Ball grinding mill shell liner provided with grading tendon

A technology of ball mills and grading ribs, which is applied in the direction of grain processing, etc., can solve the problems of reduced efficiency of crushed mineral materials, positive effect offset, impact, etc., and achieves the effect of significant grading effect and improved crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

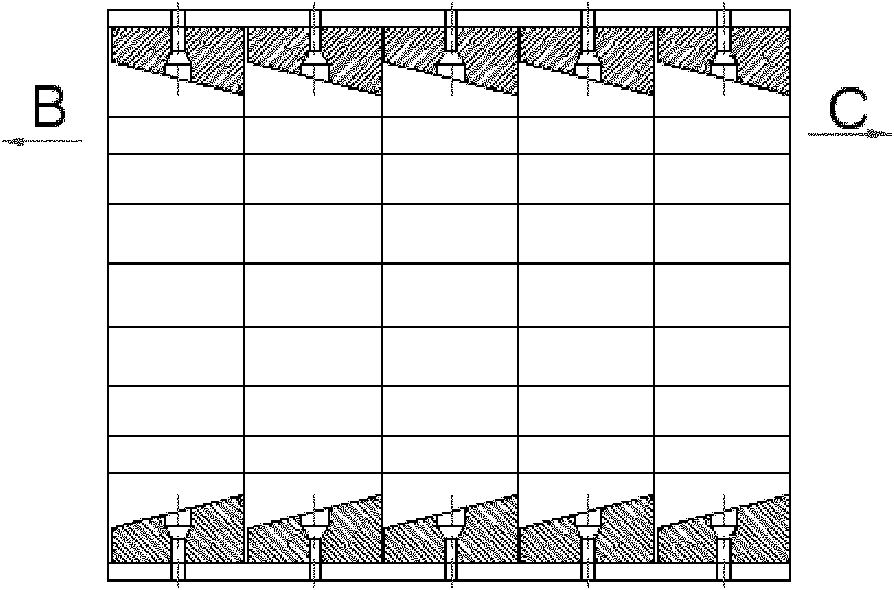

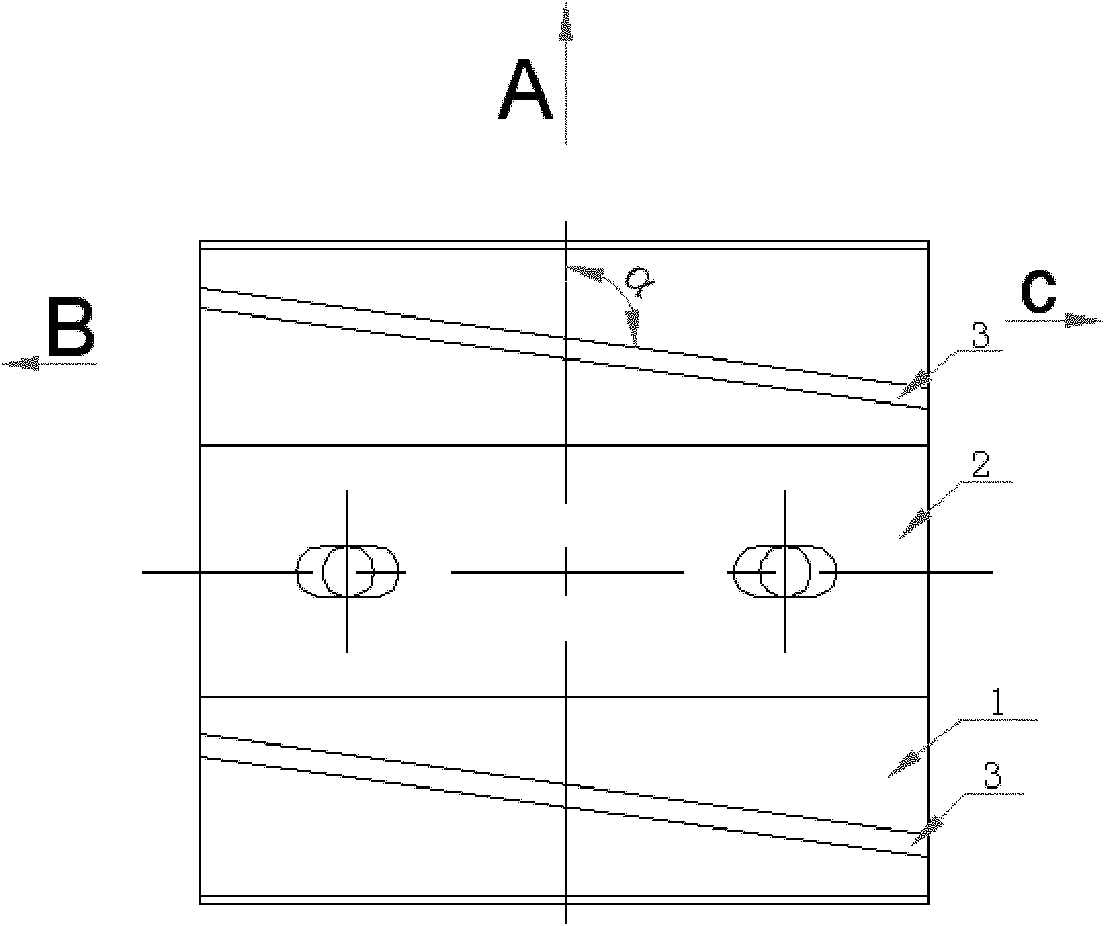

[0021] The cylinder liner of the ball mill provided with grading ribs in the present invention is provided with strip-shaped ribs 3 on the bottom plate 1 of the cylinder liner, and the strip-shaped ribs 3 are not perpendicular to the direction A in which the cylinder liner moves with the ball mill cylinder; The included angle α between the strip-shaped protruding ribs 3 and the direction A of the barrel liner moving with the ball mill barrel is 95°-120°.

[0022] In this embodiment, the height of the grading ribs 3 is 1.1 to 1.8 times the radius of the small-diameter ball and 0.2-0.7 times the radius of the large-diameter ball. The included angle α is 95°~120°.

[0023] The crushing and grinding efficiency of the cylinder liner prepared in this embodiment is 10% to 30% higher than that of the conventional cylinder liner without gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com