Patents

Literature

47results about How to "Play a crushing role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

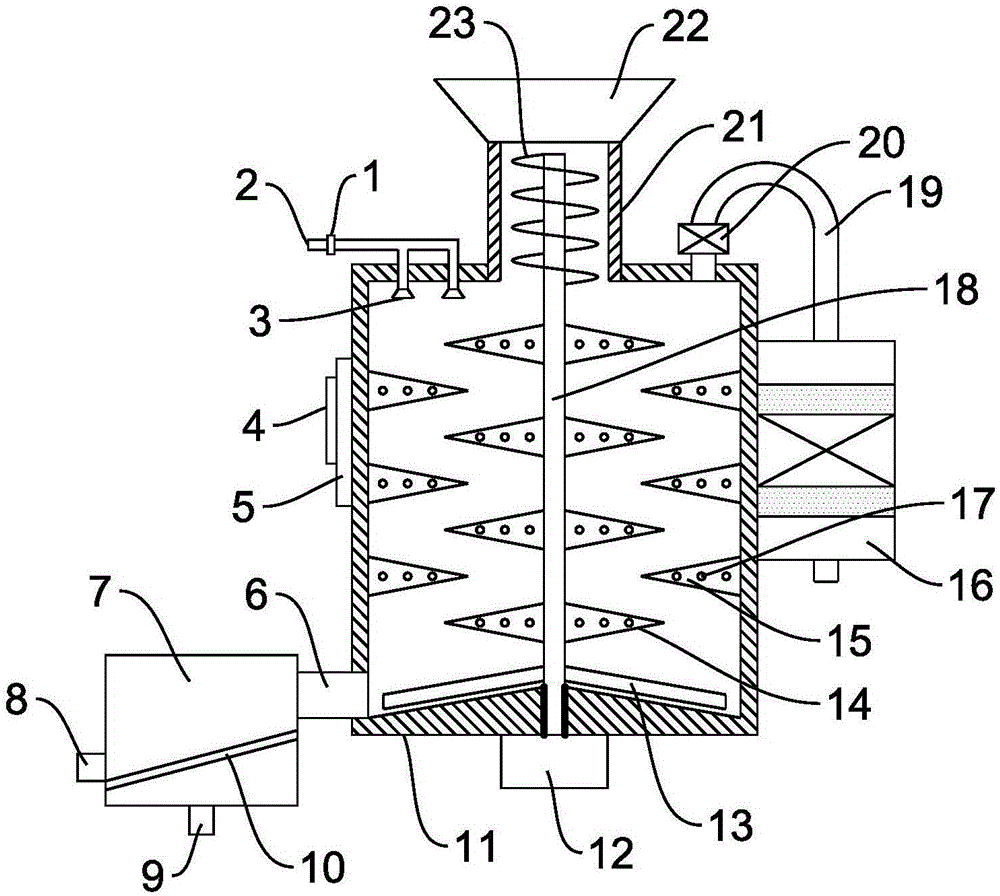

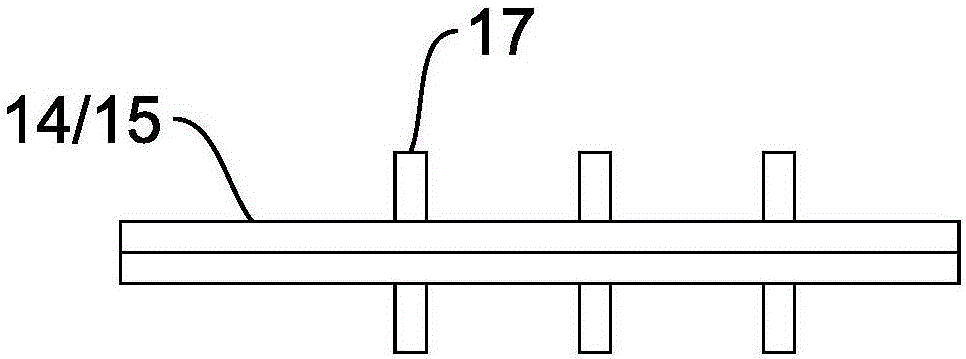

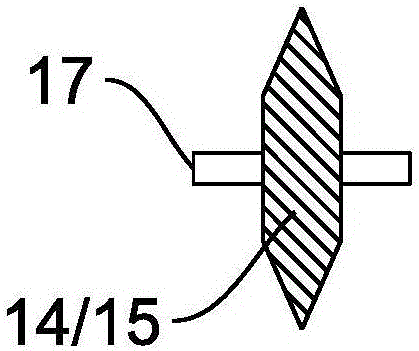

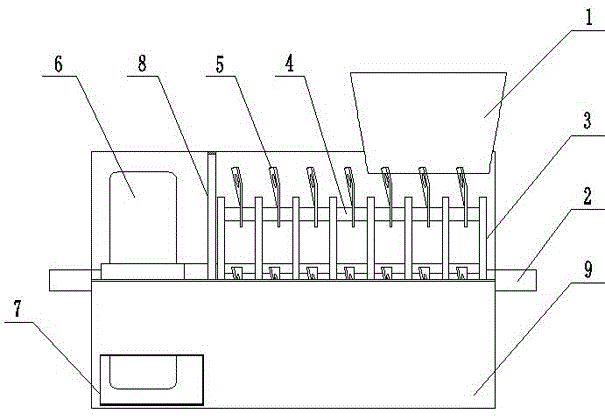

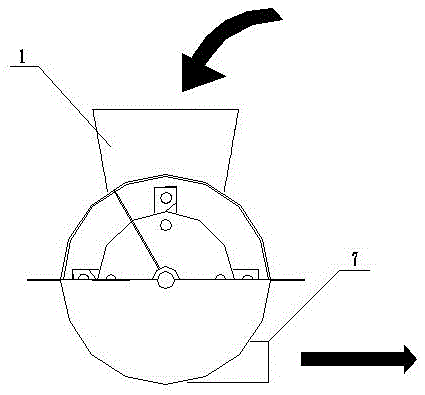

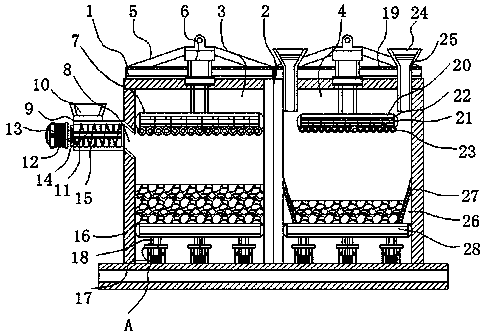

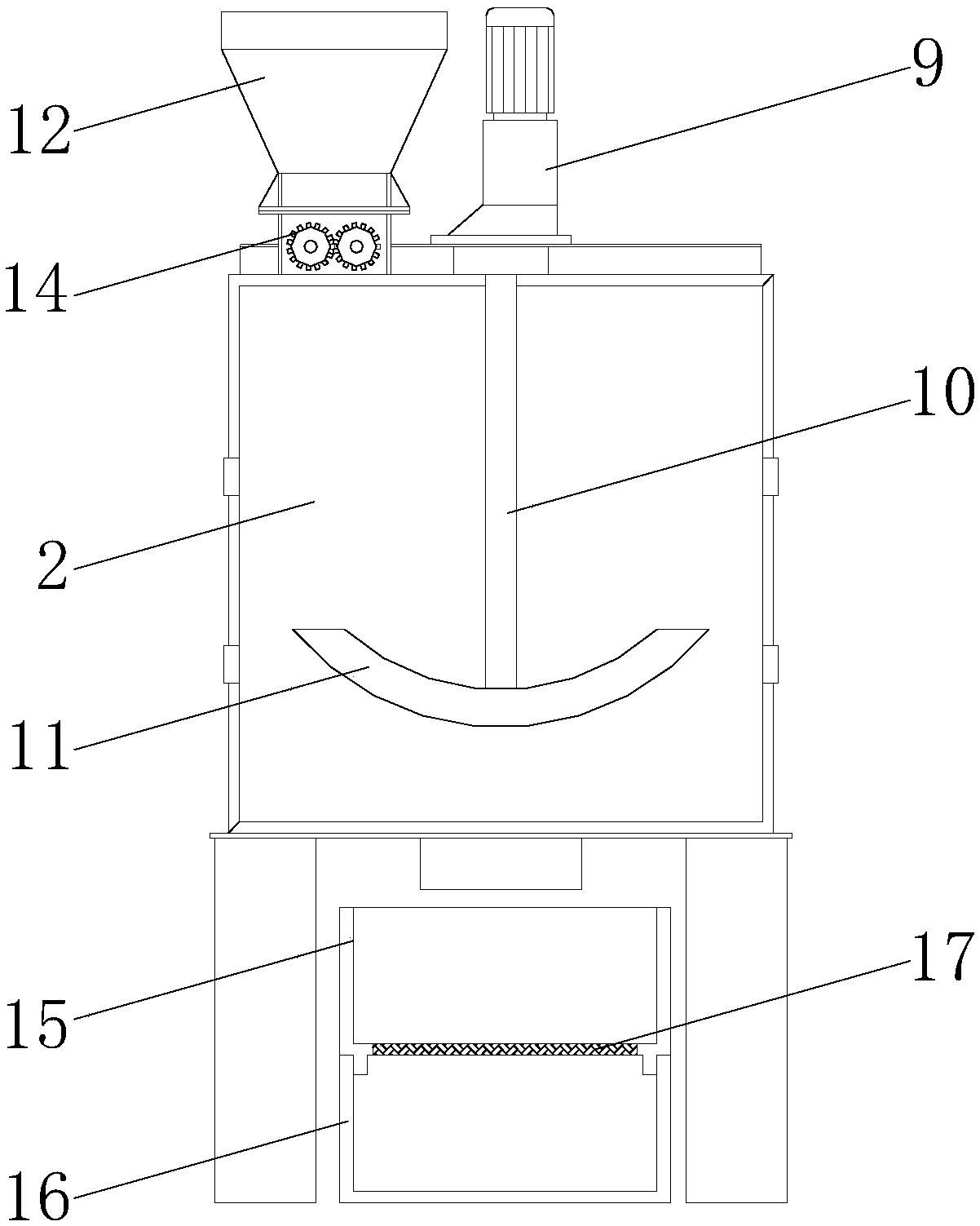

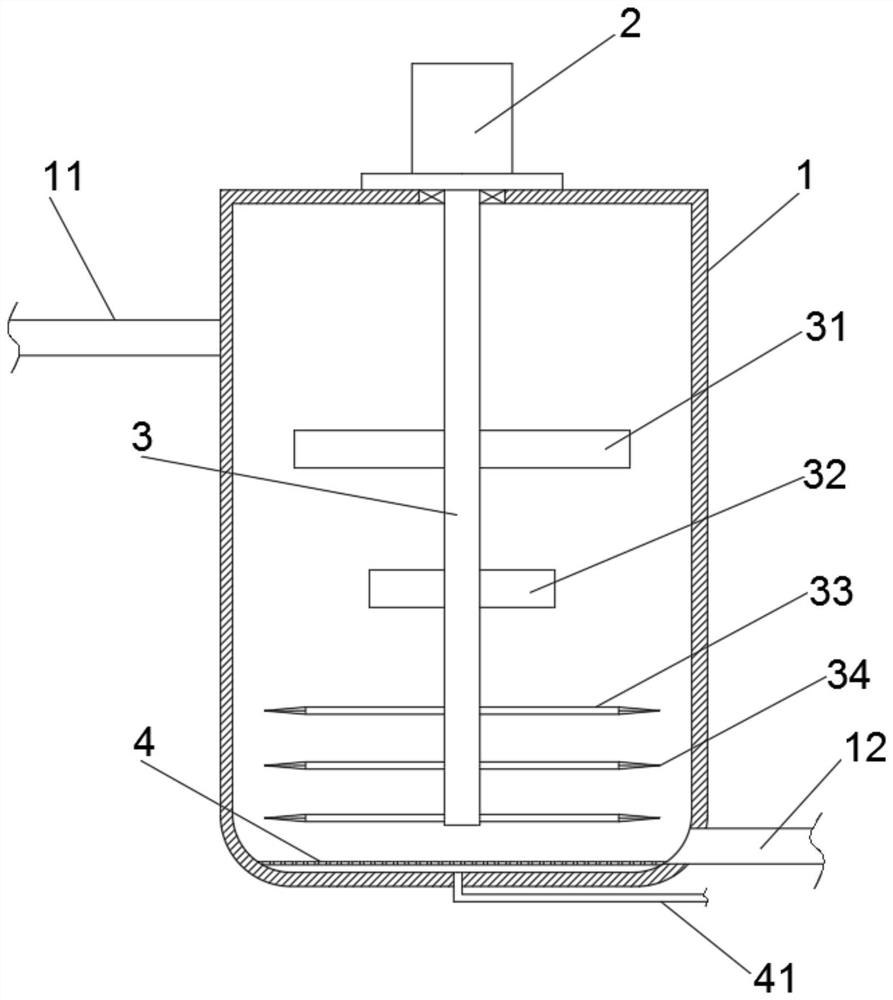

Garbage harmless and environment-friendly machining processing device

The invention discloses a garbage harmless and environment-friendly machining processing device which comprises a machine body. A material guide barrel is arranged in the middle of the top of the machine body in a through manner, a hopper is arranged at the upper end of the material guide barrel in a through manner, a center shaft is arranged at the middle portion of the inner side of the machine body, and a driving motor connected with the center shaft is further arranged at the bottom of the outer side of the machine body; a material pushing plate is arranged at the position, located on the center shaft, of the bottom of the interior of the machine body, a plurality of rotation cutter plates are arranged at the positions, located on the center shaft, of the inner side of the machine body, a plurality of fixed cutter plates arranged with the rotation cutter plates in a staggered manner are arranged on the inner wall of the machine body, and spiral blades are arranged at the positions, located on the center shaft, of the inner side of the material guide barrel; and a material discharging pipe is arranged at the bottom of the left side of the machine body, and the other end of the material discharging pipe is connected to the upper portion of the side face of a garbage storage box. By means of the garbage harmless and environment-friendly machining processing device, garbage can be rapidly smashed and processed, dust and peculiar smells in work are reduced, and popularization is facilitated.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Method for extracting astaxanthin in haematococcus pluvialis by adopting enzymolysis method and grinding method through organic solvent

The invention relates to a method for extracting astaxanthin in haematococcus pluvialis by adopting an enzymolysis method and a grinding method through an organic solvent, belonging to the field of algal pigment extraction technology. The enzymolysis time for extracting astaxanthin by adopting the existing enzymolysis method is generally more than 15 hours, and the whole extraction process only needs 3-6 hours by adopting the method through assisting the extraction of the organic solvent while grinding in the enzymolysis process, so that the time can be shortened by 57-78%, and the time cost can be greatly saved. The method comprises the steps of carrying out enzymolysis by adopting pectinase, wherein the enzymolysis pH value is 4.0-6.0; firstly drying the enzymolysis liquid, and then extracting with ethyl acetate. The extraction rate can achieve more than 97% by matching pectinase enzymolysis with specific grinding conditions as well as specific organic solvent extraction, and the purity of the obtained astaxanthin product can achieve more than 16.9%, namely that the extraction rate and purity of the astaxanthin can be further improved under the condition of greatly shortening the extraction time.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

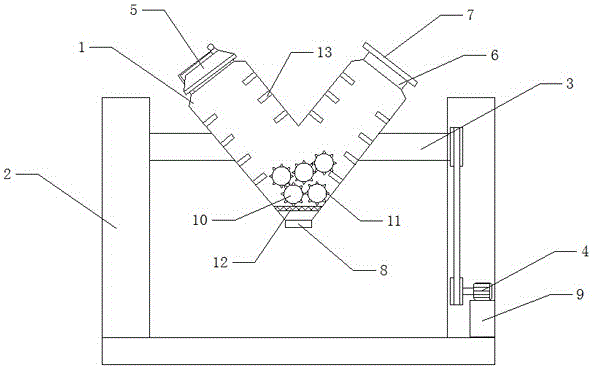

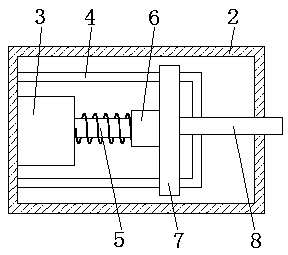

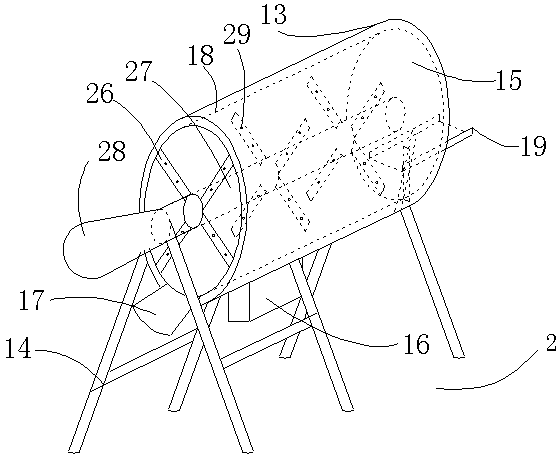

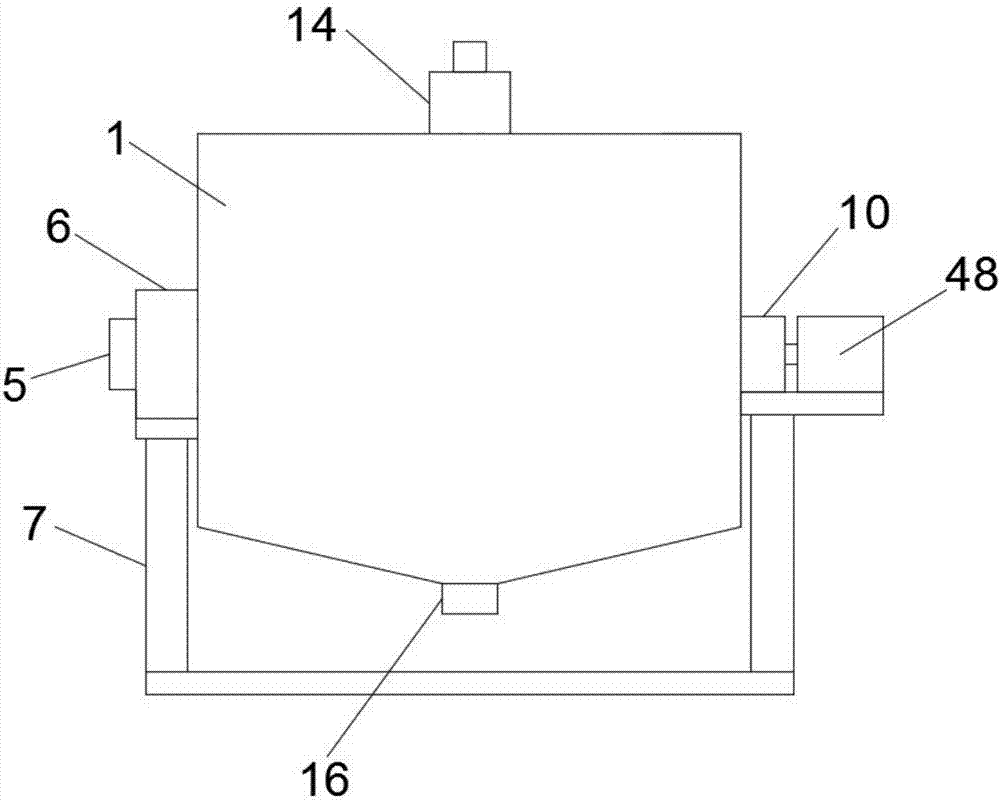

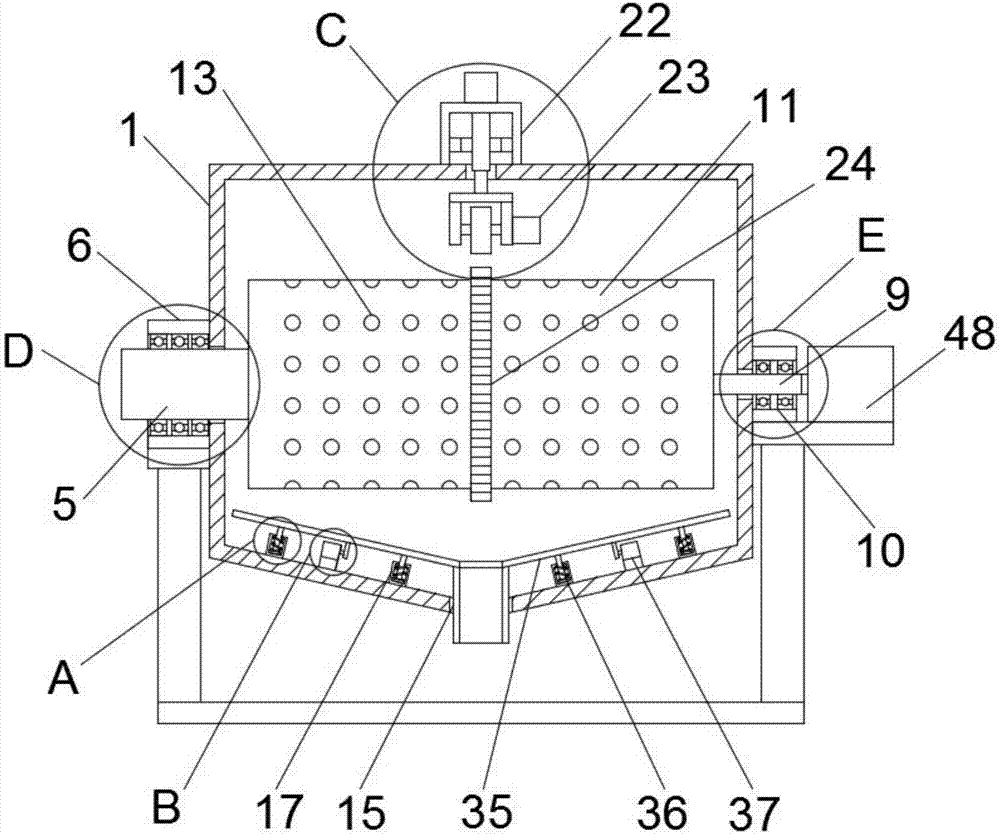

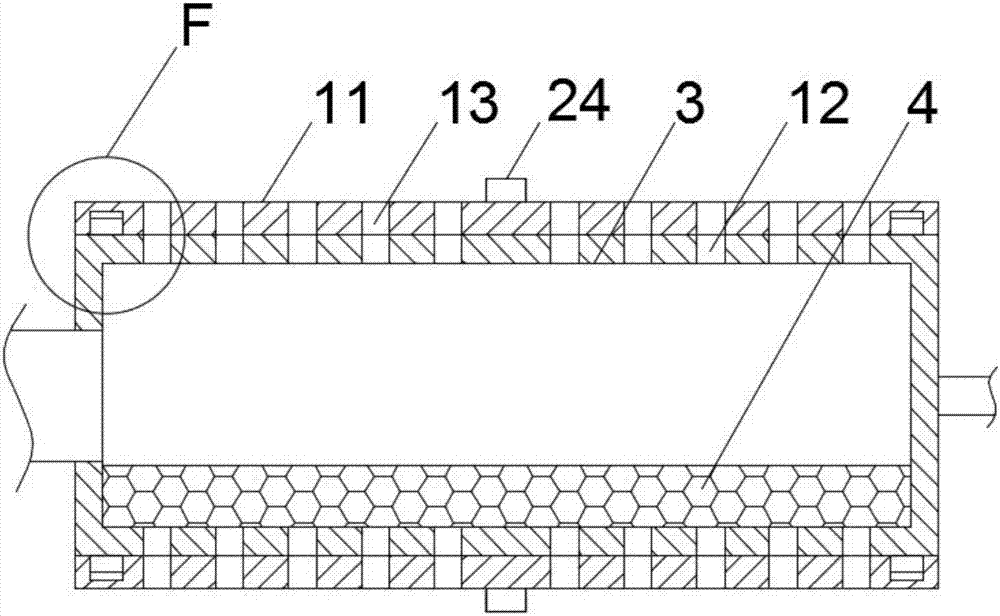

Efficient V-shaped mixer

InactiveCN105032255AReduce weightPlay a crushing roleRotating receptacle mixersTransportation and packagingMotor driveArchitectural engineering

The invention provides an efficient V-shaped mixer, comprising a V-shaped mixing drum, a base, a rotary shaft and a motor, wherein the V-shaped mixing drum is formed by butting two cylinders, the top of one cylinder is provided with a vacuum pump, the top of the other cylinder is provided with a feeding hole and a feeding cover, the bottom of the V-shaped mixing drum is provided with a discharge hole, the V-shaped mixing drum is rotationally connected with the base by means of the rotary shaft, the motor drives the V-shaped mixing drum to rotate, a bumper is mounted on the motor, mixing balls are arranged in the V-shaped mixing drum, the diameter of each mixing ball is smaller than that of the feeding hole, the mixing ball is a hollow sphere, multiple bulges are uniformly distributed on the surface of the mixing ball, the inner wall of the V-shaped mixing drum is provided with a plurality of friction rods, and the bottom of the V-shaped mixing drum is provided with a filter net. The efficient V-shaped mixer is uniform in mixing, meanwhile has a certain smashing function on materials, can prevent the materials from caking, and runs stably.

Owner:范昕昀

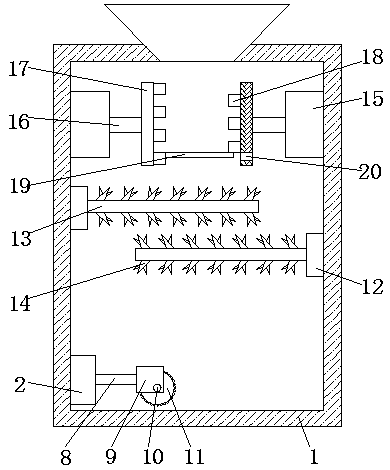

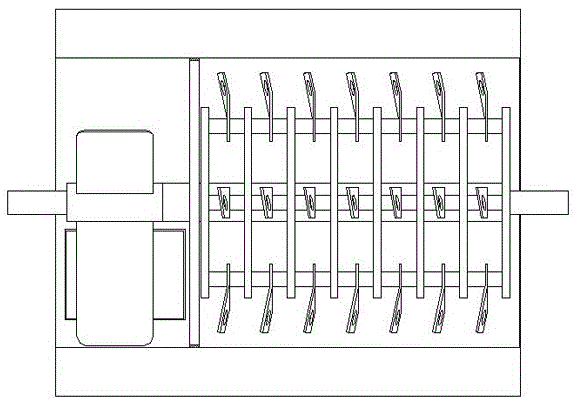

High-efficiency crushing machine for pharmacy

The invention discloses a high-efficiency crushing machine for pharmacy. The high-efficiency crushing machine comprises a machine body, the inner wall of the left side of the machine body is fixedly connected with a power box, the inner wall of the left side of the power box is fixedly connected with a stepper motor, the inner wall of the left side of the power box is fixedly connected with two limiting rods which are disposed on two sides of the stepper motor and are symmetric to each other, and an output end of the right side of the stepper motor is fixedly connected with a screw rod. The high-efficiency crushing machine is provided with an electric hydraulic propeller, an installation plate and an extruding block, thereby playing a role in extruding the medicine, and achieving an effectfor facilitating the subsequent crushing operation; and by arranging an asynchronous motor, a rotating rod and a crushing cutter blade, an effect for crushing the extruded medicine can be realized, the overall processing efficiency can be improved by adopting the two steps, i.e., the extruding step and the crushing step, the processing quality of the extruding step and the crushing step is also improved, and the efficiency is improved, and the quality is improved.

Owner:肖叶

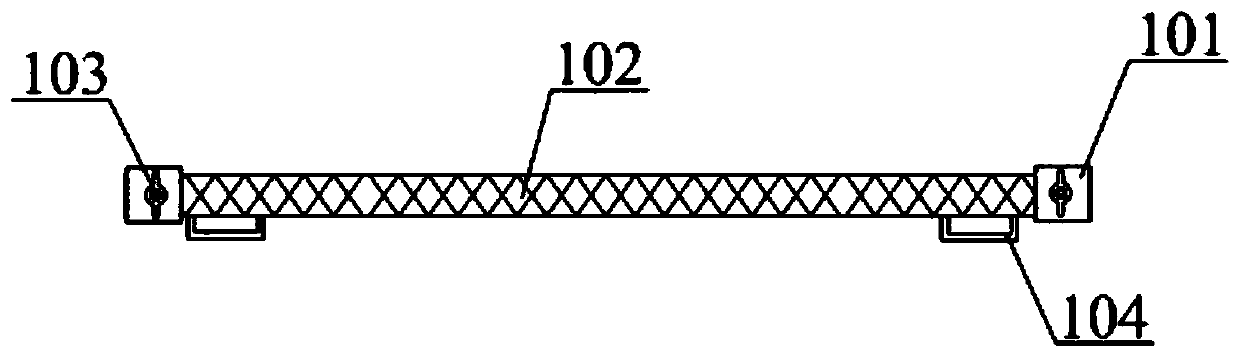

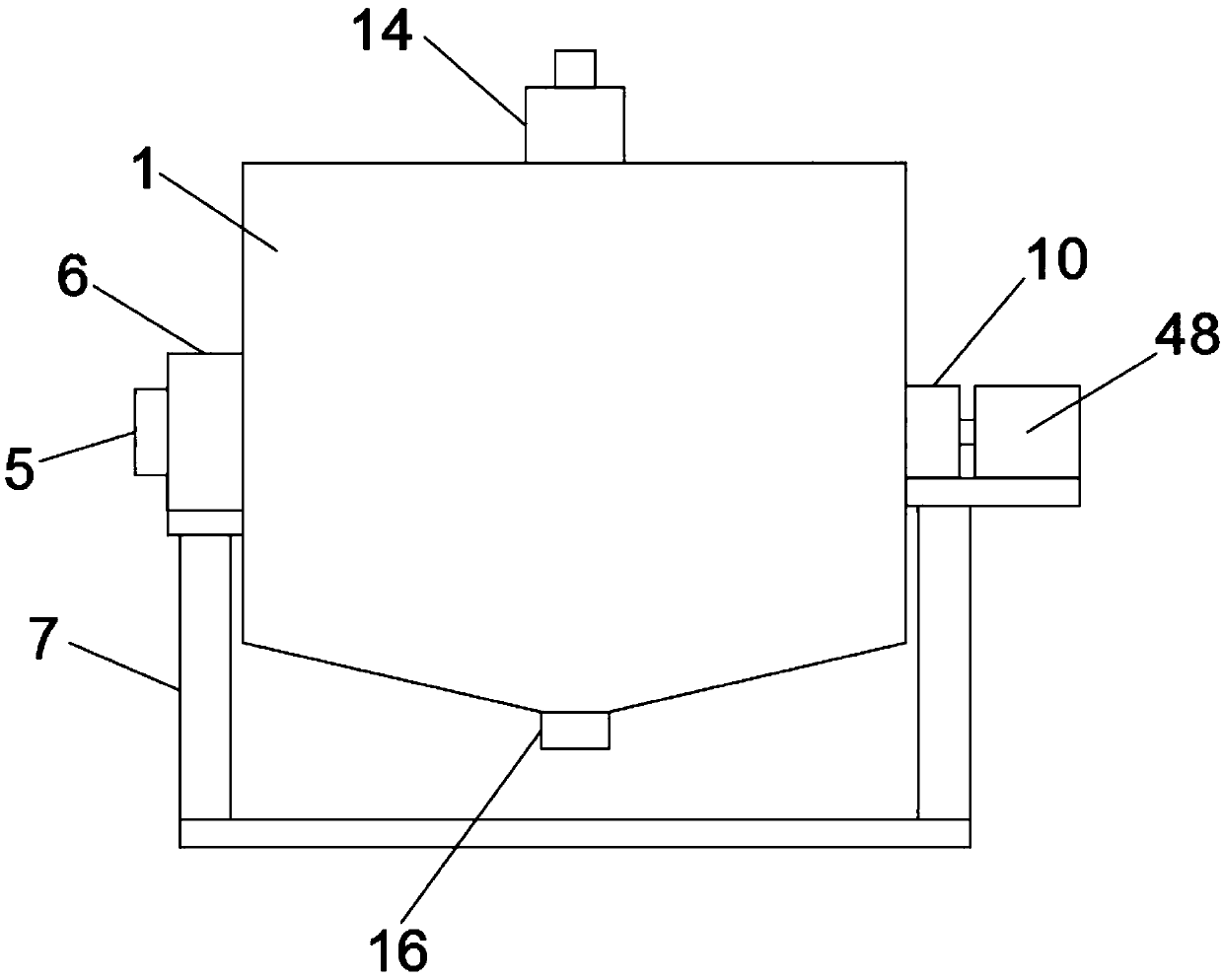

Soil sieving device

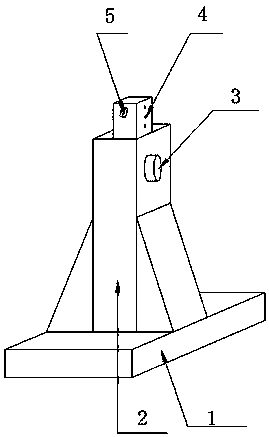

The invention discloses a soil sieving device, and belongs to the soil sieving device technology field. The soil sieving device solves the problem that stone or massive soil blocks in soil do not facilitate growth of plants. The soil sieving device comprises a soil box used to filter the soil and a support frame used to support the soil box, wherein a certain inclination angle is formed between the soil box and the horizontal plane, a feed port is arranged on the soil box along the high end of the inclined direction of the soil box, a fine soil discharge port is arranged at the bottom of the soil box along the inclined direction of the soil box, a coarse soil discharge port is arranged on the soil box along the low end of the inclined direction of the soil box, a drum screen is arranged in the soil box, a feed chute is arranged on the feed port, the feed chute extends into the drum screen, and the coarse soil discharge port is arranged below the drum screen. The soil sieving device is used to sieve the stone in the soil or separate coarse soil from fine soil through sieving.

Owner:CHONGZHOU YUNFENG AGRI PROFESSIONAL COOP

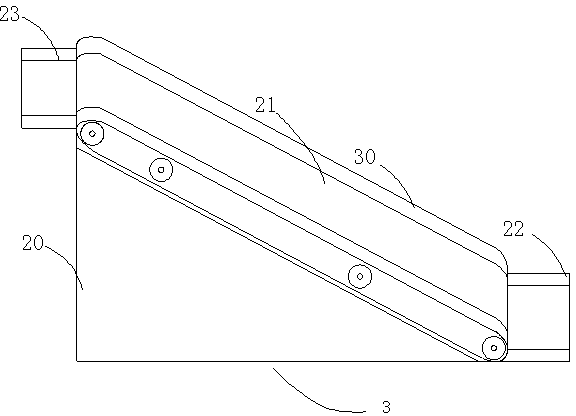

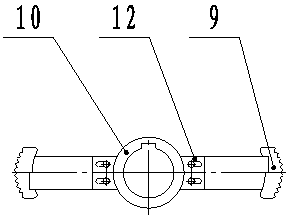

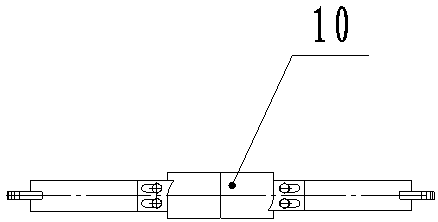

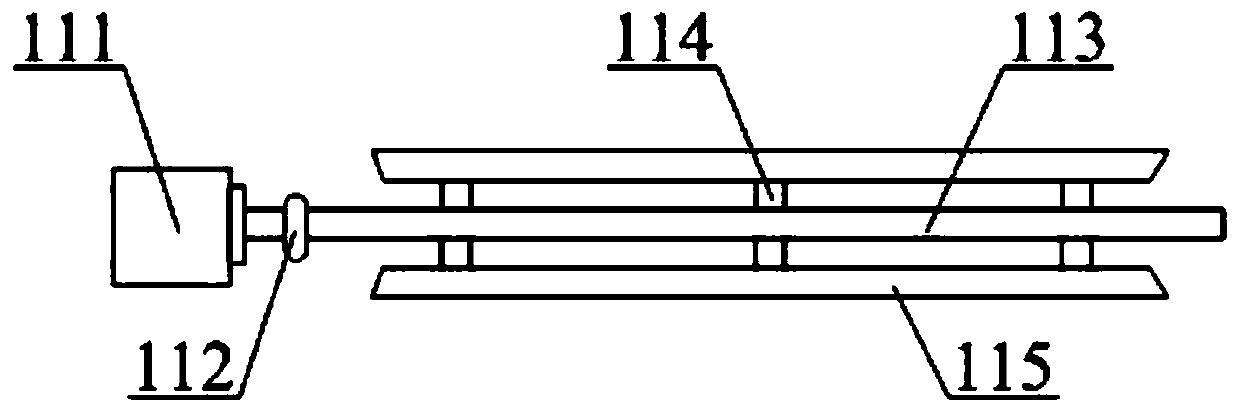

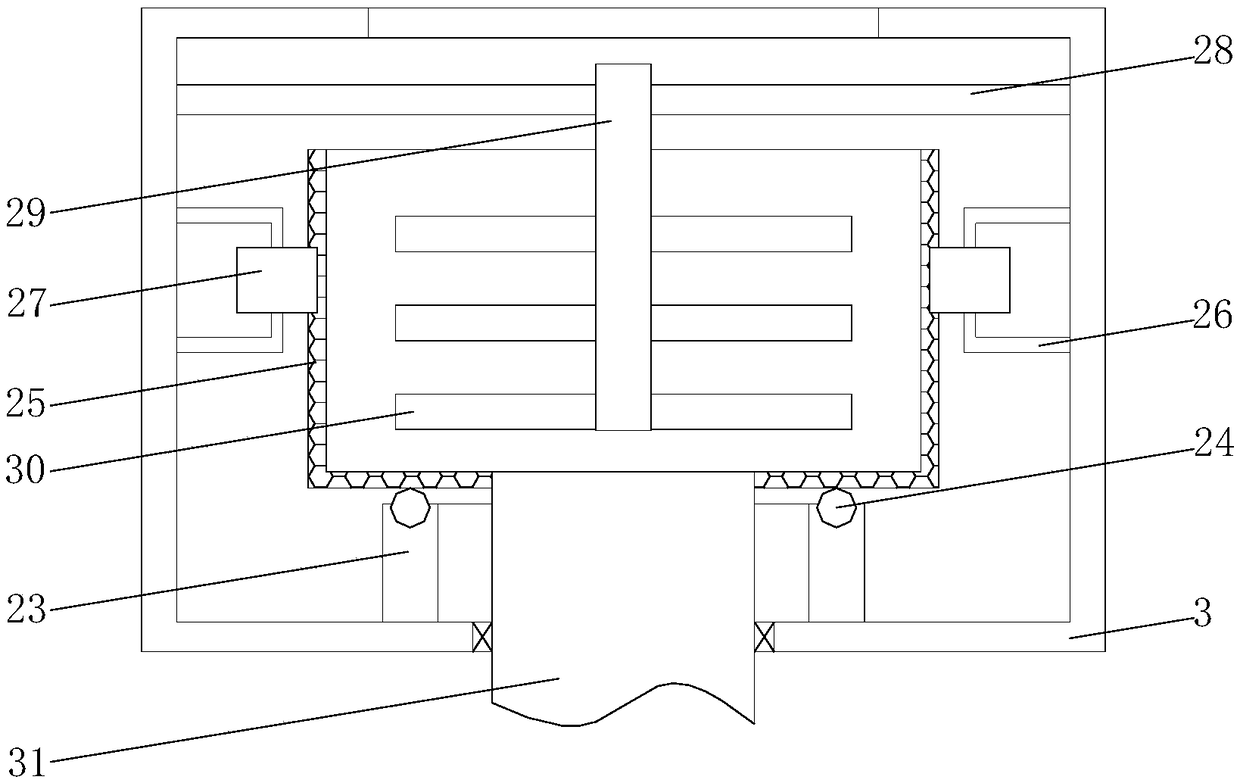

Soil breaking and screening device

The invention discloses a soil breaking and screening device, belonging to the technical field of the soil breaking and screening device, and aiming at solving the problems that stones exist in the soil, so that the soil is not uniform in fineness, and the plant cultivation is influenced. The soil breaking and screening device comprises a soil breaking device, a soil screening device connected with an output end of the soil breaking device, and a soil conveying device connected with an output end of the soil screening device; the soil breaking device is used for breaking the soil; the broken soil is sent into the soil screening device, and the soil screening device is used for filtering coarse soil, fine soil and stones; the screened soil is sent into the soil conveying device, and impurities are removed. The soil breaking and screening device is used for breaking the soil and screening the broken soil.

Owner:CHONGZHOU YUNFENG AGRI PROFESSIONAL COOP

Soil sieving machine for agricultural use

InactiveCN107335611ASolve the problem of not having efficient soil screening functionImprove practicalitySoil lifting machinesSievingAgricultural engineeringCantilever

The invention discloses a soil sieving machine for agricultural use. The soil sieving machine for agricultural use comprises a bottom plate, the two sides of the bottom of the bottom plate are fixedly connected with fixing blocks, the left side of the top of the bottom plate is fixedly connected with a first vertical post, the center of the top of the bottom plate is movably connected with a collection box, the right side of the top of the bottom plate is fixedly connected with a second vertical post, and the bottom of the left side of the first vertical post is fixedly connected with a bearing platform. The bearing platform, a first motor, a first rotating shaft, a gear, a rack plate, a sieve body, a moving post, a limiting block, a spring, connecting posts, a cantilever arm, a second motor, a second rotating shaft, crushing cutters and a controller are arranged and matched with one another, so that the efficient soil sieving effect is realized, the problem that an existing soil sieving machine does not have an efficient soil sieving function is solved, time and effort are saved when a farmer uses the soil sieving machine, the working efficiency of the farmer is improved, the practicability of the soil sieving machine for agricultural use is improved, and the soil sieving machine for agricultural use is suitable for application and popularization.

Owner:浙江聚彩精密设备有限公司

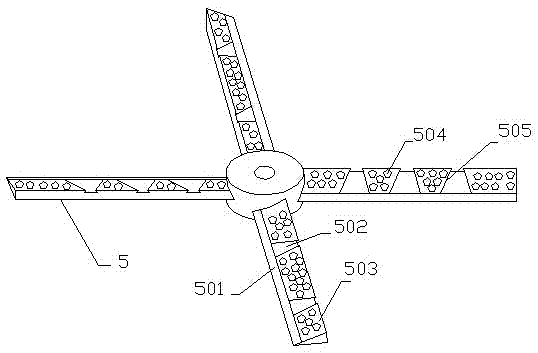

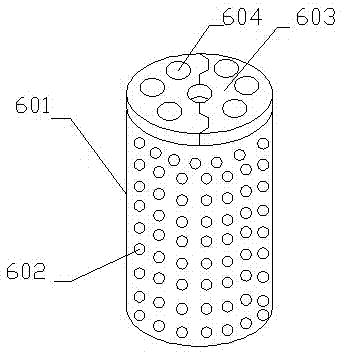

Dreg-free meshed soybean milk machine

The invention discloses a dreg-free meshed soybean milk machine which comprises a cup body, a cup cover, a machine head and a filter drum. The machine head is provided with a cutter tool composed of a cutter shaft and a cutter, the cutter is provided with multiple blades which are evenly distributed around the cutter shaft, the upper surfaces of the blades serve as oblique working faces, and the lower edges of the working faces are provided with cutter edges; the working faces are provided with multiple breaking grooves, the two ends of the breaking grooves are provided with groove inlets and groove outlets respectively, the groove inlets are connected with the cutter edges, the width of the breaking grooves is gradually decreased from the groove inlets to the groove outlets, and the two side walls of the breaking grooves are provided with cutting edges in the length direction of the side walls of the breaking grooves; the filter drum is installed on an installing seat arranged at the bottom of the cup body, the drum wall of the filter drum is provided with multiple filter holes, a cutting ring with sawteeth is arranged on the portion, surrounding each filter hole, of the inner side of the drum wall of the filter drum, and the diameter of the cutting rings is equal to that of the filter holes. According to the dreg-free meshed soybean milk machine, by improving the cutter tool and the filter drum, the cutting, smashing and grinding capacity of the cutter tool is improved, and through cooperation of the filter drum and the cutter tool, the soybean milk yield of raw materials is improved, and the content of filter dregs in soybean milk is decreased.

Owner:黄皇文

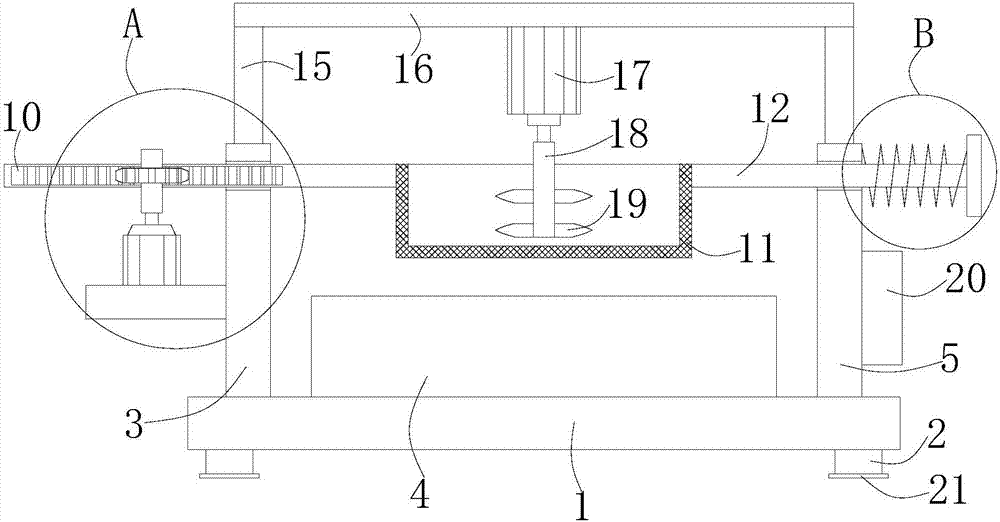

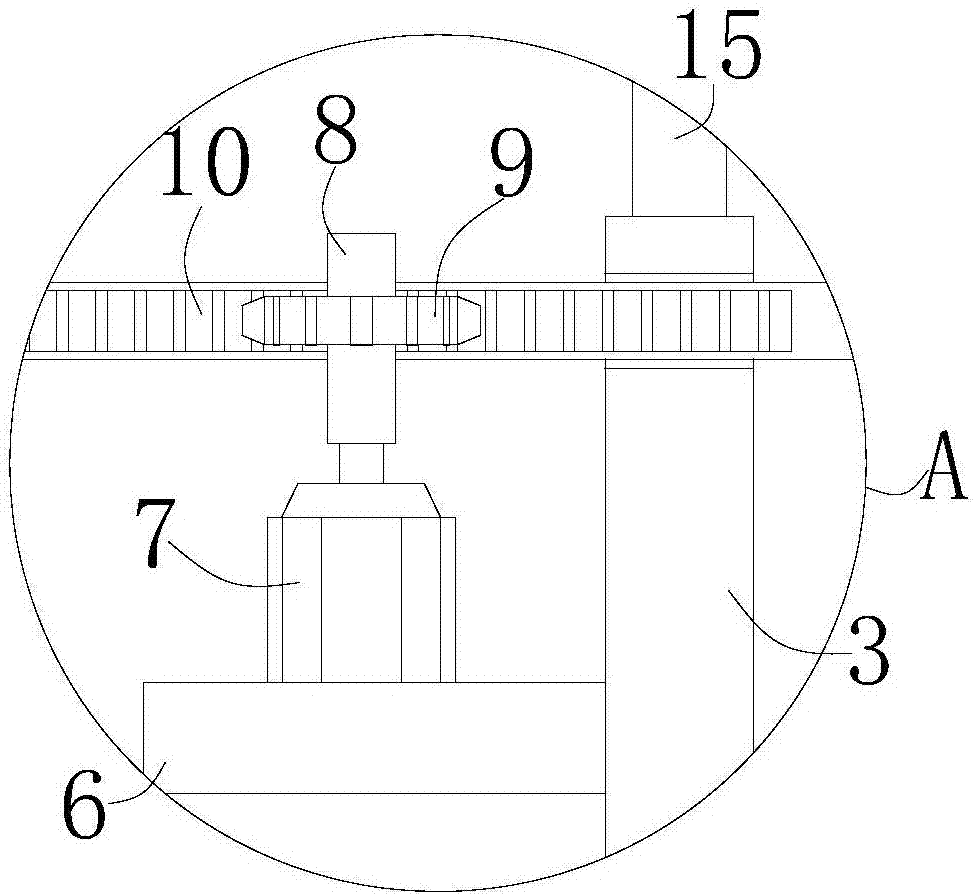

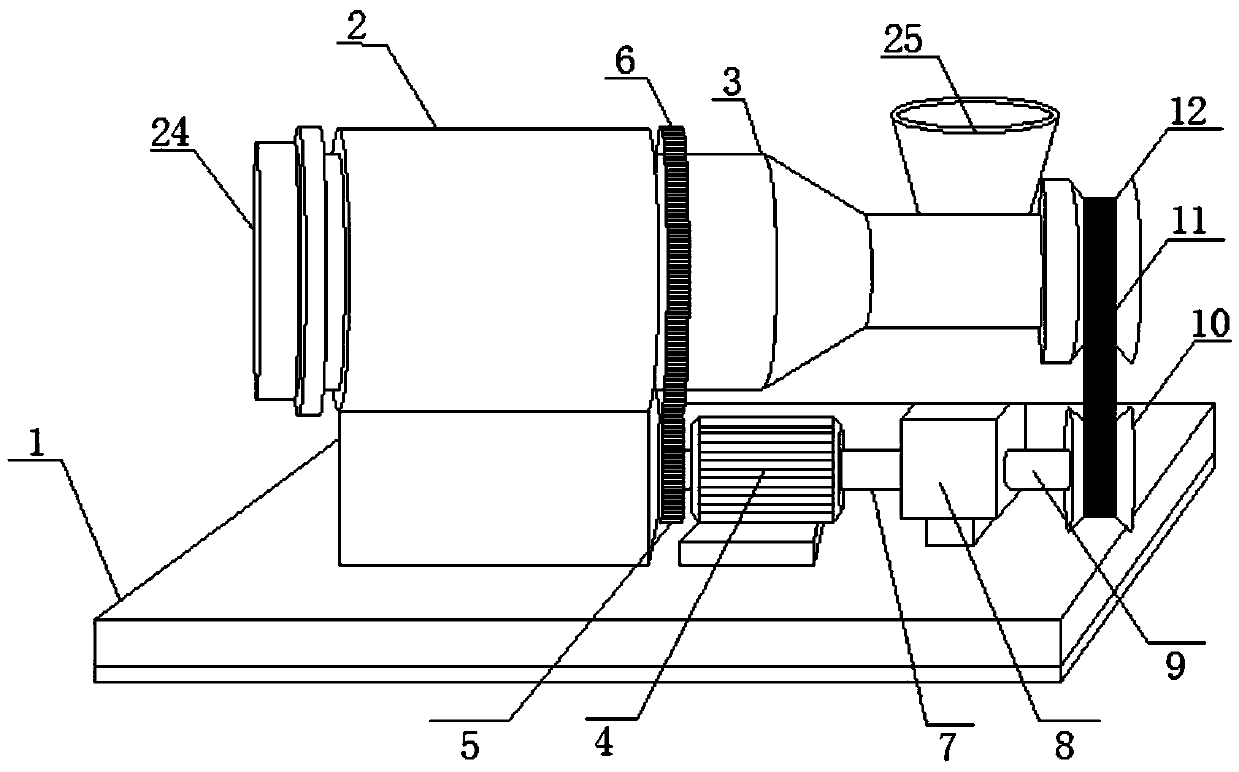

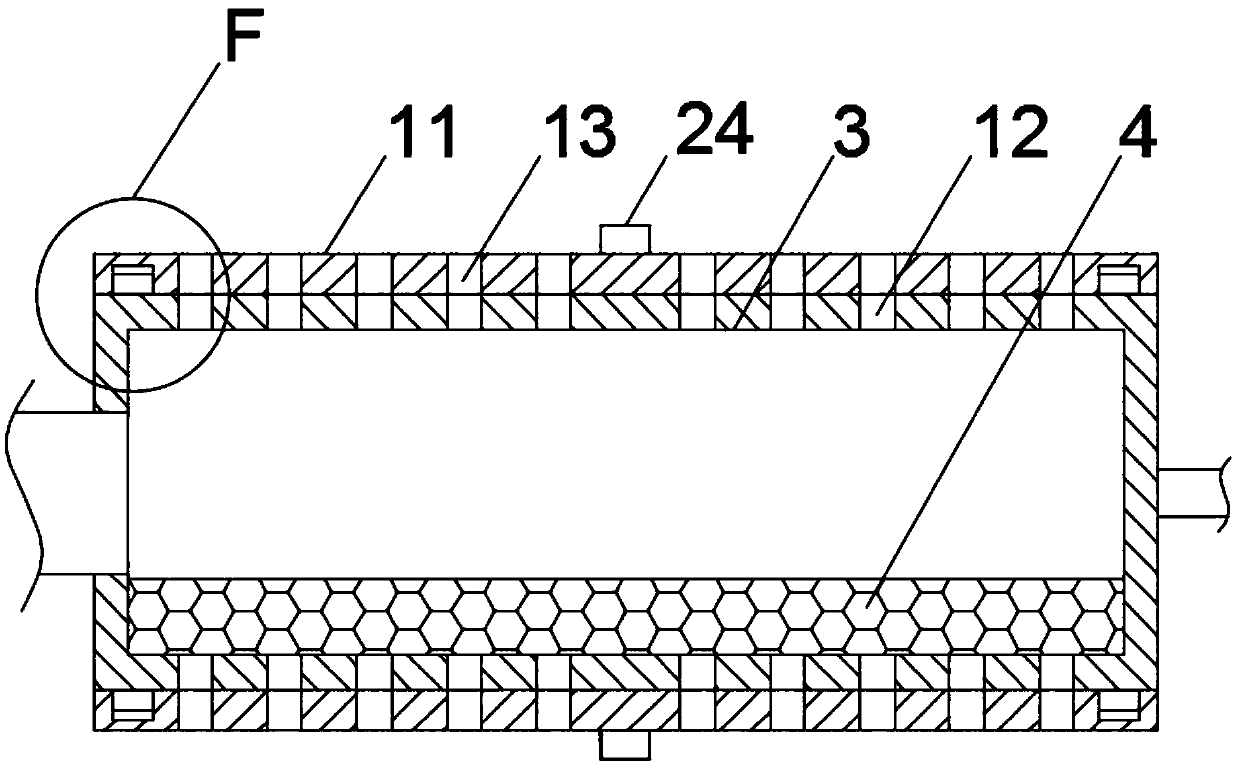

Novel electro-optical ceramic processing grinding device

InactiveCN109531395AWell groundPlay the role of conveyingEdge grinding machinesGrinding carriagesEngineeringRaw material

The invention discloses a novel electro-optical ceramic processing grinding device. The novel electro-optical ceramic processing grinding device comprises a base, a supporting block, a grinding box and a motor. The supporting block is fixedly connected to the upper end of the base. The grinding box is movably inserted and connected in the supporting block. The motor is fixedly connected to the upper end of the base. A gear is fixedly connected to one output end of the motor and is in meshing connection with a gear ring. The gear ring is fixedly in cup joint to the outer side wall of the grinding box. The side wall of one end of the grinding box is in penetrating connection with a feeding port. Electro-optical ceramic raw materials are poured in from the feeding port, the grinding box rotates along with running of the motor, a spiral conveying paddle rotates, then under driving of the spiral conveying paddle, the materials are conveyed to the positions of grinding balls, the spiral conveying paddle can achieve a conveying function at the time, and the pulverizing function can be achieved as well.

Owner:合肥易美特建材有限公司

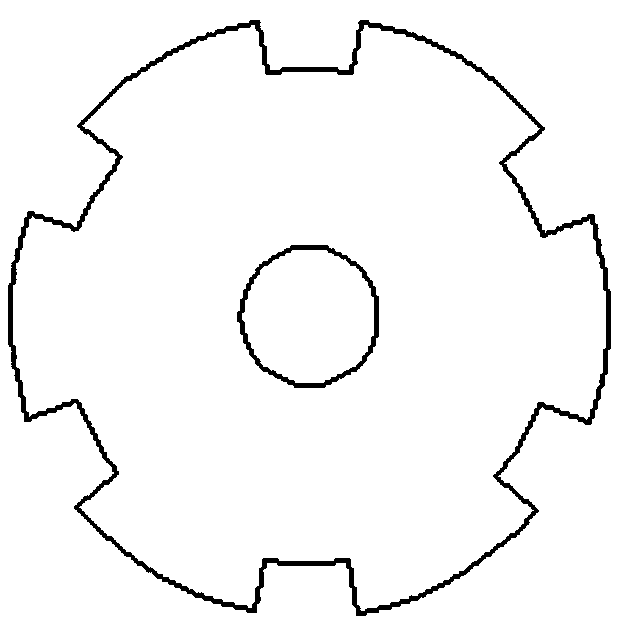

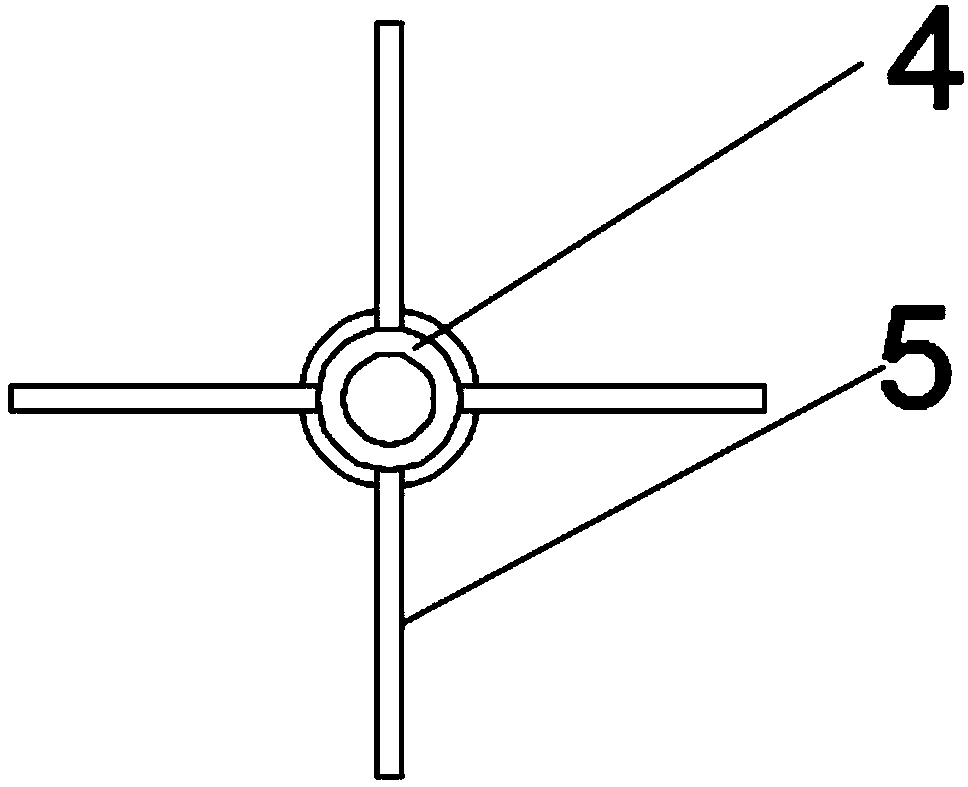

Multifunctional crusher

InactiveCN105618192ASolve the blockagePlay a crushing roleGrain treatmentsCrusherContinuous operation

The invention discloses a multifunctional crusher, comprising a crushing cavity; a feeding hole is formed in the top part of one end of the crushing cavity; a discharge hole is formed in the side wall of the other end of the crushing cavity; a main shaft is arranged in the crushing cavity; the main shaft is provided with cutters; planetary shafts are arranged in the circumferential direction of the cutters; each planetary shaft is provided with arc blades; each arc blade is arranged between every corresponding two cutters; the main shaft near the position of the discharge hole is provided with a material stop ring; and the material stop ring is near the cutters. The quality problem of crushing, i.e., the size adjustment problem, and the continuous operation problem of crushing, i.e., the machine blocking problem are solved.

Owner:QINGDAO YUXIN IND EQUIP CO LTD

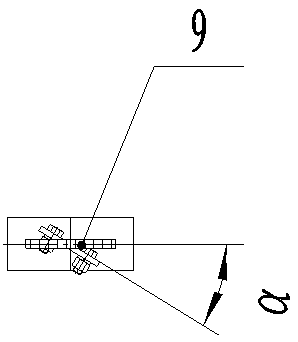

Multifunctional ball body mixer

PendingCN107617373AWell mixedPlay the role of cuttingRotating receptacle mixersTransportation and packagingEngineeringMixing effect

The invention aims to solve the technical problem of providing a multifunctional ball body mixer. The multifunctional ball body mixer has the technical features that the multifunctional ball body mixer consists of a rack, a motor, a main shaft, a spherical shell, a beating and rubbing plate, a stirring device with a tooth-shaped blade, an intermediate transmission device and a clutch device, wherein the motor outputs powder; the power is transferred to the spherical shell after being subjected to deceleration by the intermediate transmission device; the spherical shell and the main shaft rotate to different directions; the main shaft is provided with the stirring device with the tooth-shaped blade and the clutch device; the detachable beating and rubbing plate is installed in the sphericalshell; a certain cutting-up angle alpha is formed between the stirring device with the tooth-shaped blade and the main shaft, various materials can be quickly and evenly mixed, meanwhile, the multifunctional ball body mixer can perform a cutting-up function on materials which are likely to cake and bulge, and a mixing effect is obvious; since the detachable beating and rubbing plate is installedin the spherical shell, when the materials with thick particles are stirred, the beating and rubbing plate is installed and is cooperated with the stirring device with the tooth-shaped blade to form asmashing function; meanwhile, the spherical shell and the main shaft rotate to different directions so as to fully and evenly smash and stir the materials, and no dead angles are in the presence.

Owner:黑龙江省农业机械工程科学研究院齐齐哈尔分院

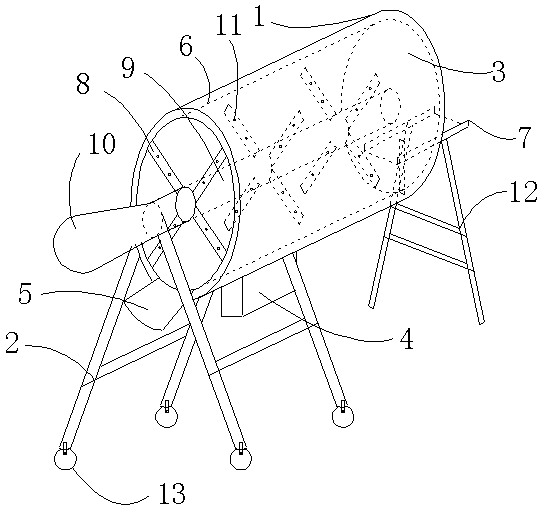

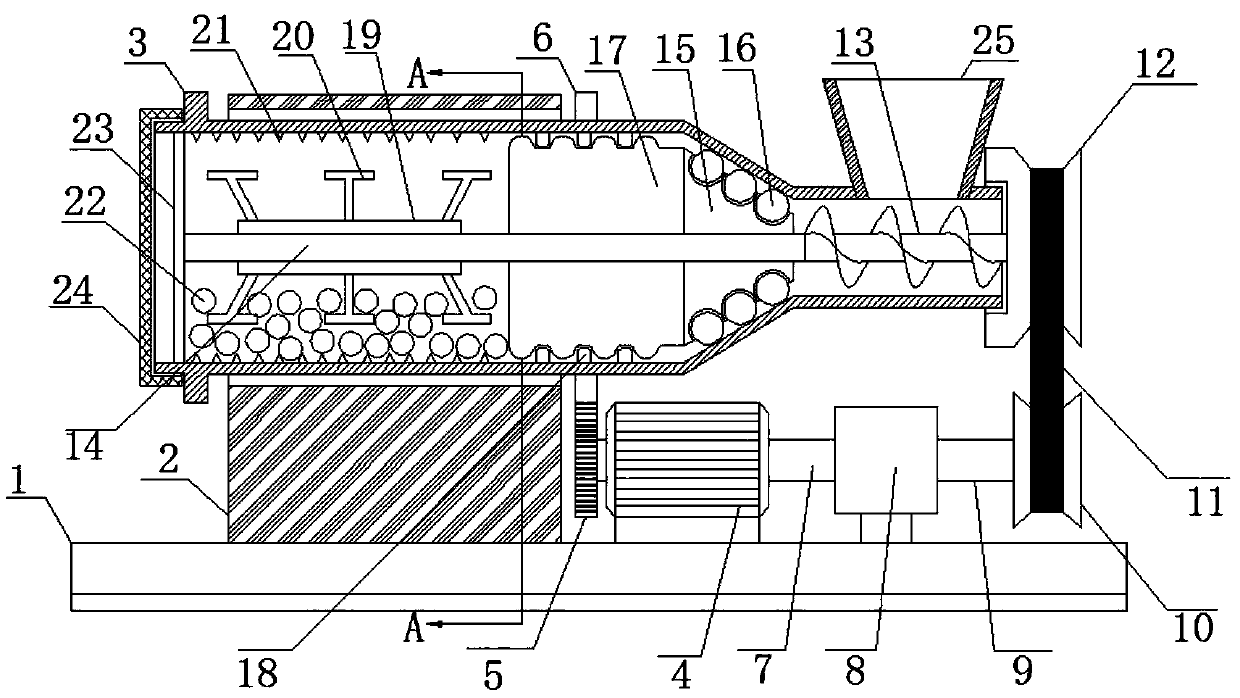

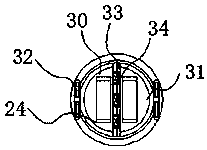

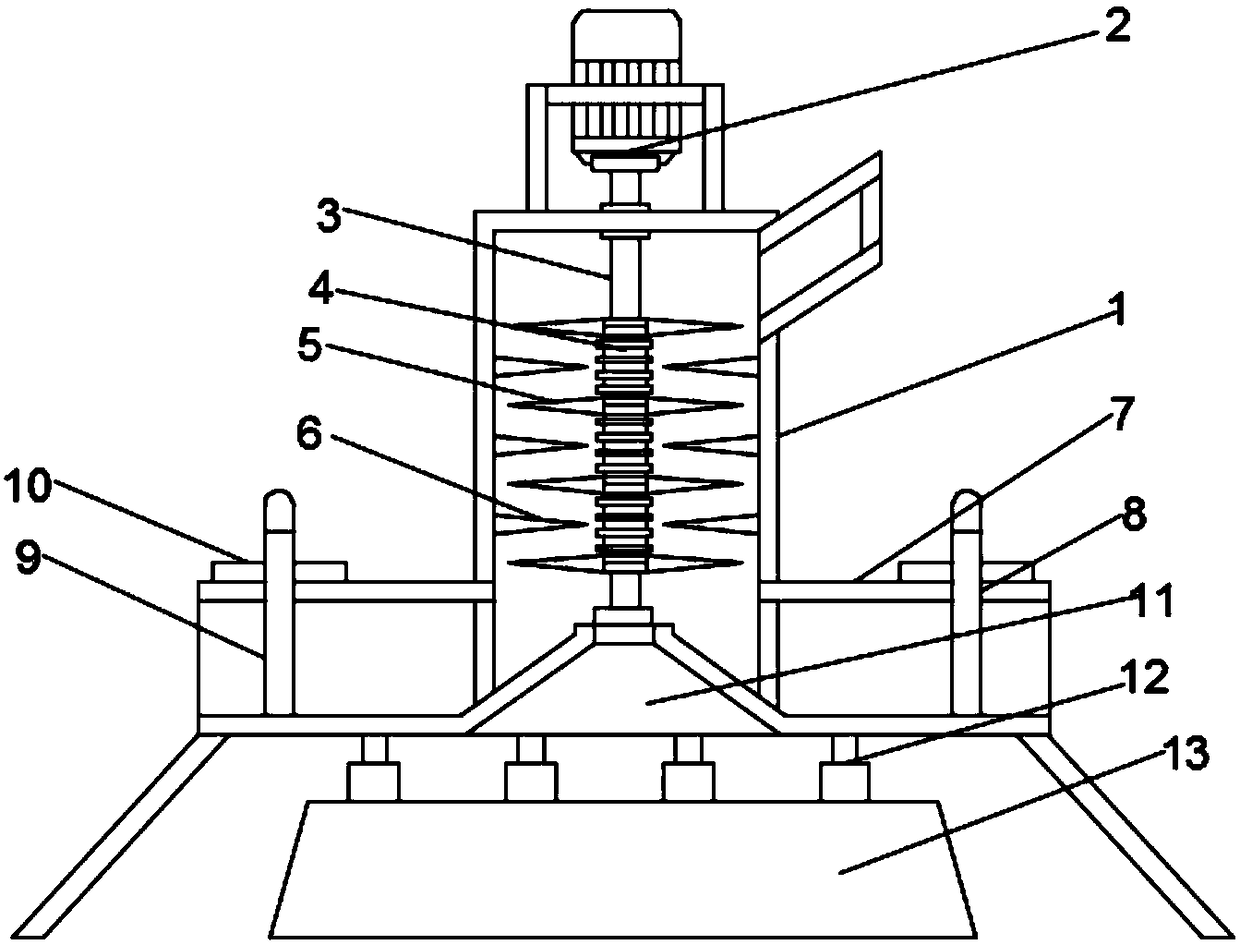

Raw material crushing equipment for production of Longquan celadon and using method thereof

ActiveCN107999211AAchieve separationImprove grinding efficiencyGrain treatmentsEngineeringMechanical engineering

The invention discloses raw material crushing equipment for production of Longquan celadon and a using method thereof. The raw material crushing equipment comprises a shell, a grinding cylinder, a supporting base, a base, a fixing base, a releasing cylinder, a driving device, a discharging cylinder, a grinding motor and a centralizing device, wherein a first opening is formed in one side of the shell, the grinding cylinder is located in the shell, and grinding beads are arranged in the grinding cylinder. One side of the grinding cylinder is fixedly provided with a feeding cylinder, the end, away from the grinding cylinder, of the feeding cylinder is rotationally connected with the supporting base, the bottom of the supporting base is fixed to the base, a second opening is formed in the side, far away from the first opening, of the shell, the end, far away from the feeding cylinder, of the grinding cylinder is fixedly provided with a rotating shaft, and the rotating shaft penetrates through the second opening and is rotationally connected with the fixing base. According to the raw material crushing equipment for production of the Longquan celadon and the using method thereof, a partof ground raw materials can be output from the discharging cylinder, so that the separation of the ground raw materials from the raw materials which are not subjected to grinding is realized, and thegrinding efficiency of the raw materials is improved.

Owner:龙泉市尚唐瓷艺发展有限公司

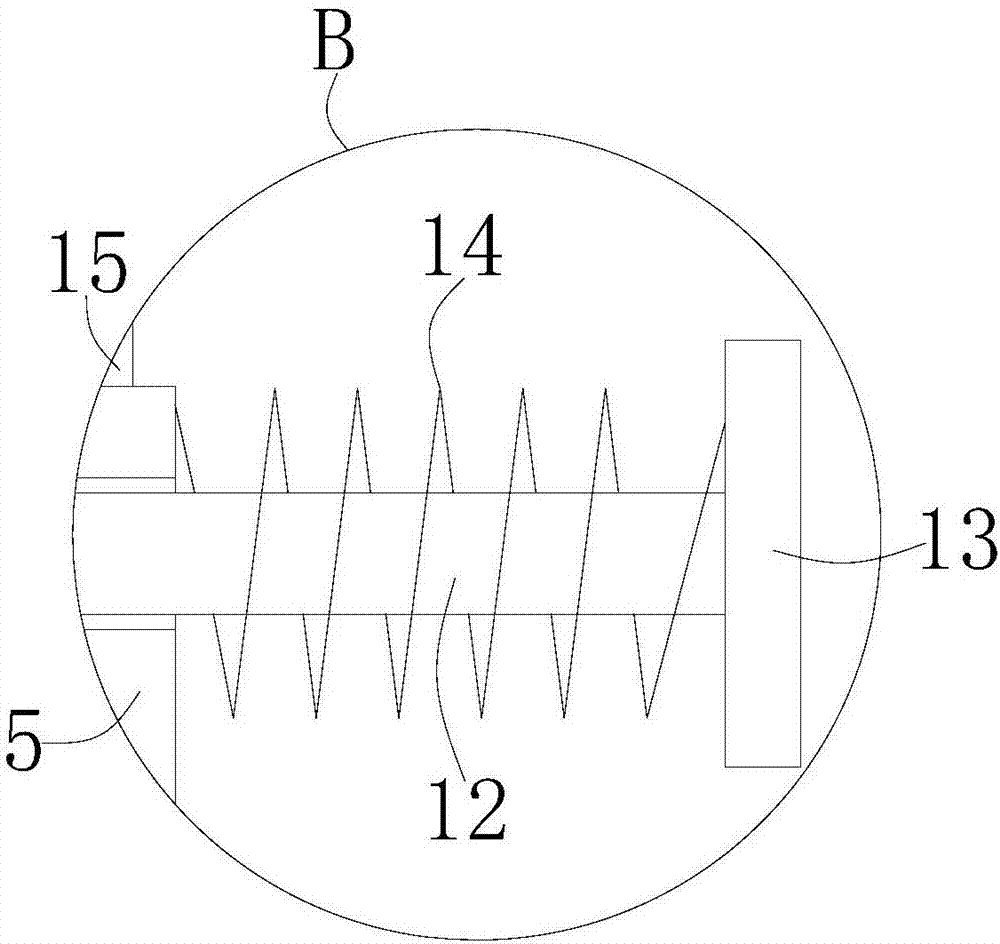

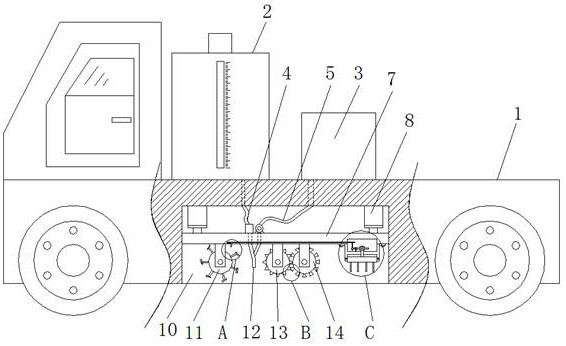

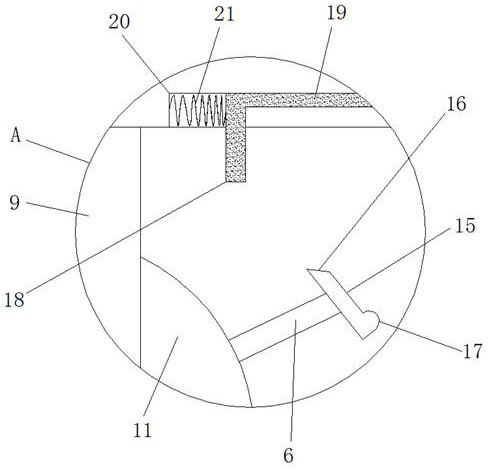

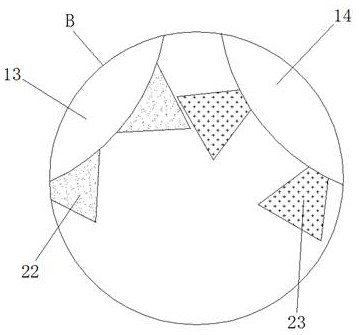

Saline-alkali soil repairing and improving device capable of carrying out multi-level mixed digging

InactiveCN112913368AImprove flatnessSolve the blockageSpadesSoil lifting machinesAlkali soilSoil science

The invention discloses a saline-alkali soil repairing and improving device capable of carrying out multi-level mixed digging. The saline-alkali soil repairing and improving device capable of carrying out the multi-level mixed digging comprises an improving and repairing vehicle, an improvement agent storage tank, an air pump tank, a material guiding pipe, an air pipe, a telescopic hydraulic cylinder, an installation frame, a telescopic cabin and a spring, wherein the improvement agent storage tank is arranged on the top of the improving and repairing vehicle; the improving and repairing vehicle on one side where the improvement agent storage tank is positioned is provided with the air pump tank; the front side of a supporting plate is connected with a ditching roller through the installation frame; the right side of the ditching roller is provided with a discharging pipe; one side of the right side of the discharging pipe is provided with a first smashing roller and a second smashing roller; and meanwhile, the right side of the second smashing roller is provided with an installation cover. By use of the saline-alkali soil repairing and improving device capable of carrying out the multi-level mixed digging, the structure of an existing saline-alkali soil repairing device is improved, when soil is dug, especially by aiming at land of which the soil is wet, the problems that splashing soil blocks are attached to a material outlet to cause blockage can be solved, and the integral surface of the soil can be leveled.

Owner:查桂霞

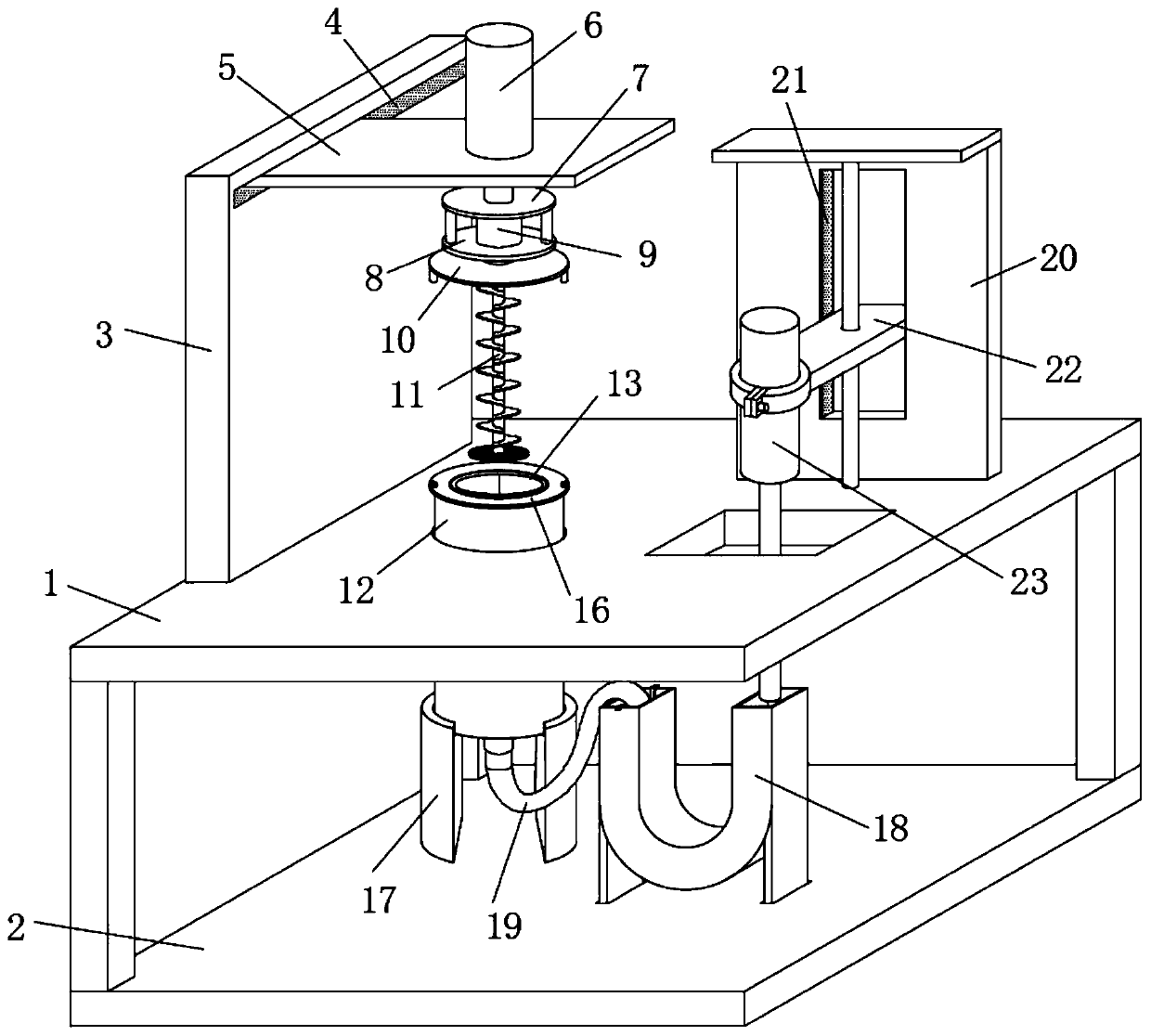

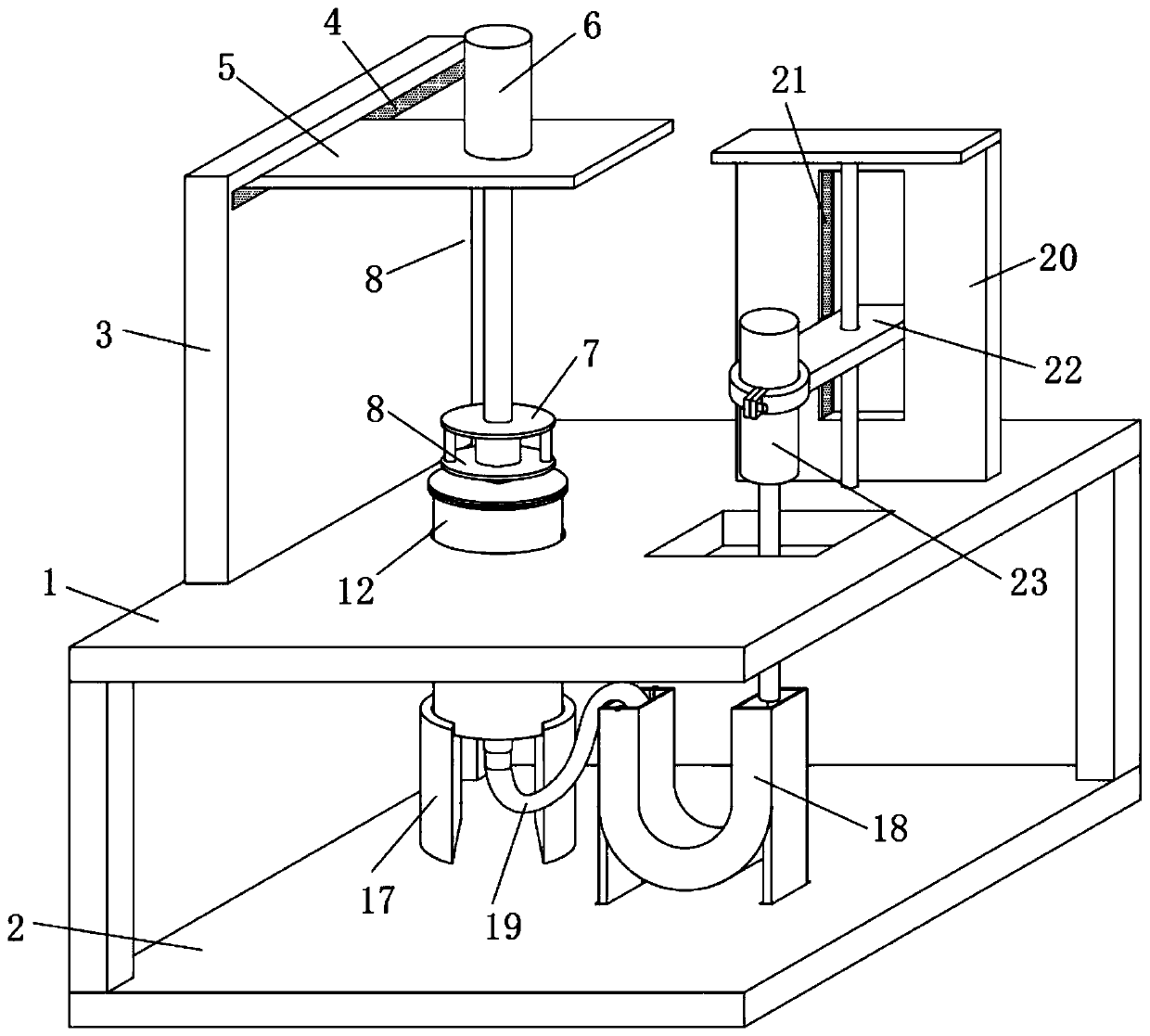

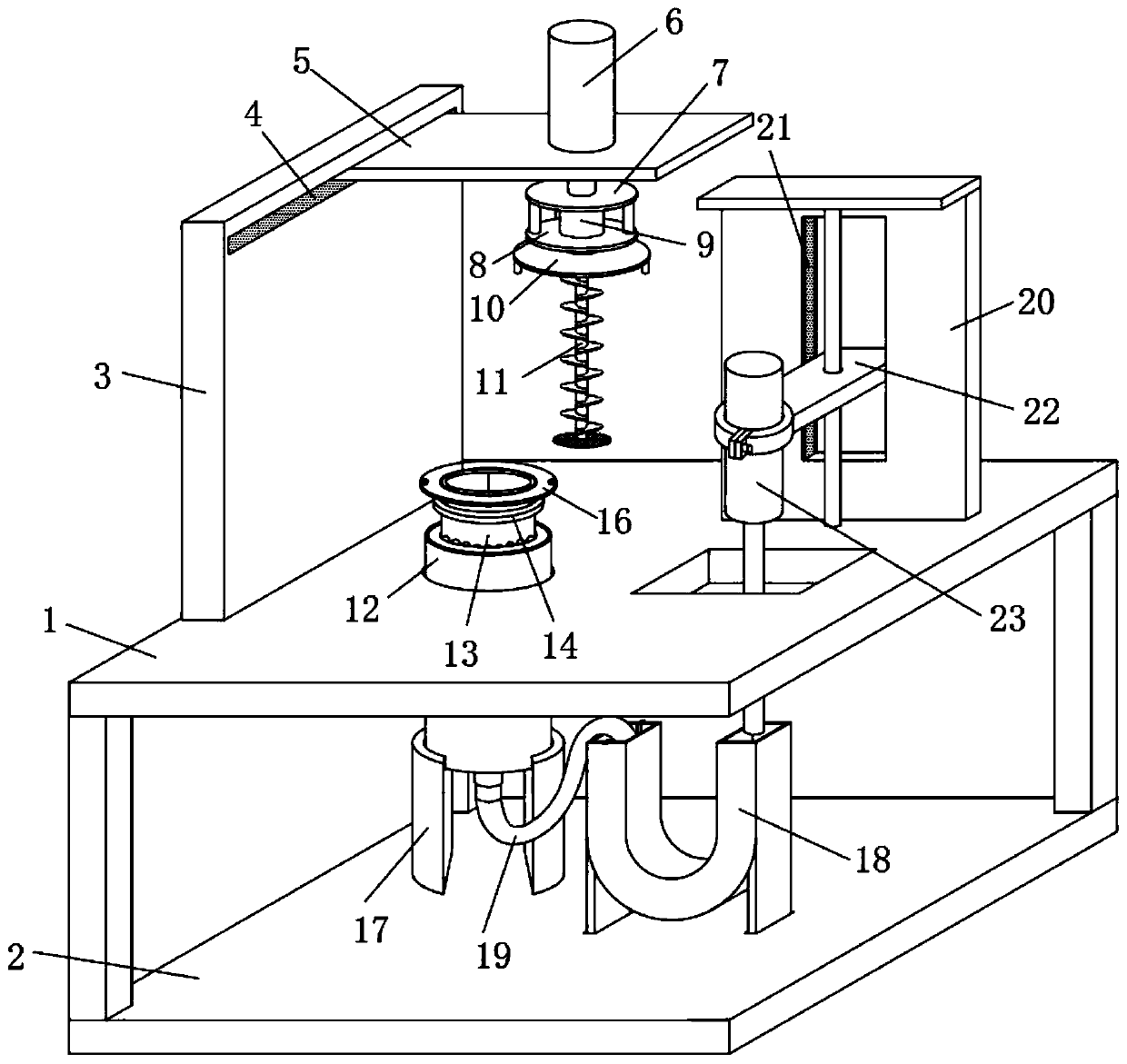

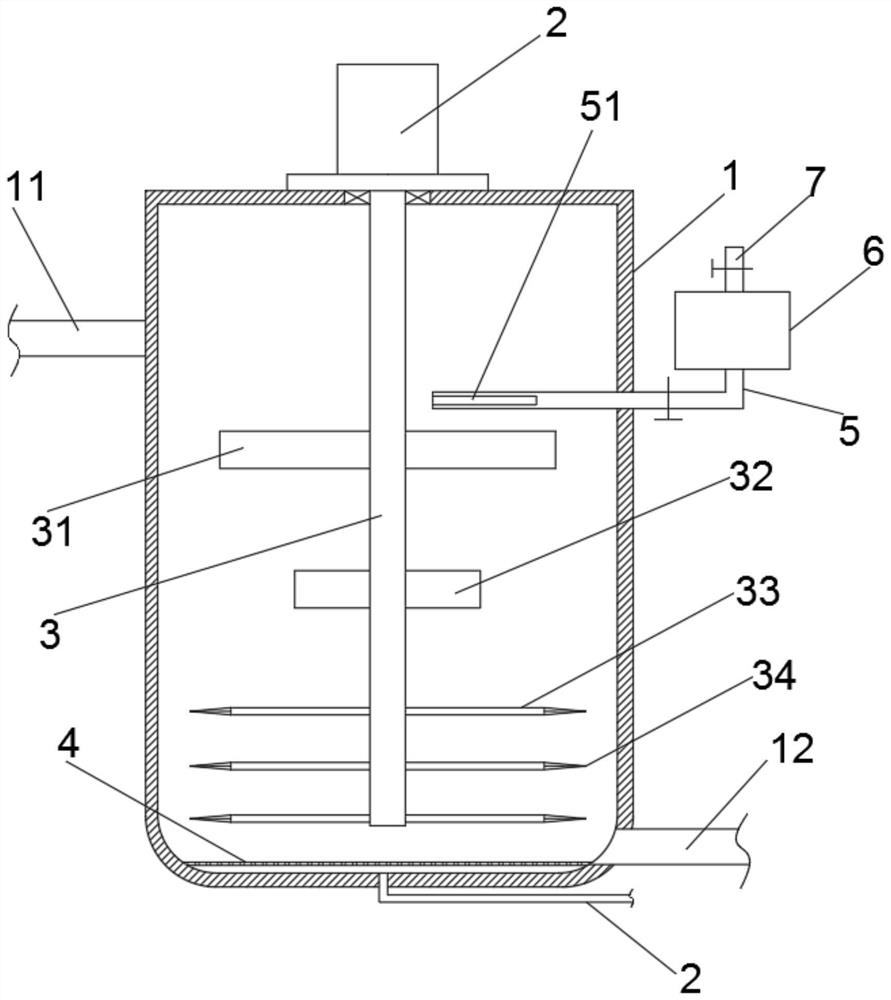

Device for detecting salt content in pickled food

InactiveCN110726811AEasy to cleanSimple and fast operationPreparing sample for investigationTesting foodSalt contentEngineering

The invention discloses a device for detecting a salt content in pickled food, and belongs to the field of food detection. The device for detecting the salt content in the pickled food comprises an upper operating floor and a lower operating floor, which are fixedly arranged up and down, wherein a vertical plate is fixed at the left end of the upper side of the upper operating floor, a horizontalmoving plate is installed on the first vertical plate through a horizontal electric guide rail, by means of the cooperative of a crushing and stirring mechanism, a rotatable inner cylinder and a fixedouter cylinder, crushing and centrifuging of a material are realized, liquid is thrown to the inner wall of the outer cylinder and is introduced into a U-shaped tube through a hose pipe for detection, an extracting solution filtered by the U-shaped tube can also be detected by a liftable salimeter, the salimeter does not need to be manually held for operation, so that the operation is simple andconvenient, furthermore, the operation steps do not need to be operated separately, so that the operation smoothness and the operation efficiency are high, factory-made requirements can be easily satisfied, and at the same time, the inner cylinder can be detached from the inside of the outer cylinder and the U-shaped tube can be detached from the lower operating floor to conveniently clean various components subsequently.

Owner:徐州健一家健康管理有限公司

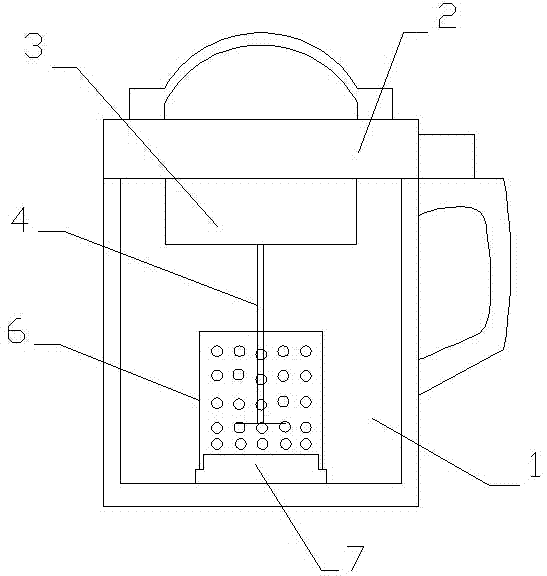

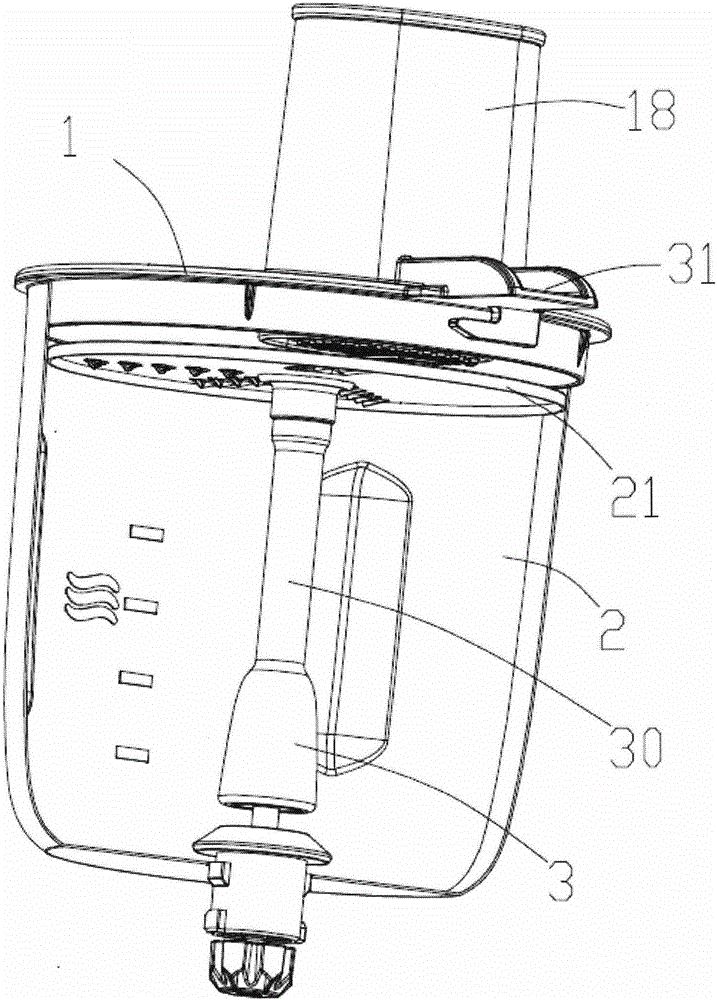

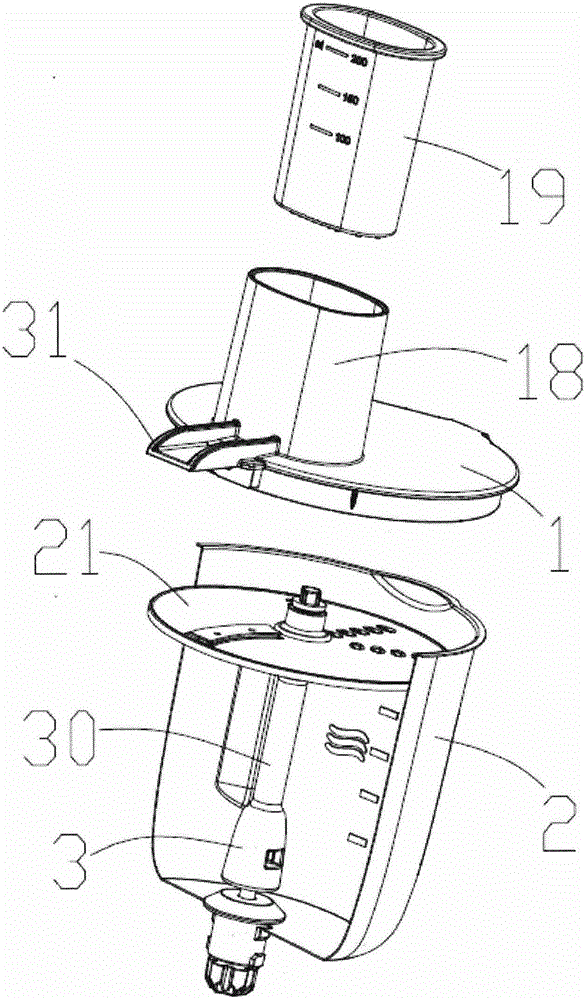

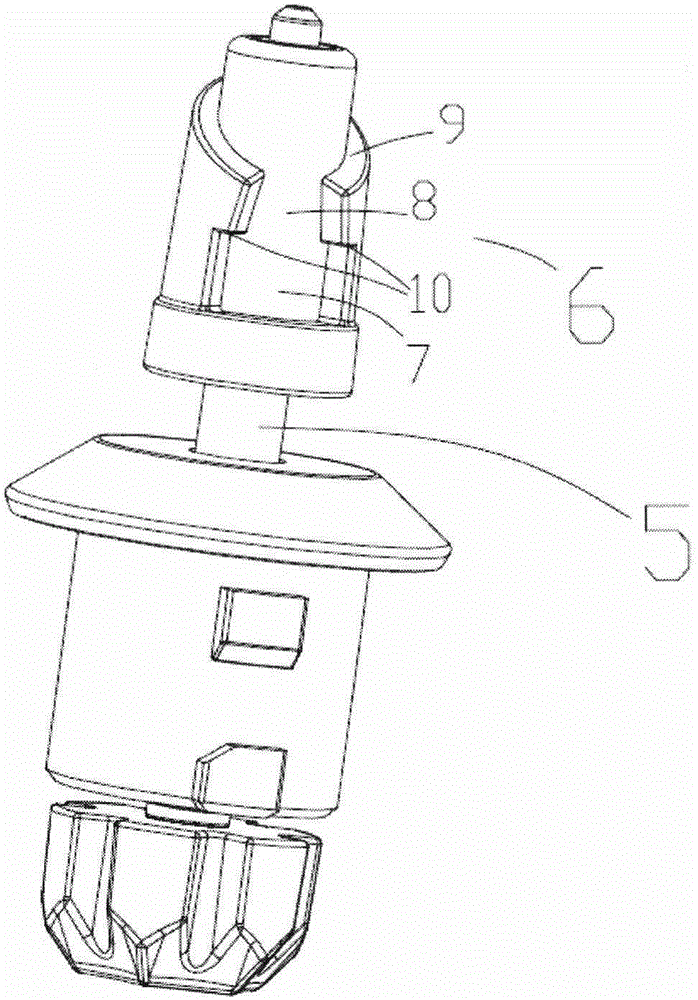

Soup cooker

ActiveCN106108608AEasy to cleanRealize the shredding functionVessels with intergral heatingEngineeringCooker

The invention discloses a soup cooker which comprises a cup lid, a cup body, a tool rest arranged inside the cup body and a smashing tool arranged on the tool rest. The tool rest is of a cylindrical structure with an installation hole. A main shaft is sleeved with the tool rest. The main shaft is provided with a locking portion fixed to the installation hole. Due to close fit of the installation hole and the main shaft, the tool and the main shaft are detachably connected, the tool is disassembled to clean the tool bit, and cleaning is convenient.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

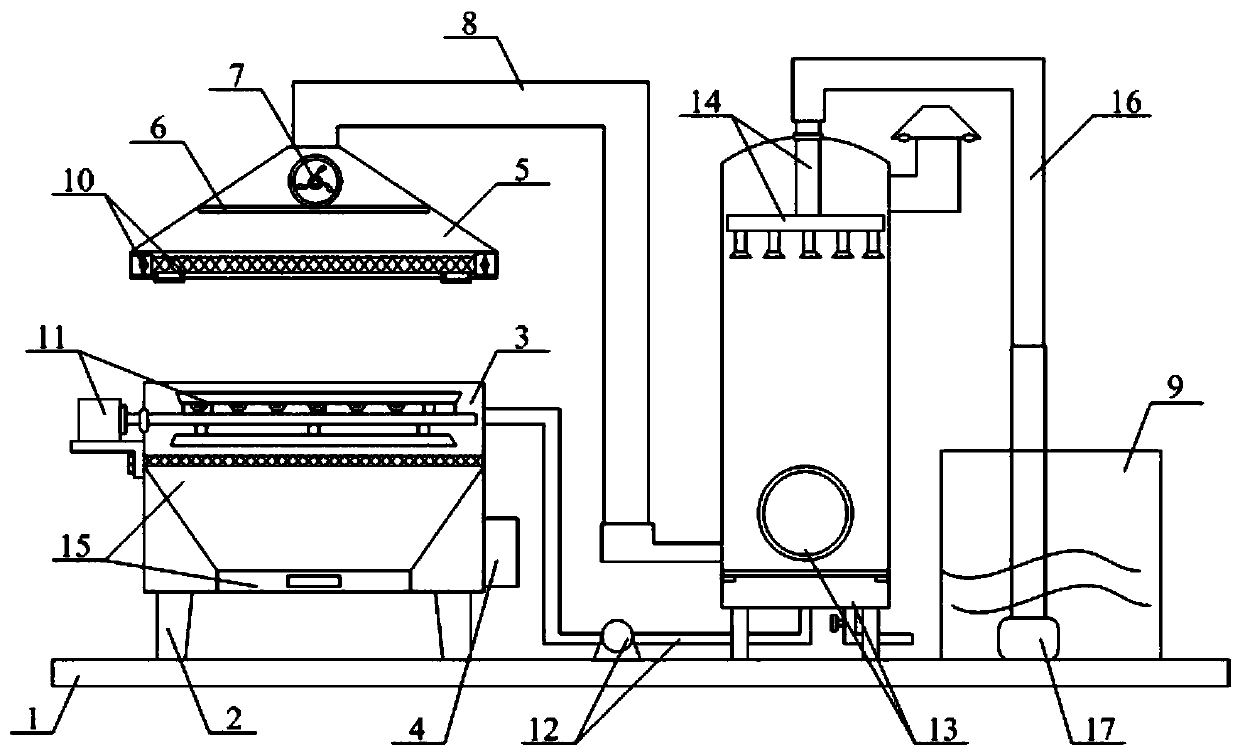

Waste residue and waste gas recovery treatment system for industrial deslagging roller

InactiveCN110604992AImprove recycling efficiencyReasonable structural designCombination devicesGas treatmentSlagWater storage tank

The invention provides a waste residue and waste gas recovery treatment system for an industrial deslagging roller. The recovery treatment system comprises a support mounting base plate, a support column, a waste residue recovery box, an electrical control box, a suction hood, a support cross rod, an exhaust fan, a gas guide pipe, a water storage tank, a slag charge prevention waste gas recovery screen plate structure, a waste residue crushing plate structure, a backflow dust suppression pipe structure, a waste gas treatment tank structure, a waste gas treatment spraying coil pipe structure, awaste residue filtering hopper structure, a water guide pipe and a submersible pump. The recovery treatment system is specially designed for the industrial residue discharge roller, the air suction hood is arranged on the upper portion of the industrial residue discharge roller, and the waste residue recovery box is arranged on the lower portion of the industrial residue discharge roller and usedfor conducting recovery treatment on waste residues and waste gas; in addition, waste residues of the industrial residue discharging roller can be effectively crushed, filtered and recycled, the treatment effect on the waste residues is better, and the recycling efficiency is higher; meanwhile, waste gas is subjected to spraying treatment and purification, so that practicability is high, and popularization is facilitated.

Owner:扬州光华化工设备有限公司

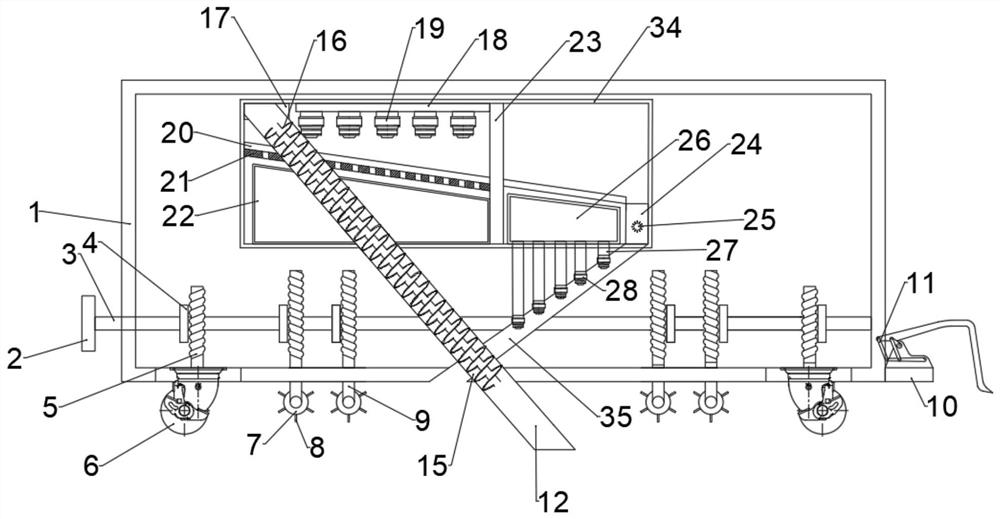

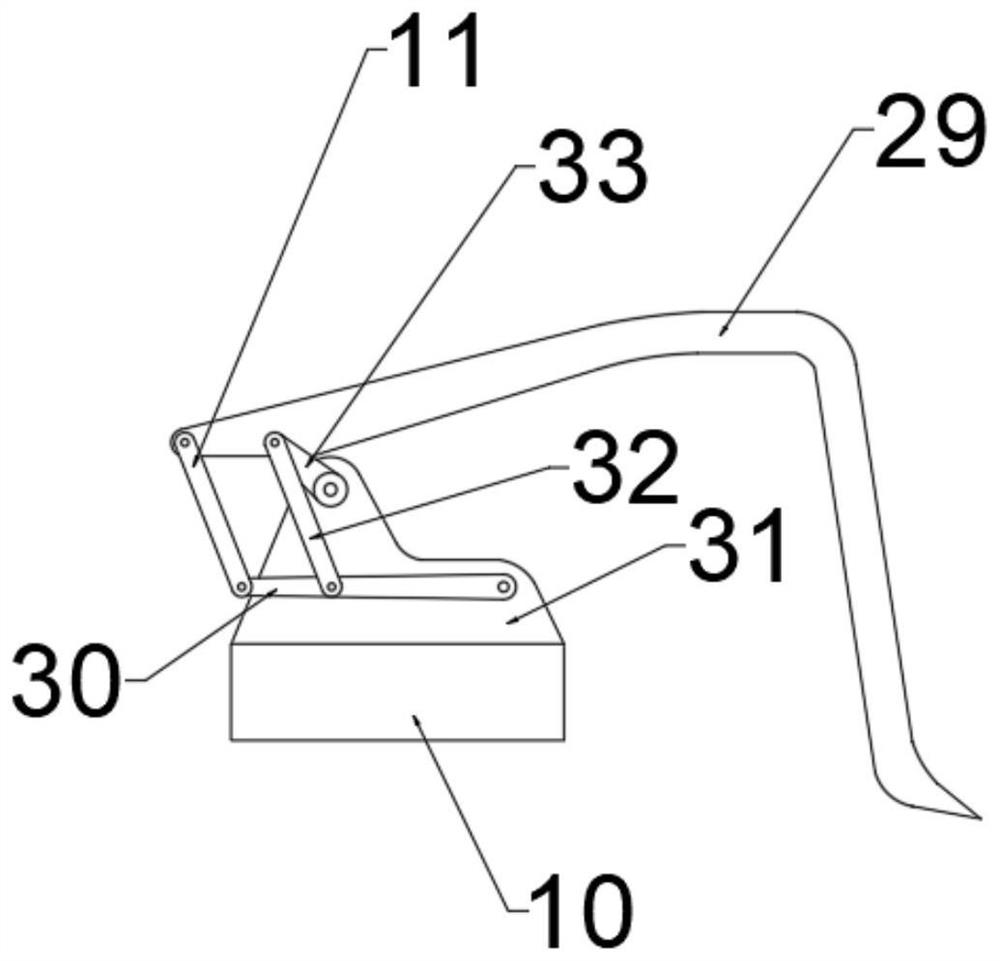

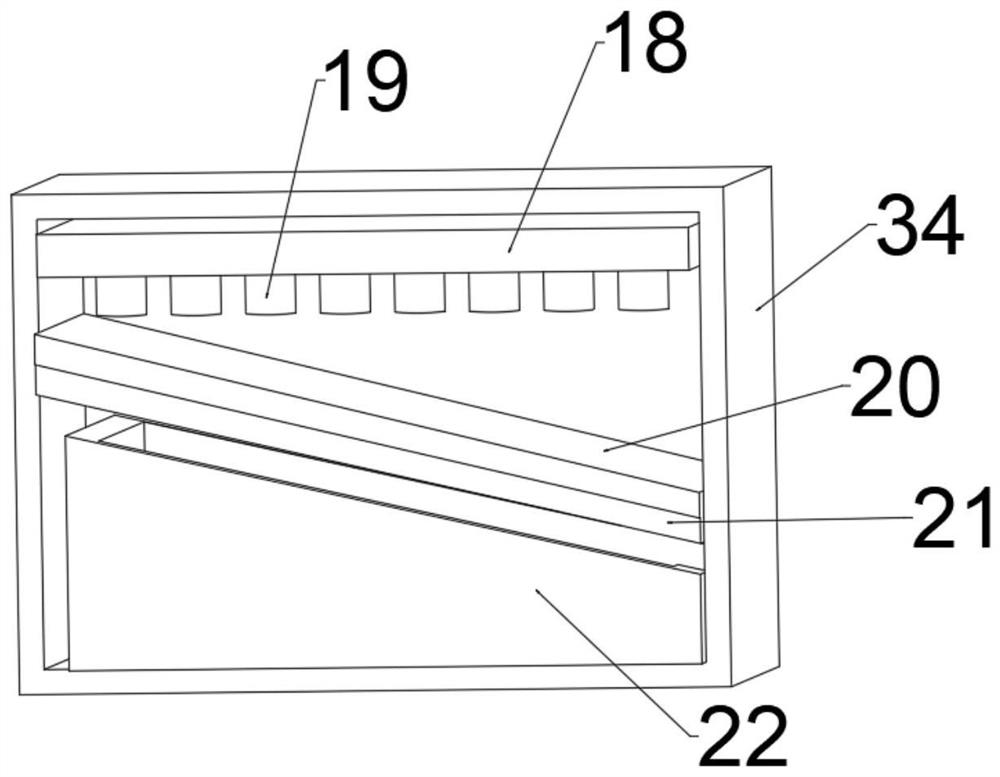

Industrial contaminated soil remediation device

InactiveCN112108511AAvoid damageImprove applicabilitySoil lifting machinesSpadesSoil remediationMechanical engineering

The invention discloses an industrial contaminated soil remediation device which comprises a box body, a fixing table is arranged at the lower part of the right side of the box body, a fixing block isarranged at the upper part of the fixing table, a second connecting rod is arranged on the right side of the shell wall of the fixing block, a first connecting rod is arranged at the left end of thesecond connecting rod, and a soil turning block is arranged at the end, away from the second connecting rod, of the first connecting rod. A third connecting rod is arranged at the middle of the secondconnecting rod. A fourth connecting rod is arranged at the end, away from the second connecting rod, of the third connecting rod and rotationally connected with the top end of the shell wall of the fixing block. When the device operates, the device can be moved through rolling wheels, soil enters a processing box through a conveying pipe and a feeding pipe, is repaired in the processing box, enters a discharging pipe after repairing is completed, and is guided out through a soil outlet pipe, so that soil repairing is completed, and after repairing is completed, the fourth connecting rod rotates again, so that the right end of a soil turning block is lifted up, the soil turning block is prevented from damaging a normal pavement, and the applicability of the soil turning block is improved.

Owner:卢超

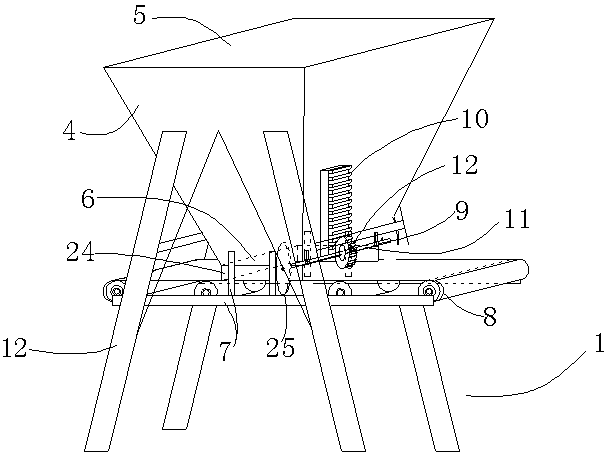

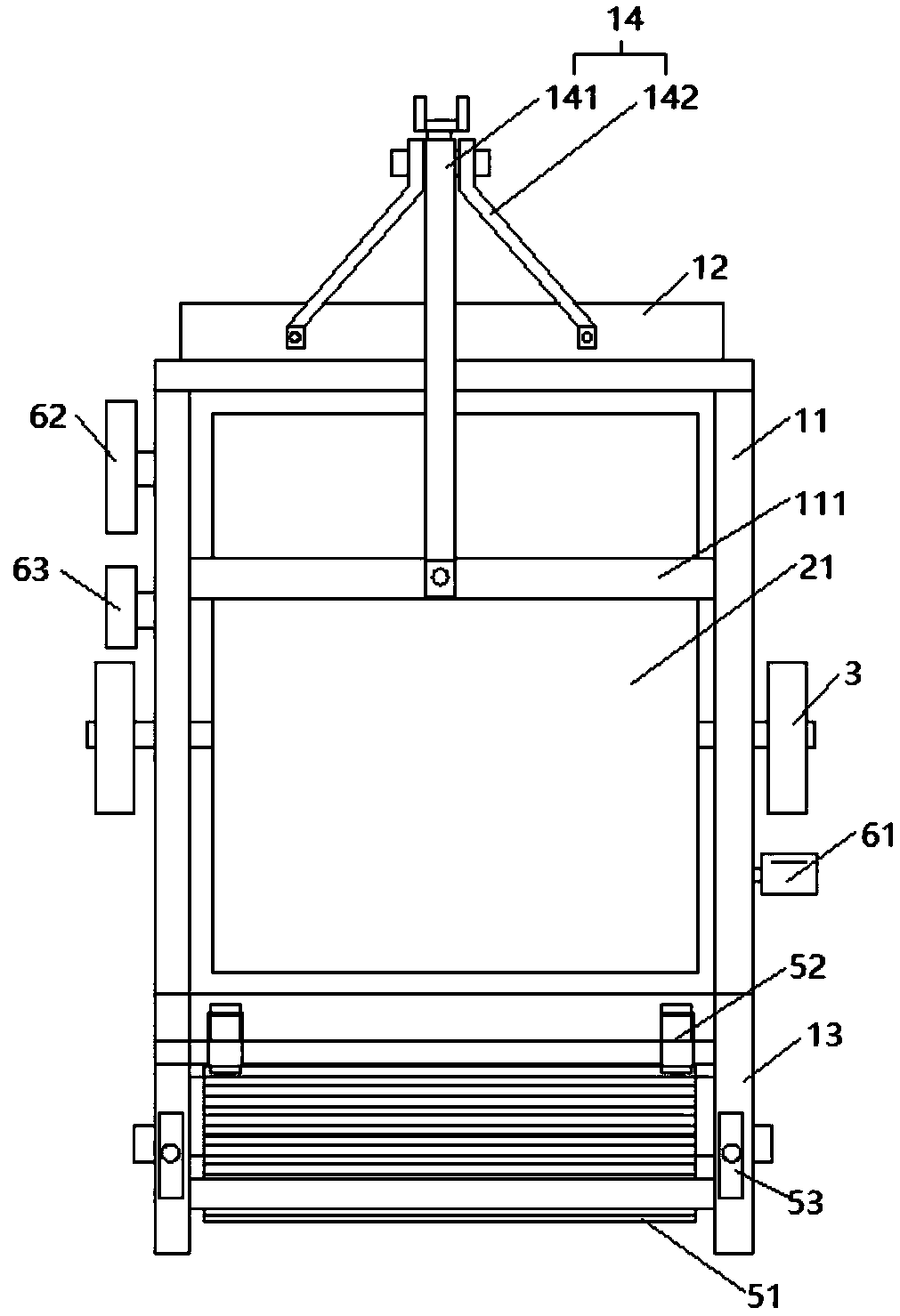

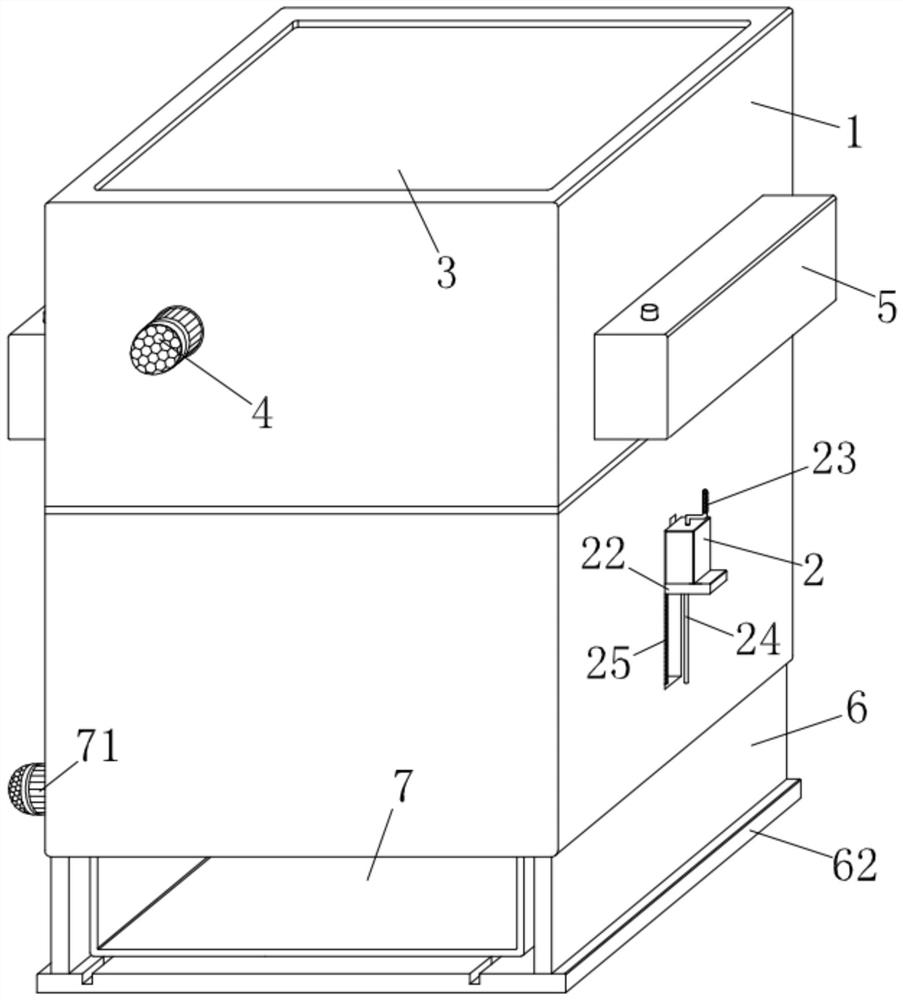

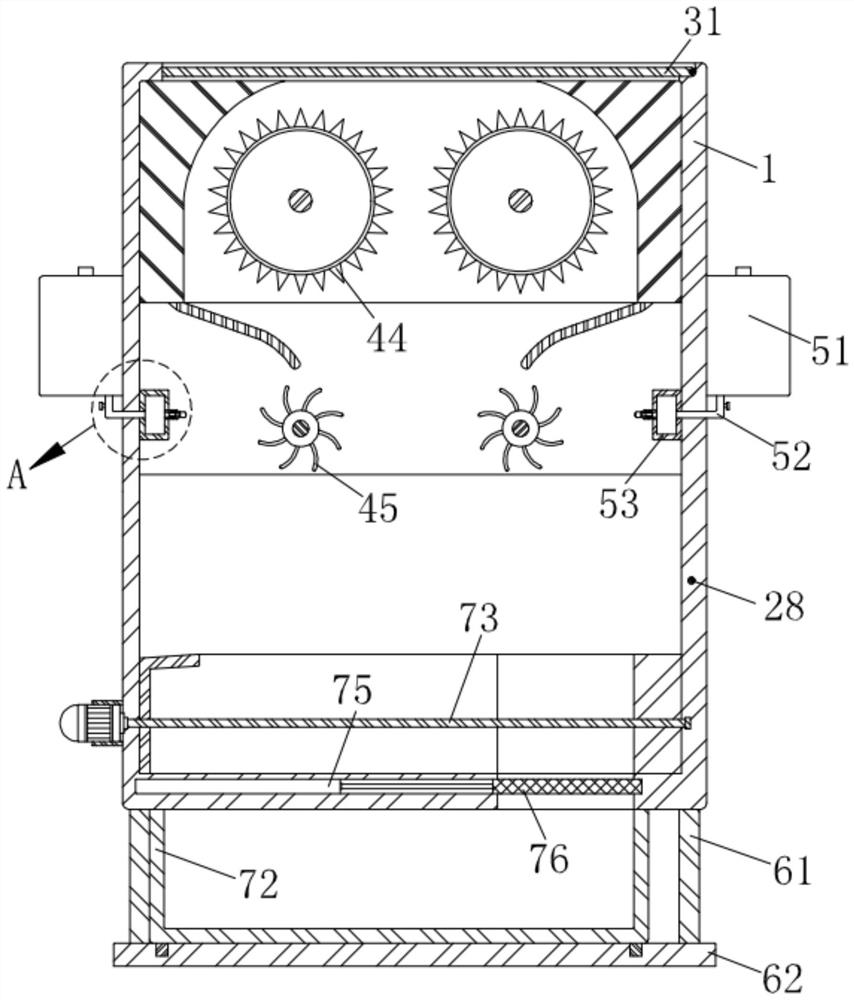

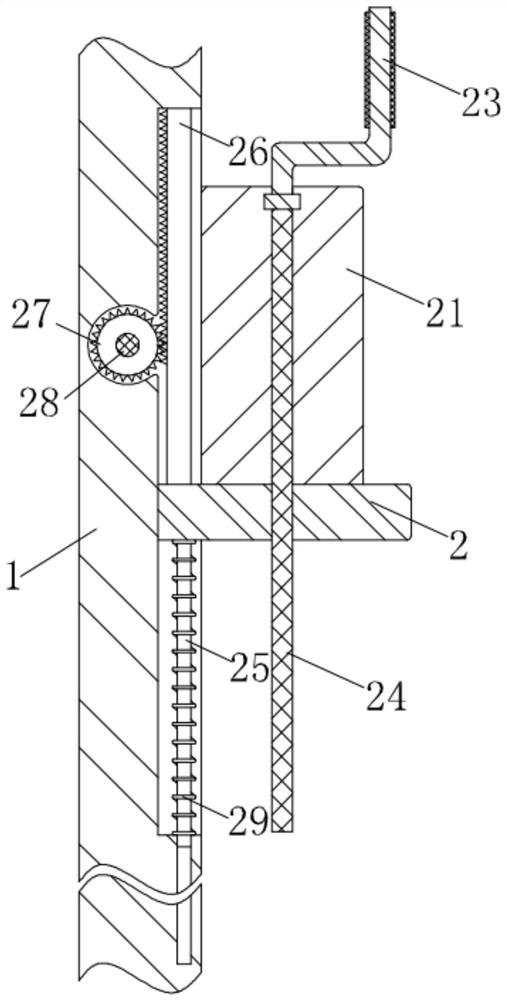

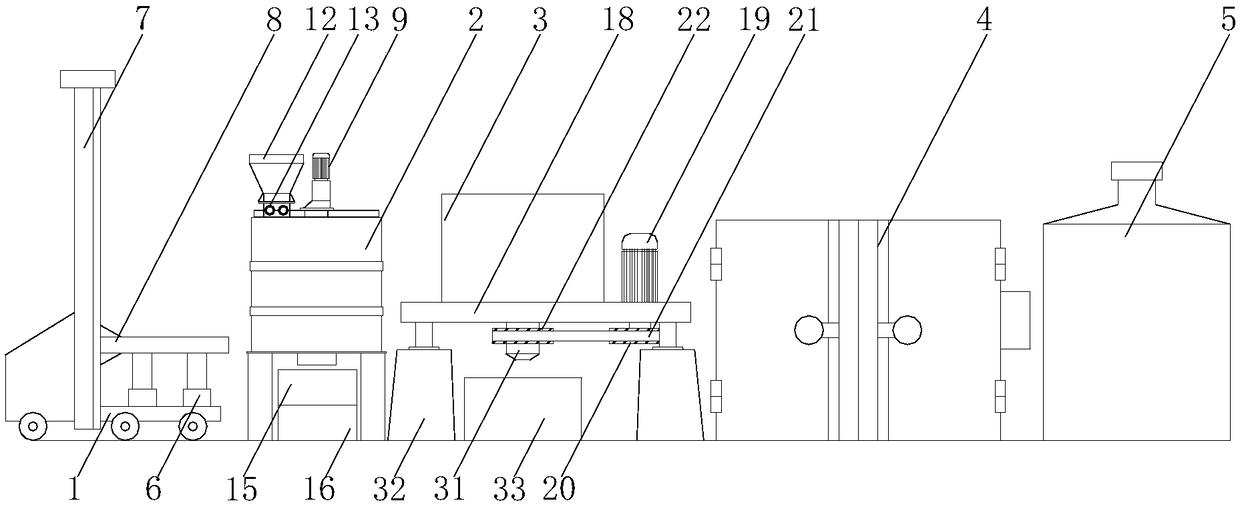

Biomass fuel compression equipment with classifying structure

The invention discloses biomass fuel compression equipment with a classifying structure, and relates to the technical field of biomass fuel processing. The biomass fuel compression equipment with theclassifying structure comprises a box body and a first compression mechanism, a partition plate is welded to the middle end of the interior of the box body, the first compression mechanism is arrangedon one side of the interior of the box body, a second compression mechanism is arranged on the other side of the interior of the box body, and a driving mechanism is arranged on the top of the firstcompression mechanism. The biomass fuel compression equipment with the classifying structure has the beneficial effects that the second compression mechanism and the first compression mechanism are arranged, the box body which is of a large cuboid structure can be divided into two small cuboid structures with the same volume through the plate block type partition plate, therefore, classifying typecompression operation can be conducted on biomass fuel in different forms separately under hollow cooperation of the second compression mechanism and the first compression mechanism by means of the dividing structure, and the overall applicability and practicability of the device are improved.

Owner:张文钊

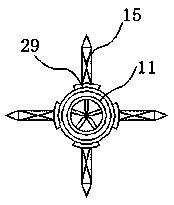

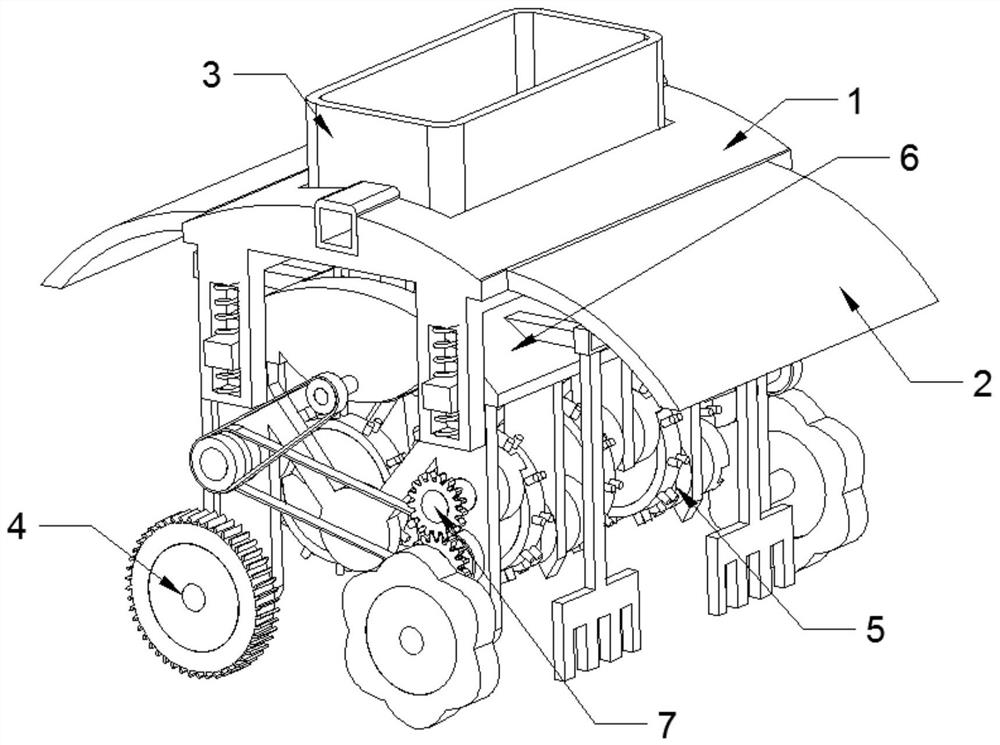

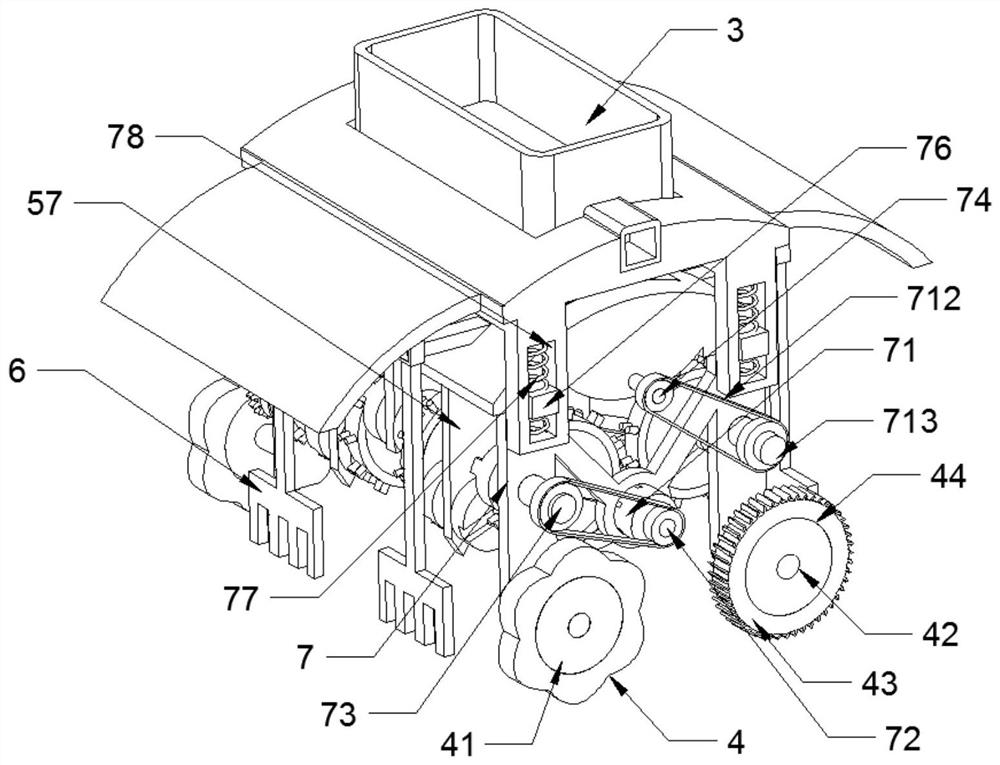

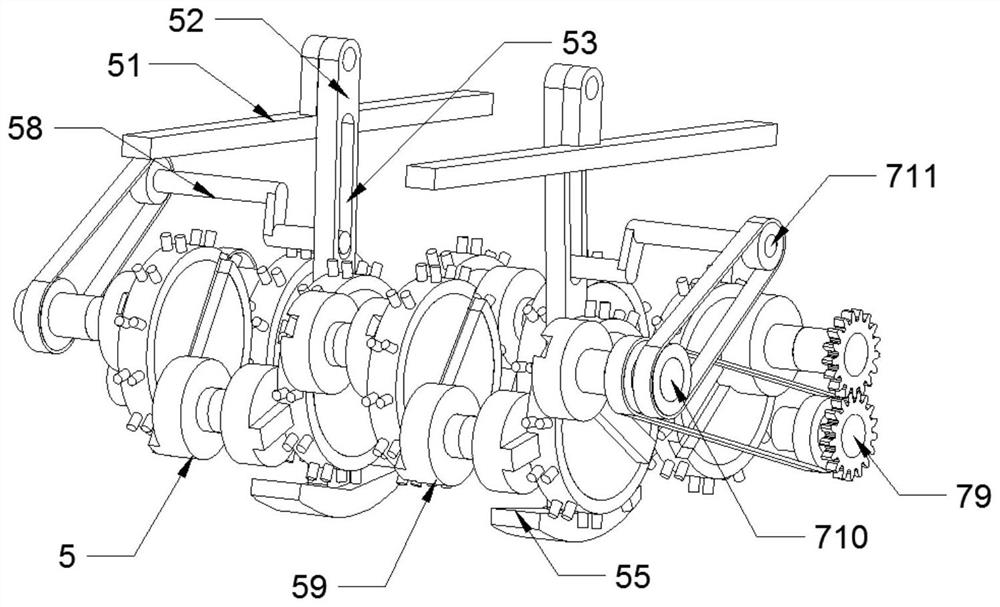

Straw crushing body and crushing returning apparatus with same

PendingCN108377754ASpread evenlyFully contactedLoadersCrop conditionersAgricultural engineeringEngineering

The invention discloses a straw crushing body and a crushing returning apparatus with the same and belongs to the field of agricultural machinery. The straw crushing body comprises a housing, a pickuproller, a main crushing roller, an auxiliary crushing roller, a first straw transfer roller, a second straw transfer roller, and a dual-roller crushing component; the main crushing roller is positioned above the right of the pickup roller; the auxiliary crushing roller is positioned above the left of the main crushing roller; the first straw transfer roller is positioned among the pickup roller,the main crushing roller and the auxiliary crushing roller; the second straw transfer roller is positioned on the left of the auxiliary crushing roller above the main crushing roller; a housing outletis arranged below the right of the main crushing roller. The straw crushing body has the advantages that the auxiliary crushing roller is designed at the upper right corner of the main crushing roller, part of straw is transferred to the auxiliary crushing roller through the two straw transfer rollers to take deep crushing, crushing time of straw from a housing inlet to the housing outlet can beextended, the straw can be fully crushed accordingly, and the straw may be finer and more uniform at the housing outlet.

Owner:NANZHANG COUNTY HUASHENG MACHINERY MFG

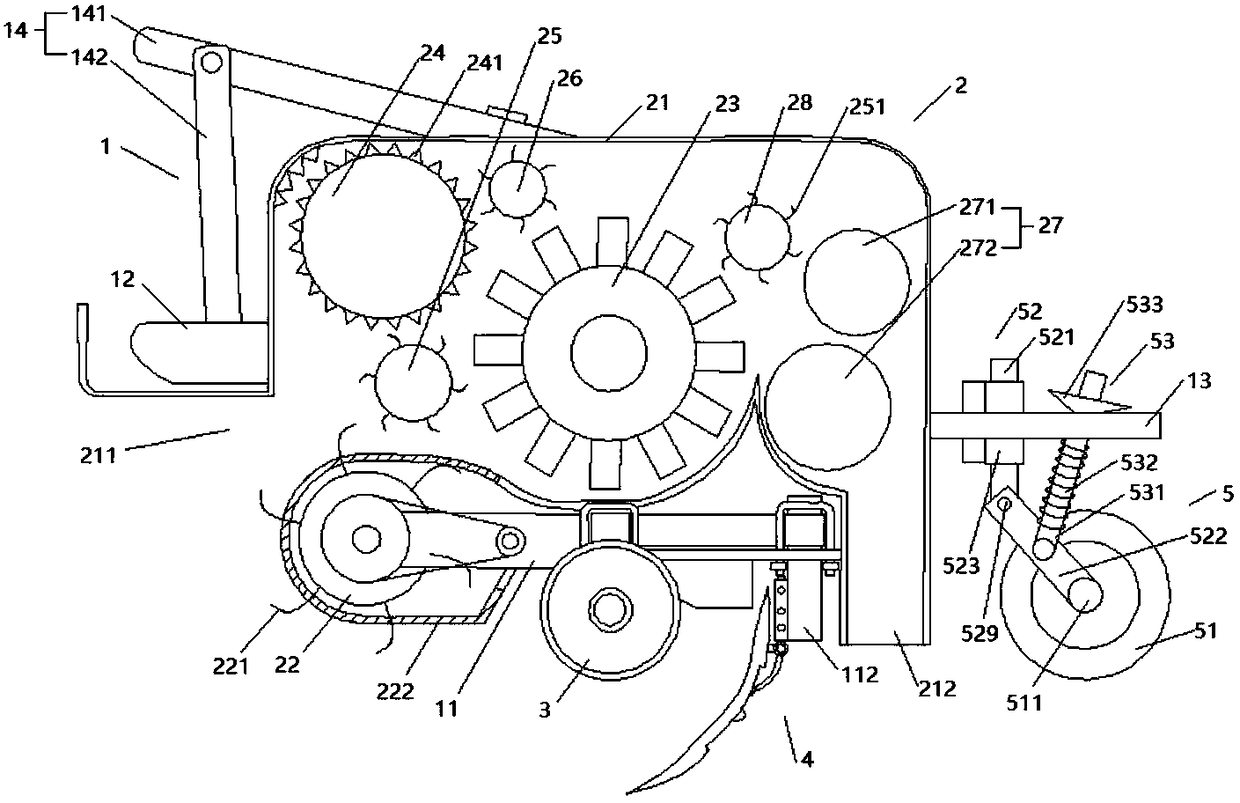

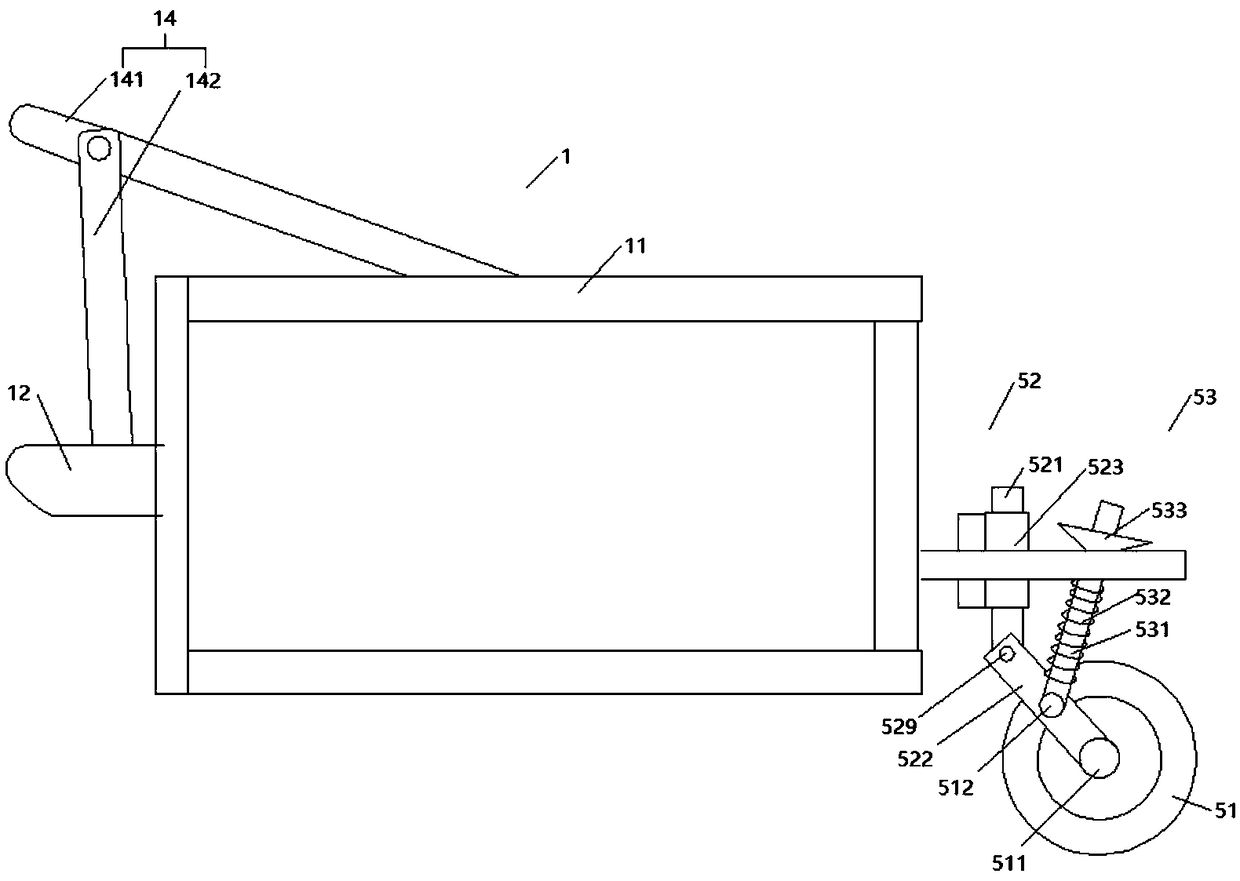

Agricultural scarifier

PendingCN111955071AImprove soil loosening efficiencyImprove soil loosening effectSpadesPloughsAgricultural engineeringStructural engineering

The invention discloses an agricultural scarifier. The agricultural scarifier comprises a suspension, mud guards, a water tank and a frame, wherein the suspension is fixedly arranged at the bottom ofthe water tank; the frame is movably arranged at the bottom end of the suspension; the mud guards are fixedly arranged on two sides of the frame; a soil loosening mechanism which can rotate back and forth and float up and down to improve the soil loosening efficiency is movably arranged on the inner wall of the frame; moving mechanisms which can stably rotate to drive the frame to move up and downare movably arranged on two sides of the soil loosening mechanism; and transmission mechanisms which rotate to drive the soil loosening mechanism to work stably are arranged on two sides of the soilloosening mechanism in a rotating manner and are positioned on corresponding positions of the moving mechanisms. The agricultural scarifier can loosen soil on the ground according to the situation ofthe loosening ground, can improve the soil loosening effect of a machine on the ground while combing and leveling of the loosened ground is guaranteed, so that the loosened soil has balanced depth, next sowing of users for farmland ground can be facilitated, and the soil loosening efficiency of users can be improved.

Owner:长沙开湖设备有限公司

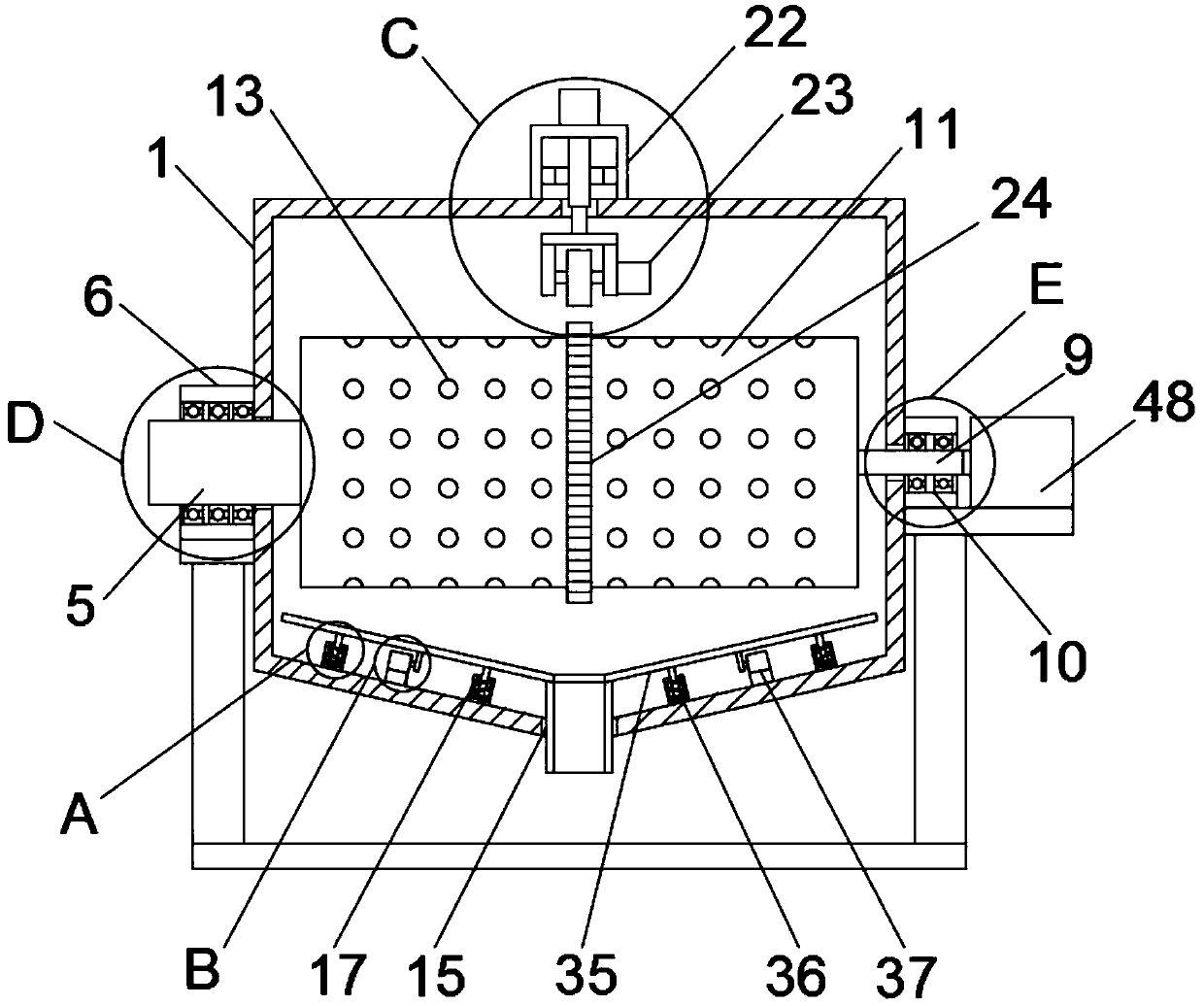

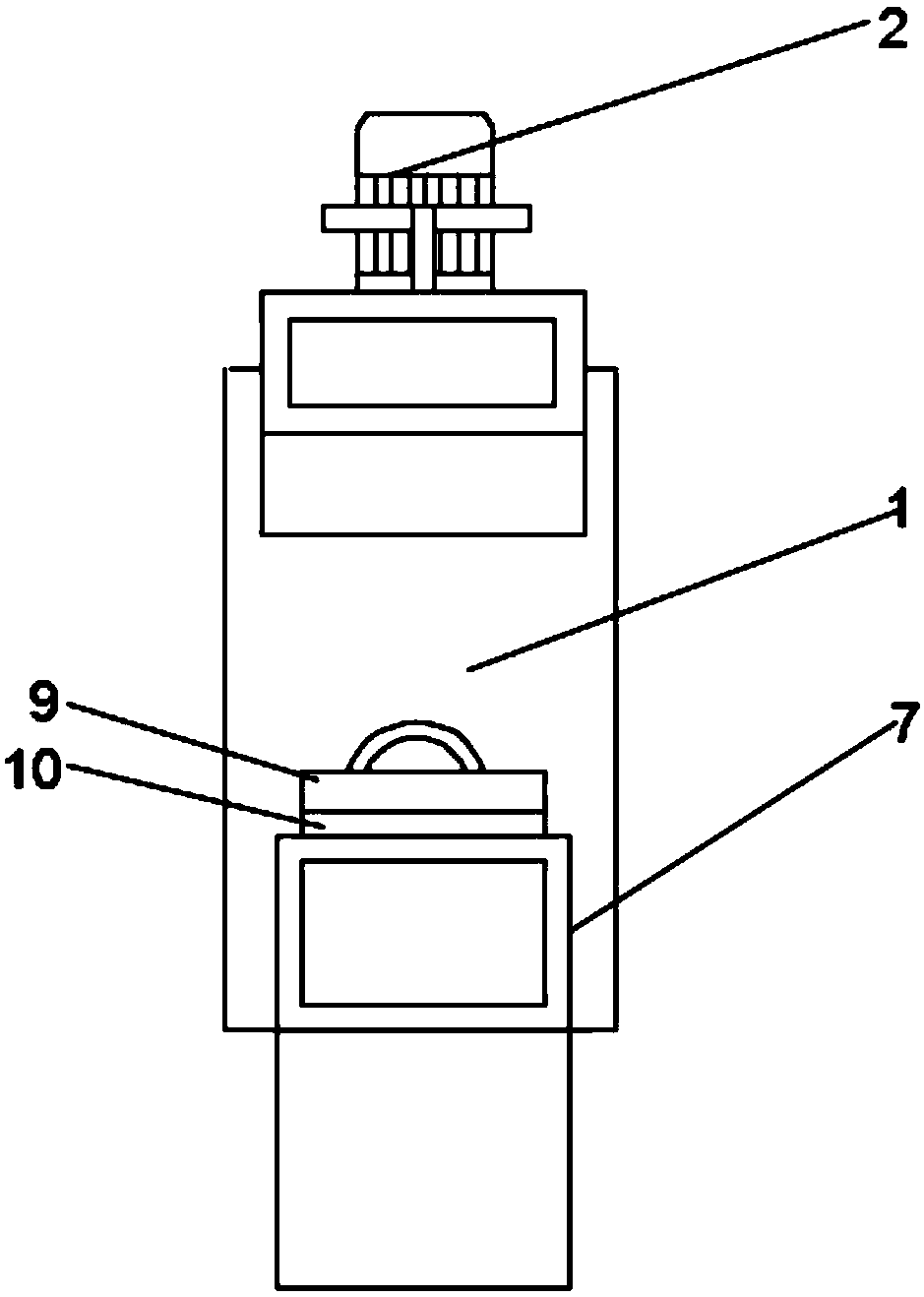

Sealable medical waste recovery device

InactiveCN113649113APlay a crushing rolePlay the role of distributionSolid waste disposalMedical waste disposalMedical wasteInfection risk

The invention relates to the technical field of medical waste treatment, in particular to a sealable medical waste recovery device. The sealable medical waste recovery device comprises a box body, wherein a supporting mechanism is fixedly connected to the box body; a driving mechanism is arranged on the box body, and a sealing mechanism is arranged in the box body and on the driving mechanism jointly; a crushing mechanism is arranged in the box body, and a disinfection mechanism is arranged on the box body; and an extrusion mechanism is arranged in the box body. By means of the crushing mechanism, plastic medicine bottles large in size or fluffy medical waste small in density can be crushed conveniently, so that too much storage space in the box body is prevented from being occupied, and the recovery efficiency of the device is guaranteed. The disinfection mechanism is arranged on the box body, so that the disinfection effect on the medical waste in the crushing process is conveniently achieved, and the infection risk generated in the transfer process is reduced. The extrusion mechanism is arranged on the box body, so that the crushed medical waste is conveniently extruded into blocks, the occupied space of the medical waste in the box body is further reduced, and the recovery efficiency of the device is improved.

Owner:刘志鹏

Chemical mixer

InactiveCN108514850AEasy to installGuaranteed stabilityTransportation and packagingMixer accessoriesBiochemical engineeringVacuum tube

The invention discloses a chemical stirrer. A vacuum device is arranged on the upper side of the motor, a vacuum tube is arranged on the upper side of the vacuum device, a pressure gauge is arranged on the right side of the vacuum tube, a control panel is arranged on the right side of the pressure gauge, a base is arranged on the right side of the motor, a supporting column is arranged on the upper side of the base, a bearing is arranged on the upper side of the supporting column, a clamping pipe hole is arranged at the top of the supporting column, a clamping pipe device switch is arranged onthe outer side of the clamping pipe hole, a rotating shaft is arranged on the right side of the bearing, a stirring tank is arranged on the right side of the rotating shaft, the lower side of the stirring tank is provided with a clamp, and the lower side of the clamp is provided with a discharge port, the right side of the stirring tank is provided with a liquid feeding pipe, a solid feeding pipeand a powder feeding pipe, the lower side of the liquid feeding pipe is provided with a liquid storage bin, a water pump is arranged in the liquid storage bin, and a solid storage bin is arranged onthe lower side of the solid feeding pipe.

Owner:常州市飞腾工业自动化技术有限公司

Film residue reduction system

InactiveCN109127673AReduce work intensityAcidification effect is goodSolid waste disposalTransportation and packagingAgricultural engineeringHydraulic cylinder

The invention discloses a film residue reduction system. The system comprises a charging platform, an acidification box, a dehydration box and an oven, wherein the top of the top of the charging platform is fixedly connected with a hydraulic cylinder, one side of the charging platform is fixedly connected with a fixing plate, a charging plate is glidingly connected with one side of the fixing plate, the top of the acidification box is fixedly connected with a first motor, an output end of the first motor is fixedly connected with a rotating shaft, and the bottom of the rotating shaft is fixedly connected with stirring blades. The charging platform, the hydraulic cylinder, the fixing plate and the charging plate can play a charging role during reduction of film residues, and the working intensity is reduced; the acidification box, the first motor, the rotating shaft and the stirring blades can play an acidification role during reduction of film residues; the acidification effect on thefilm residues is better through stirring, and a third motor and a grinding gear play a crushing role on film residues in larger sizes during discharging, so that the film residues are more thoroughlyacidized.

Owner:深圳市伟绿达科技有限公司

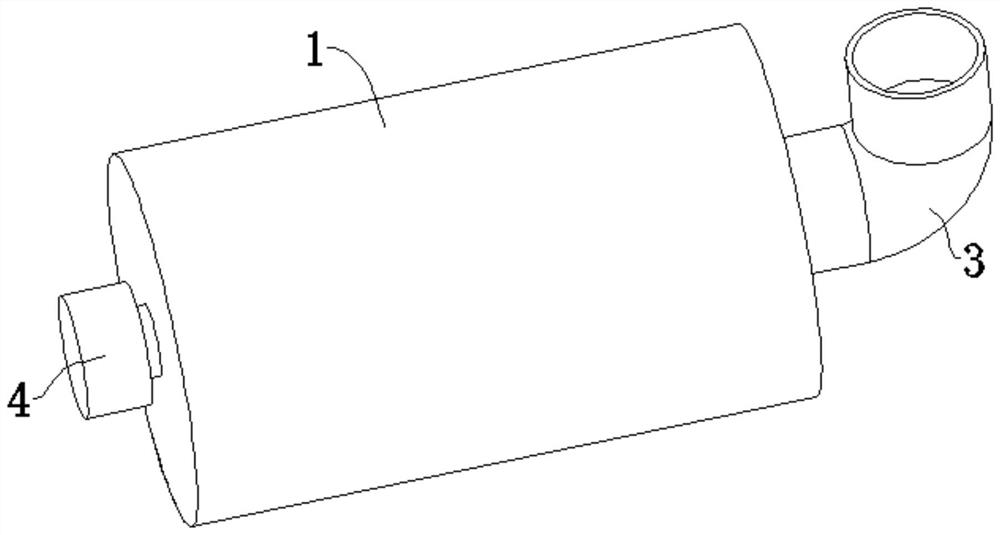

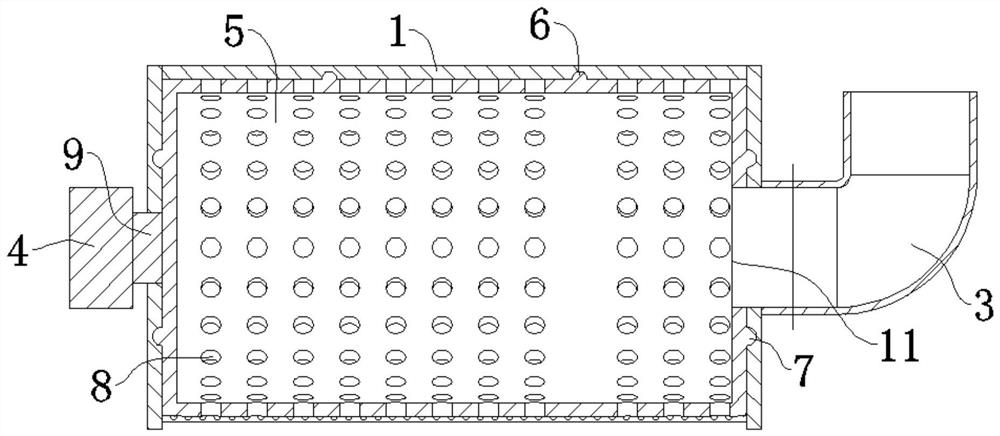

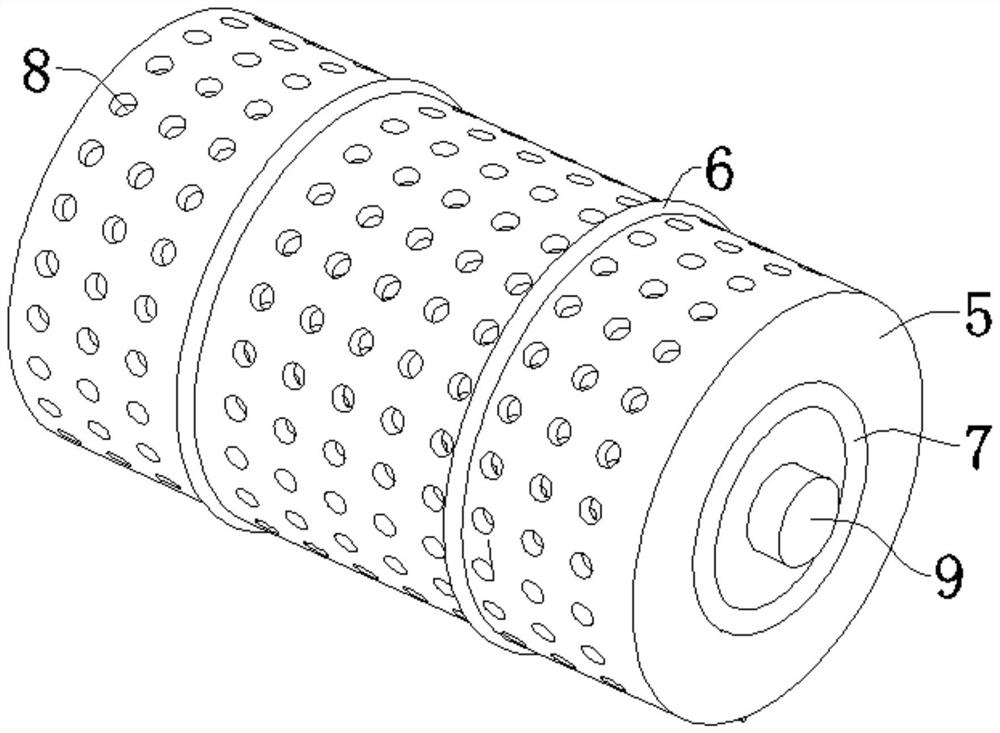

A raw material crushing equipment for Longquan celadon production and its use method

ActiveCN107999211BAchieve separationImprove grinding efficiencyGrain treatmentsElectric machineryEngineering

The invention discloses raw material crushing equipment for production of Longquan celadon and a using method thereof. The raw material crushing equipment comprises a shell, a grinding cylinder, a supporting base, a base, a fixing base, a releasing cylinder, a driving device, a discharging cylinder, a grinding motor and a centralizing device, wherein a first opening is formed in one side of the shell, the grinding cylinder is located in the shell, and grinding beads are arranged in the grinding cylinder. One side of the grinding cylinder is fixedly provided with a feeding cylinder, the end, away from the grinding cylinder, of the feeding cylinder is rotationally connected with the supporting base, the bottom of the supporting base is fixed to the base, a second opening is formed in the side, far away from the first opening, of the shell, the end, far away from the feeding cylinder, of the grinding cylinder is fixedly provided with a rotating shaft, and the rotating shaft penetrates through the second opening and is rotationally connected with the fixing base. According to the raw material crushing equipment for production of the Longquan celadon and the using method thereof, a partof ground raw materials can be output from the discharging cylinder, so that the separation of the ground raw materials from the raw materials which are not subjected to grinding is realized, and thegrinding efficiency of the raw materials is improved.

Owner:龙泉市尚唐瓷艺发展有限公司

Treatment process of dibenzoyl methane production waste

PendingCN113620317AReduce contentHigh purityOther chemical processesSolid sorbent liquid separationChemistryEnvironmental chemistry

The invention discloses a treatment process of dibenzoyl methane production waste, which comprises the steps of: mixing sodium chloride as dibenzoyl methane production waste with water according to a mass ratio of 1: (3-5), then feeding the mixture into flotation equipment, stirring, carrying out flotation, removing upper organic impurities, then taking out a mixed solution in the flotation equipment, carrying out adsorption, concentration, precipitation and separation, washing solid substances with an organic solvent, and drying the solid substances to obtain industrial salt. According to the method, the defects in the prior art are overcome, the content of organic impurities in the industrial salt is reduced, and the purity of the industrial salt is improved.

Owner:ANHUI JIAXIAN FUNCTIONAL AUXILIARY

Material crushing device for decorative building material

InactiveCN108787072ASolve the problem of relatively large vibrationReduce vibrationGrain treatmentsArchitectural engineeringBuilding material

The invention discloses a material crushing device for a decorative building material, and relates to the technical field of decorative building materials. The material crushing device comprises a boxbody, the top of the box body is fixedly connected with a motor through a support, the bottom of the motor is rotationally connected with a crushing shaft through an output shaft, the end, far away from the motor, of the crushing shaft penetrates through the box body and extends into the box body, the end, located in the box body, of the crushing shaft is rotationally connected with the bottom ofthe inner wall of the box body, a crushing cutter sleeve is fixedly connected to the portion, located inside the box body, of the outer wall of the crushing shaft, the surface of the outer wall of the crushing cutter sleeve is fixedly connected with crushing knives, reinforcing blades are fixedly connected to the two sides of the inner wall of the box body, the reinforcing blades and the crushingknives are arranged in a staggered mode, discharging troughs are fixedly connected to the two sides of the lower end of the outer wall of the box body, and movable troughs are formed in the tops of the discharging troughs. According to the material crushing device, the problems that an existing material crushing device is large in vibration during working, and a large amount of dust is prone to be caused during discharging are solved.

Owner:安吉吉来雅装饰材料有限公司

Method for grinding to form powder by using steam-exposition assisted konjac wet method

InactiveCN102524706BStrong penetrating powerReduce dosageFood shapingFood preparationCell wallOligosaccharide

The invention provides a method for grinding to form powder by using a steam-exposition assisted konjac wet method. According to the method, the problems that in the technology for producing the power by using konjac, the purity of products processed by adopting a dry method is not high, a wet method process season is short, the cost is slightly high, and the like are solved. Due to the adoption of steam-exposition assistance, the consumption of a protecting agent in the technology of producing the powder by using the konjac wet method is reduced, energy consumption of the production process is reduced and the yield and the purity of refined powder are improved. The method comprises the steps of pretreatment of the konjac as a raw material, steam-exposition treatment of the konjac, steam-exposition konjac wet-method grinding and the like. The method has the advantages that: due to the use of steam exposition, on one hand, cell walls are damaged, and on the other hand, konjac glucomannan is partially degraded into oligosaccharide, and thereby the contacted area of the protecting agent and the konjac glucomannan is increased, the purity of the konjac glucomannan in konjac powder is improved, and the functional value of the konjac powder is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

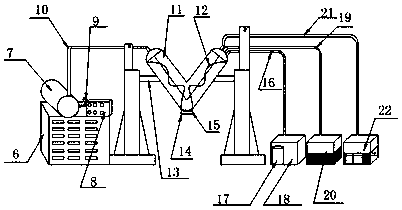

A powder spraying three-pass dryer

ActiveCN105486045BImprove the quality of drying operationsImprove drying efficiencyDrying machines with non-progressive movementsHeating arrangementSlagPowder Spray

The invention discloses a powder spraying three-pass drier. The powder spraying three-pass drier comprises a roller drier body. Communicators are installed at the two ends of the roller drier body. The communicator located on the left side of the roller drier body is communicated with a powder burning furnace through a material conveying pipe, and the communicator located on the right side of the roller drier is communicated with a slag separator through a material conveying pipe. The slag separator is communicated with a draught fan through a material conveying pipe. The draught fan is communicated with a dust remover through a material conveying pipe. The dust remover is connected with a dry wood powder collecting device and a powder sending draught fan device respectively through material conveying pipes. The powder sending draught fan device is communicated with the powder burning furnace through a material conveying pipe. The material conveying pipe between the roller drier body and the powder burning furnace is provided with a wet wood powder feeding device communicated with the corresponding material conveying pipe. According to the powder spraying three-pass drier, it is ensured that wood powder can stay in the drier for a long time in the working process, the amount of the wood powder is large, the automation degree is high, slag and dust in the wood powder can be removed, the quality of drying work is improved, meanwhile, the drying work on wet wood powder is achieved, and the three-pass drying efficiency and use value are achieved.

Owner:ANHUI DING BEAM BIO ENERGY TECH DEV CO LTD

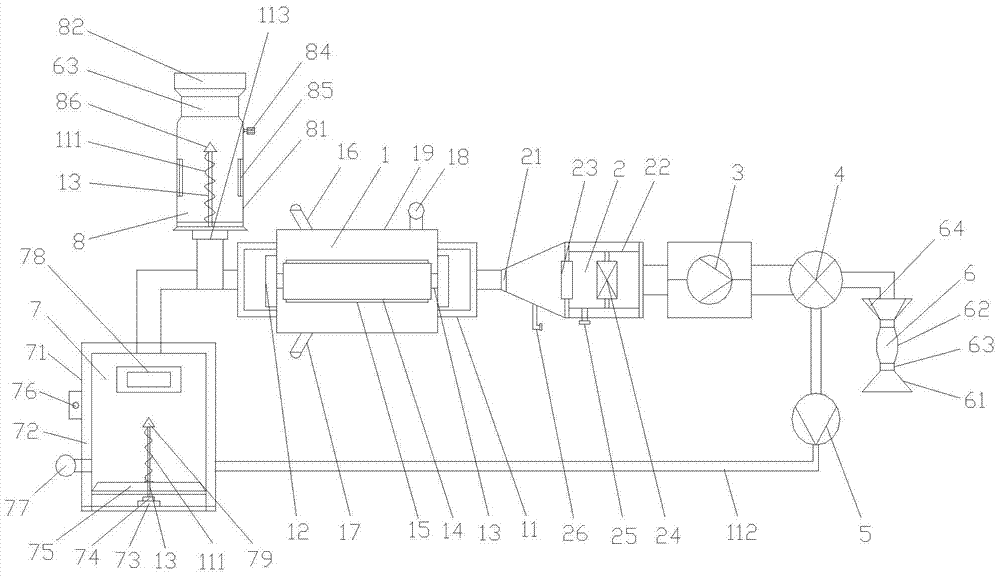

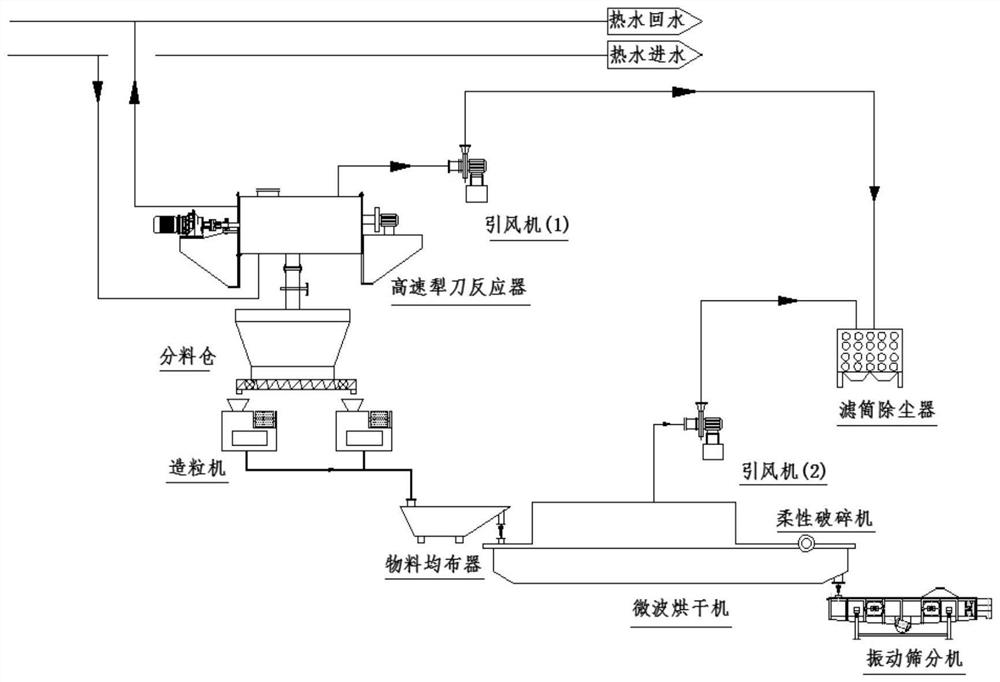

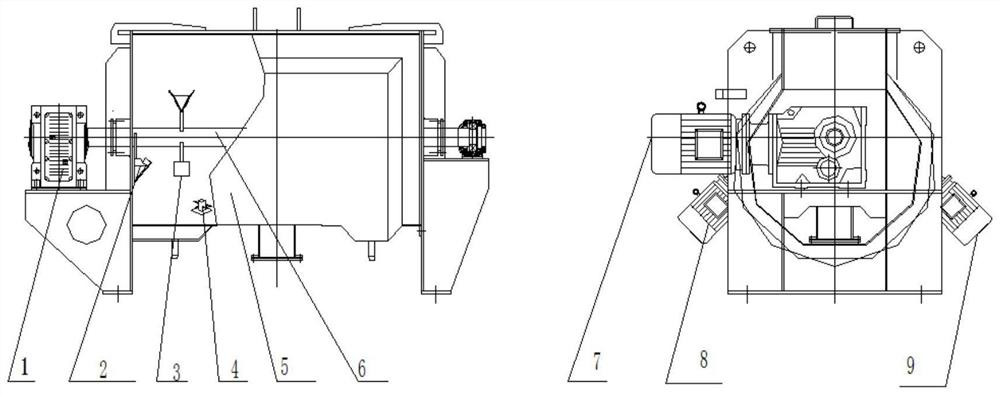

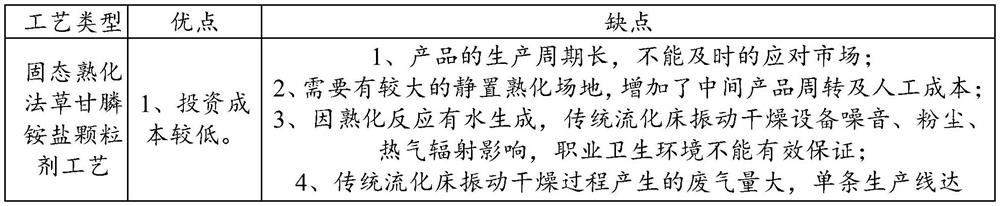

System and method for continuously producing ammonium glyphosate granules

ActiveCN112221424AShorten thorough mixing timePlay a crushing roleBiocideMaterial granulationHigh energyProcess engineering

The invention discloses a system for continuously producing ammonium glyphosate granules. The system comprises a high-speed coulter reactor provided with a feed port, a heating device, a first induceddraft fan and a discharge port, a material distribution bin with the feed port being connected with a discharge port of the high-speed coulter reactor, a granulator with the feed port being connectedwith a discharge port of the material distribution bin, a material uniform distributor with the feed port being connected with a discharge port of the granulator,, a microwave dryer with the feed port being connected with a discharge port of the material uniform distributor, wherein the microwave dryer is provided with a second induced draft fan, a flexible crusher with the feed port being connected with a discharge port of the microwave dryer, a vibrating screen classifier with the feed port being connected with a discharge port of the flexible crusher, and a filter cartridge dust remover with the feed port being respectively connected with a discharge port of the first induced draft fan and a discharge port of the second induced draft fan. The system is high in production efficiency andgood in product quality, and can solve the problems of high energy consumption, unsatisfactory occupational health environment, high tail gas treatment operation cost, high later environment-friendlywastewater treatment cost and the like in the existing glyphosate granule production process.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com