Multifunctional ball body mixer

A multi-functional, mixer technology, applied in mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of unsatisfactory mixing effect and mixing efficiency, and achieve the effect of remarkable mixing effect and avoidance of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The main technical features of the patent of the present invention are: a motor (2) is installed under the frame (1) as a power output, the motor (2) and the main shaft (3) are connected by a belt, and after the power is transmitted to the main shaft (3), Then it is transmitted to the intermediate transmission device (8) through the clutch device (7) at the other end of the main shaft (3). The spherical shell (4) adopts a spherical crown-shaped discharge gate, which avoids the residue of materials during discharge.

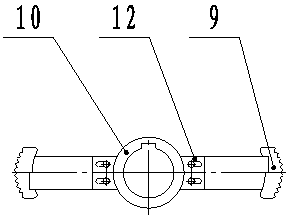

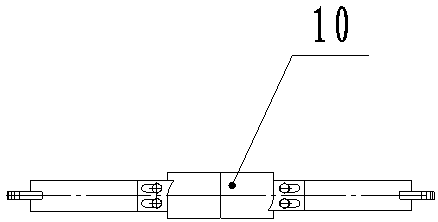

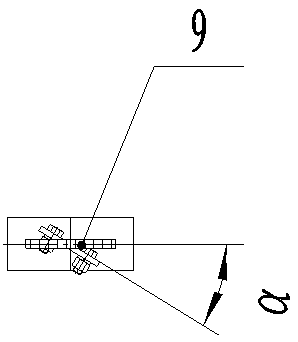

[0020] The main shaft (3) is fixed on the frame (1) through the bearing seat, and 7 sets of stirring devices (6) with toothed blades (9) are installed on the main shaft (3), and the stirring device (6) rests on the spacer sleeve (11 ) is fixed on the main shaft (3), the stirring device (6) is composed of a shaft sleeve (10), a support plate (12), and a toothed blade (9), and the shaft sleeve (10) and the support plate (12) are welded into one, Adjustable e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com