Industrial metal waste crushing and grinding device

An industrial metal and grinding device technology, applied in the direction of grain processing, etc., can solve the problems of low grinding and grinding efficiency, long grinding and grinding working hours, inconvenient collection of metal waste, etc., to achieve the effect of easy collection and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

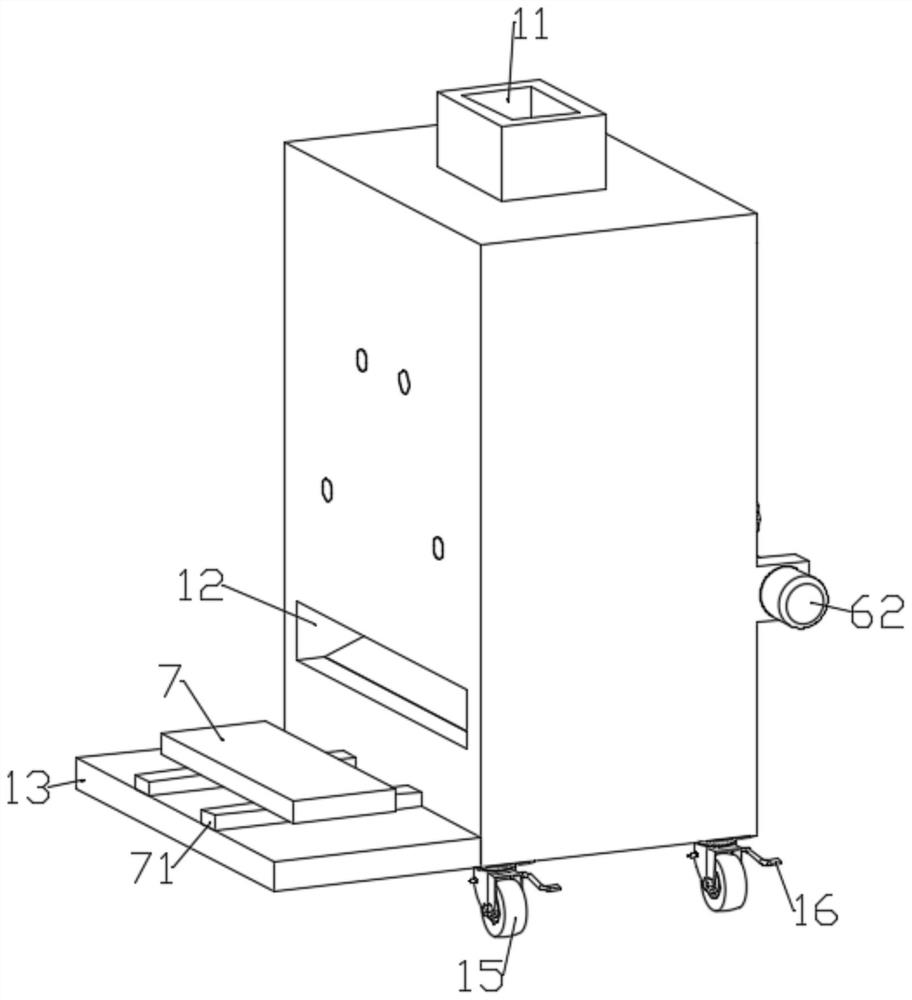

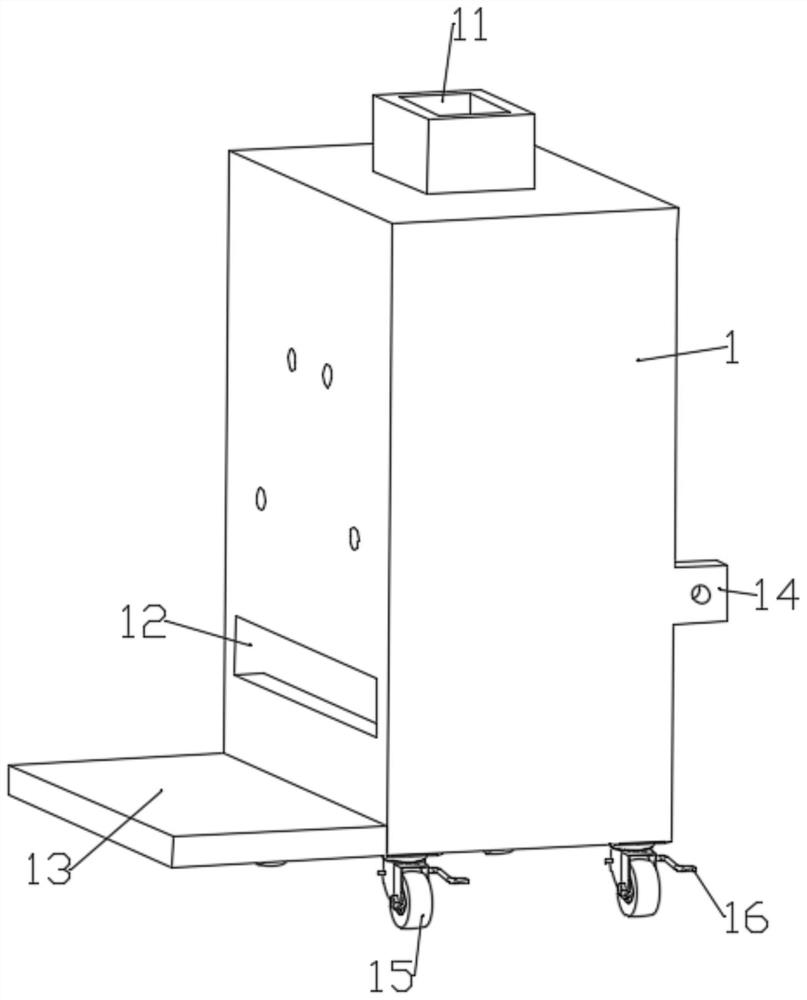

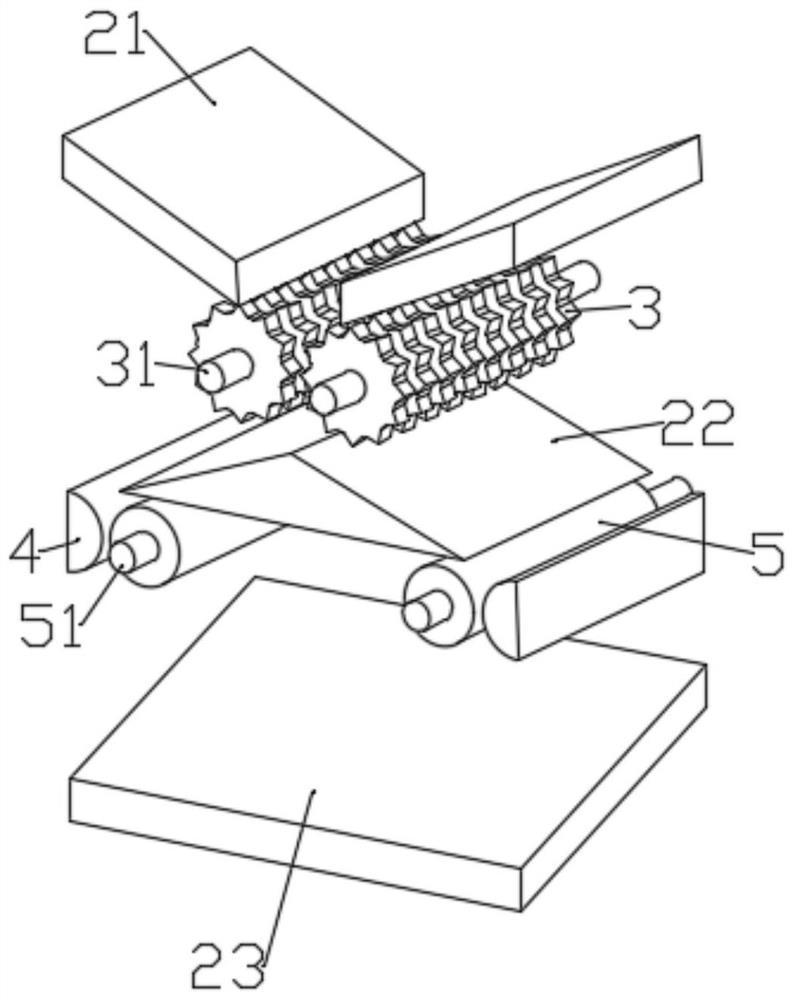

[0025] see Figure 1-5 , a crushing and grinding device for industrial metal waste, comprising a box body 1, a crushing roller 3 and a movable grinding wheel 5, the top of the box body 1 is equipped with a feeding cylinder 11, and the lower part of the front side of the box body 1 is opened with a Outlet 12, a pair of symmetrically arranged first rotating shafts 31 are installed on the top of the box body 1, and a pair of crushing rollers 3 are installed on the outer surfaces of the first rotating shafts 31. One end of the first rotating shaft 31 is fixedly connected with the output ends of a pair of first motors 32, and the rotation directions of the output ends of a pair of first motors 32 are opposite, and a pair of symmetrical The fixed grinding wheel 4 is provided, the side of the fixed grinding wheel 4 is provided with a movable grinding wheel 5, a pair of the movable grinding wheels 5 are fixedly installed on the outer surfaces of a pair of second rotating shafts 51, a ...

Embodiment 2

[0031] see Figure 1-5 , an industrial metal waste crushing and grinding device, on the basis of Example 1, a plurality of symmetrically arranged universal wheels 15 are fixedly installed on the bottom of the box body 1, and brake pedals 16 are arranged in the universal wheels 15 , to facilitate the movement and fixation of the position of an industrial metal waste crushing and grinding device, the fixed grinding wheel 4 is set in a semi-cylindrical shape, and the movable plate 7 is set on the lower side of the discharge port 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com