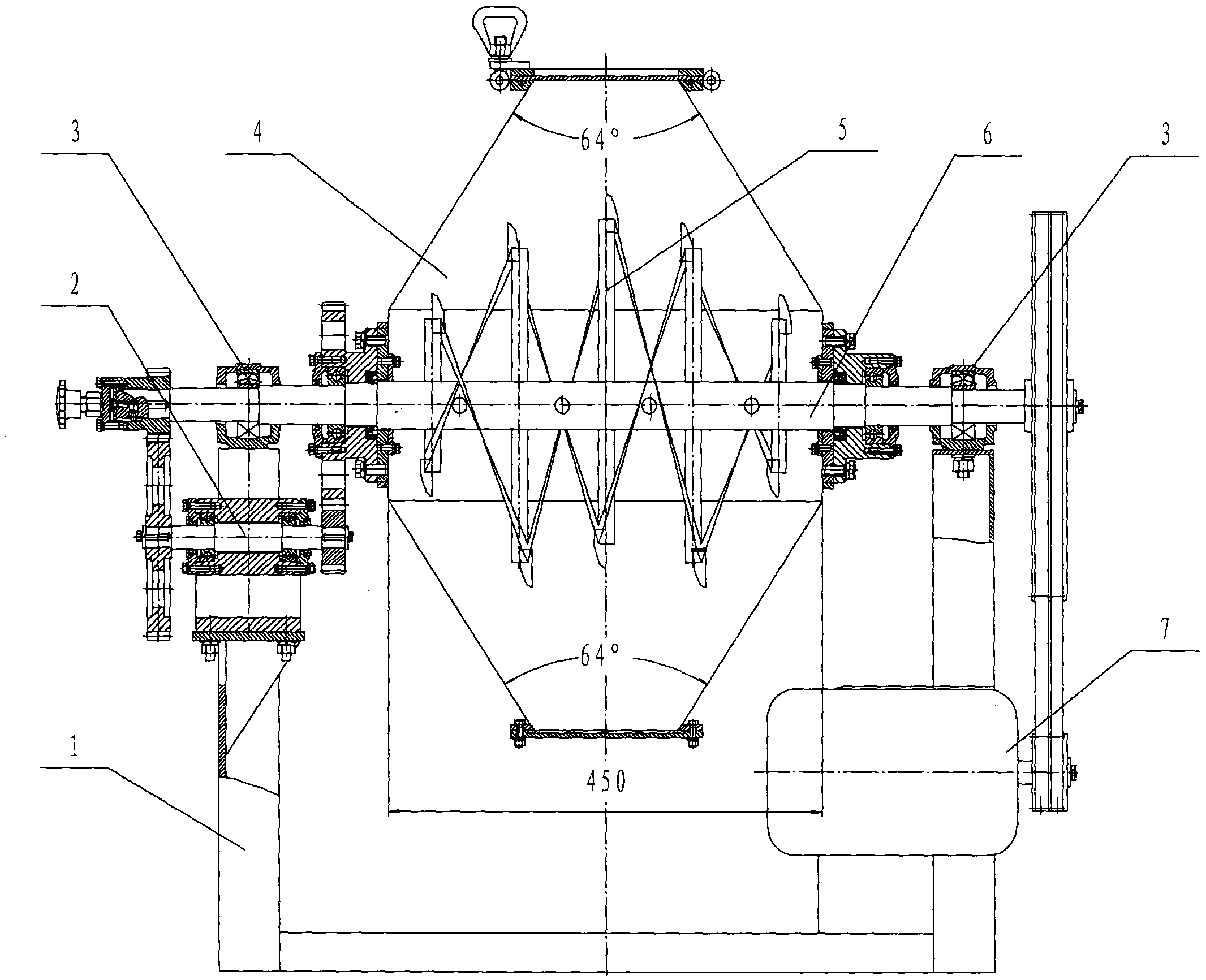

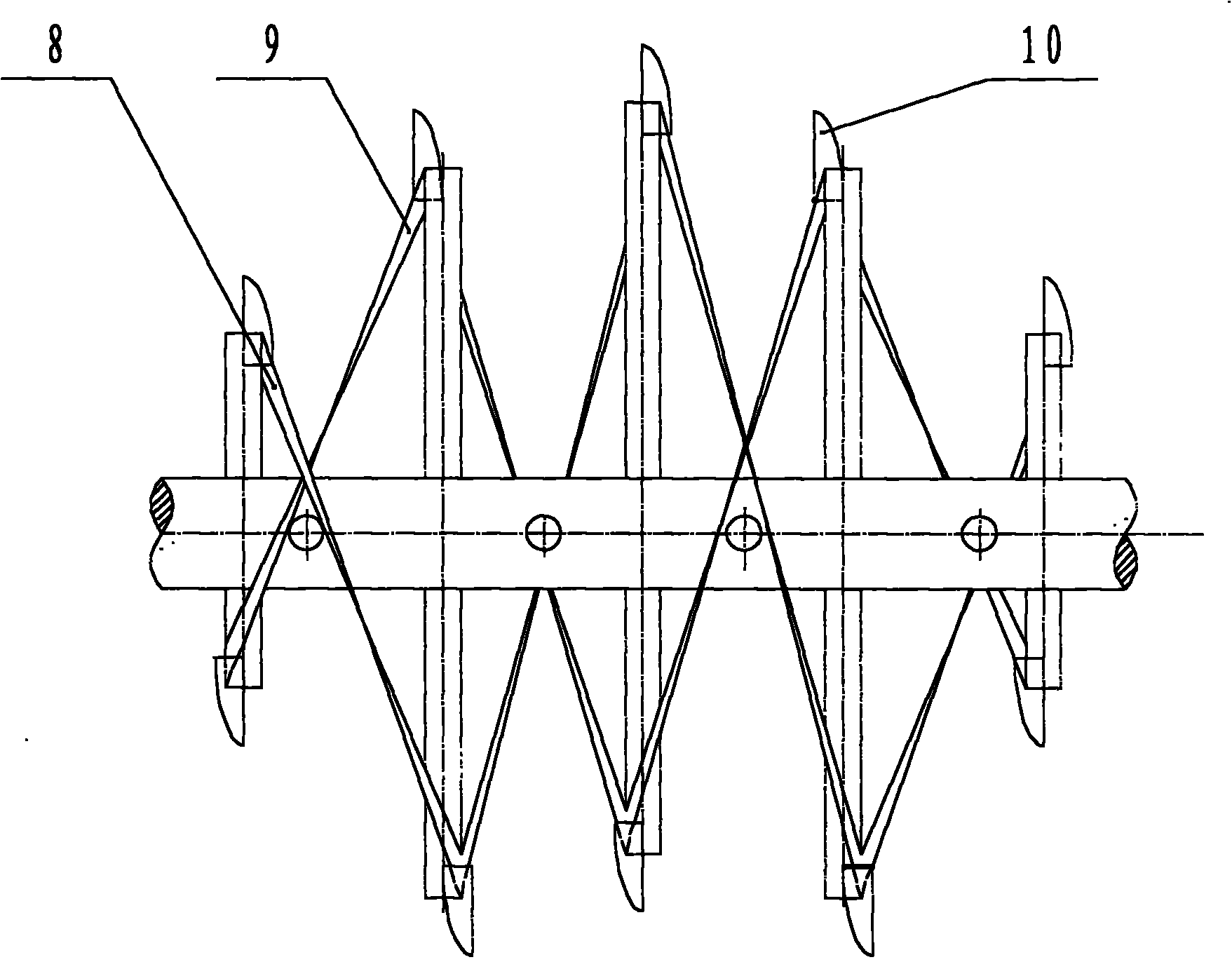

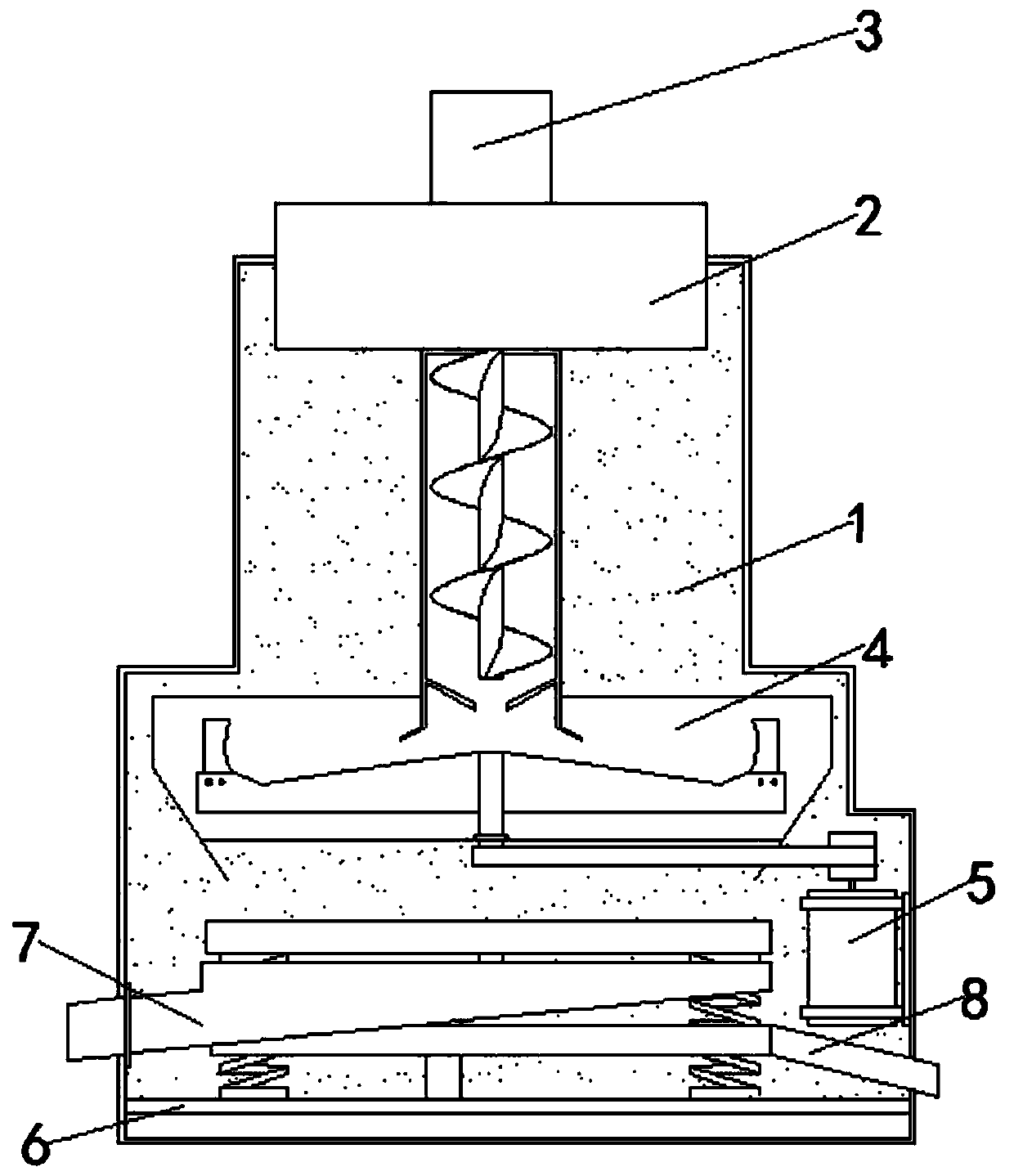

Abnormally-shaped auger drum-type mixer

InactiveCN103831049AWell mixedStir wellRotating receptacle mixersTransportation and packagingEngineeringMixing effect

An abnormally-shaped auger drum-type mixer with adjustable zigzag blades. A drum body and a main shaft rotate in the same direction with different speeds; an abnormally-shaped auger is mounted on the main shaft; the abnormally-shaped auger comprises a diameter-variable forward screw belt and a diameter-variable backward screw belt; adjustable zigzag blades are mounted at the top of the screw belts; the mixer can mix a plurality of materials rapidly and uniformly, and has significant mixing effect on powdery materials with certain viscosity and poor fluidity.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

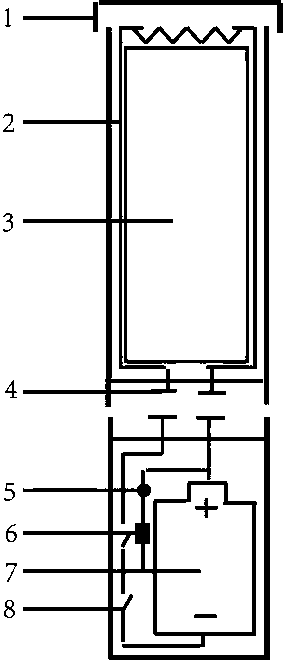

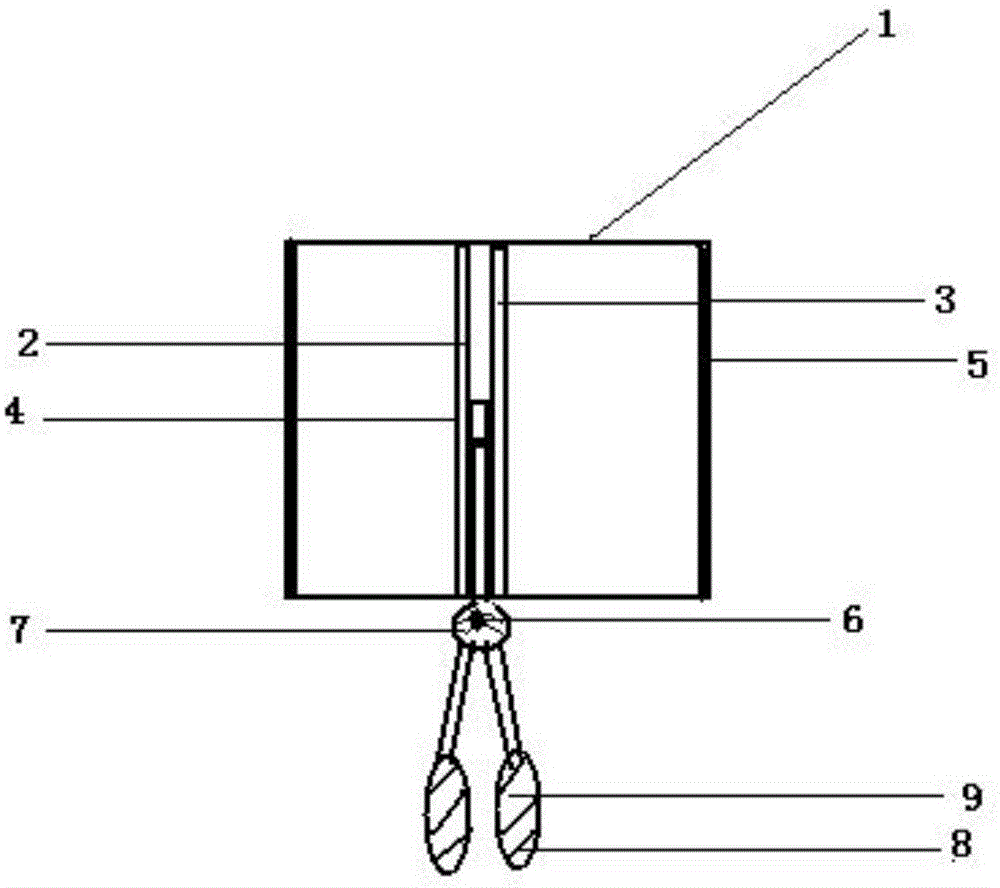

Electronic cutting device and metal fusing agent grain

PendingCN109020769AEasy to carryEasy to operateExplosivesWelding apparatusElectrical resistance and conductanceEngineering

The invention discloses an electronic cutting device, which comprises a cavity casing provided with a plug in at an opening end, wherein the cavity is separated divided into a control cavity and a grain cavity; the grain cavity is arranged at the opening end; a metal fusing reagent grain is built in the grain cavity; a resistance wire is arranged at a the cavity opening; a driving circuit is builtin the control cavity, and comprises a battery and a switch; the battery is connected in series with the resistant wire; the switch is embedded in the wall of the control cavity wall; the metal fusing agent grain consists of the following materials in percentage by mass: 60 to 70 percent of oxidizing agents, 15 to 25 percent of reducing agents, 4 to 8 percent of igniting agents and 4 to 8 percentof gas generating forming agents in percentage by mass. The heat is provided through igniting the igniting agents by the resistance wire; oxidizing agents and reduction reducing agents react to generate fusion metal which is sprayed out by gas obtained after the gas generating agents are heated; , so that the cutting effect is further achieved. The cutting device does not need additional power supplies and air sources, and can be used in special environments such as underwater environments and land environments; the carrying is convenient; the operation is simple; high practicability and wideapplicability are realized.

Owner:NANJING FORESTRY UNIV

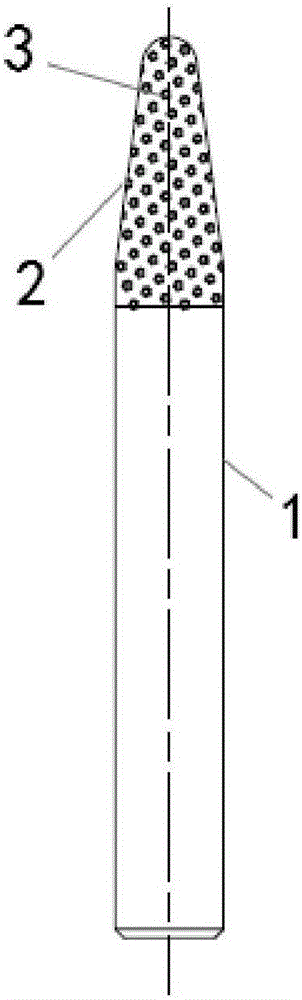

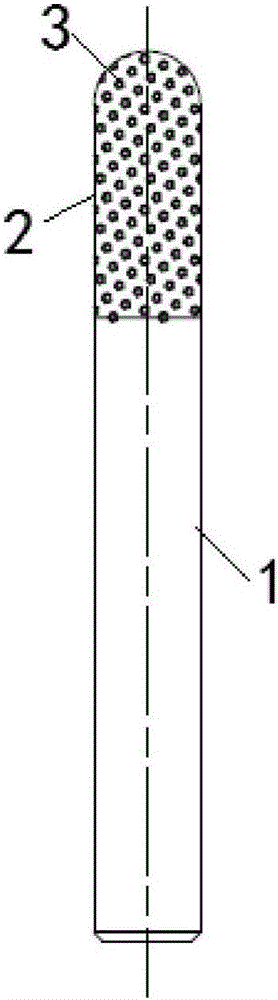

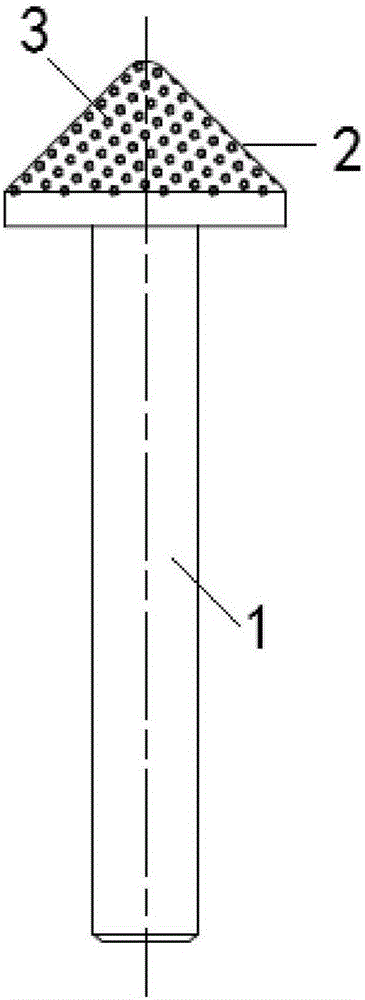

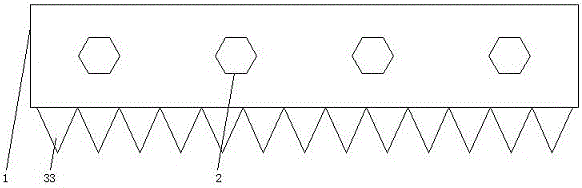

Stone graving knife capable of achieving ordered arrangement for diamond brazing, and preparation method

InactiveCN105966133AEfficient use ofExtend your lifeOther artistic work equipmentsModel makingDiamond turningSingle crystal

The invention discloses a stone graving knife capable of achieving ordered arrangement for diamond brazing, and a preparation method, and belongs to the technical fields of tools. The stone graving knife is divided into a working part, that is, a knife bit, and a clamping part, that is, a knife handle, wherein the working part is composed of a steel matrix of a core part, and nickel-based brazing filler metals and monocrystal diamonds on the surface; the clamping part is composed of a steel matrix and forms an integrated structure with the steel matrix of the core part of the working part; the monocrystal diamonds on the surface of the working part are in a state of ordered arrangement; and the nickel-based brazing filler metals are used for connecting and fixing the monocrystal diamonds and the matrixes. The stone graving knife and the preparation method, which are disclosed by the invention, have the following advantages: during realization for the uniform distribution and ordered arrangement of the diamonds, optimization for the spacing of the diamonds can be realized according to the differences of abrasion cutting objects and abrasion cutting conditions, and at this moment, the diamonds can be effectively utilized, a cutting effect can be exerted, and adequate chip removal and washing cooling can be achieved; and moreover, the connection strength of the diamonds and the matrixes is high, and the optimization purpose of prolonging the life of the tool while increasing the abrasion cutting efficiency can be realized.

Owner:LANGFANG SUPOWER DIAMOND TECH

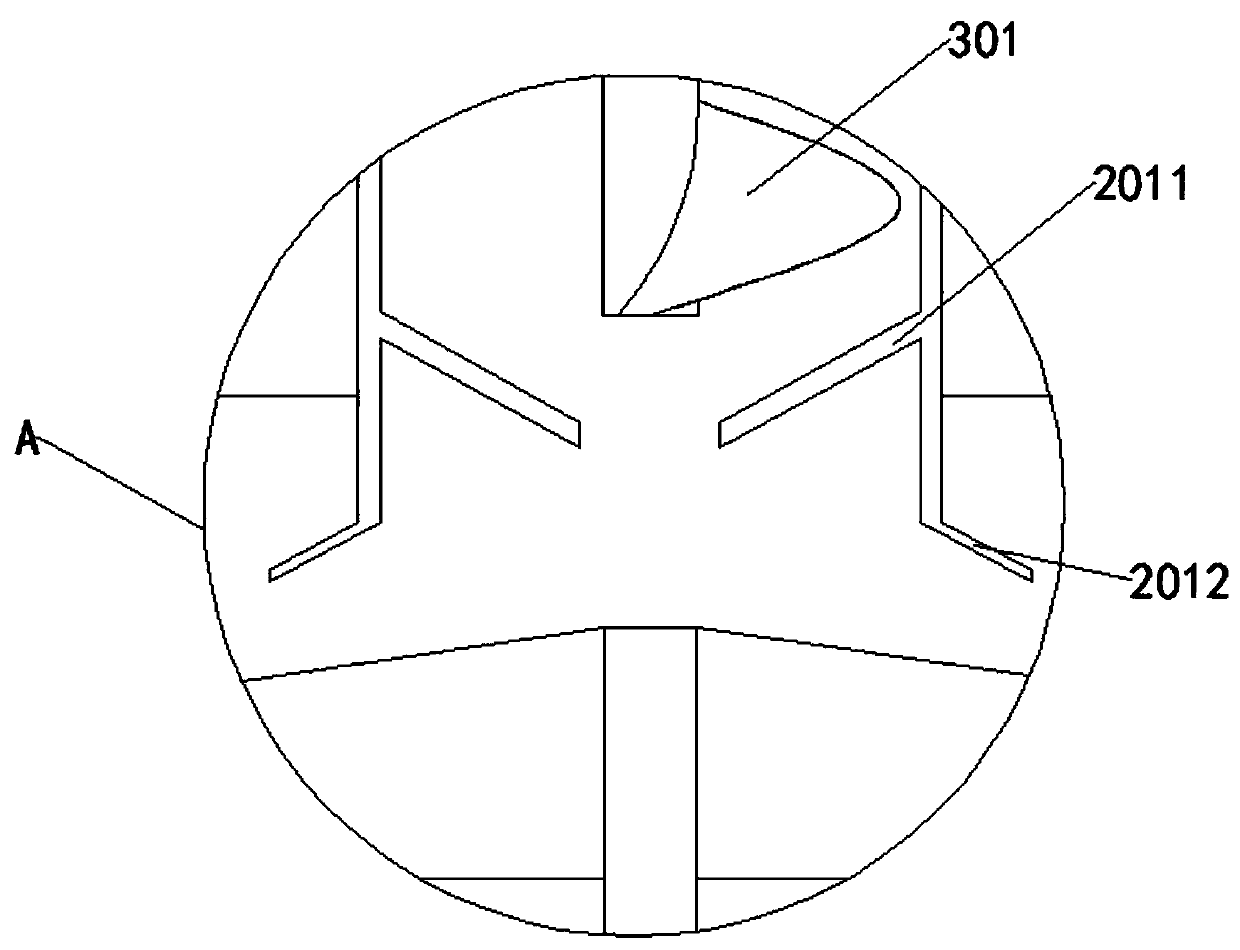

Multifunctional ball body mixer

PendingCN107617373AWell mixedPlay the role of cuttingRotating receptacle mixersTransportation and packagingEngineeringMixing effect

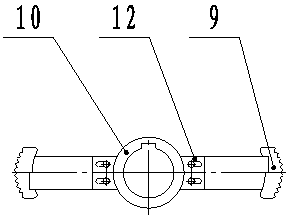

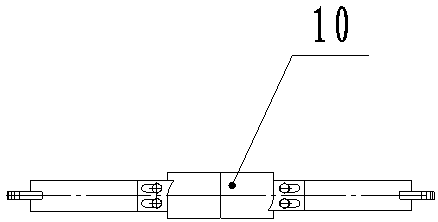

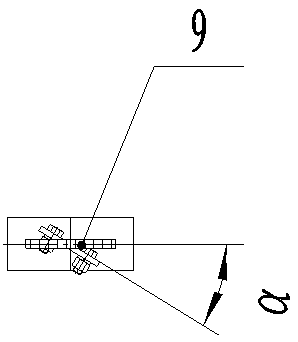

The invention aims to solve the technical problem of providing a multifunctional ball body mixer. The multifunctional ball body mixer has the technical features that the multifunctional ball body mixer consists of a rack, a motor, a main shaft, a spherical shell, a beating and rubbing plate, a stirring device with a tooth-shaped blade, an intermediate transmission device and a clutch device, wherein the motor outputs powder; the power is transferred to the spherical shell after being subjected to deceleration by the intermediate transmission device; the spherical shell and the main shaft rotate to different directions; the main shaft is provided with the stirring device with the tooth-shaped blade and the clutch device; the detachable beating and rubbing plate is installed in the sphericalshell; a certain cutting-up angle alpha is formed between the stirring device with the tooth-shaped blade and the main shaft, various materials can be quickly and evenly mixed, meanwhile, the multifunctional ball body mixer can perform a cutting-up function on materials which are likely to cake and bulge, and a mixing effect is obvious; since the detachable beating and rubbing plate is installedin the spherical shell, when the materials with thick particles are stirred, the beating and rubbing plate is installed and is cooperated with the stirring device with the tooth-shaped blade to form asmashing function; meanwhile, the spherical shell and the main shaft rotate to different directions so as to fully and evenly smash and stir the materials, and no dead angles are in the presence.

Owner:黑龙江省农业机械工程科学研究院齐齐哈尔分院

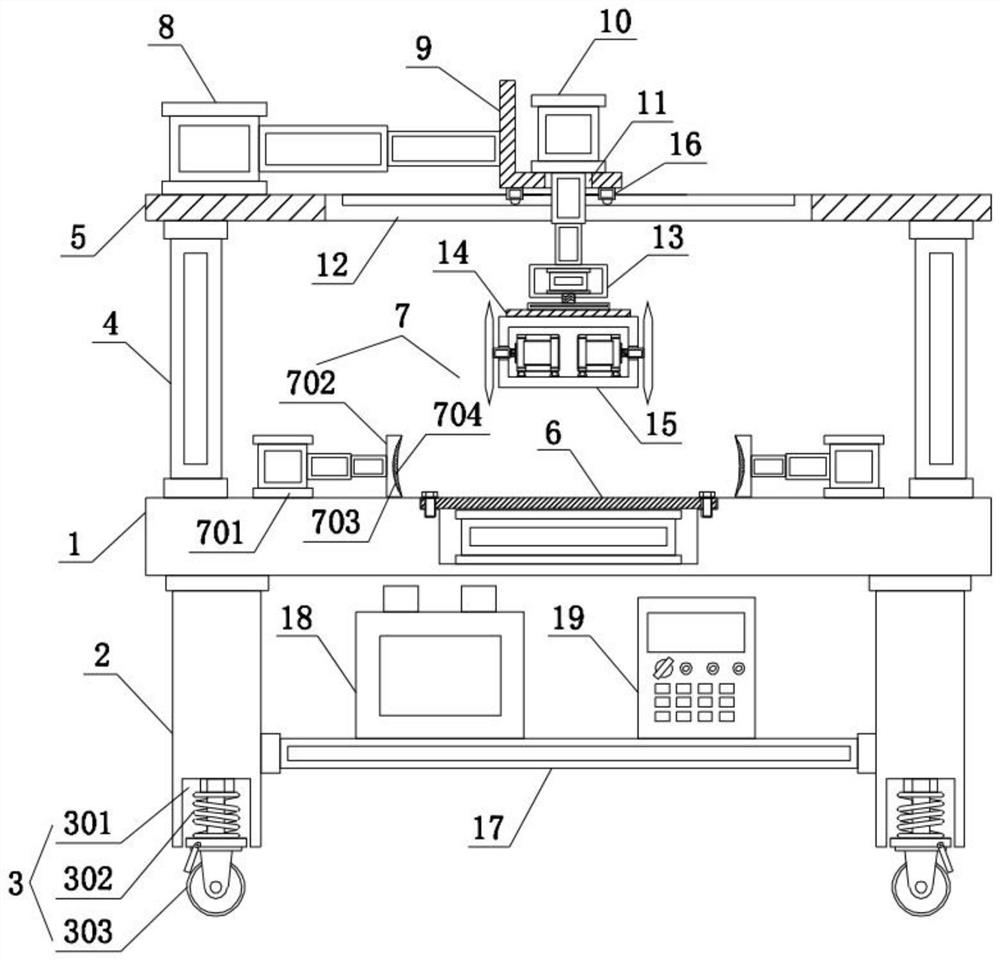

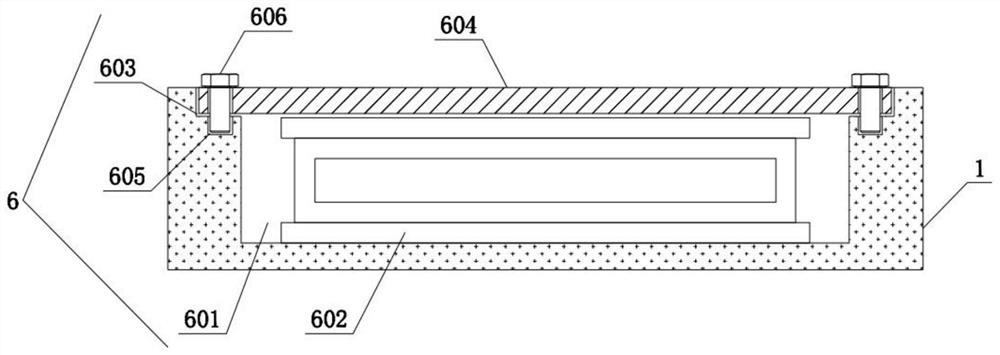

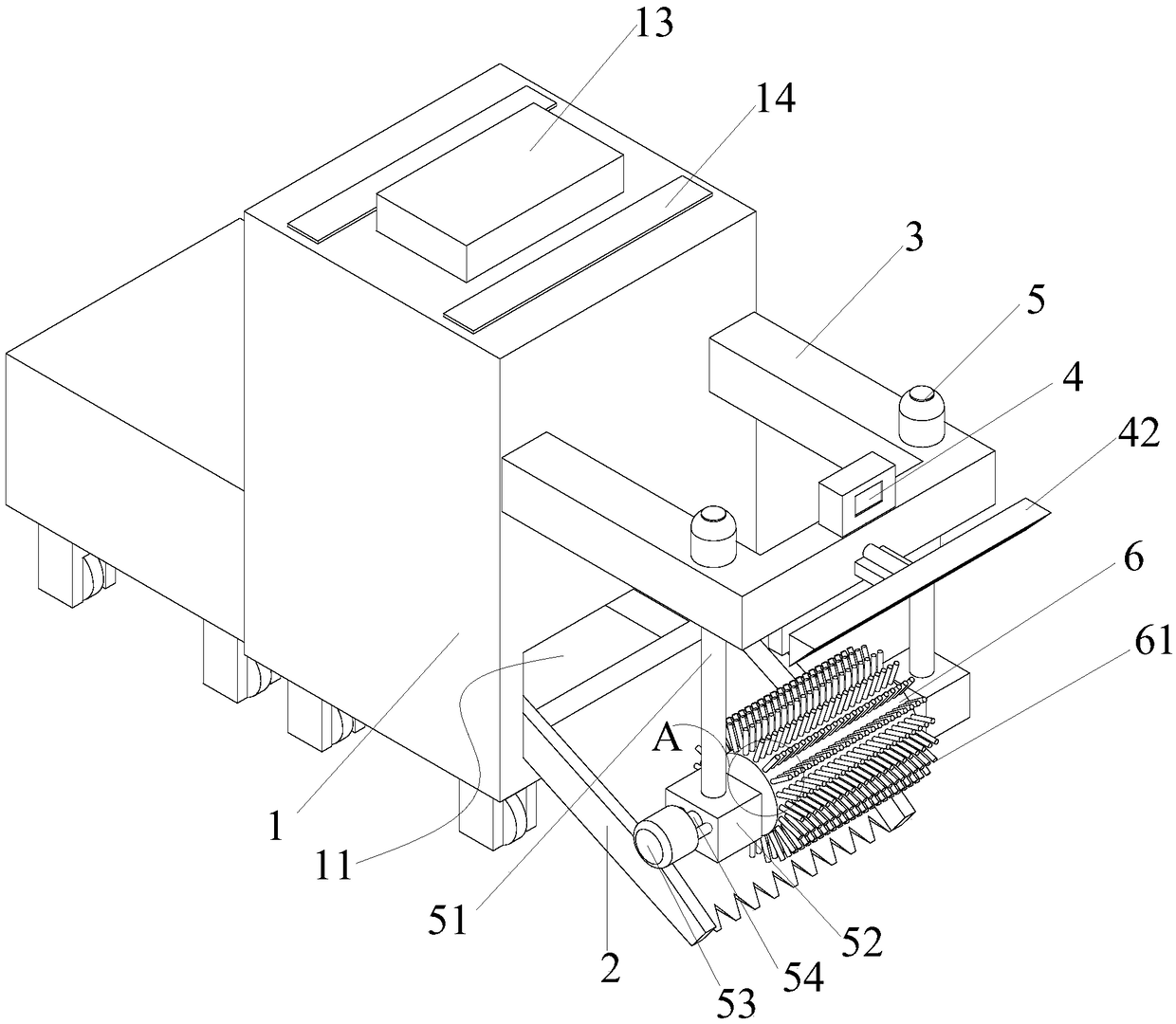

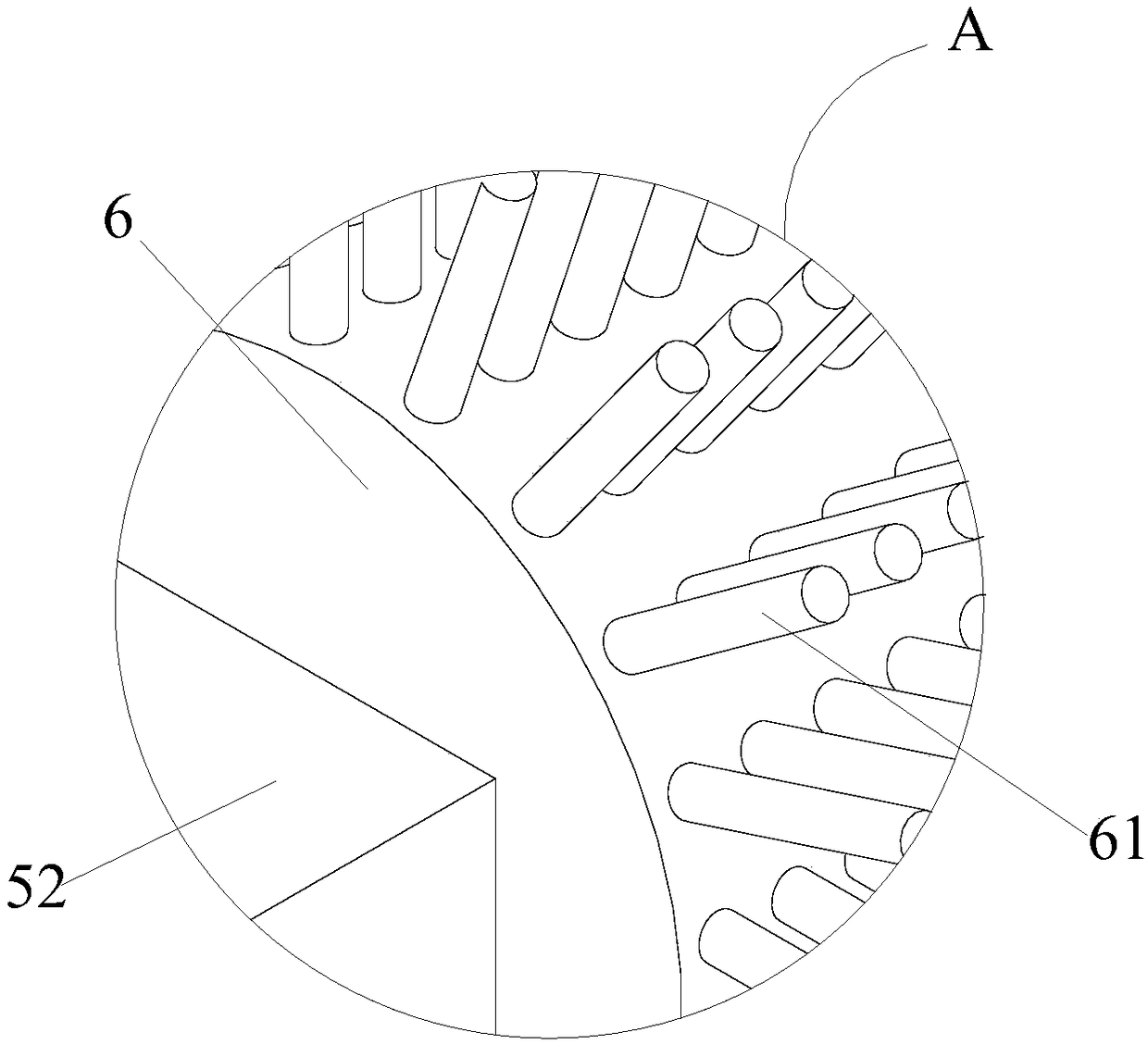

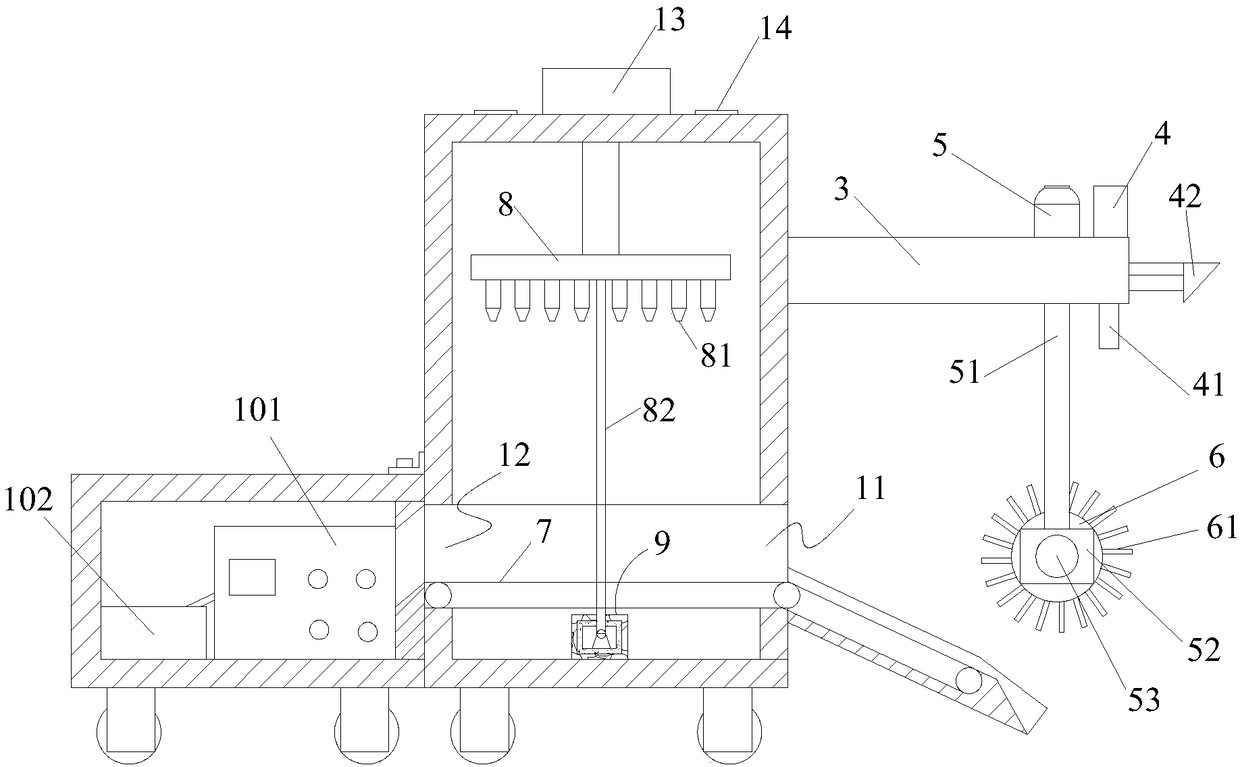

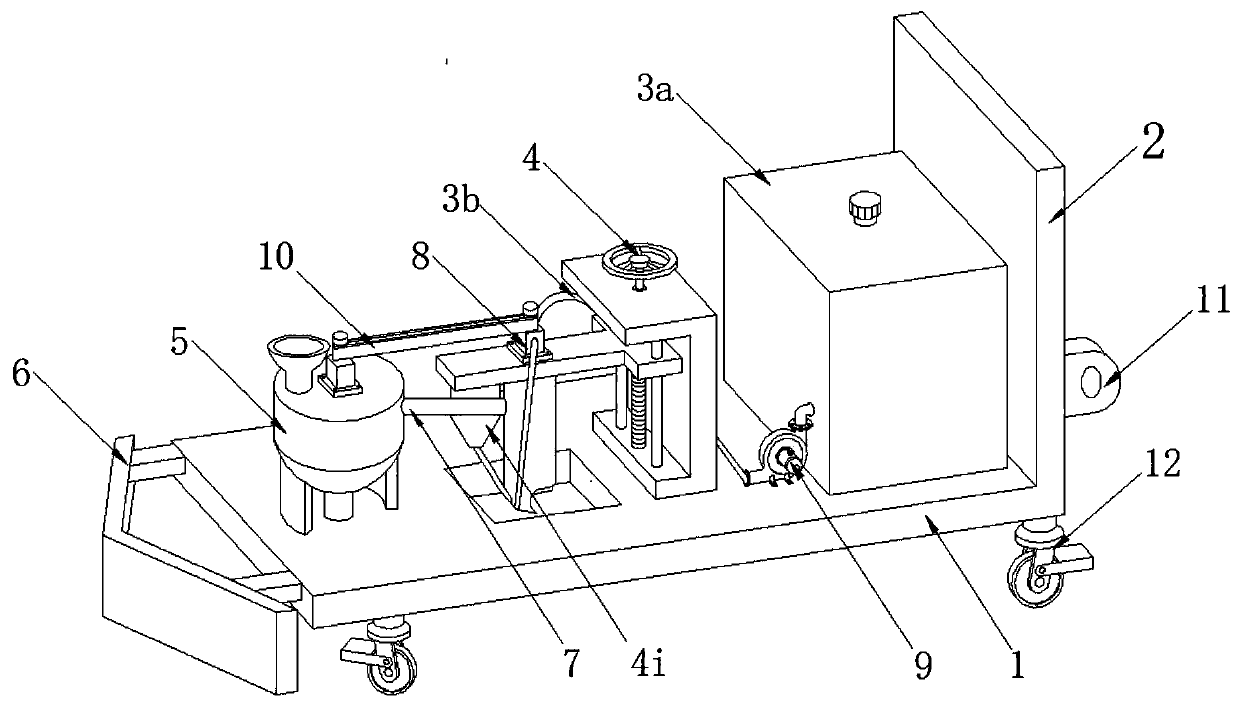

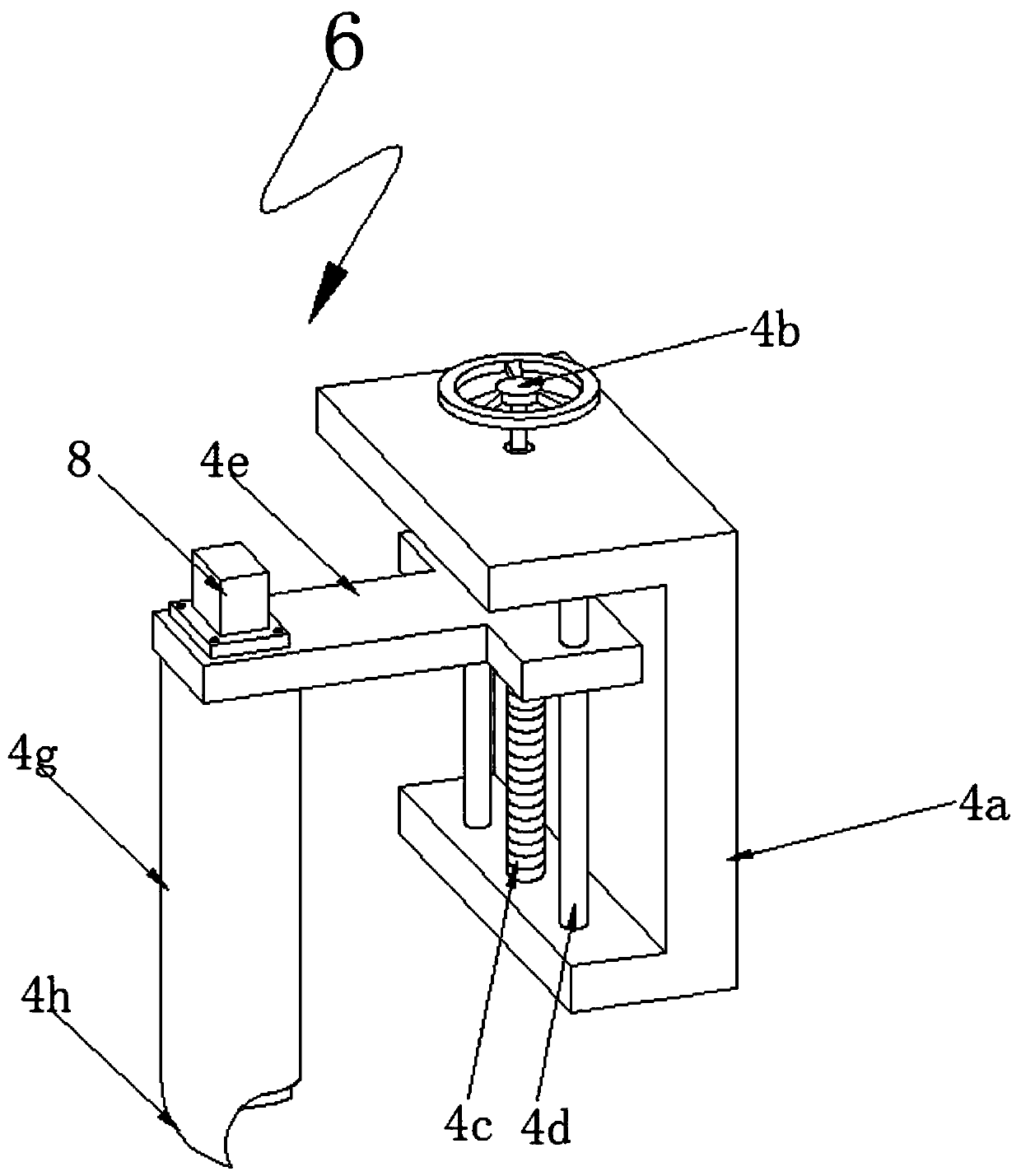

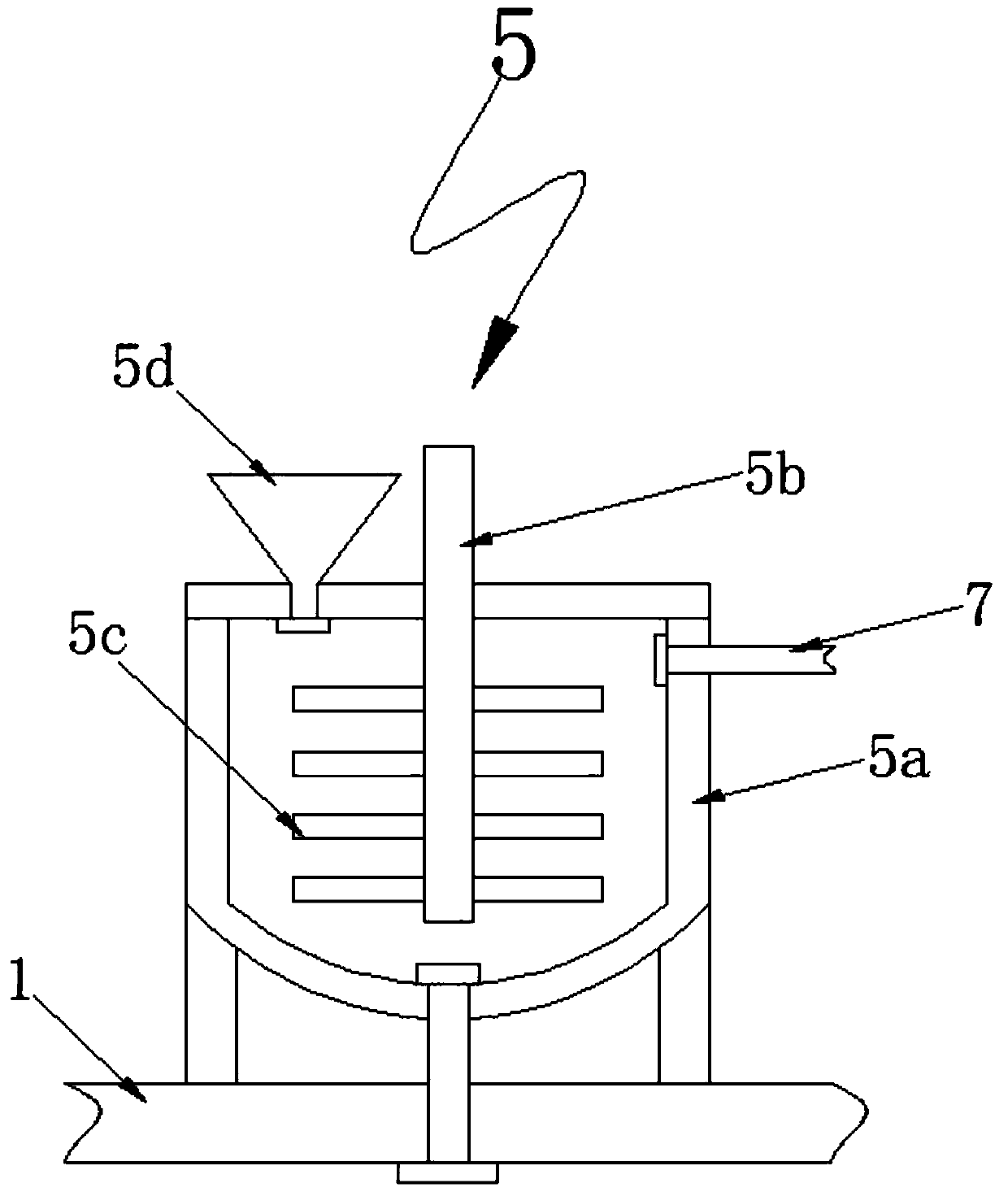

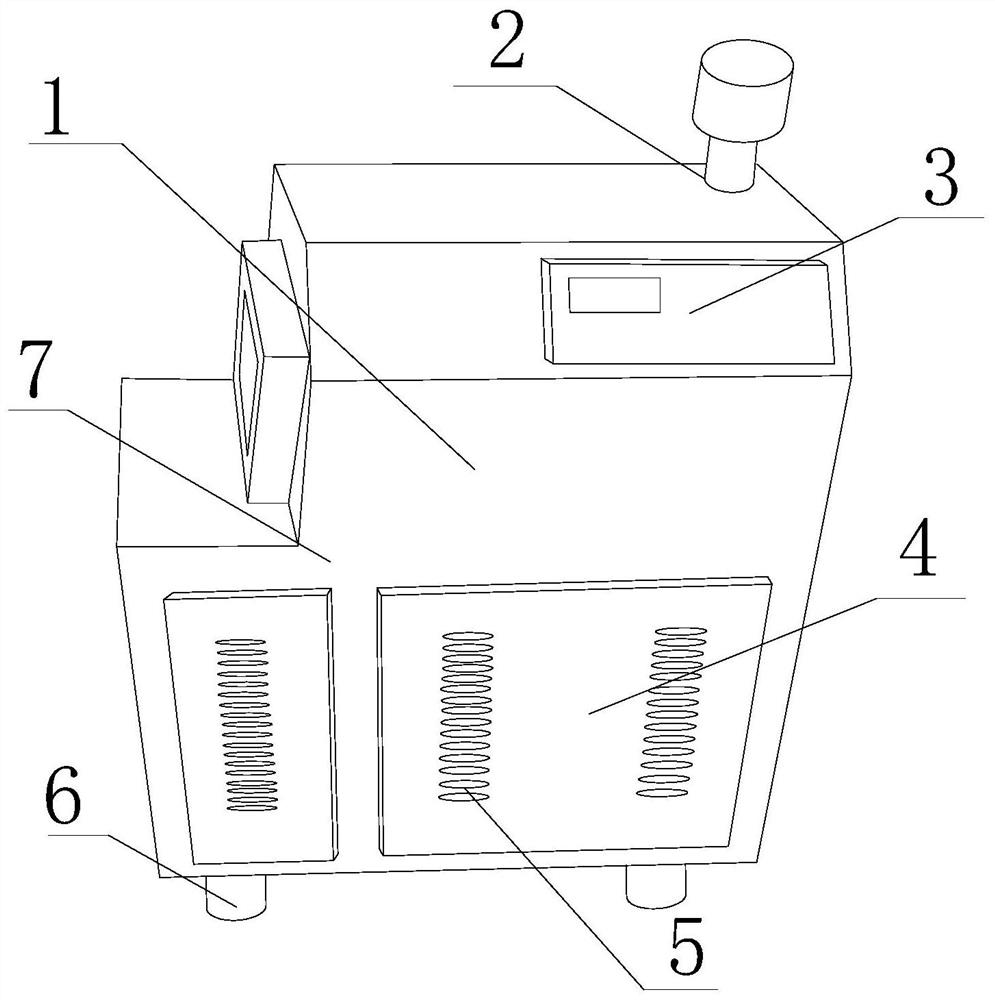

Plasma cutting machine convenient to use

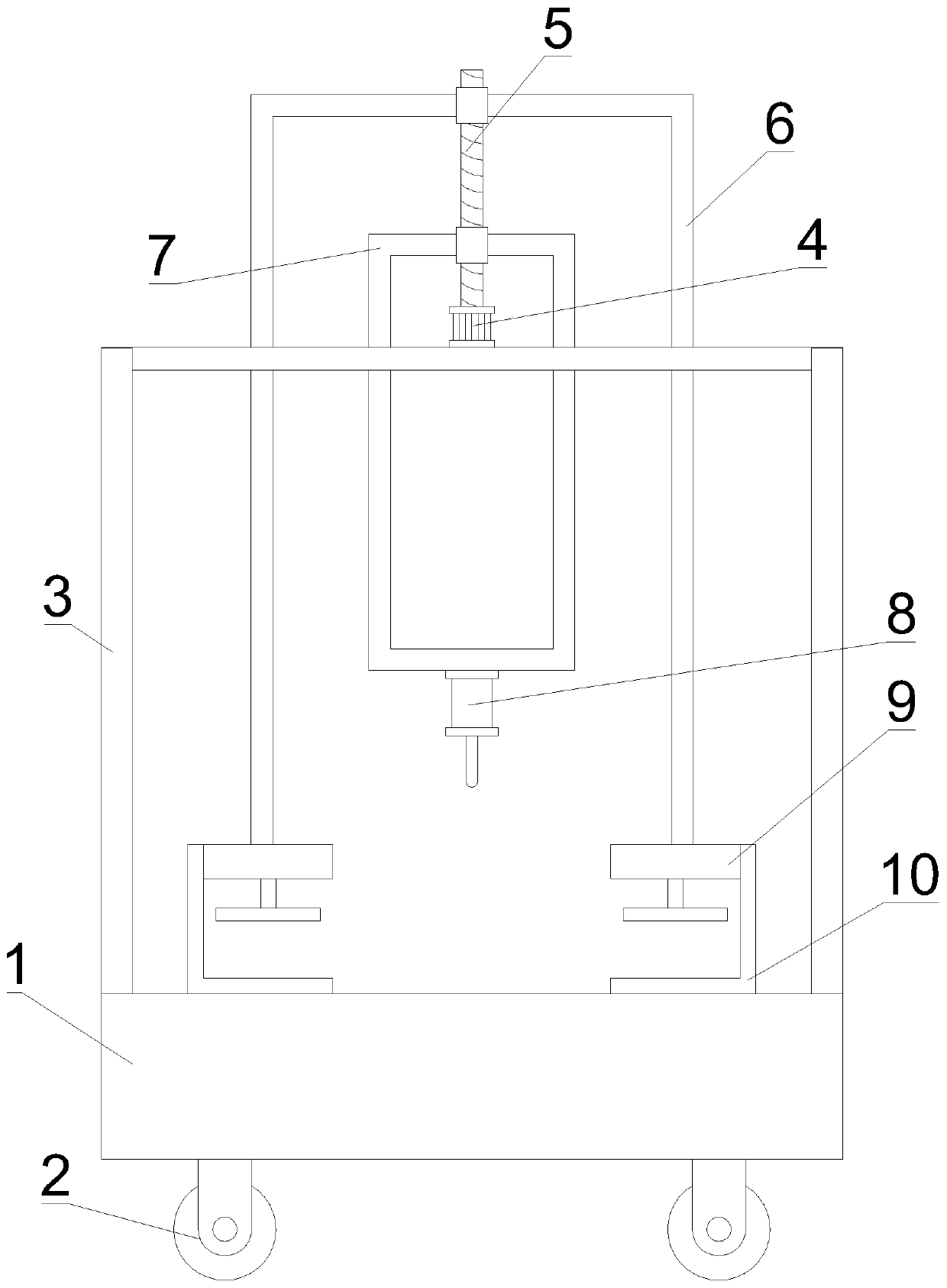

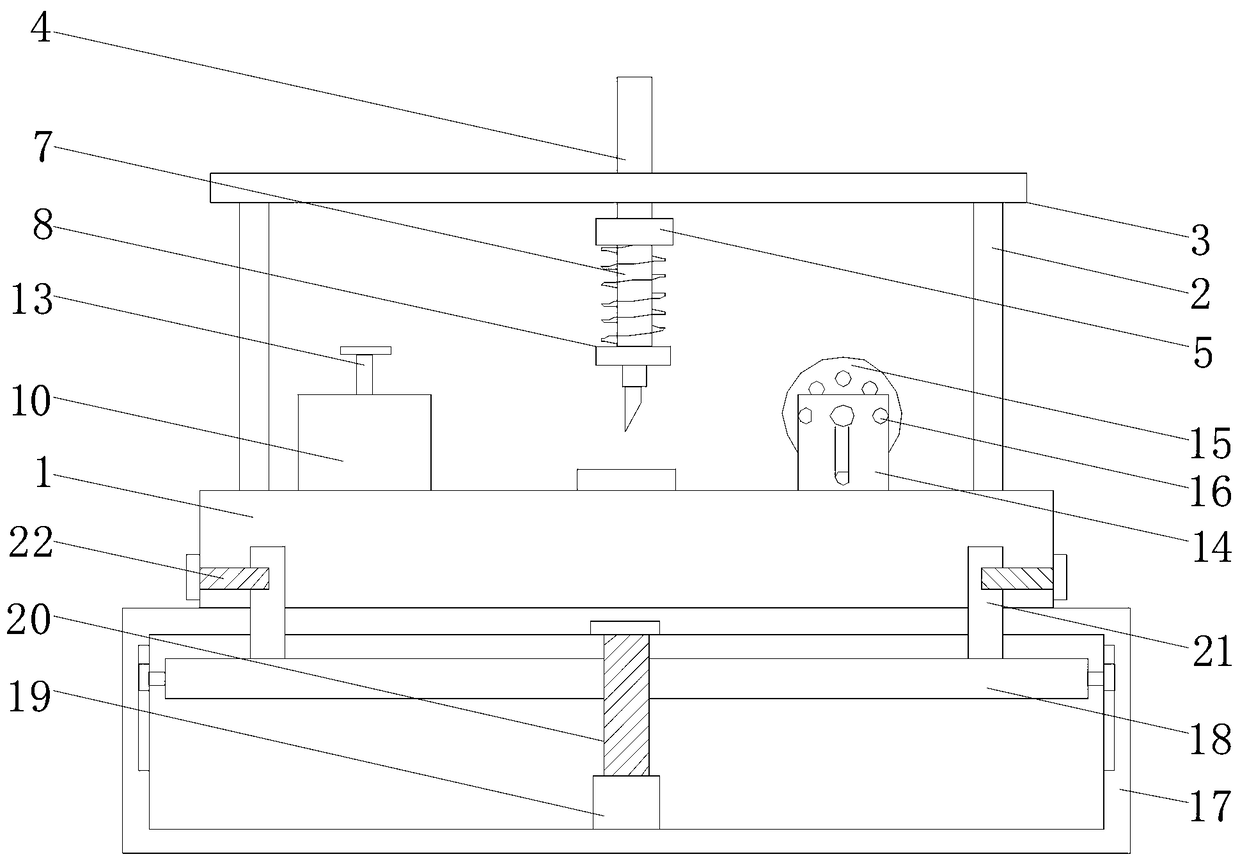

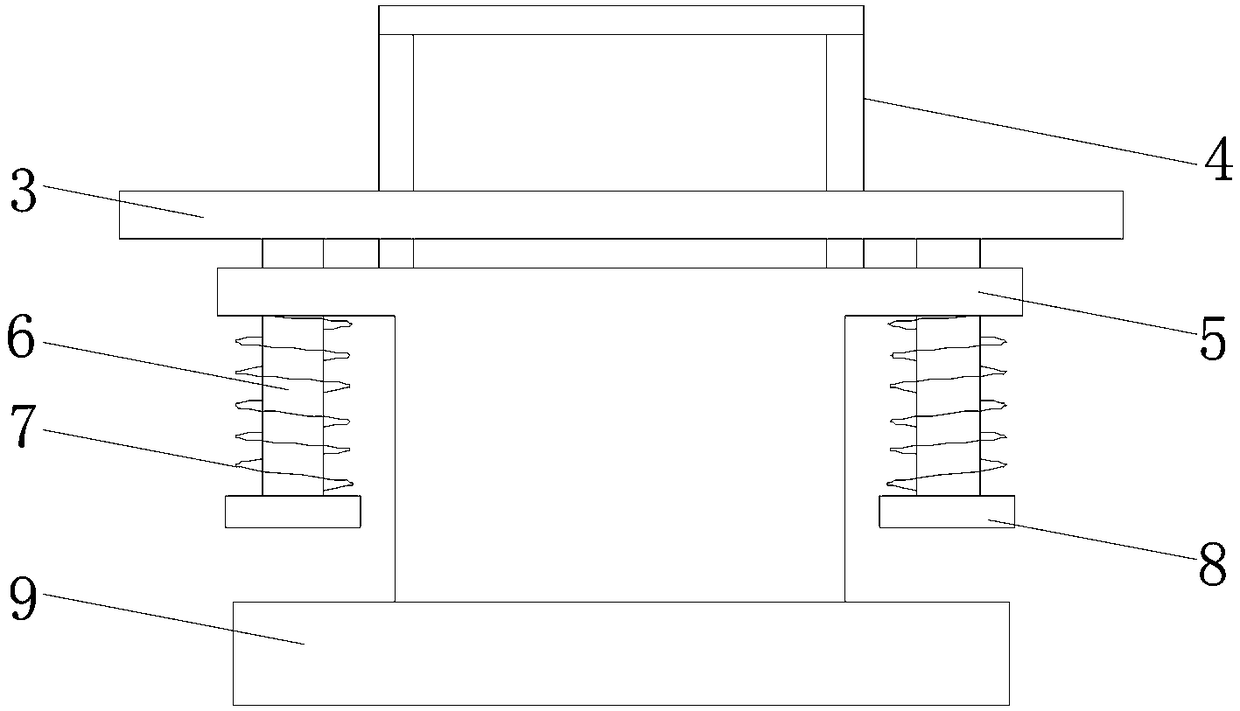

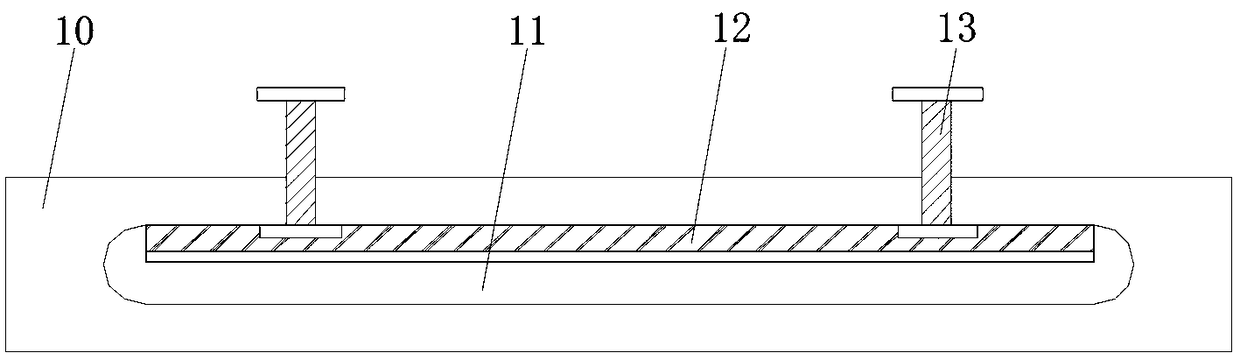

ActiveCN110091042APlay the role of cuttingImprove work efficiencyPlasma welding apparatusEngineeringMoving frame

The invention provides a plasma cutting machine convenient to use. The plasma cutting machine convenient to use comprises a base, a cutting machine body and a moving assembly. A rack is mounted on thetop of the base. The rack is of a U-shaped structure. The rack is provided with a first motor. The output end of the first motor is connected with a threaded rod. The threaded rod penetrates througha moving frame and a U-shaped frame in sequence to be in threaded connection with the moving frame and the U-shaped frame. The moving frame is a rectangular frame. The moving frame is located below the U-shaped frame. The moving frame and the U-shaped frame both penetrate through the top of the rack and are slidably connected with the rack. Fixed parts are mounted on vertical parts of the two endsof the U-shaped frame correspondingly. The bottoms of the fixed parts are provided with fixed plates. The cross section of each fixed plate is of an L-shaped structure. The fixed plates are mounted on the top of the base. The cutting machine body is arranged at the bottom of the moving frame. The plasma cutting machine convenient to use has the advantages of achieving the clamping, fixing and cutting effects on workpieces, greatly improving the working efficiency and being convenient to move and fix.

Owner:NANTONG HUINING MECHANICAL & ELECTRICAL TECH CO LTD

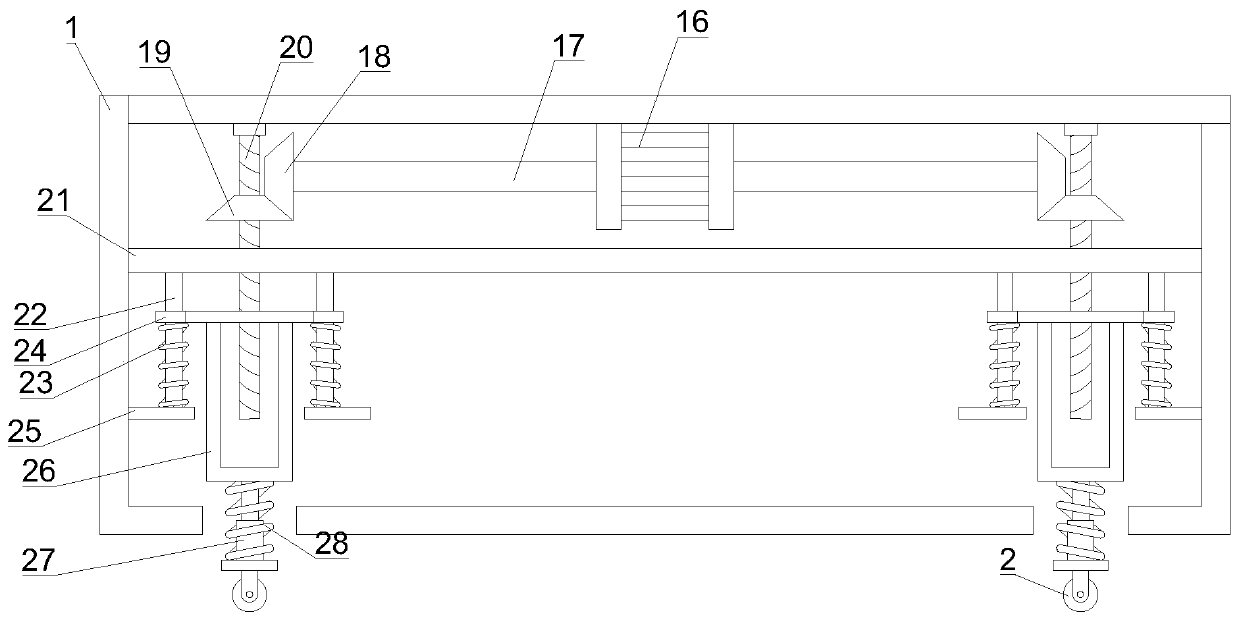

Cutting equipment for machining mechanical parts

PendingCN112658750AImprove shock resistanceMove doesn't happenFeeding apparatusLarge fixed membersWorkbenchMachining

The invention discloses cutting equipment for machining mechanical parts and belongs to the field of machining. The cutting equipment comprises a workbench, supporting legs are fixedly connected to the four corners of the bottom of the workbench correspondingly, moving mechanisms are fixedly installed at the bottoms of the supporting legs correspondingly, and stand columns are fixedly connected to the four corners of the top of the workbench correspondingly. A top plate is fixedly connected among the tops of the stand columns, an adsorption mechanism is fixedly installed at the top of the workbench, limiting mechanisms are fixedly installed at the positions, located on the left side and the right side of the adsorption mechanism, of the top of the workbench, and a first telescopic air cylinder is fixedly installed on the left side of the top of the top plate. The output end of the first telescopic air cylinder is fixedly connected with an L-shaped plate, a second telescopic air cylinder is fixedly installed at the top of the L-shaped plate, and a through hole is formed in the position, corresponding to the output end of the second telescopic air cylinder, of the top of the L-shaped plate. The adsorption mechanism is arranged and used for adsorbing a to-be-cut mechanical part to the workbench so that a worker can conduct cutting work conveniently.

Owner:湖南鸿云钢模科技有限公司

Environment-friendly electrical equipment used in factory and using method of electrical equipment

ActiveCN109330492ASolve the problem of time-consuming and laborious recyclingTo achieve the purpose of energy saving and environmental protectionCarpet cleanersFloor cleanersBristleElectrical devices

The invention relates to the technical field of electrical equipment, and discloses environment-friendly electrical equipment used in a factory and a using method of the electrical equipment. The electrical equipment comprises a cleaning machine, a material inlet and a material outlet are formed in the cleaning machine, the lower end of the material inlet is fixedly provided with a shovel plate bucket, the cleaning machine is provided with two telescoping air cylinders, and the telescoping air cylinders are connected with installation blocks respectively. A cleaning roller is rotationally connected between the two installation blocks, a plurality of bristles are arranged on the circumferential side of the cleaning roller in an array, the cleaning machine is provided with a track, one end of the track is rotationally installed in the shovel plate bucket, and the other end of the track is rotationally connected to the material outlet. A spraying pipe is fixedly installed on the inner wall at the upper end of the cleaning machine, and the cleaning machine is fixedly connected with a material storage box. By arranging the shovel plate bucket, the cleaning roller, the track and the material storage box, debris on the road surface is cleaned away through the cleaning roller into the shovel plate bucket, the debris is recovered into the material storage box through the track, the problem the recovery of the debris wastes time and labor is solved, and the aims that the factory saves energy and is environmentally friendly are achieved.

Owner:CHAOHU JINHUI AUTOMATIC CONTROL EQUIP

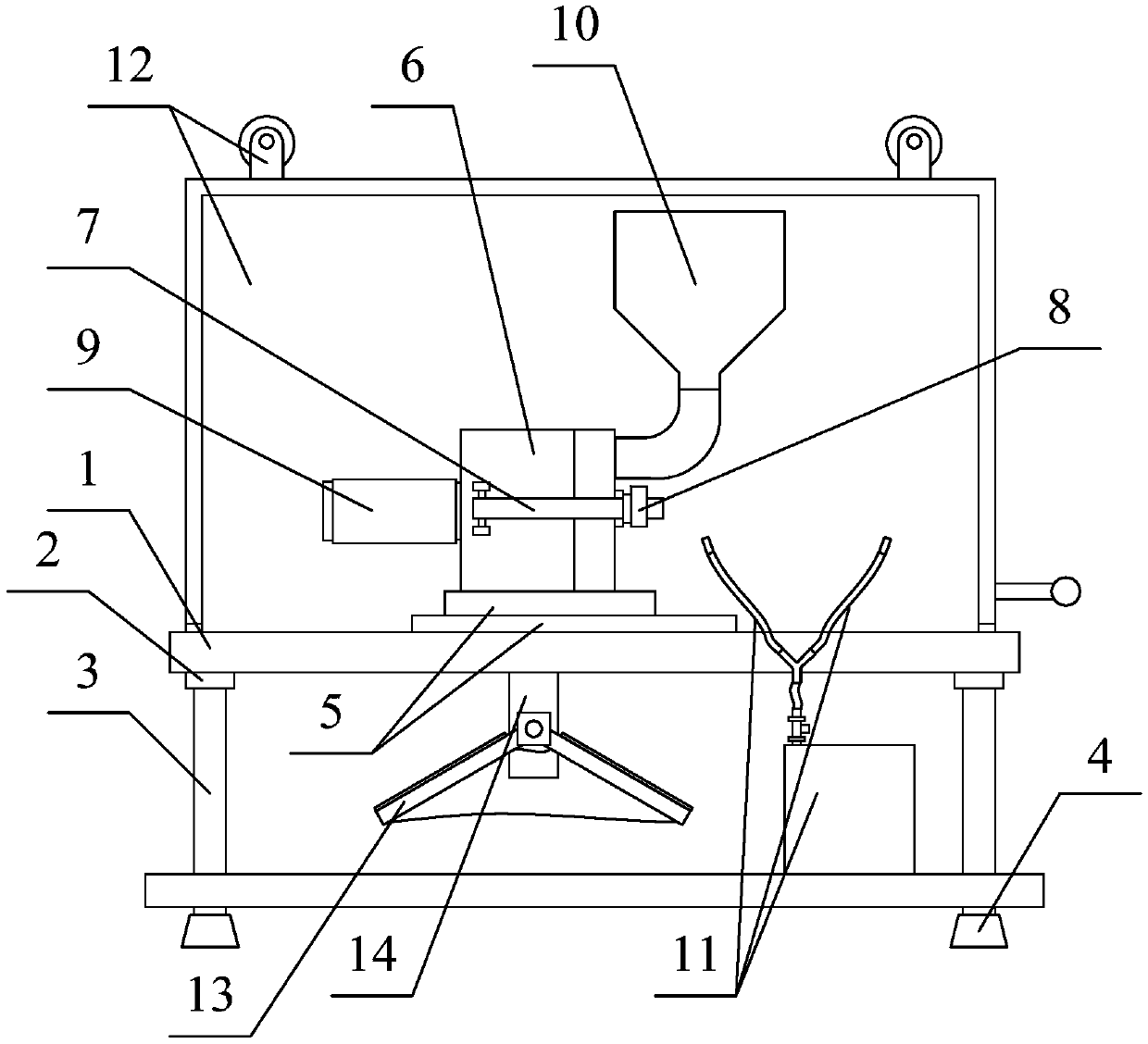

Rapid integrated agricultural seeder

InactiveCN111466183AEnables watering and softening of the soilPlay the role of cuttingPlantingTransportation and packagingWater deliveryAgricultural engineering

The invention relates to the technical field of agricultural planting equipment, and particularly discloses a rapid integrated agricultural seeder. The rapid integrated agricultural seeder comprises abottom plate, wherein a vertical plate is fixedly connected to the right side edge of the upper surface of the bottom plate; a water delivery device, a digging device and a soil filling and fertilizing integrated box are fixedly mounted on the upper surface of the bottom plate from right to left in sequence; a scraper is further fixedly mounted at the rear end of the bottom plate; and a soil outlet pipe communicates with a portion between the digging device and the soil filling and fertilizing integrated box. According to the rapid integrated agricultural seeder, under the rotation action ofa spiral digging rod, a soil layer can be dug, and furthermore, the crushed soil layer and soil can be transported upwards and conveyed into the soil filling and fertilizing integrated box through thesoil outlet pipe for backfilling; and through an annular staggered cutter additionally arranged on the lower portion of the spiral digging rod and a leakage hole formed in the side wall of the annular staggered cutter, an effect of cutting the soil layer can be achieved, and under the driving of the spiral digging rod, interval plugging on a communication portions of seed pipes can be realized bythe side wall of the annular staggered cutter, so that a purpose of interval seeding is achieved.

Owner:谈静

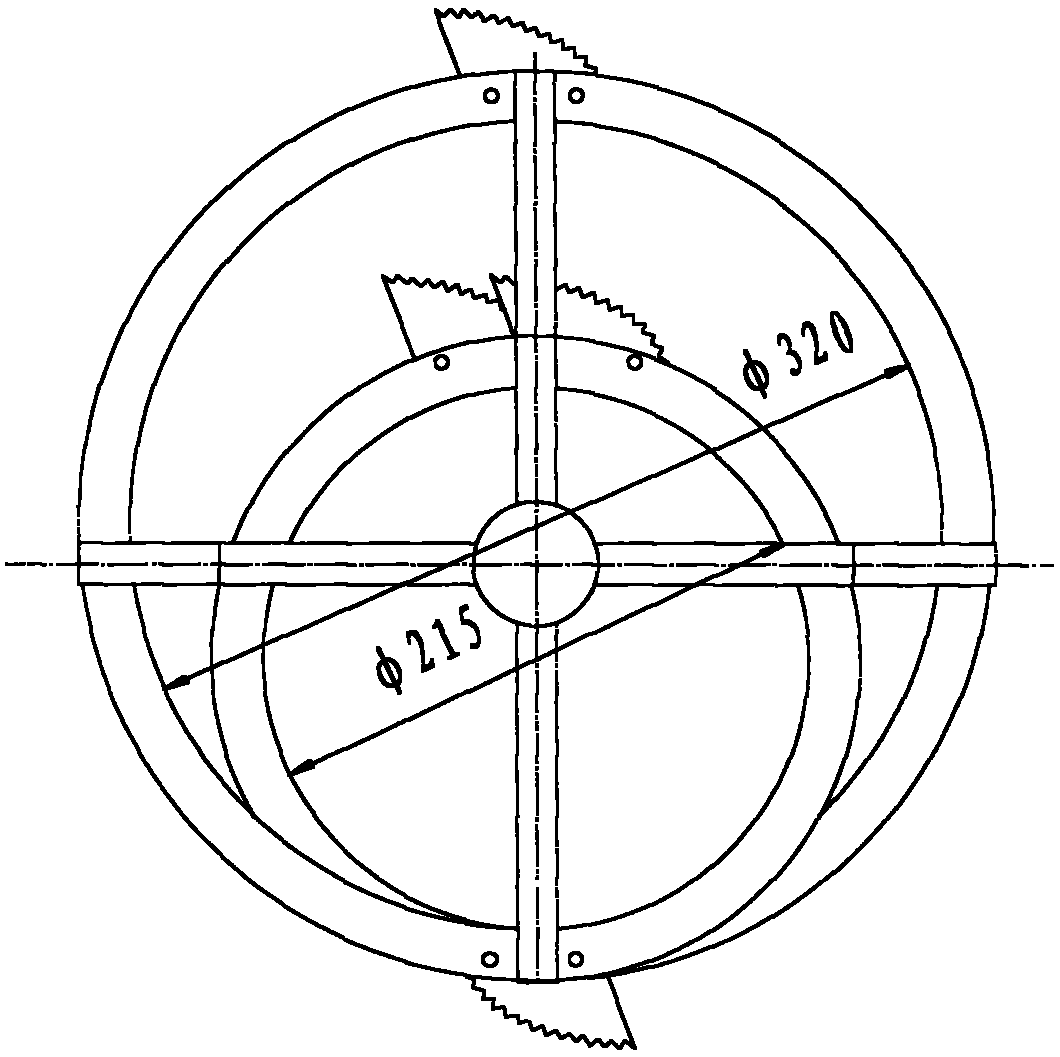

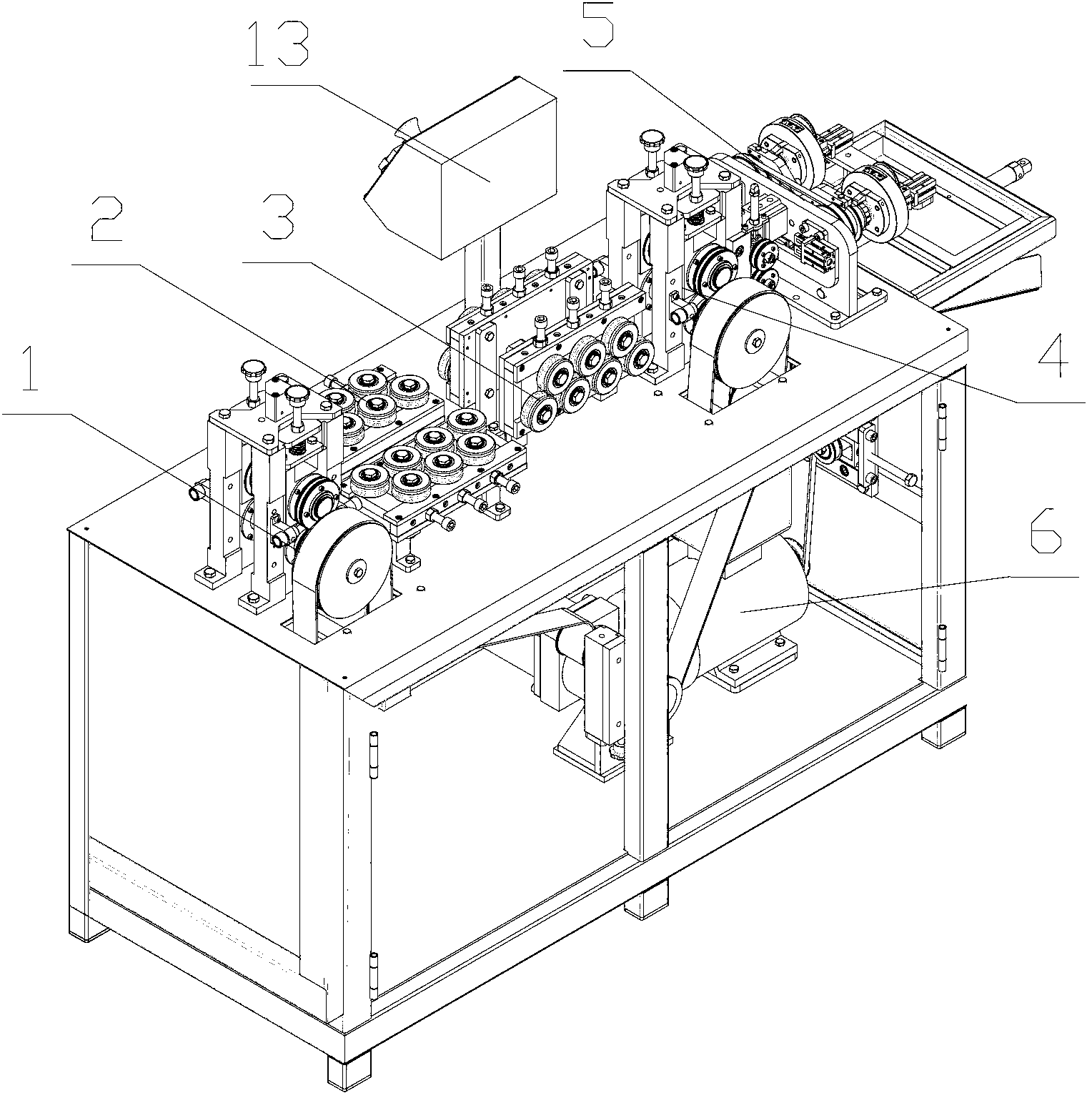

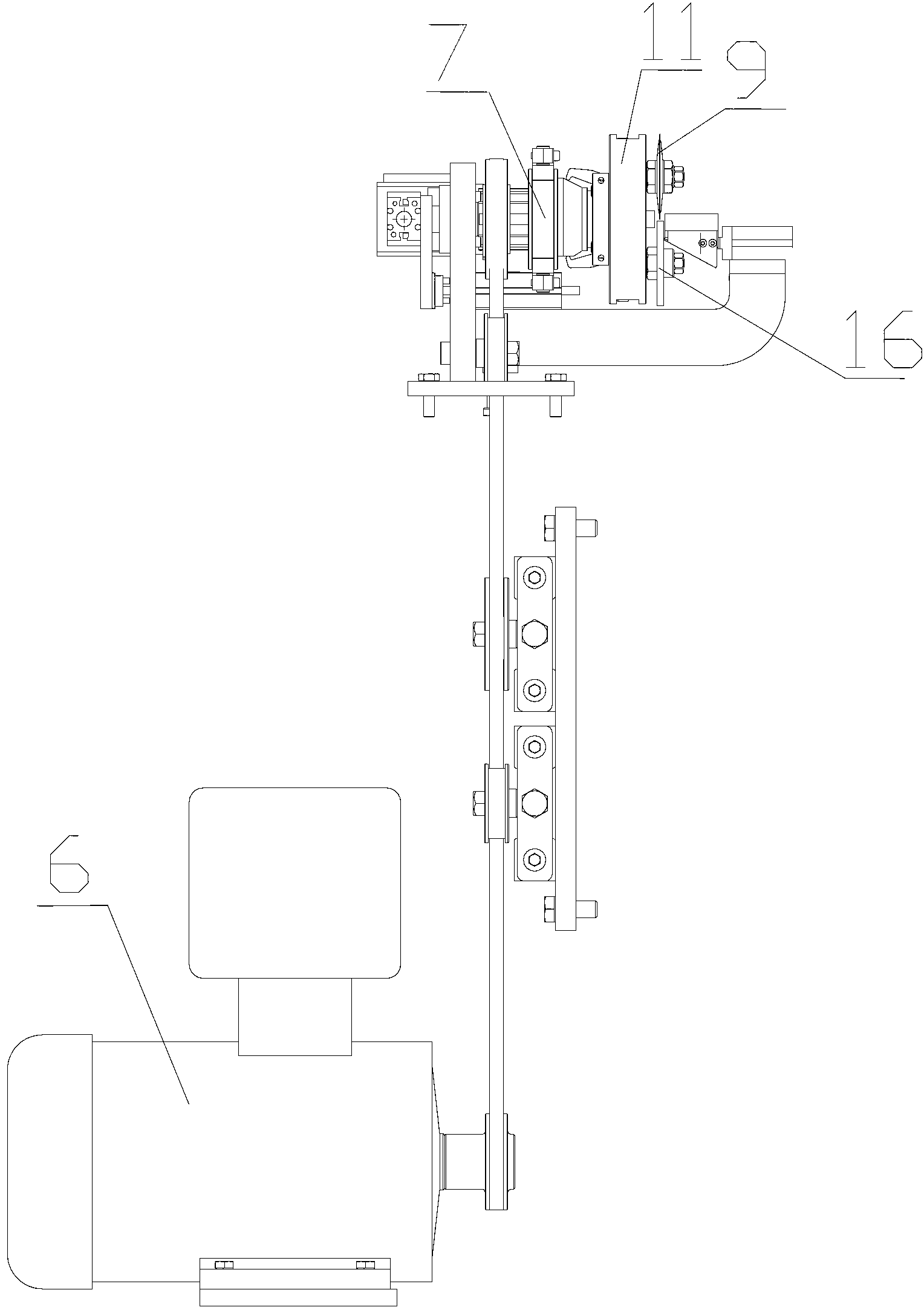

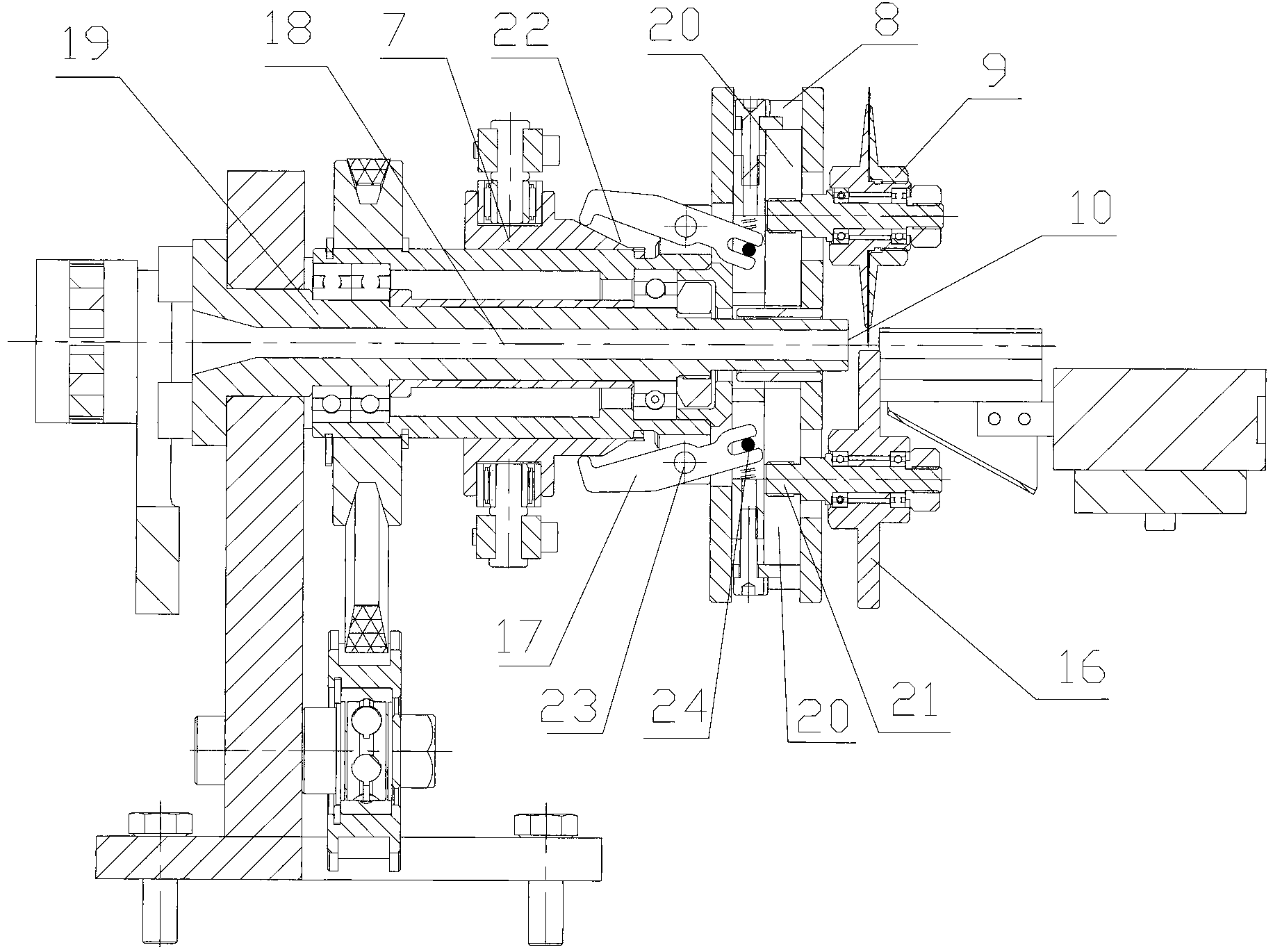

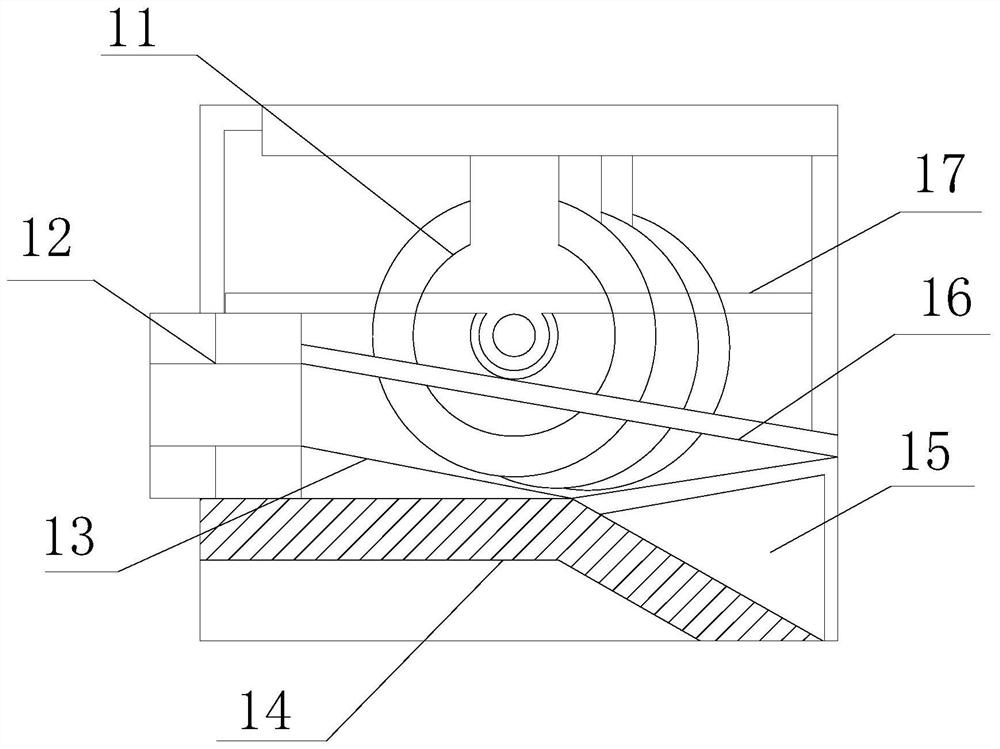

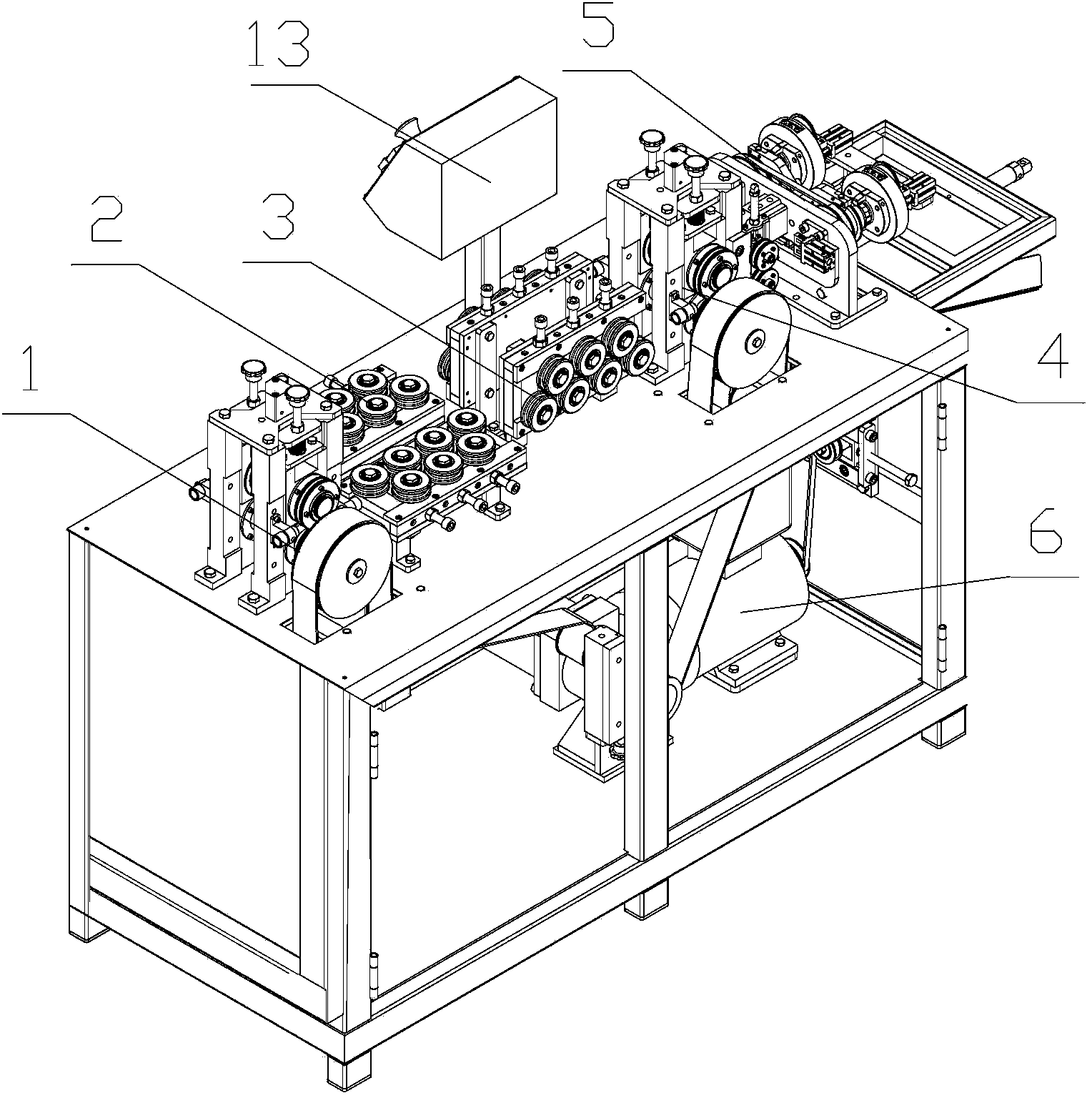

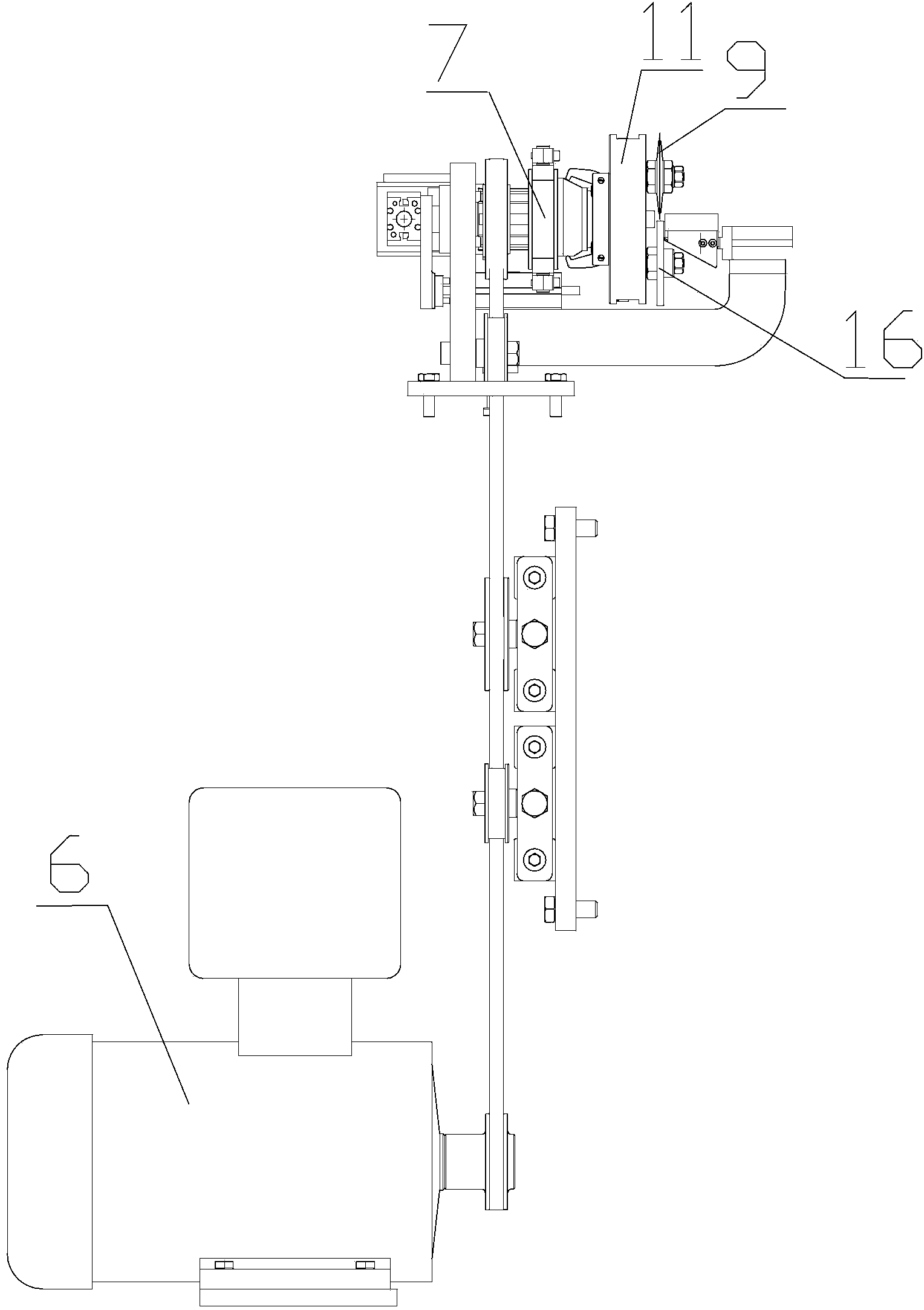

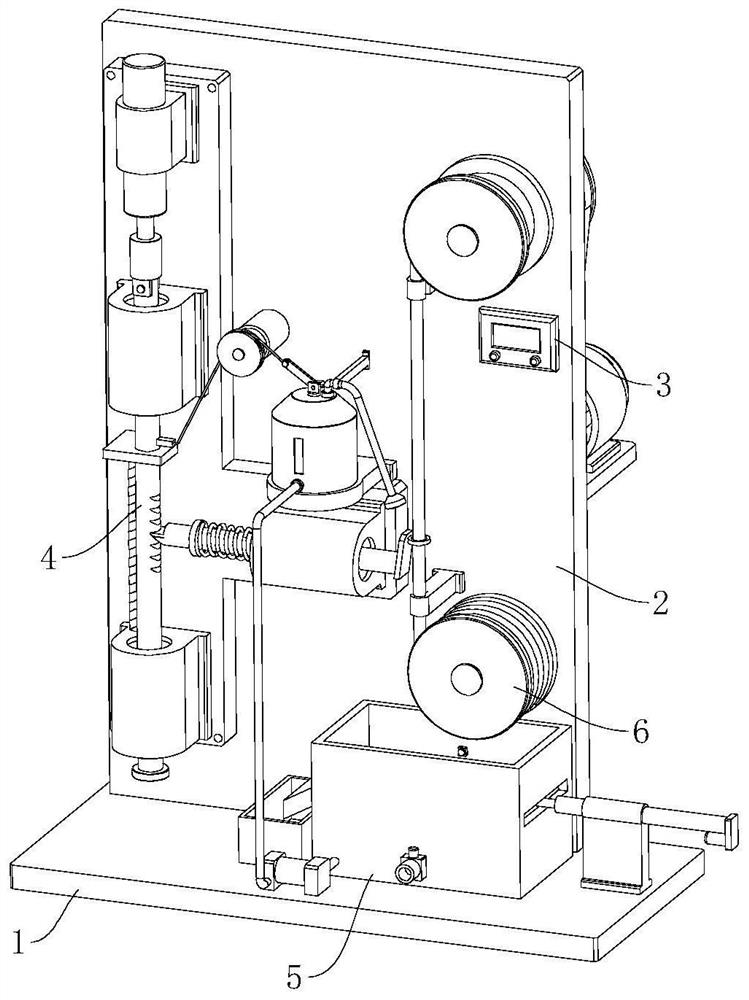

Lead delay element rotary cutter

ActiveCN102935527AFlat sectionFast revolutionShearing machinesShearing machine accessoriesScrapPersonal computer

The invention provides a lead delay element rotary cutter which comprises a rotary cutting assembly, a feeding detection mechanism, a horizontal and vertical straightening mechanism, a tensioning device, a linear (or disc type) wire inlet platform and an industrial personal computer which are all arranged on a worktable. A lead delay cord is driven by the feeding detection mechanism which is driven by a stepping motor and straightened by the straightening mechanism, passes a hollow lead delay cord fixing shaft of the rotary cutting assembly and then butts against the rotary cutting position, a high-accuracy coder detects required cutting length information and then sends instructions to rotary cutting blades, a rotary cutting cylinder arranged on the rotary cutting assembly pushes the rotary cutting blades to radially move towards the axis of the lead delay cord fixing shaft to cut off the lead delay cord, and rotary cutting is completed. The radially symmetrically arranged rotary cutting blades and rotary cutting riding wheels simultaneously apply force in the axis direction on the circumference of the lead delay cord, radial thrust in all directions is offset, the section of a cut lead delay element is level and does not deform, U-shaped section cannot be formed, and product scraps are few.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

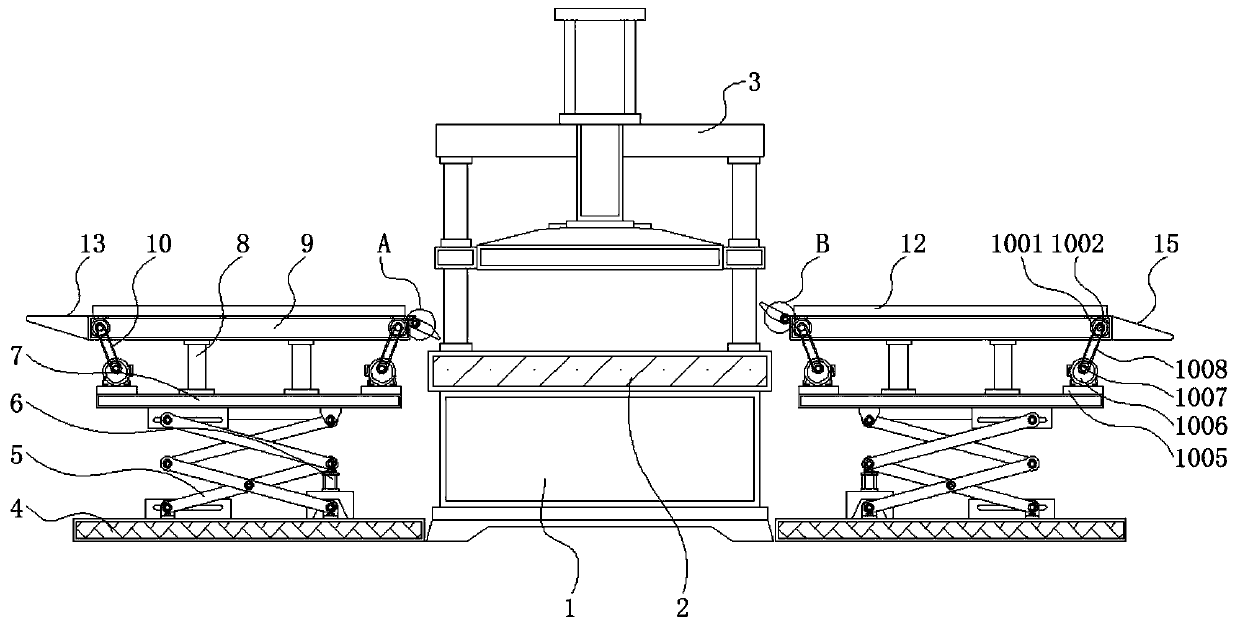

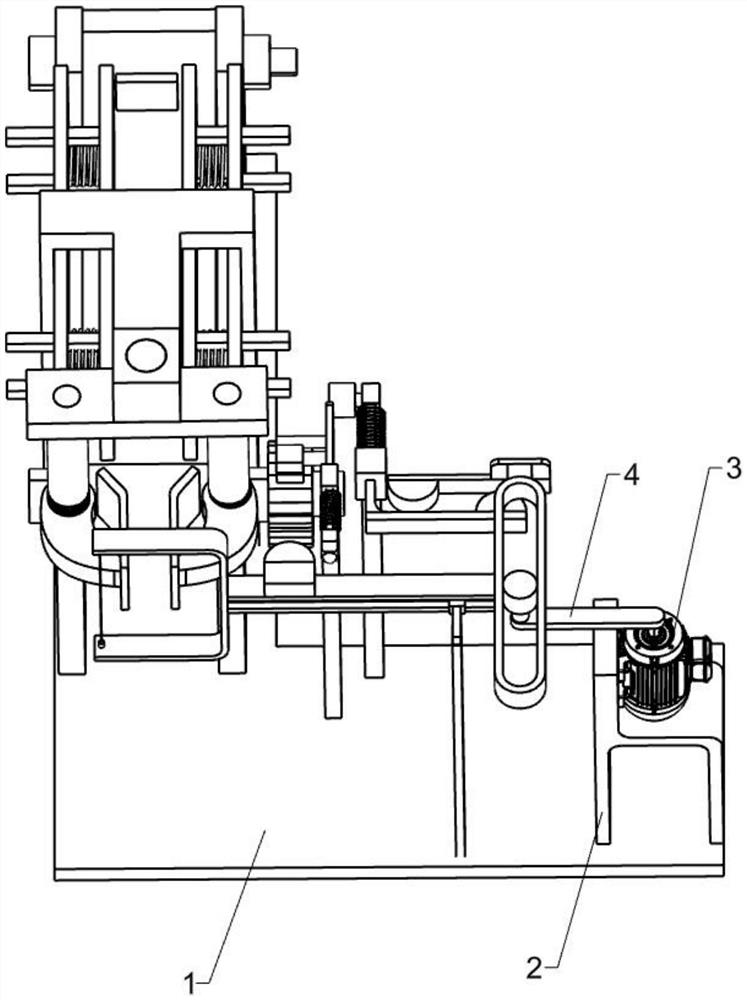

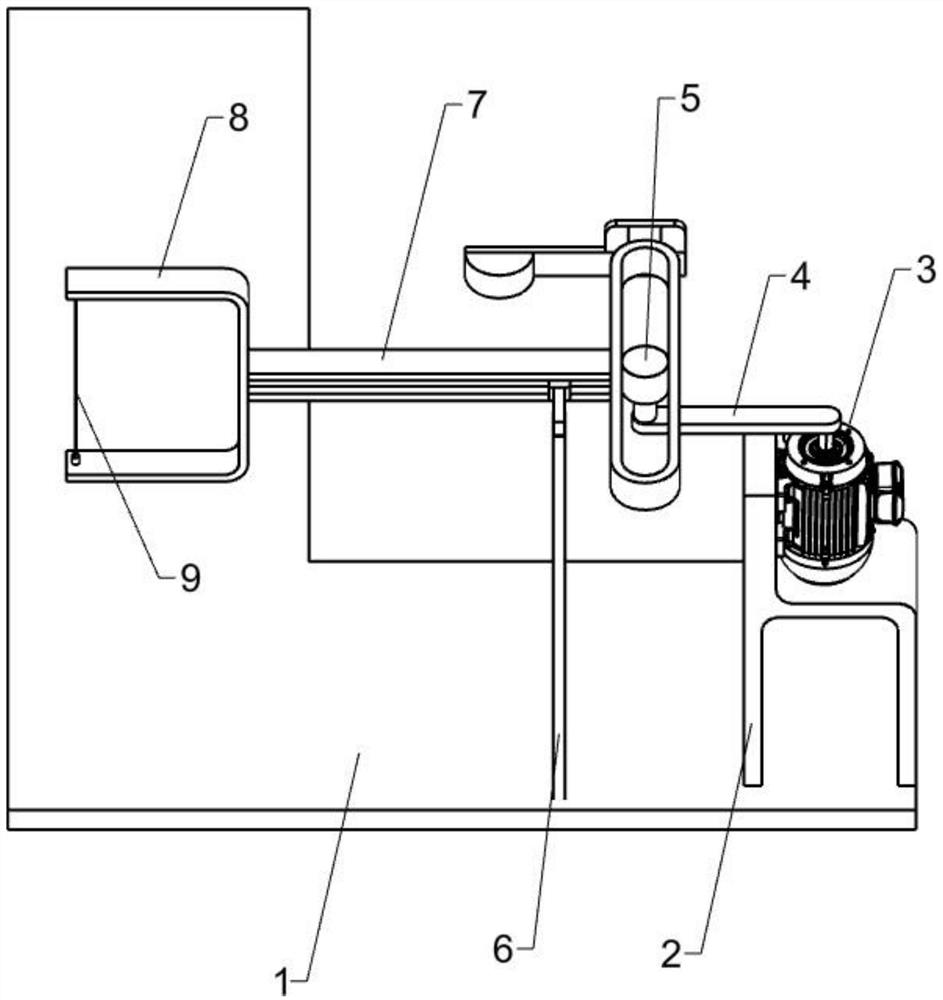

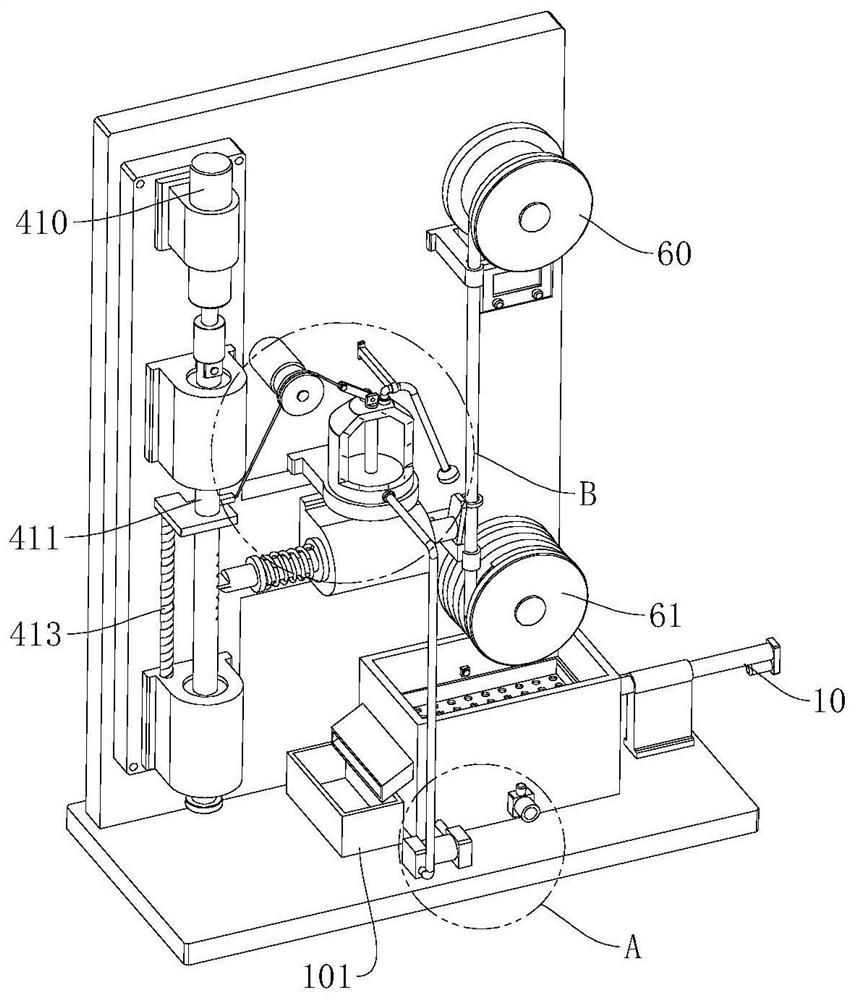

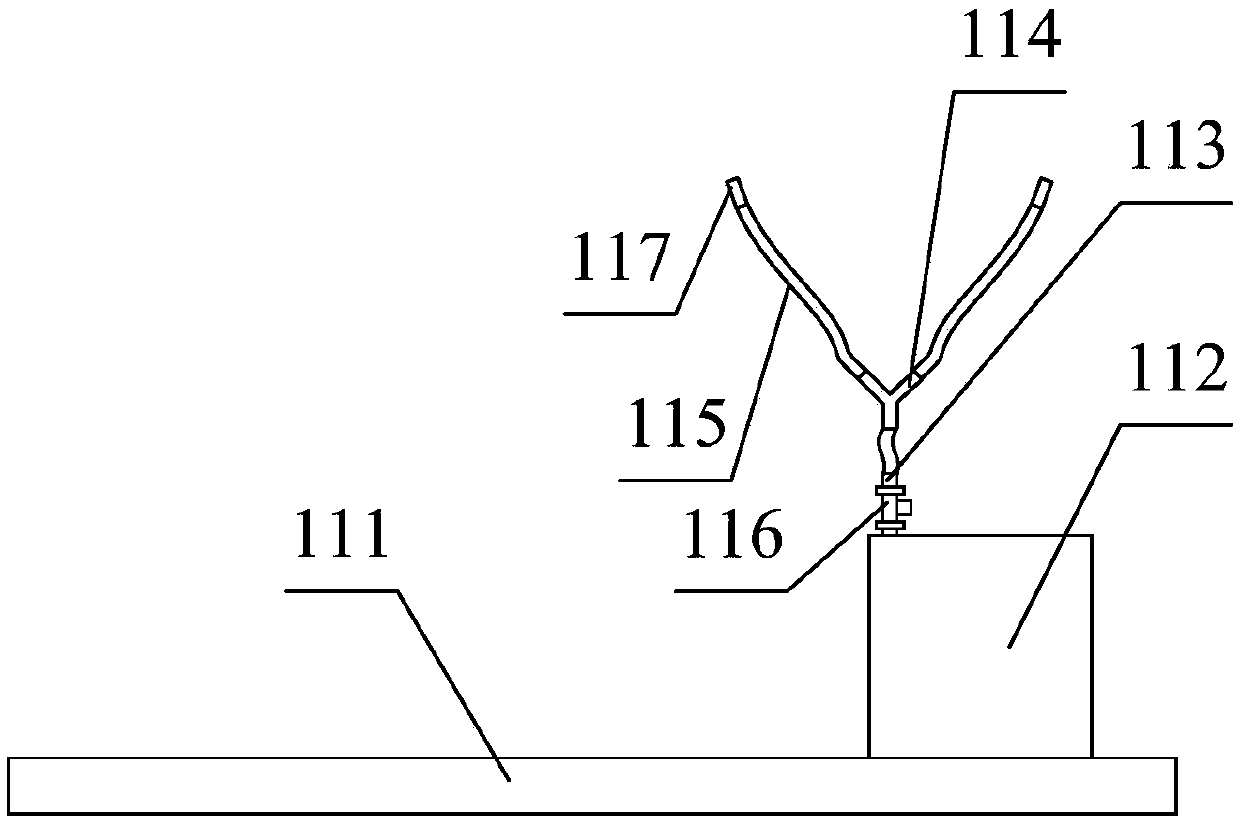

Rapid feeding machine for hydraulic machine

The invention discloses a rapid feeding machine for a hydraulic machine and relates to the technical field of hydraulic machines. The rapid feeding machine comprises a hydraulic machine main body andconveying mechanisms. A hydraulic machine workbench is fixed above the hydraulic machine main body. A fixed outer frame is mounted on the outer side of the upper portion of the hydraulic machine workbench. Bases are correspondingly arranged on the left side and the right side of the hydraulic machine main body. Hydraulic lifting arms are mounted above the bases. Hydraulic oil cylinders are arranged below one sides of the hydraulic lifting arms. Lifting seats are mounted above the hydraulic lifting arms. Support frames are fixedly arranged above the middle portions of the lifting seats. Mounting frames are mounted above the support frames. The conveying mechanisms are arranged inside the mounting frames. Dustproof shielding plates are fixedly arranged above the two sides inside the mountingframes. Protection barrier plates are fixedly arranged above the dustproof shielding plates. The rapid feeding machine has the beneficial effects that by arranging the hydraulic lifting arms and thehydraulic oil cylinders, the lifting seats are driven to lift up and down conveniently, the use is quite flexible, and the bases can stably support the lifting seats.

Owner:太田机械江苏有限公司

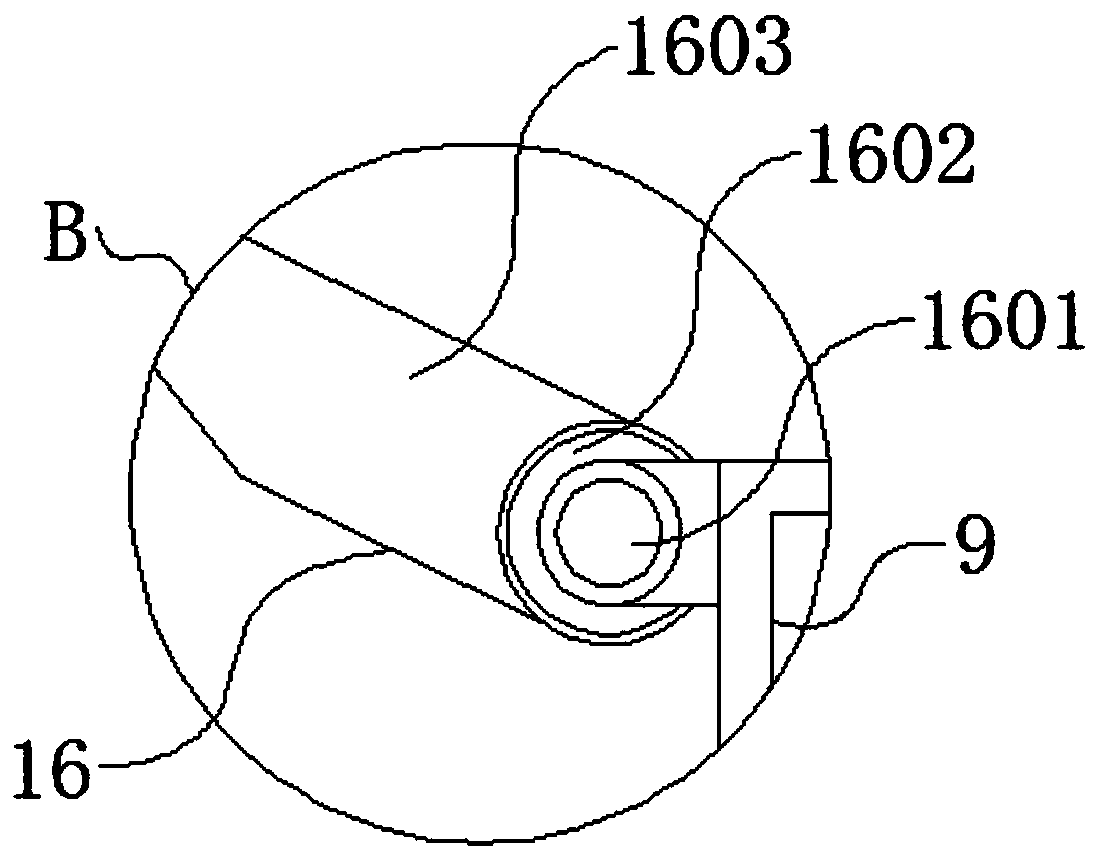

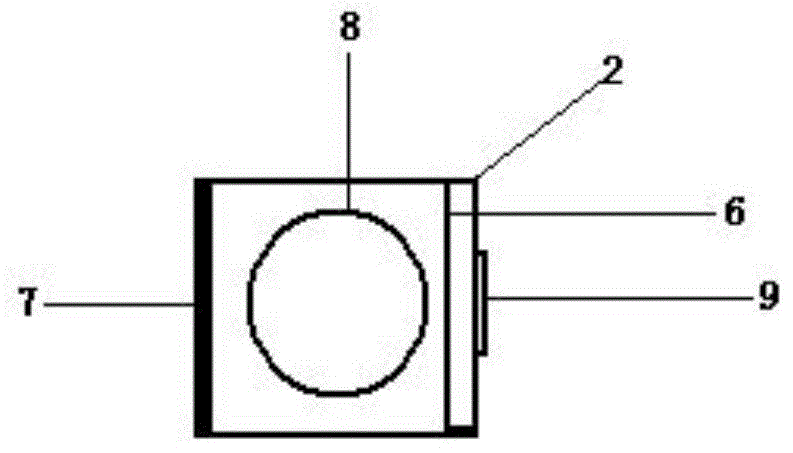

Impeller assembly of guide type sewage pump

PendingCN111043071AImprove efficiencyPlay the role of cuttingPump componentsPumpsStructural engineeringSewage

Owner:浙江丰民泵业有限公司

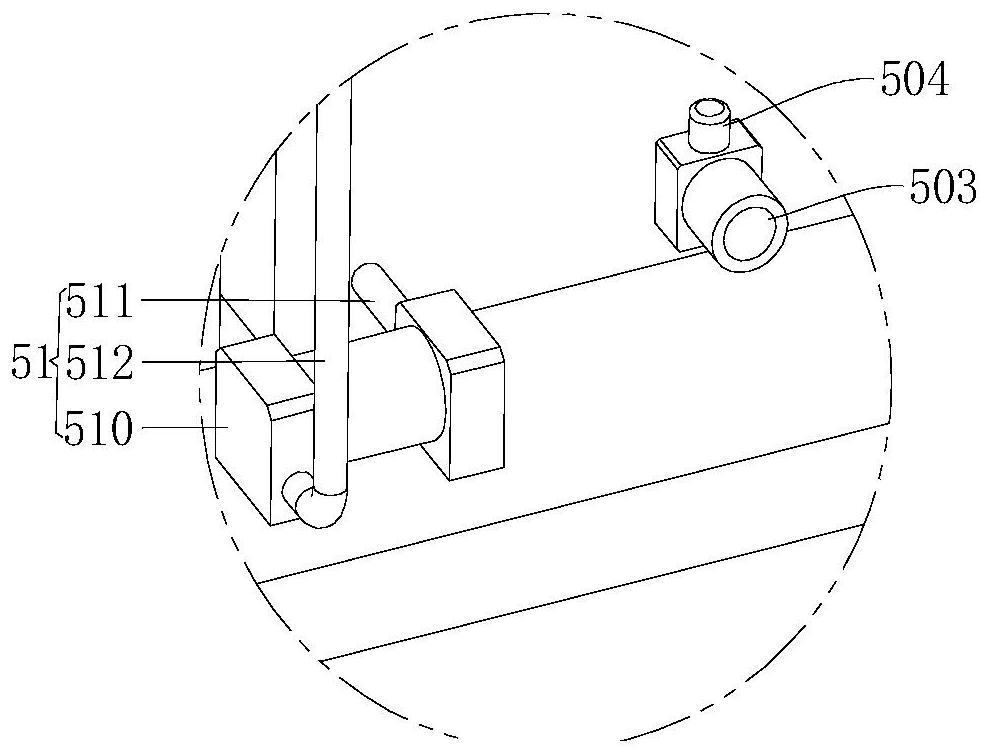

Wire cutting device with clamping mechanism

InactiveCN109306616AGood stabilization effectPlay the role of cuttingSevering textilesMetal working apparatusWire cuttingEngineering

The invention discloses a wire cutting device with a clamping mechanism. The wire cutting device comprises a platform, supporting rods are fixedly connected to the top of the platform, the tops of thesupporting rods are fixedly connected with a top plate, a movable handle is arranged on the top of the top plate, and the bottom of the movable handle is fixedly connected with a cutter holder. The bottom of the top plate is fixedly connected with fixing rods, the bottoms of the fixing rods are fixedly connected with baffles, the bottom of the cutter holder is provided with springs, the outer surfaces of the fixing rods are sleeved with the springs, a cutter is welded to the bottom of the cutter holder, and the top of the platform is fixedly connected with a clamping base. By arranging the clamping base, a strip-like opening, a rubber plate, a bolt, a fixed plate, a winding roller, an insertion rod, a fixing frame, a movable plate, a motor, a screw, clamping rods and threaded pins, the problems are solved that an existing wire cutting device is not provided with the clamping mechanism, during cutting, a nylon product is easy to loosen, when the nylon product is cut, the cutting platform can shake, and the stability is poor.

Owner:睢宁德宇商贸有限公司

Tea seed shelling device with centrifugal collision-type cutting deflection screening classification

The invention provides a tea seed shelling device with centrifugal collision-type cutting deflection screening classification, and belongs to the technical field of tea seed processing. The device comprises a device shell, a material placing cylinder, a feeding pipe, a guide plate, a guide plate II, a motor I, a spiral pipe, a cutter shell, a shaft column, a limiting plate, a blade, a solid pipeline, a motor II, a base, a motor III, a deflection rack, a carrying plate, a through hole, a scribing sheet, a spring, a finished product discharging groove and a waste material discharging groove. Thematerial placing cylinder is nested in the top surface of the device shell, the feeding pipe is arranged in the bottom middle of the material placing cylinder in a penetrating way, the feeding pipe is arranged inside the device shell, the bottom inner side of the feeding pipe is fixedly connected to the guide plate, the bottom outer side of the feeding pipe is fixedly connected to the guide plateII, the top surface of the feeding pipe is fixedly connected to the motor I through a bracket, the bottom of the motor I is rotationally connected to the spiral pipe, the spiral pipe is positioned inthe feeding pipe, the middle of the inner part of the device shell is fixedly connected to the cutter shell, and the bottom middle of the cutter shell is movably connected to the shaft column througha bearing.

Owner:湖南生泰茶油股份有限公司

Intaglio fence shears

The invention relates to a gardening tool, in particular to intaglio fence shears. The intaglio fence shears are composed of a die and a shears body, wherein the die is fixedly connected with the shears body through a fastener, the shears body is composed of a first shears blade and a second shears blade, the shears blades are connected together through a connecting part rivet in a riveting mode, the blade edge of the first shears blade and the blade edge of the second shears blade are parallel, the cutting edge of the first shears blade and the cutting edge of the second shears blade are opposite, and blade stopping walls are arranged at the positions, opposite to the blade edges, of the die.

Owner:南京麦思德餐饮管理有限公司

A kind of fine collection and utilization equipment for wood that does not meet the standards of building monitoring

InactiveCN109318306BAvoid damageReduce areaProfiling/shaping machinesArchitectural engineeringWood plank

Owner:南京溧水高新产业股权投资有限公司

A rubber pad line cutting machine

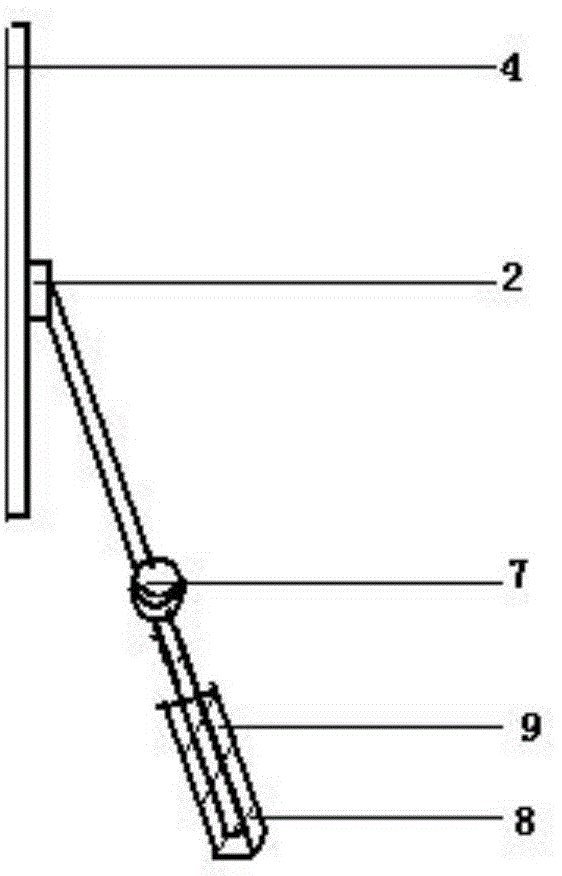

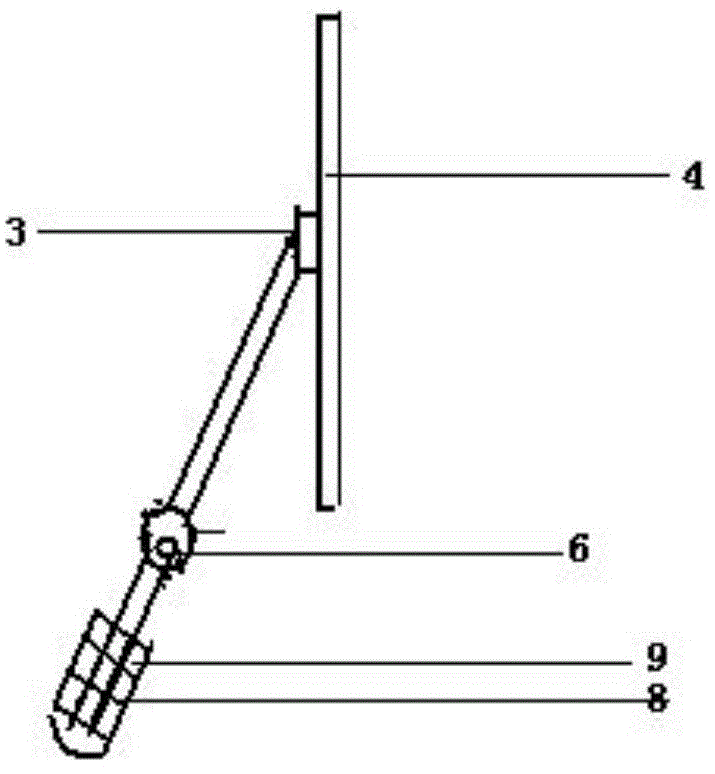

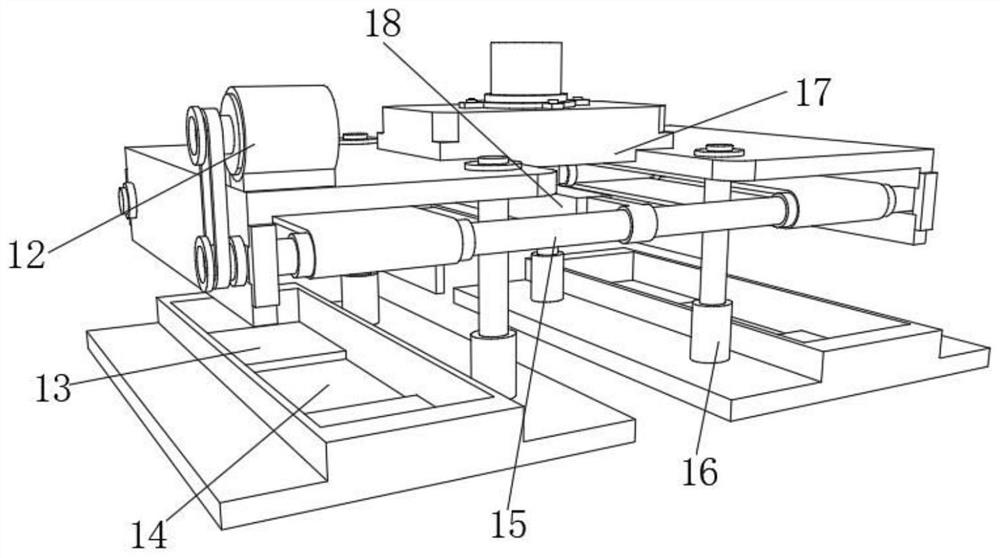

ActiveCN111590670BRealize automatic feedingConsistent cut sizeMetal working apparatusElectric machineWire cutting

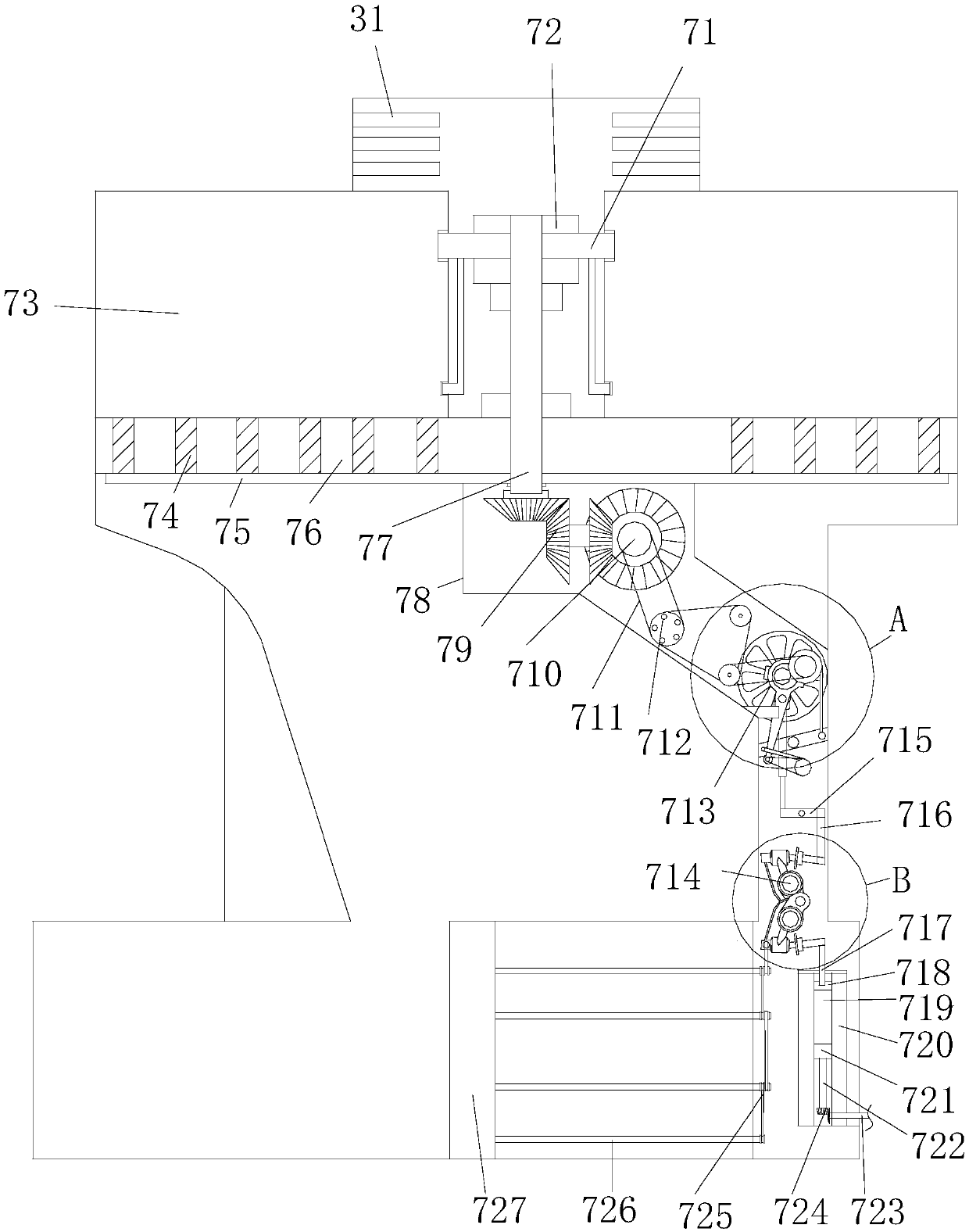

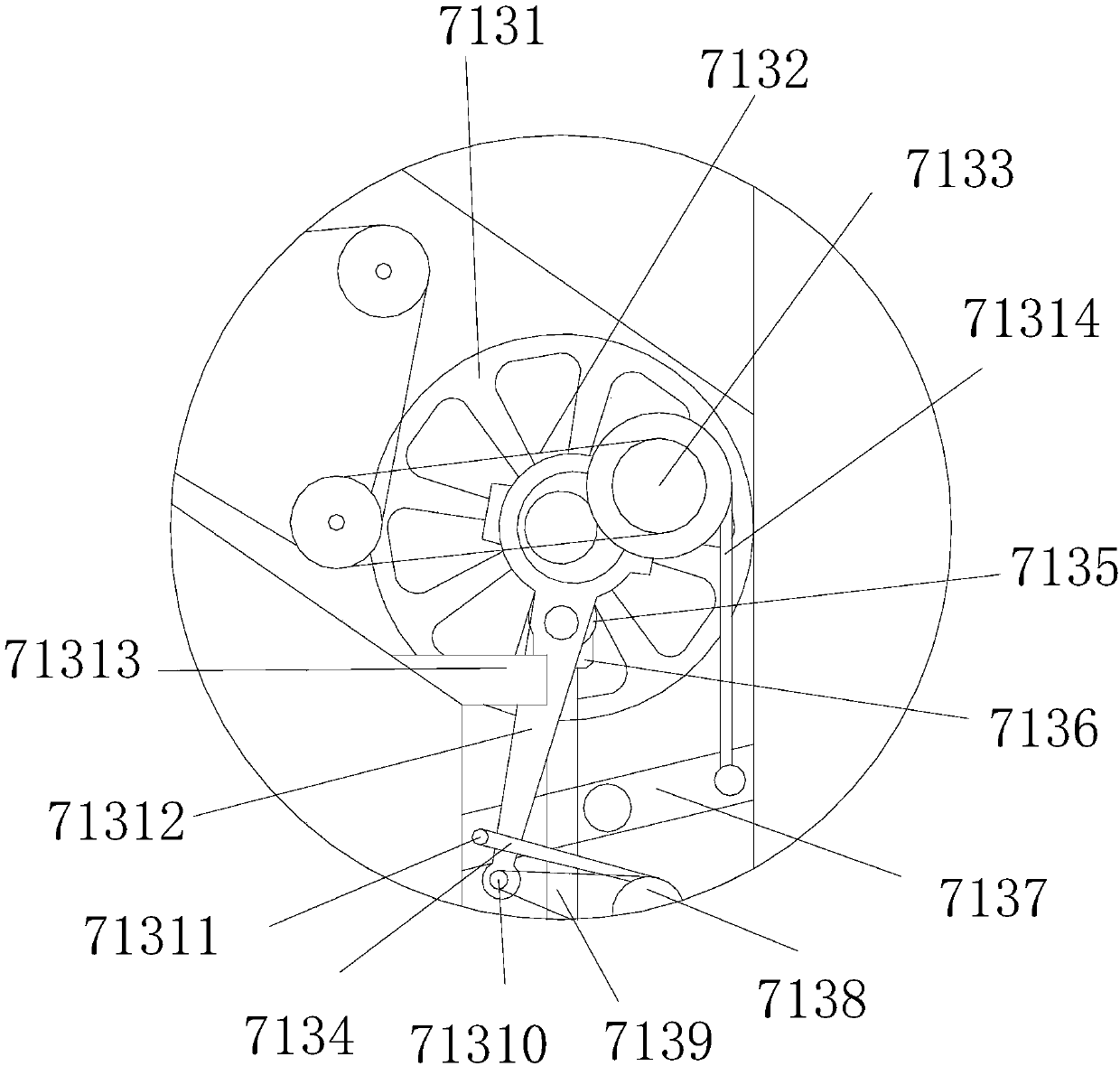

The invention relates to a wire cutting machine, in particular to a rubber pad wire cutting machine. The technical problem of the present invention is to provide a rubber pad line cutting machine with automatic feeding, automatic cutting, smooth and tidy incision, consistent cutting size and high precision. The technical embodiment of the present invention is: a rubber pad line cutting machine, including a base plate, a support seat, a motor, a swing lever, a swing wheel, a pole one, a T-shaped guide rail, a U-shaped frame, an electric cutting line and a transmission device etc., the base plate is L-shaped, the support base is affixed to the base plate, the motor is installed on the support base, the swing bar is fixed on the output shaft of the motor, the swing wheel is rotatably connected to the swing bar, and the pole one is affixed to the base plate. In the present invention, the roller pushes down the pushing device 1 through the contact between the bump 2 and the bump 3, and the pushing device 1 moves upward through the contact between the bump 1 and the universal ball.

Owner:南京固瑞橡胶有限公司

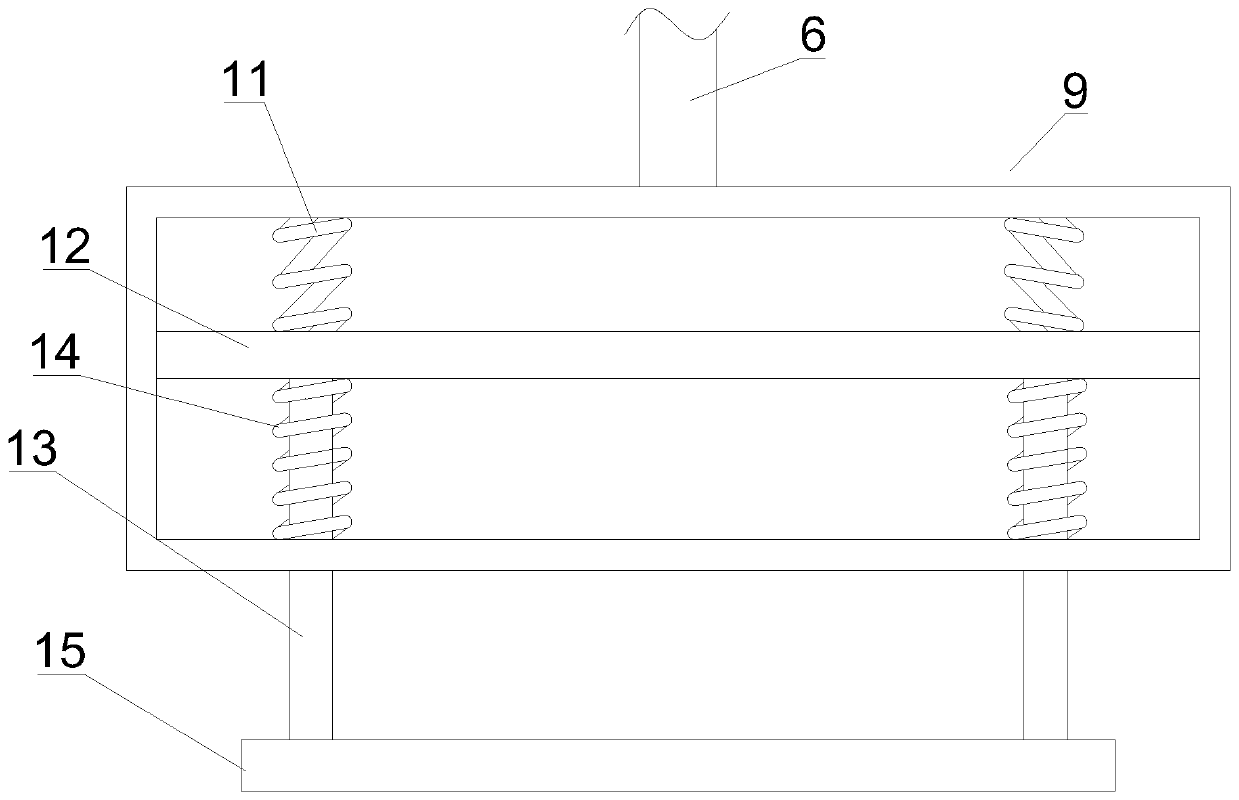

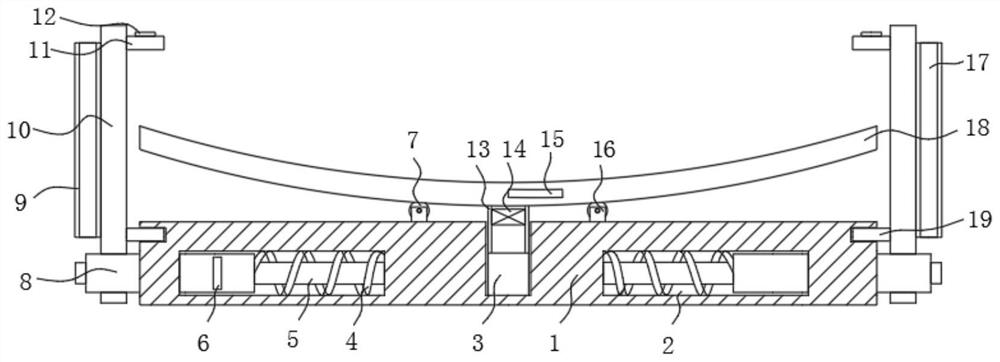

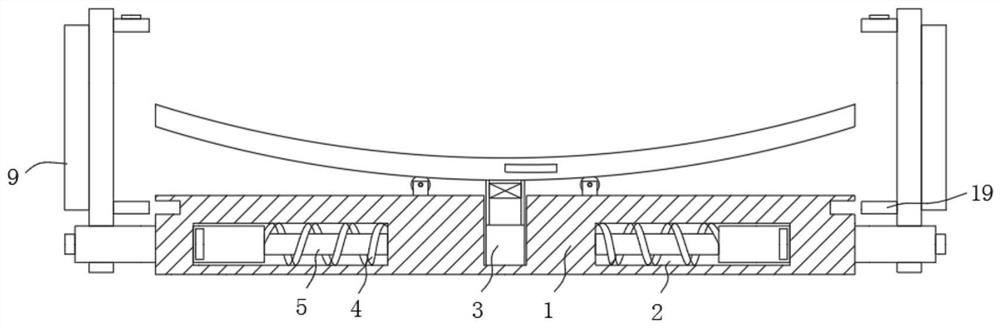

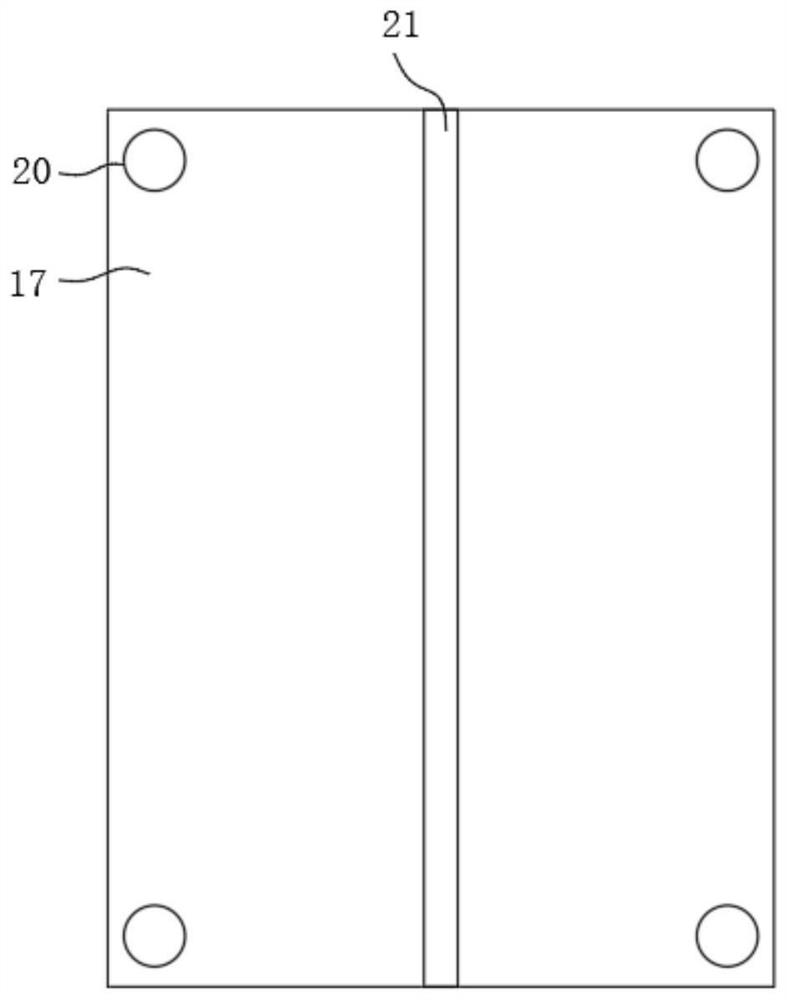

Infant warm-keeping device

ActiveCN112914303APlay a role in keeping warmReduce heat exchangeCarriage/perambulator accessoriesChildren furnitureEngineeringFull Term Infant

The invention discloses a baby warm-keeping device which comprises a trolley plate and a bed plate arranged in an arc shape. A moving assembly capable of enabling the bed plate to slide left and right is arranged on the trolley plate, mounting cavities are symmetrically formed in the trolley plate, movable plates are connected into the mounting cavities through expansion assemblies, protection plates are mounted on the movable plates, a storage assembly and an adsorption assembly are installed on the two side walls of each protection plate correspondingly, an air cavity with an upward opening is formed in the center of the trolley plate, an assembly column is slidably connected into the air cavity, and a sealing corrugated pipe is connected between the bottom end of the assembly column and the bottom side wall of the air cavity. The whole warm-keeping quilt can cover the bed plate so as to cover an infant, so that a warm-keeping effect is achieved, the infant can be automatically wrapped by the quilt, and the situation that the infant wakes up due to the fact that the baby carriage is too narrow and the body of the infant is turned over when the quilt is manually laid is avoided.

Owner:张道明

A kind of lead extension body rotary cutting machine

ActiveCN102935527BFast revolutionGuaranteed to be verticalShearing machinesShearing machine accessoriesPersonal computerHorizontal and vertical

The invention provides a lead delay element rotary cutter which comprises a rotary cutting assembly, a feeding detection mechanism, a horizontal and vertical straightening mechanism, a tensioning device, a linear (or disc type) wire inlet platform and an industrial personal computer which are all arranged on a worktable. A lead delay cord is driven by the feeding detection mechanism which is driven by a stepping motor and straightened by the straightening mechanism, passes a hollow lead delay cord fixing shaft of the rotary cutting assembly and then butts against the rotary cutting position, a high-accuracy coder detects required cutting length information and then sends instructions to rotary cutting blades, a rotary cutting cylinder arranged on the rotary cutting assembly pushes the rotary cutting blades to radially move towards the axis of the lead delay cord fixing shaft to cut off the lead delay cord, and rotary cutting is completed. The radially symmetrically arranged rotary cutting blades and rotary cutting riding wheels simultaneously apply force in the axis direction on the circumference of the lead delay cord, radial thrust in all directions is offset, the section of a cut lead delay element is level and does not deform, U-shaped section cannot be formed, and product scraps are few.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

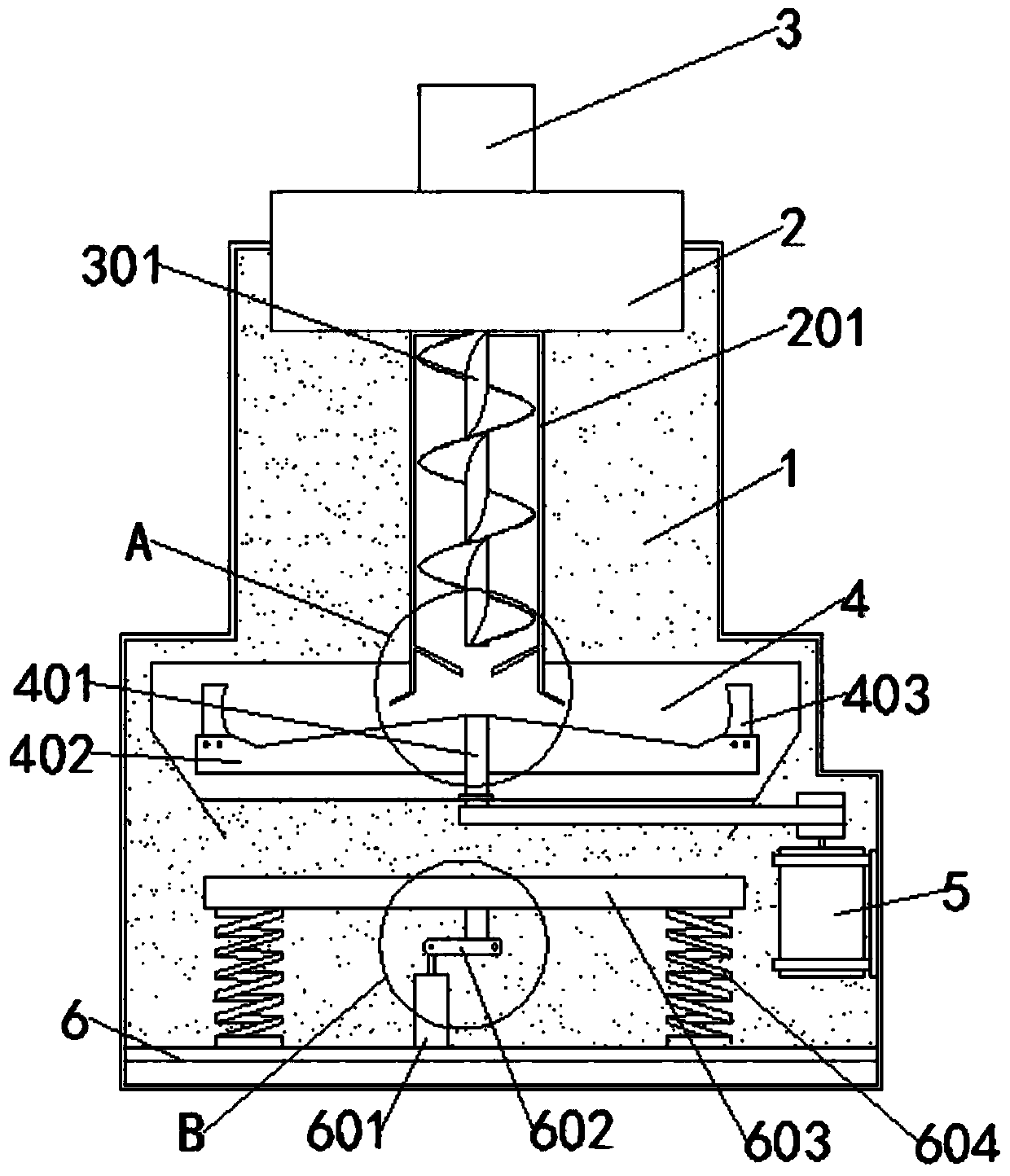

Energy-saving feed processing granulator

InactiveCN109924526APlay the role of cuttingTake advantage ofFeeding-stuffUtilization rateFeed processing

The invention discloses an energy-saving feed processing granulator structurally including a hinge, a ventilating cylinder, a crushing cylinder, a feed inlet, a granulating tray, a dregs outlet, a granulating mechanism, a base, a storage box, a motor base and a motor. The motor and the storage box are arranged on the base side by side, the motor base is also arranged on the bottom of the motor, and the granulating tray is arranged above the storage box vertically; the granulating tray communicates with the storage box, one side of the granulating tray is equipped with the dregs outlet, the other side of the granulating tray is equipped with the ventilating cylinder movably through the hinge, the center of the top surface of the granulating tray is vertically equipped with the crushing cylinder, and one side of the crushing cylinder is fixedly equipped with the feed inlet. With arrangement of the granulating mechanism, a triangular transmission structure, a guide mechanism, secondary transmission mechanism and a push plate, wheat stalks and other materials are made into a feed; with adopting of a linkage mechanical structure, the degree of automation is high; with adopting of a rolling compaction method and blades, the materials are fully utilized, the utilization rate of materials and the production efficiency are improved, and the practicability is enhanced.

Owner:杨舒淞

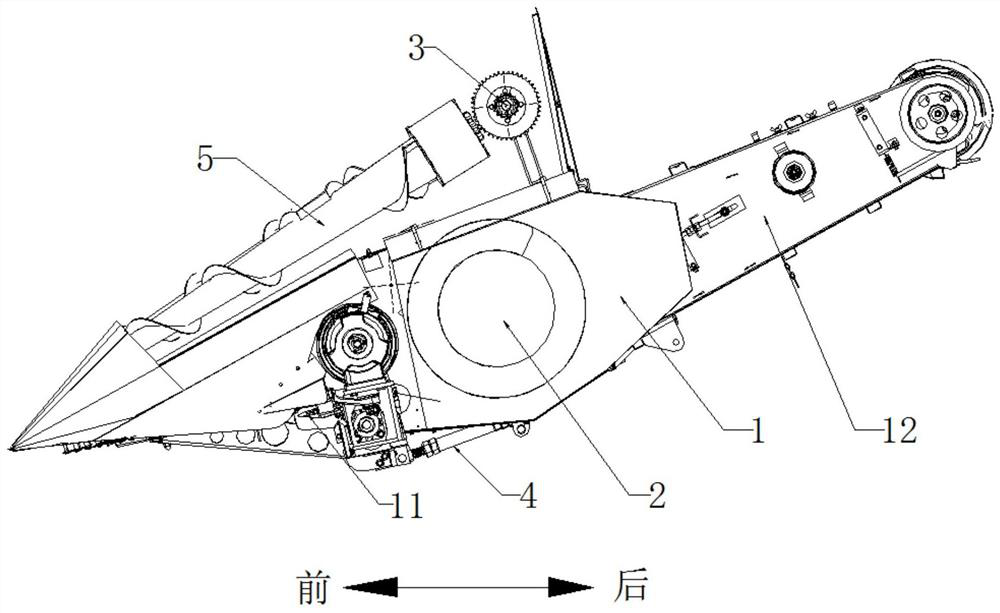

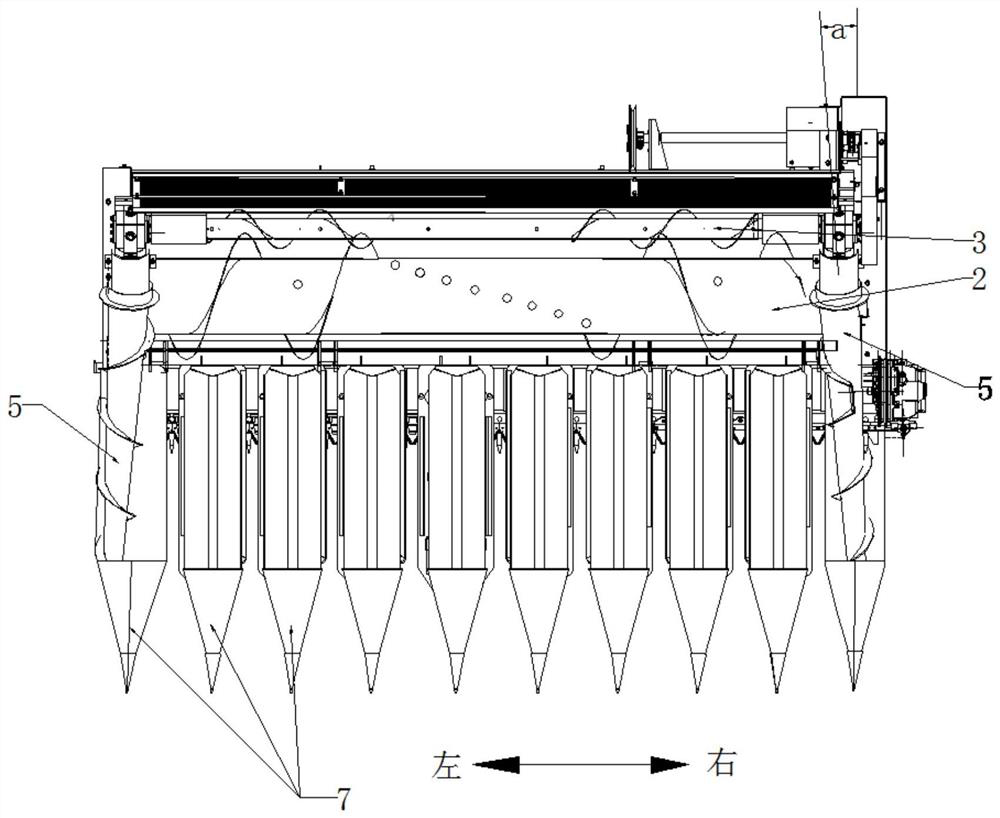

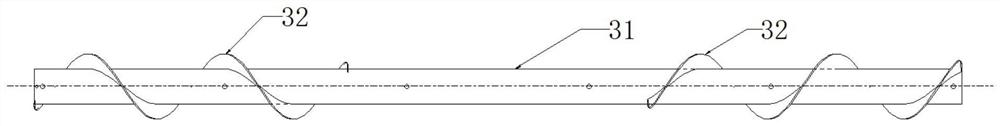

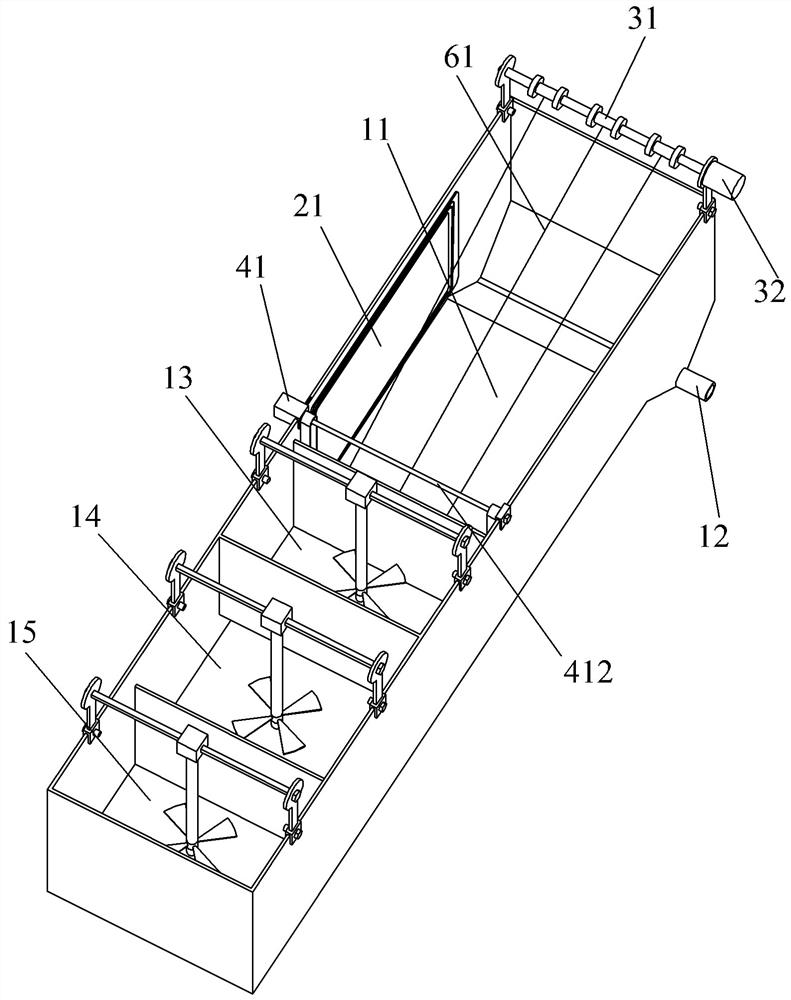

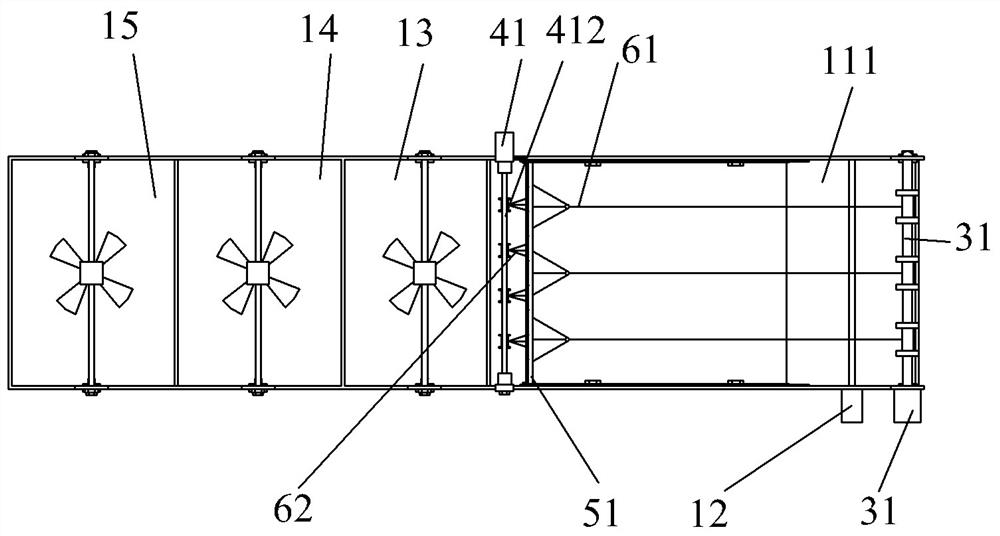

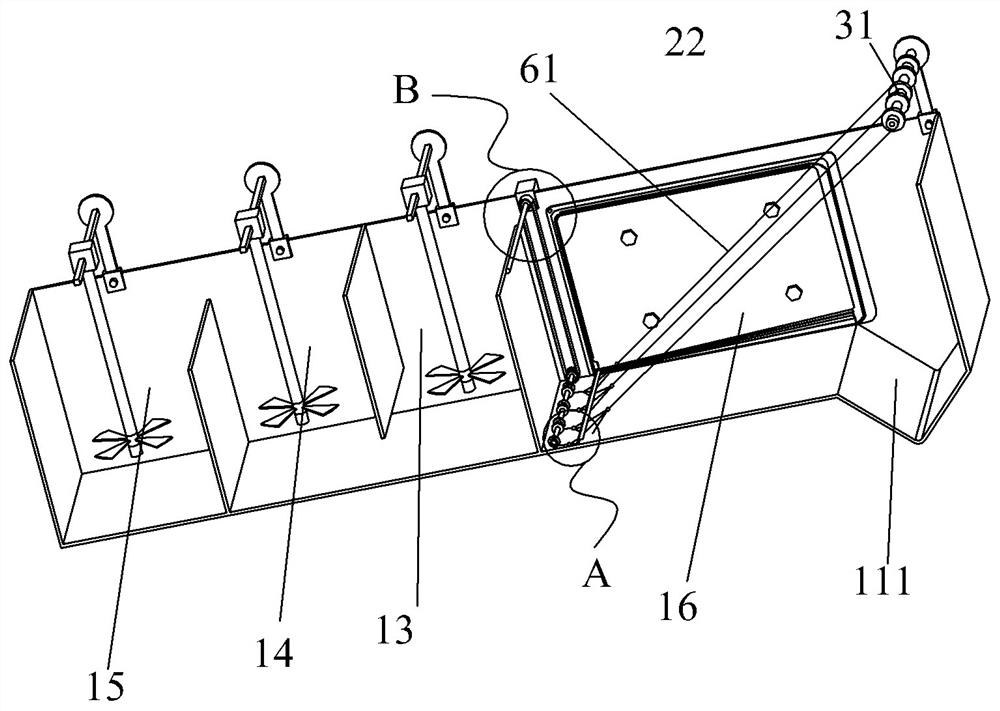

High-stalk crop harvesting header device and harvester

ActiveCN111887011AImprove reliabilityImprove performanceAgricultural lifting devicesHeadersBulrush milletAgricultural engineering

The invention relates to a high-stalk crop harvesting header device and a harvester. The high-stalk crop harvesting header device comprises a header body and a feeding auger, wherein the feeding augeris rotatably mounted at the rear end of the header body, the high-stalk crop harvesting header device further comprises a pushing device, the pushing device is rotatably connected with the rear end of the header body, and is located above the feeding auger. The header device has the beneficial effects that the pushing device is arranged above the feeding auger, the condition that high-stalk cropsare in overlapped connection to the rear wall of the header body can be avoided, the crops can be conveyed downwards to the feeding auger, the problems that when the header harvests the high-stalk crops, stem ears are in overlapped connection to the rear wall of the header and cannot be collected, and ear losses are caused, are solved, and therefore, the harvesting efficiency is improved; and theharvesting loss of the header is effectively reduced. The harvester is good in performance, reasonable in structure, convenient to replace, high in adaptability and high in reliability when being used for harvesting the high-stalk crops, is particularly suitable for high-quality and high-efficiency harvesting of sorghum, quinoa, millet and other crops, and fills the market blank.

Owner:LOVOL HEAVY IND

A kind of cable recovery equipment

ActiveCN112222031BAvoid displacementRemoval job went wellCleaning using toolsCleaning using liquidsWater sourceElectrical connection

The present invention relates to the field of cable cleaning devices, in particular to a cable recycling device, which includes a base and a vertical plate, and also includes a controller, a scraping mechanism, a flushing mechanism and a conveying mechanism. The scraping mechanism includes a scraping head, a push assembly and a side pressure assembly , the flushing mechanism includes a water supply tank, a conveying assembly and a spray washing assembly, the conveying mechanism includes a first set of rollers, a second set of rollers and a rotating assembly, the rotating assembly is arranged on the back of the stand, the first set of rollers and the second The sets of rollers are arranged symmetrically on the outer wall of the vertical plate, the first set of rollers is socketed with the rotating assembly, the second set of rollers is rotatably connected with the vertical plate, the pushing assembly, the conveying assembly and the rotating assembly are connected with the controller For electrical connection, the present invention and a cable recovery device can effectively fix the cable, prevent its displacement, scrape more thoroughly, and have higher efficiency. At the same time, impurities can be discharged in time to prevent pollution of the cleaning water source, and it is beneficial to cleaning Sewage recycling.

Owner:砀山红旗电缆有限公司

Automatic medicine smashing device for traditional Chinese medicine materials

ActiveCN108672070APlay the role of interceptionAvoid cloggingCleaning using liquidsGrain treatmentsEngineeringTraditional Chinese medicine

The invention provides an automatic medicine smashing device for traditional Chinese medicine materials. The automatic medicine smashing device comprises a working plate, connecting discs, supportingcolumns, antiskid feet, an installing base, a smashing shell, a fastening thread rod, a fastening nut, a motor, a feeding hopper structure, a washing box structure, a protecting cover structure, an intercepting cover structure and a discharging head. The connecting discs are welded to the left side and the right side of the lower surface of the working plate correspondingly, and meanwhile the supporting columns are welded to the lower ends. The lower portions of the outer walls of the supporting columns are sleeved with the antiskid feet. The smashing shell is installed on the longitudinal middle portion of the upper surface of the working plate. The fastening thread rod is in shaft connection with the left side of the front surface of the smashing shell, and meanwhile the fastening nut isconnected to the right side in a thread manner. The motor is installed on the left surface of the smashing shell. According to the automatic medicine smashing device, by means of arrangement of the feeding hopper structure, when Chinese herbal medicine is placed, the automatic medicine smashing device can have a function of intercepting the large Chinese herbal medicine beneficially, and then theproblem that the automatic smashing device is blocked by the overlarge Chinese herbal medicine is avoided.

Owner:北京俊苗山民族医学研究院

A sewage magnetic loading clarification process and its system

ActiveCN112110528BReduce disturbancePrevent leakageWater/sewage treatment by magnetic/electric fieldsFlocculationCurrent limiting

The invention relates to a sewage magnetic loading clarification process and system, comprising a floc generation unit, a nucleation unit, a magnetic floc generation unit and a precipitation unit. Wherein, the sedimentation unit includes a sedimentation tank, and the two side walls of the sedimentation tank are provided with a first limiting groove, a second limiting groove, a third limiting groove, a fourth limiting groove, a fifth limiting groove and a mud scraper Guide groove. The mud scraping device includes a first mud scraper, a second mud scraper and a flow restrictor. Since the first guide column and the second guide post on the flow restrictor slide along the guide groove of the mud scraper, the inclination of the flow restrictor The angle is always the direction of its displacement track, which greatly reduces the disturbance of the restrictor plate to the sedimentation tank. And because the flow restrictor is connected with the upper end of the most mud scraper, so that after the mud scraping device finishes scraping, the flow restrictor is folded down to be parallel to the second mud scraper, which can reduce the lifting and lowering of the mud scraper. Disturbance of the sludge in the sedimentation tank during the process.

Owner:JIANGSU QICHUANG ENVIRONMENTAL SCI & TECH

A rope coring drill

The invention discloses a rope core taking drill which comprises an outer pipe assembly and an inner pipe assembly. A reamer (23) is arranged in the outer wall assembly, and an inner pipe (14) and a third layer core pipe (15) are arranged in the inner pipe assembly. The rope core taking drill is characterized in that the lower end of the reamer (23) in the outer pipe assembly is connected with an external connector (16), and the lower end of the external connector (16) is connected with an external drill head (19). The lower end of the inner pipe (14) of the inner pipe assembly is connected with an inner drill head (20), and the inner drill head (20) protrudes forwards relative to the external drill head (19). The inner drill head is inserted into the outer drill head in a spline mode, and the inner drill head can be fished out together with the inner pipe, a clamping spring seat (18) and a clamping spring are arranged at the lower portion of the inner side of the third layer core pipe (15), and a blocking spring (17) is arranged on the outer side of the third layer core pipe (15). Regarding complex formation of fracture development, hard brittle fracture, soft and hard interbedding and the like, the drill has the advantages of prolonging the service life to the largest extent, increasing drill lifting intervals, improving the core recovery rate and the like.

Owner:李国民 +1

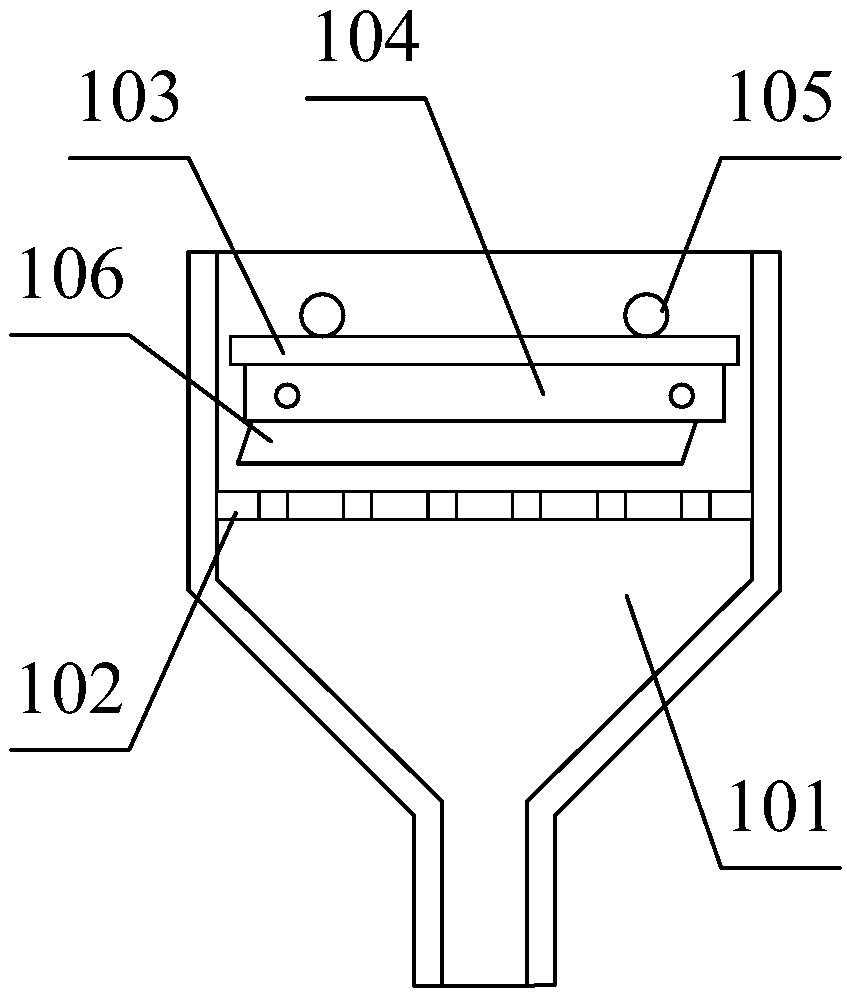

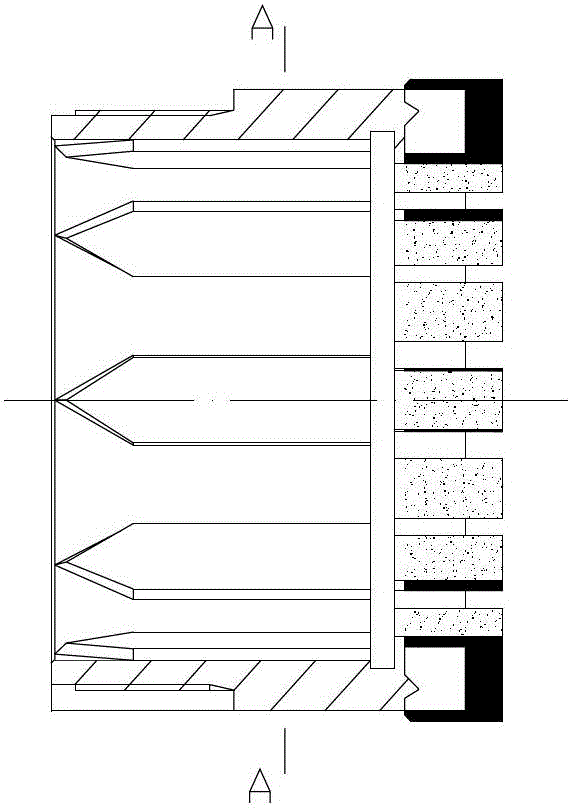

Medical drug intermediate rapid grinding and screening integrated machine equipment

InactiveCN113042174AGuaranteed size consistencyImprove reaction efficiencyGrain treatmentsStructural engineeringMechanical engineering

The invention discloses medical drug intermediate rapid grinding and screening integrated machine equipment, and relates to the technical field of drug intermediate rapid grinding and screening. The equipment aims to solve the problem about medical intermediate screening. The equipment specifically comprises a body box, discharging openings are formed in the outer walls of the two sides of the bottom of the body box correspondingly, a box door is fixed to the outer wall of the front face of the body box through hinges, a handle is arranged on the outer wall of one side of the front face of the box door, bottom plates are arranged on the outer walls of the two sides of the body box correspondingly, and grinding mechanisms are arranged on the outer walls of the tops of the two bottom plates. Guide grooves are formed in the outer walls of the tops of the two bottom plates, discharging holes are formed in the outer walls of the tops of the two guide grooves, partition plates are arranged on the inner walls of the two sides of the bottom of the body box correspondingly, a fixing seat is arranged on the inner wall of the bottom, close to the position between the two partition plates, of the body box, and a screening mechanism is arranged on one side of the fixing seat. According to the equipment, the size consistency of discharged medical intermediates is ensured, and the subsequent reaction efficiency of the medical intermediates is improved.

Owner:景淑英

Modeling lawn shears

The invention relates to a gardening tool, in particular to a pair of modeling lawn shears. A fixed handle is connected with a work box, the fixed handle is connected with a cutting handle in a riveting mode through a rivet, the tail end of the cutting handle is fixedly connected with a steering block, the steering block is connected with a blade, the blade is located in the work box, the blade is arranged in the horizontal direction, a blade stop wall is arranged in the work box, and a mould is located in the work box and under the blade.

Owner:江苏麦格美节能科技有限公司

Cutter harvesting structure for vegetable harvesting machine

PendingCN106576573AEasy to harvestPlay the role of cuttingMowersAgricultural engineeringAgricultural machinery

The invention provides a cutter harvesting structure for a vegetable harvesting machine, and belongs to the technical field of agricultural machinery. The cutter harvesting structure for the vegetable harvesting machine comprises a machine frame, a cutter combination and a transmission mechanism; the machine frame comprises a first shell and a second shell which are arranged oppositely; the two ends of the cutter combination are respectively connected with the first shell and the second shell; the cutter combination is driven to work through the transmission mechanism; the cutter combination comprises a first cutter, a second cutter and a third cutter which are arranged in a stacking manner; saw teeth are formed on the adjacent sides of the first cutter and the second cutter; the first cutter is fixedly connected with the first shell and the second cutter; the second cutter is movably connected with the first shell and the second shell; the second cutter is movably connected with the first shell and the second shell. The device can knock clods on vegetables, so that the harvested vegetables are cleaner.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com