Sand hydraulic classification method and device

A hydraulic grading and sand technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as poor sand grading effect, secondary dust pollution, large screen wear, etc., to achieve flexible layout and grading Good effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

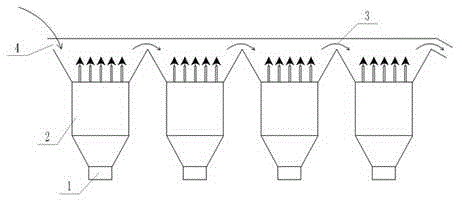

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A hydraulic classification device for sand in the present invention is characterized in that the device includes a plurality of hydraulic classification chambers. There is a collection bin 2 below each hydraulic classification chamber, a discharge port 4 at the bottom, a liquid injection port 1 and an overflow port 3 at the top, and several water spray pipes 5 inside; the several water spray pipes 5. There is a flow control device on it.

[0014] In the above-mentioned hydraulic classification device for sand, multiple hydraulic classification chambers are arranged horizontally, left and right, and may also be vertically arranged vertically.

[0015] A hydraulic grading method for sand, characterized in that: the construction waste sand suspension is fed from the liquid injection port 1 of the first-stage hydraulic grading chamber, and at the same time, water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com