Tea seed shelling device with centrifugal collision-type cutting deflection screening classification

A technology for screening and sorting tea and fruit, applied in the direction of shelling, grading, pod removal, etc., can solve the problems of slow production progress, low efficiency, insufficient drying process, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

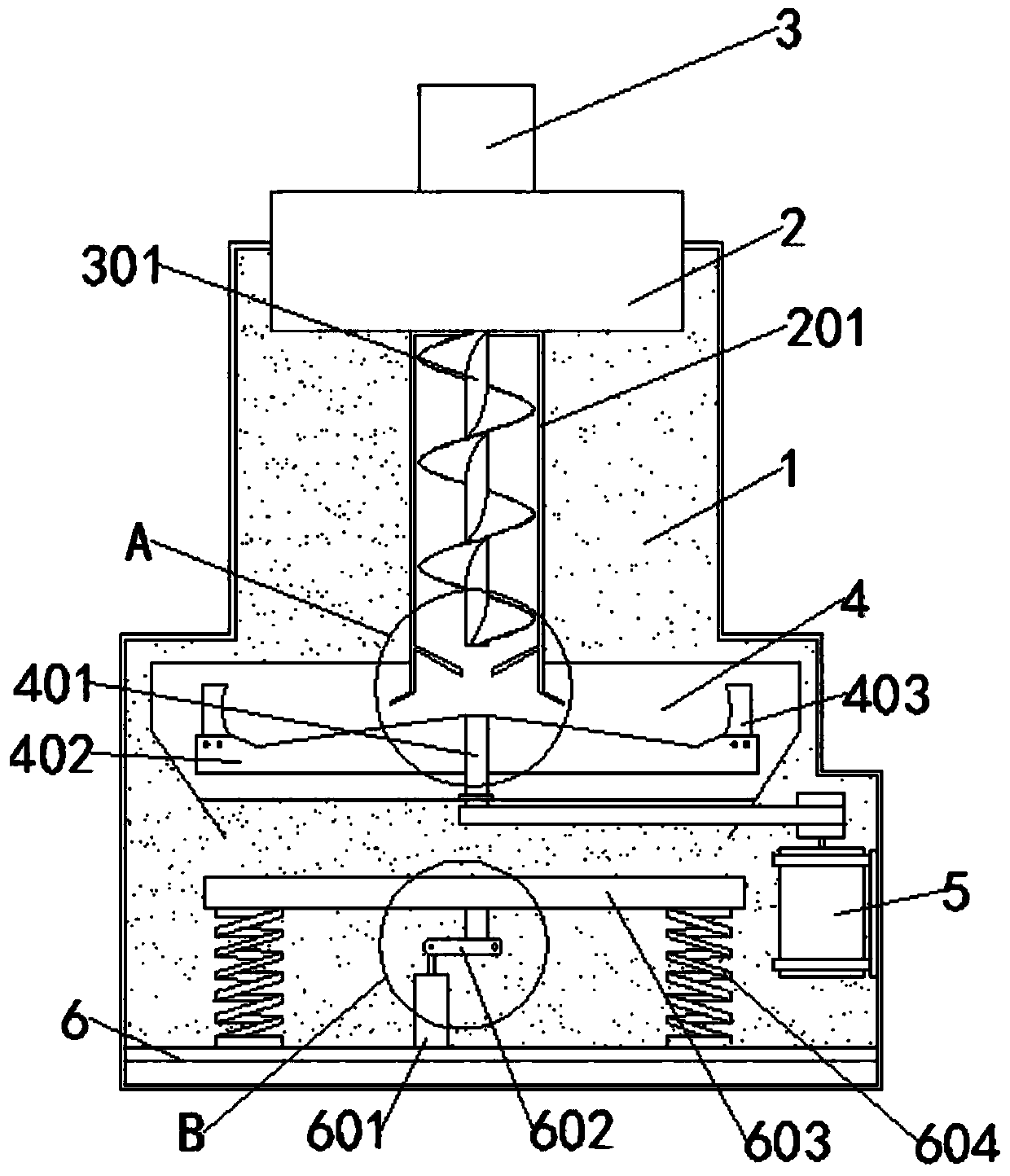

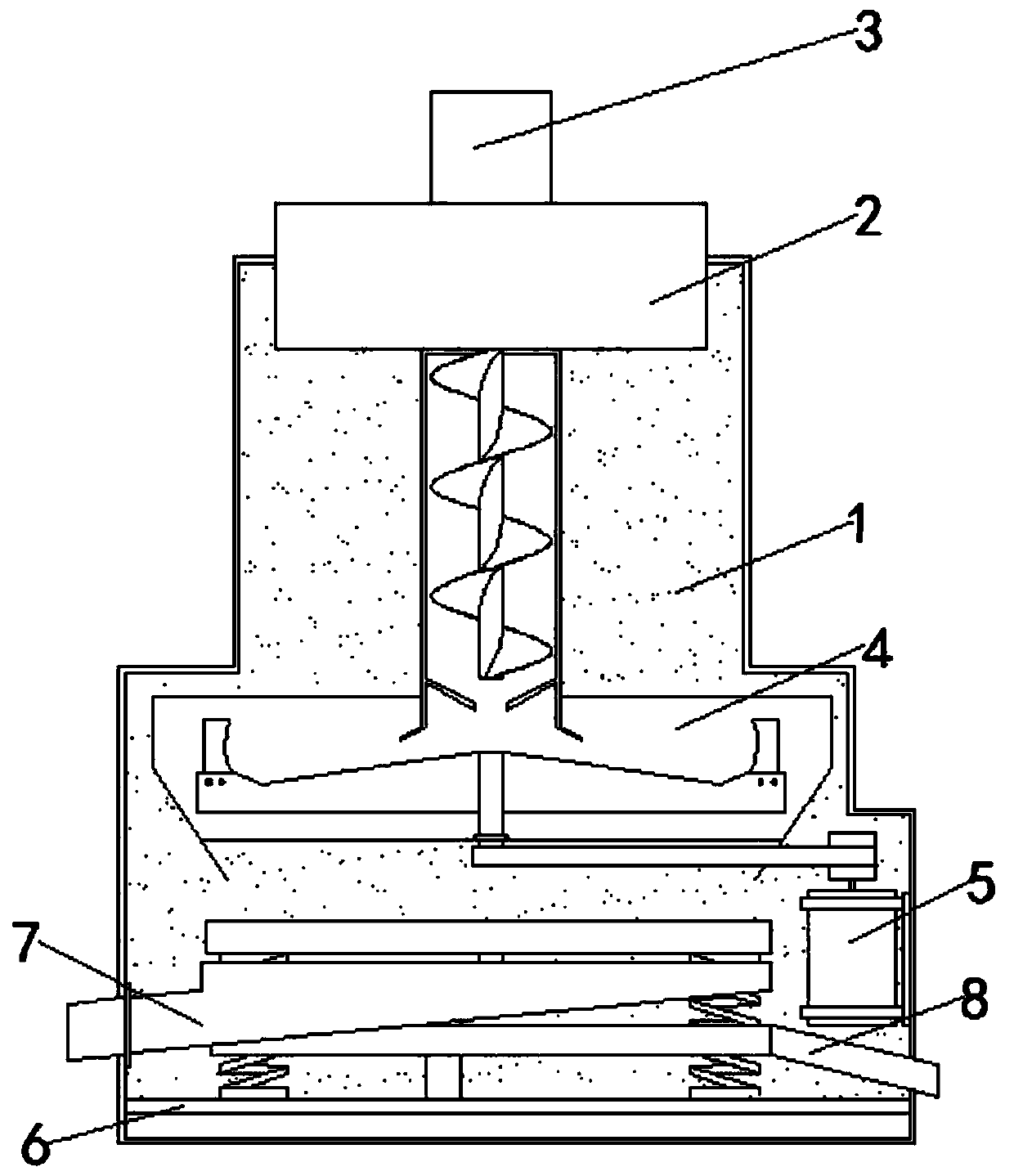

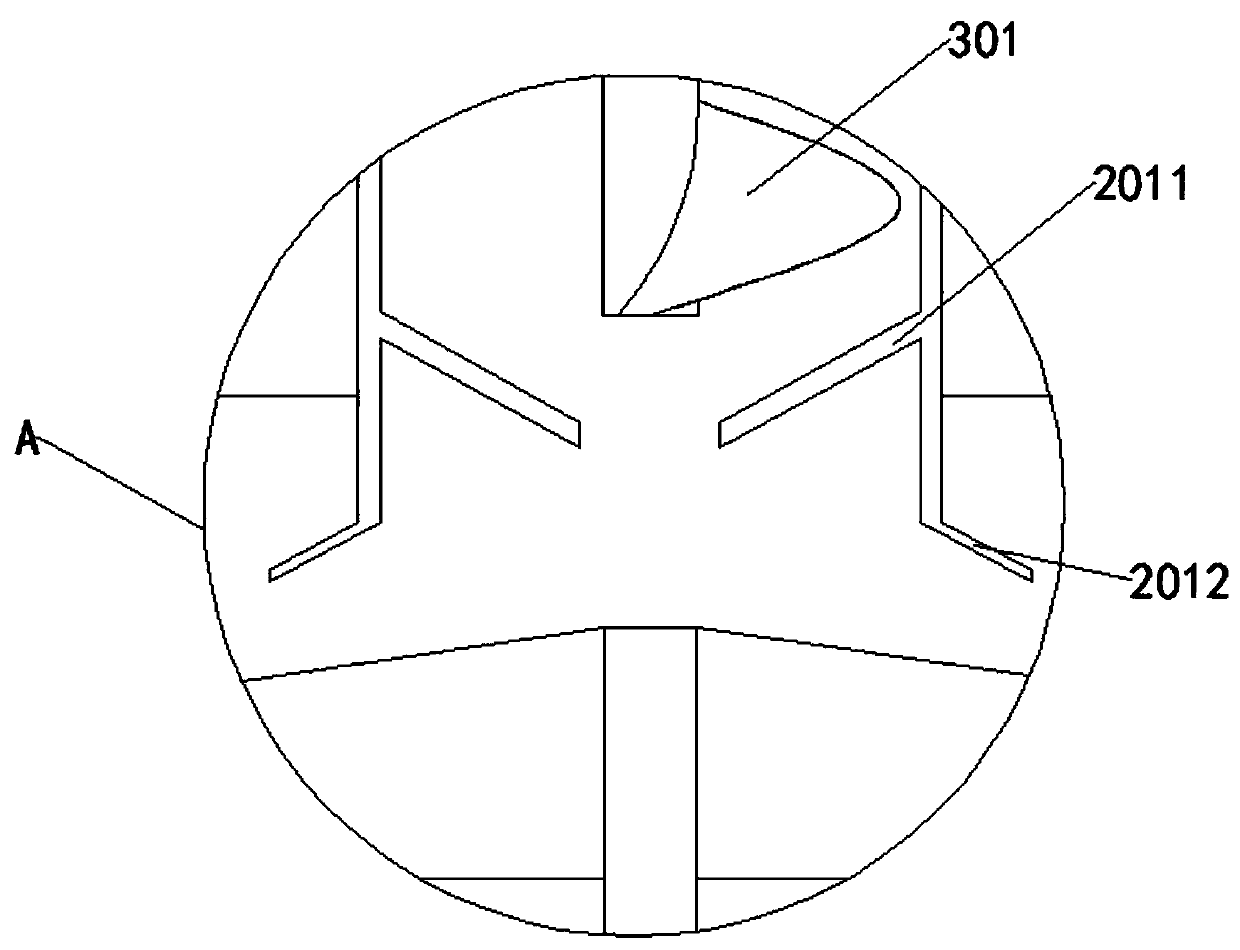

[0029] see Figures 1 to 7 , in an embodiment of the present invention, a tea fruit shelling device for centrifugal collision type cutting, deflection, screening and classification, comprising a device casing 1, a material barrel 2, a feeding tube 201, a guide plate 2011, a guide plate 2 2012, a motor 3, and a spiral tube 301, cutter shell 4, shaft column 401, limit plate 402, blade 403, solid pipe 404, motor two 5, base 6, motor three 601, deflection frame 602, loading plate 603, through hole 6031, scribe 6032 , spring 604, finished product discharge chute 7 and waste material discharge chute 8, the top surface of the device shell 1 is nested with a material barrel 2, and the middle of the bottom of the material barrel 2 is provided with a feed pipe 201, and the feed pipe 201 is located in the device shell 1 Inside, the inner side of the bottom of the feeding tube 201 is fixedly connected with a guide plate 2011, the outer side of the bottom of the feeding tube 201 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com