Waste residue and waste gas recovery treatment system for industrial deslagging roller

A waste gas recovery and treatment system technology, applied in gas treatment, grain treatment, use of liquid separation agent, etc., can solve the problems of dusty waste gas treatment effect, lack of waste residue and waste gas recovery and treatment system, etc., to achieve reasonable structure design and improve treatment effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

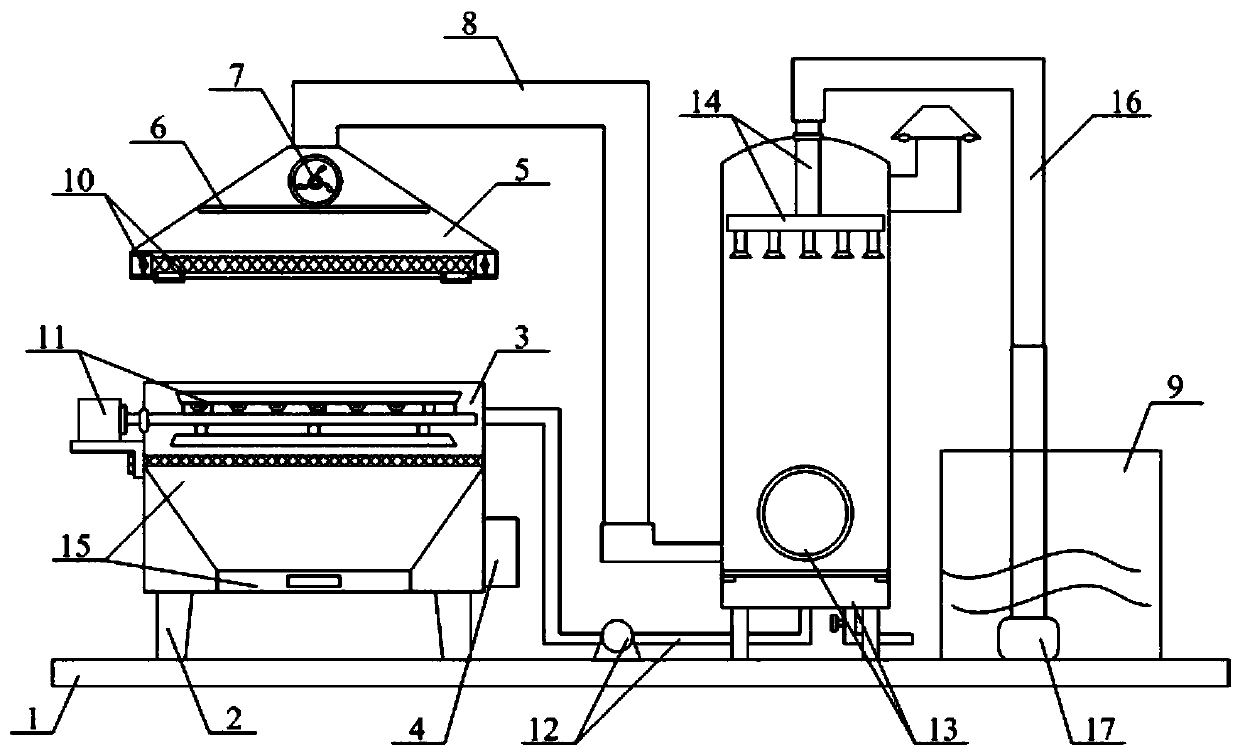

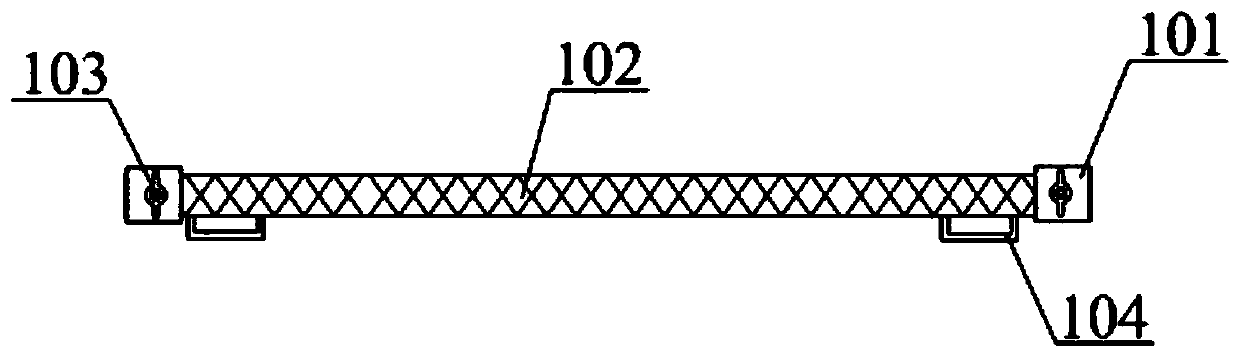

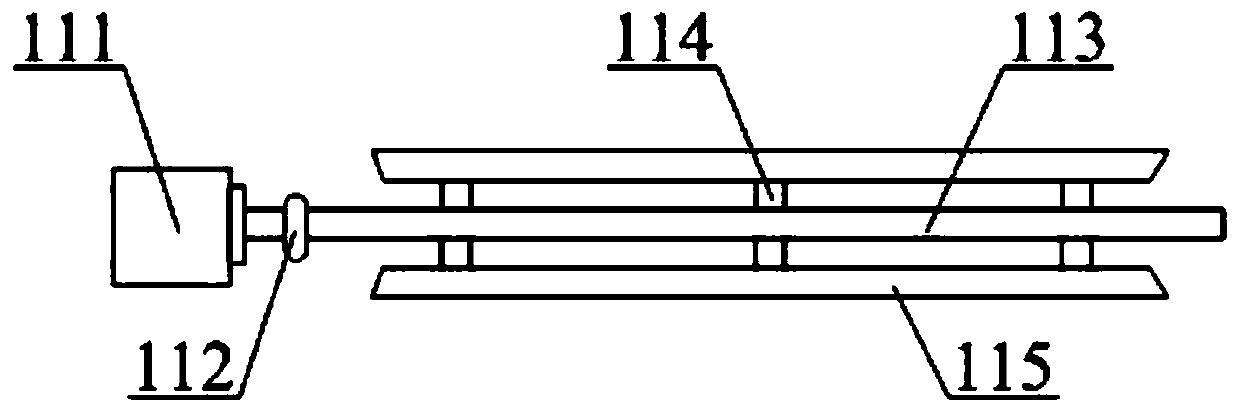

[0036] as attached figure 1 To attach figure 2 As shown, the present invention provides an industrial waste slag and waste gas recovery treatment system for a slag discharge drum, including a support installation base plate 1, a support column 2, a waste slag recovery box 3, an electrical control box 4, an air suction cover 5, and a support bar 6 , exhaust fan 7, air guide pipe 8, water storage tank 9, slag prevention waste gas recovery screen structure 10, waste slag crushing plate structure 11, backflow dust suppression pipe structure 12, waste gas treatment tank structure 13, waste gas treatment spray coil structure 14. Waste residue filter bucket structure 15, water guide pipe 16 and submersible pump 17. One end of the support column 2 is bolted to the four corners of the lower surface of the waste residue recovery box 3, and the other end is bolted to the upper surface of the support installation base plate 1. side position; the electrical control box 4 bolts are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com