A soft ferrite raw material grinding and crushing device

A soft magnetic ferrite and crushing device technology, applied in grain processing, etc., can solve problems such as low efficiency, high consumption, and poor control accuracy, and achieve the effects of easy use, improved efficiency, and prevention of waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

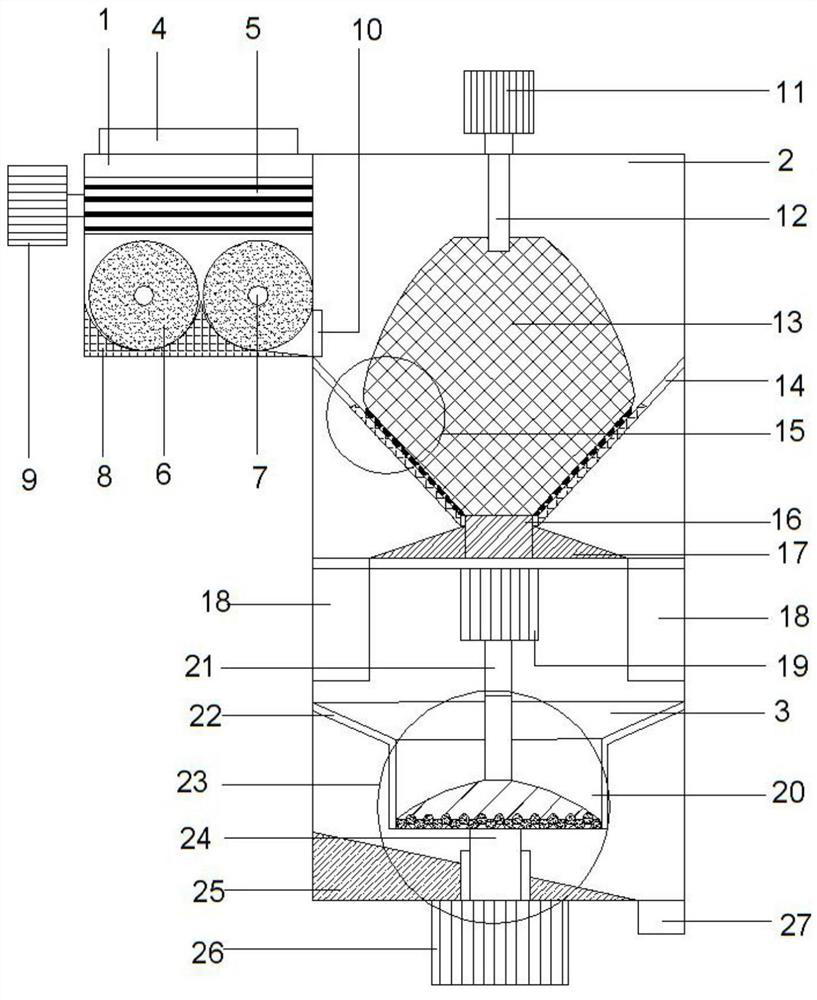

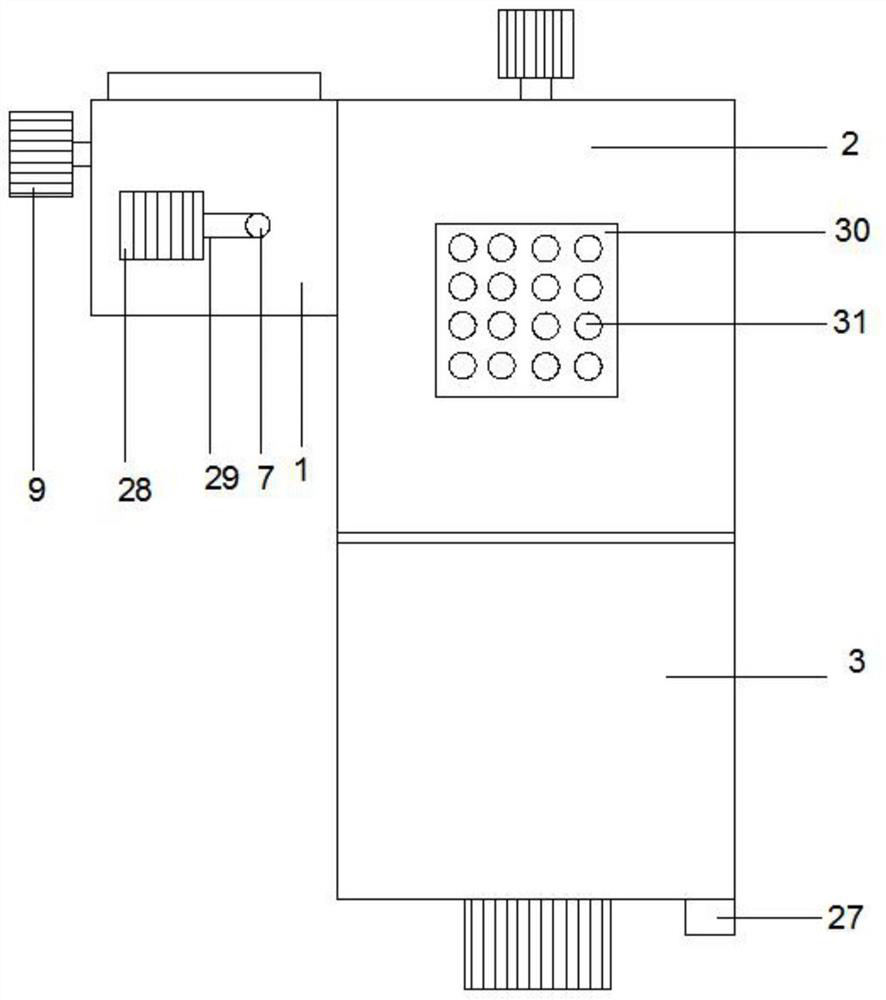

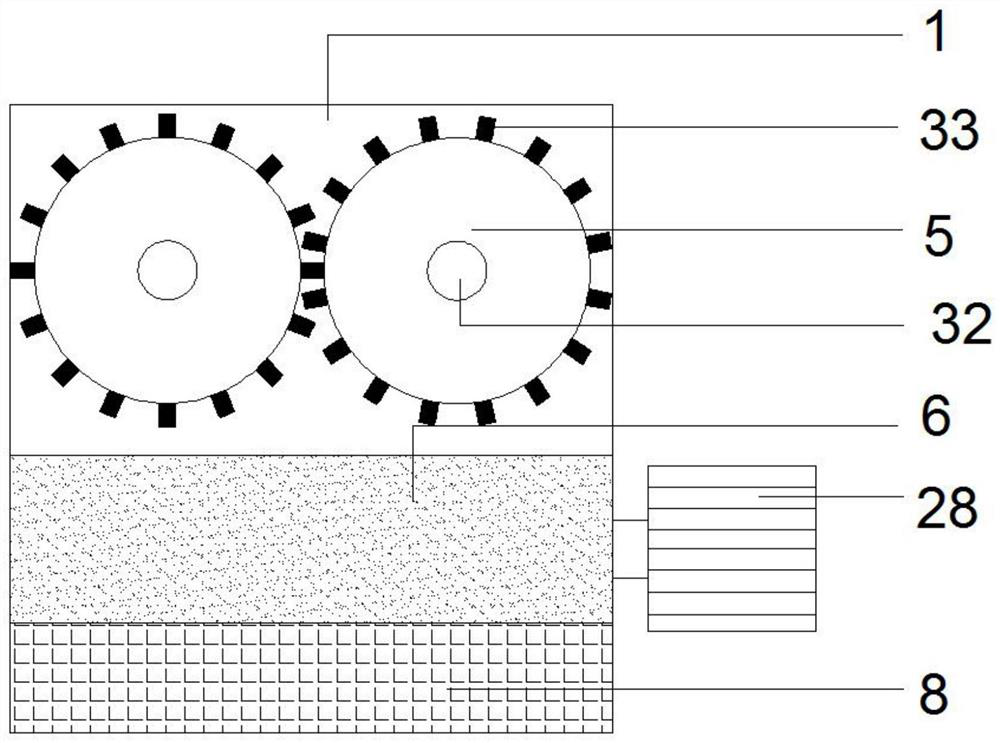

[0029] refer to Figure 1-5 , a soft ferrite raw material grinding and crushing device, comprising a feeding hopper 1, a grinding box 2 and a fine grinding box 3 below the grinding box 2, the upper end of the feeding hopper 1 is provided with a feeding port 4, and the feeding hopper 1 Two first grinding rollers 5 are arranged on the top, and the first grinding rollers 5 are rotationally connected with the side wall of the feed hopper 1 through the first roller shaft 32 arranged at the center, and one end of the first roller shaft 32 runs through the feed hopper 1 is connected to the output shaft of the external first motor 9, and two second grinding rollers 6 are arranged below the first grinding roller 5, and the second grinding rollers 6 are rotatably connected to the side wall of the feeding hopper 1 through the second roller shaft 7 , and the second roller shaft 7 passes through the side wall of the feed hopper 1 and is connected to the output shaft of the fourth motor 28,...

Embodiment 2

[0038] Such as Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the first grinding roller 5 is provided with grinding teeth 33, and the two first grinding rollers 5 are meshed through the grinding teeth 33, and the feeding hopper 1 The inner side wall is slidingly connected with the grinding teeth 33; the upper end surface of the grinding plate 8 is an arc-shaped concave surface slidingly connected with the second grinding roller 6, and the connection between the grinding plate 8 and the first communication port 10 is curved and inclined. The first grinding roller 5 effectively pulverizes the raw material with large particle size, and facilitates the subsequent continuous grinding and facilitates the lip grinding of the pulverized large particle size raw material by the second grinding roller 6, thereby improving the overall grinding efficiency.

Embodiment 3

[0040] Such as Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1-2. Preferably, the upper half of the grinding block 13 is set in a smooth arc shape, and a plurality of grinding blocks are set on the side where the lower half is slidably connected with the grinding side plate 14. Bump 35. Effectively improve the grinding efficiency of the grinding block 13 for grinding materials, and prevent materials from accumulating on the grinding block 13 at the same time.

[0041] In order to facilitate the material to fall into the fine grinding box 3, and to facilitate the fine grinding of the material by the pressure plate 36 and the screening plate 39, preferably, the two sides of the bottom of the grinding box 2 are provided with symmetrical second communication ports 18 and fine grinding The box 3 is connected, and the bottom of the grinding box 2 is located around the pillar 16 and is provided with an inclined block 17, and the inclination direction is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com