Dreg-free meshed soybean milk machine

A soymilk machine and machine head technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of rough taste, troublesome use, and affecting the pulping rate of raw materials, so as to improve the roughness, prevent the filter cartridge from loosening, and improve The effect of crushing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

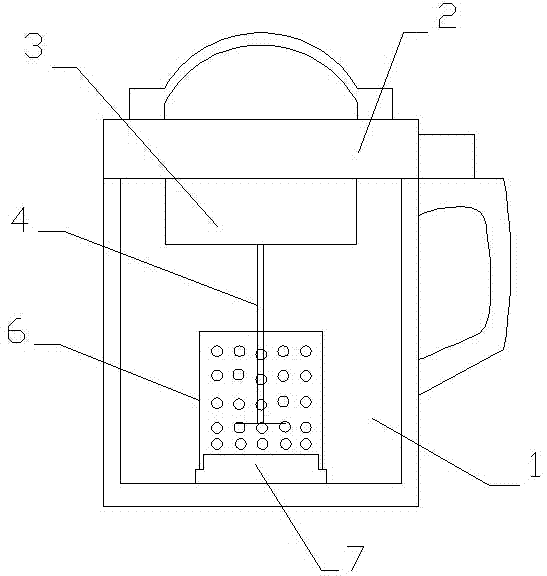

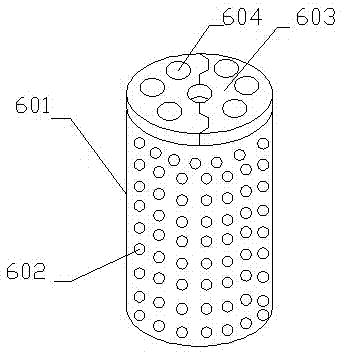

[0025] Embodiment 1: as Figure 1~5 As shown, a soymilk machine without slag and mesh includes a cup body 1, a cup cover 2 and a machine head 3. Installed on the machine head 3, the cutter shaft 4 driven by the motor in the machine head 3 drives the cutter at the end of the knife shaft 4 to rotate, and the filter cartridge 6 is installed on the mounting seat 7 at the bottom of the cup body 1, and the wall of the filter cartridge 6 A filter hole 602 is provided;

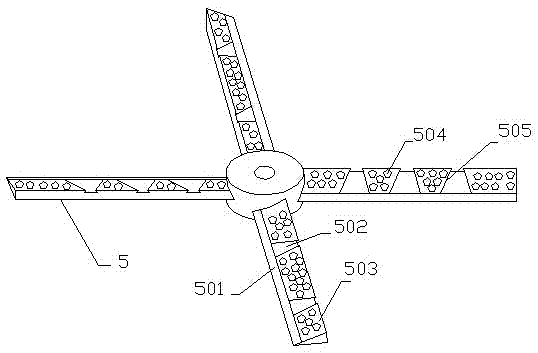

[0026] Wherein, described cutting knife comprises four blades 5, and blade 5 upper surface is provided with inclined working surface 503, and the lower edge of working surface 503 is provided with blade 501, and the crushing groove 502 that axis is perpendicular to blade 501 is set on working surface 503 , and the crushing grooves 502 on the adjacent blades 5 are set to three and two respectively, so that the crushing grooves 502 on the two blades 5 are not on the same circumference, the cross section of the crushing...

Embodiment 2

[0031] Embodiment 2: as Image 6 As shown, further improvements can be made on the basis of Embodiment 1. For example, a grinding device can be provided. The grinding device is a grinding cylinder 8 sleeved on the filter cartridge 6. A grinding layer composed of grinding particles is set, there is a grinding gap between the grinding cylinder 8 and the filter cylinder 6, and the cylinder wall of the grinding cylinder 8 is provided with fine holes, and the aperture of the fine holes is smaller than the aperture of the filter hole 602 on the filter cartridge 6, and the grinding cylinder 8 is installed on the mounting seat 7 at the bottom of the cup body 1, and is driven to rotate by the motor in the mounting seat 7, so that the relative rotation occurs between the grinding cylinder 5 and the filter cylinder 6, and the filter hole 602 enters the grinding gap from the filter cylinder 6 The slurry is ground, and the ground slurry is discharged from the pores.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com