Patents

Literature

37results about How to "Improve crushing and grinding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Swing type coffee bean crushing and grinding equipment

The invention discloses swing type coffee bean crushing and grinding equipment. The equipment comprises a base, supporting feet, a left fixing frame, a right fixing frame and a crushing tank; the leftfixing frame is fixedly connected at the left end of the base; the right fixing frame is fixedly connected at the right end of the base; the crushing tank is arranged between the left fixing frame and the right fixing frame; a motor is fixedly connected on the upper surface of the crushing tank; a crankshaft is arranged inside the crushing tank; a sliding block is arranged below a feeding port; the right end of a connecting rod is hinged to the side wall of the sliding block; a plurality of main crushing blades are distributed on the crankshaft; a plurality of auxiliary crushing blades are fixedly connected on the inner walls of the left side and the right side of the crushing tank; a fixing rod is arranged below the main crushing blades; a sieve plate is arranged below the fixing rod; and a grinding hammer head is fixedly connected at the lower end of the crankshaft. Coffee beans are intermittently placed into the crushing tank, so that the coffee beans are crushed more thoroughly, and the crushing efficiency is improved; the coffee beans are crushed through cooperation of the main crushing blades with the auxiliary crushing blades; and the sieve plate is vibrated up and down, sothat the crushed coffee beans fall to the bottom of the crushing tank favorably.

Owner:张先吉

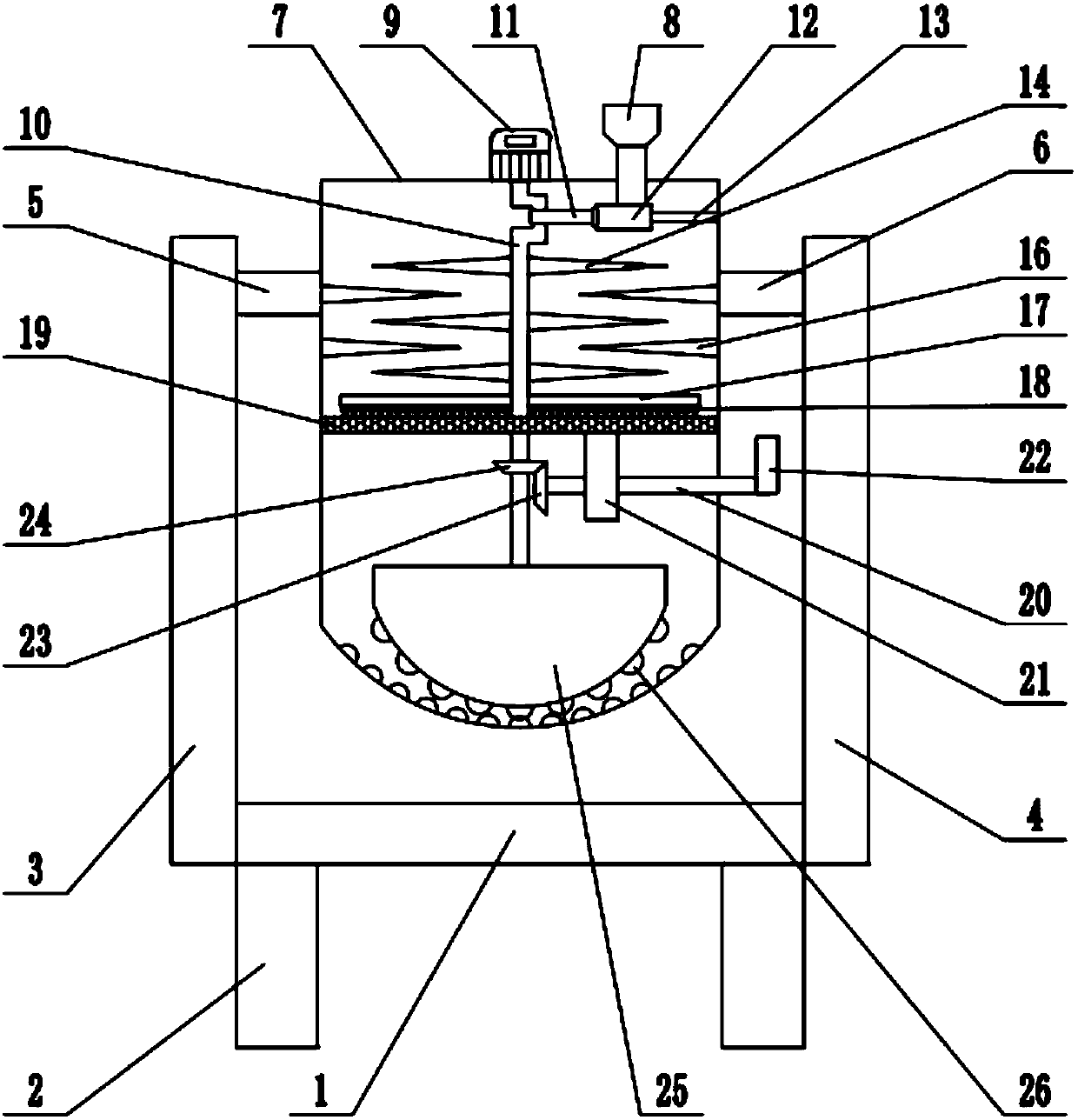

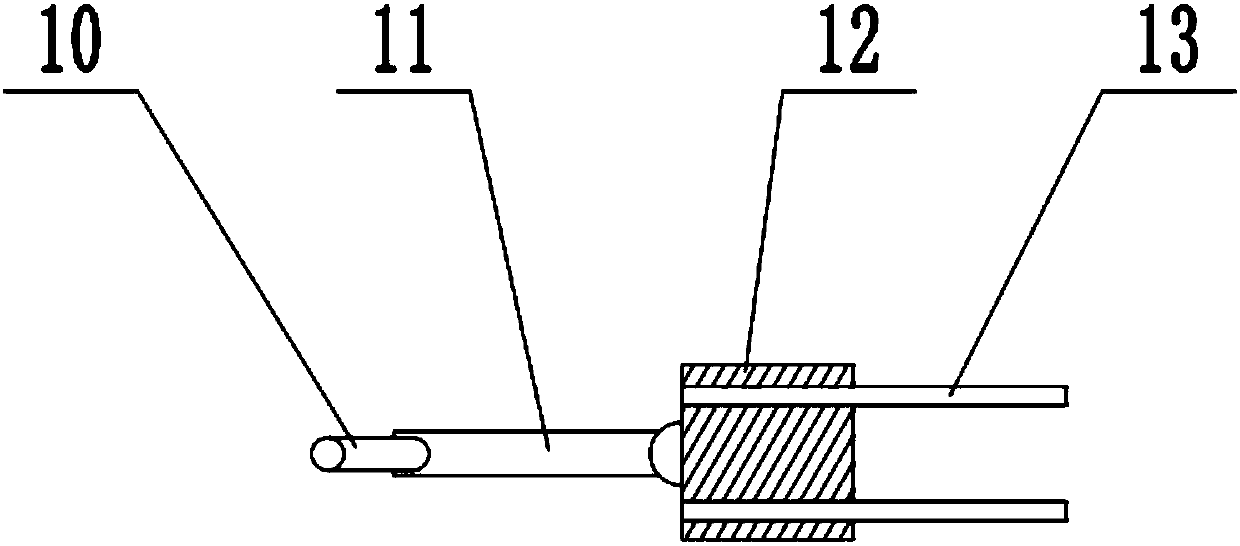

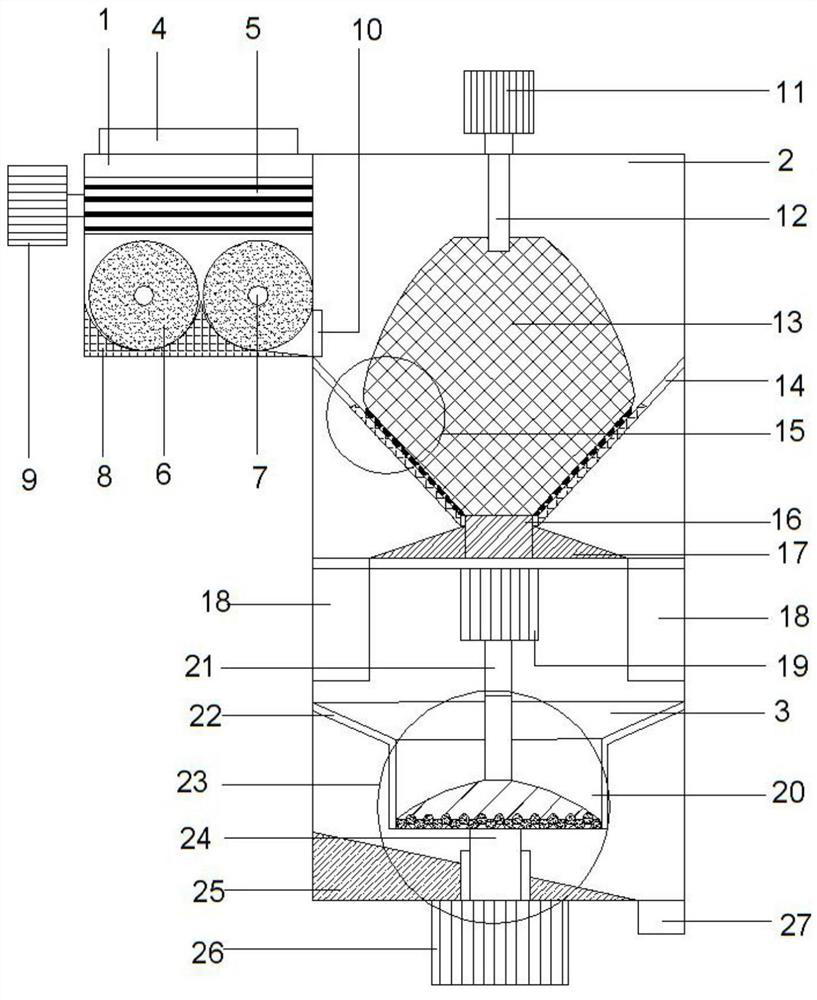

Traditional Chinese medicine smashing-grinding-drying integrated equipment

InactiveCN107570308AImprove crushing and grinding efficiencyImprove drying efficiencyDrying gas arrangementsGrain treatmentsEngineeringTraditional Chinese medicine

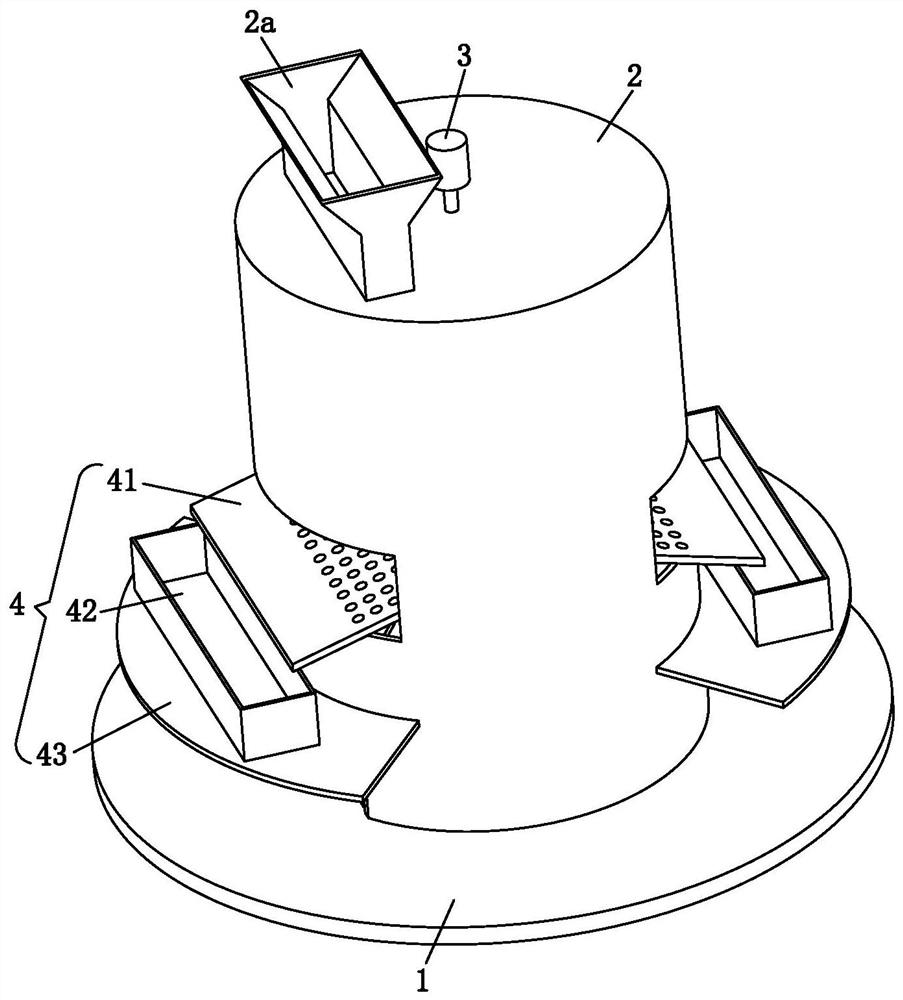

The invention discloses traditional Chinese medicine smashing-grinding-drying integrated equipment. The traditional Chinese medicine smashing-grinding-drying integrated equipment comprises a bottom plate, a cylinder body, a motor, an incomplete bevel gear, a first bevel gear, a second bevel gear, a hollow rotary shaft, a first smashing blade, a second smashing blade, a grinding hemisphere, a grinding shell, a filter screen, a third bevel gear, a fourth bevel gear, a fifth bevel gear and a drying device. The drying device comprises a draught fan, a heating device and air outlet holes. Accordingto the traditional Chinese medicine smashing-grinding-drying integrated equipment, the motor, the incomplete bevel gear, the first bevel gear, the second bevel gear, the hollow rotary shaft and the grinding hemisphere cooperate to drive the first smashing blade and the grinding hemisphere to rotate positively and negatively, the smashing and grinding efficiency is improved, so that traditional Chinese medicine is smashed and grinded more sufficiently and rapidly. The third bevel gear, the fourth bevel gear and the fifth bevel gear cooperate to drive the cylinder body and the hollow rotary shaft to rotate reversely, and thus the smashing and grinding efficiency is further improved. The drying device is used for drying the traditional Chinese medicine while the traditional Chinese medicineis smashed and grinded, and thus the drying efficiency is high.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

Method for extracting astaxanthin in haematococcus pluvialis by adopting enzymolysis method and grinding method through organic solvent

The invention relates to a method for extracting astaxanthin in haematococcus pluvialis by adopting an enzymolysis method and a grinding method through an organic solvent, belonging to the field of algal pigment extraction technology. The enzymolysis time for extracting astaxanthin by adopting the existing enzymolysis method is generally more than 15 hours, and the whole extraction process only needs 3-6 hours by adopting the method through assisting the extraction of the organic solvent while grinding in the enzymolysis process, so that the time can be shortened by 57-78%, and the time cost can be greatly saved. The method comprises the steps of carrying out enzymolysis by adopting pectinase, wherein the enzymolysis pH value is 4.0-6.0; firstly drying the enzymolysis liquid, and then extracting with ethyl acetate. The extraction rate can achieve more than 97% by matching pectinase enzymolysis with specific grinding conditions as well as specific organic solvent extraction, and the purity of the obtained astaxanthin product can achieve more than 16.9%, namely that the extraction rate and purity of the astaxanthin can be further improved under the condition of greatly shortening the extraction time.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

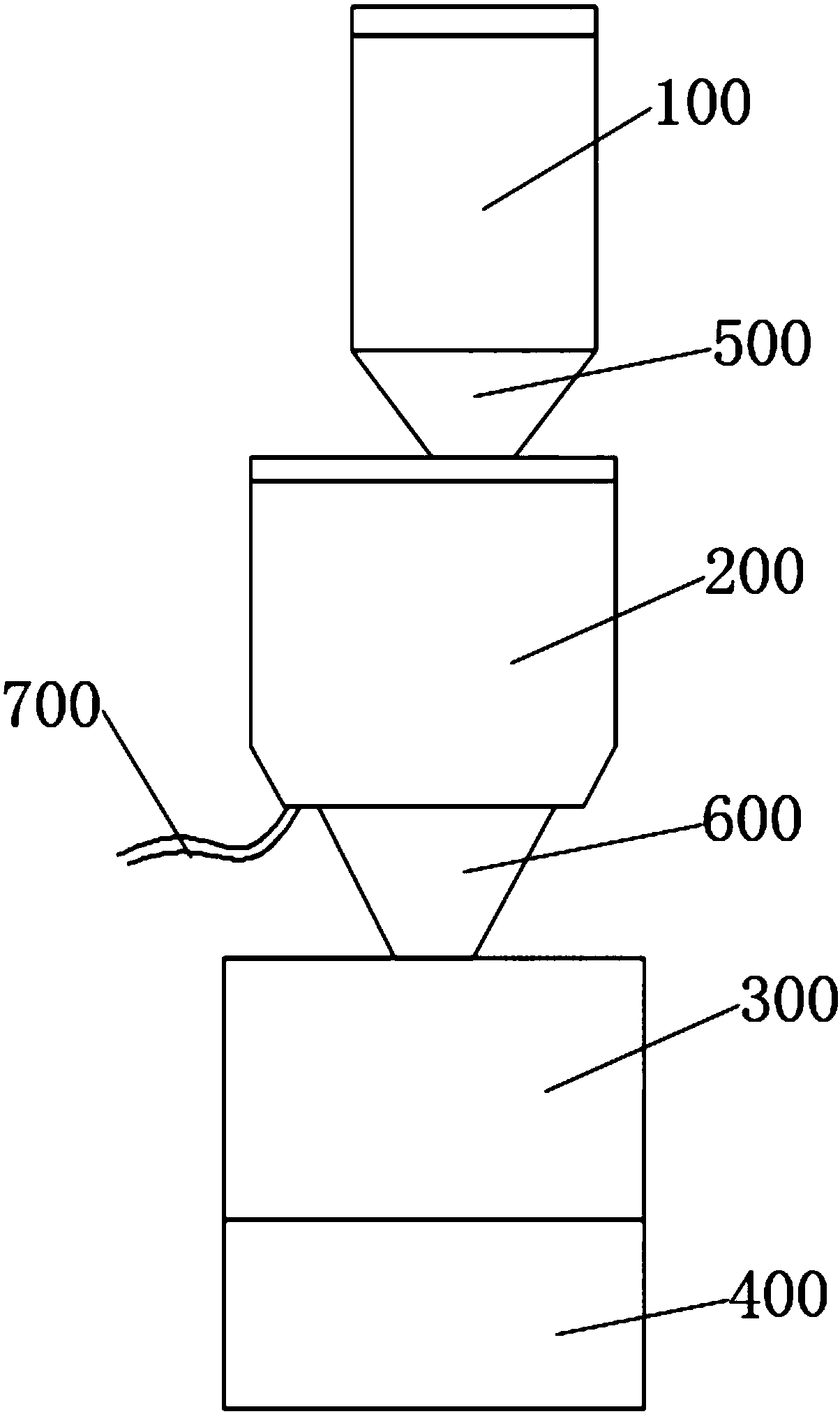

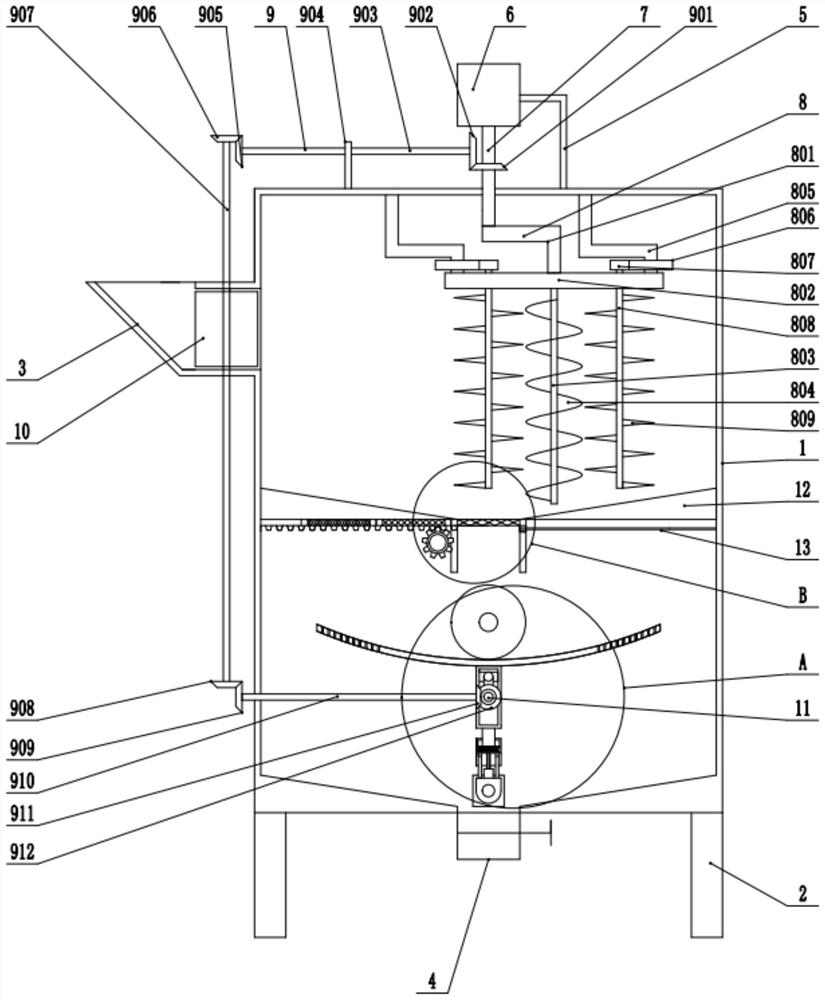

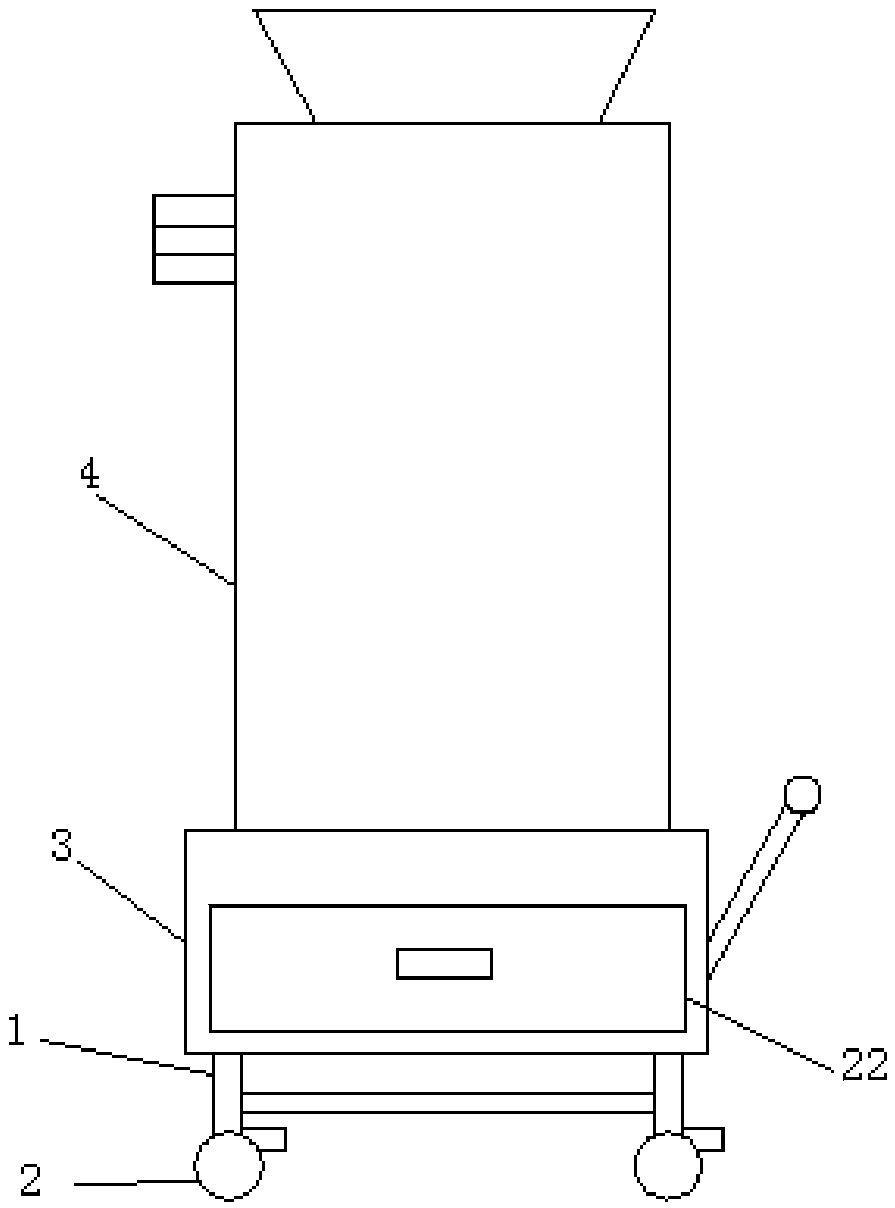

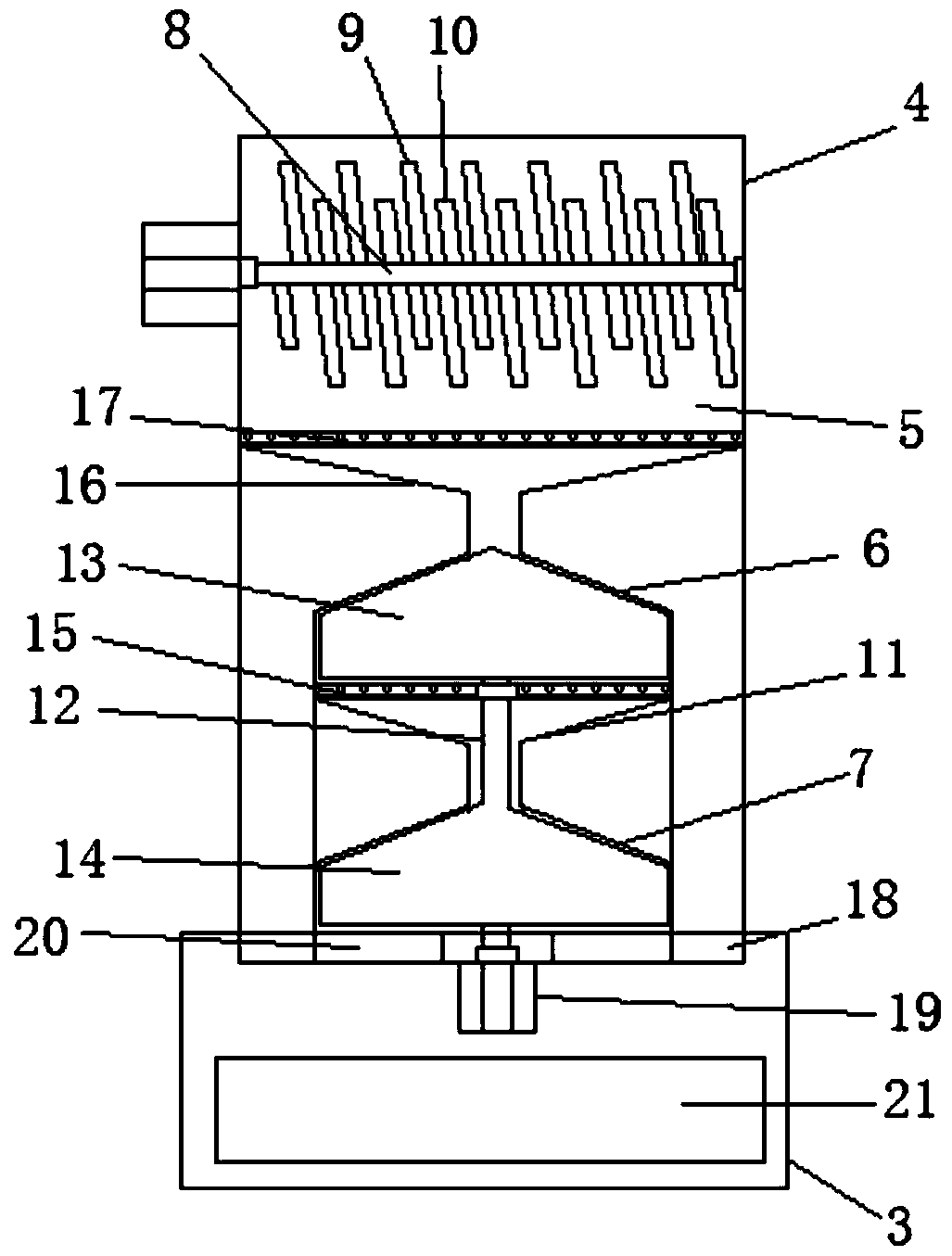

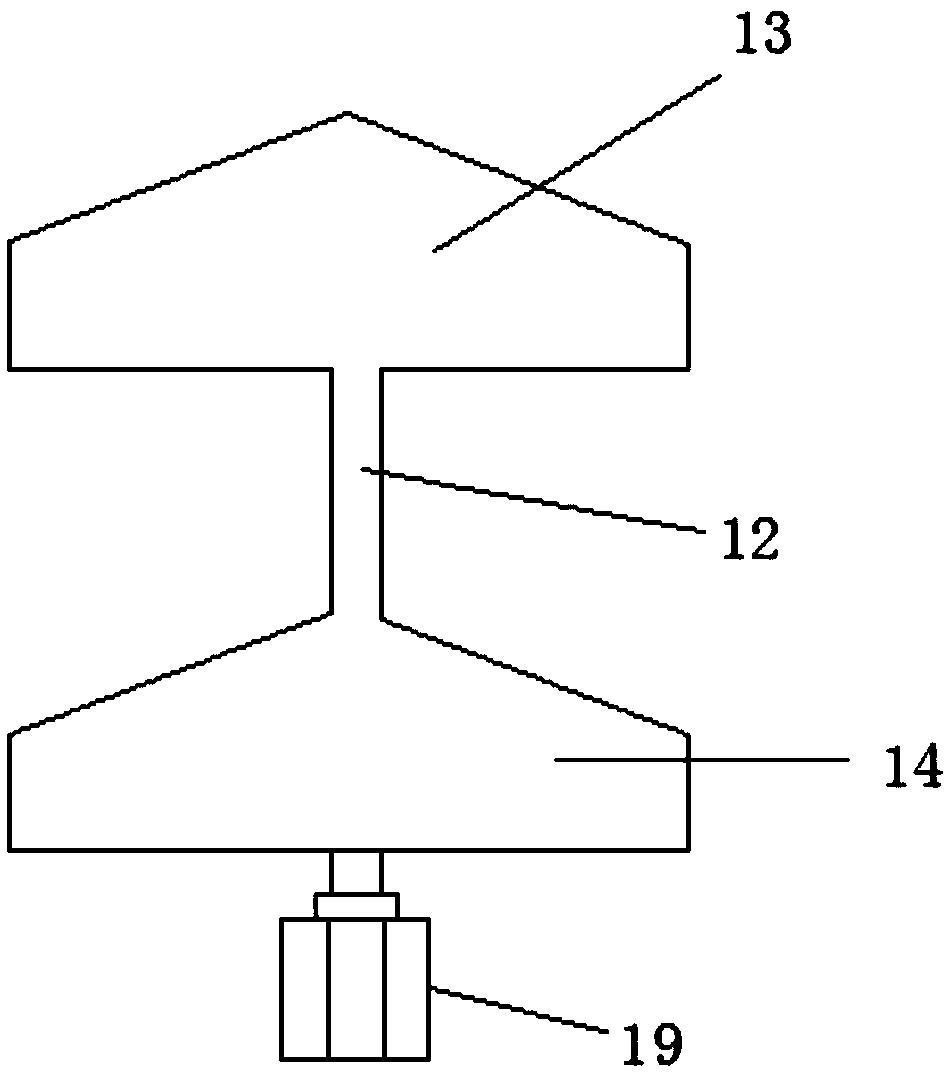

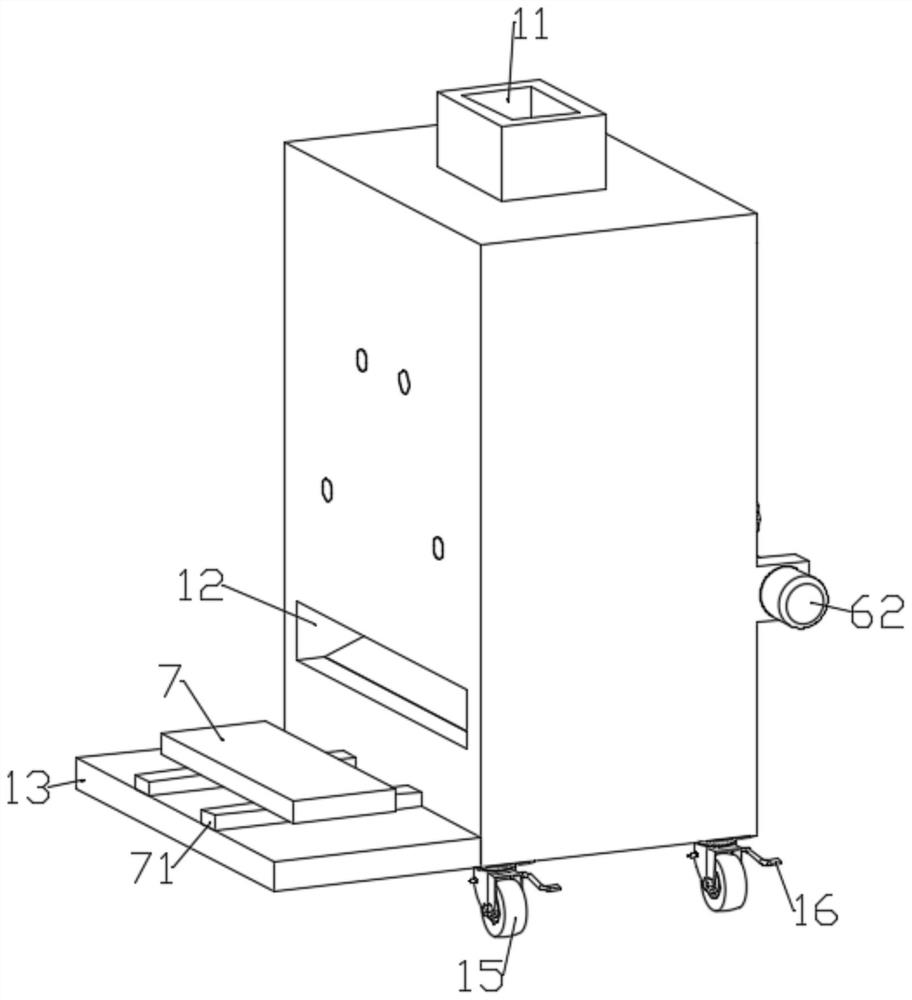

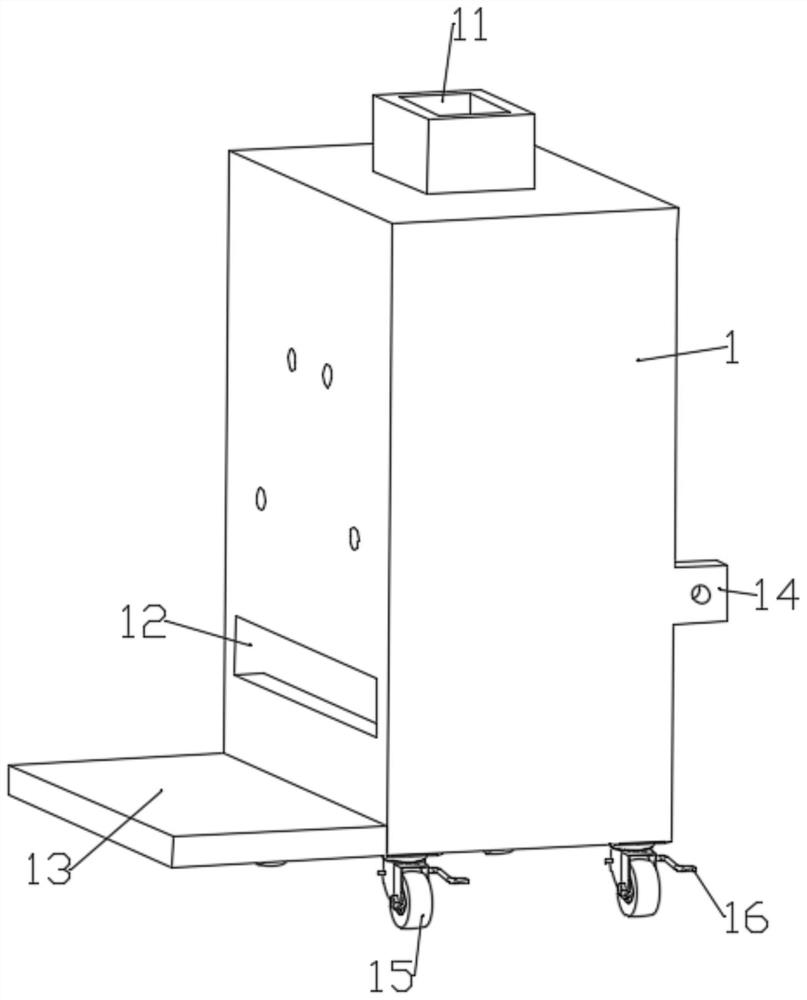

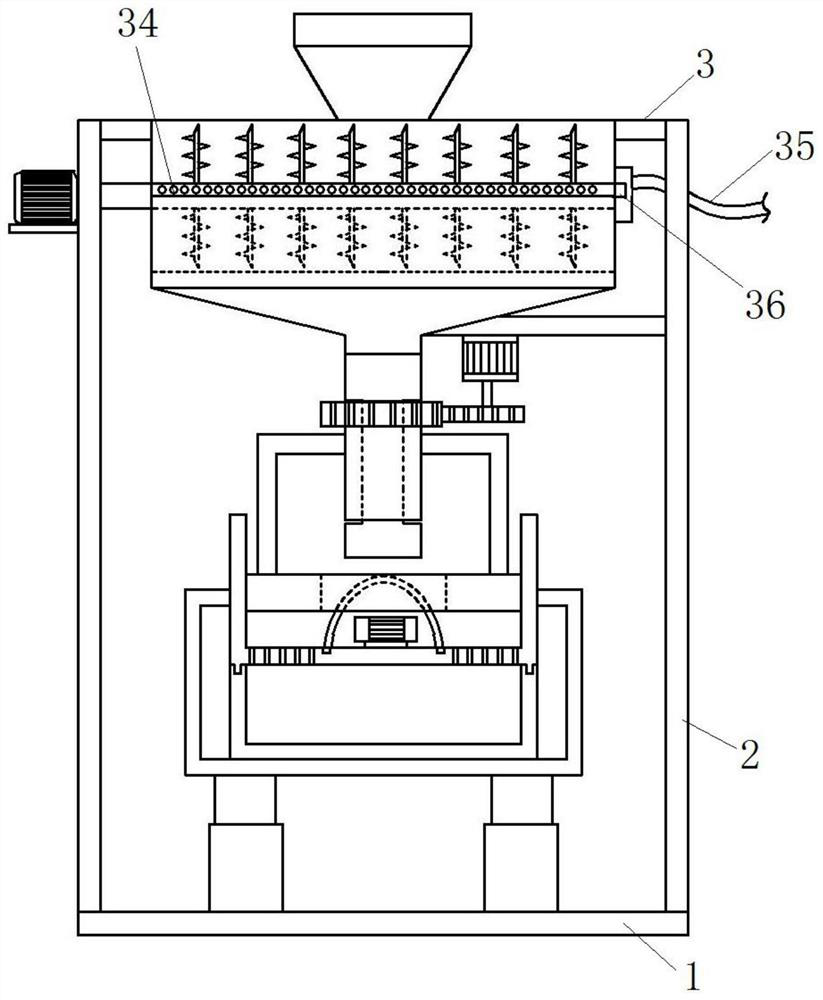

Kitchen waste treatment equipment

PendingCN108356051ASmooth rotationDoes not affect grinding actionTransportation and packagingSolid waste disposalElectricityEngineering

The invention relates to kitchen waste treatment equipment. The kitchen waste treatment equipment comprises a support, a crushing and grinding device, a solid-liquid separation device, a drying and deodorizing device, a first stock bin and a control device, wherein the crushing and grinding device, the solid-liquid separation device, the drying and deodorizing device, the first stock bin and the control device are arranged in the support and are sequentially arranged from top to bottom; the solid-liquid separation device is provided with a first discharge port and a second discharge port; thefirst discharge port is connected to a liquid discharge pipe; the second discharge port is connected to a feed port of the drying and deodorizing device; and the control device is electrically connected to the crushing and grinding device, the drying and deodorizing device and the solid-liquid separation device. The kitchen waste treatment equipment has the advantages that the structure is simple,the full-automatic operation is realized, the use is convenient, the environmental pollution caused by kitchen waste can be avoided from the source, and the kitchen waste can be conveniently recycled.

Owner:深圳市富利臻环保科技有限公司

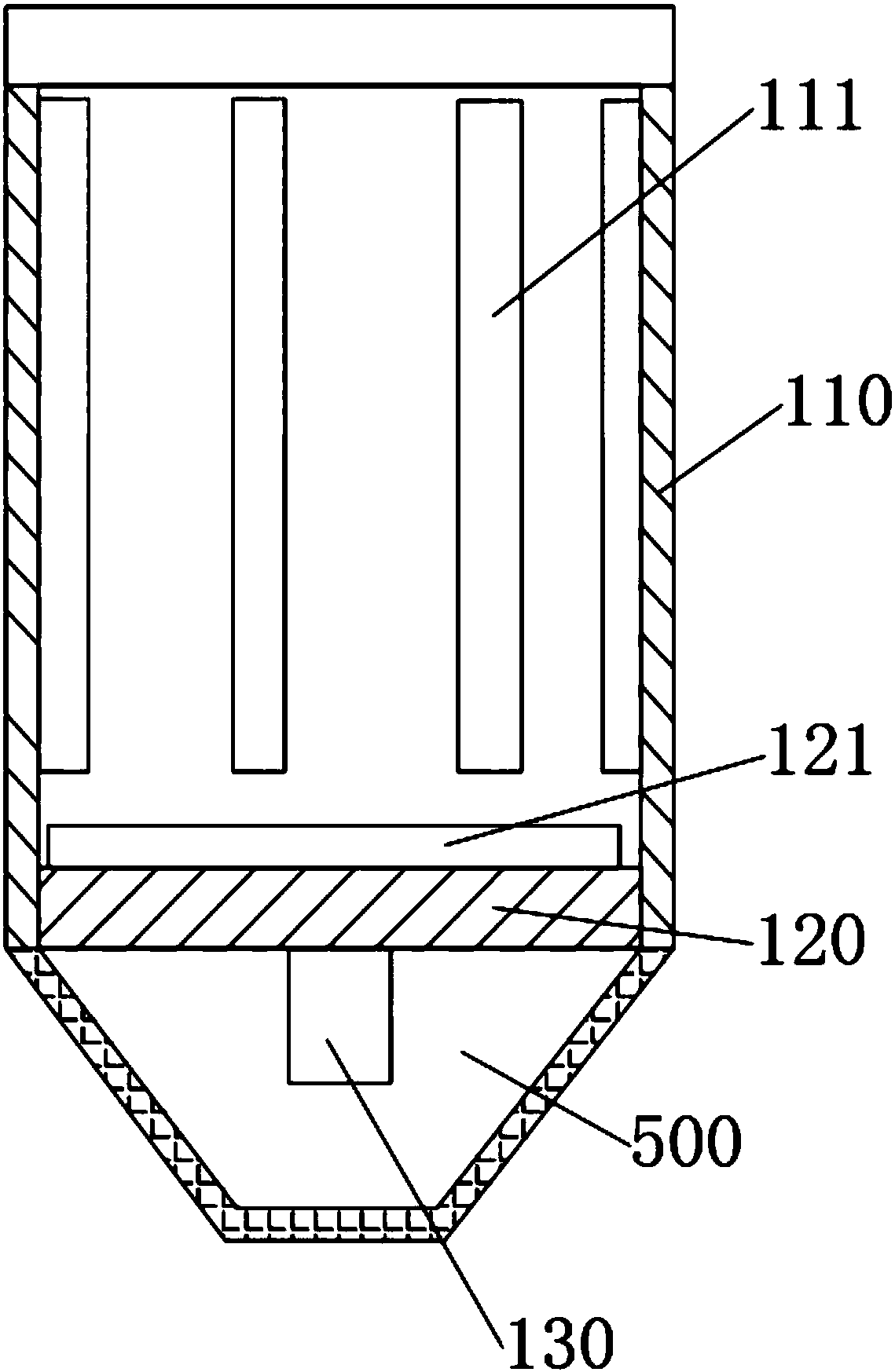

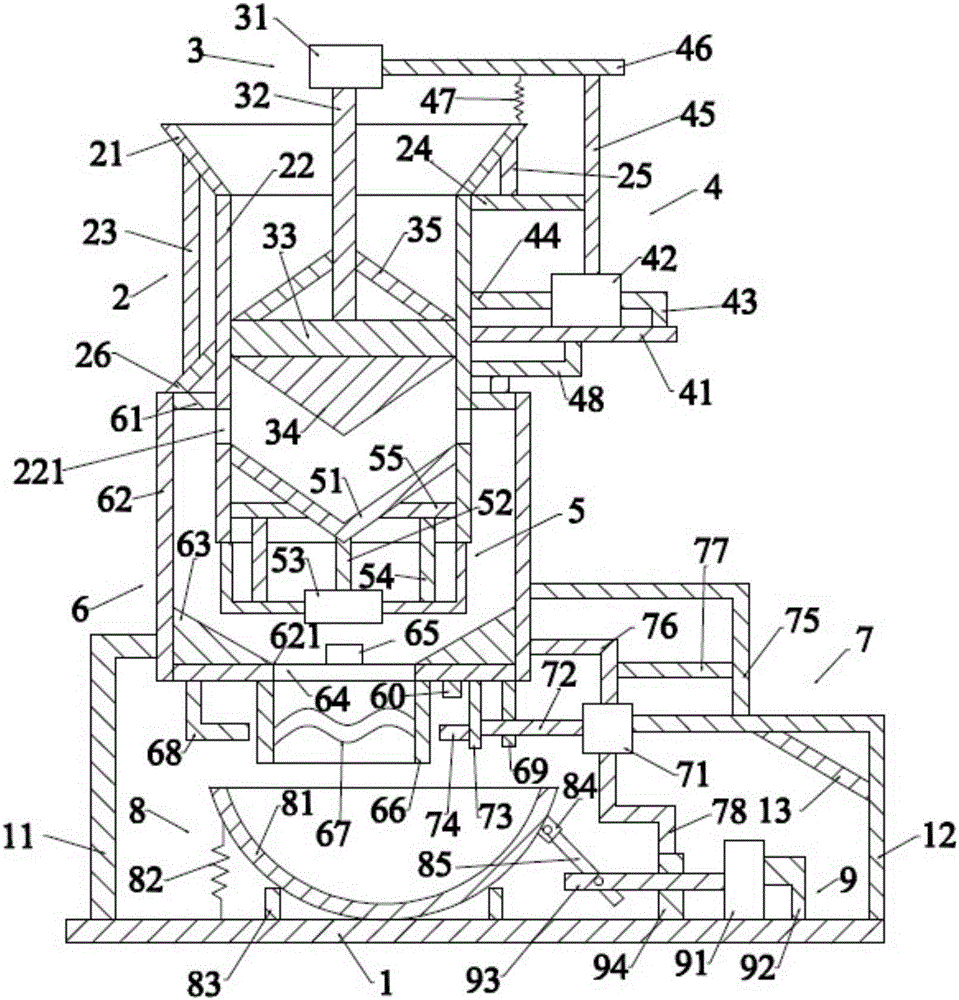

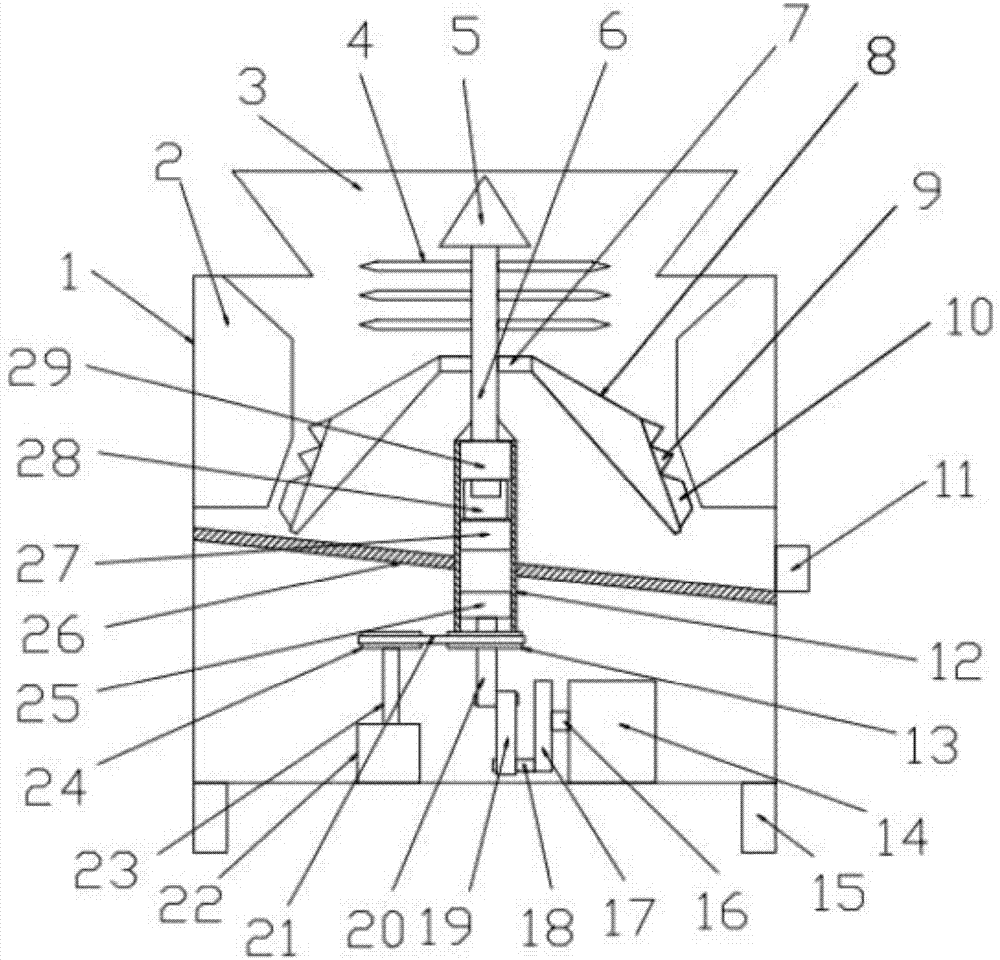

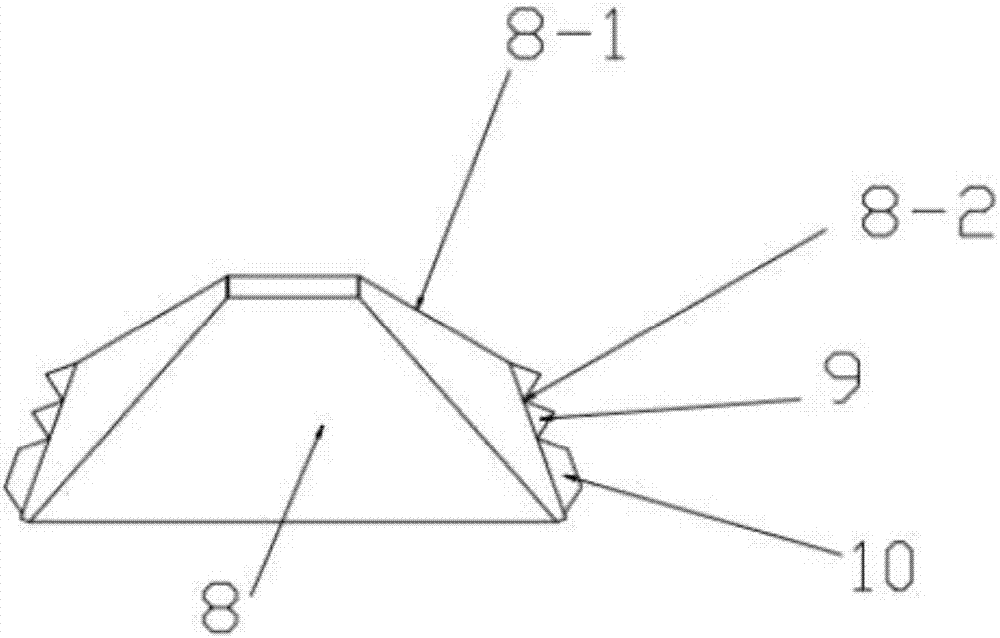

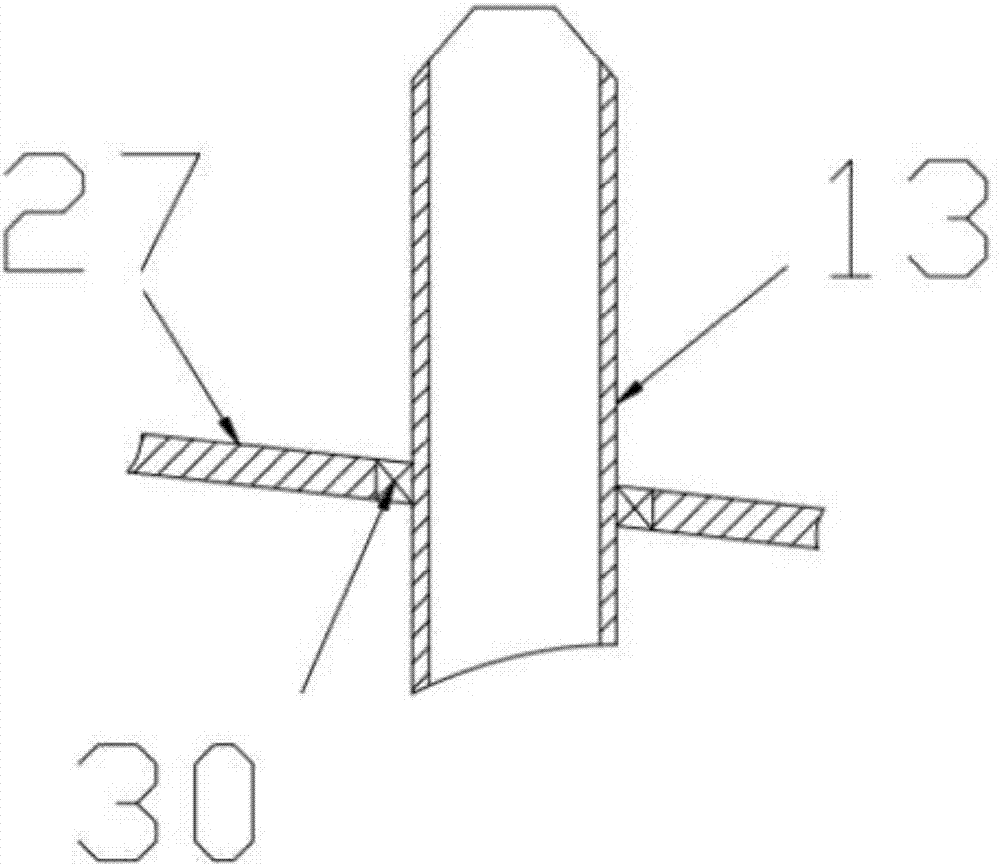

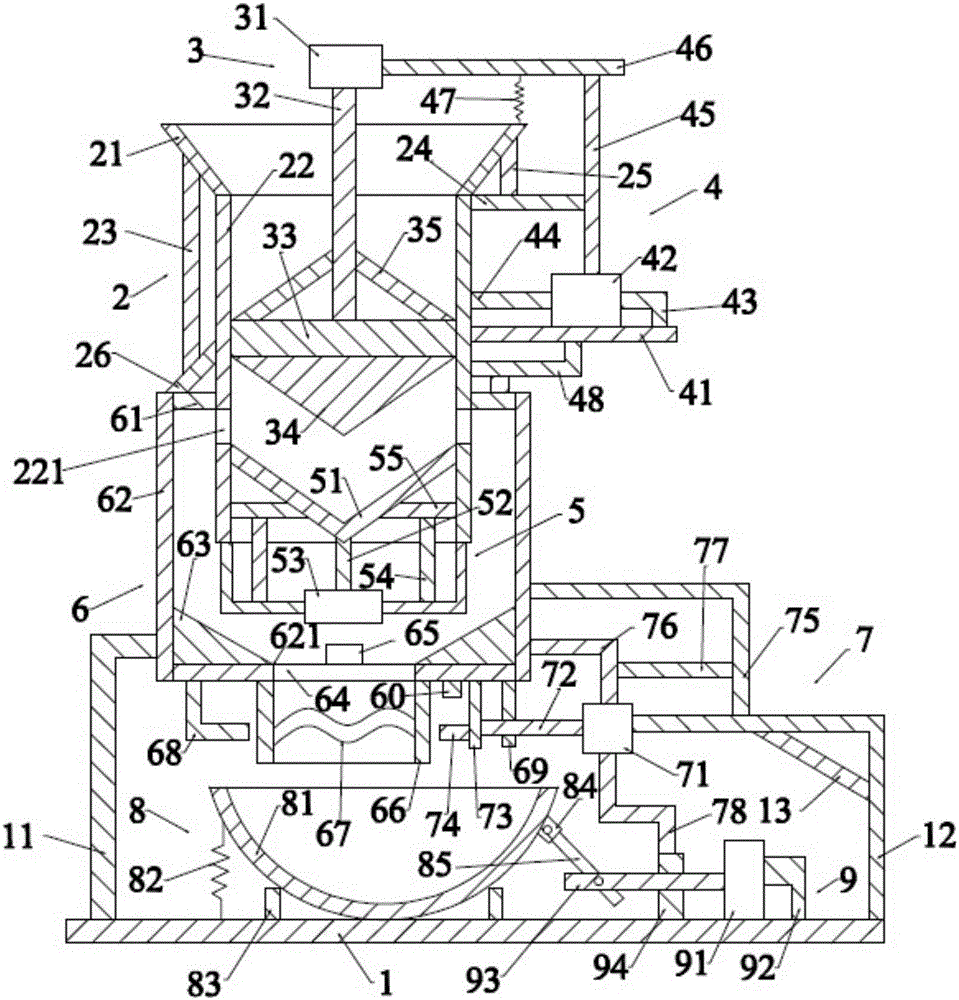

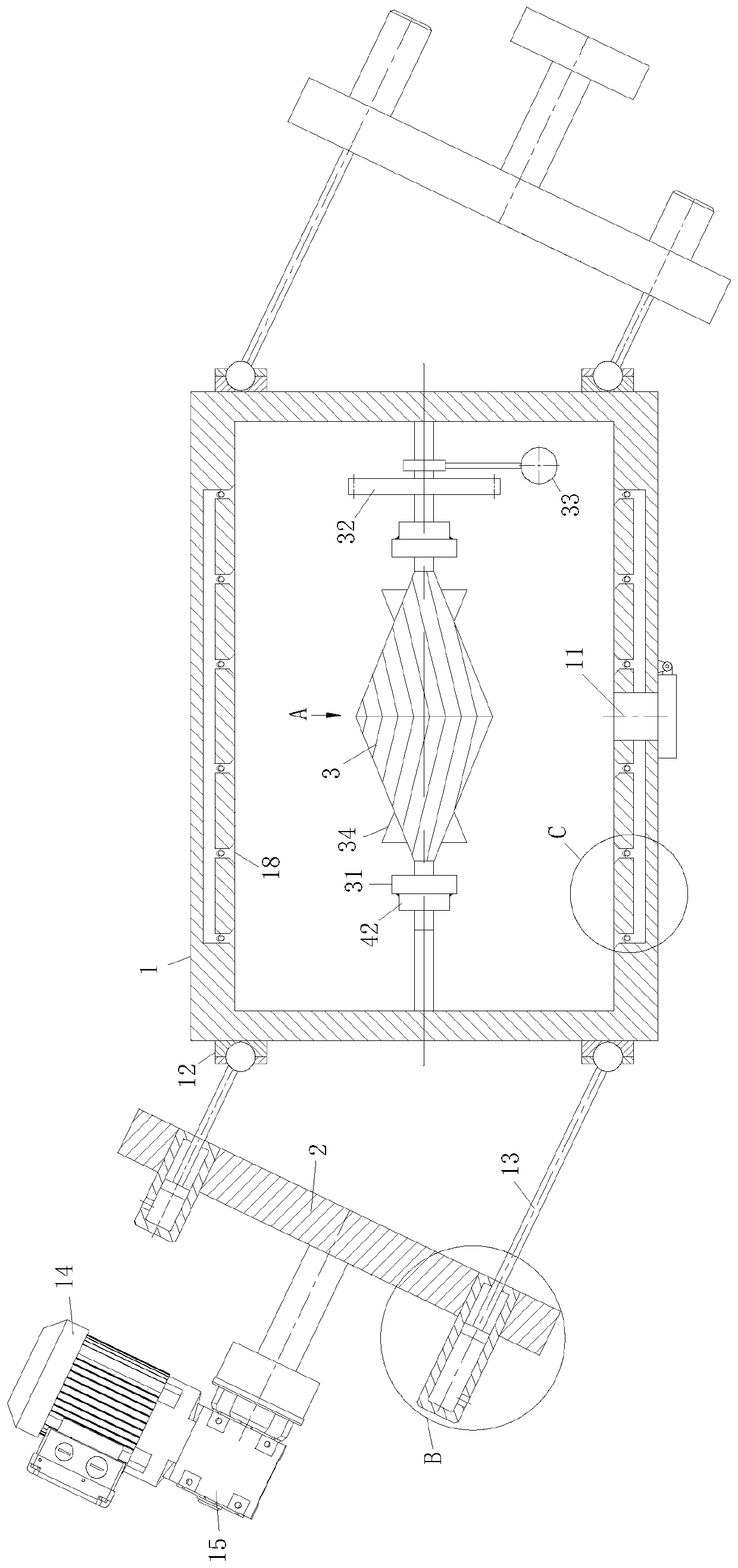

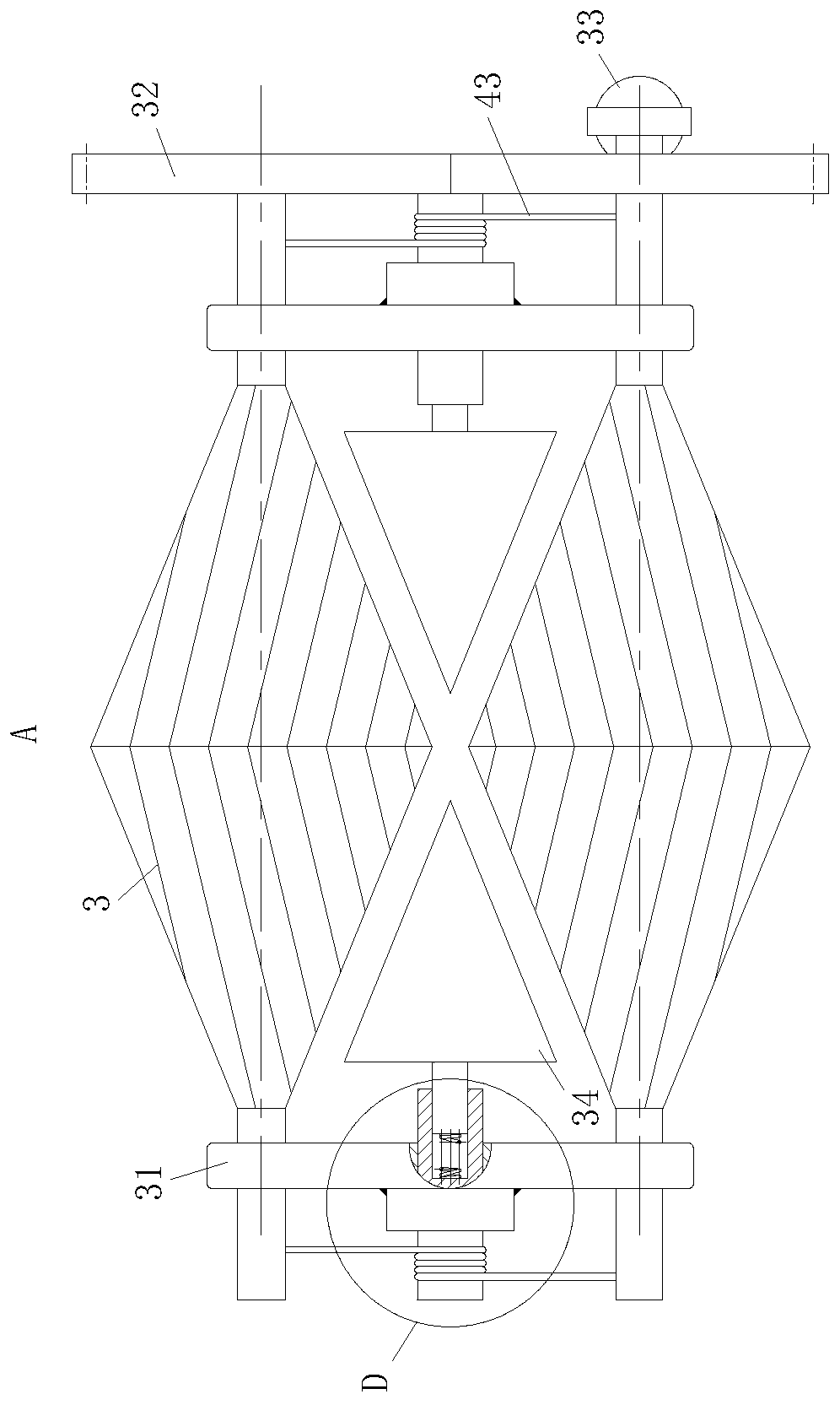

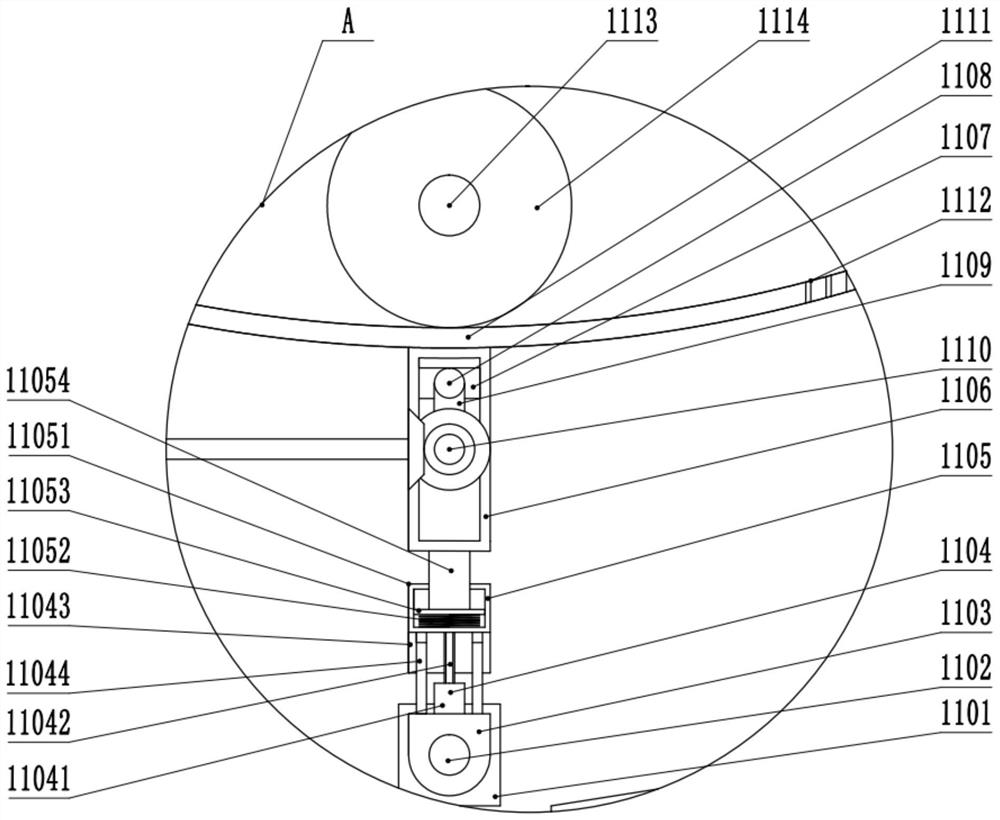

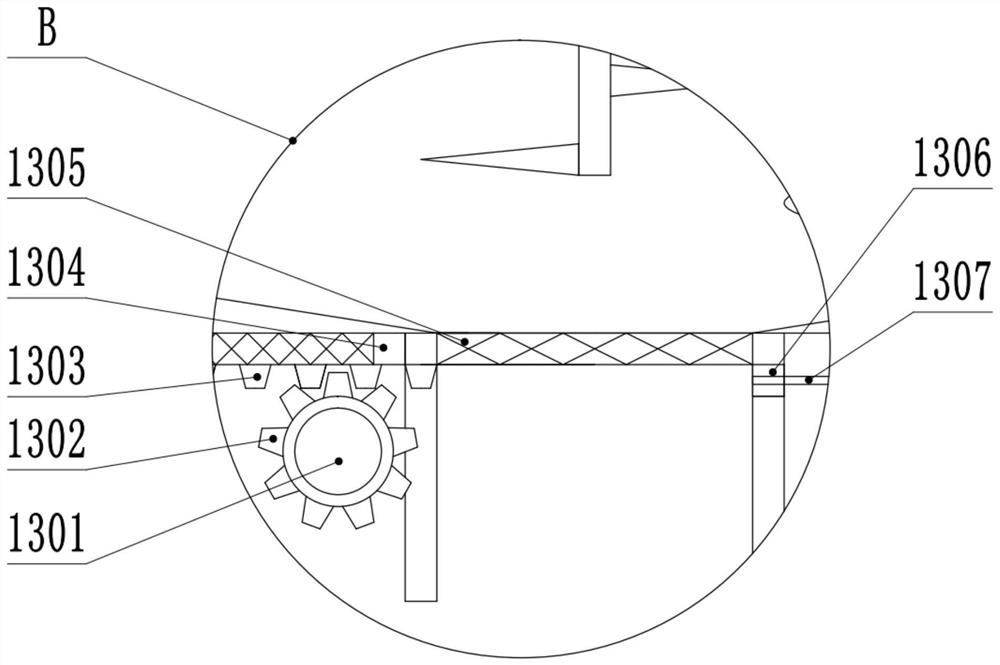

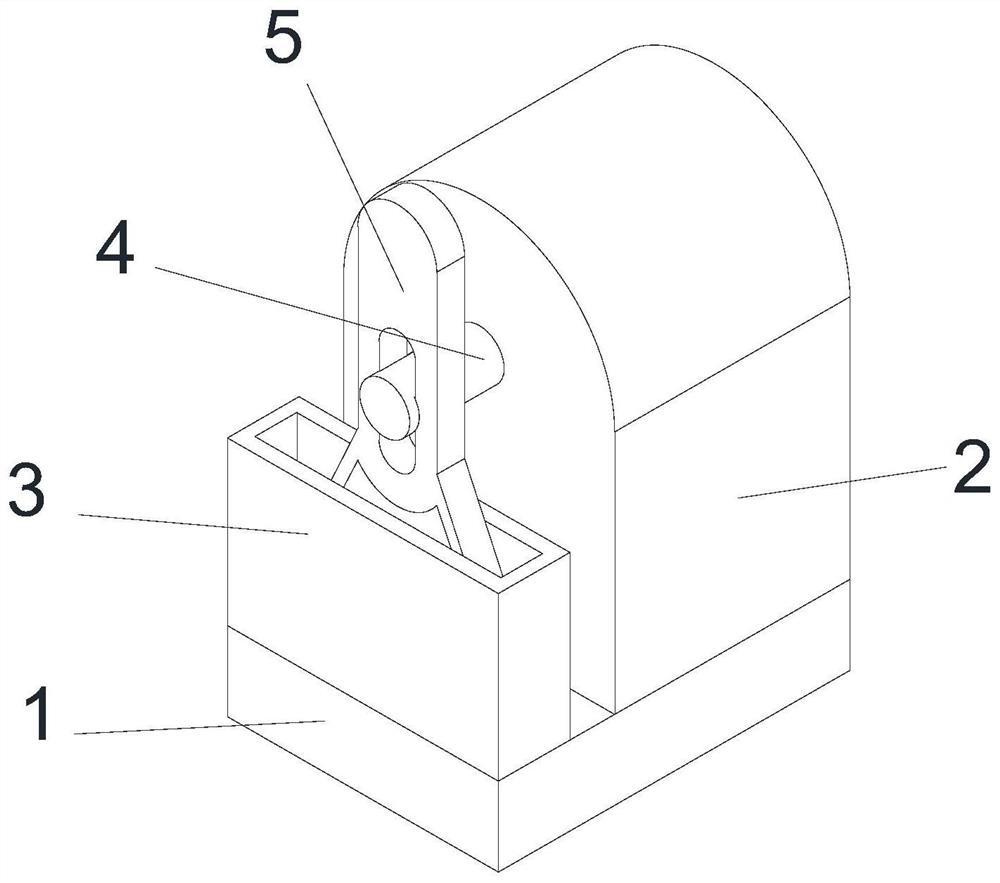

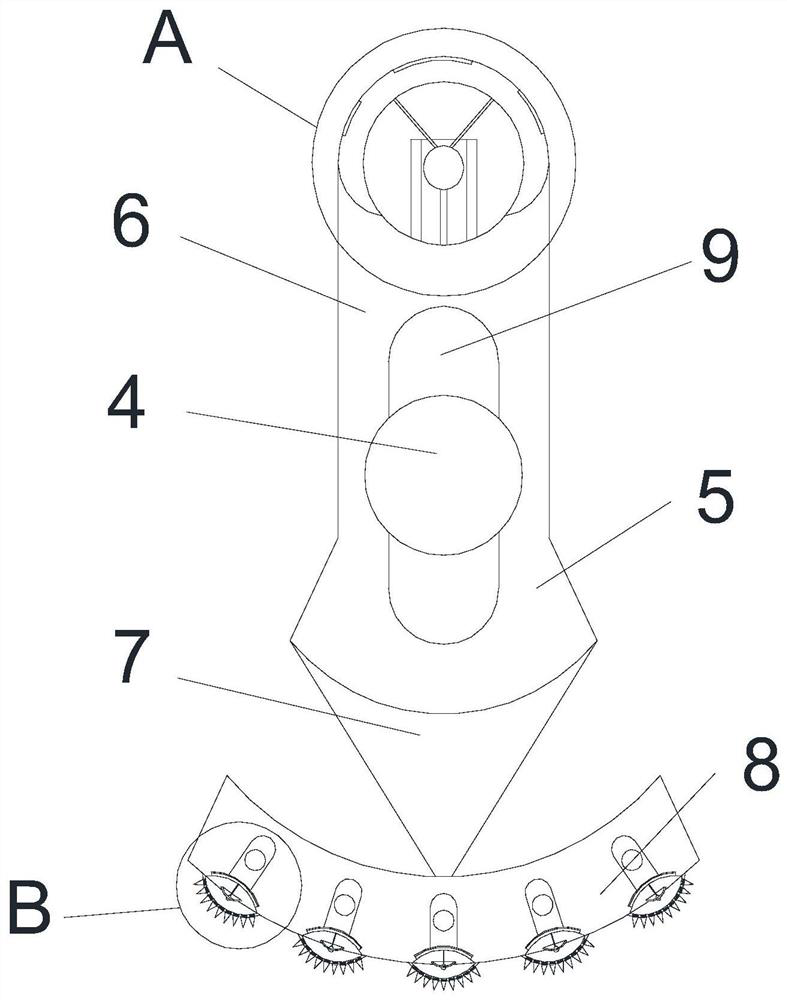

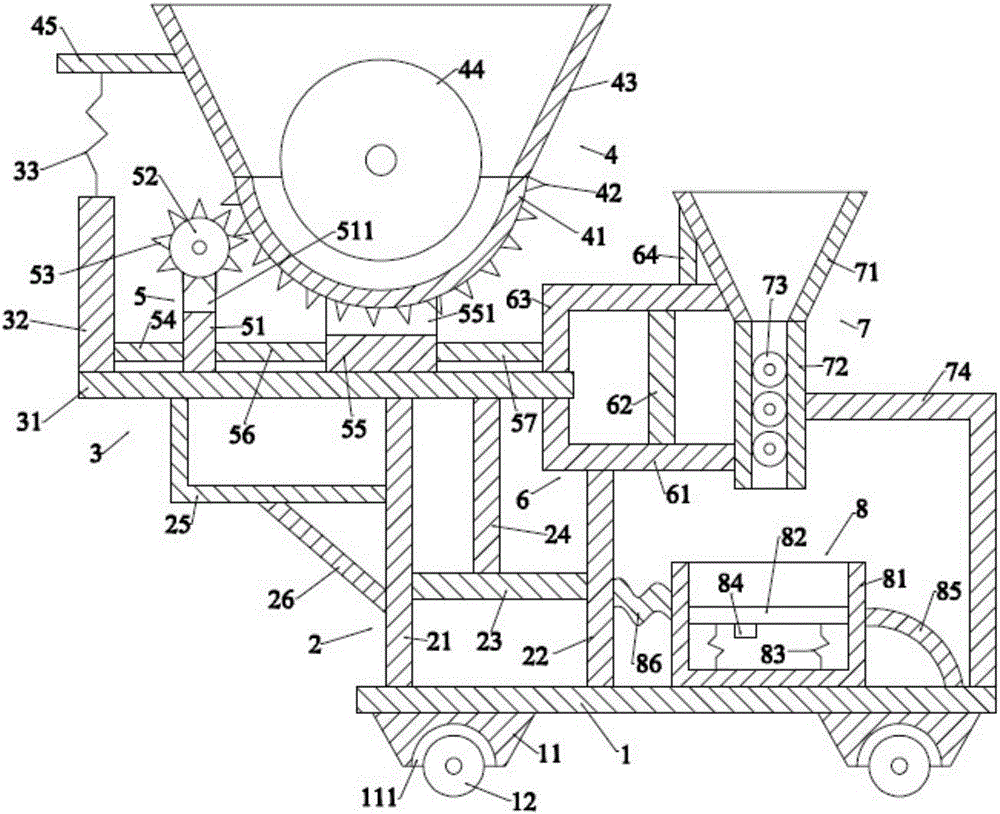

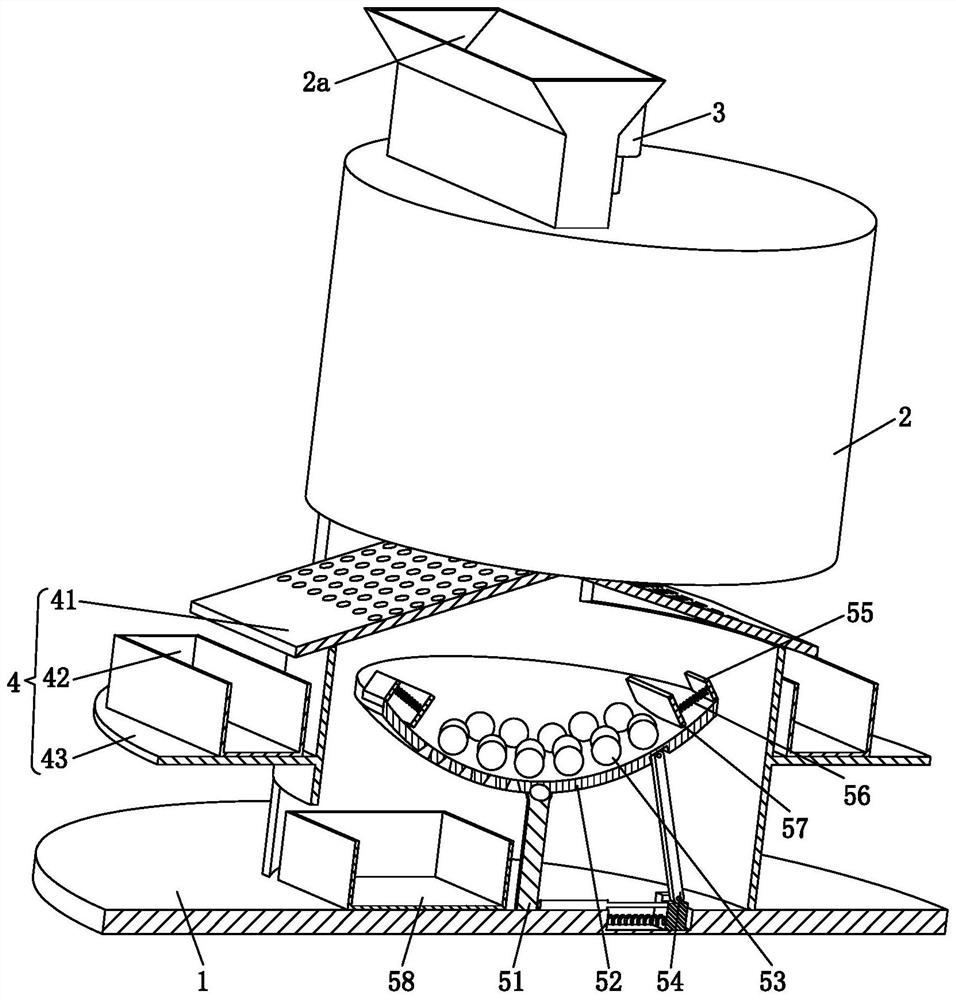

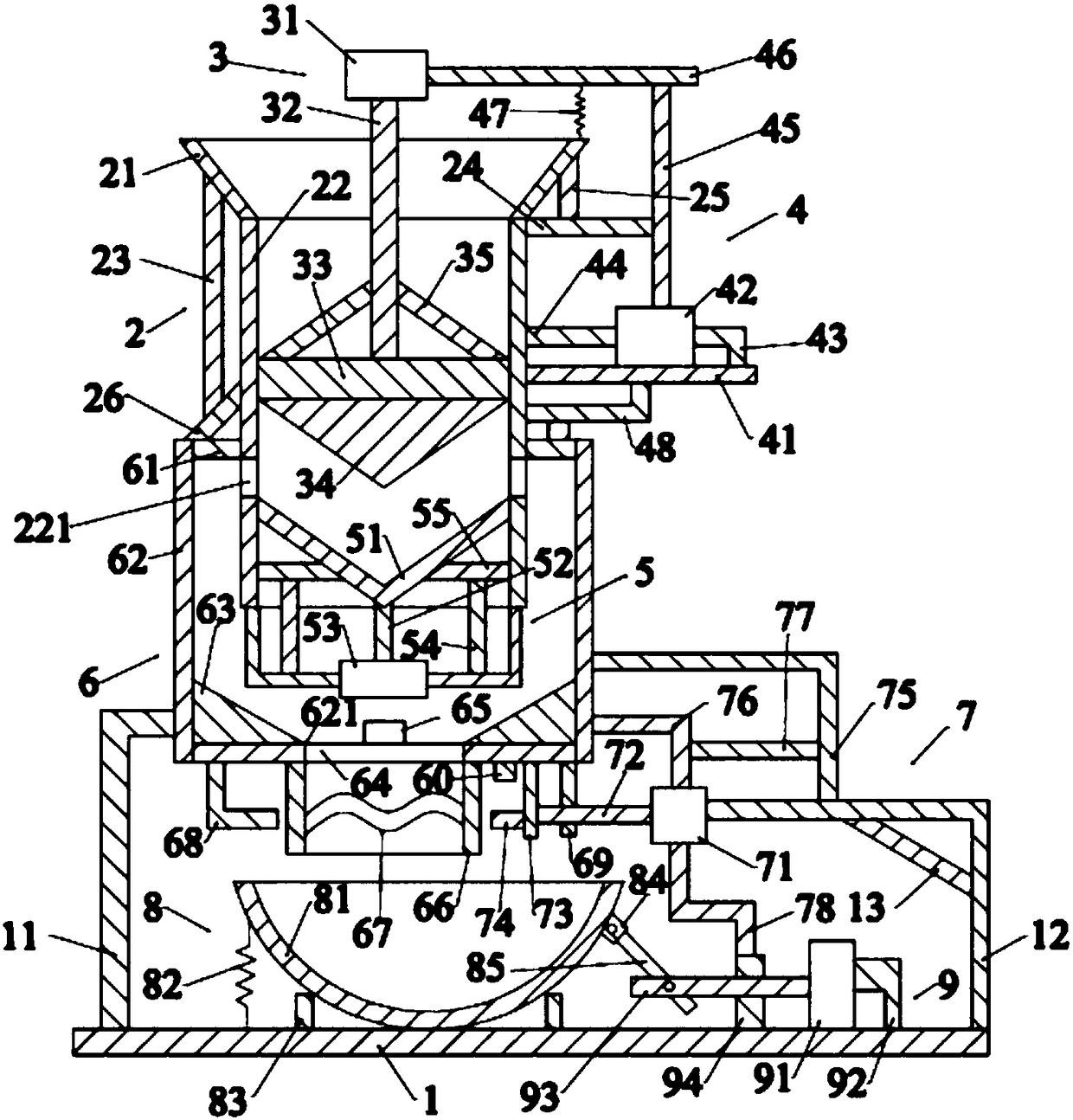

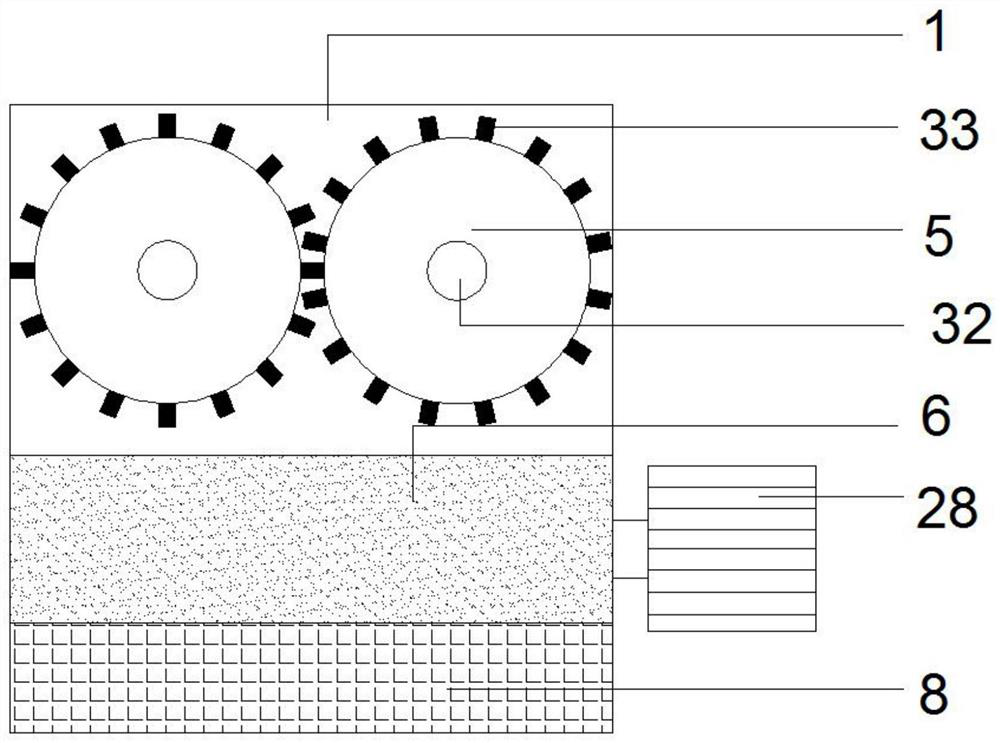

Medicine crushing processing equipment

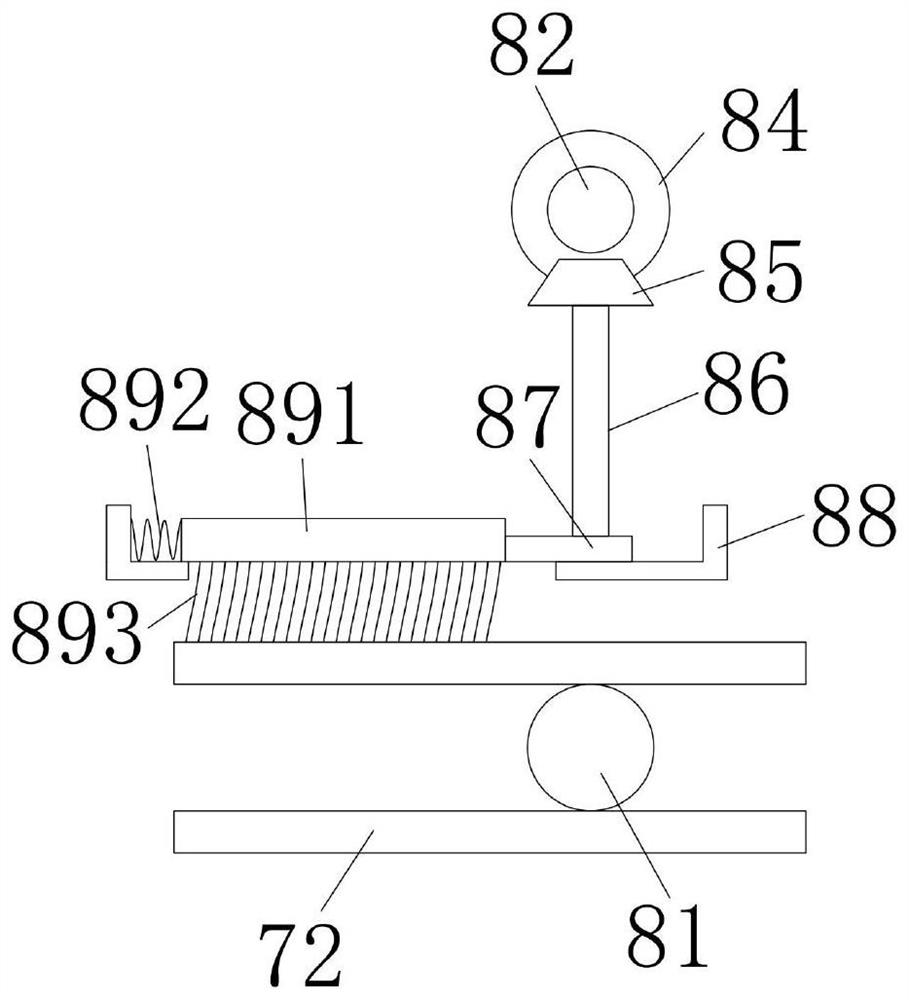

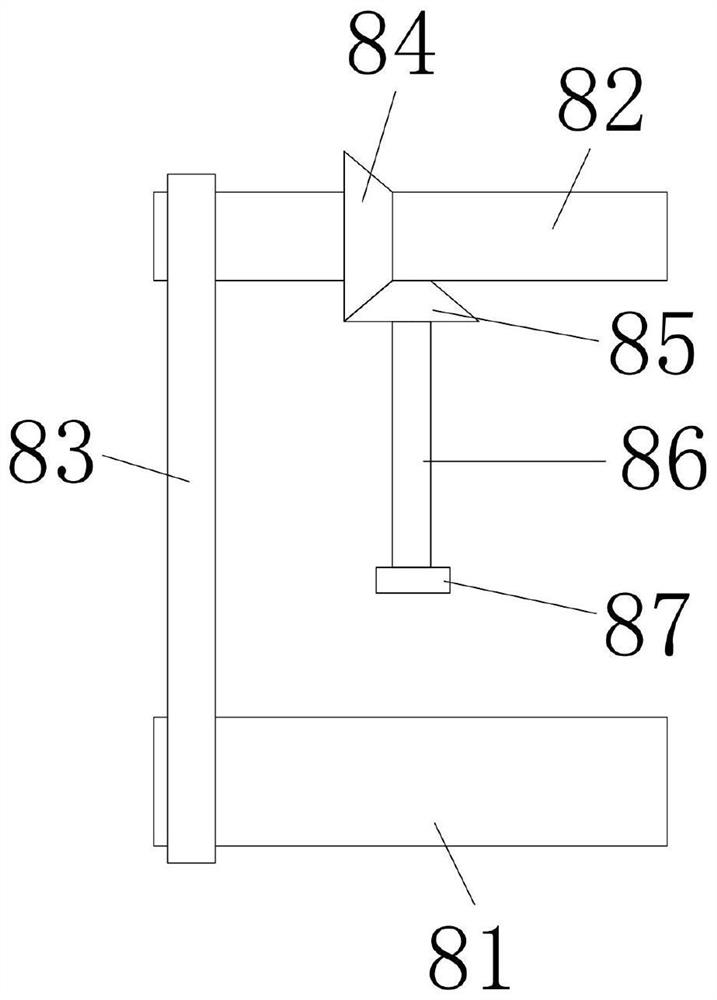

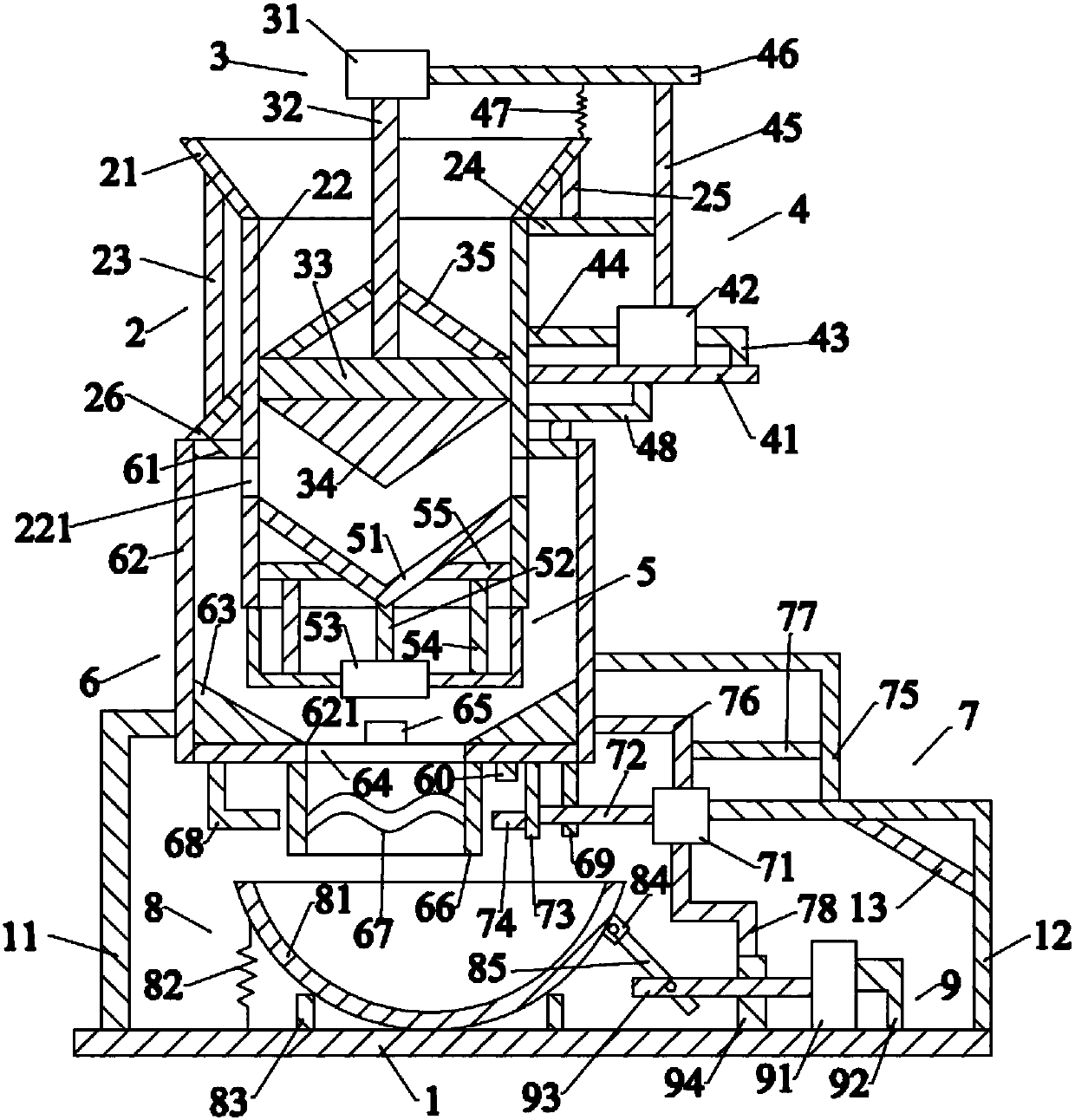

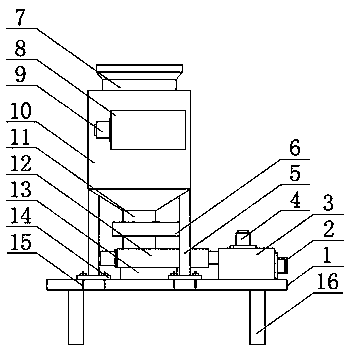

Medicine crushing processing equipment comprises a bottom plate (1), a frame device (2), a crushing device (3), an air cylinder device (4), a motor device (5), a filtering device (6), a knocking device (7), a recycling device (8) and a pushing device (9). The bottom plate (1) is provided with a first support (11), a second support (12) and a first inclined rod (13). The frame device (2) comprises a feeding hopper (21), a first frame (22), a first vertical rod (23), a first cross rod (24) and a second vertical rod (25). The crushing device (3) comprises a first motor (31), a first rotary shaft (32), a first rotary block (33) and a crushing block (34). The air cylinder device (4) comprises a second cross rod (41), a first air cylinder (42), a third support (43), a third cross rod (44) and the like. The medicine crushing processing equipment can improve medicine crushing efficiency and achieve uniform crushing and grinding.

Owner:浙江贝尼菲特药业有限公司

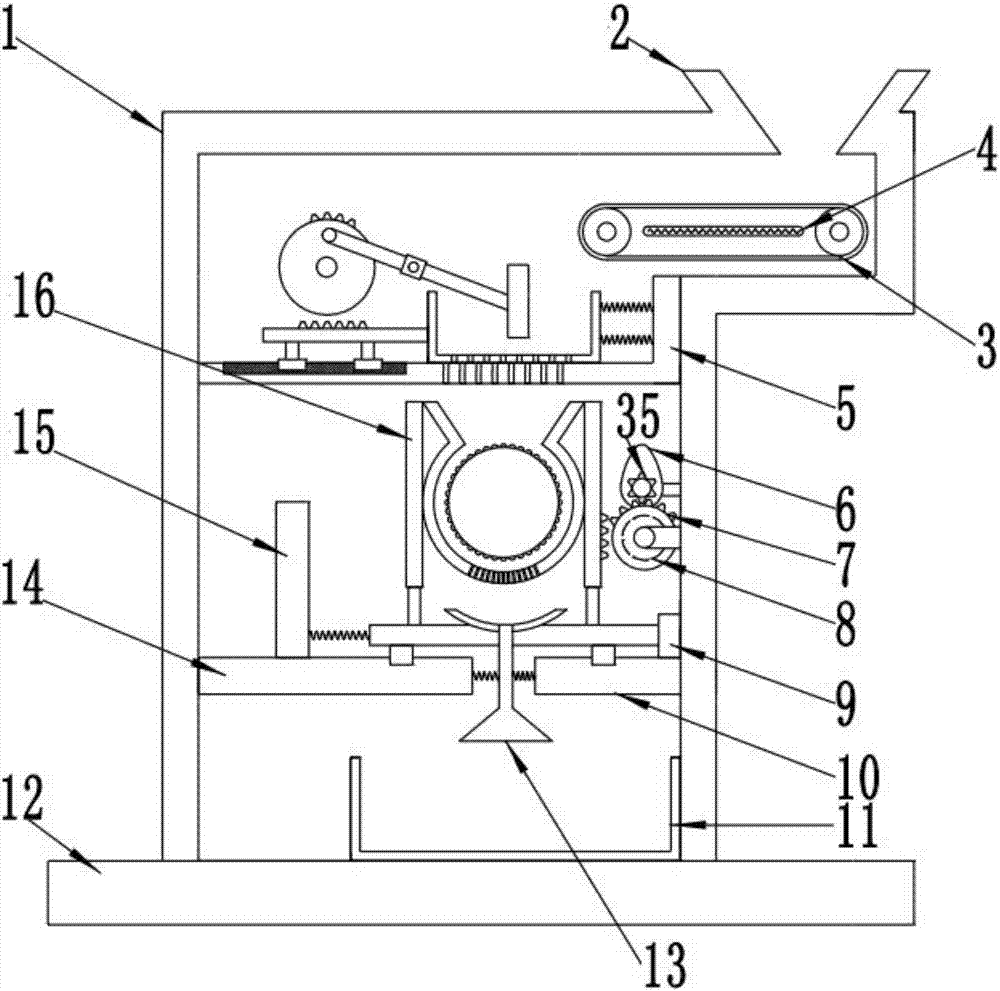

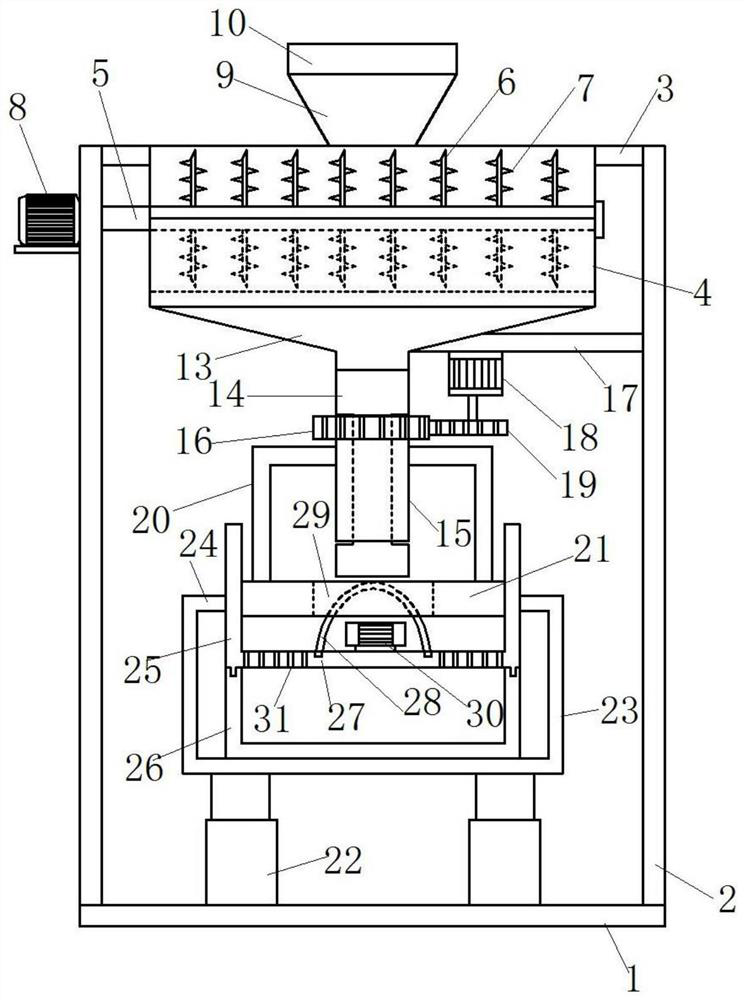

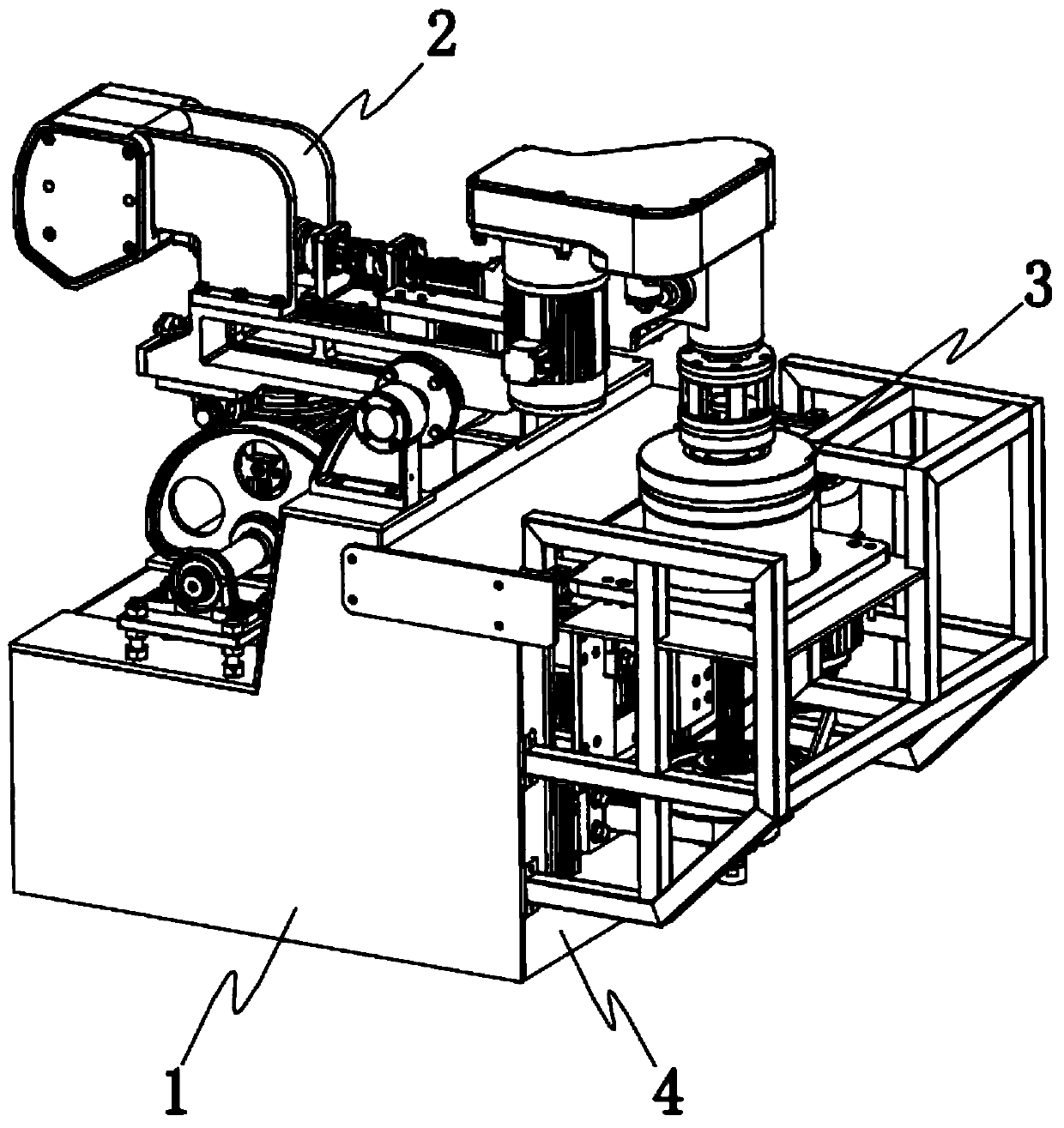

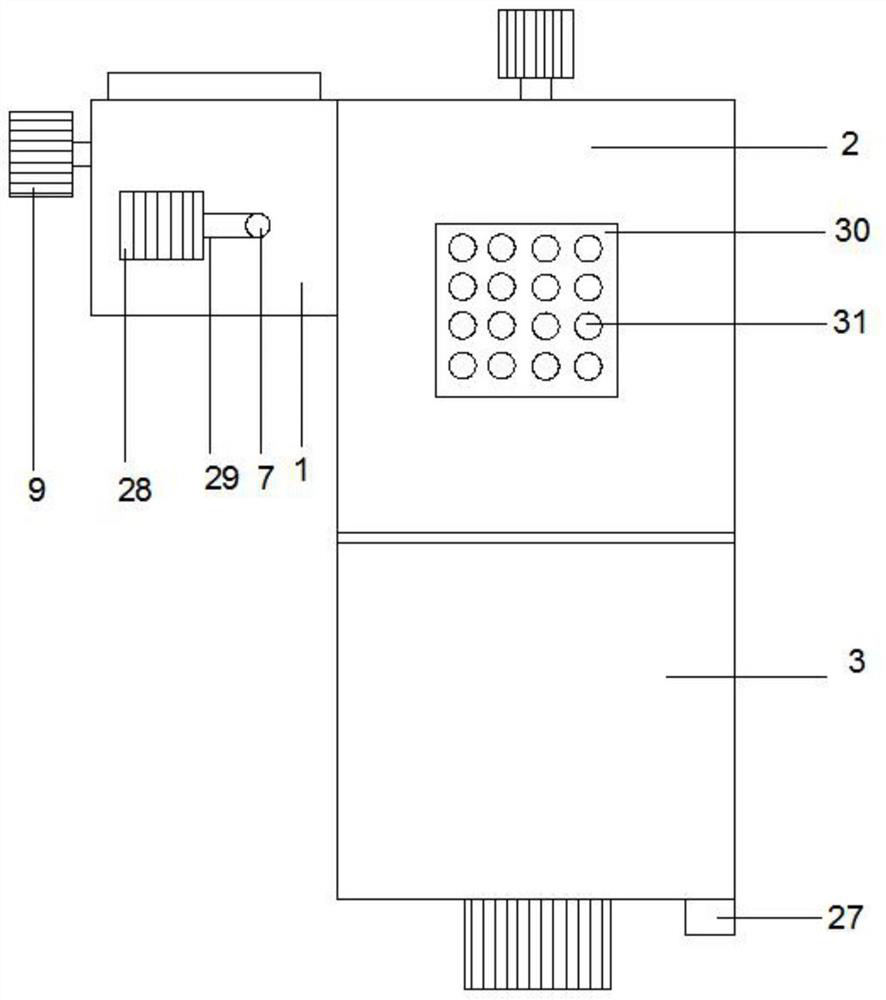

Fine grinding type traditional Chinese medicinal material processing device

ActiveCN107537662AImprove crushing and grinding efficiencyImprove grinding efficiencyGrain treatmentsEngineeringMaterials processing

The invention discloses a fine grinding type traditional Chinese medicinal material processing device. The fine grinding type traditional Chinese medicinal material processing device comprises a shell, a feeding hole, a bottom plate, a conveyor belt, a crushing mechanism and a grinding mechanism, wherein the shell is arranged at the upper end of the bottom plate; the feeding hole is arranged in the upper end of the shell; the conveyor belt is arranged below the feeding hole; the crushing mechanism is arranged below the left side of the conveyor belt; the crushing mechanism comprises an L-shaped plate, an incomplete gear B, a rack plate, a connecting rod, a crushing hammer, a crushing groove, a first spring, a sliding chute, a slide block, a second blanking hole, a third blanking hole and asleeve; the grinding mechanism is arranged below the crushing mechanism; the grinding mechanism comprises a cam, an incomplete gear A, a rotating motor, a grinding cavity, a grinding roll, a telescopic plate, strip-shaped teeth, a receiving port and a first blanking hole. The fine grinding type traditional Chinese medicinal material processing device has the advantages of simple structure, high grinding efficiency, complete grinding, good grinding effects and high practicability.

Owner:江西杏林白马药业股份有限公司

High-efficiency traditional Chinese medicine crushing and grinding device

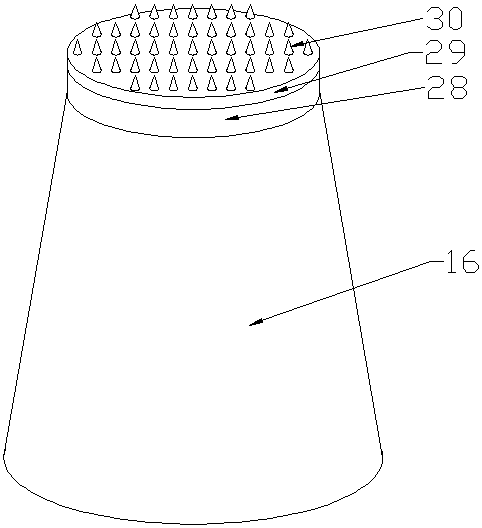

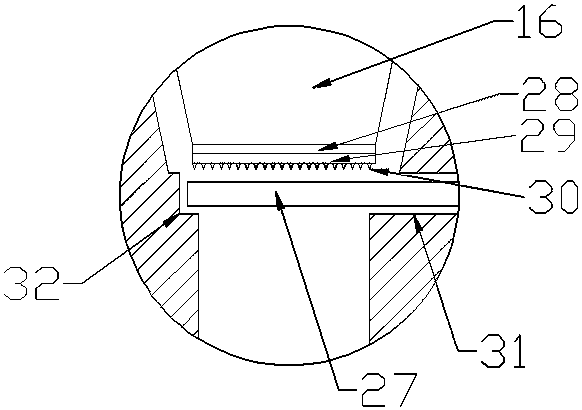

InactiveCN107961872ACleverly structuredReasonable arrangementGrain treatmentsEngineeringGrinding teeth

The invention discloses a high-efficiency traditional Chinese medicine crushing and grinding device. The high-efficiency traditional Chinese medicine crushing and grinding device comprises a shell. Supporting feet are symmetrically arranged at the bottom of the shell left and right. A feed hopper is arranged at the top of the shell. A fixing block is arranged at the inner top end of the shell andis in an annulus shape. A partition plate is arranged in the middle of the shell and obliquely arranged rightwards and downwards. A discharging outlet is formed in the position, corresponding to the bottom end of the partition plate, of the upper portion of the right side wall of the shell. A vertical rotary drum is mounted in the middle of the shell in a sleeved mode. The vertical rotary drum vertically penetrates through the partition plate and is mounted on a bearing arranged in the corresponding position of the partition plate in a sleeving mode. A vertical rotary shaft is mounted at the top end of the vertical rotary drum in a sleeved mode. A flow guiding block is arranged at the position, corresponding to the fixing block, of the vertical rotary shaft and is of a conical shell structure. The flow guiding block is fixedly connected with the vertical rotary shaft through a connecting block. Crushing teeth and grinding teeth are arranged on the outer side face of the flow guiding block. The high-efficiency traditional Chinese medicine crushing and grinding device provided by the invention is ingenious in structure arrangement and reasonable in layout, and high-efficiency crushing and grinding of traditional Chinese medicines are achieved.

Owner:李姗姗

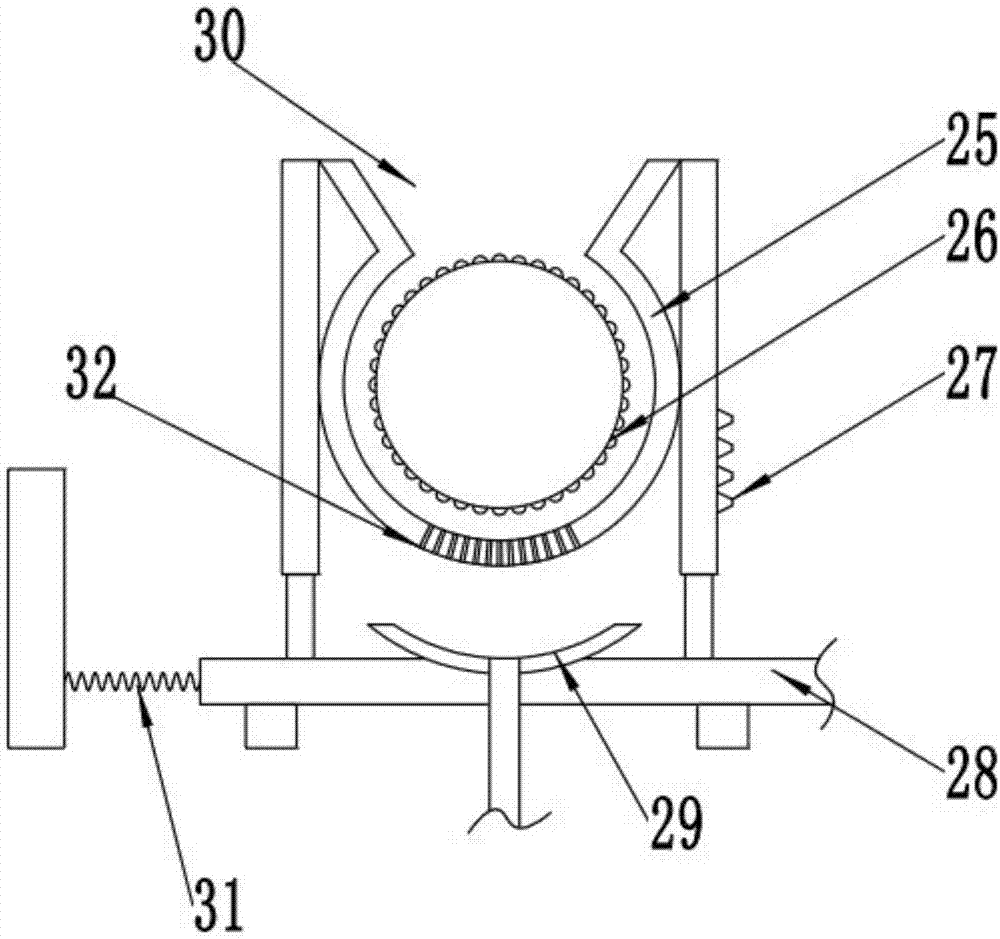

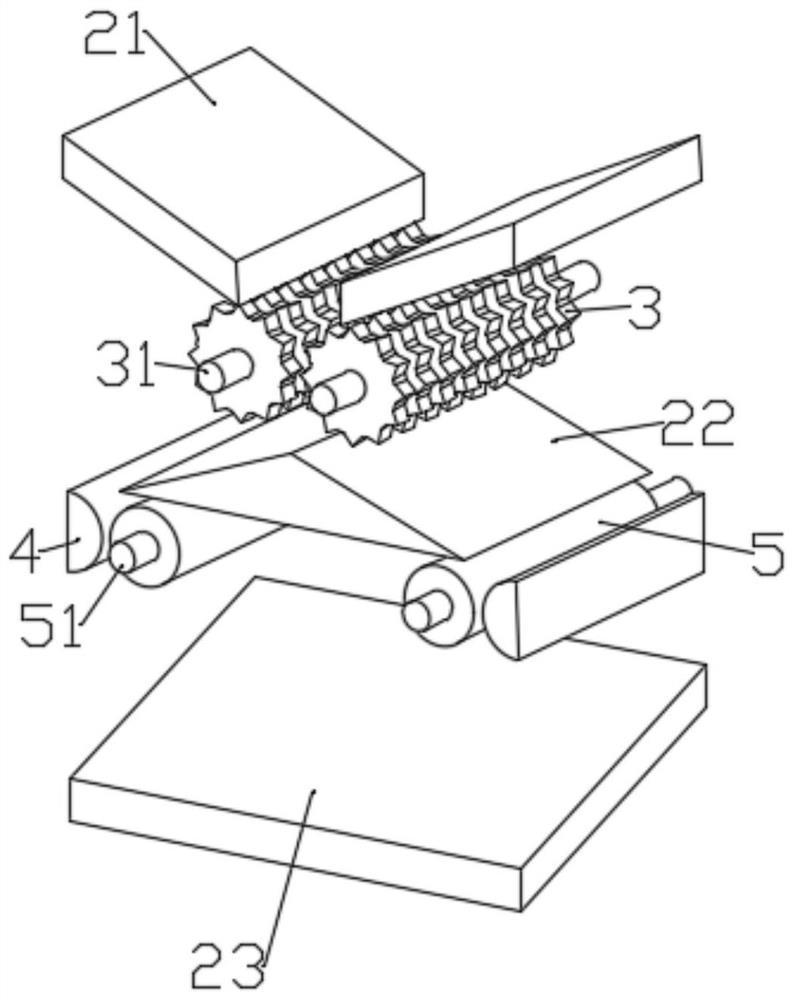

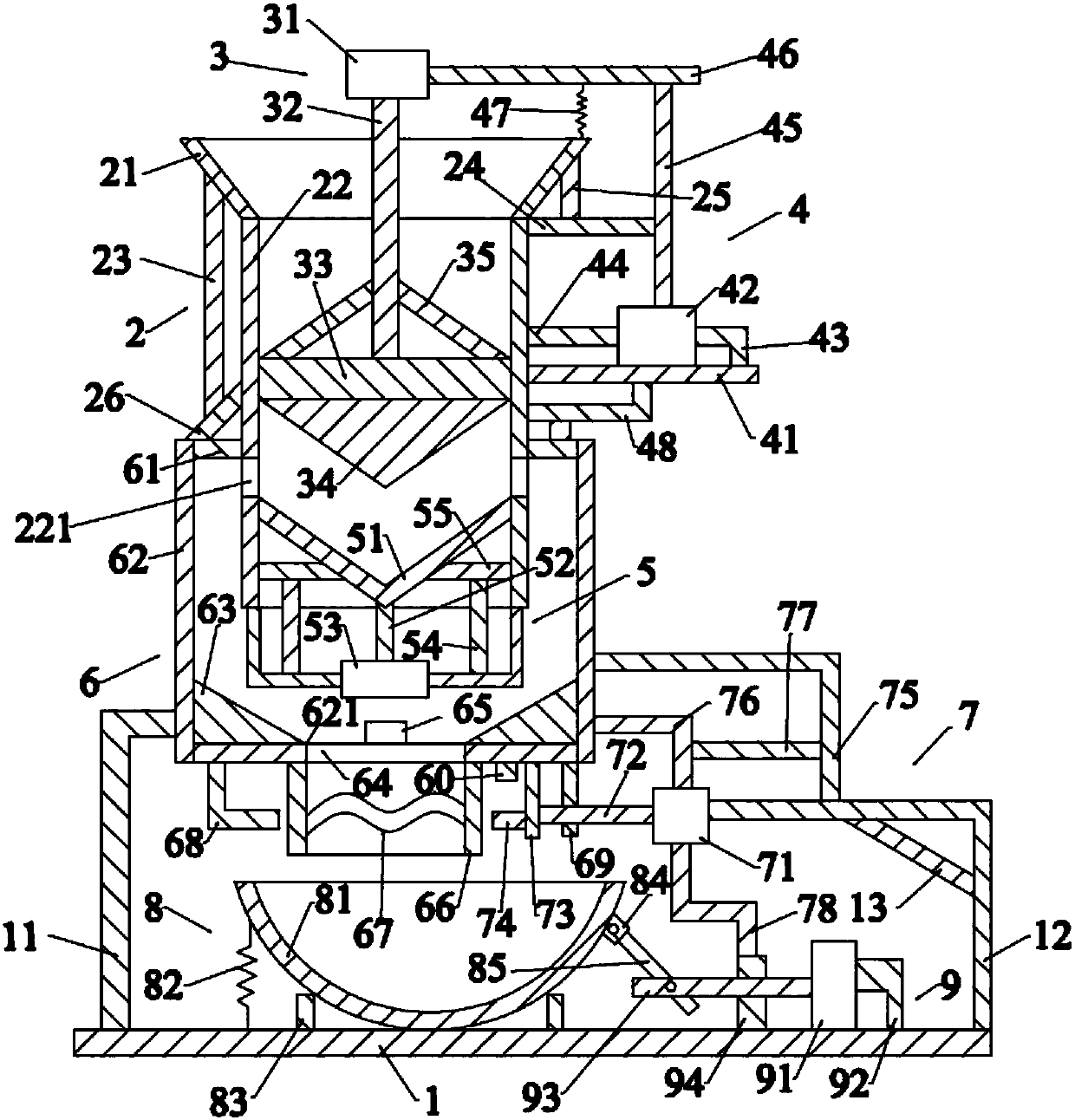

Medicinal material crushing and grinding processing device

The invention discloses a medicinal material crushing and grinding processing device. The medicinal material crushing and grinding processing device comprises a bottom plate (1), a frame body unit (2), a crushing unit (3), an air cylinder unit (4), a motor unit (5), a filtering unit (6), a knocking unit (7), a recovering unit (8) and a pushing unit (9). A first support (11), a second support (12) and a first oblique rod (13) are arranged on the bottom plate (1). The frame body unit (2) comprises a feed hopper (21), a first frame body (22), a first vertical rod (23), a first transverse rod (24) and a second vertical rod (25). The crushing unit (3) comprises a first motor (31), a first rotary shaft (32), a first rotary block (33) and a crushing block (34). The air cylinder unit (4) comprises a second transverse rod (41), a first air cylinder (42), a third support (43), a third transverse rod (44) and the like. The medicinal material crushing and grinding processing device can improve the medicinal material crushing efficiency and uniformly crush and grind medicinal materials.

Owner:SHENZHEN SPRING OF LIFE MEDICINE & MEDICAL EQUIP RES INST CO LTD

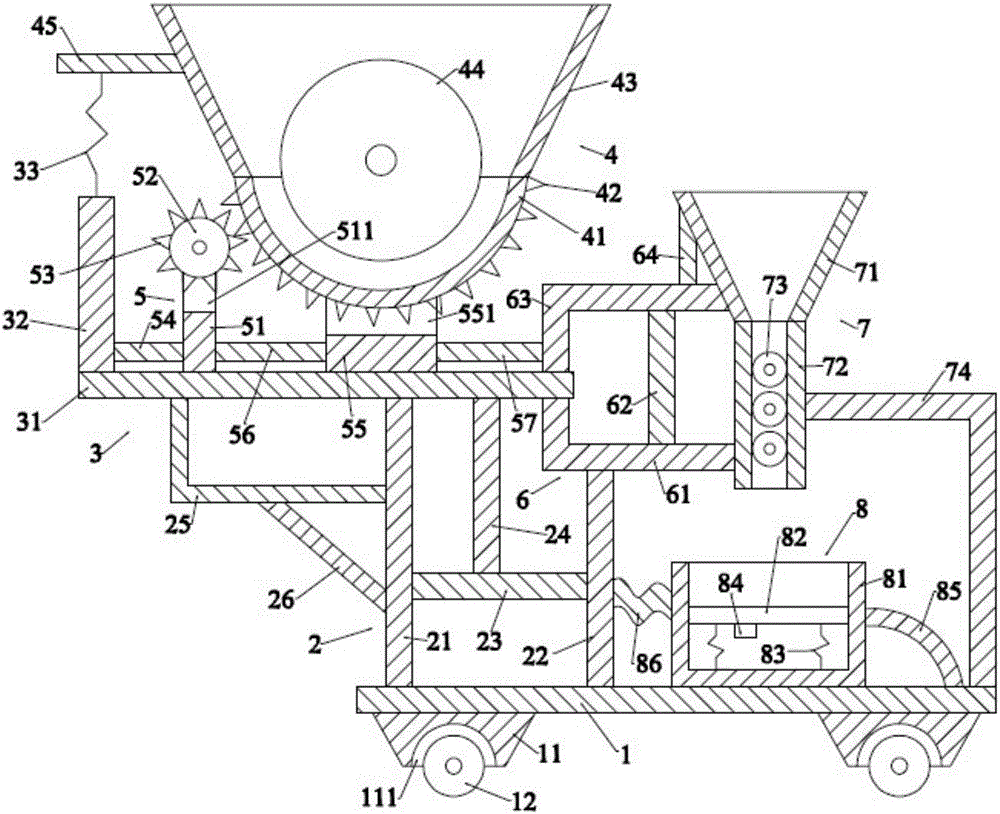

Economical and environment-friendly superfine pulverizing system for traditional Chinese medicines

An economical and environment-friendly ultrafine pulverization system for traditional Chinese medicine, including a bottom plate, a bracket device, a support plate device, a pulverization device, a driving device, a fixing device, a grinding device and a recovery device. The bottom plate is provided with a first support block and a first The roller, the bracket device includes a first support rod, a second support rod, a first cross bar, a third support rod, a first bracket and a first oblique rod, and the support plate device includes a support plate, a fourth support rod, and a first spring, The crushing device includes a crushing frame, a first sawtooth, a first feed hopper, a crushing wheel, and a first fixed rod, and the driving device includes a fifth support rod, a second roller, a second sawtooth, a second cross bar, a sixth support rod, The third horizontal bar and the fourth horizontal bar, the fixing device includes a second bracket, the first vertical bar, the third bracket and the second vertical bar, and the grinding device includes a second feeding hopper, a grinding frame, a grinding wheel, and a fourth bracket. The invention can quickly crush and grind the traditional Chinese medicine, and the crushing and grinding are relatively uniform and sufficient.

Owner:蒙泽喜

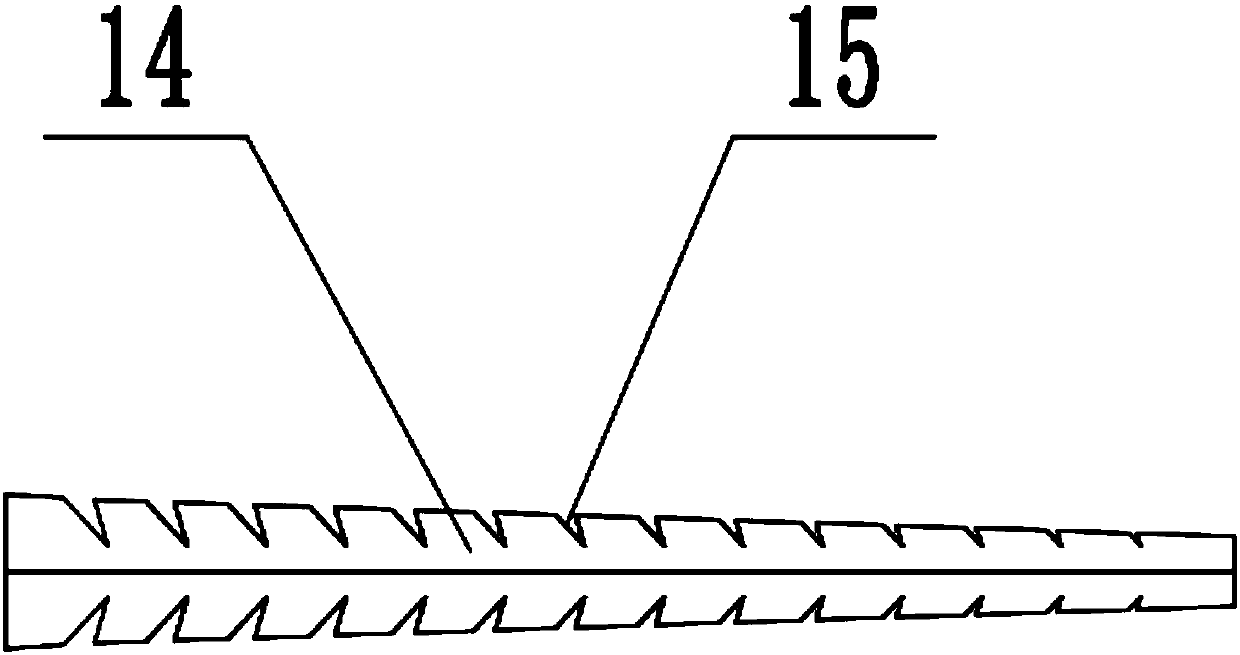

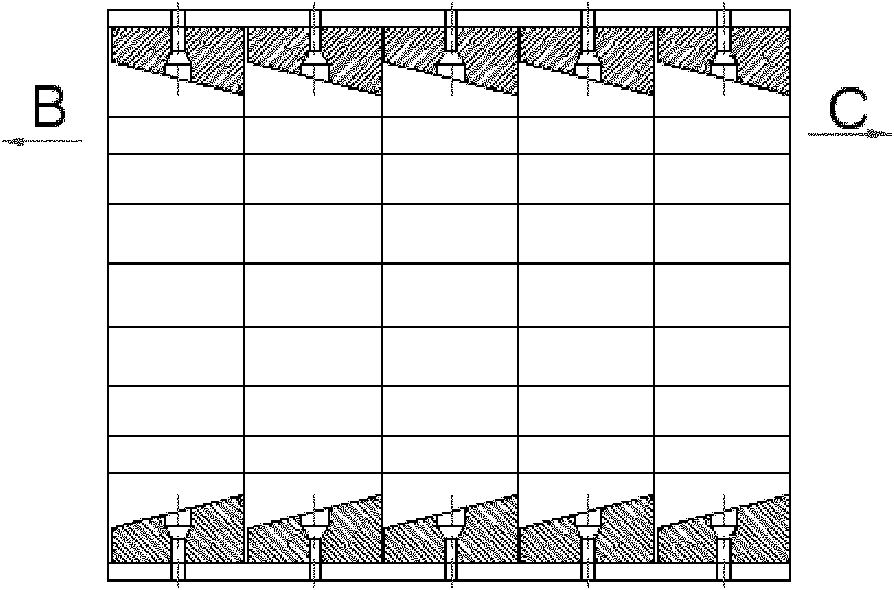

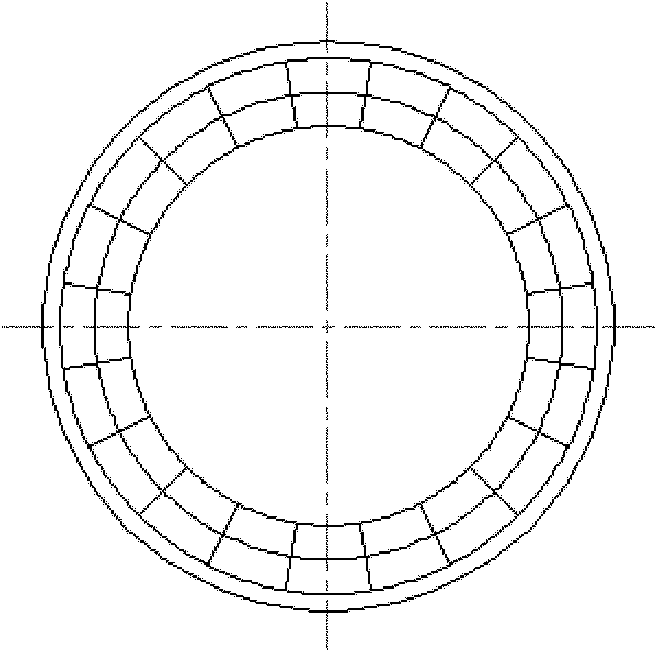

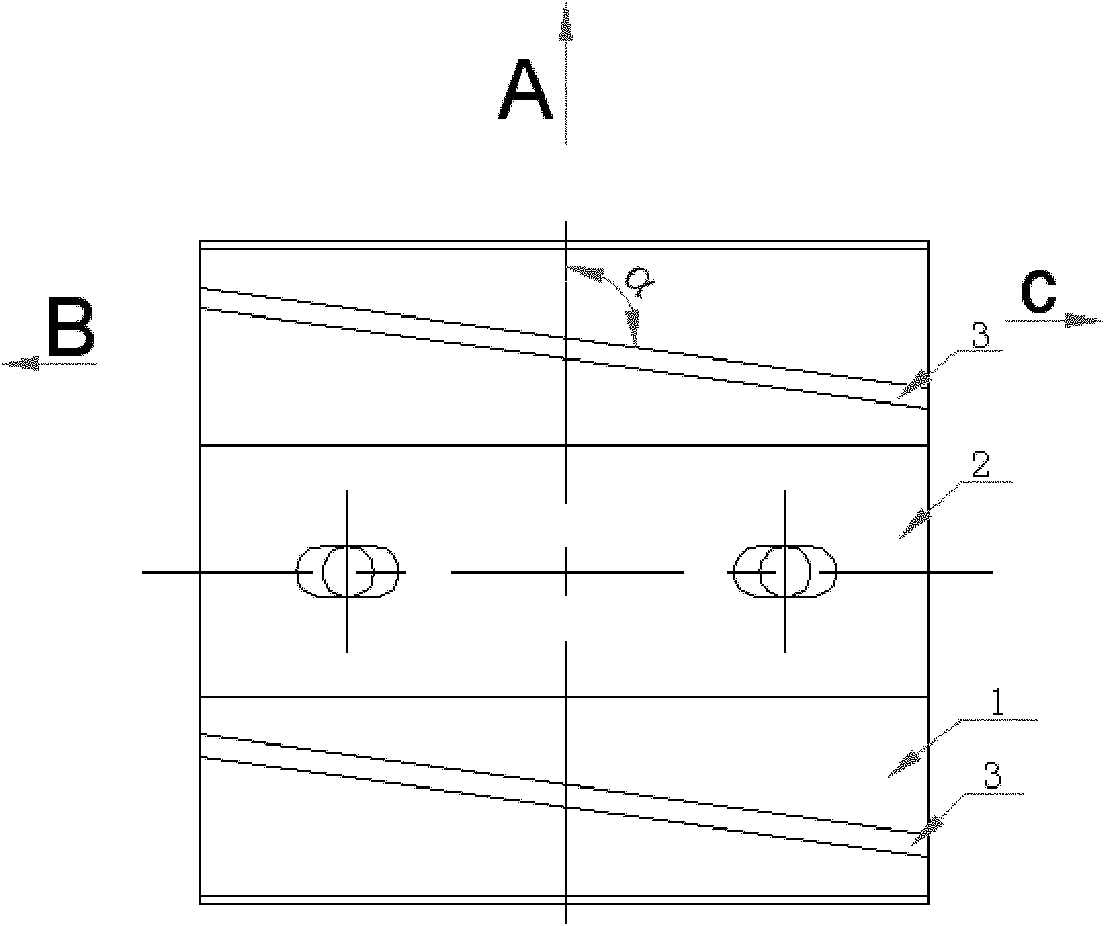

Ball grinding mill shell liner provided with grading tendon

InactiveCN101947489AGrading effect is goodAvoid severe wear and tearGrain treatmentsEngineeringBall mill

The invention discloses a ball grinding mill shell liner provided with a grading tendon. A strip-type bulging tendon is arranged on the base plate of the shell liner, and is not vertical to the shell liner along the movement direction of a ball grinding mill shell; the included angle of the strip-type bulging tendon and the shell liner along the movement direction of the ball grinding mill shell is 95 degrees to 120 degrees; and the height of the grinding tendon is more than the radius of a small-diameter grinding ball, and smaller than the diameter of the small-diameter grinding ball and the radius of a big-diameter grinding ball. The ball grinding mill shell liner of the invention utilizes the grading tendon to push a part of small-diameter grinding balls to the discharge hole of the ball grinding mill so as to the spherical surface height of the feeding hole of the ball grinding mill to be lowered, and the space accommodating mineral aggregate on the feeding hole to be increased, thus effectively improving the crushing efficiency of the mineral aggregate; and most of the big-diameter grinding balls can only cross the grading tendon from the small-diameter grinding ball, thus avoiding the grading tendon from being abraded and ensuring the lower service life of the grading tendon. The ball grinding mill shell liner of the invention has simple and reasonable structure, is easy to process and manufacture, is not easy to abrade, has obvious grading effect, and can effectively improve the crushing and grinding efficiency of the ball grinding mill.

Owner:湖南华民控股集团股份有限公司

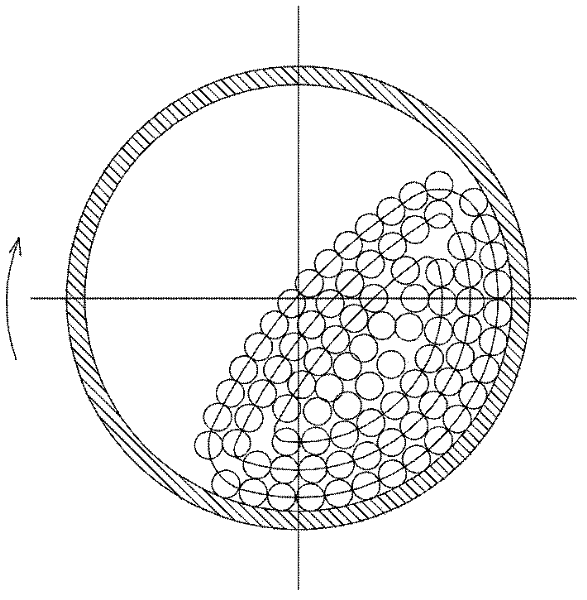

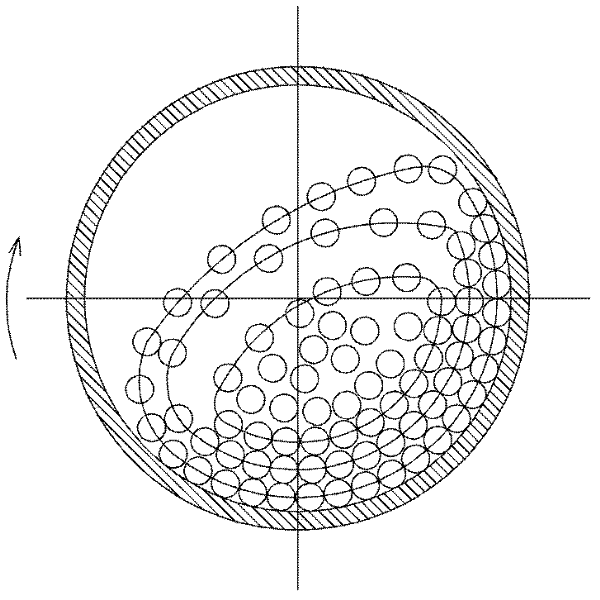

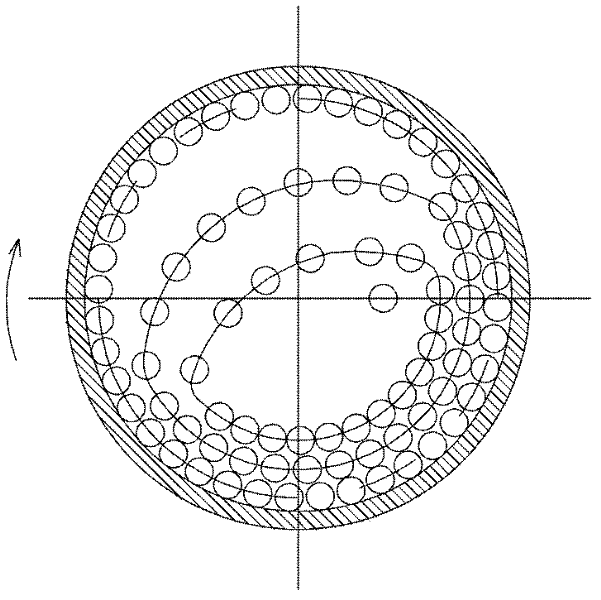

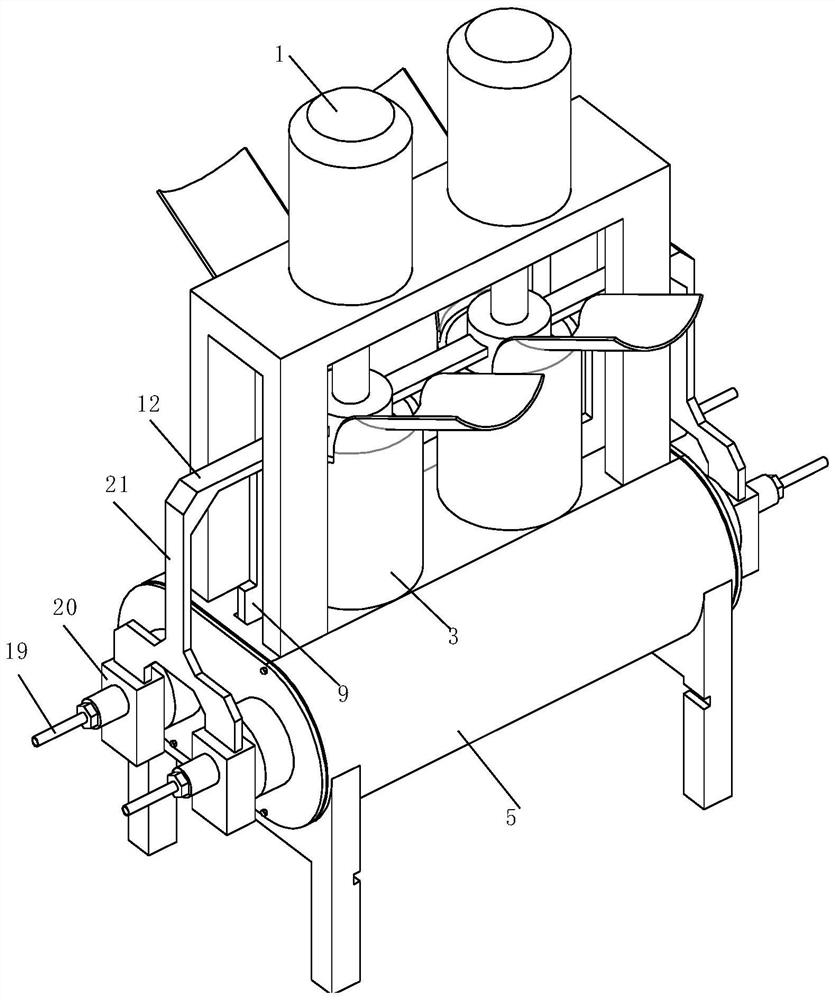

Subcritical variable-speed ball mill

InactiveCN102397807AImprove crushing and grinding efficiencySmooth startGrain treatmentsFluid couplingPower grid

The invention discloses a subcritical variable-speed ball mill, which comprises a base, a ball mill barrel, a motor and a hydraulic coupler, wherein the motor is controlled by using a control circuit; a main shaft of the motor is connected with a clutch-hydraulic coupler-reduction box in sequence; and an output shaft of the reduction box is in mechanical transmission connection with the ball mill barrel. Compared with the prior art, the subcritical variable-speed ball mill has the advantages: limit on the critical rotating speed of the conventional ball mill is broken through, the ball mill can well and accurately rotate at a variable speed between 0.5nk and 1nk, the defects of short grinding distance caused by small relative speed difference of inertia motion of materials and ballstone during constant-speed rotation of the conventional ball mill are overcome, the contact frequency of a raw material and ballstone is increased, the smashing and grinding efficiencies of the ball mill are increased, the ball milling time is shortened, electric energy is saved, energy is saved by 30-50 percent in comparison to a ball mill which cannot rotate at a variable speed, the start-up and speed change of the ball mill are stable and do not impact a power grid, and the like.

Owner:MODENA TECH LTD

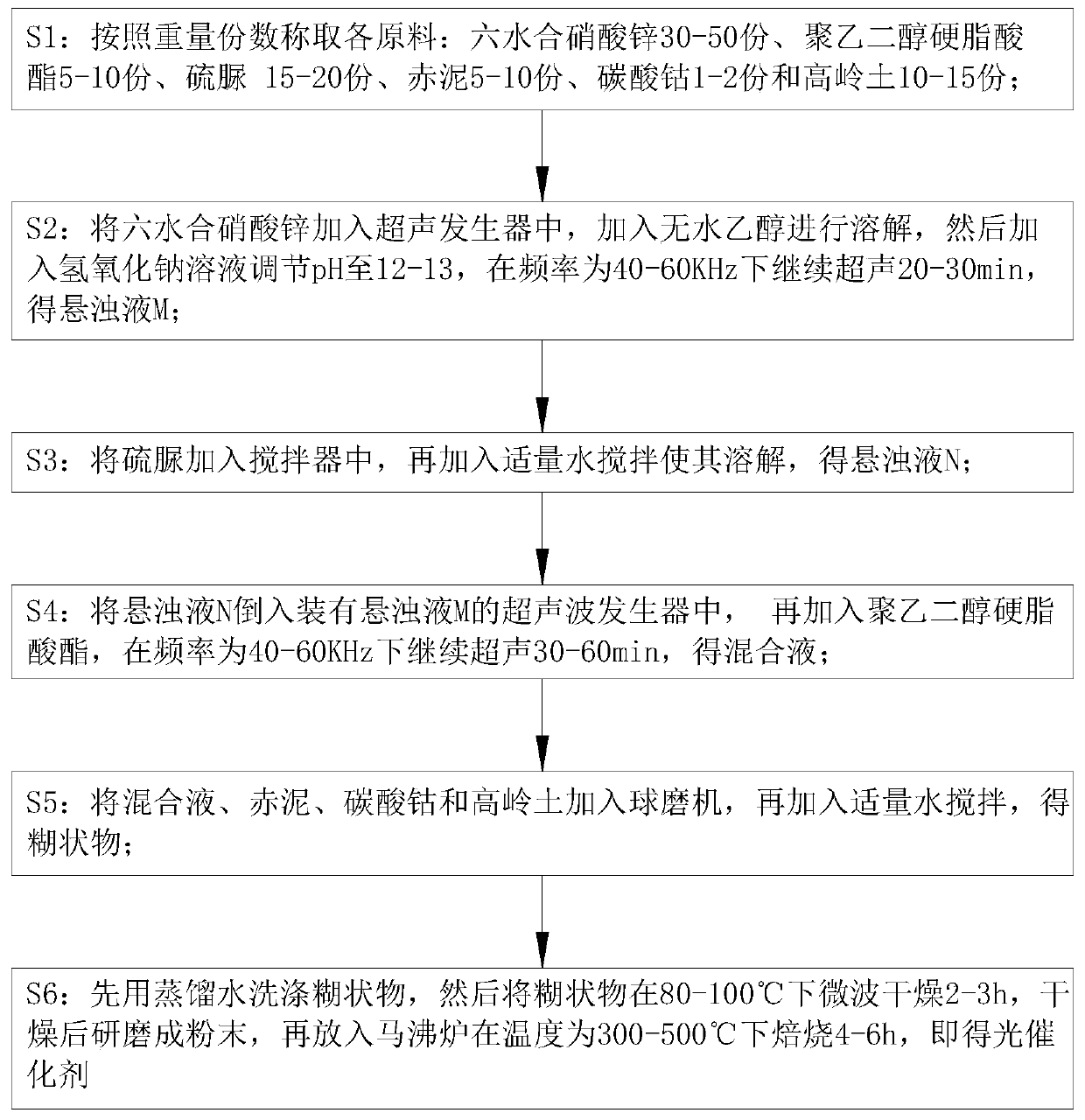

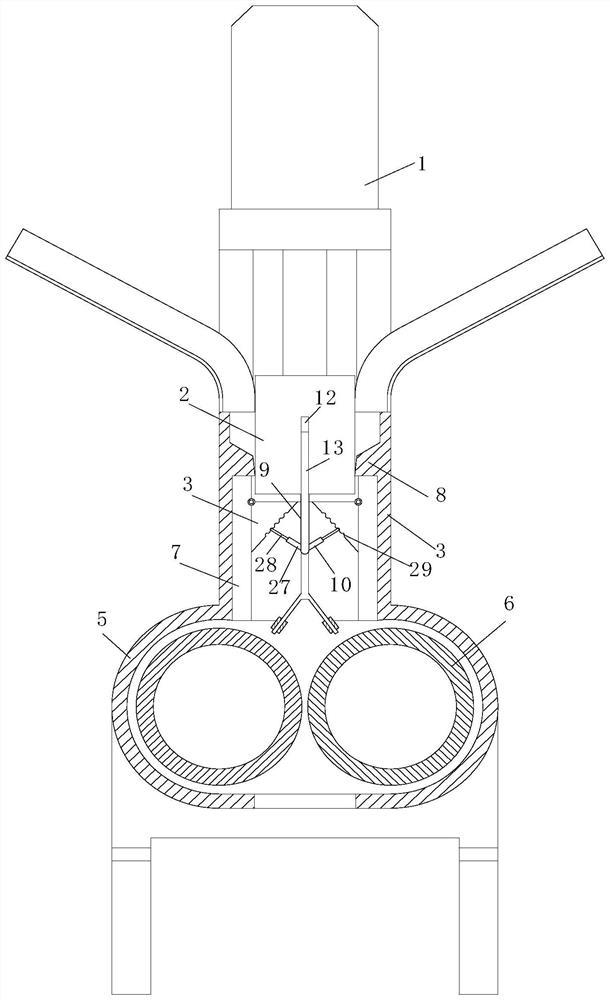

Preparation method of loaded zinc oxide photocatalyst

PendingCN110227436AIncrease the probability of collisionImprove grinding and crushing efficiencyCatalyst activation/preparationGrain treatmentsElectric machineryBall mill

Belonging to the technical field of photocatalytic materials, the invention in particular relates to a preparation method of a loaded zinc oxide photocatalyst. A ball mill adopted by the preparation method includes: a cylinder, a discharge port, ball seats, connecting rods, inclined plates, a motor and a speed reducer. The discharge port is disposed on a circumferential side of the cylinder; millballs are loaded in the cylinder; a set of parallel inclined plates are disposed on the sides at two ends of the cylinder; one sides of the inclined plates close to the cylinder are equipped with twoconnecting rods; the connecting rods and the ball seats on the cylinder are connected through joint bearings; the inclined plates located on one sides of the cylinder are driven by the speed reducer and motor; and the rotating shafts of the inclined plates rotate on the rack. According to the invention, the cylinder is driven to rotate through the inclined plates and connecting rods, as the connecting rods and the cylinder are connected through the joint bearings, the inclined plates can drive one side of the cylinder to rotate during rotation and the other side to do reciprocating inclined swing, thus increasing the rollover speed of the raw material mixture and mill balls in the cylinder, and then improving the grinding and crushing efficiency of the ball mill.

Owner:YANCHENG TEACHERS UNIV

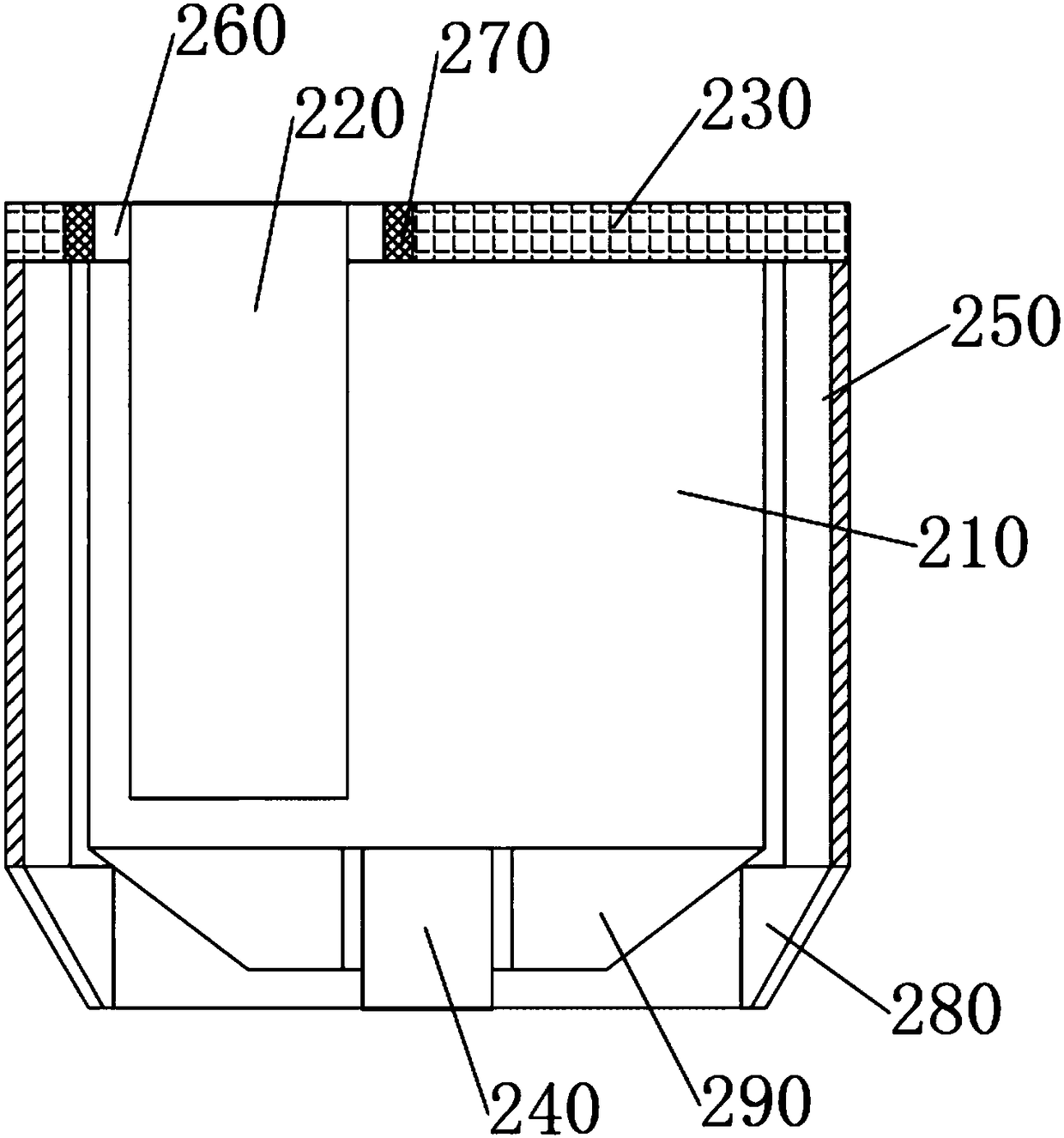

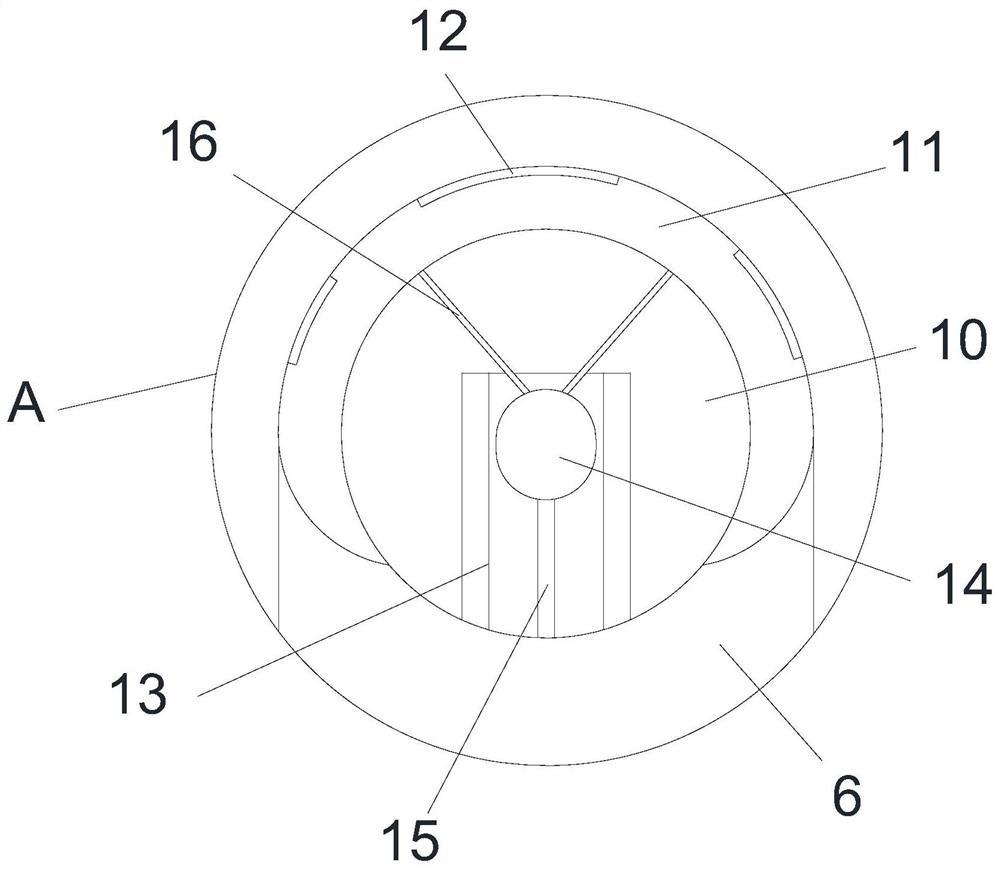

Crushing and grinding device for traditional Chinese medicine

The invention discloses a crushing and grinding device for a traditional Chinese medicine and relates to the field of traditional Chinese medicines. The crushing and grinding device comprises a box body, the bottom of the box body is fixedly connected with supporting legs, the side edge of the box body is fixedly connected with a feeding port, the lower surface of the box body is fixedly connectedwith a discharging port, the upper surface of the outer side of the box body is fixedly connected with a motor support, and the motor support is fixedly connected with a first motor. An output shaftof the first motor is fixedly connected with a rotating shaft, the end, away from the first motor, of the rotating shaft is fixedly connected with a crushing mechanism, and the rotating shaft is fixedly connected with a transmission mechanism. A feeding mechanism is fixedly connected to the portion, located in the feeding port, of the transmission mechanism, the inner side of the box body is fixedly connected with a grinding mechanism, and the middle portion of the inner side of the box body is fixedly connected with a collecting plate. A screening and adjusting mechanism is fixedly connectedto the inner wall of the box body. According to the crushing and grinding device for the traditional Chinese medicine, the traditional Chinese medicine can be fully crushed by arranging the crushing mechanism, dust can be prevented from overflowing when the traditional Chinese medicine is crushed by arranging the feeding mechanism, the crushing and grinding efficiency of the traditional Chinese medicine is improved, and meanwhile the labor cost is effectively saved.

Owner:曾梁

Material grinding device

ActiveCN112808361AImprove crushing and grinding efficiencyEasy to grindGrain treatmentsDrive shaftStructural engineering

The invention discloses a material grinding device, and relates to the field of material processing. The material grinding device comprises a base table, wherein a driving equipment box is fixedly installed on the right side of the top of the base table; driving equipment is arranged in the driving equipment box; a material box is fixedly installed on the left side of the top of the base table; and a driving shaft is fixedly installed at the output end of the driving equipment in the driving equipment box. According to the material grinding device provided by the invention, when the driving shaft begins to rotate, due to the relation between a groove in the driving shaft and an adjusting groove in a main plate, during rotating of the driving shaft, the two ends of the grinding device are limited by the driving shaft and gravity, so that materials in the material box can be strongly impacted; and meanwhile, a lower plate is arc-shaped rubber, the materials can be preliminarily impacted and crushed by the lower plate, and the materials can be better ground when being refined by the top end of the main plate, so that the material crushing and grinding efficiency is improved.

Owner:山东青牧牧业科技有限公司

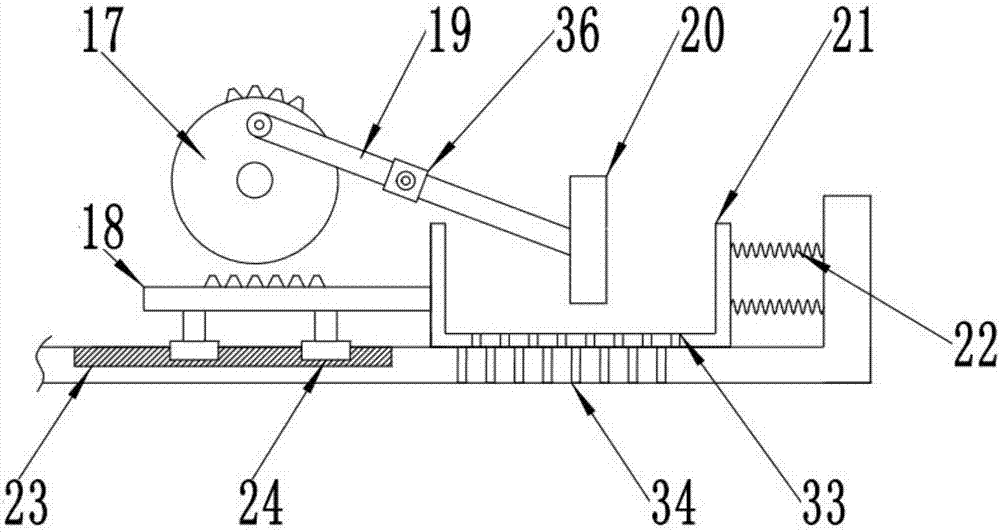

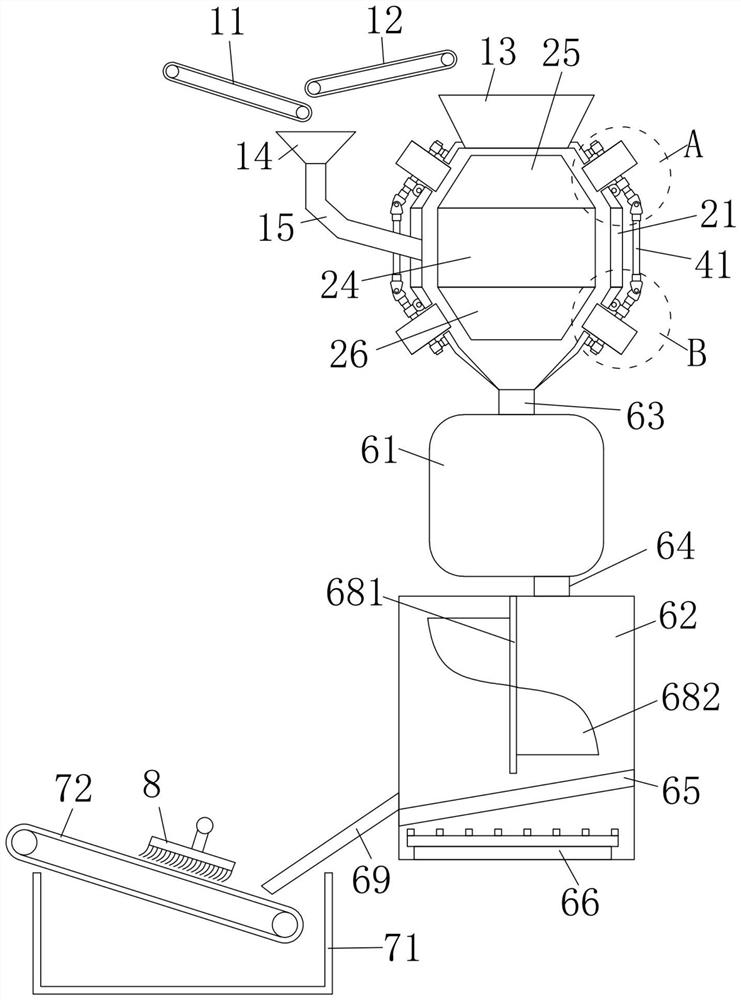

Economical and environment-friendly superfine smashing system for traditional Chinese medicines

The invention discloses an economical and environment-friendly superfine smashing system for traditional Chinese medicines. The system comprises a baseplate, a bracket device, a support plate device, a smashing device, a driving device, a fixing device, a grinding device and a recovering device; a first support plate and a first roller are arranged on the baseplate; the bracket device includes a first support rod, a second support rod, a first cross bar, a third support rod, a first bracket and a first inclined rod; the support plate device includes a support plate, a fourth support rod and a first spring; the smashing device includes a smashing frame, a first saw tooth, a first feed hopper, a smashing wheel and a first fixing rod; the driving device includes a fifth support rod, a second roller, a second saw tooth, a second cross bar, a sixth support rod, a third cross bar and a fourth cross bar; the fixing device includes a second bracket, a first vertical rod, a third bracket and a second vertical rod; and the grinding device includes a second feed hopper, a grinding frame, a grinding wheel and a fourth bracket. The system can quickly and effectively smash and grind the traditional Chinese medicines, and is more uniform and sufficient in smashing and grinding.

Owner:深圳市中科智诚科技有限公司

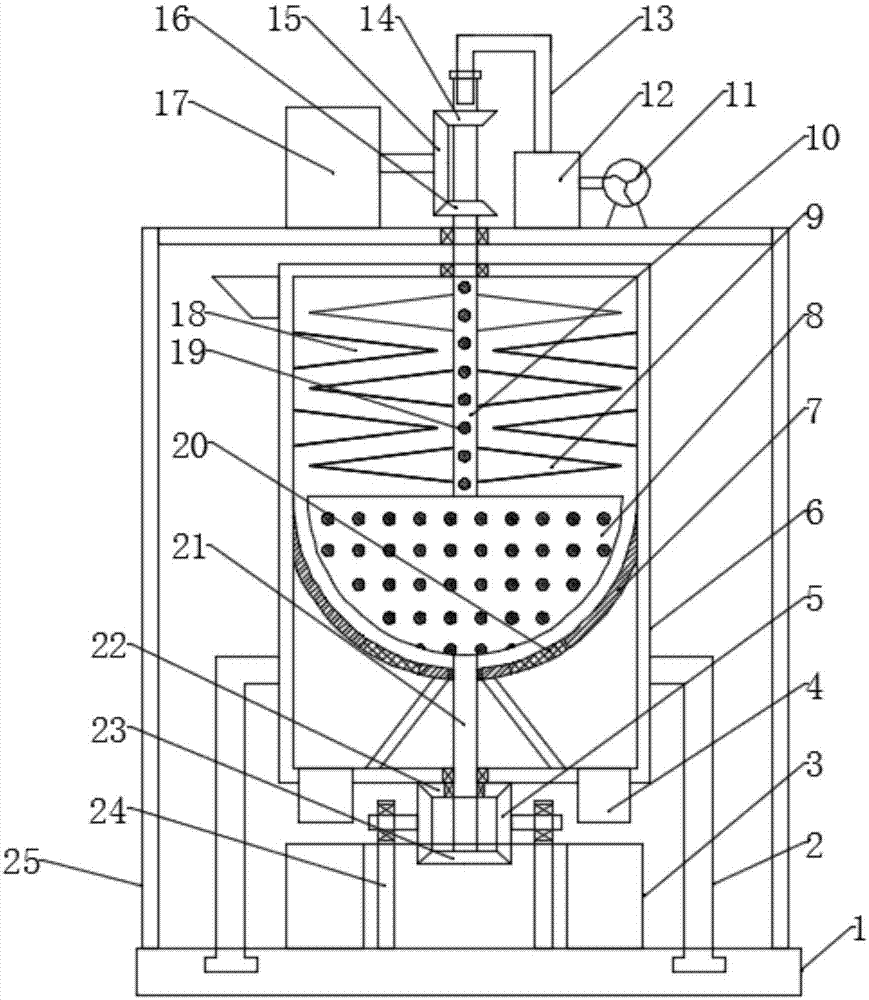

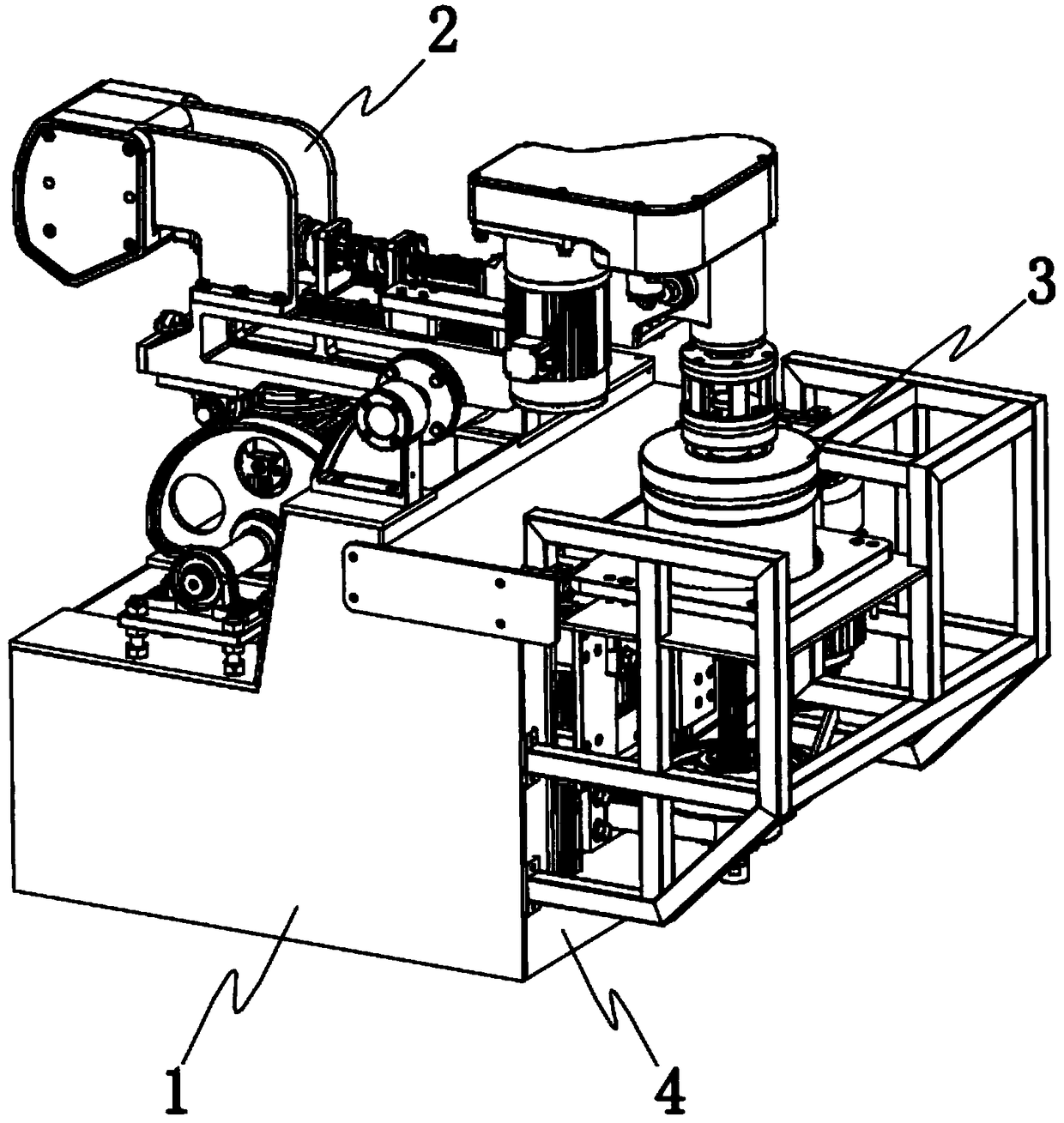

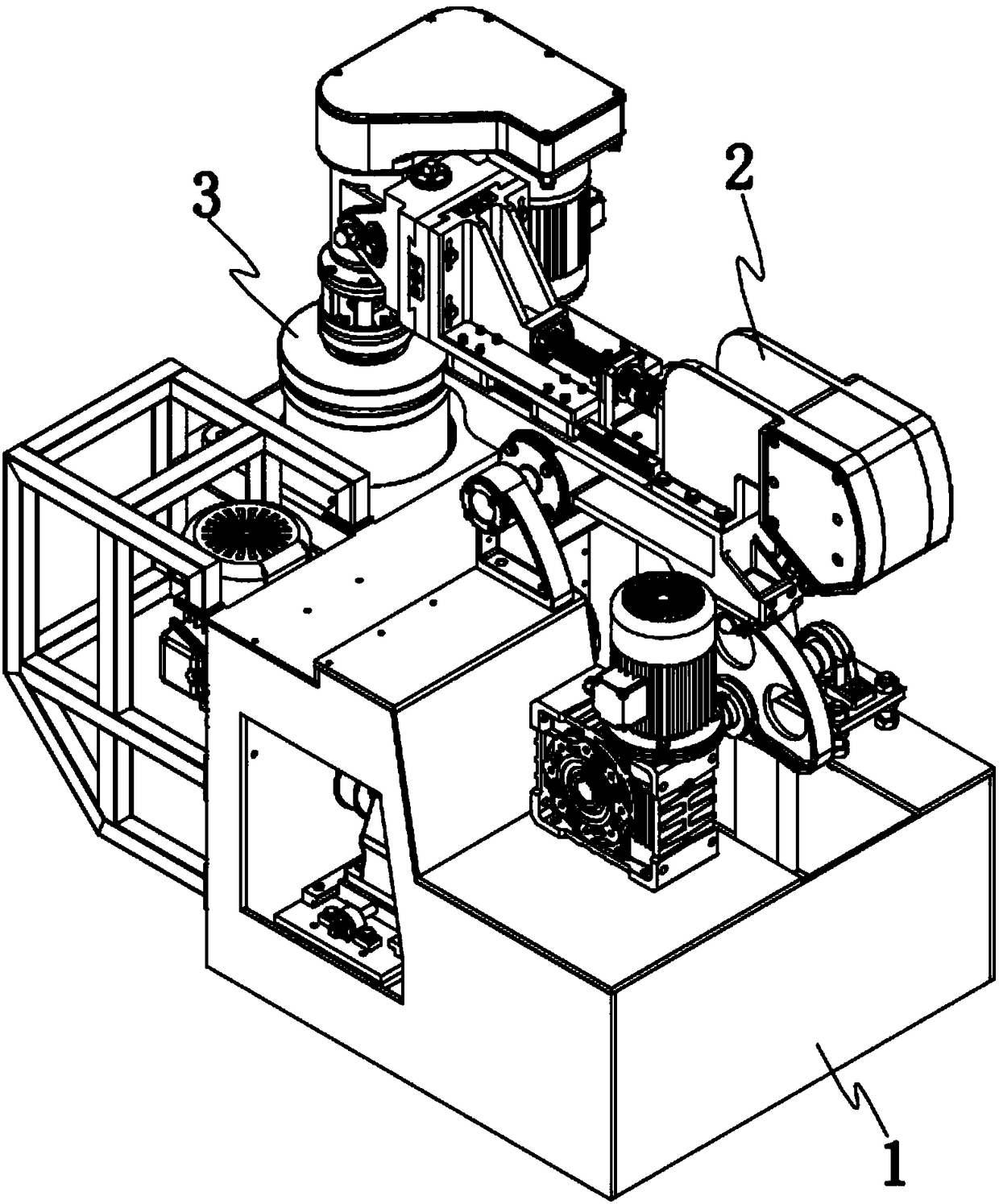

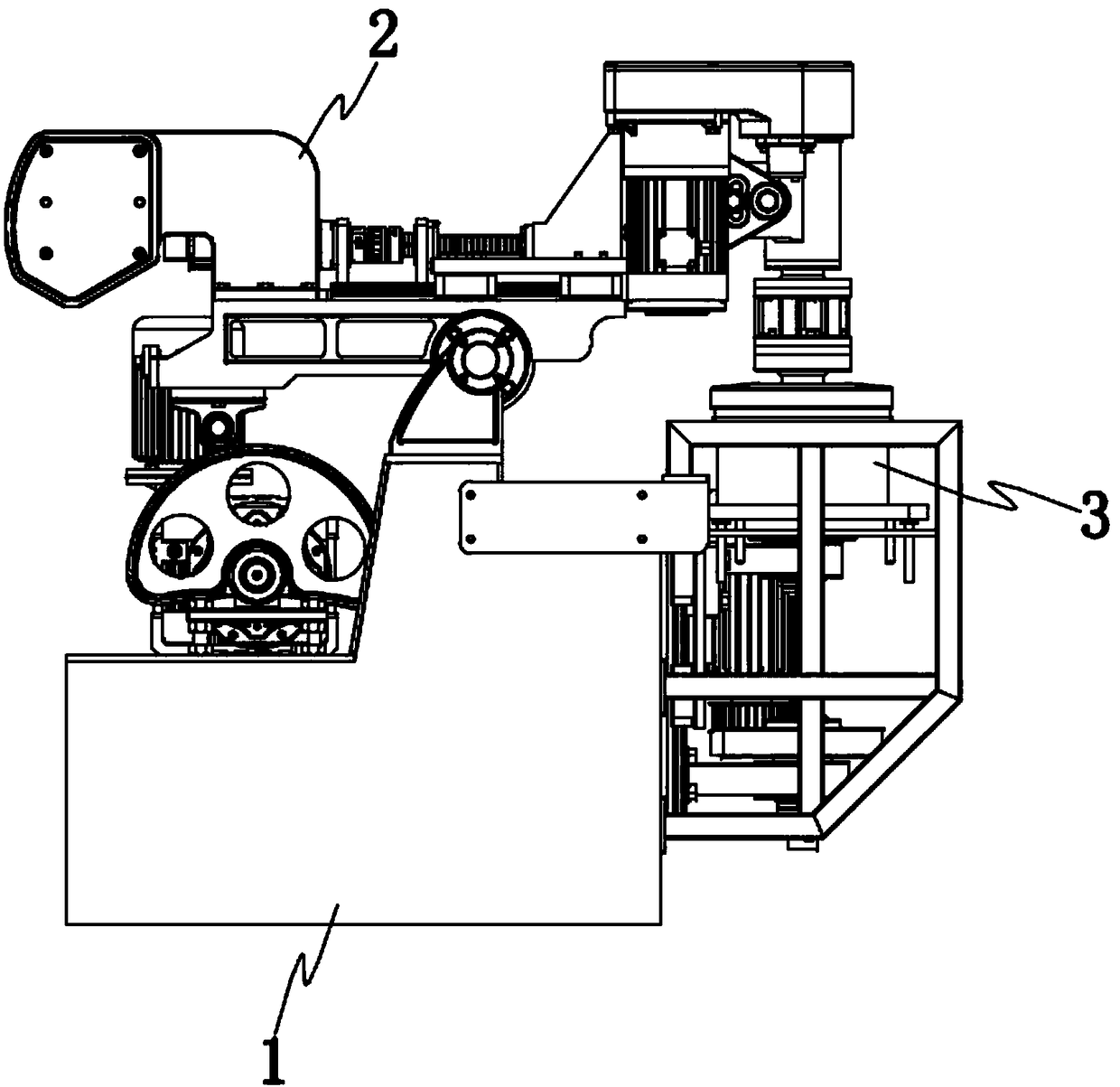

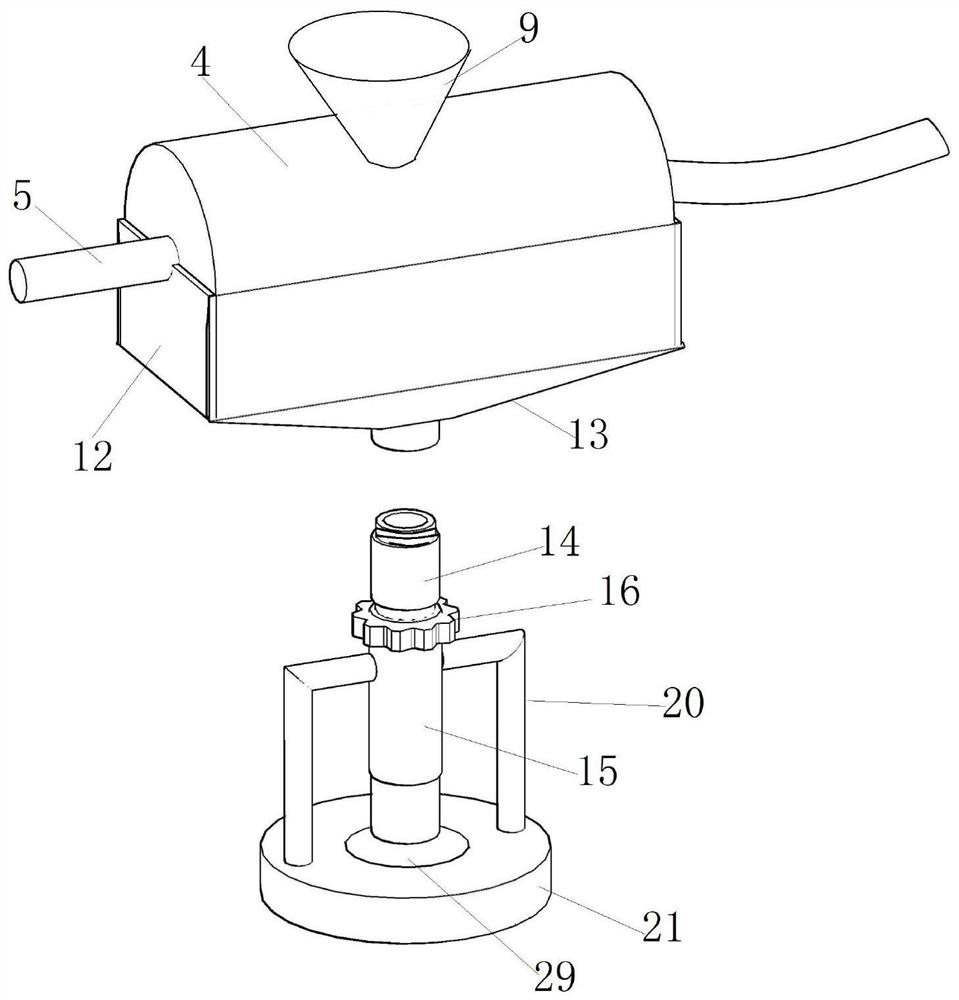

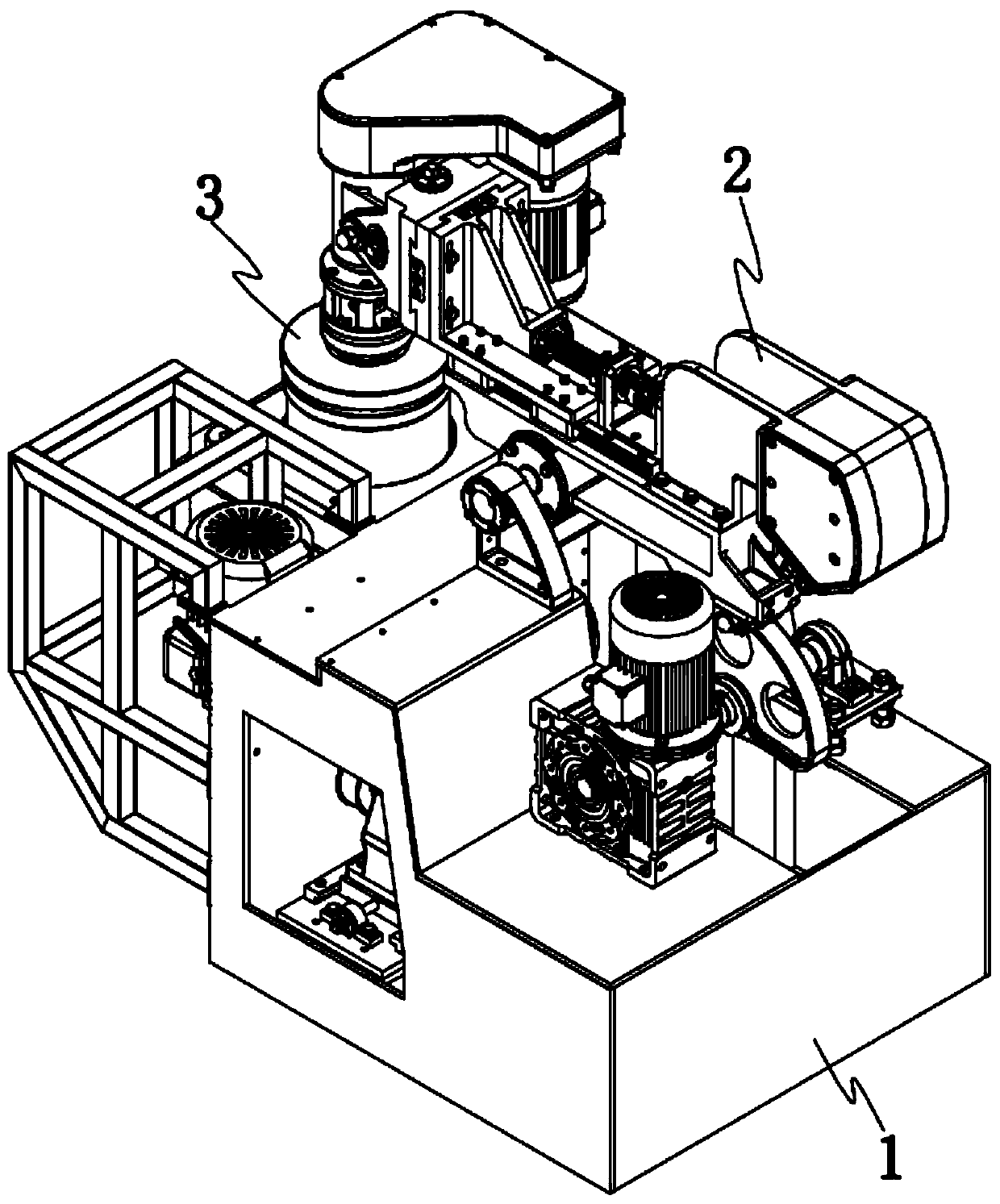

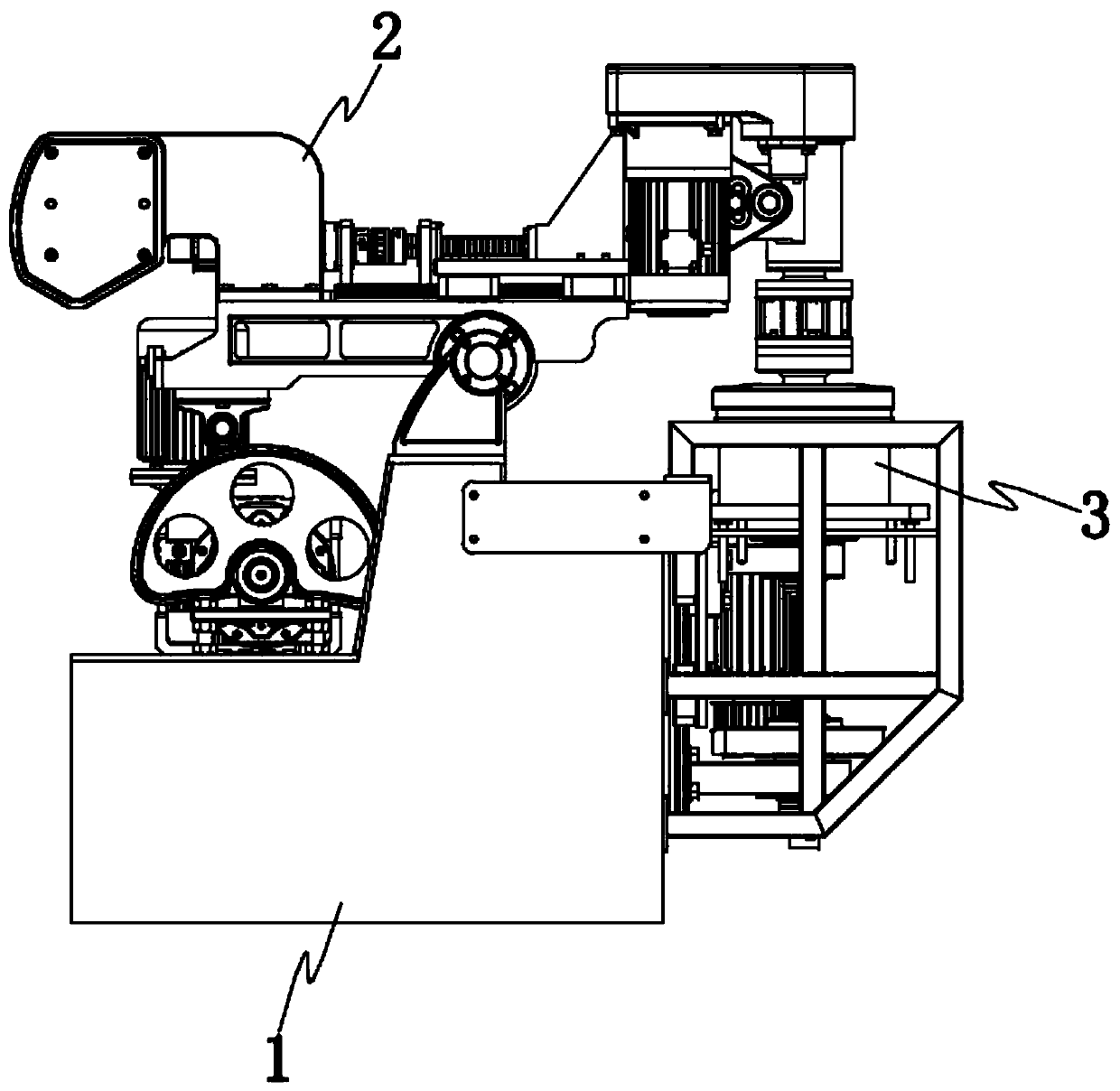

Large traditional Chinese medicinal material mashing and grinding machine

InactiveCN108176484AGood mashing and grinding effectLarge amount of processingGrain treatmentsManual medicineEngineering

The invention relates to a large traditional Chinese medicinal material mashing and grinding machine. The large traditional Chinese medicinal material mashing and grinding machine comprises a machinecabinet table. A mashing and grinding mechanism is arranged on the tabletop at the upper end of the machine cabinet table, and a material pot rotation driving mechanism is arranged on the outer side end face of a front end plate of the machine cabinet table. A material pot ascending and descending driving mechanism is arranged on the inner side end face of the front end plate. The mashing and grinding mechanism comprises a wane base, the position, close to one side, of the upper end face of the wane base is in sliding connection with a sliding block, and the position, close to the other side,of the upper end face of the wane base is provided with a first drive motor and a balance weight block. The sliding block is provided with a second drive motor. The equipment is large in pulverizing and grinding force, and medicinal material processing is finished at a time. The pulverizing and grinding efficiency is high, the medicine mashing effect is good, and the equipment mechanism positionscan be conveniently adjusted. Usage is convenient, the manual medicine mashing manner is replaced, the medicine material processing amount is large, and the large traditional Chinese medicinal material mashing and grinding machine is suitable for daily usage of large medicine stores.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

Processing equipment for barley wort powder

The invention relates to processing equipment for barley wort powder. The processing equipment for the barley wort powder comprises a support frame, wherein moving slide wheels are installed at the bottom end of the support frame separately; a storage box is fixedly welded to the top end of the support frame; mutually-communicated processing boxes are fixedly arranged at the top of the storage box; and a crushing chamber, a first grinding chamber and a second grinding chamber are sequentially arranged in the processing box from top to bottom. Through the arrangement for a first rotary motor, asecond rotary motor, the moving slide wheels and a push-pull rod, the processing equipment for the barley wort powder is simple in structure, low in cost, convenient to move, and applicable to some small enterprises; through the arrangement for the crushing chamber, the first grinding chamber and the second grinding chamber, the processing equipment for the barley wort powder is high in crushinggrinding efficiency, capable of carrying out grinding for many times, high in grinding accuracy, and capable of effectively improving the production quality; and through the arrangement for a storagecase and the storage box, the processing equipment for the barley wort powder is capable of preventing barley powder from being diffused into air to cause waste for the barley powder during discharge,suitable for being widely popularized, and capable of effectively meeting the use needs of people.

Owner:顶能科技有限公司

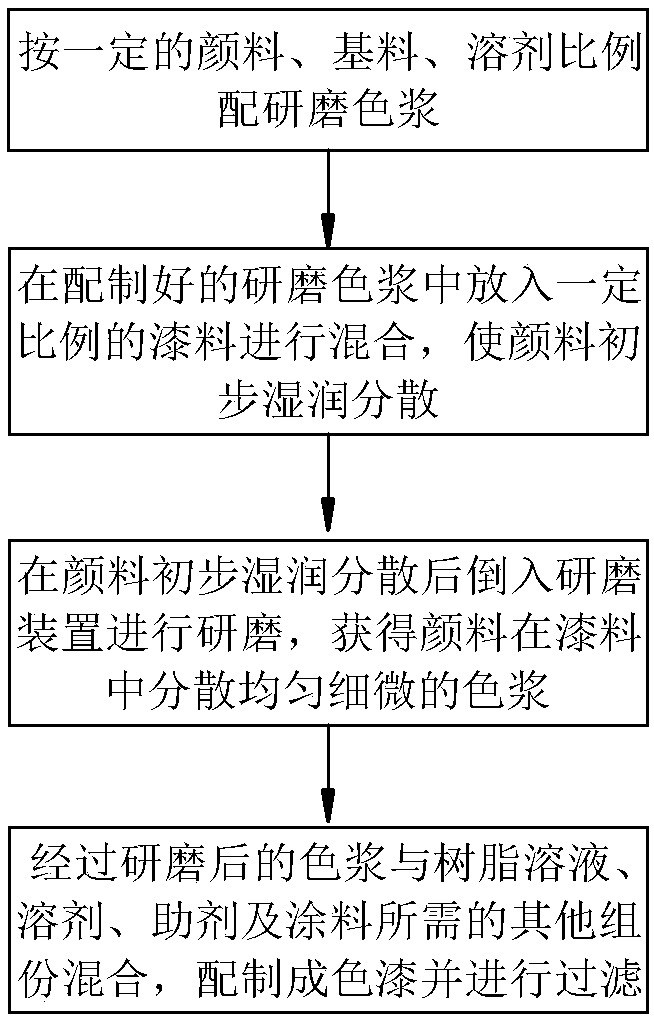

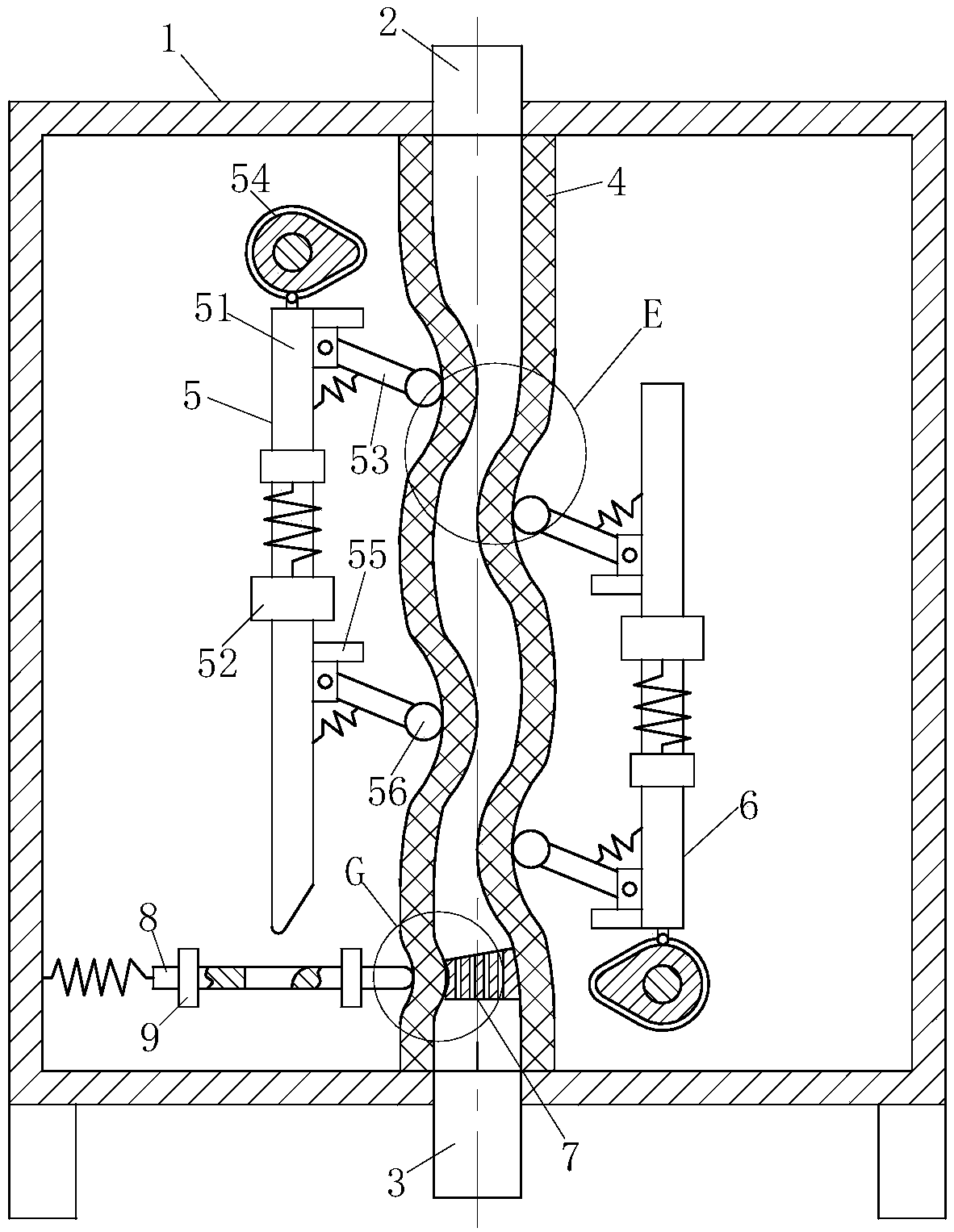

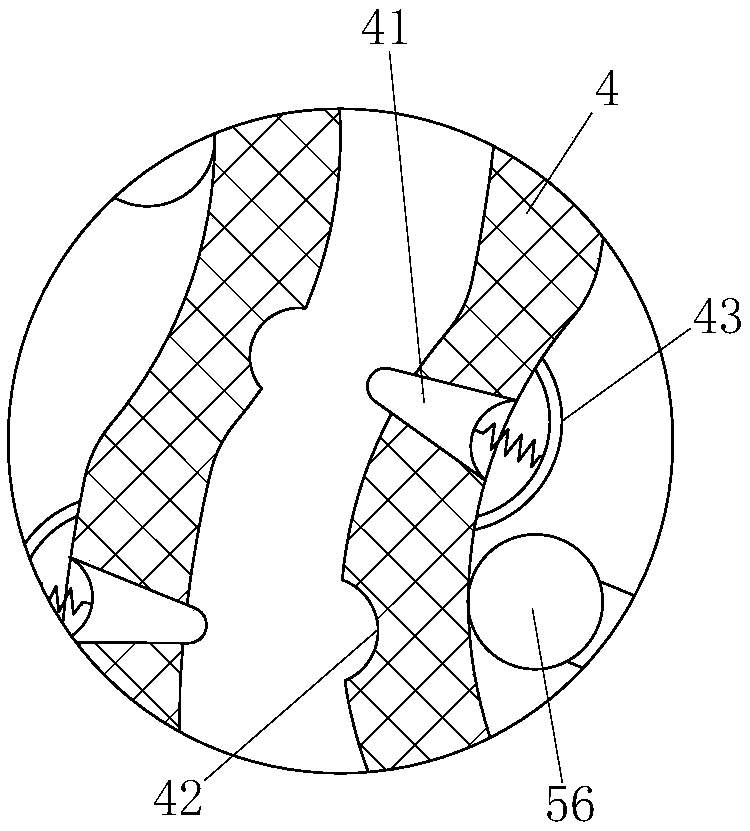

Production method of building coating

PendingCN109174378AImprove crushing and grinding efficiencyRealize the effect of multiple rollingCoatingsGrain treatmentsCamMethods of production

The invention belongs to the technical fields of coating production and processing and specifically relates to a production method of a building coating. In the method, a grinding device is used; thegrinding device comprises a cylinder, a feeding hole, a discharging hole, grinding belts, a first pushing module and a second pushing module; the feeding hole is formed in the top of the cylinder; thedischarging hole is formed in the bottom of the cylinder; grinding belts are symmetrically arranged inside the cylinder, and two ends of the grinding belts are respectively connected with the top andthe bottom of the cylinder; the first pushing module is located at the left side inside the cylinder; the second pushing module is located at the right side inside the cylinder; the first pushing module and the second pushing module are same in structure and are in central symmetry; the first pushing module comprises a sliding rod, a guide ring, a pushing rod and a cam; and due to the rotation ofthe cams in the first pushing module and the second pushing module, the sliding rods move up and down to drive the pushing rods to extrude the grinding belts, the outer sides of the two grinding belts are in intermittent rolling contact, and then, a coating passing through the grinding belts are crushed and ground, so that the crushing and grinding efficiencies of the coating is increased.

Owner:杨大鹏

Multifunctional glass recovery device

InactiveCN113634322AFlexible adjustment of crushing finenessImprove crushing and grinding efficiencyGlass recyclingCleaning using toolsProcess engineeringGlass particle

The invention discloses a multifunctional glass recovery device, and belongs to the field of recovery devices. The multifunctional glass recovery device comprises a feeding part, a crushing part and a cleaning part. The feeding part comprises a first conveying belt, a second conveying belt, a material guide plate and a feeding hopper. Transported glass waste is classified through the arranged feeding part, waste with large particles is put into an inlet in the top of the crushing part to be fully ground and crushed, materials with small particles can enter the crushing part from the middle of the crushing part to be directly and finely ground, the grinding and crushing efficiency can be improved through classified grinding of the materials, and the processing speed is improved; the crushing fineness of the crushing part can be flexibly adjusted so as to achieve the optimal crushing effect; and the crushed glass is discharged into the cleaning part to be cleaned, and finally clean and perfectly crushed glass particles are output to facilitate secondary utilization.

Owner:广州益环再生资源科技股份有限公司

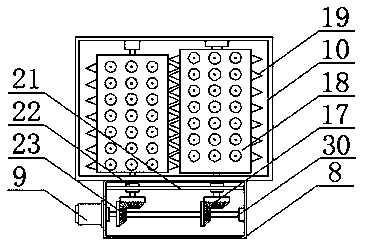

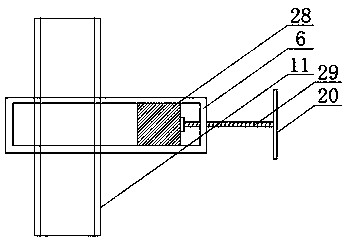

A crushing and grinding device for medicinal materials

The invention discloses a medicinal material crushing and grinding processing device. The medicinal material crushing and grinding processing device comprises a bottom plate (1), a frame body unit (2), a crushing unit (3), an air cylinder unit (4), a motor unit (5), a filtering unit (6), a knocking unit (7), a recovering unit (8) and a pushing unit (9). A first support (11), a second support (12) and a first oblique rod (13) are arranged on the bottom plate (1). The frame body unit (2) comprises a feed hopper (21), a first frame body (22), a first vertical rod (23), a first transverse rod (24) and a second vertical rod (25). The crushing unit (3) comprises a first motor (31), a first rotary shaft (32), a first rotary block (33) and a crushing block (34). The air cylinder unit (4) comprises a second transverse rod (41), a first air cylinder (42), a third support (43), a third transverse rod (44) and the like. The medicinal material crushing and grinding processing device can improve the medicinal material crushing efficiency and uniformly crush and grind medicinal materials.

Owner:SHENZHEN SPRING OF LIFE MEDICINE & MEDICAL EQUIP RES INST CO LTD

Organic pigment grinding and crushing device

InactiveCN108855553ARealize the function of double grinding and crushingGrinding and crushing is effectiveGrain treatmentsEngineeringPigment

The invention discloses an organic pigment grinding and crushing device, comprising a bearing plate, wherein supporting rods are fixed at four corners at the lower end of the bearing plate, four mounting plats are fixed at the upper end of the bearing plate, a support column is fixed at the upper end of each of the four mounting plates, a crushing box is jointly fixed to the upper end of the foursupport columns, a crushing cavity is arranged in the crushing box, a protection case is fixed at the side wall of one end of the crushing box, a protection cavity is arranged in the protection case,a rotation mechanism is arranged in the protection cavity and one end of the rotation mechanism is connected with a first crushing device. The organic pigment grinding and crushing device is a modified grinding and crushing device with functions of double grinding and crushing of organic pigment and control of blanking velocity, solving a situation of poor using effects or impact on using effectscaused by poor crushing of organic pigment and enhancing stability; the organic pigment grinding and crushing device is available for controlling blanking velocity according to demand, easy to operateand convenient to use.

Owner:龚卫珍

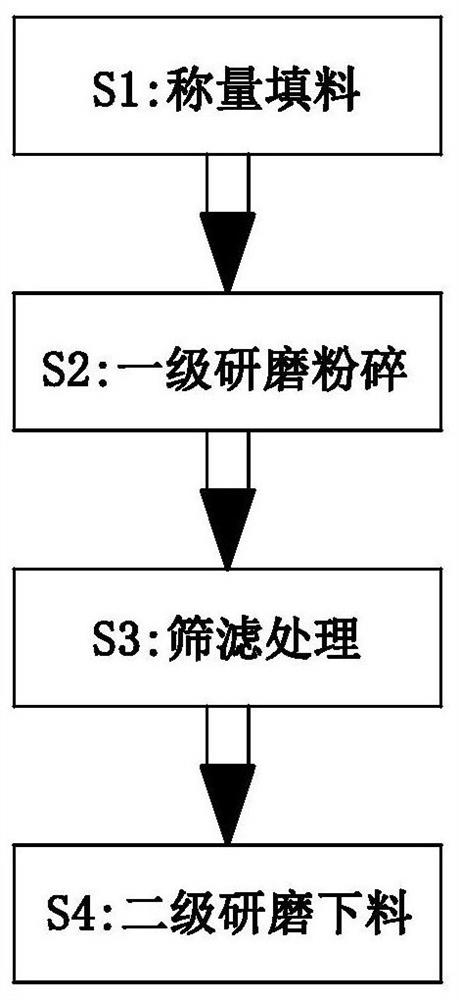

Production process of water-based intumescent fire-retardant coating

InactiveCN113522501AImprove crushing and grinding efficiencyIncrease productivityGrain treatmentsProcess engineeringRaw material

The invention relates to a production process of a water-based intumescent fire-retardant coating. Production equipment used in the production process comprises a bottom plate, a protective shell, a first grinding and crushing device, a screening and filtering device and a second grinding and crushing device. The process can solve the possible problems in a grinding and crushing process of an existing water-based intumescent fire-retardant coating raw material, which include the following problems that a, the water-based intumescent fire-retardant coating raw material is ground and crushed by means of a traditional crushing and grinding machine, a crushing and grinding effect is poor, final raw material fineness cannot meet a use requirement, and the material needs to be screened, ground and crushed again, so that production efficiency is reduced; and b, a discharge hole of the traditional crushing and grinding machine is prone to blockage, the discharge hole can only be unblocked manually after being blocked, unblocking difficulty is high, and unblocking time is long, so that labor intensity of workers is increased, discharge efficiency of the water-based intumescent fire-retardant coating raw material is reduced, and then the production efficiency of the water-based intumescent fire-retardant coating is reduced.

Owner:高杰

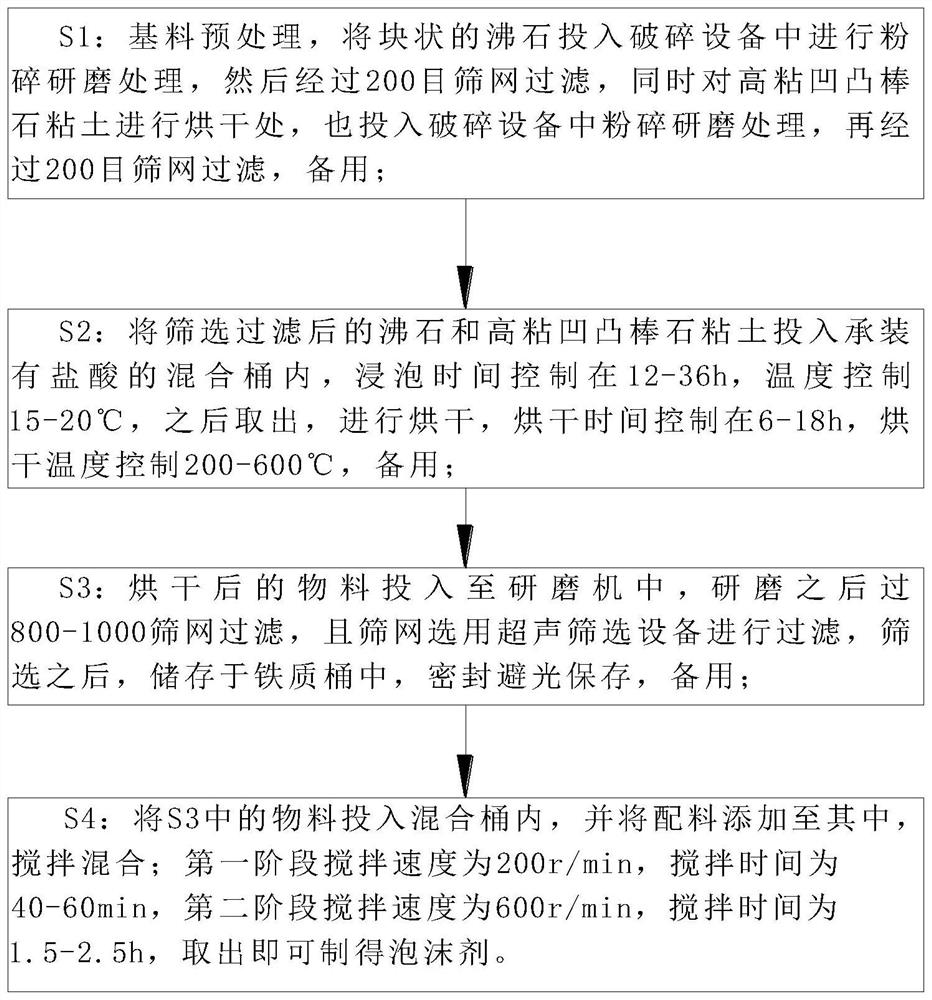

Foaming agent with high universality for construction and preparation method thereof

ActiveCN114522788AReduce crushing and grinding pressureImprove crushing and grinding efficiencyTransportation and packagingPlastic recyclingFoaming agentMetallurgy

The invention belongs to the technical field of foaming agent production, and particularly relates to a high-universality foaming agent for construction and a preparation method thereof.The preparation method of the foaming agent comprises the following steps that S1, base material pretreatment is conducted, specifically, blocky zeolite is put into crushing equipment to be subjected to crushing and grinding treatment for standby application; s2, putting the screened and filtered zeolite and high-viscosity attapulgite clay into a mixing barrel filled with hydrochloric acid, and soaking for later use; s3, the dried materials are put into a grinding machine and filtered through a 800-1000-mesh screen after being ground, ultrasonic screening equipment is selected for filtering through the mesh screen, and after screening, the materials are stored in an iron barrel and stored in a sealed dark place for standby application; s4, the materials in the S3 are put into a mixing barrel, ingredients are added into the mixing barrel, and stirring and mixing are conducted; the stirring speed in the first stage is 200r / min and the stirring time is 40-60 minutes, and the stirring speed in the second stage is 600r / min and the stirring time is 1.5-2.5 hours, and taking out to obtain the foaming agent.

Owner:BEIJING MUNICIPAL CONSTR +1

Industrial metal waste crushing and grinding device

InactiveCN112774782AImprove crushing and grinding efficiencyEasy to collectGrain treatmentsGrinding wheelWaste material

The invention discloses an industrial metal waste crushing and grinding device. The industrial metal waste crushing and grinding device comprises a box body, crushing rollers and movable grinding wheels, wherein a pair of symmetrically-arranged first rotating shafts are rotatably mounted at the upper part in the box body; a pair of crushing rollers are rotatably mounted on the outer surfaces of the pair of first rotating shafts; a pair of symmetrically-arranged fixed grinding wheels are fixedly mounted on the left side and the right side of the middle in the box body; the movable grinding wheels are arranged on the sides of the fixed grinding wheels; rotating transmission mechanisms capable of rotating oppositely are arranged at the ends of a pair of second rotating shafts; a metal waste guiding mechanism is arranged in the box body; and a collecting box placing mechanism is arranged at the bottom of the front side of the box body. According to the industrial metal waste crushing and grinding device, metal wastes crushed by the pair of crushing rollers are distributed between a pair of movable grinding wheels and fixed grinding wheels and are ground; the industrial metal waste crushing and grinding efficiency is improved; and a collecting box placing mechanism is arranged, so that the crushed and ground industrial metal wastes can be conveniently collected by a collecting box.

Owner:麻江县金泰工业废渣综合利用回收有限责任公司

A solid chemical crushing device based on air blowing

The invention discloses a solid chemical smashing device based on air blowing. The device comprises a cylinder, a grinding hammer and a shell. A vertical connecting rod is fixedly connected to the lower end of a piston rod of the cylinder, the grinding hammer is fixedly mounted at the lower end of the connecting rod, and a piston is fixedly mounted in the middle of the connecting rod to divide the interior of the shell into an upper sealed cavity and a lower sealed cavity; an air inlet device is communicated with the upper portion of the upper sealed cavity and comprises a first air inlet pipe, an air filter, a turbocharging device, a second air inlet pipe and a first one-way valve; a communication pipe is further connected to the upper portion of the upper sealed cavity, an inclined air inlet is communicated with the lower end of the communication pipe, and the other end of a first air outlet pipe is connected to the turbocharging device. By means of the turbocharging device, air which is exhausted at a high speed is used for pushing a turbine to rotate so as to increase the air flow speed in the air inlet pipes, the air inlet quantity is increased, the inlet air flow speed is increased, it is guaranteed that air with sufficient force is blown out of the air inlet, and a stirring effect is achieved.

Owner:YANCHENG YONGYUE NEW MATERIAL CO LTD

A kind of solid drug pulverizer

A solid medicine pulverizer comprises a bottom plate (1), a frame body device (2), a pulverizing device (3), a cylinder device (4), a motor device (5), a filtering device (6), a knocking device (7), a recovery device (8) and a pushing device (9). A first support (11), a second support (12) and a first oblique rod (13) are arranged on the bottom plate (1). The frame body (2) comprises a feed hopper (21), a first frame body (22), a first vertical rod (23), a first transverse rod (24) and a second vertical rod (25). The pulverizing device (3) comprises a first motor (31), a first rotating shaft (32), a first rotating block (33) and a pulverizing block (34). The cylinder device (4) comprises a second transverse rod (41), a first cylinder (42), a third support (43), a third transverse rod (44) and the like. By means of the solid medicine pulverizer, medicine pulverizing efficiency can be improved, and pulverizing and grinding can be made uniform.

Owner:JIANGSU CANCER HOSPITAL

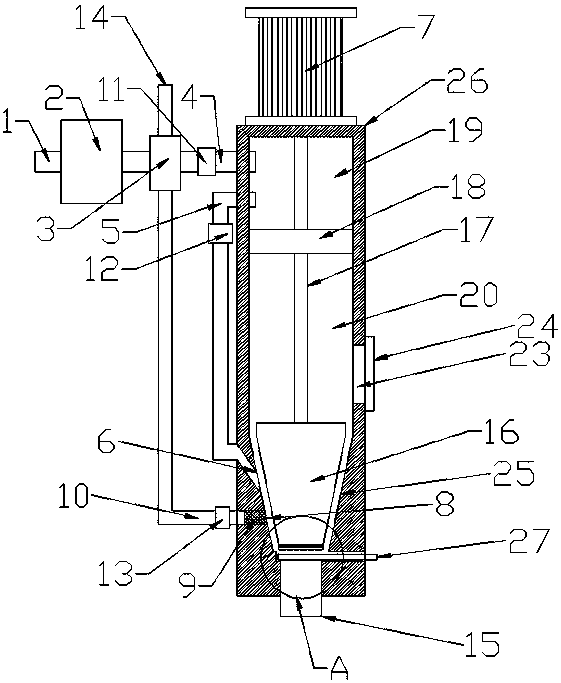

A device for crushing and grinding medicinal materials of traditional Chinese medicine

ActiveCN109759206BImprove crushing and grinding efficiencyAvoid easy cloggingSievingScreeningMedicinal herbsMechanical engineering

The invention relates to the technical field of devices for the traditional Chinese medicine department, in particular to a medicinal material smashing and grinding device for the traditional Chinesemedicine department. According to the device, a medicine screening mechanism is adjusted to the upper end of a flow guide protrusion and located in a through hole of a grinding disc through an air cylinder, traditional Chinese medicinal materials are placed into a smashing barrel from a feeding opening, an end cover is closed, a first motor is started to drive a rotating shaft to rotate, then a stirring rod on the rotating shaft and a smashing cutter are driven to smash the traditional Chinese medicine materials in the smashing barrel, the traditional Chinese medicine materials smashed to thesuitable size leak from a first leaking hole, enter an H-shaped pipe from a gradual contracting type flow guide cover, fall to the flow guide protrusion from an opening in the lower end of the H-shaped pipe, and are distributed to the periphery of a grinding groove through the flow guide protrusion, the traditional Chinese medicinal materials are grinded through the grinding disc, and the medicinal materials well grinded leak into a collecting groove from a second material leaking hole smoothly. The first material leaking hole and the second material leaking hole cannot be blocked easily. In the overhauling process, a casing pipe is held, the H-shaped pipe is screwed, thus the casing pipe communicating with the H-shaped pipe and the grinding disc are disassembled at the same time, and overhauling of the disassembled lower portion, the smashing barrel portion at the upper end, and the medicine screening mechanism at the lower end is convenient.

Owner:张保全

A large-scale crushing and grinding machine for Chinese herbal medicines

InactiveCN108176484BGood mashing and grinding effectLarge amount of processingGrain treatmentsManual medicineElectric machinery

The invention relates to a large traditional Chinese medicinal material mashing and grinding machine. The large traditional Chinese medicinal material mashing and grinding machine comprises a machinecabinet table. A mashing and grinding mechanism is arranged on the tabletop at the upper end of the machine cabinet table, and a material pot rotation driving mechanism is arranged on the outer side end face of a front end plate of the machine cabinet table. A material pot ascending and descending driving mechanism is arranged on the inner side end face of the front end plate. The mashing and grinding mechanism comprises a wane base, the position, close to one side, of the upper end face of the wane base is in sliding connection with a sliding block, and the position, close to the other side,of the upper end face of the wane base is provided with a first drive motor and a balance weight block. The sliding block is provided with a second drive motor. The equipment is large in pulverizing and grinding force, and medicinal material processing is finished at a time. The pulverizing and grinding efficiency is high, the medicine mashing effect is good, and the equipment mechanism positionscan be conveniently adjusted. Usage is convenient, the manual medicine mashing manner is replaced, the medicine material processing amount is large, and the large traditional Chinese medicinal material mashing and grinding machine is suitable for daily usage of large medicine stores.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

Medicinal material processing device

InactiveCN108380348ASimple structureEasy to useSievingScreeningMaterials processingMechanical engineering

The invention discloses a medicinal material processing device. The medicinal material processing device comprises a base plate (1), a frame body device (2), a smashing device (3), an air cylinder device (4), a motor device (5), a filtering device (6), a knocking device (7), a recovery device (8) and a push device (9). A first support (11), a second support (12) and a first slanting pole (13) arearranged on the base plate (1). The frame body device (2) comprises a feeding hopper (21), a frame body (22), a first vertical rod (23), a first cross bar (24) and a second vertical rod (25). The smashing device (3) comprises a first motor (31), a first rotating shaft (32), a rotating block (33) and a smashing block (34). The air cylinder device (4) comprises a second cross bar (41), a first air cylinder (42), a third support (43), a third cross bar (44) and the like. By adoption of the medicinal material processing device, medicine smashing efficiency can be improved and medicine can be evenly smashed and ground.

Owner:QUANZHOU QUANGANG CANPENG MASCH EQUIP CO LTD

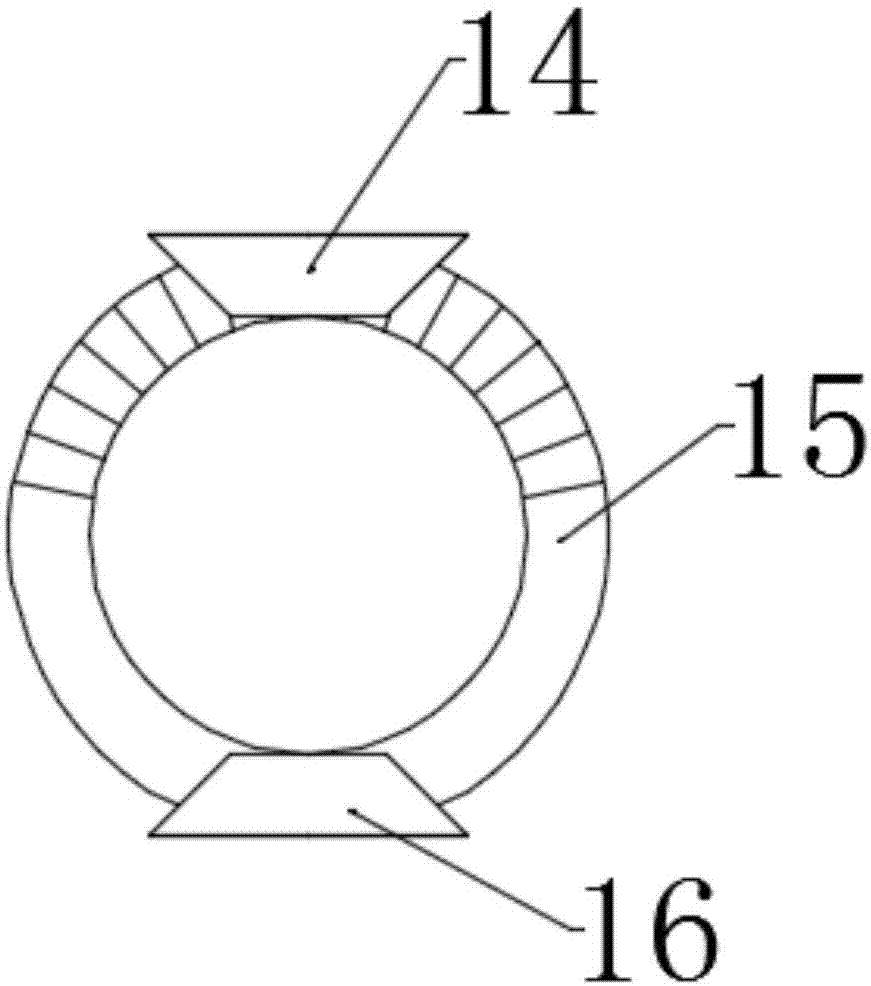

A soft ferrite raw material grinding and crushing device

ActiveCN111068883BEfficient crushingConvenient post-processing fine grindingGrain treatmentsPlate pressureSoft magnet

The invention discloses a soft ferrite raw material grinding and crushing device, which relates to the technical field of soft ferrite processing. It includes a feeding hopper, a grinding box and a fine grinding box. Two first grinding rollers are arranged on the top of the feeding hopper, two second grinding rollers are arranged under the first grinding roller, and a grinding plate is arranged under the second grinding roller. , there is a pillar at the center of the bottom of the grinding box, the pillar is surrounded by a circle of grinding side plates, the top of the grinding box is rotatably connected to the first rotating shaft, the lower end of the first rotating shaft is fixed with a grinding block, the upper end of the fine grinding box is equipped with a cylinder, and the lower end of the cylinder is connected to a telescopic rod , a pressure plate is fixed at the bottom of the telescopic rod, and the pressure plate is located directly above the screening plate and has the same size. The invention overcomes the deficiencies of the prior art, has reasonable design, is convenient to use, can effectively continuously grind and pulverize ferrite raw materials, improves the effect and efficiency of grinding and pulverization, promotes the production and processing of ferrite, and prevents waste of raw materials.

Owner:天长市华磁磁电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com