Method for enriching ilmenite

An ilmenite and enrichment technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of low classification efficiency, weakened magnetic force, waste of ilmenite raw materials, etc., to reduce waste of resources, The effect of uniform magnetic force and improvement of concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

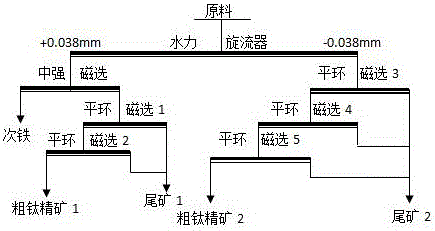

[0033] A method of enriching ilmenite, such as figure 1 shown, including the following steps:

[0034] (1) Grinding a certain vanadium-titanium magnetite in Panxi area and removing iron by weak magnetic field (at this time, the raw material TiO 2 The grade is 9.85%), and it is classified by hydrocyclone to obtain materials with two particle sizes of +0.038mm and -0.038mm; the magnetic field strength of weak magnetic iron removal is 1200 gauss; the feed pressure of hydrocyclone 0.20MPa, the diameter of the settling nozzle used in the hydrocyclone is 18mm, the diameter of the overflow nozzle is 40mm, and the angle of the cone angle is 13°;

[0035] (2) The +0.038mm material obtained after step (1) is subjected to medium-intensity magnetic separation to remove iron to obtain coarse titanium ore; the magnetic field strength of medium-intensity magnetic separation is 3500 Gauss;

[0036](3) Add the crude titanium ore obtained after step (2) into the toothed medium box of the flat...

Embodiment 2

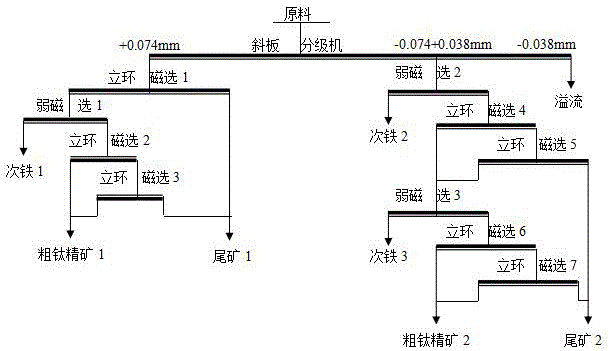

[0040] A method for enriching ilmenite, comprising the steps of:

[0041] (1) Grinding a certain vanadium-titanium magnetite in Panxi area and removing iron by weak magnetic field (at this time, the raw material TiO 2 The grade is 9.62%), and it is classified by hydrocyclone to obtain materials with two particle sizes of +0.038mm and -0.038mm; the magnetic field strength of weak magnetic iron removal is 1000 gauss; the feed pressure of hydrocyclone The diameter of the grit nozzle used in the hydrocyclone is 16mm, the diameter of the overflow nozzle is 30mm, and the cone angle is 10°;

[0042] (2) The +0.038mm material obtained after step (1) is subjected to medium-intensity magnetic separation to remove iron to obtain coarse titanium ore; the magnetic field strength of medium-intensity magnetic separation is 4000 Gauss;

[0043] (3) Add the coarse titanium ore obtained after step (2) into the toothed medium box of the flat ring magnetic separator (the toothed medium box has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com