Treatment process of dibenzoyl methane production waste

A dibenzoylmethane and production waste technology, which is applied in the direction of solid adsorbent liquid separation, alkali metal chloride, alkali metal halide purification, etc., can solve the problems of solid waste sodium chloride treatment difficulties, etc., to achieve effective and The effect of rapid separation, improvement of purity and reduction of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

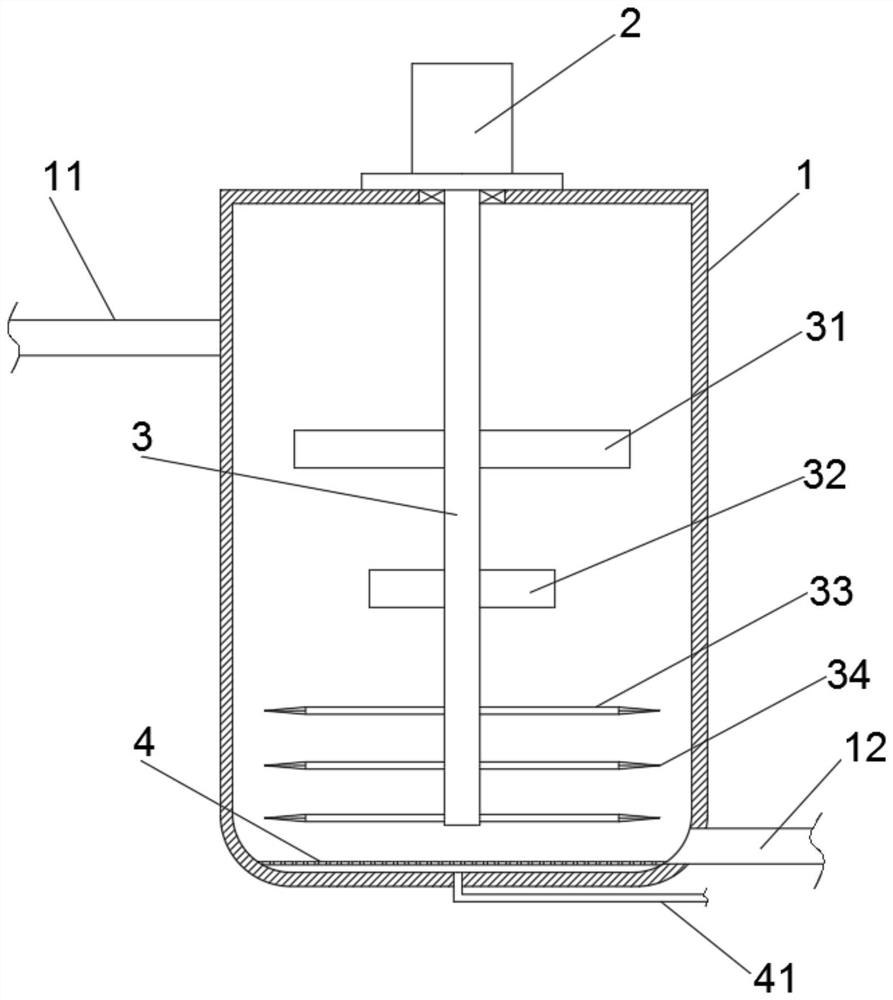

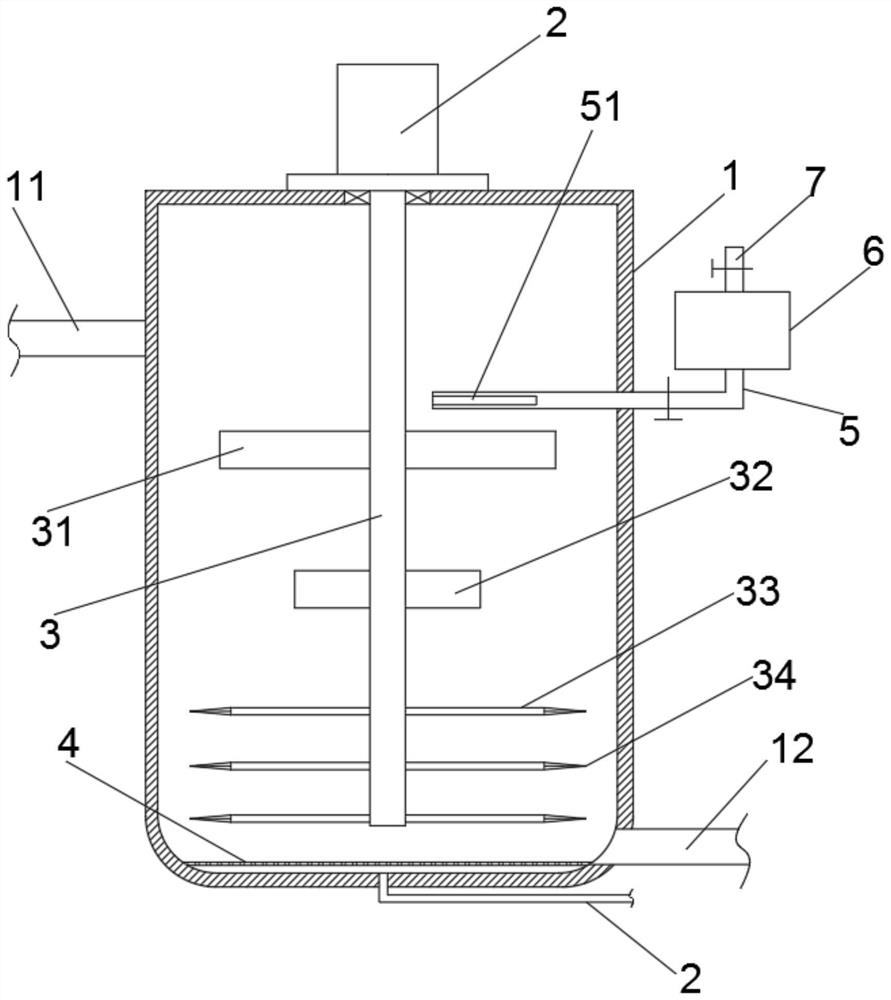

[0026] The dibenzoylmethane production waste sodium chloride and water are mixed evenly at a mass ratio of 1:4, and then sent to a flotation device for stirring and flotation to remove organic impurities in the upper layer.

[0027] The flotation equipment used includes a flotation cylinder, the top of the flotation cylinder is equipped with a stirring motor electrically connected to an external power supply, the stirring motor is equipped with an agitator, and the agitator includes a stirring rod, a first paddle, a second paddle and an air The gasification rod, the length of the first paddle is greater than the length of the second paddle, and the first paddle is installed on the stirring rod above the second paddle, the gasification rod is a round rod with a tapered structure on the top, and the gasification The rod is installed at the lower part of the stirring rod, and the length of the first paddle is greater than that of the second paddle, so that the bubbles generated by...

Embodiment 2

[0032] The dibenzoylmethane production waste sodium chloride and water are mixed uniformly at a mass ratio of 1:6, and then sent to a flotation device for stirring and flotation to remove organic impurities in the upper layer.

[0033] The flotation equipment used includes a flotation cylinder, the top of the flotation cylinder is equipped with a stirring motor electrically connected to an external power supply, the stirring motor is equipped with an agitator, and the agitator includes a stirring rod, a first paddle, a second paddle and an air The gasification rod, the length of the first paddle is greater than the length of the second paddle, and the first paddle is installed on the stirring rod above the second paddle, the gasification rod is a round rod with a tapered structure on the top, and the gasification The rod is installed at the lower part of the stirring rod, and the length of the first paddle is greater than that of the second paddle, so that the bubbles generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com