A large-scale crushing and grinding machine for Chinese herbal medicines

A technology of traditional Chinese medicinal materials and grinding machine, which is applied in the direction of grain processing, etc., can solve the problems of high pounding efficiency, low crushing and grinding force, and large labor consumption, and achieves high grinding and grinding efficiency, large processing capacity of medicinal materials, and good grinding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

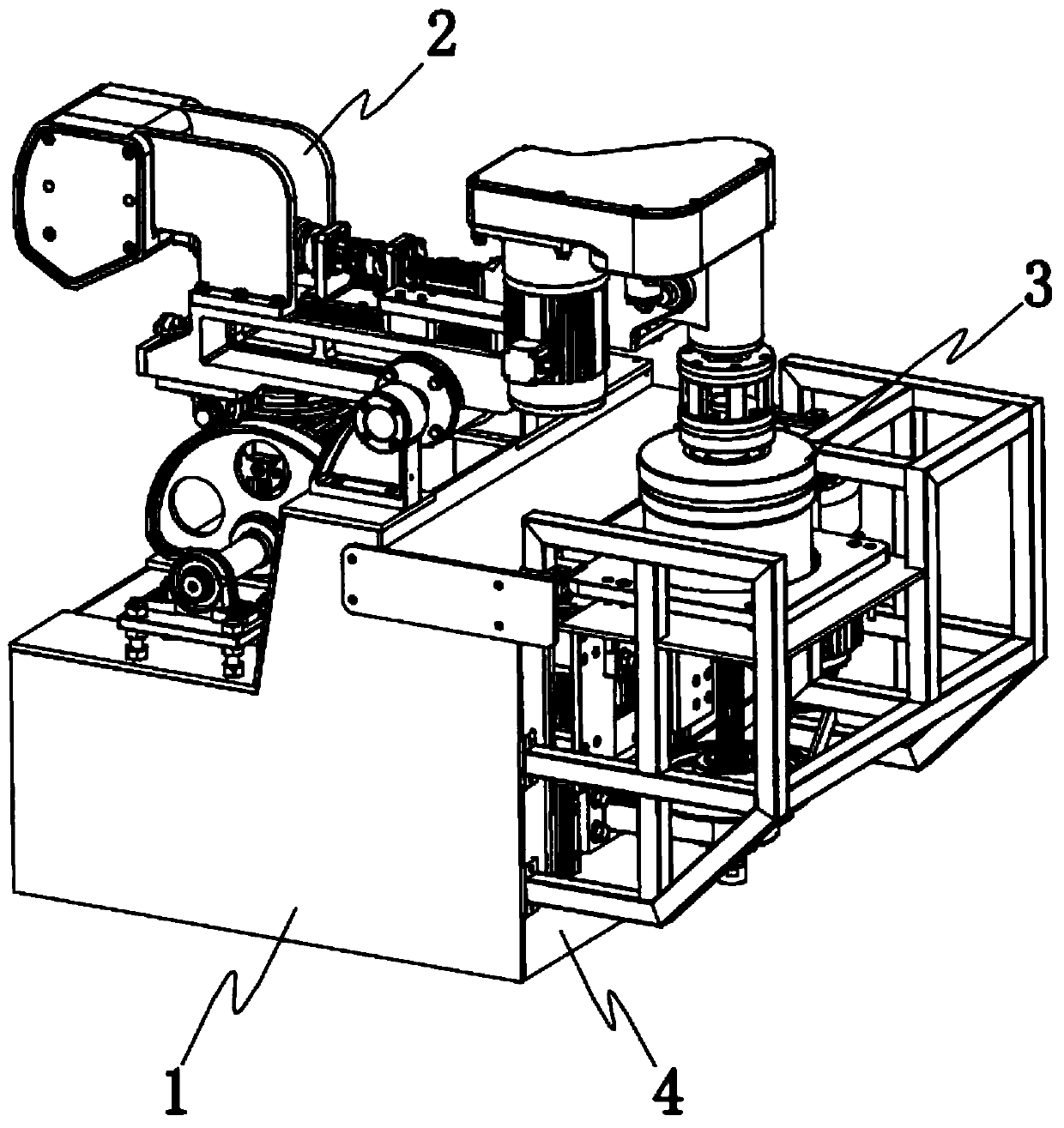

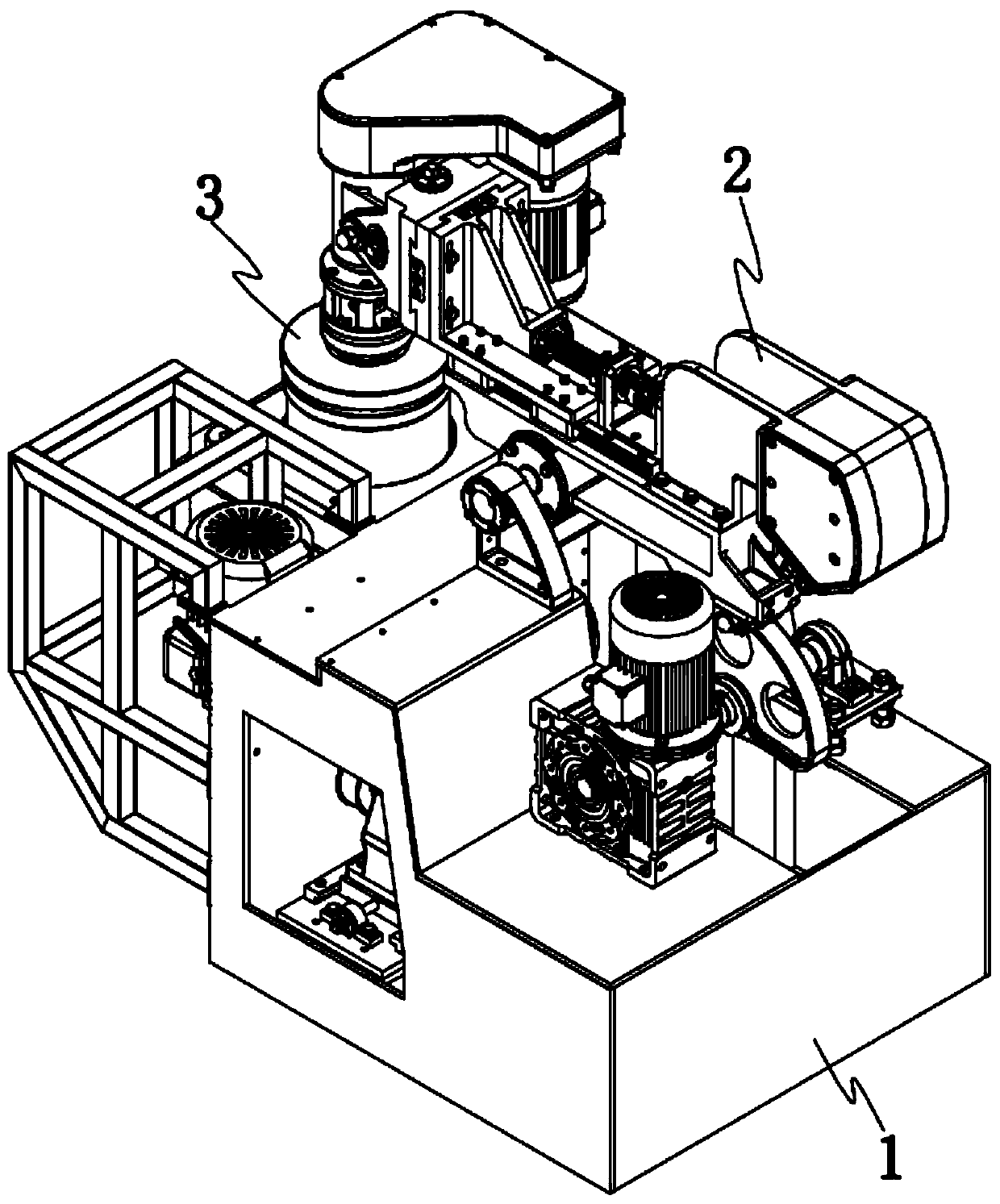

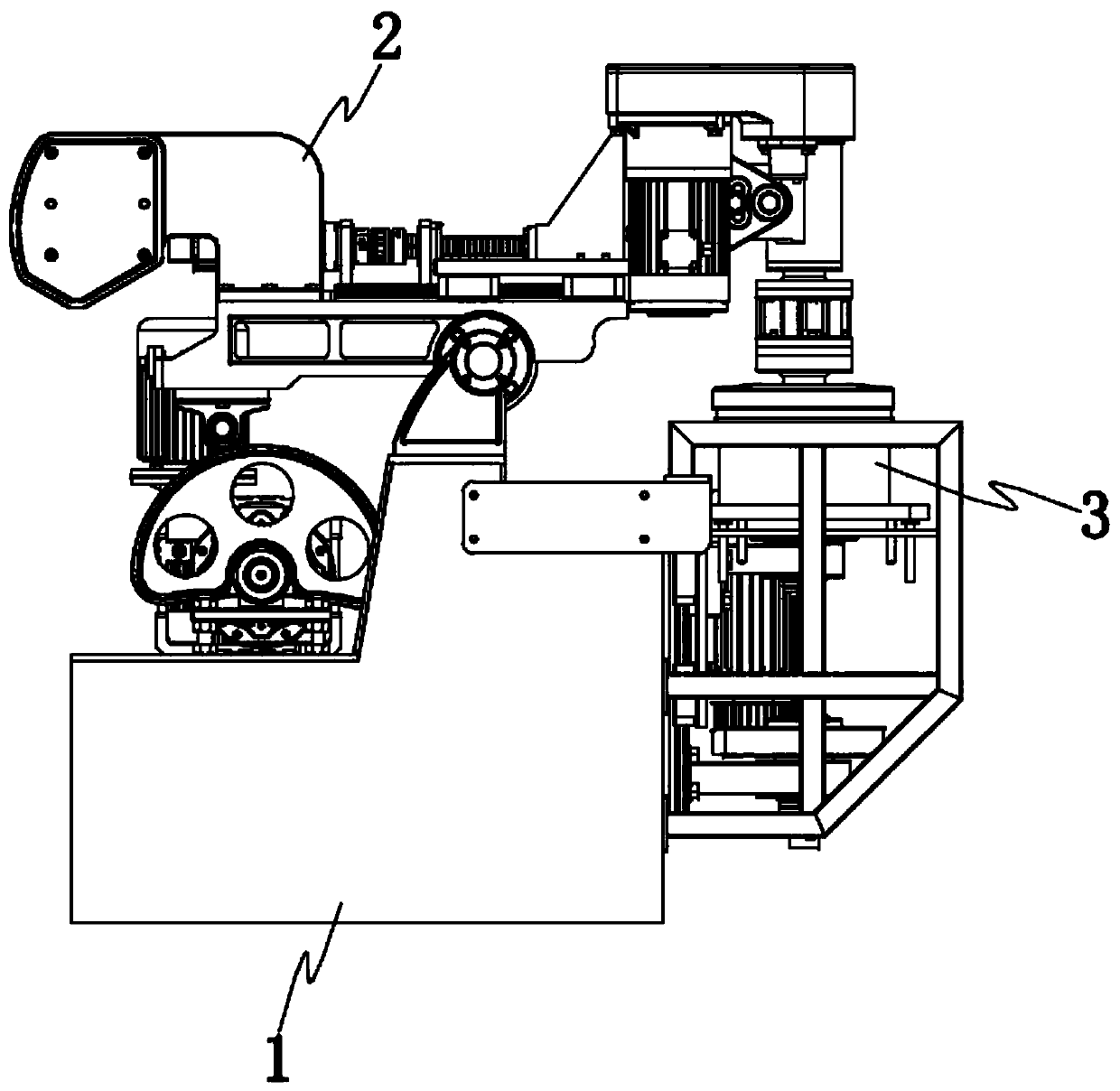

[0033] The crushing and grinding mechanism 2 of the traditional Chinese medicinal material crushing and grinding machine crushes and grinds the medicinal materials through the grinding ball 207 on the front end side, and the grinding ball 207 is fixed on the lower end of the vertical rotating shaft 214, and the grinding ball 207 is driven by the second driving motor 206. Rotate, and the second driving motor 206 is installed on the sliding block 203 of seesaw seat 201, and the first driving motor 213 rotating shaft of sliding block 203 and seesaw seat 201 upper end is connected by driving screw rod 204 simultaneously, and the first driving motor 213 drives the sliding block 203 to slide along the slide rail I202 on the upper end of the seesaw seat 201 by driving the screw rod 204, thereby adjusting the back and forth horizontal position of the grinding ball 207, and at the same time, a counterweight 205 is provided on the upper end of the seesaw seat 201 on one side , the middle...

Embodiment 2

[0035] The feeding pot rotation drive mechanism 3 of the traditional Chinese medicinal materials smashing and grinding machine is to fix the feeding pot 304 for placing the medicinal materials on the upper end of the driving shaft I303, and drive the feeding pot 304 to rotate by driving the driving shaft I303 to rotate. The shaft I303 is connected with a fixed driving pulley I307, and the driving pulley I307 is connected with the fourth driving motor 301 fixed on the outer end surface of the front end plate 4 through belt transmission, and the driving pulley I307 is driven by the fourth driving motor 301 to rotate. Realize the rotation of the discharge pot 304 that drives the shaft I 303 and the top of the shaft, and the rotation direction of the discharge pot 304 is opposite to the rotation direction of the grinding ball 207, so that the medicinal materials in the discharge pot 304 are efficiently ground, and the grinding effect is good. The upper end of the shaft I 303 is fix...

Embodiment 3

[0037] When the upper and lower driving mechanism 5 of the feeding pot of the Chinese medicinal material smashing and grinding machine adjusts the upper and lower height positions of the feeding pot 304, the fifth driving motor 504 is first started, and the fifth driving motor 504 drives the pulley II 506 and the threading connection through a belt drive. The drive shaft II 505 of the fixed driving pulley II 506 rotates, and the drive shaft II 505 drives the ratchet II 507 to rotate, and drives the rotary wheel II 508 abutting against the contour surface of the ratchet II 507 to move up and down, thereby driving the adjustment shaft 509 of the piercing rotary wheel II 508 to move up and down, and The adjustment shaft 509 can drive the slide plate 302 at the end of the shaft to slide up and down along the vertical slide rail 308 on the front end plate 4, so that the slide plate 302 drives the upper mount 305 and the drive shaft I 303 fixedly connected with the upper mount 305 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com