Multifunctional crusher

A pulverizer, multi-functional technology, applied in the field of mechanical equipment, can solve the problems of straw clogging, crushing size, inability to flexibly control by adjusting equipment parameters, machine clogging, etc., to reduce secondary displacement, avoid clogging, and speed up material discharge speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment the present invention is described in further detail:

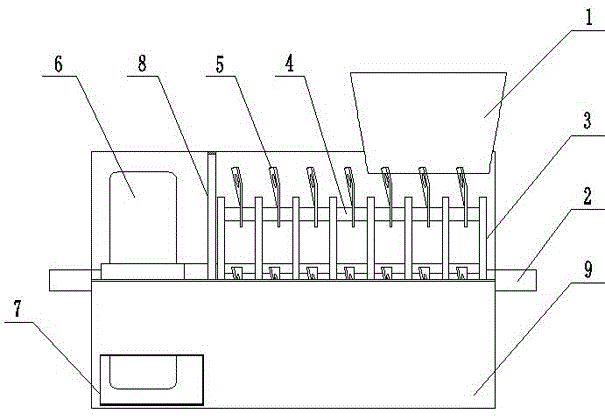

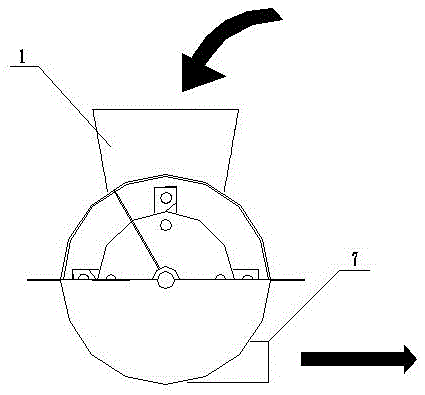

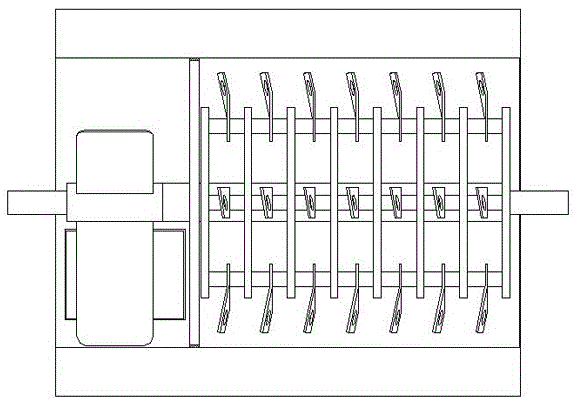

[0037] Such as figure 1 , 2 , 3, and 4, the working principle of the multifunctional pulverizer is that the straw material 10 is fed into the crushing chamber 9 through the feed port 1, and the rotation of the main shaft 2 is driven by the motor to realize the rotation and axial rotation of the arc-shaped blade 5. Step by step advancement realizes multi-stage hammering on the straw 10 to achieve pulverization and size control of pulverization, and then the pulverized straw material 10 is discharged from the discharge port 7 through the rotation of the discharge knife row 6 .

[0038] The crushed stalks are not discharged from the bottom of the crushing cavity, but are discharged from the side of the other end of the feed port 1 through the discharge knife row 6 . In the crushing chamber 9, the straw material 10 moves axially along the main shaft direction from the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com