Patents

Literature

35results about How to "Uniform magnetic force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive recovery process of intense-weathering poor vanadium titano-magnetite

InactiveCN103157551AImproved flotation indicatorsHigh yieldFlotationWet separationMagnetiteProduct base

The invention provides a comprehensive recovery process of intense-weathering poor vanadium titano-magnetite. The comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite comprises the steps of prescreening, crushing, dry separation, primary grinding, primary magnetic separation, secondary grinding, secondary magnetic separation, strong magnetic separation, floating separation and syrup mixing, and titanium floating separation. The process of titanium floating separation comprises the steps of rough separation, scavenging for two times, and fine separation for four times. According to the comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite, the problems that a throwing tail is high in grade and recovery rate of titanium concentrate is low when an existing process and an existing device are used for processing the intense-weathering poor vanadium titano-magnetite are solved. The index of finished products based on the comprehensive recovery process is that the grade of iron ore concentrate is 64% and yield of the iron ore concentrate is 37%, the grade of the titanium concentrate is 42% and the yield of the titanium concentrate is 41%, and the grade of fine-grain gangue iron is lower than 7% and the grade of titanium is lower than 1%.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI

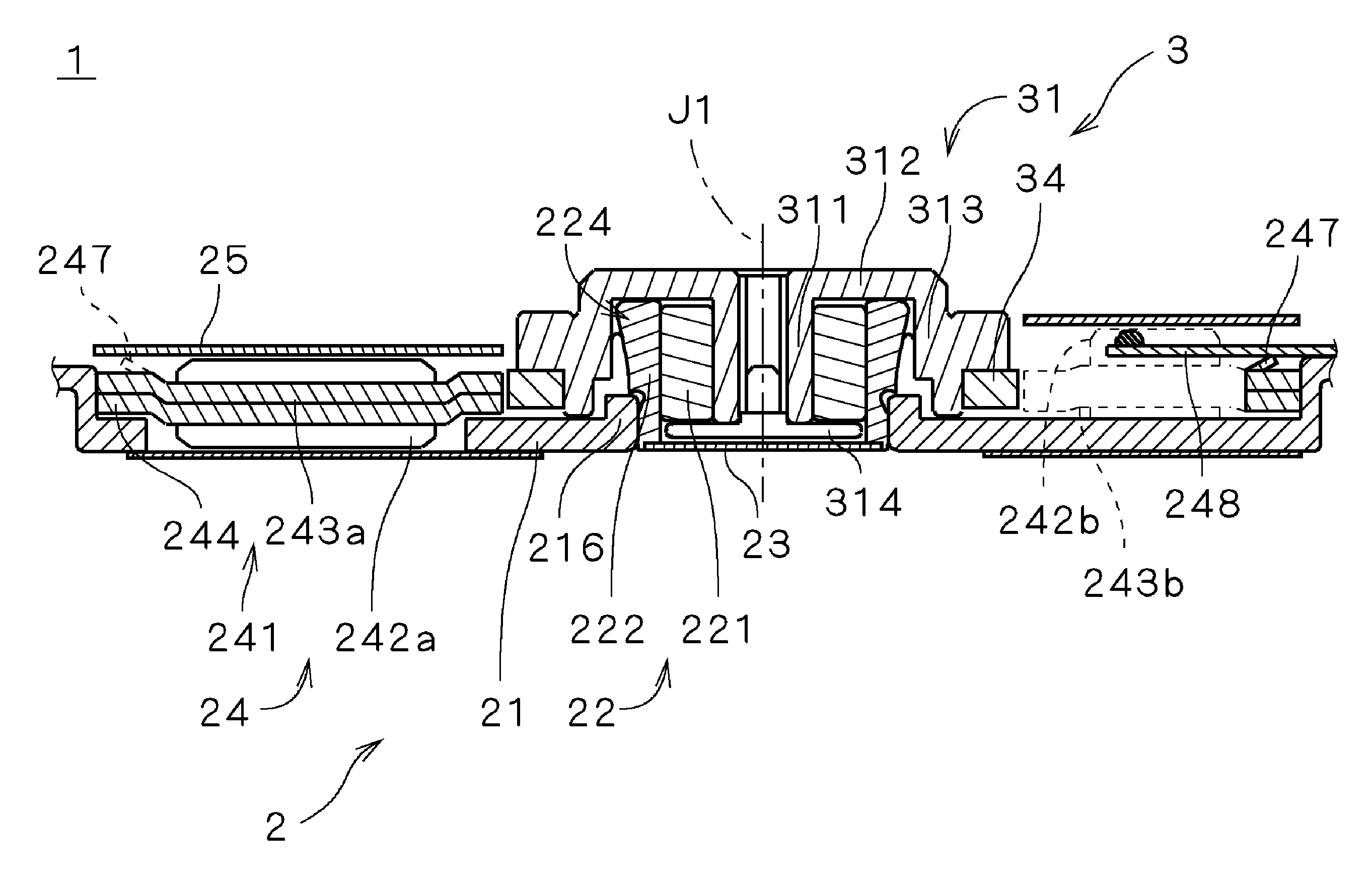

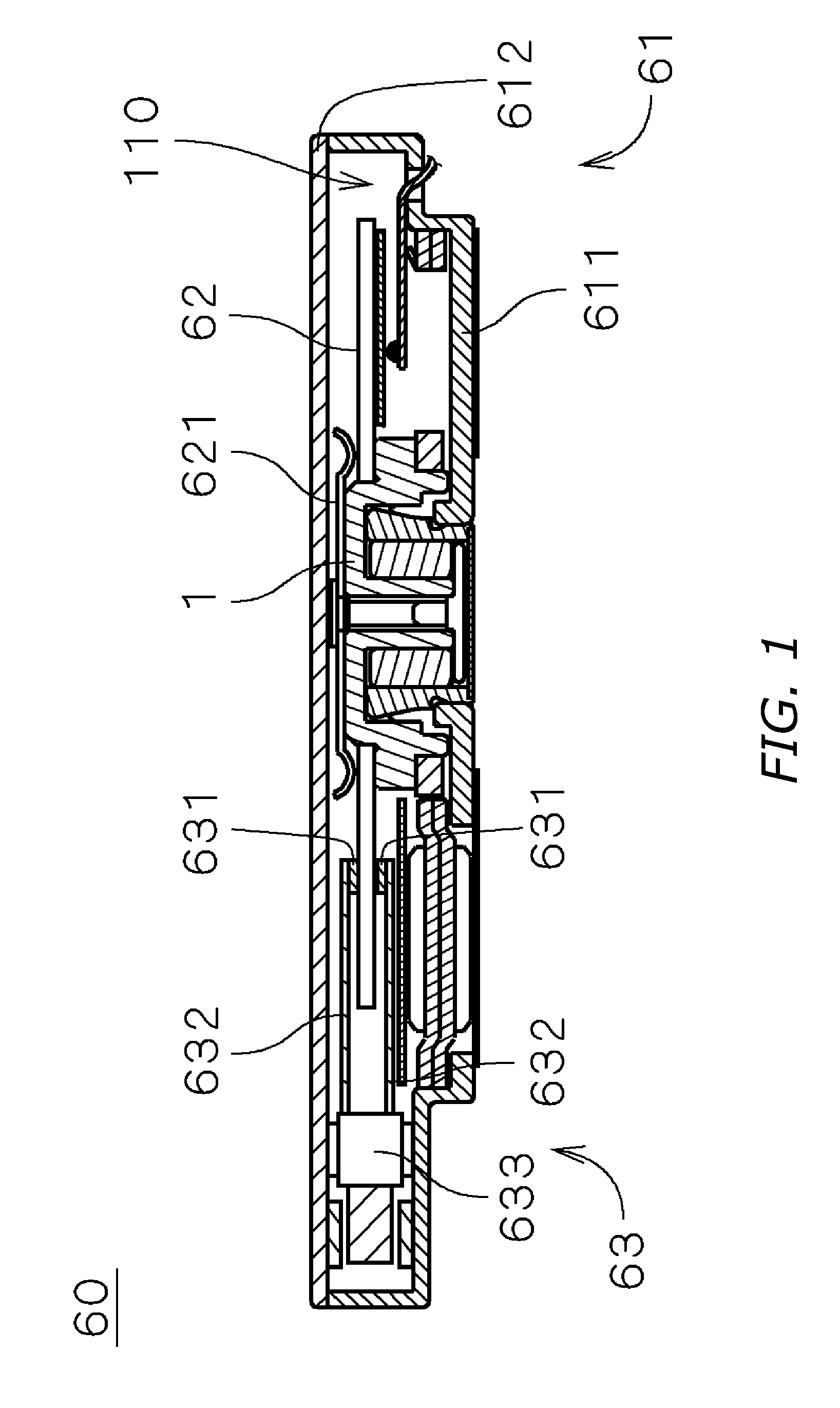

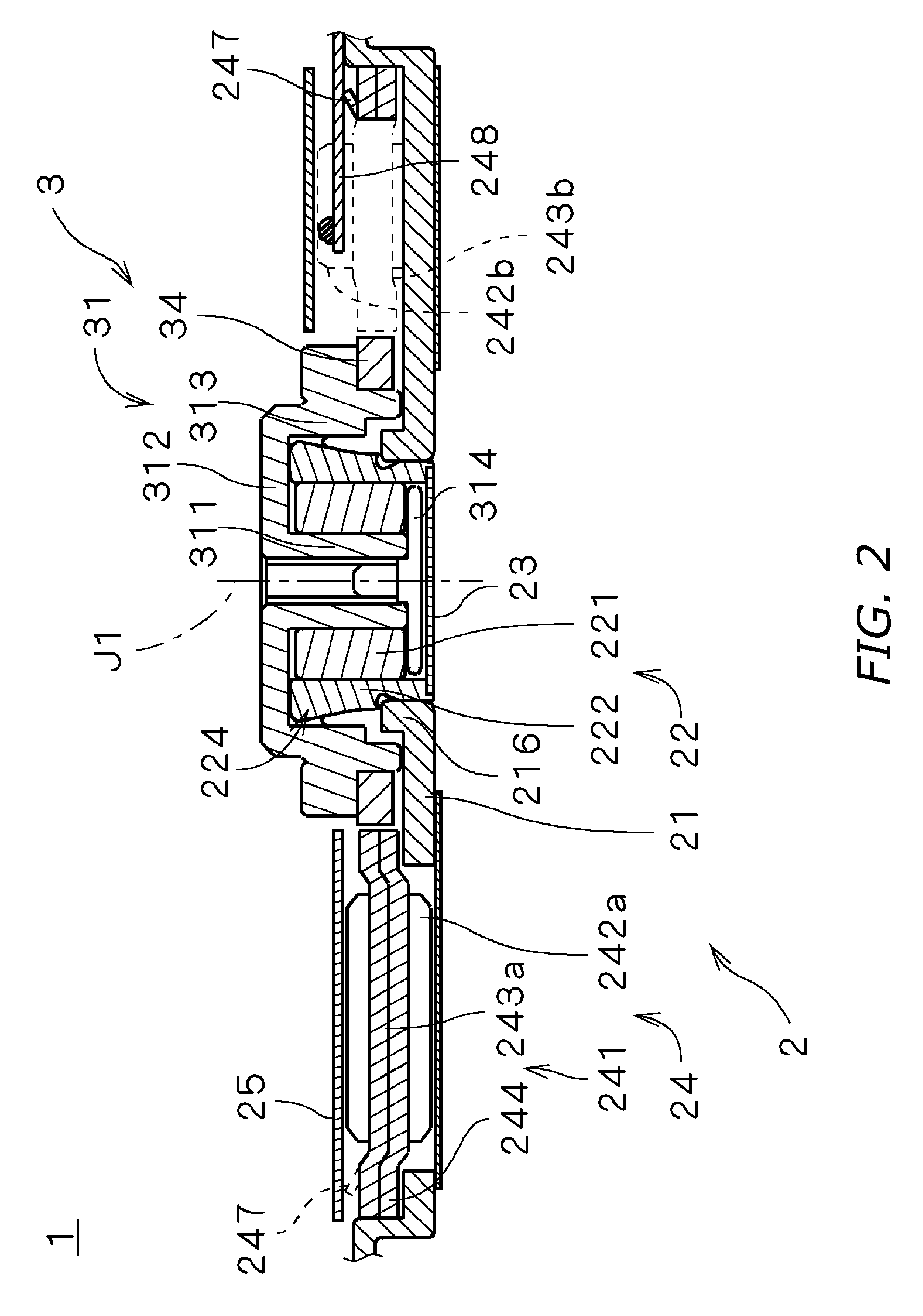

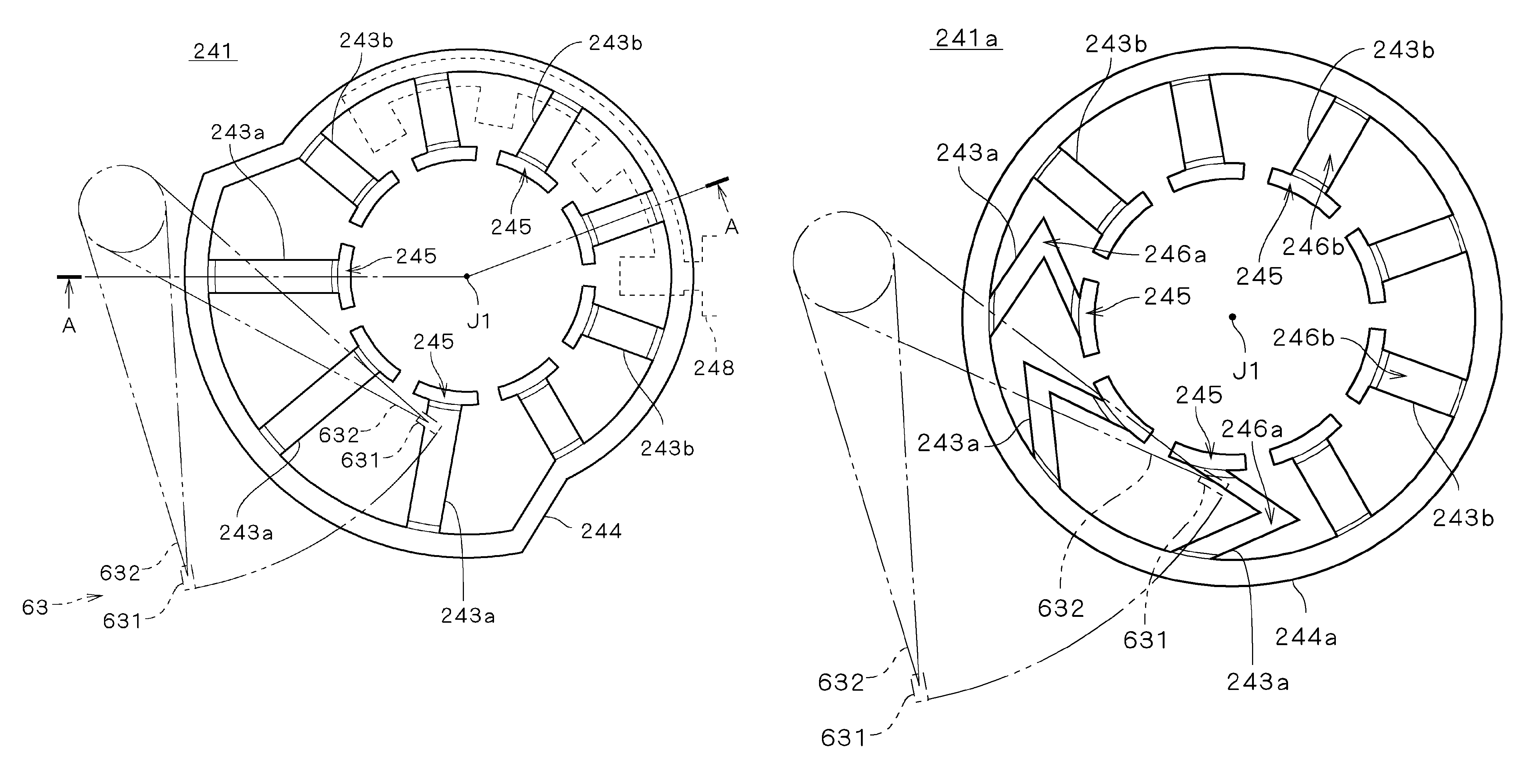

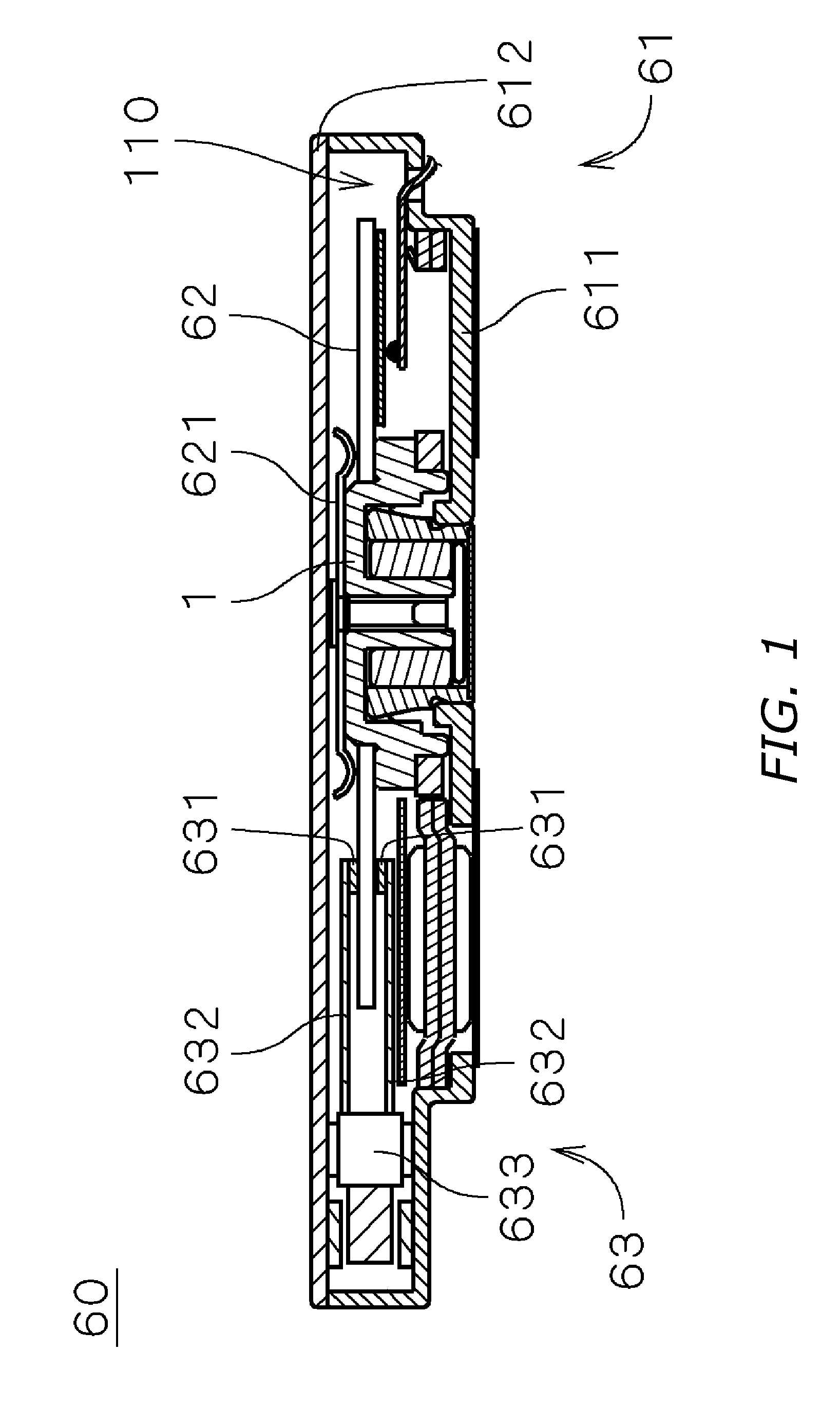

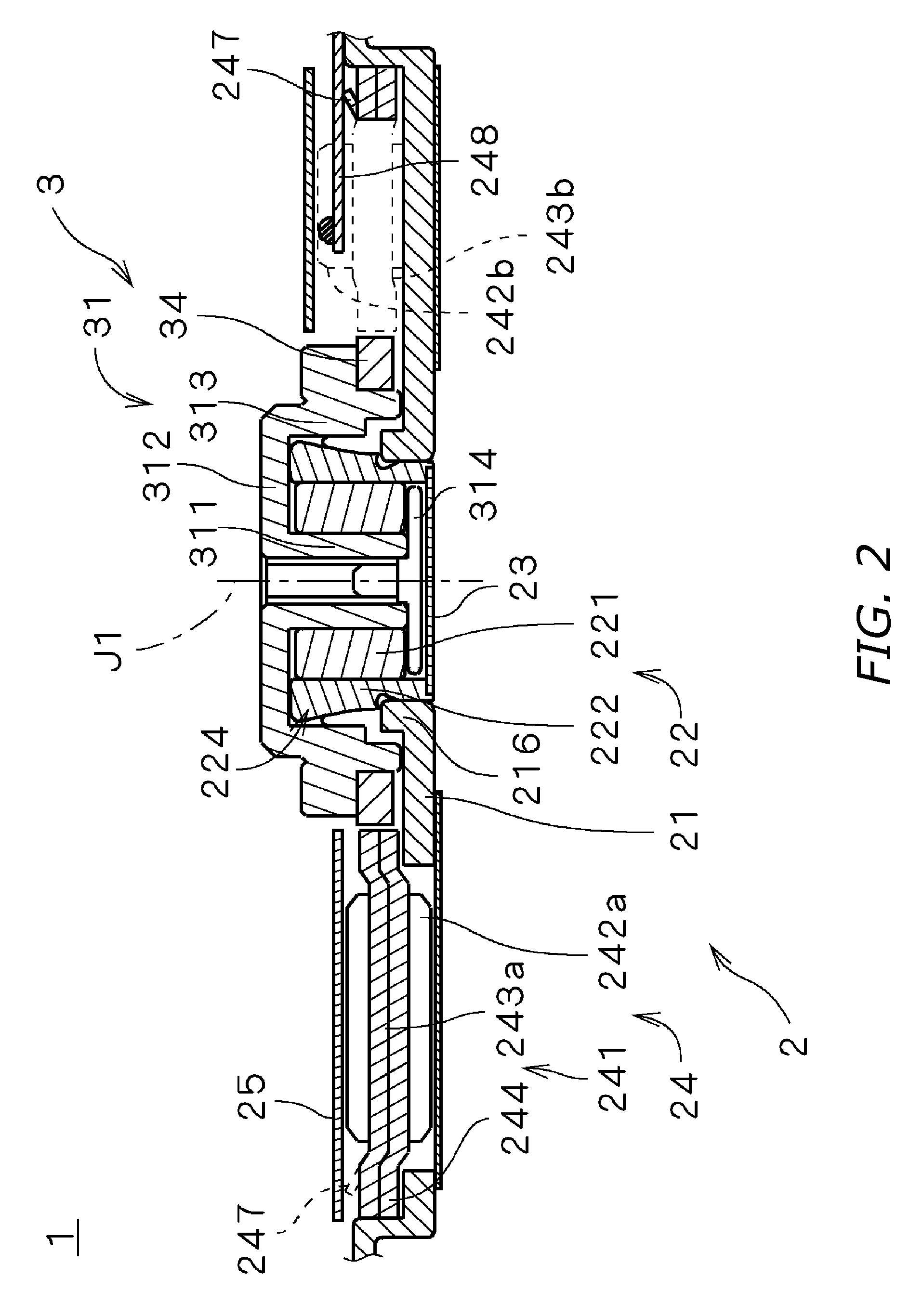

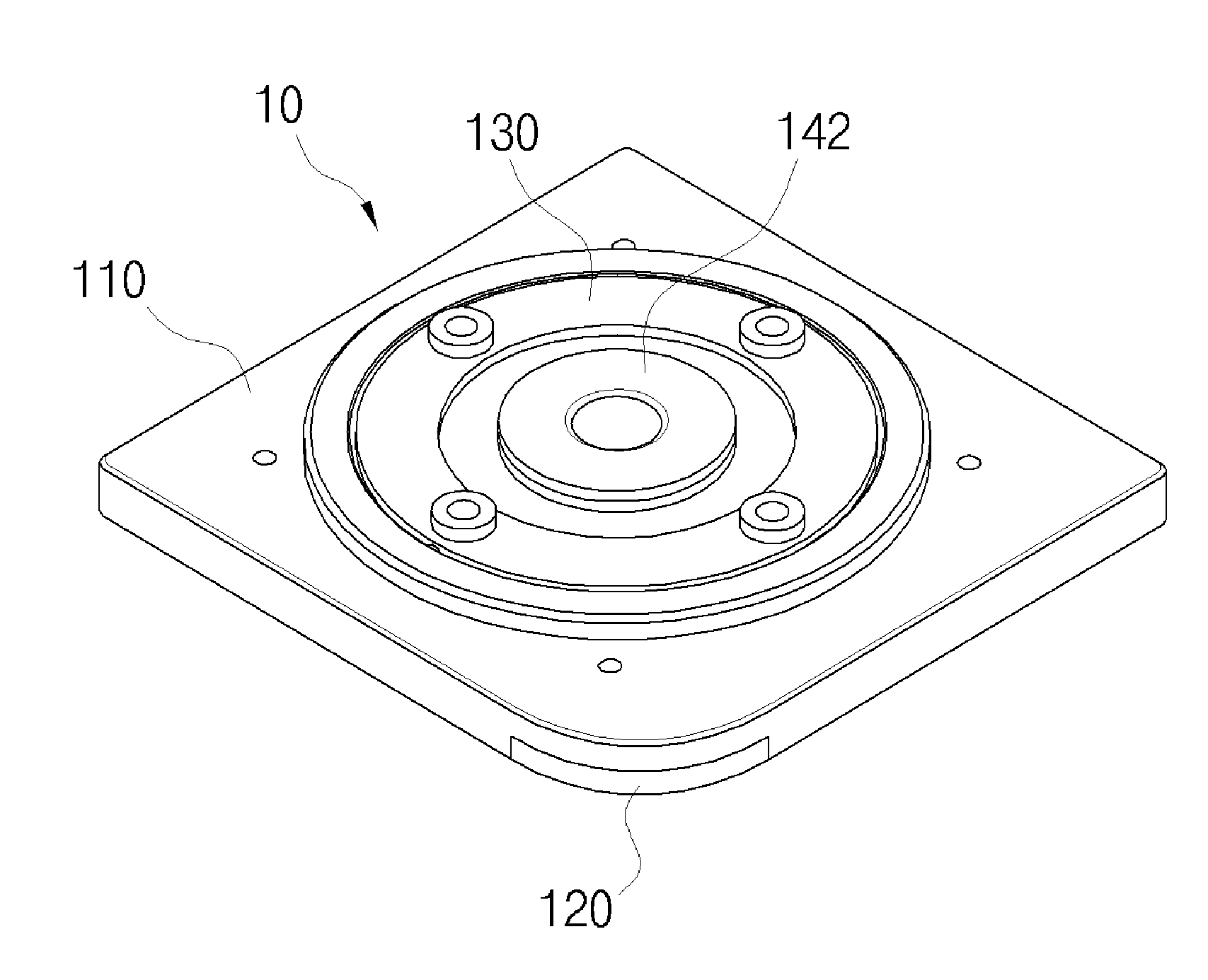

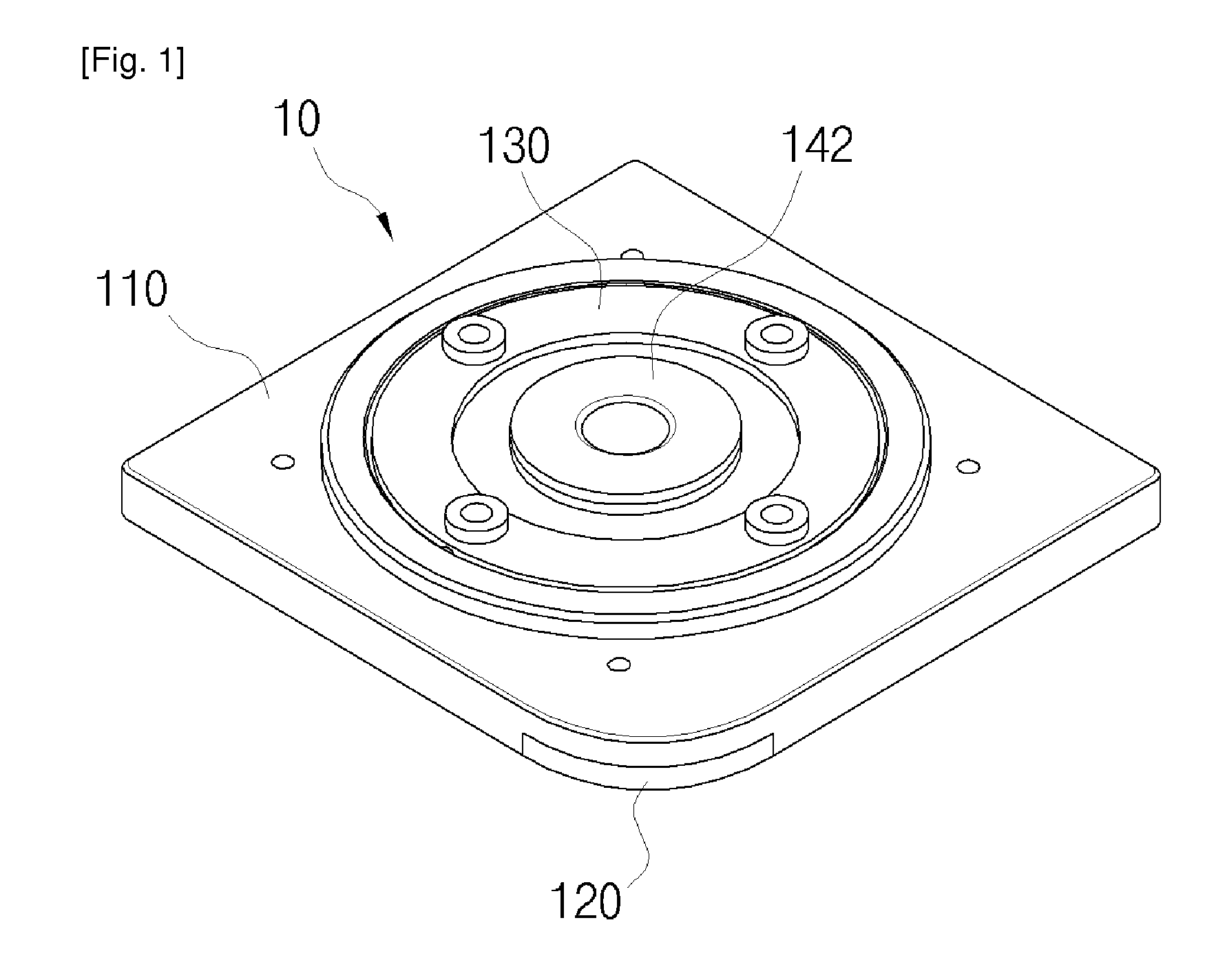

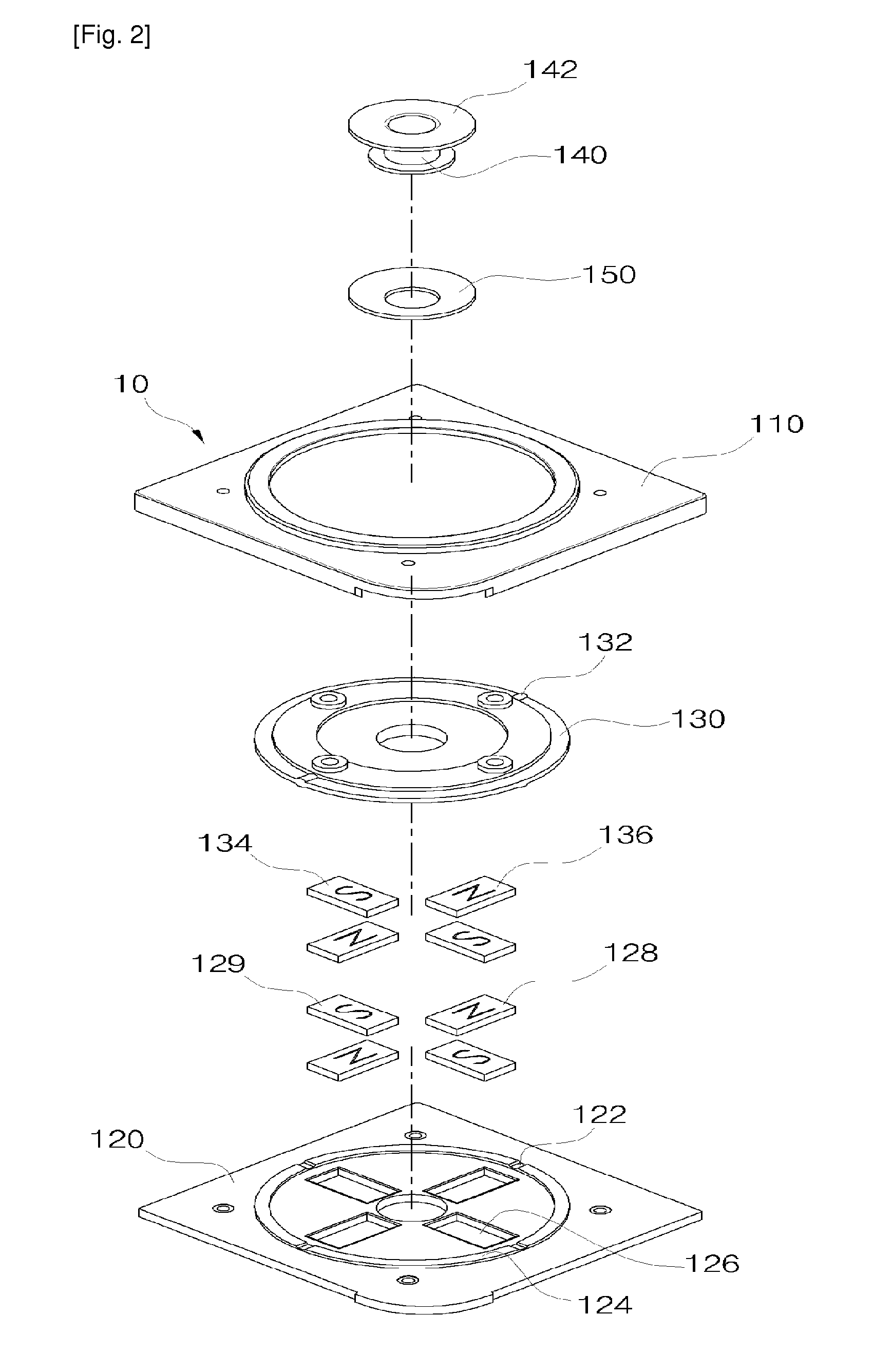

Stator Used for Recording Disk Driving Motor, Recording Disk Driving Motor, and Recording Disk Driving Device

InactiveUS20060232159A1Thickness and dimension is reducedDimension be reducedWindingsMagnetic circuit shape/form/constructionStatorEngineering

The wire winding height of the first teeth over which the head portion moves is lower than the wire winding height of the second teeth over which is out of the moving range of the head portion. The first wire winding portion is formed so as to be radially longer than the second wire winding portion. With the configuration mentioned above, the number of winding of the wire around the first teeth (243a) is maintained without reducing the torque and varying the uniformity of the magnetic force in the circumferential direction which the stator generates.

Owner:NIDEC CORP

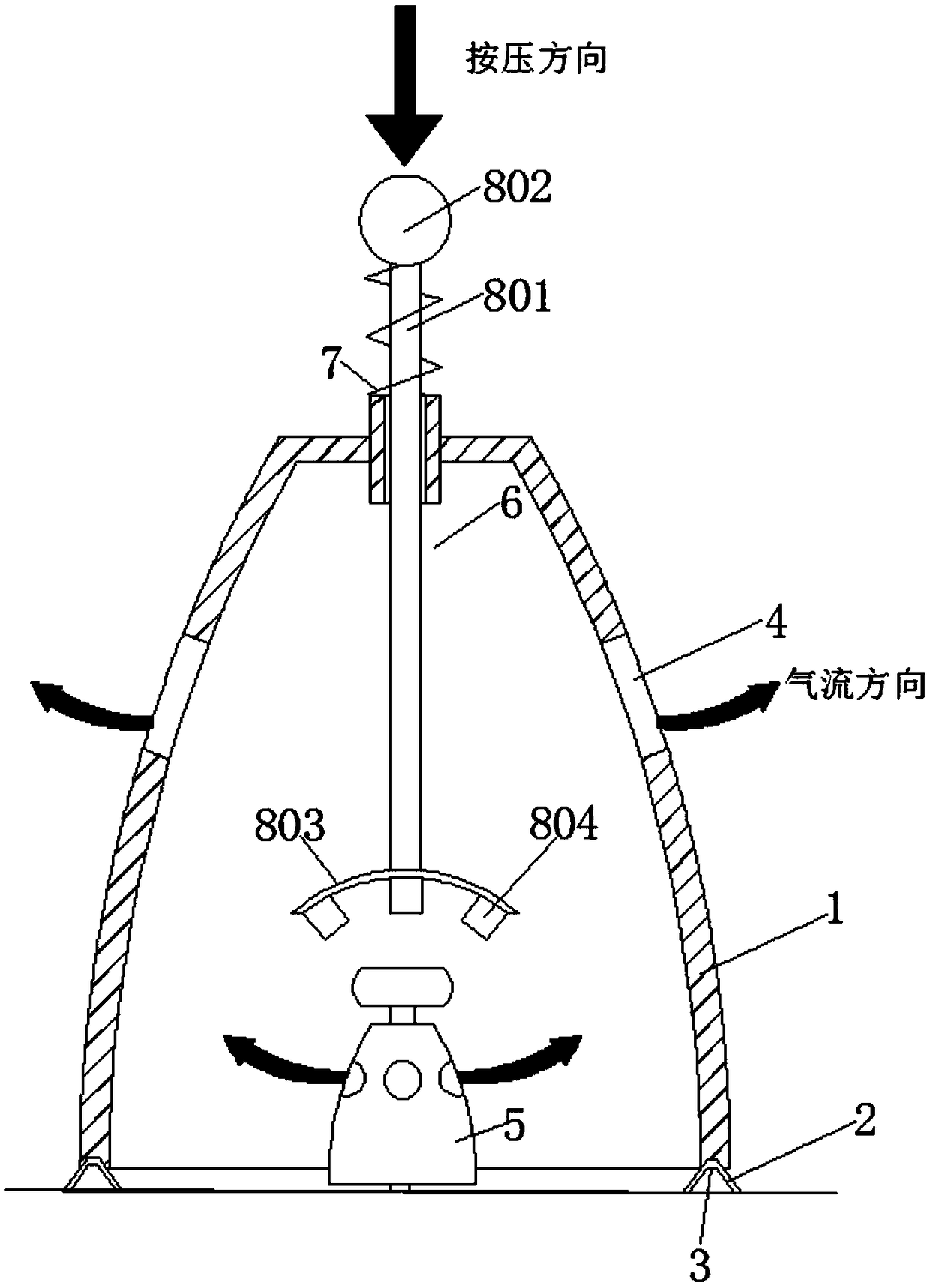

Pressure cooker safety relief device

InactiveCN108968670AFlexible and fast pressure relief and exhaustPrevent burnsPressure-cookersEngineeringHigh pressure

The invention provides a pressure cooker safety relief device, and relates to the field of household kitchen ware. The pressure cooker safety relief device comprises a conical shell, the inside of theshell is hollow, an opening is formed in the bottom of the shell, a sealing strip is embedded into the bottom of the shell, a groove is formed in the bottom of the sealing strip, an exhaust hole is formed in the outer surface of the shell, a pressure-limiting valve is arranged inside the shell, the top of the shell is communicated with a faucet pipe, a magnetic control device is connected into the faucet pipe, and a supporting spring is connected onto the magnetic control device. According to the pressure cooker safety relief device, permanent magnets have magnetic force, an arc-shaped blockis driven to move down in the pressing process of a pulling handle, the magnetic force of the permanent magnets can drive the pressure-limiting valve to move up when the arc-shaped block moves down toapproach the pressure-limiting valve, high-pressure gas inside a pressure cooker can be exhausted by up movement of the pressure-limiting valve, and the pressure cooker can be more flexibly and rapidly relieved and exhausted.

Owner:田飞标

Stator used for recording disk driving motor, recording disk driving motor, and recording disk driving device

InactiveUS7525231B2Dimension be reducedReduce thicknessWindingsMagnetic circuit rotating partsEngineeringConductor Coil

The wire winding height of the first teeth over which the head portion moves is lower than the wire winding height of the second teeth over which is out of the moving range of the head portion. The first wire winding portion is formed so as to be radially longer than the second wire winding portion. With the configuration mentioned above, the number of winding of the wire around the first teeth (243a) is maintained without reducing the torque and varying the uniformity of the magnetic force in the circumferential direction which the stator generates.

Owner:NIDEC CORP

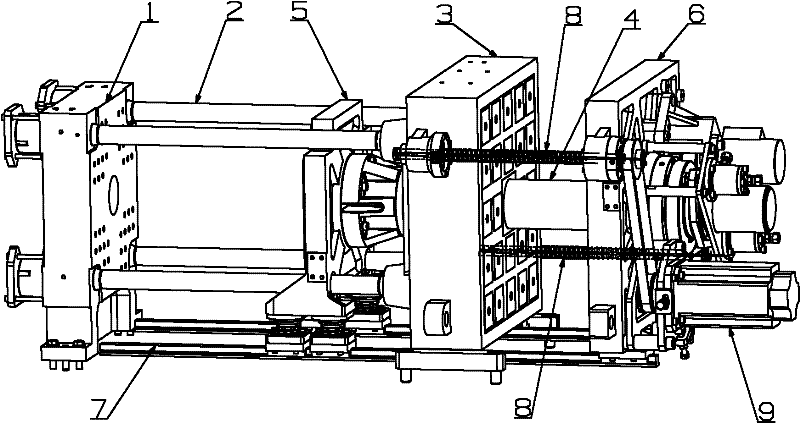

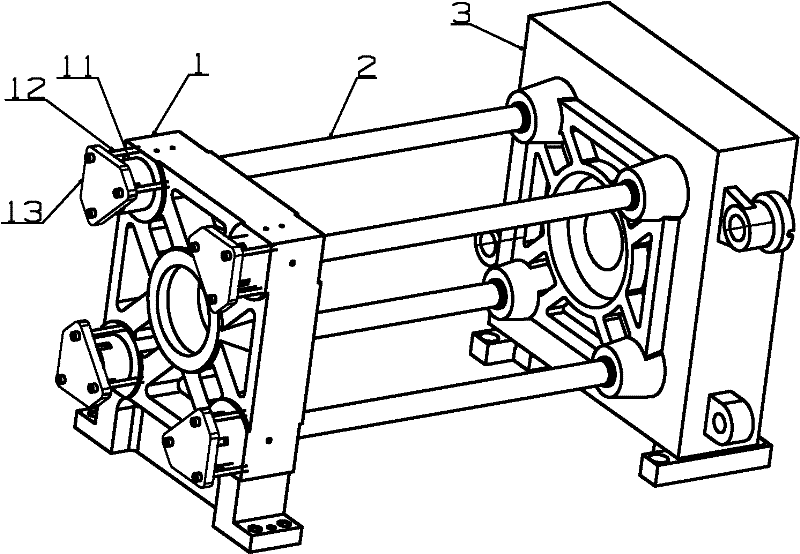

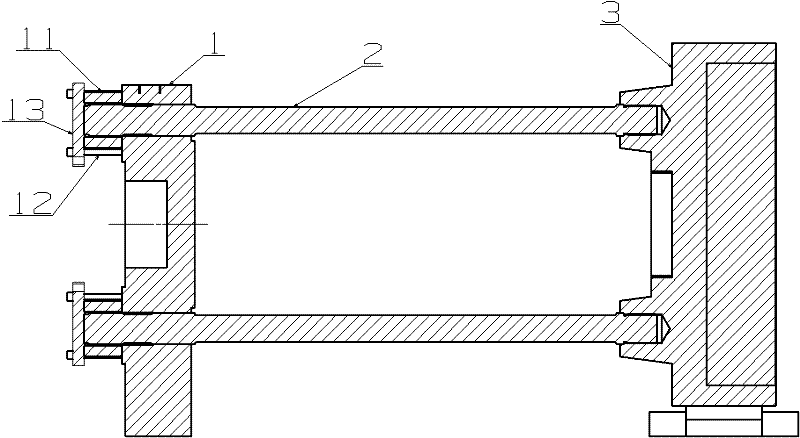

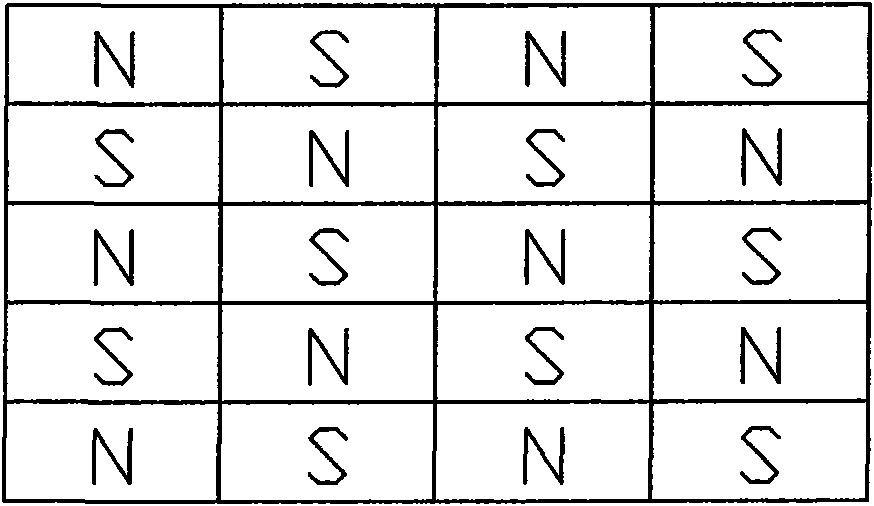

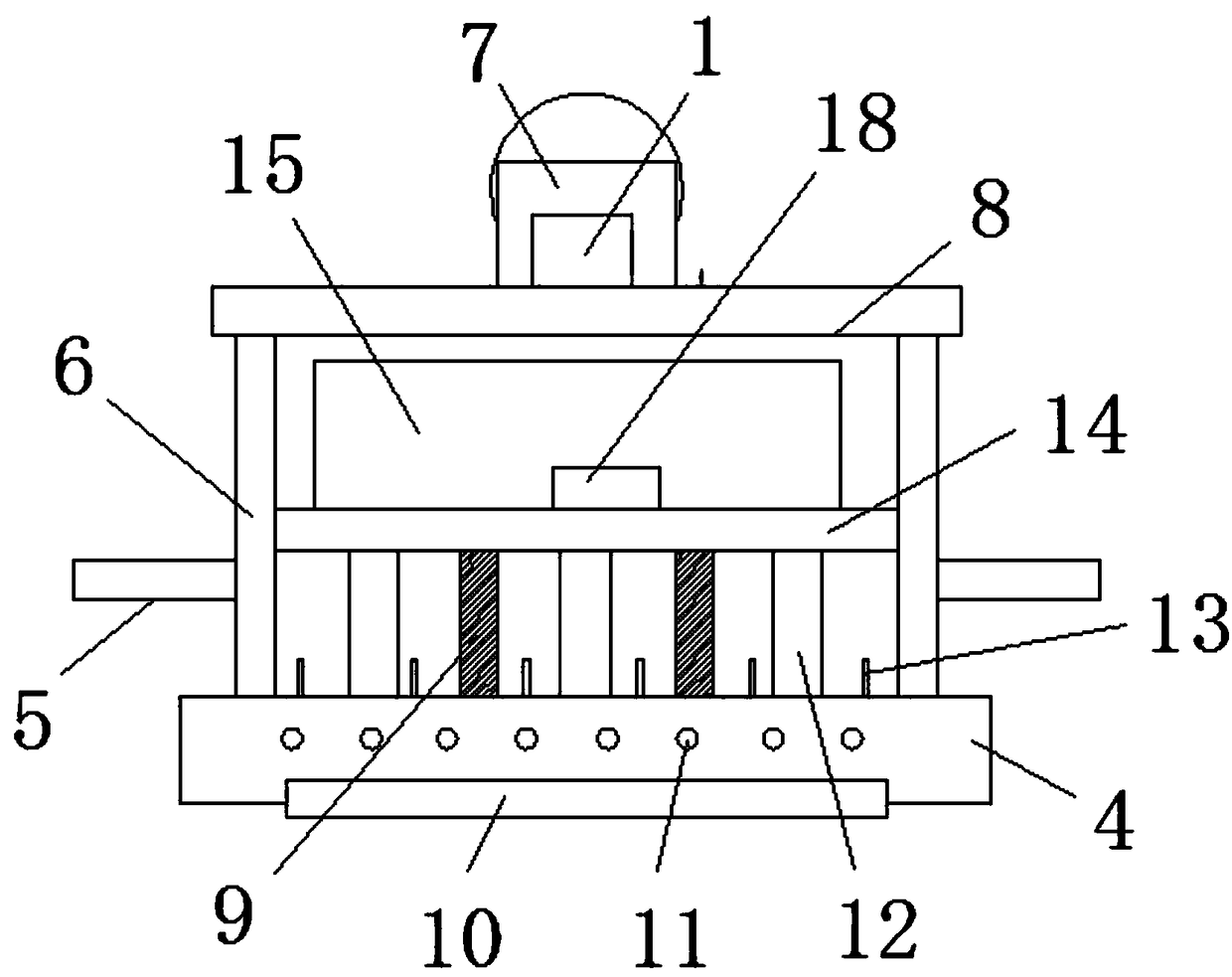

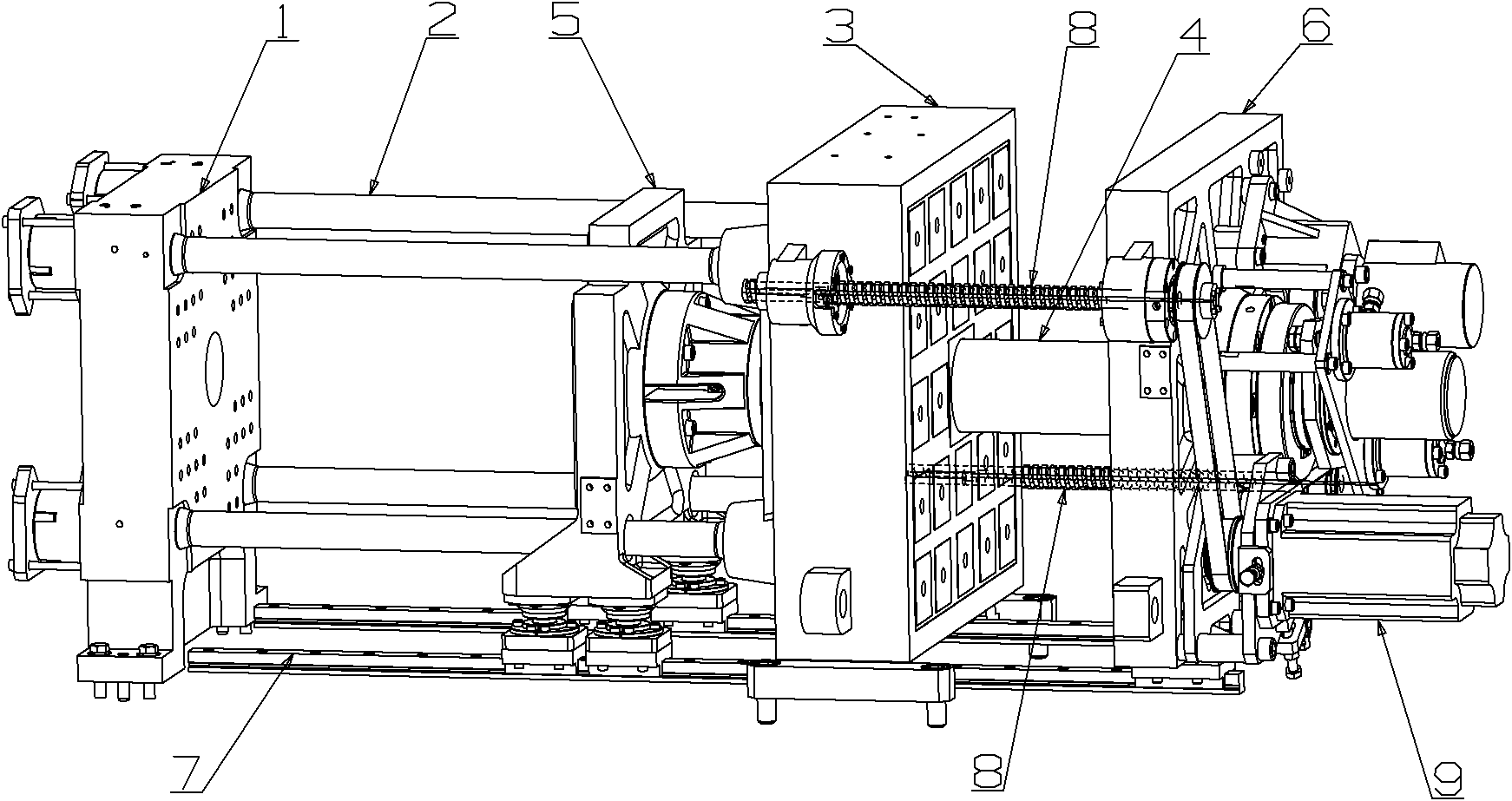

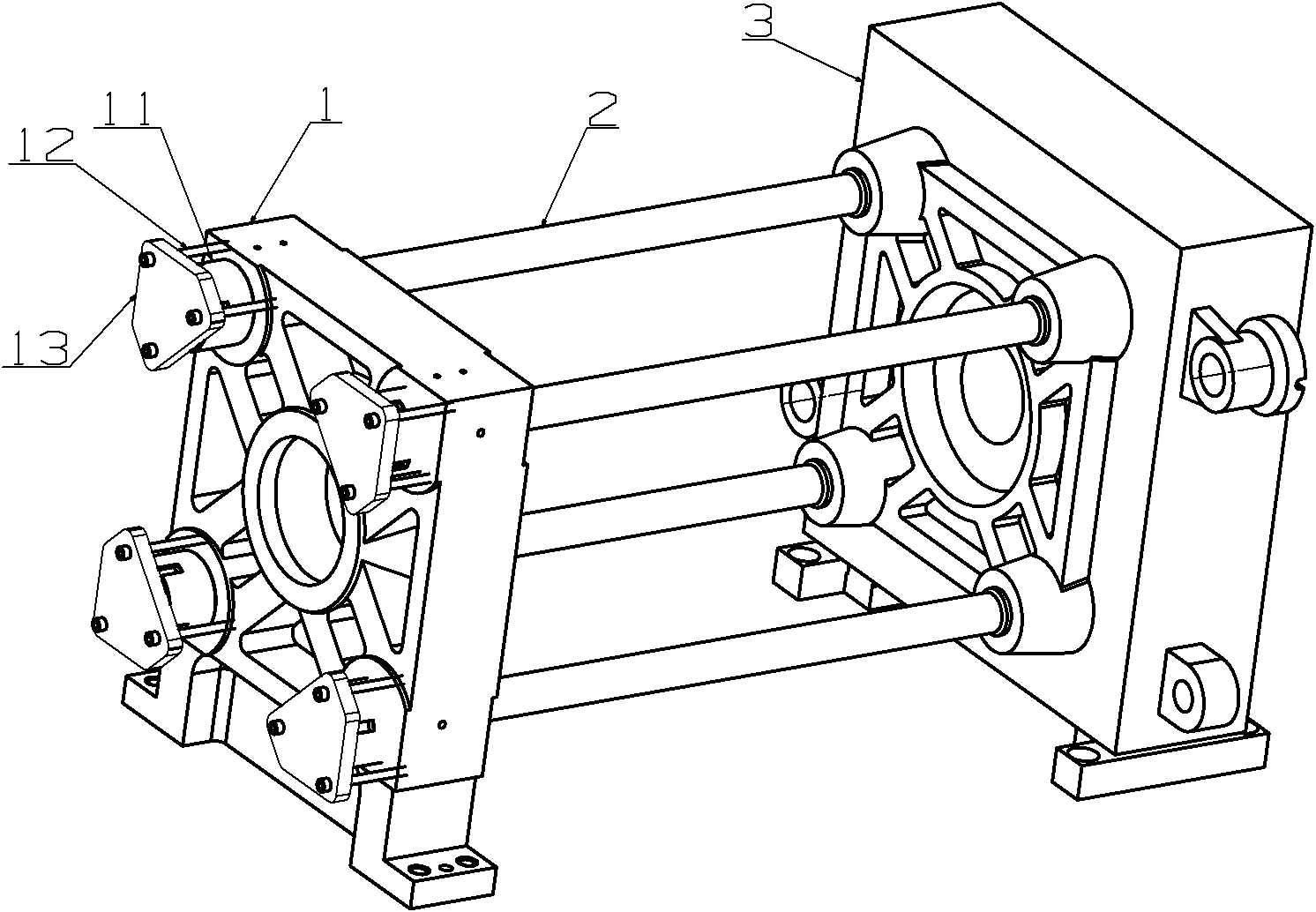

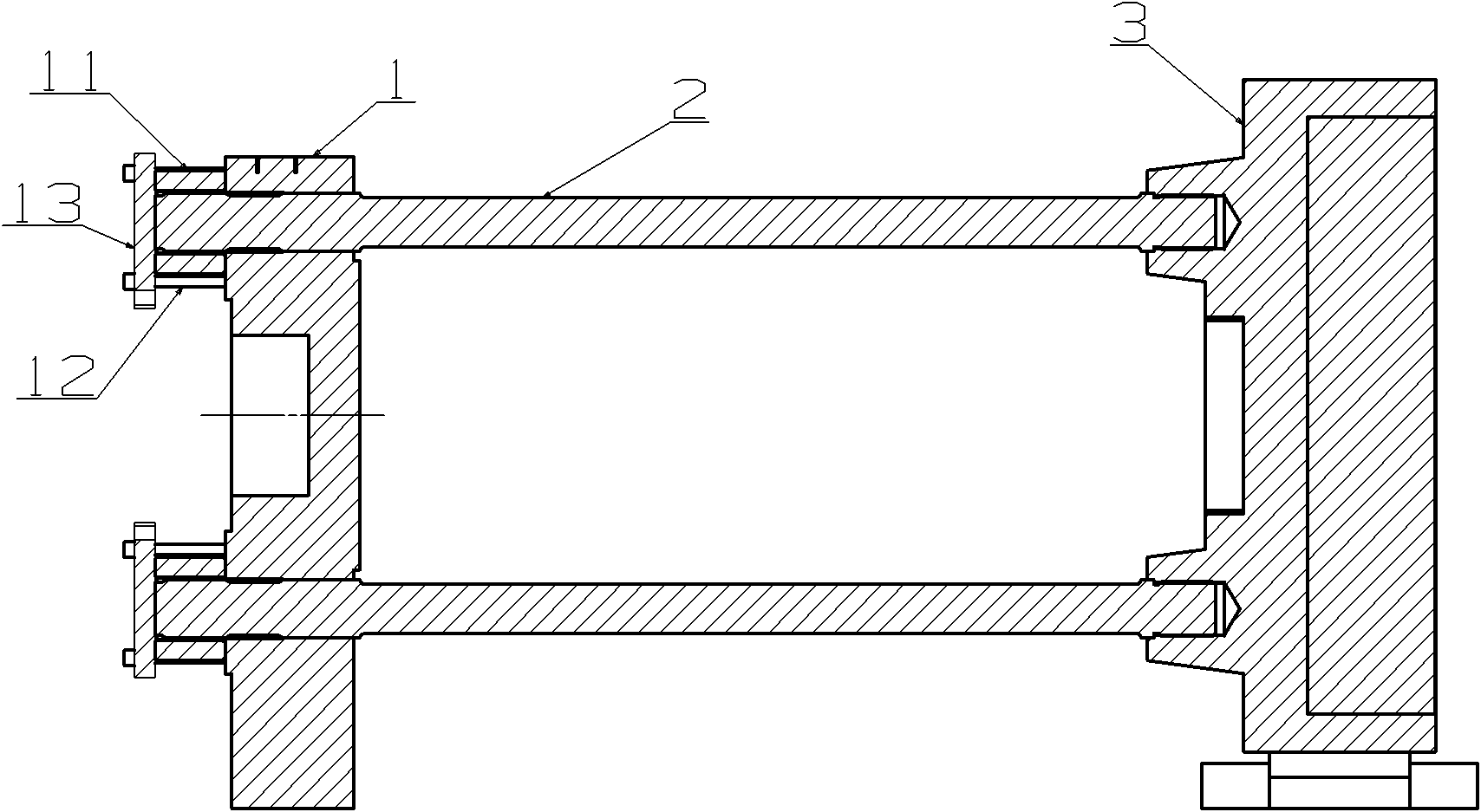

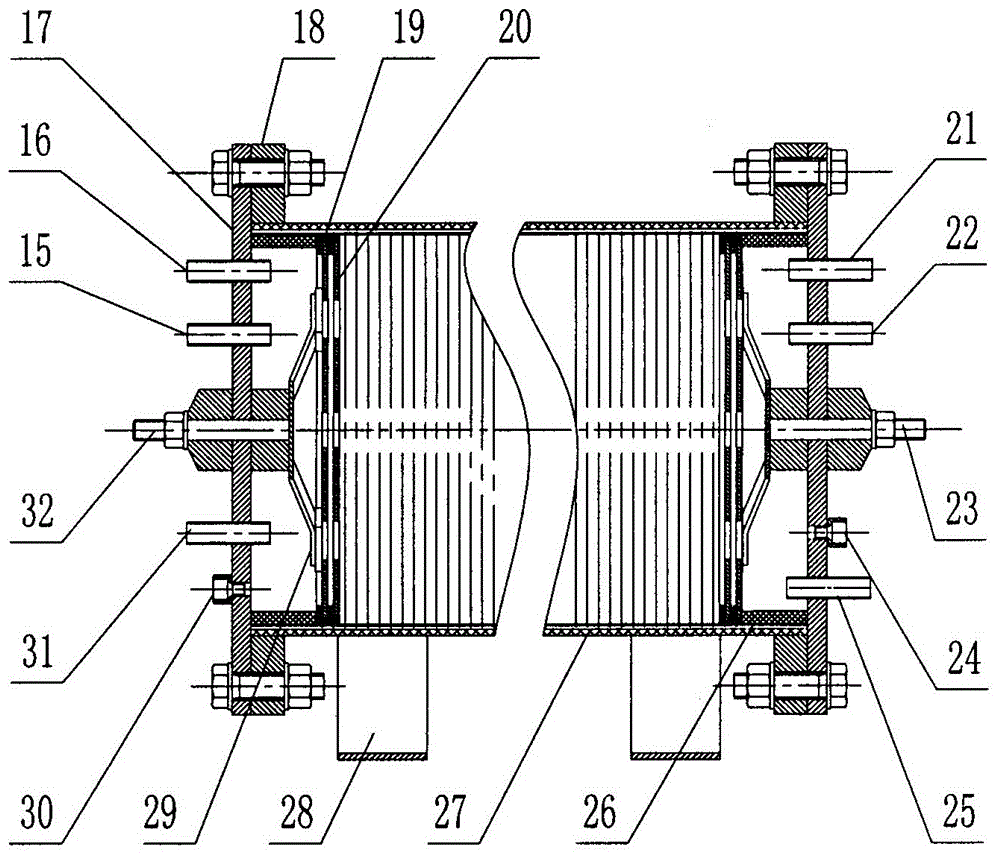

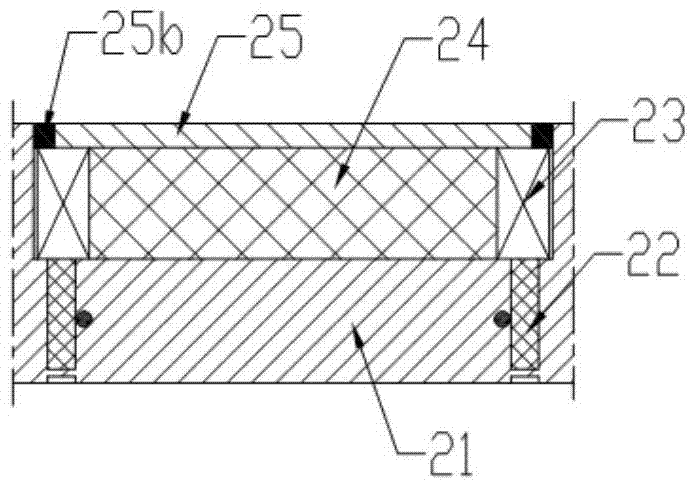

Electromagnetic mold clamping mechanism of injection molding machine

The invention provides an electromagnetic mold clamping mechanism of an injection molding machine, comprising a head plate, a secondary plate and an end plate which are sequentially arranged in parallel, wherein a magnetic plate is arranged between the secondary plate and the end plate; the magnetic plate is fixedly connected with the head plate through a pulling rod; a mold moving mechanism is arranged between the magnetic plate and the end plate; a mold adjusting column is arranged on the back of the secondary plate; the mold adjusting column is connected with a mold adjusting mechanism after penetrating through the central hole of the magnetic plate and the center of the end plate; the plane of the tail end of the magnetic plate is provided with the center hole, and is also equally provided with a plurality of magnetic poles in lines and rows; coils on the magnetic poles generate magnetic force after positively charging; the magnetic force tensions the end plate and the magnetic plate; and the coils on the magnetic poles do not generate the magnetic force to external parts after negatively charging. The mechanism has the advantages that: 1, the end plate can be equally absorbed on the magnetic plate; 2, the mechanism can strengthen the close attach between the magnetic plate and the end plate so as to ensure size and stability of mold clamping force; 3, the mechanism is energy-saving; 4, the mechanism is safe; and 5, the gap delta between the magnetic plate and the end plate is ensured.

Owner:NINGBO HAITIAN HUAYUAN MACHINERY

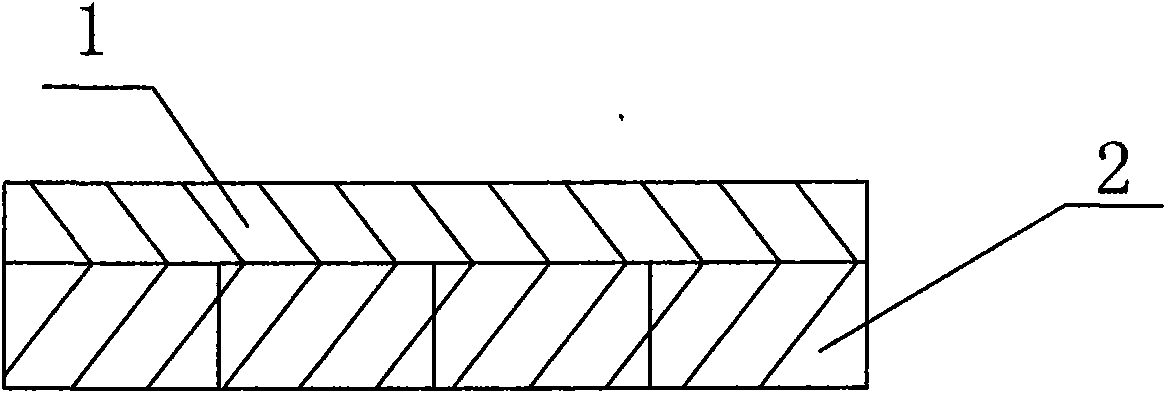

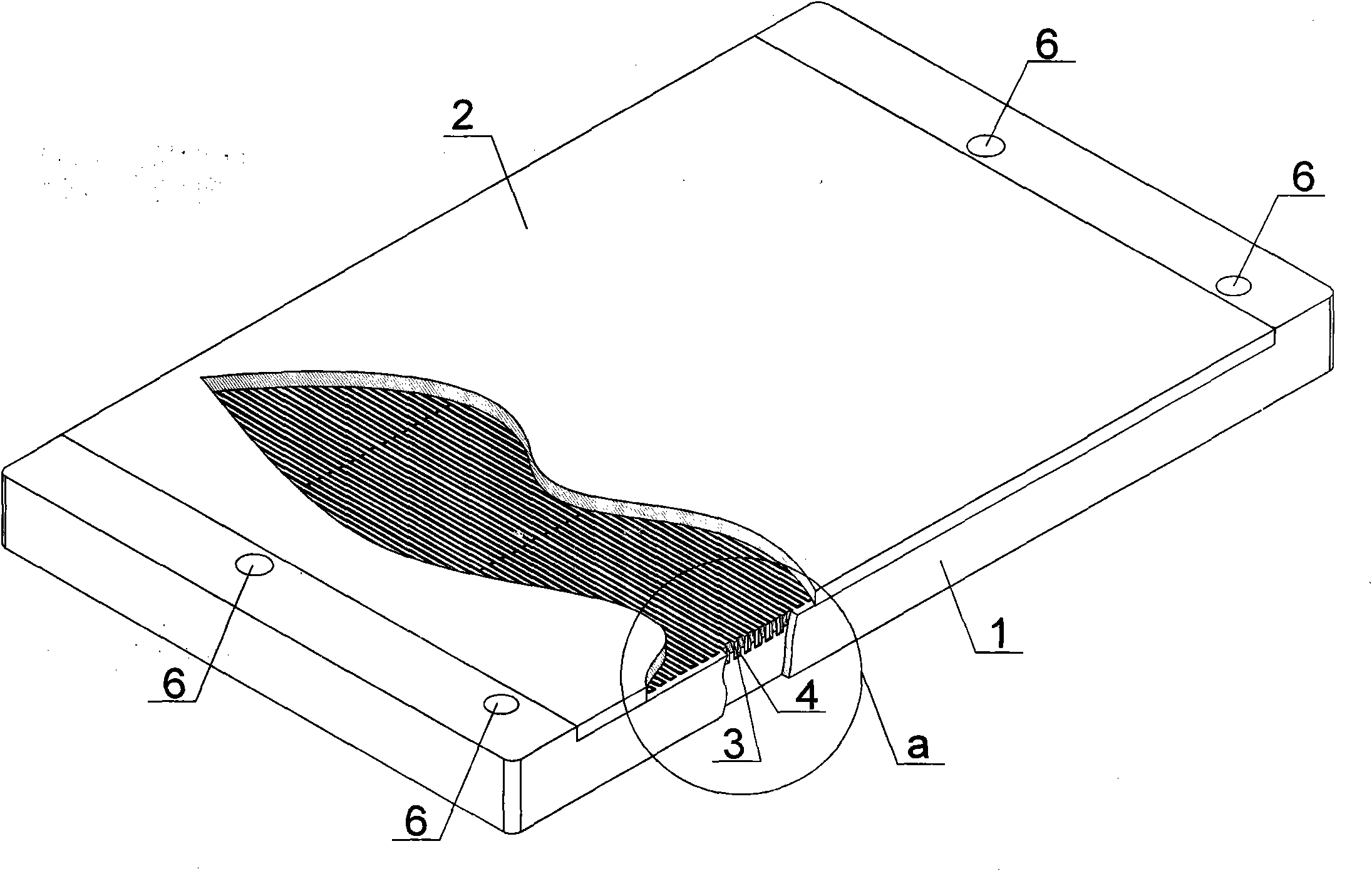

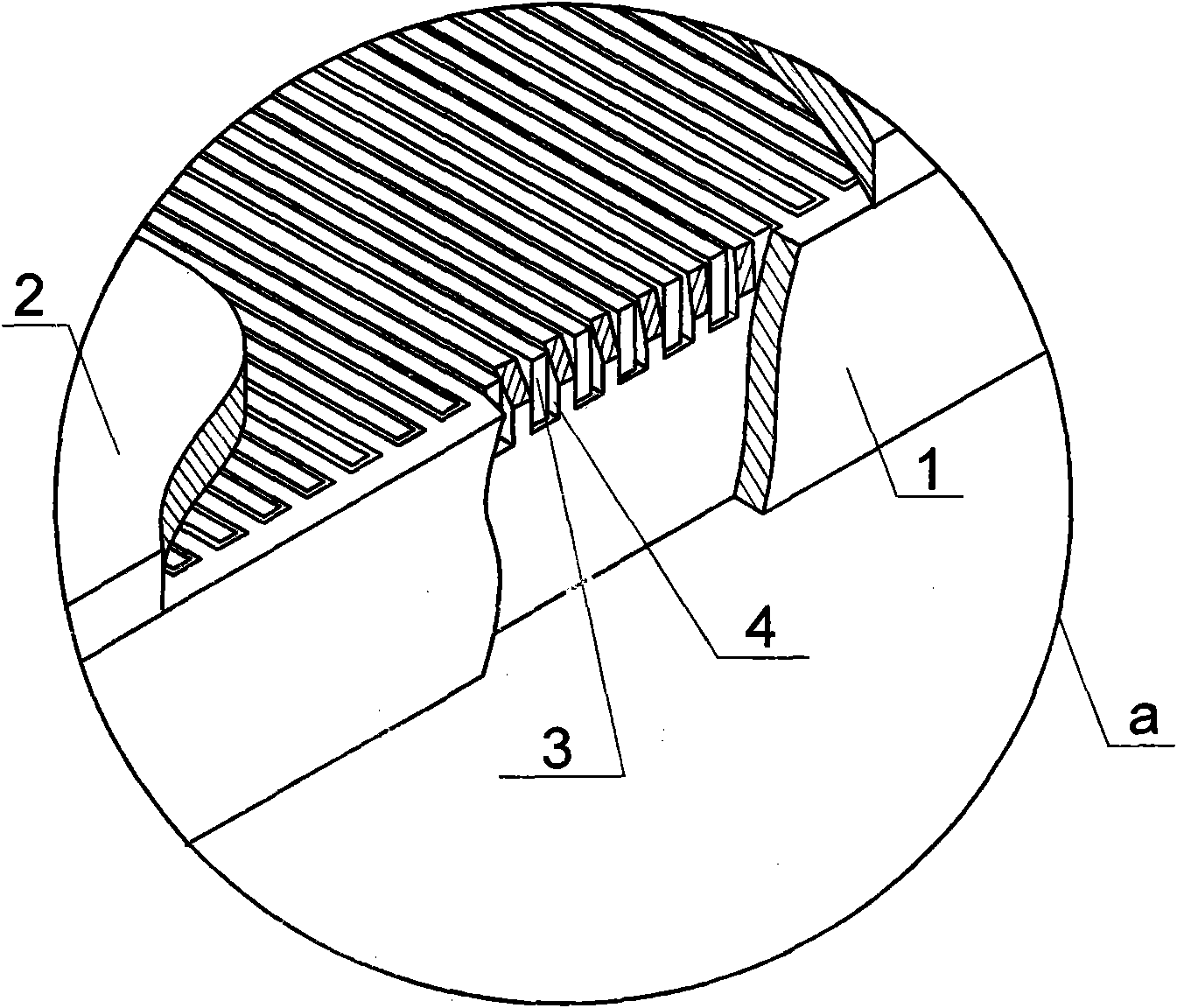

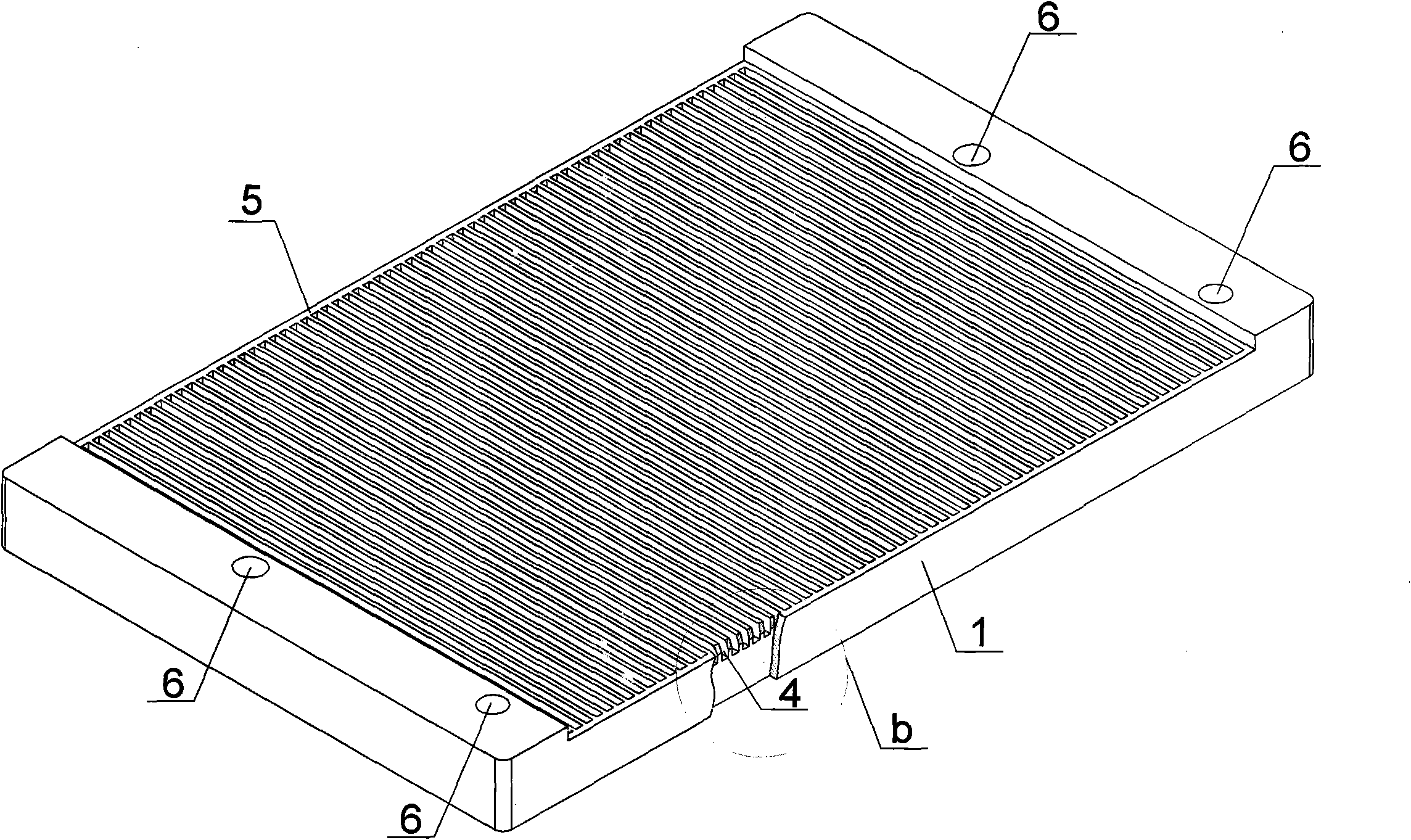

Device for constituting permanent magnet full-acting surface

InactiveCN101630565AHigh sorting capacityIncrease production capacityPermanent magnetsInductances/transformers/magnets manufactureMagnetic tension forceHorizontal and vertical

The invention discloses a device for constituting a permanent magnet full-acting surface, comprising a micro permanent magnet and a magnetic conductor. In the invention, the permanent magnet acting surface is an upper flat surface which is composed of a plurality of micro permanent magnets with the same size (the size thereof is 18*18*18 mm-2*2*2 mm) which are in parallel arrangement in a horizontal and vertical manner tightly; the micro permanent magnets are adsorbed onto the surface of the magnetic conductor by utilizing magnetic force thereof; the polarities of adjacent two micro permanent magnets are opposite; the excitation direction of the single permanent magnet is vertical to the magnetic conductor. The device is applicable to the separation equipment of weak magnetic substances with the permanent magnet separation specific susceptibility being (15-600)*10<-6> cm<3> / g, and can also be applicable to non-metallic mineral equipment for removing weak magnetic substances. The device provided by the invention has the advantages of balanced magnetic force of the acting surface, big magnetic force of the acting surface, adjustable magnetic field strength and gradient, no loss of magnet force of the acting surface, high yield of separation, wide adaptability and the like.

Owner:WUHAN PEAKREALM MAGNETIC TECH CO LTD

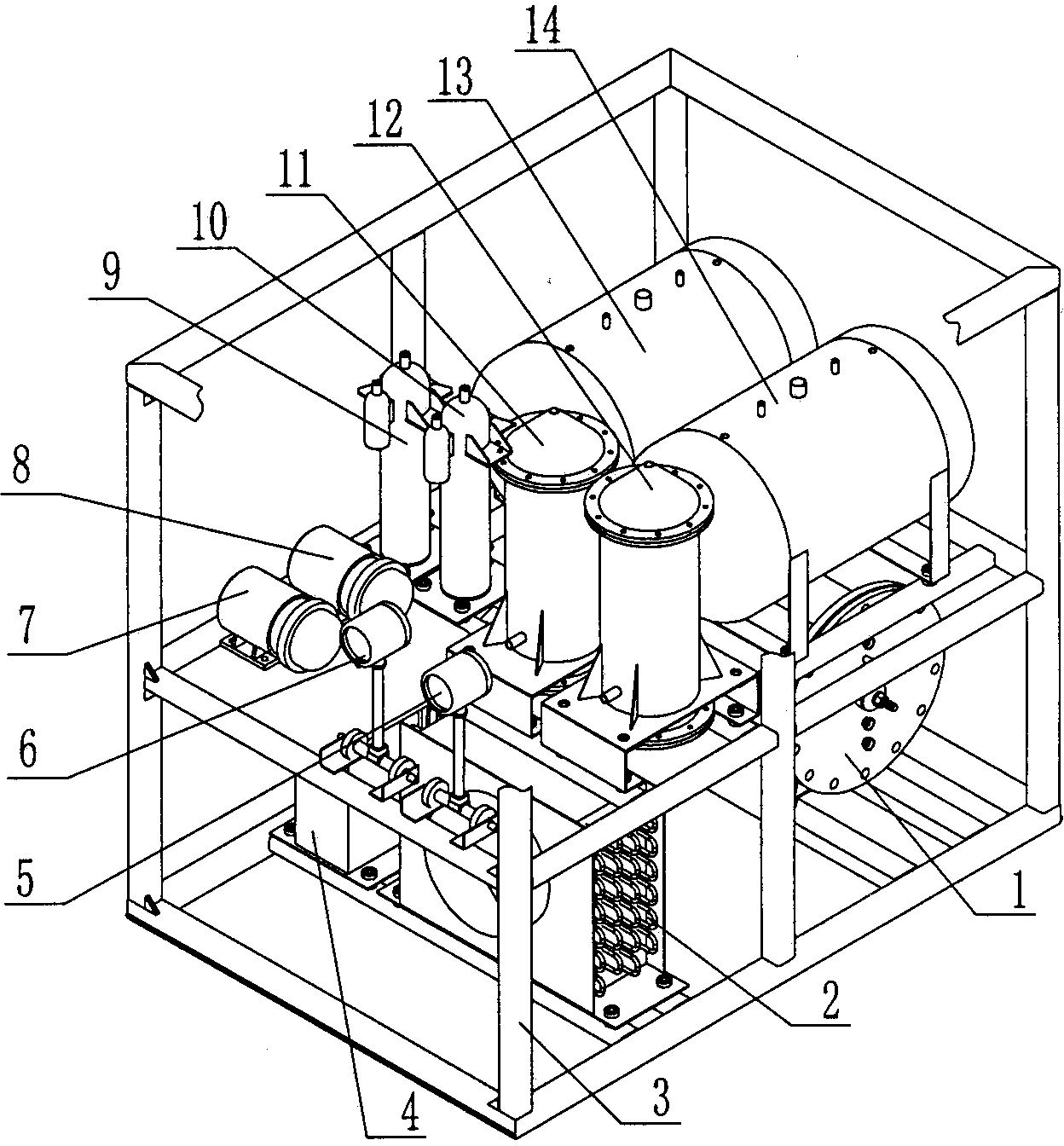

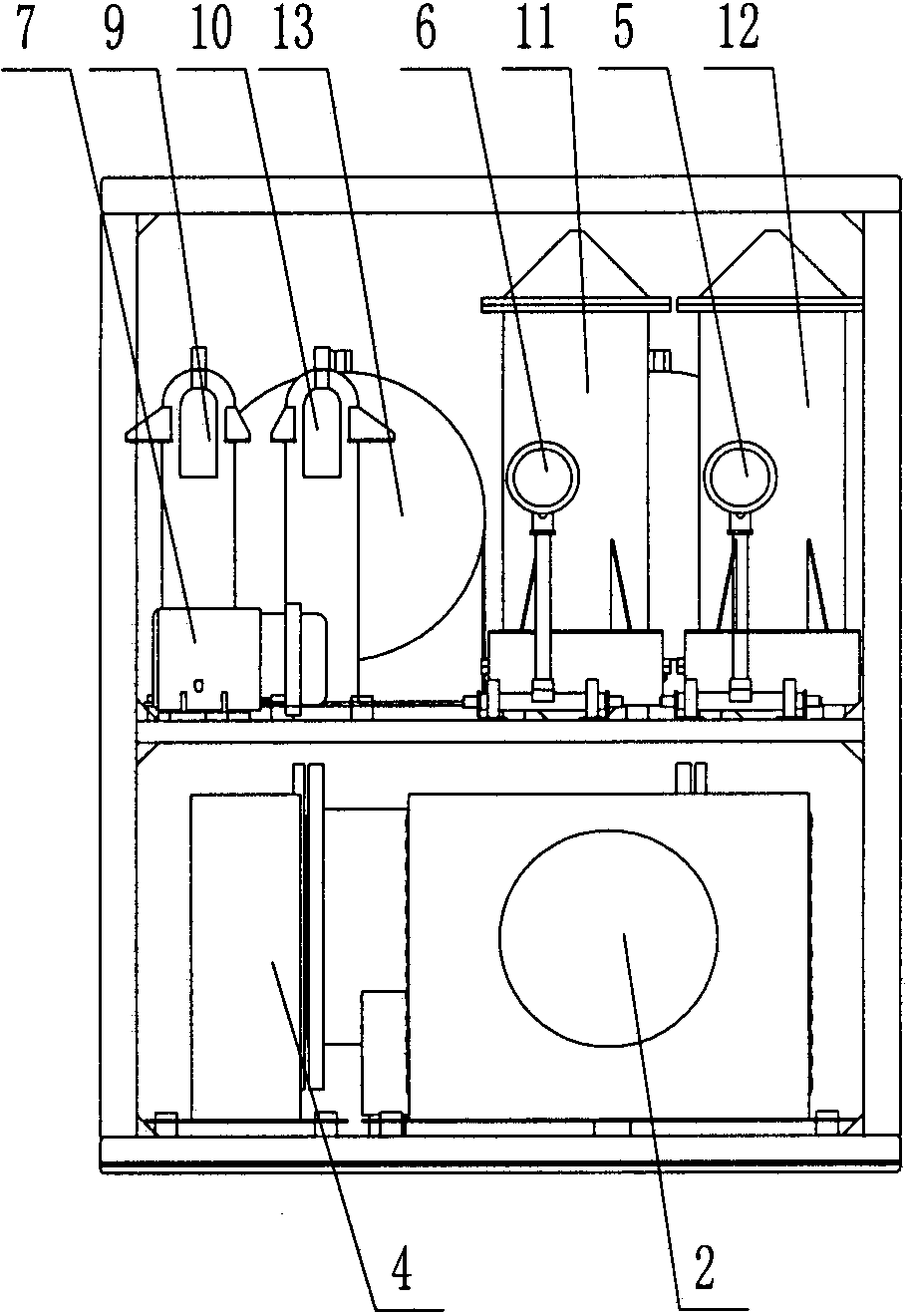

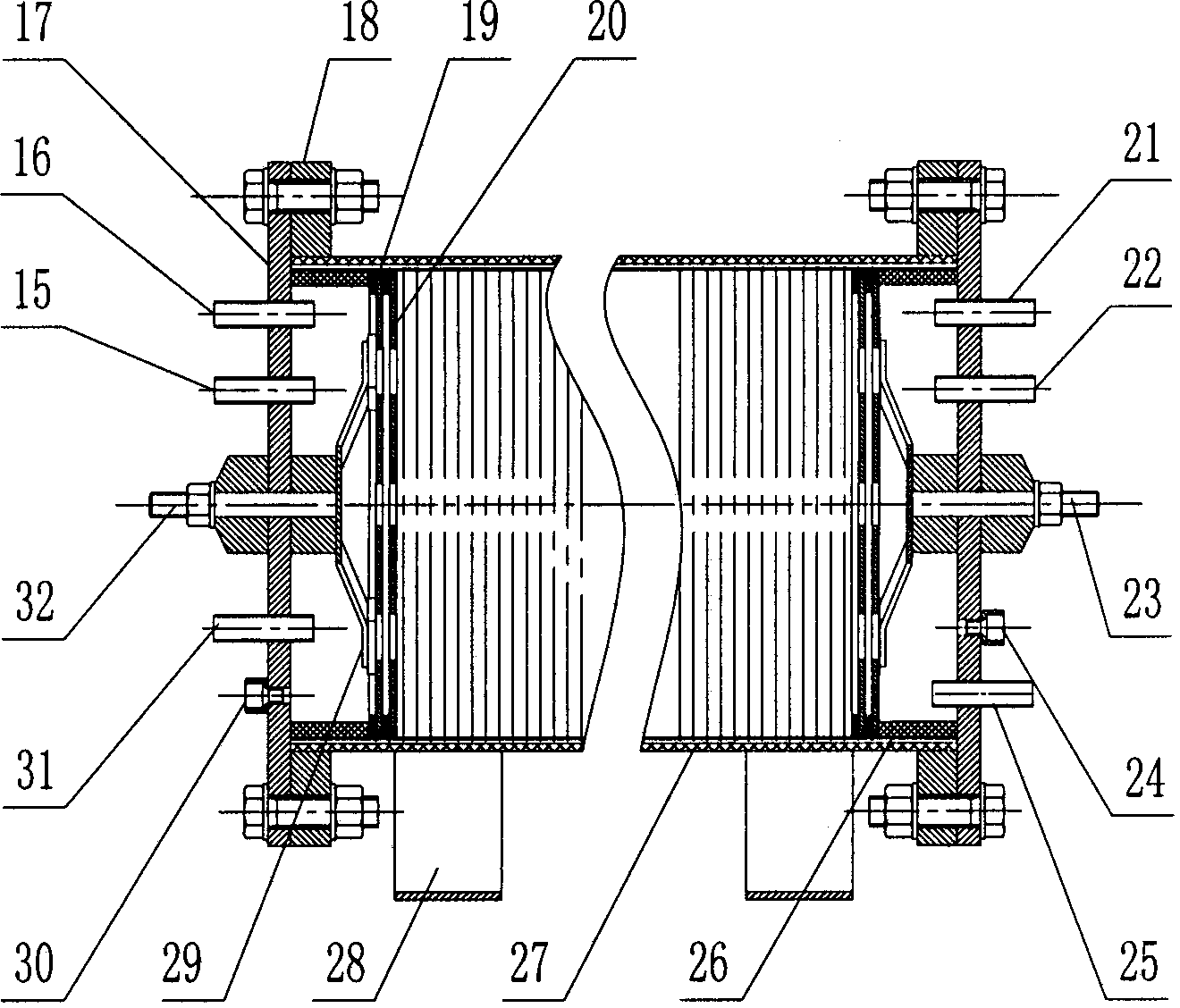

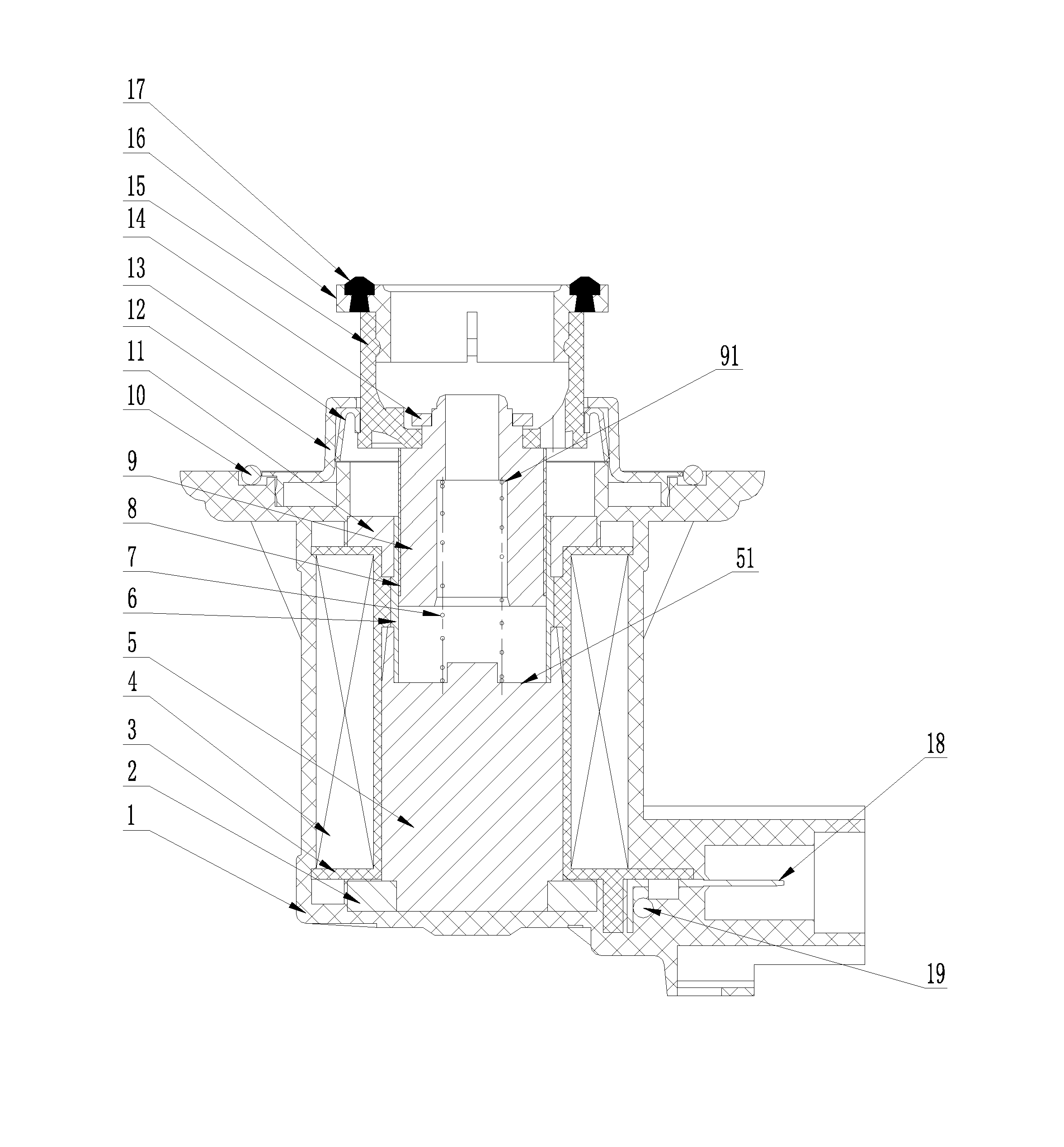

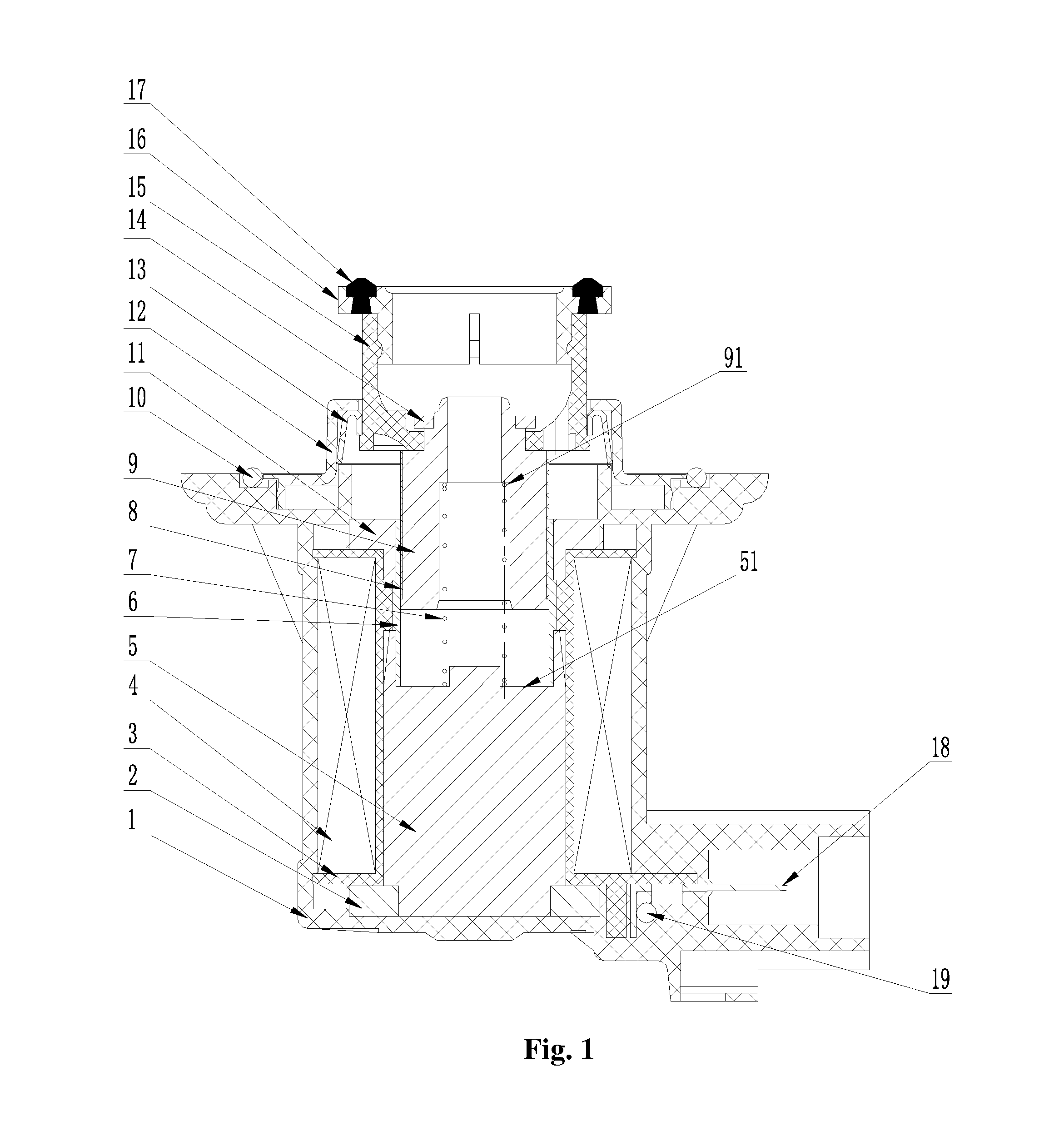

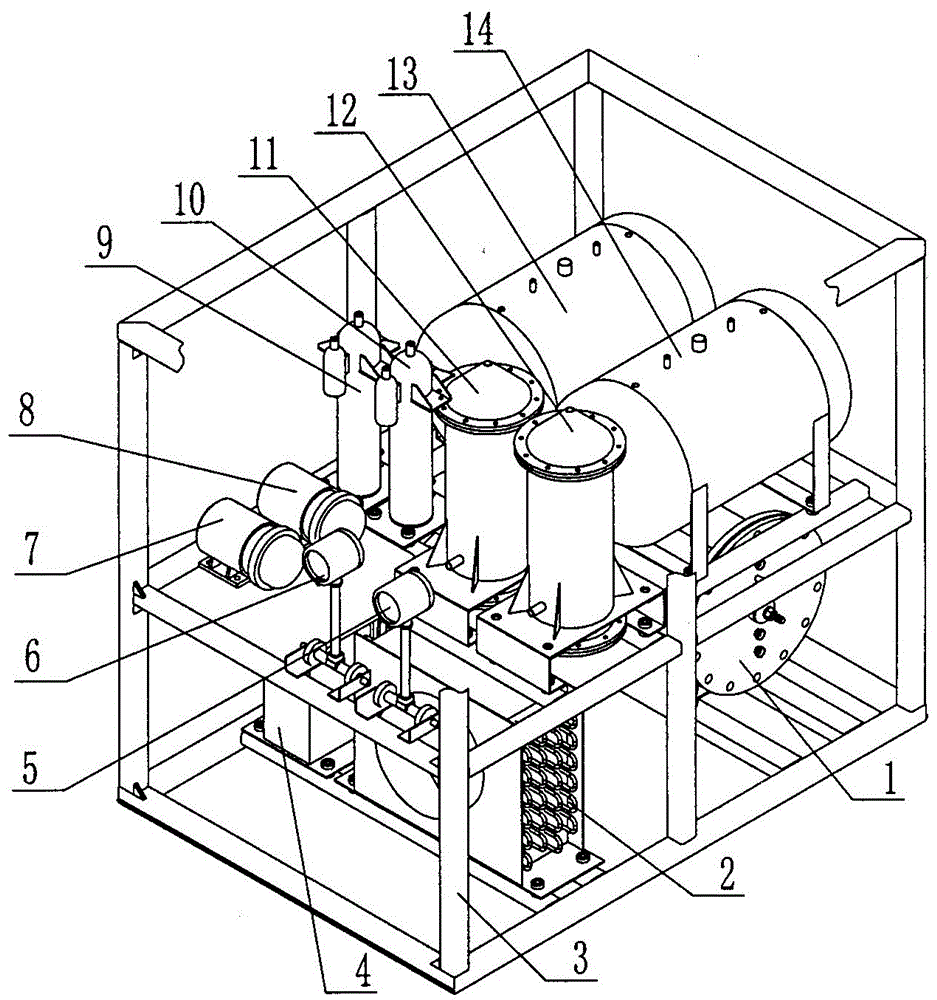

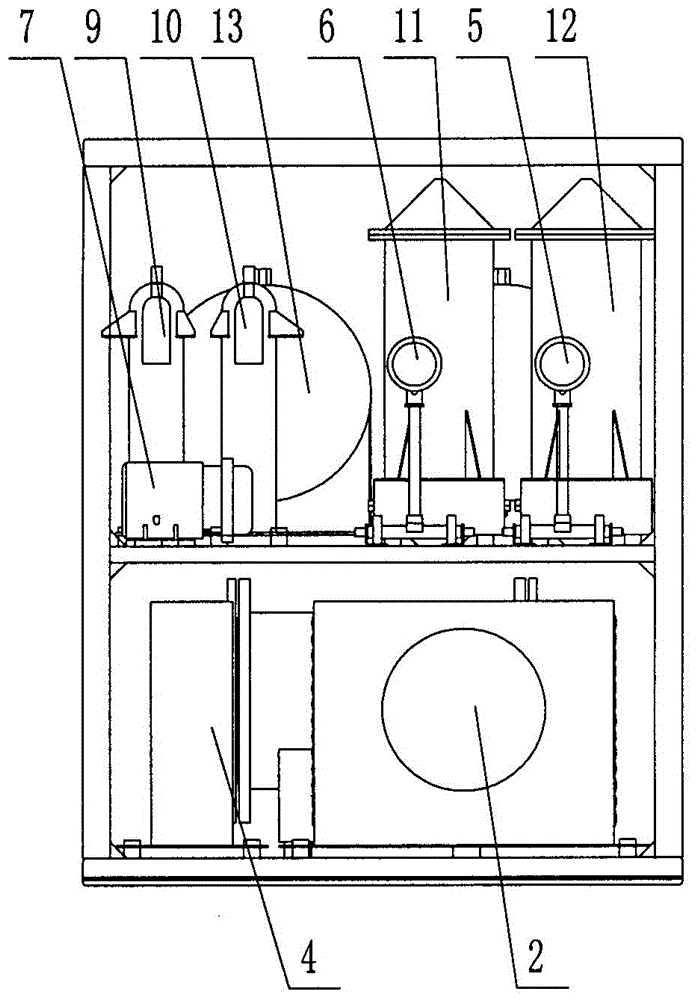

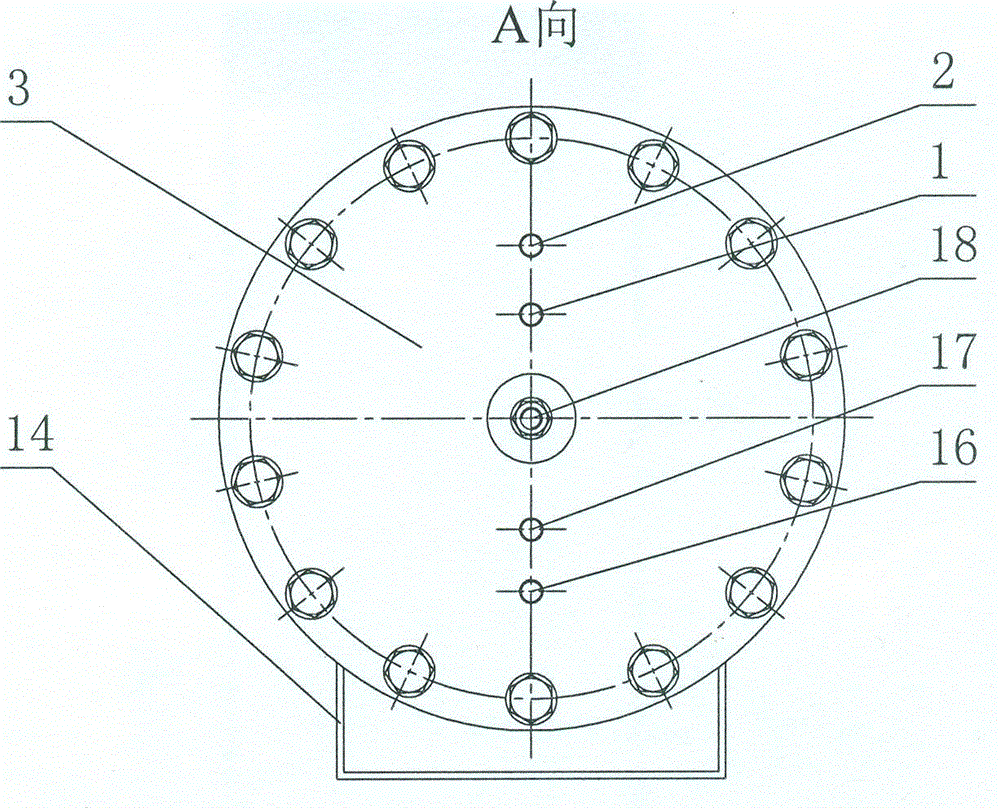

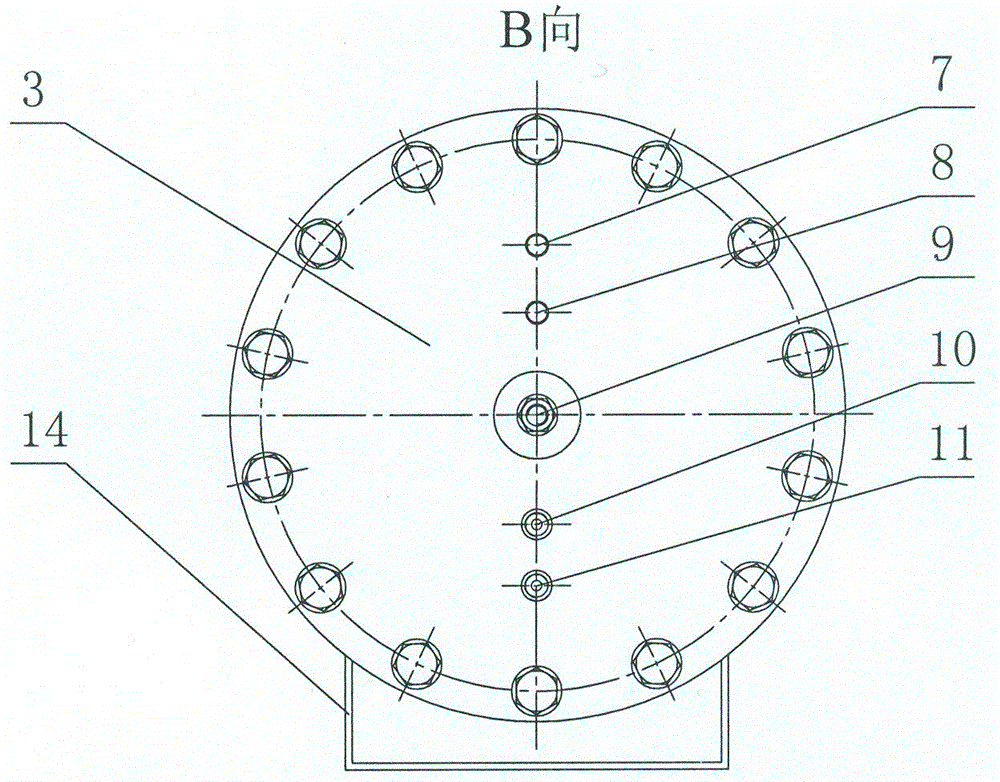

Oxy-hydrogen mixed gas integrated generating device

ActiveCN104294309AEven by forceUniform magnetic forceCellsChemical industryFlame arresterHigh energy

The invention provides an oxy-hydrogen mixed gas integrated generating device. The common problems of the existing oxy-hydrogen generators, such as high price, low gas yield, high energy consumption and incomplete safety setting, are solved. The invention has the technical main points that at least one closed electrolysed water generator is adopted, an oxy-hydrogen mixed gas dry and wet combined flame arrester of an identical structure is adopted, a hydrogen output and an oxygen output of the electrolysed water generator are respectively connected with gas inlets of hydrogen and oxygen liquid storing and gas filtering tanks, and an electrolyte circulating input and an electrolyte circulating output of the electrolysed water generator are connected with a heat exchanger and a heat radiator after being connected with an electrolyte circulating pump through filters. The oxy-hydrogen mixed gas integrated generating device is compact in structural arrangement and reasonable in design, has great pressure relief and explosion preventing properties and can effectively prevent oxy-hydrogen mixed gas backfire and explosion danger. Compared with the same class of products, the oxy-hydrogen mixed gas integrated generating device has the advantages of no gas leakage, no liquid leakage, no current leaking loss, energy conservation, safe and reliable use, high electrolysis efficiency, high gas yield, few heat losses and remarkable improvement on safe and continuous running efficiency.

Owner:刘枫

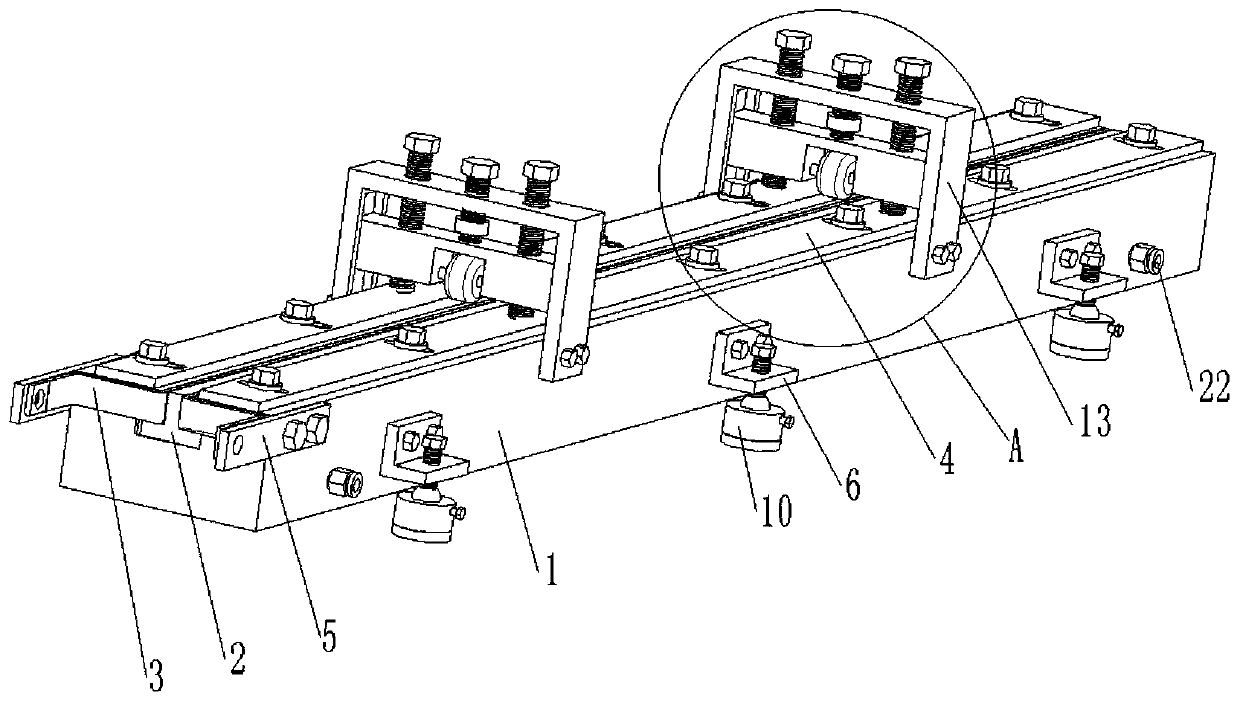

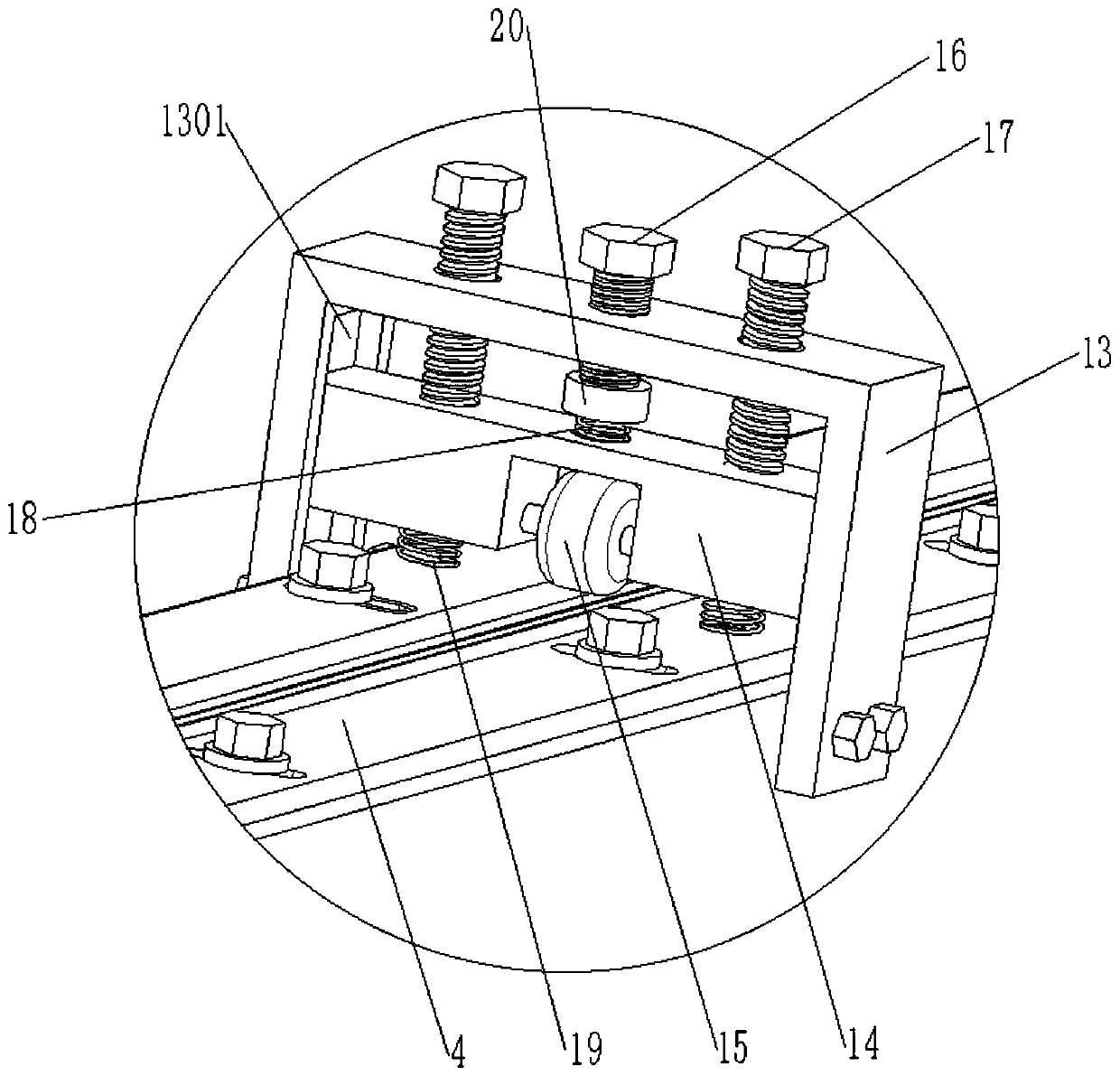

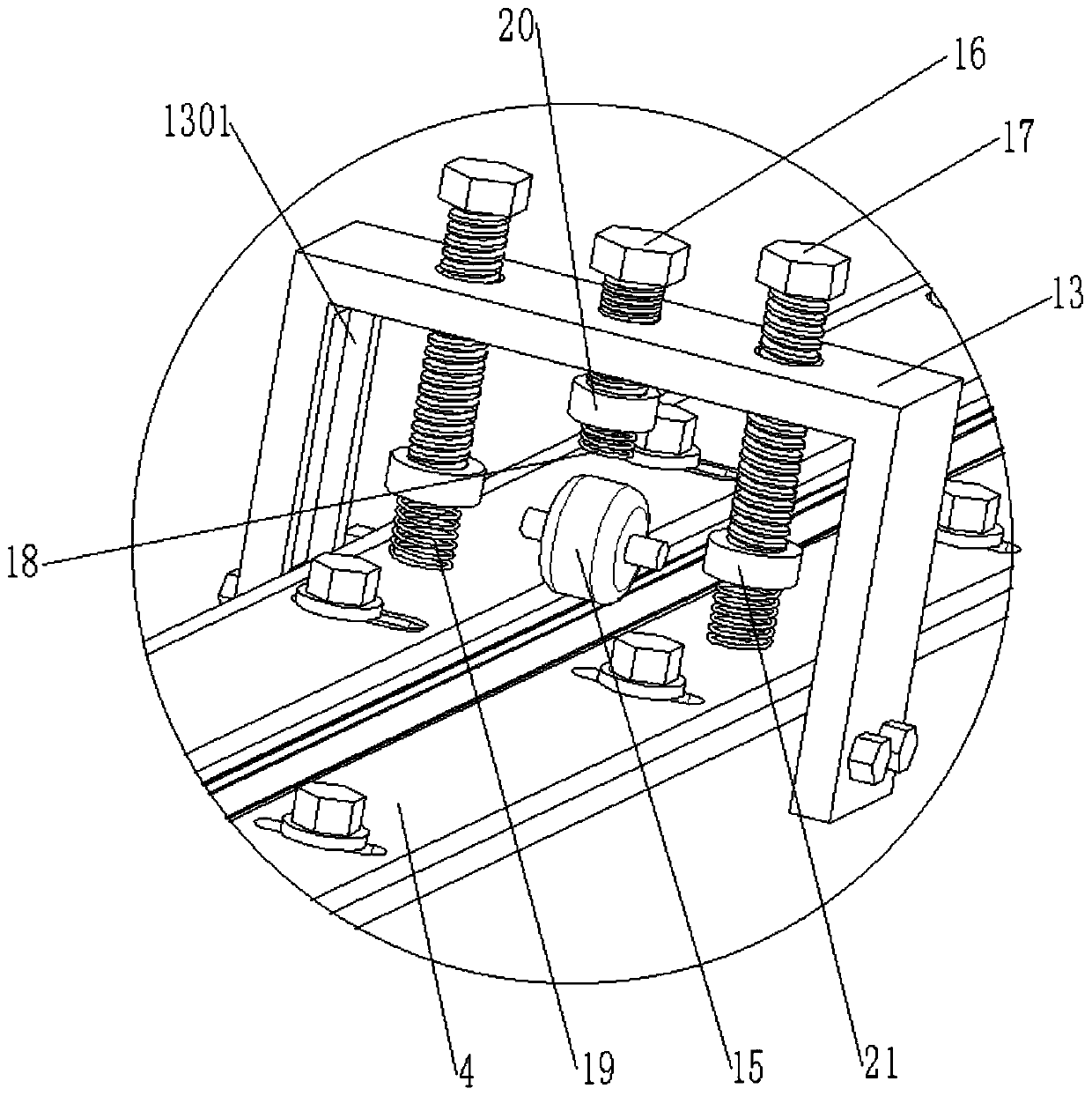

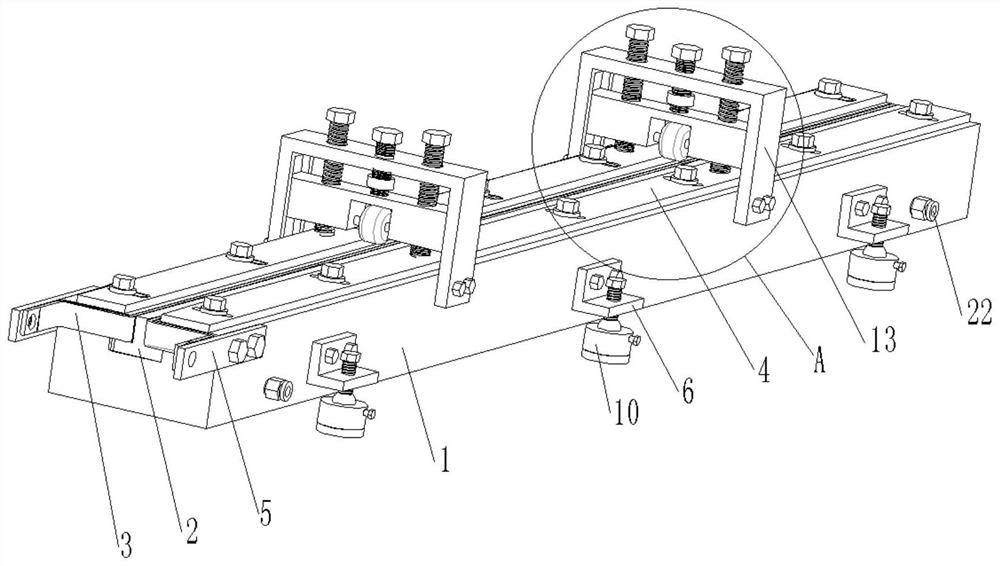

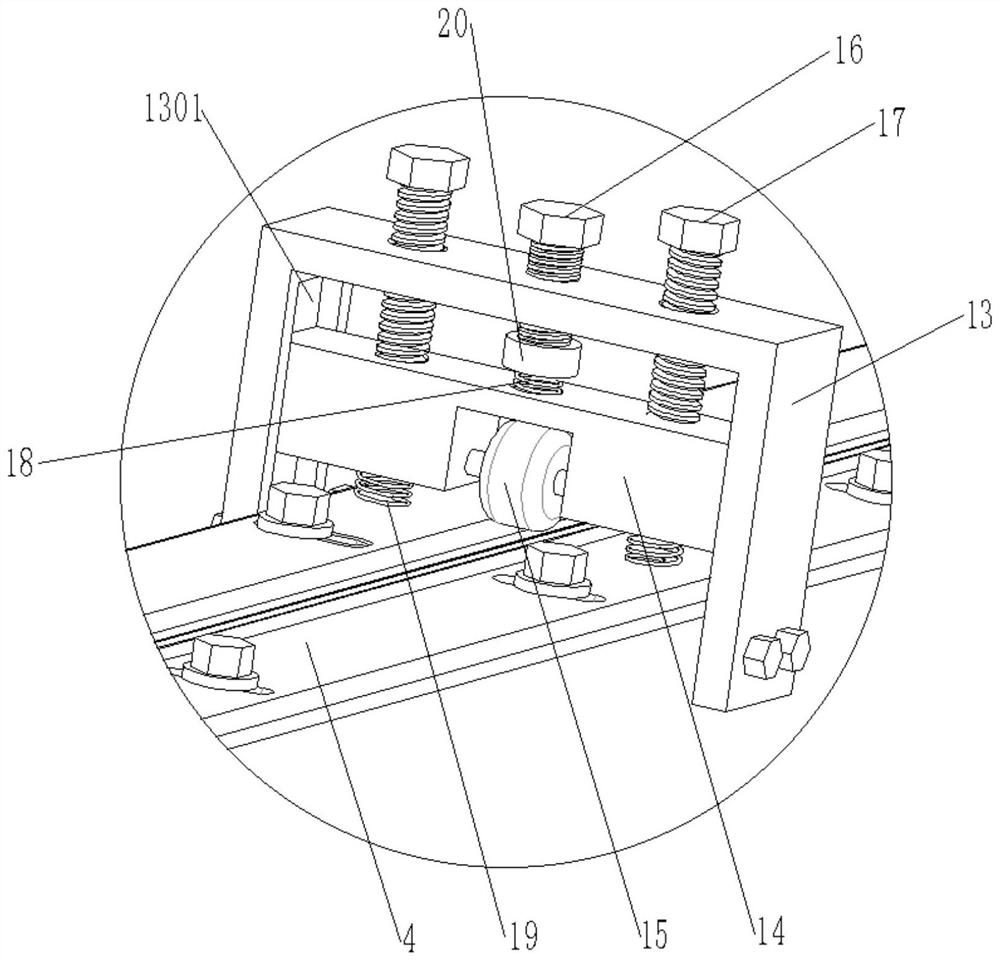

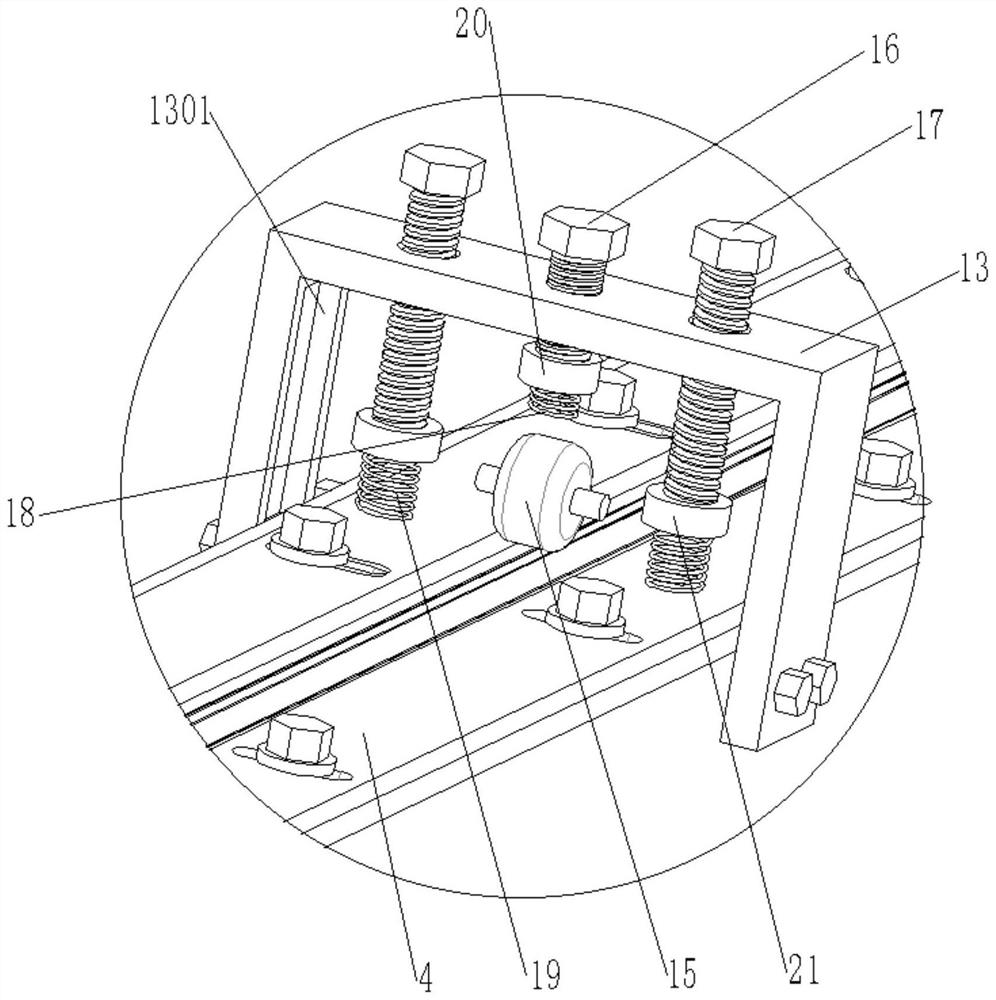

Uniform magnetizing plate for magnetic rubber strip

ActiveCN110415914AUniform magnetic forceIncrease distanceMagnetic bodiesEngineeringMechanical engineering

The invention discloses a uniform magnetizing plate for a magnetic rubber strip. The uniform magnetizing plate comprises a base; a rectangular through groove is formed in the upper end surface of thebase in the length direction of the base; a magnetizing line mounting core block is arranged in the rectangular through groove; two magnetizing line mounting through grooves parallel to each other areformed in the upper end surface of the magnetizing line mounting core block in the length direction of the magnetizing line mounting core block; magnetizing lines are arranged in the mounting throughgrooves; the two ends of each magnetizing line extend out to the outer sides of the two ends of the base and the magnetizing line mounting core block respectively; one ends, located on the outer sideof the tail end of the magnetizing line mounting core block, of the two magnetizing lines are connected together, and the two magnetizing lines are conducted at the connecting position; and a plurality of height adjusting mechanisms are arranged on the two side walls of the base in the length direction of the base. The height adjusting mechanisms are arranged, so that the purpose that a tractionpoint of a traction machine, the bottom wall of a slide way and the rubber strip are located on the same plane at a discharge point of a cooling device can be achieved; and the lower surface of the rubber strip slides completely against the bottom wall of the slide way, so that the magnetic rubber strip is uniform in magnetic force.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

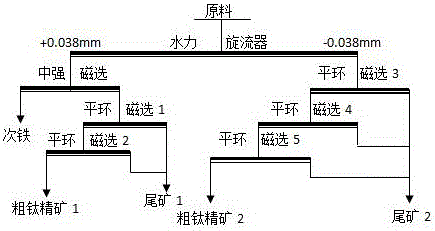

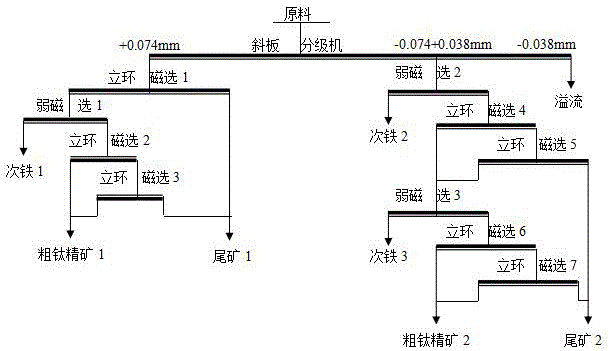

Method for enriching ilmenite

The invention discloses a method for enriching ilmenite. The method comprises the steps of carrying out grinding, weak magnet deironing and classification on an ilmenite raw material to obtain materials with two particle sizes of +0.038 mm and -0.038 mm; carrying out medium and strong magnet iron removing on the material with the particle size of +0.038 mm, so as to obtain coarse titanium ore; carrying out magnetic separation on the coarse titanium ore, so as to obtain coarse titanium concentrate 1 and tailings 1; and carrying out magnetic separation on the material with the particle size of -0.038 mm, so as to obtain coarse titanium concentrate 2 and tailings 2. According to the method, different gradient values are obtained through utilizing the difference of mineral magnetism and accurately adopting different magnetic field strength and media, the enrichment of ilmenite is effectively achieved, the level of the obtained coarse titanium concentrate 1 can be improved to 26 to 28%, the recovery rate can reach 80 to 85%, an available method is further provided for enrichment and recycling of ilmenite with the ultrafine-particle size of -0.038 mm, ilmenite tailings with the particle size of -0.038 mm in a conventional technology are effectively enriched and recycled, and resource waste is reduced.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

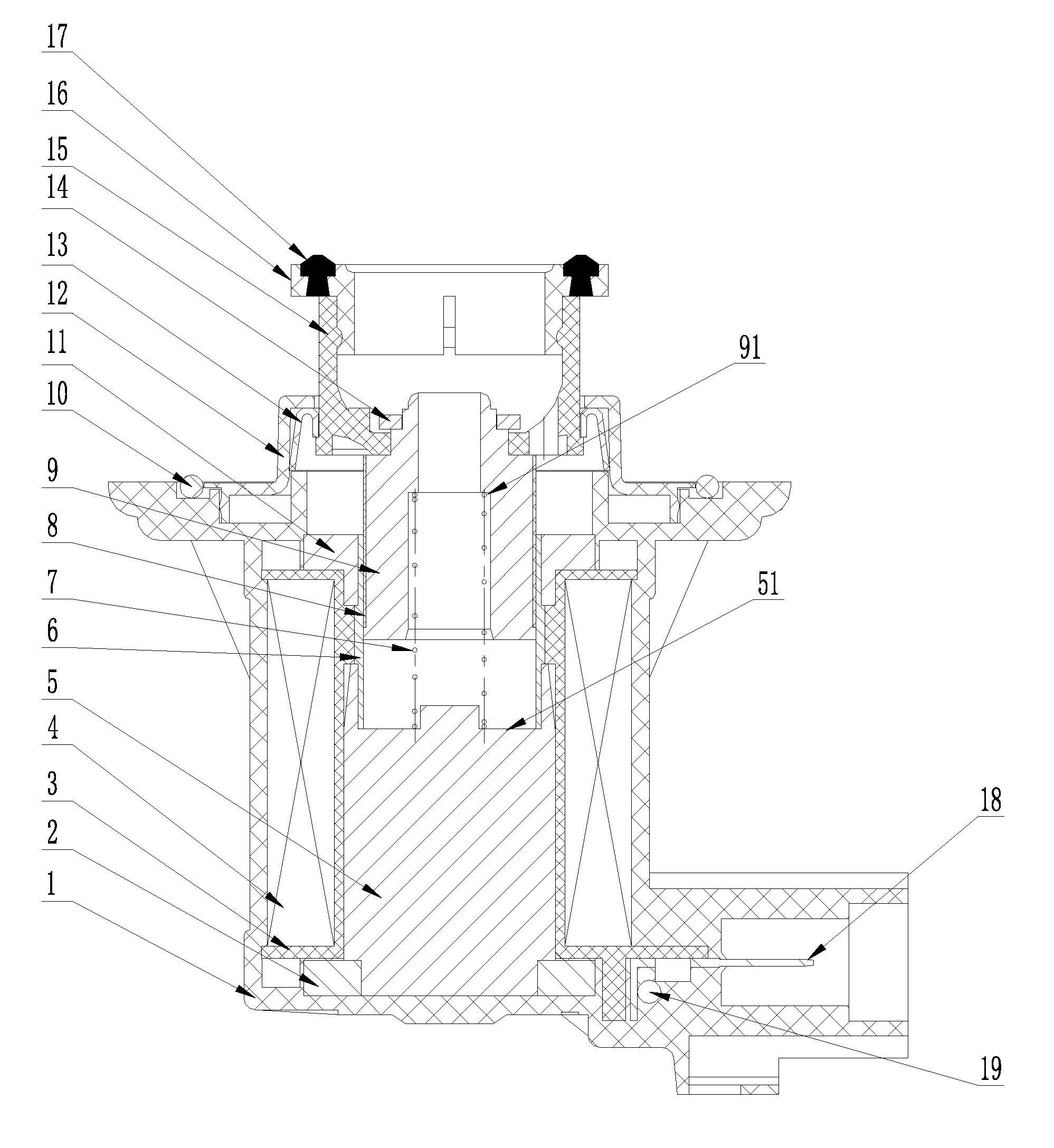

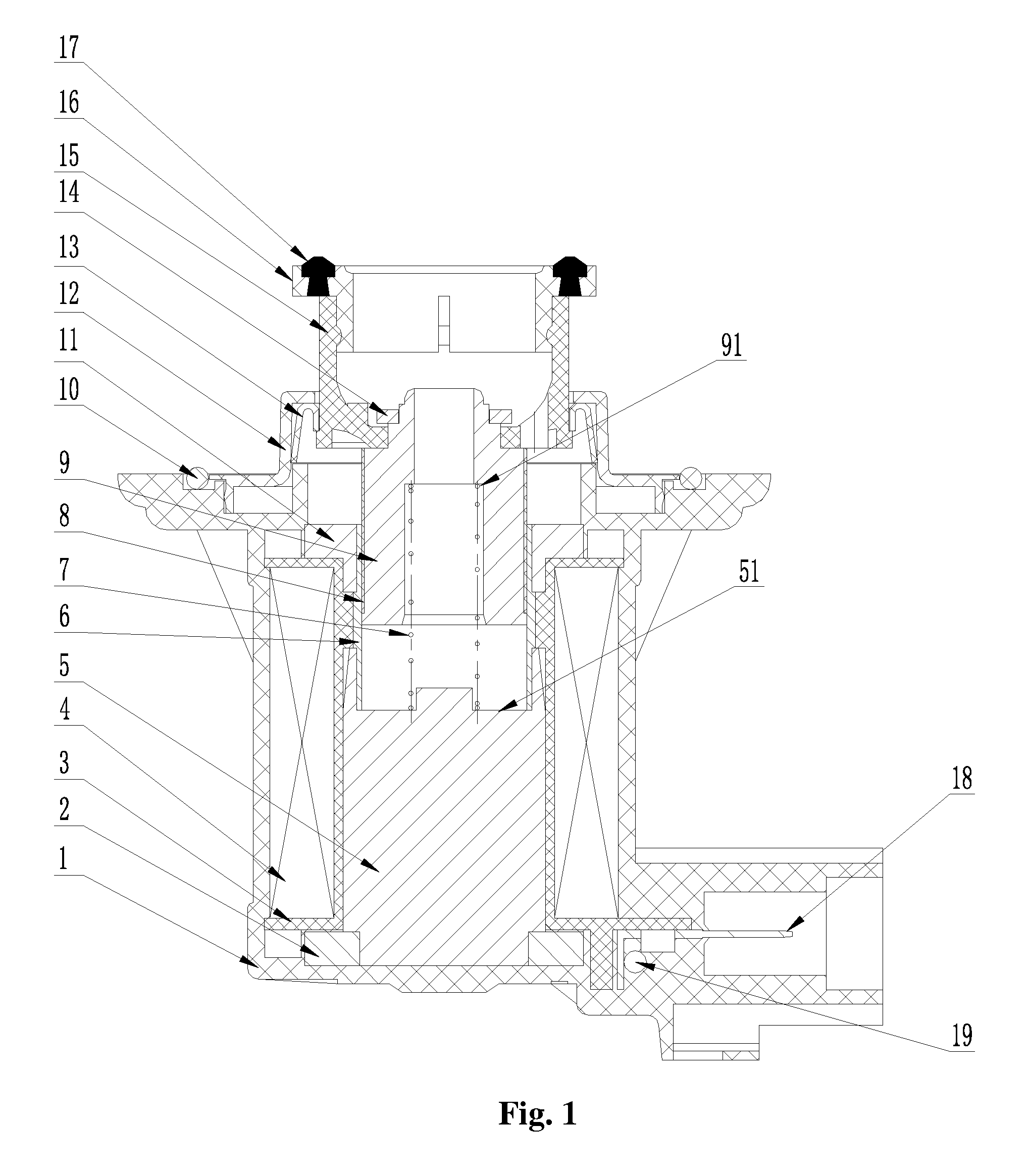

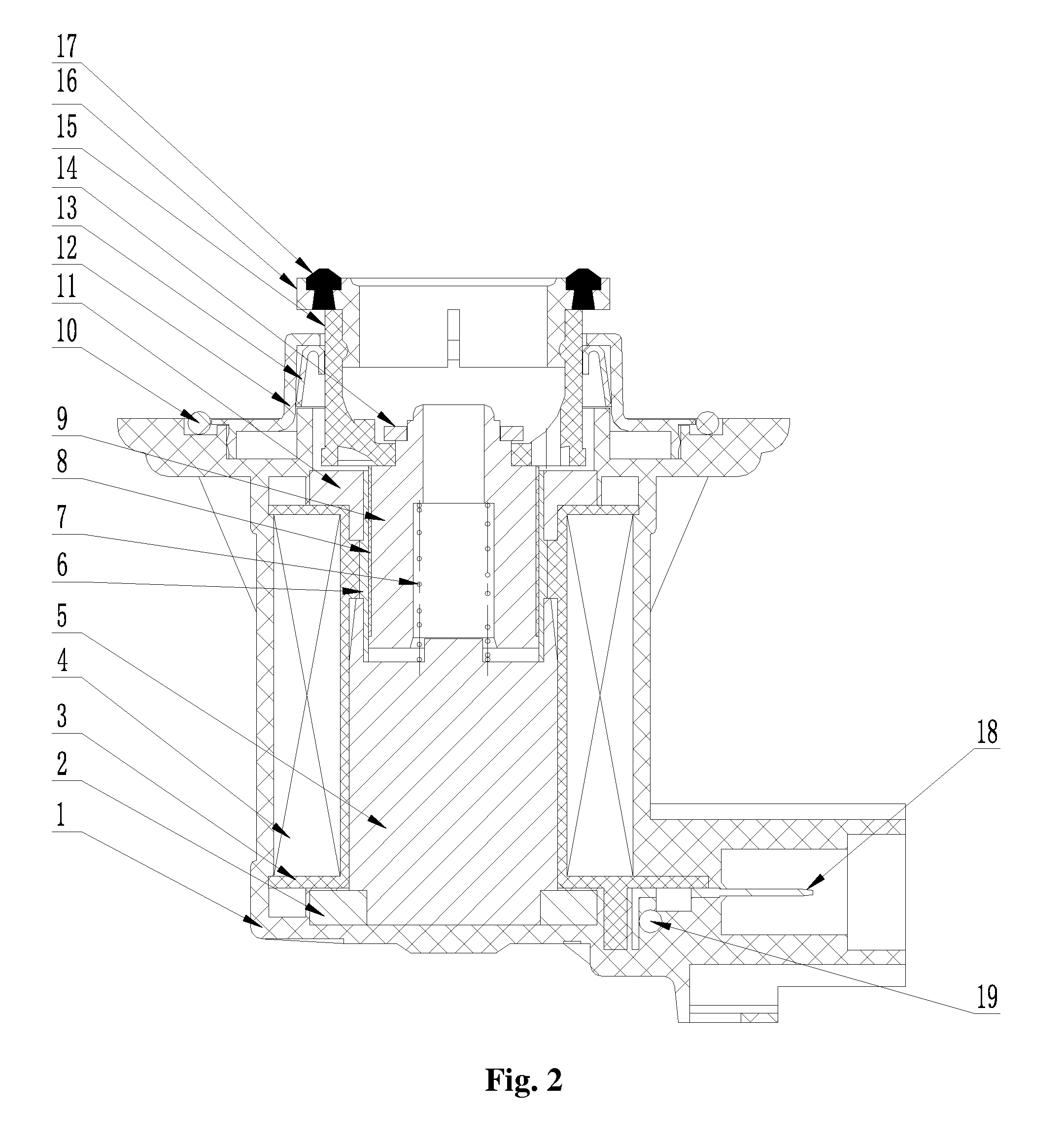

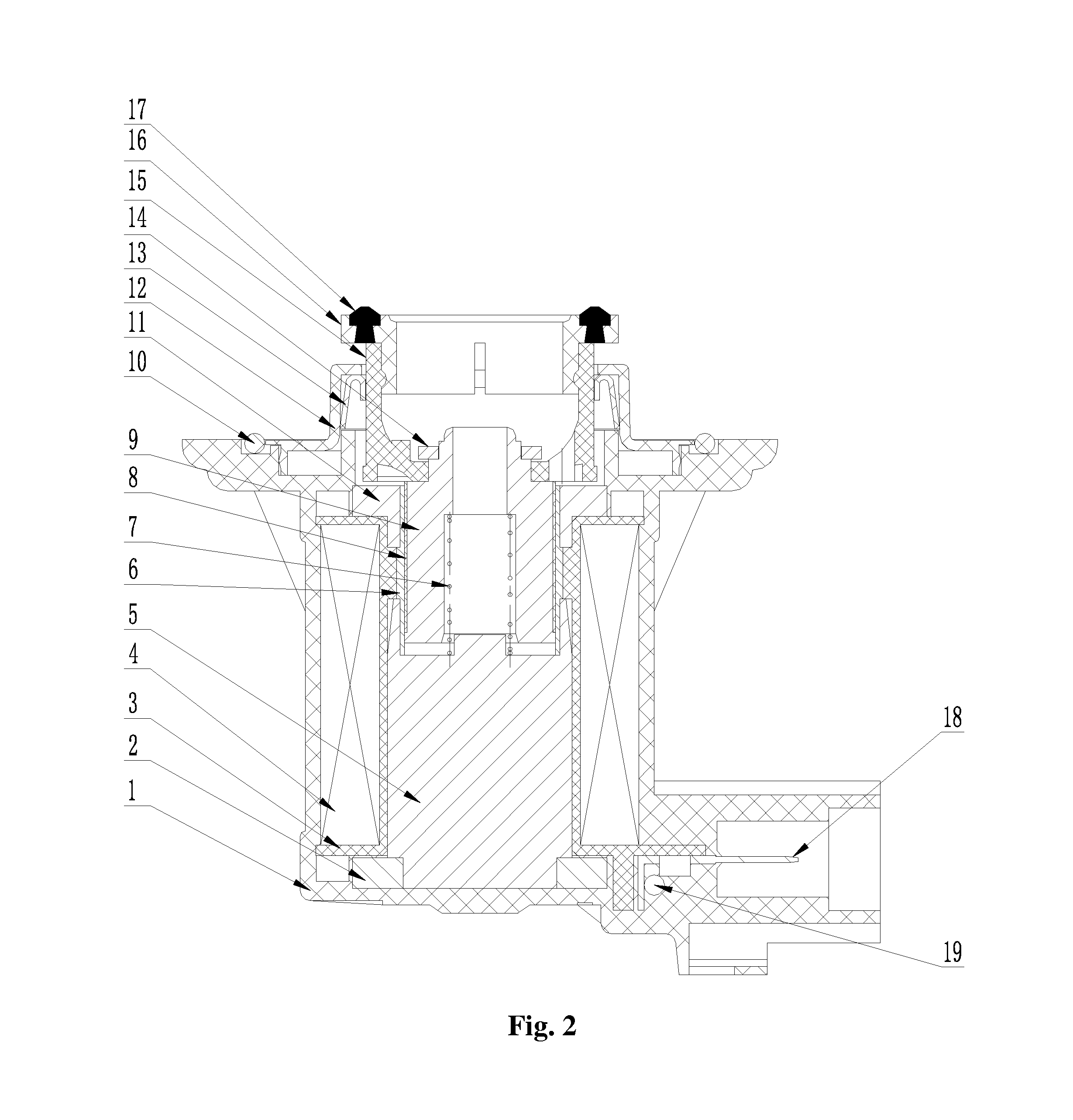

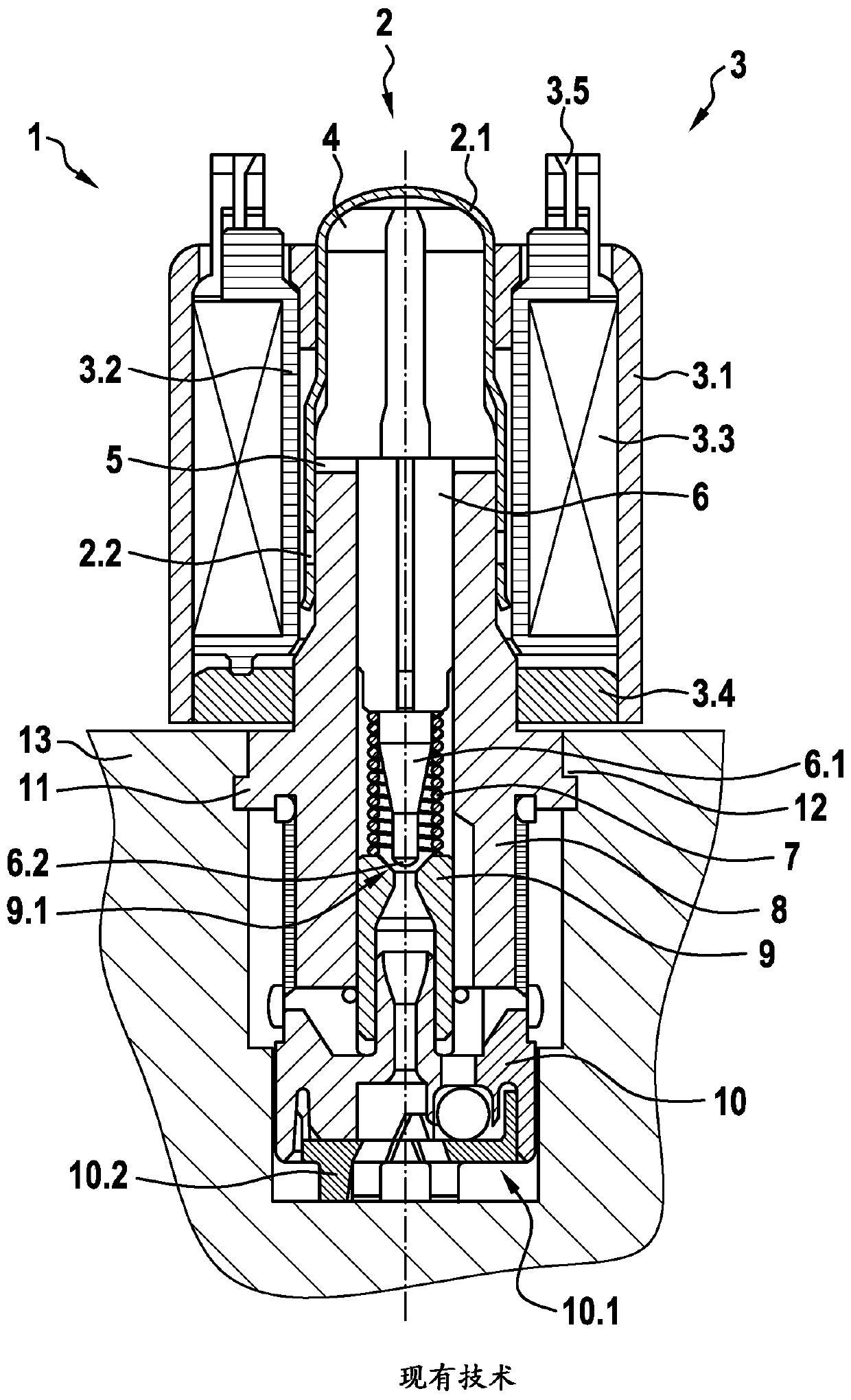

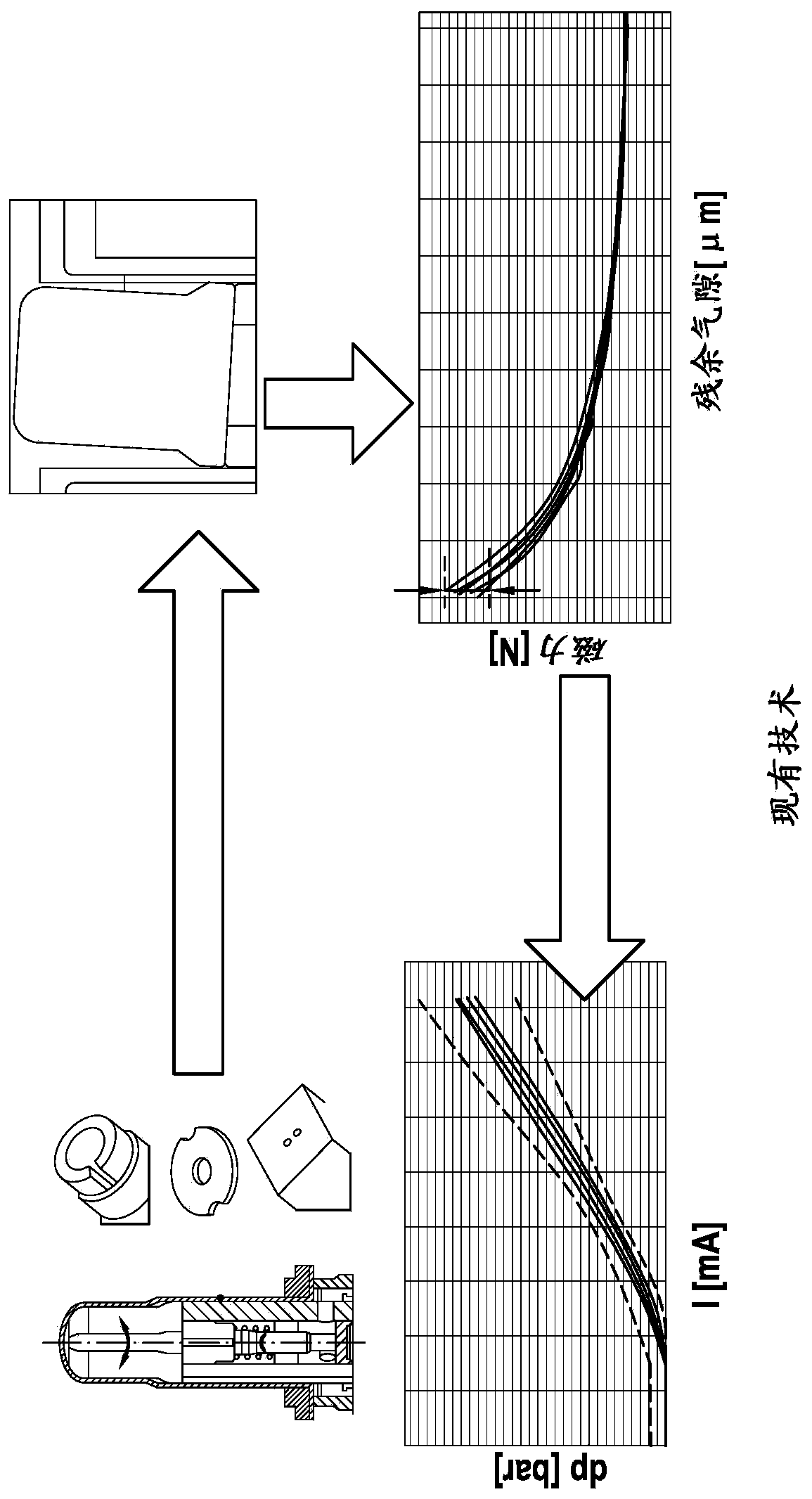

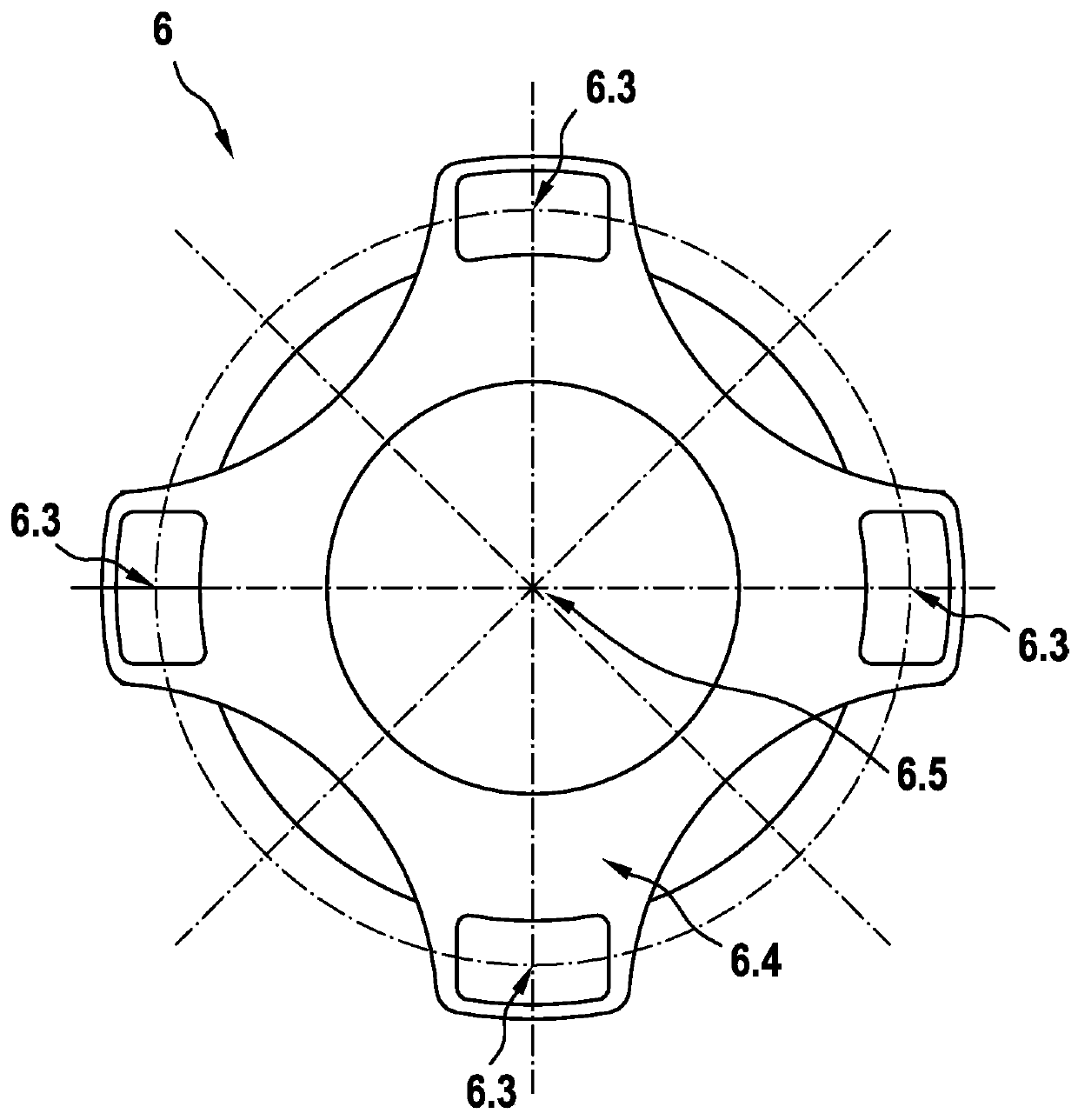

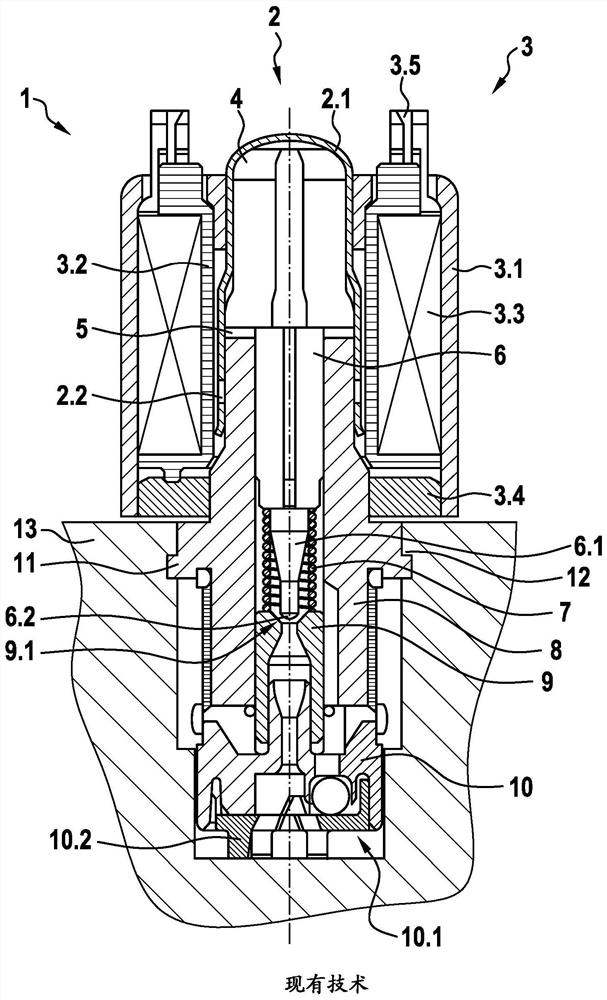

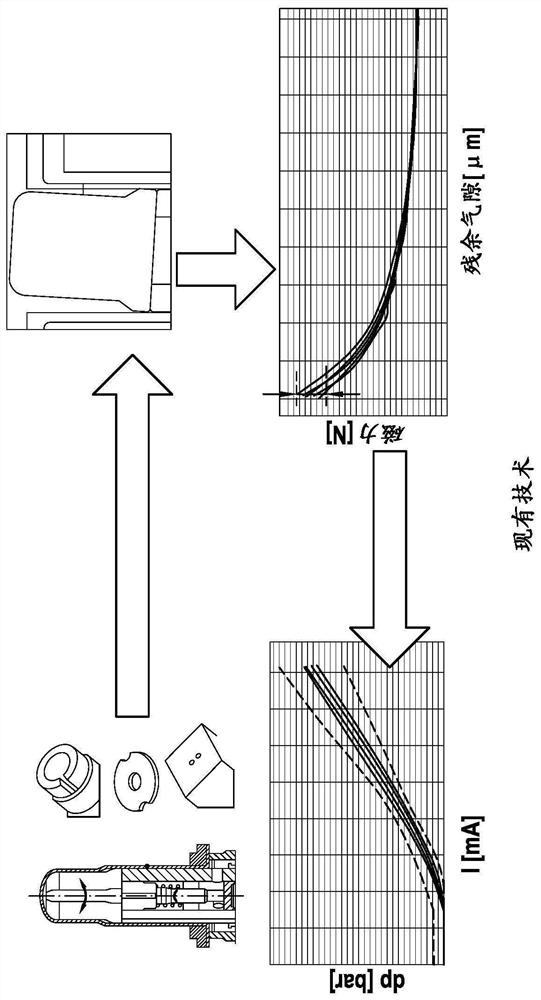

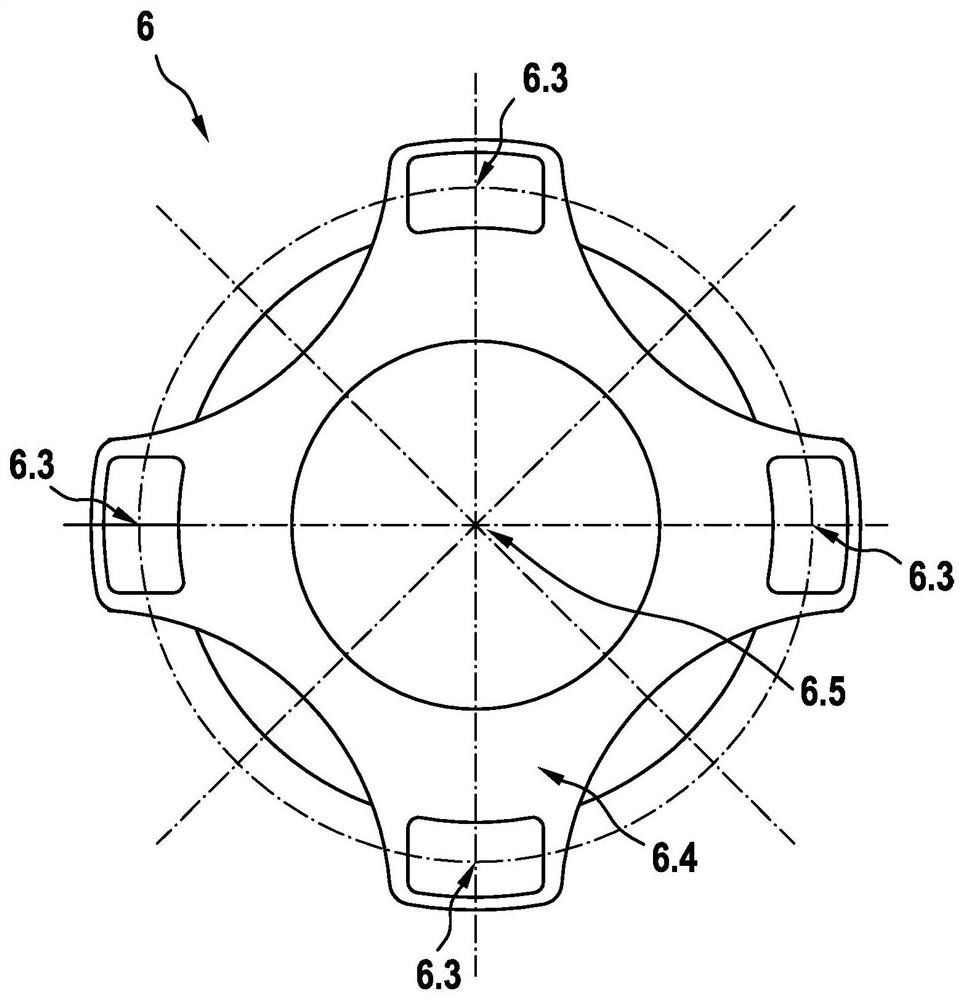

Electromagnetic relief valve for turbocharger

InactiveUS9453584B2Increase forceSimple structureOperating means/releasing devices for valvesCombustion enginesForce linesTurbocharger

An electromagnetic relief valve for turbocharger includes a valve body and an electromagnetic bonnet. The bottom of the valve body is provided with a static core, the periphery of the static core is provided with a magnetic conductive disc, the top of the magnetic conductive disc is provided with a coil holder, which is provided with a coil winding wrapped around the periphery of the static core. The top of the valve body is provided with a dynamic core corresponding to the static core, a compressed spring is provided between the dynamic core and the static core, and the exterior of the dynamic core is provided with a sliding bearing and the periphery of the dynamic core is provided with an integrated magnetic cover with a magnetic ring matched with the magnetic conductive disc. The relief valve actuates and forms a more uniform magnetic force line.

Owner:WANG YAOTING

Swing hinge apparatus of cellular phone

InactiveUS20100205773A1Increased durabilityReduce frictionSubstation equipmentHingesEngineeringCellular telephone

Owner:DIABCELL

Sewage treatment device provided with magnetically strengthened MBR (membrane bioreactor) and sewage treatment method of sewage treatment device

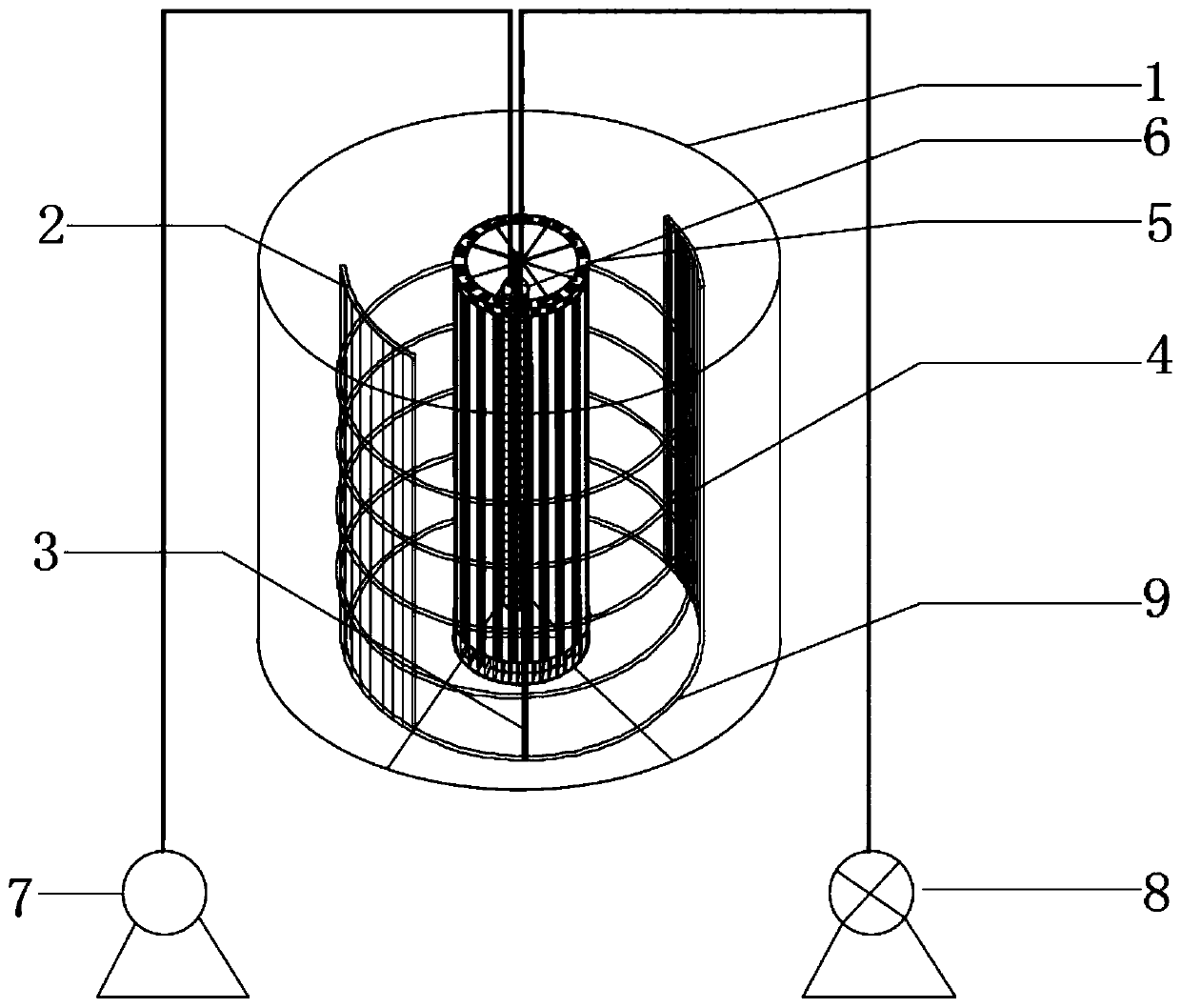

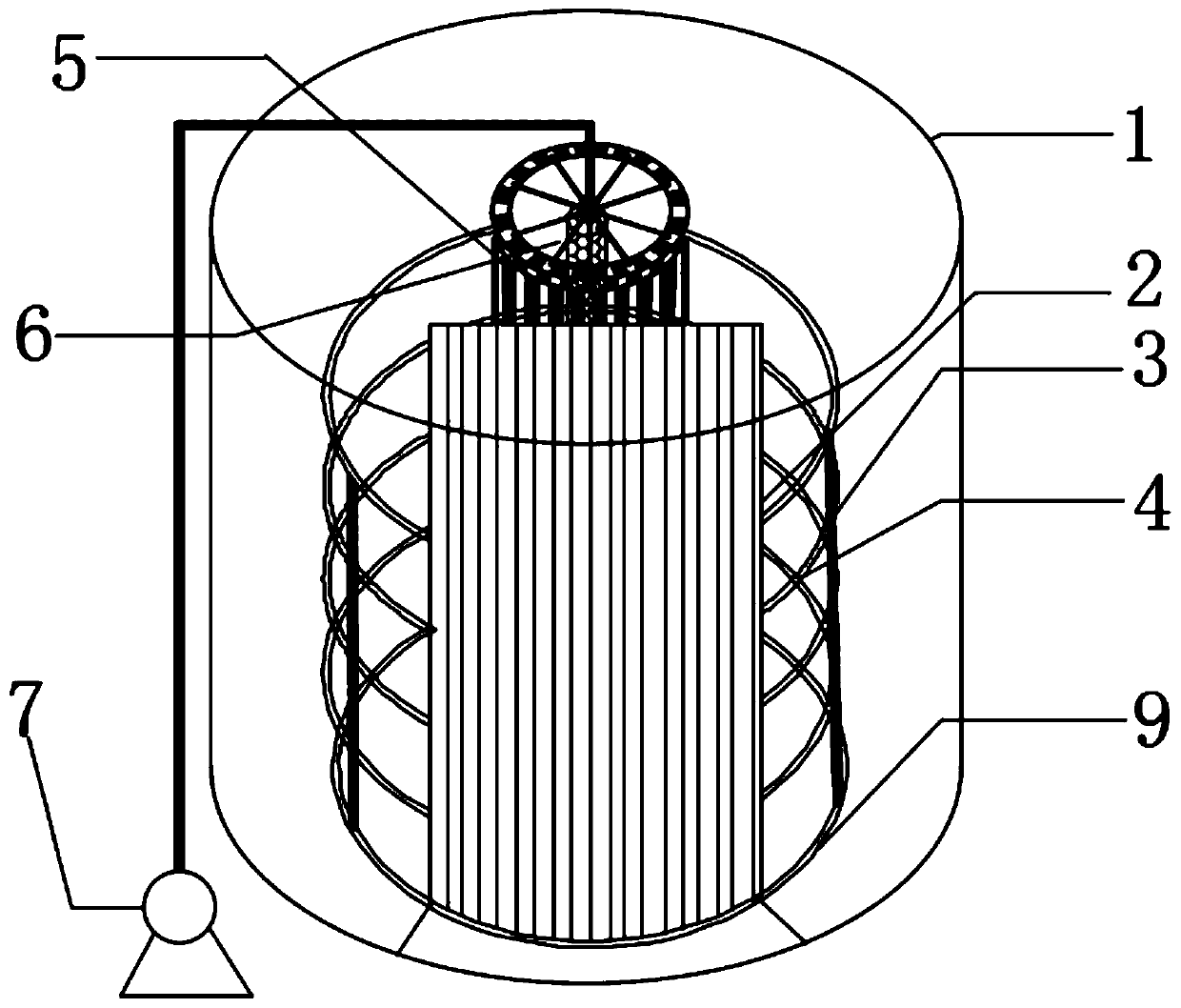

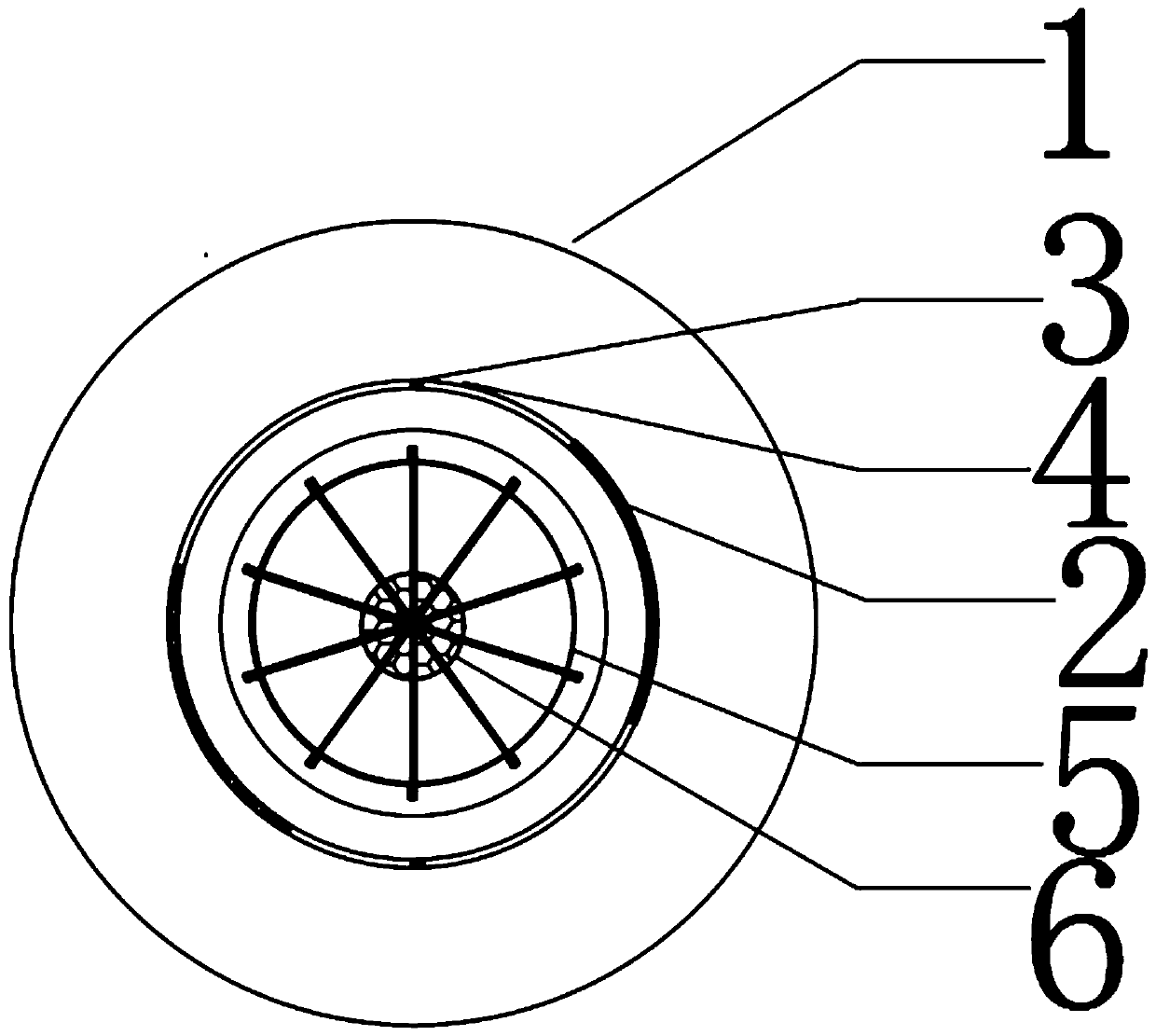

PendingCN109912017AHigh activityReduce difficultyWater/sewage treatment by magnetic/electric fieldsSustainable biological treatmentMagnetEngineering

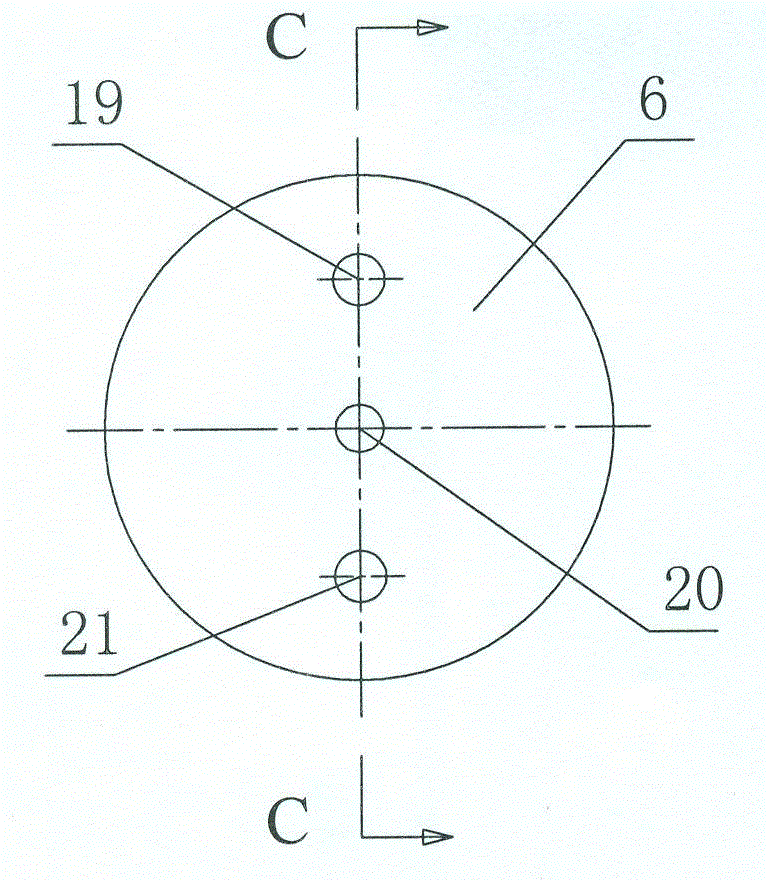

A sewage treatment device provided with a magnetically strengthened MBR (membrane bioreactor) comprises a cylindrical casing provided with an upward opening, static magnets, magnetic coil props, magnetic coils, a cylindrical MBR membrane assembly, a scavenging conduit, an aeration pump and a suction pump, wherein an accommodating cavity is formed in the cylindrical casing; the static magnets, themagnetic coil props, the magnetic coils, the cylindrical MBR membrane assembly and the scavenging conduit are arranged in the accommodating cavity; a ring-shaped clamp groove which is concave downwards is formed in the bottom of the accommodating cavity; at least two magnetic coil props are arranged and uniformly distributed on the ring-shaped clamp groove; the magnetic coils are clamped in bayonets of the magnetic coil props. The sewage treatment device has the advantages as follows: 1, by means of the magnetization effect of a magnetic field, a water molecule structure is changed, water molecular viscosity of sewage is reduced, water molecule activity is improved, difficulty of water molecules passing the MBR membrane is reduced, and membrane pollution is reduced; 2, with the adoption ofthe static magnets and the magnetic coils which can be increased or decreased, strength and direction of magnetic action on the sewage in the device are adjusted, and meanwhile, the magnetic coils can be taken as magnetic conductive rings, so that magnetic force loss is reduced and the magnetic field with uniform magnetic force is manufactured.

Owner:YANGTZE UNIVERSITY

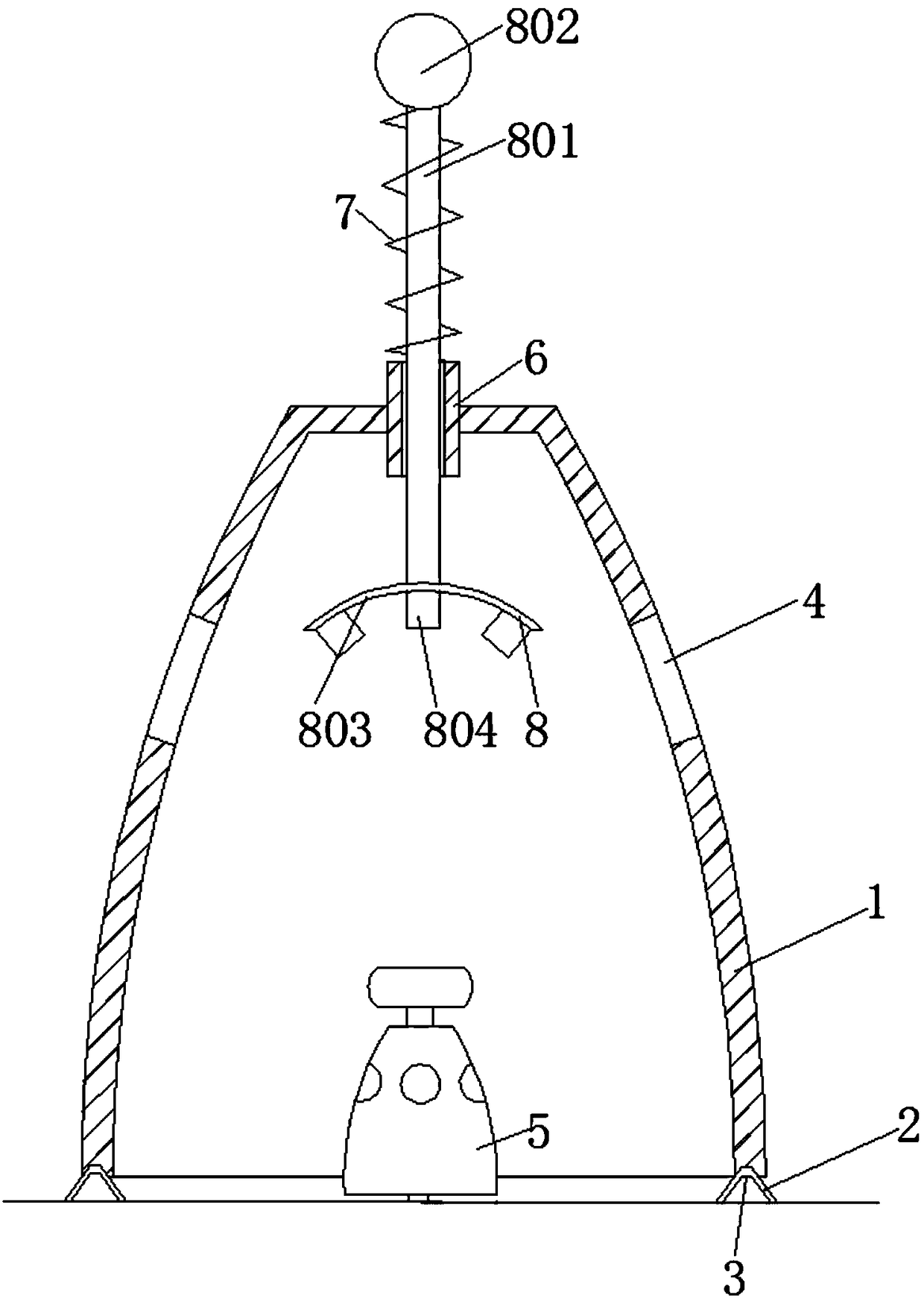

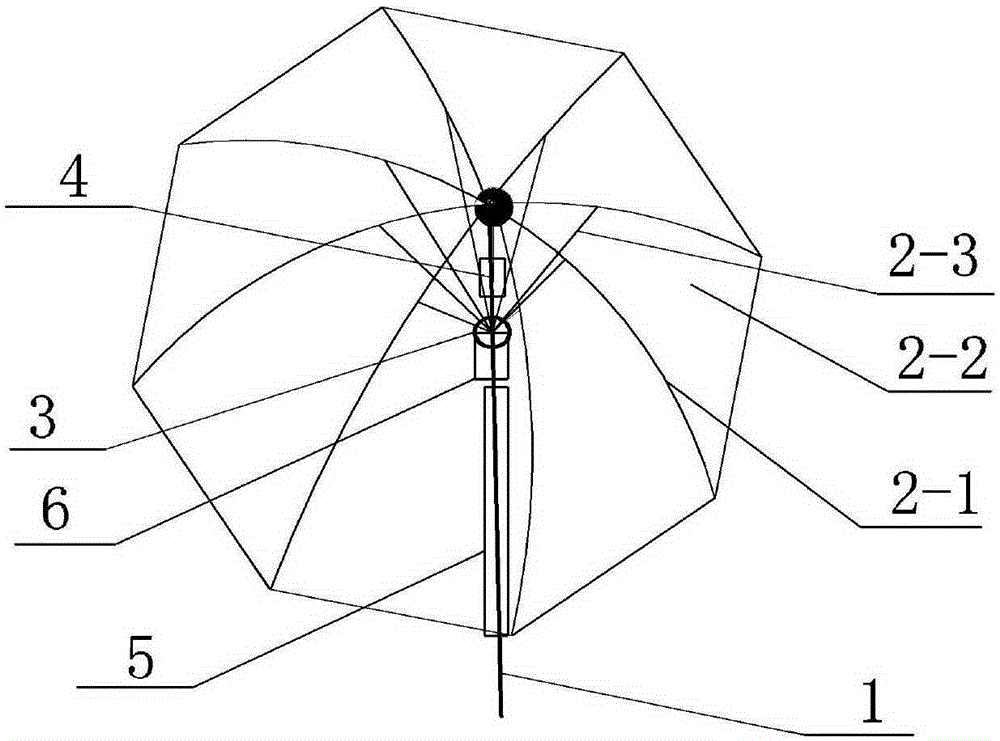

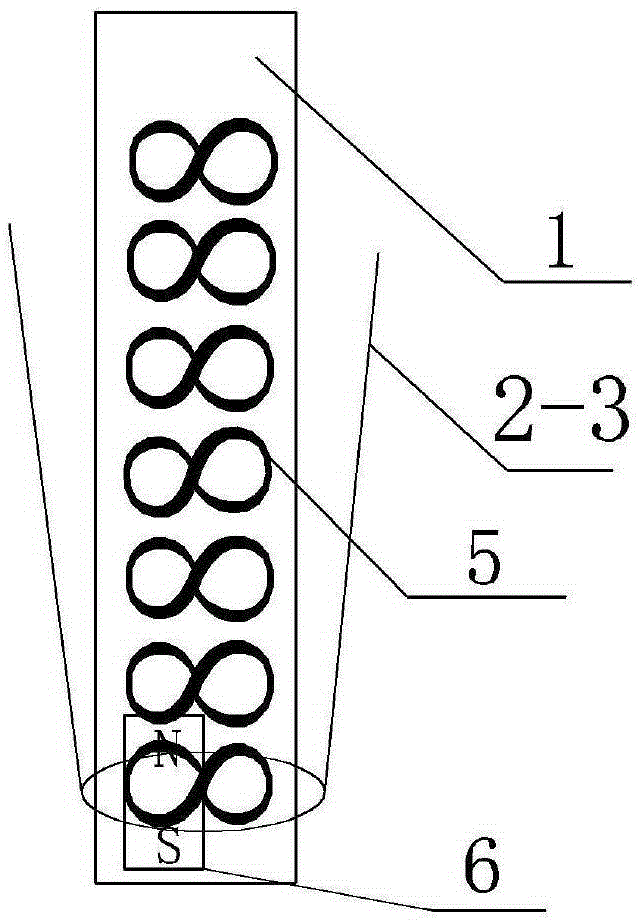

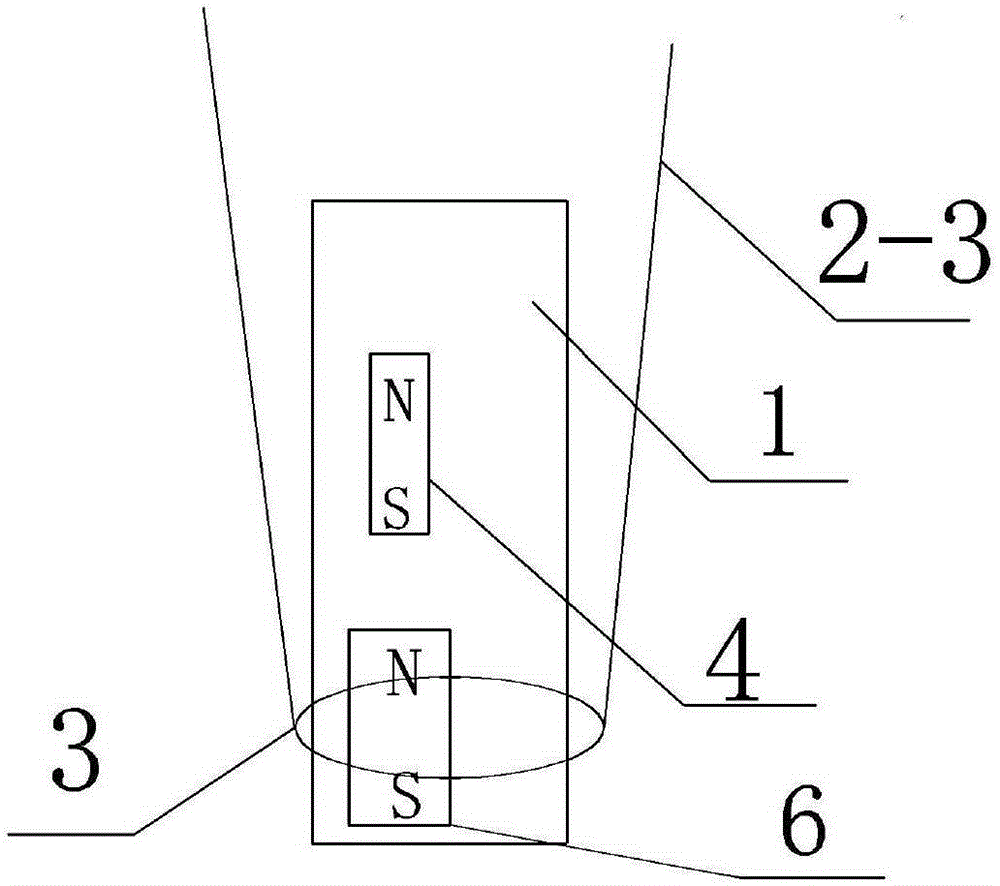

Magnetic suspension umbrella

InactiveCN105193040AAvoid deformationNot easy to damageWalking sticksUmbrellasMagnetic polesElectromagnetic induction

The invention discloses a magnetic suspension umbrella, and in particular discloses an umbrella using electromagnetic induction phenomenon and magnetism. The magnetic suspension umbrella comprises an umbrella pole and an umbrella rack arranged on the umbrella pole, wherein the umbrella rack consists of an umbrella spoke, an umbrella cover and a strutting spoke; the umbrella spoke supports the umbrella cover and is connected with the strutting spoke; the other end of the strutting spoke is in articulated connection with a sliding block which is supported in a longitudinal slippage manner on the umbrella pole; a magnet is inlaid in one end, close to one end of the umbrella cover, in the umbrella pole; an 8-shaped coil arranged longitudinally is fixed in the other end of the umbrella pole; a magnet is connected to the sliding block and can slide on the umbrella pole, and the movement track of the magnet during opening of the umbrella passes through the 8-shaped coil; and the magnetic poles of the two magnets are placed oppositely. The umbrella disclosed by the invention can be opened with a very small force due to the electromagnetic induction phenomenon, and because of the buffering of the magnetism of the magnets, the umbrella can be prevented from being damaged when wind and rain are heavy in a windy and rainy day, so that the service life of the umbrella is greatly prolonged.

Owner:GUANGXI UNIV

Electromagnetic Relief Valve for Turbocharger

InactiveUS20160215899A1Increasing magnetic areaSimple structureOperating means/releasing devices for valvesCombustion enginesMagnetic coreRelief valve

The invention provides a new electromagnetic relief valve for turbocharger, comprising a valve body and an electromagnetic bonnet. The bottom of the valve body is provided with a static core, the periphery of the static core is provided with a magnetic conductive disc, the top of the magnetic conductive disc is provided with a coil holder, which is provided with a coil winding wrapped around the periphery of the static core. The top of the valve body is provided with a dynamic core corresponding to the static core, a compressed spring is provided between the dynamic core and the static core, and the exterior of the dynamic core is provided with a sliding bearing and the periphery of the dynamic core is provided with an integrated magnetic cover with a magnetic ring matched with the magnetic conductive disc. The relief valve actuates and forms a more uniform magnetic force line.

Owner:WANG YAOTING

Solenoid valve for controlling the brake pressure of a wheel brake

ActiveCN109843667AImproved pressure regulation accuracyUniform magnetic forceOperating means/releasing devices for valvesABS control systemsSolenoid valveEngineering

The invention relates to a solenoid valve for controlling the brake pressure of a wheel brake of a slip-regulatable hydraulic brake system of a motor vehicle. The solenoid valve includes a valve element which is arranged at least partly in a valve insert in a longitudinally movable manner and interacts with a valve seat and which is acted upon by a force component acting in the opening direction with respect to the valve seat by means of a spring device in the assembled position and can be actuated by means of an electromagnetic actuator in the closing direction with respect to the valve seat.The valve element is arranged between an armature and the valve seat, and the valve element is equipped with a contact surface on which the valve element is operatively connected to the armature. Thesolenoid valve is characterized in that the contact surface is designed such that a non-rectangular intersection angle is formed between the central axis of the valve element and the contact surface.

Owner:ROBERT BOSCH GMBH

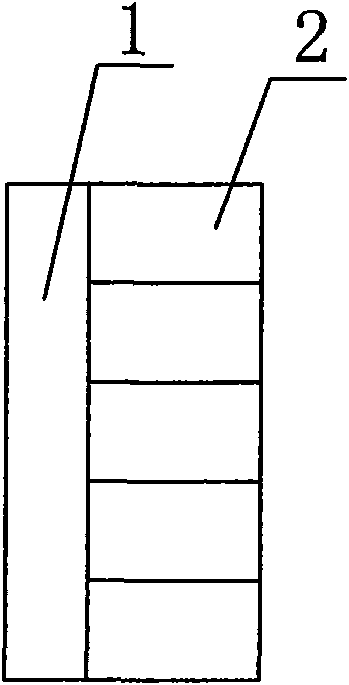

Tin dipped baseboard for glass sealed diode

InactiveCN102925840AMake sure the magnetic strengthUniform magnetic forceHot-dipping/immersion processesSemiconductor/solid-state device manufacturingBaseboardEngineering

The invention discloses a tin dipped baseboard for a glass sealed diode. The tin dipped baseboard is composed of a substrate, magnetic strips and a panel, wherein the substrate is a non-magnetic metal board and is provided with a plurality of parallel distributed slots; the magnetic strips are disposed in the slots; and the panel is a metal board having a good magnetic conductive performance, and covers and is fixed on the upper surface of a concave platform. The baseboard disclosed in the invention solves an extremely-severe economic loss problem of a production enterprise, and is a good substitute of baseboards in the prior art, wherein the problem is caused by of a tin dipped baseboard which is a plastic magnetic board, has the disadvantages of short service life, easy damage and unstable magnetic force and is used in the prior art.

Owner:GUANGDONG EDE SEMICON

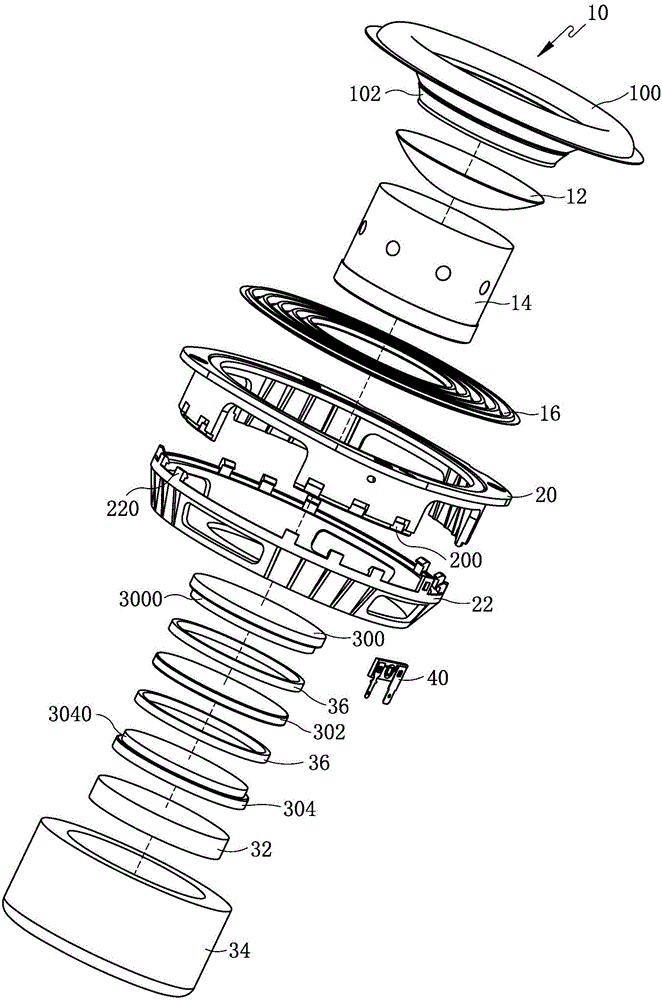

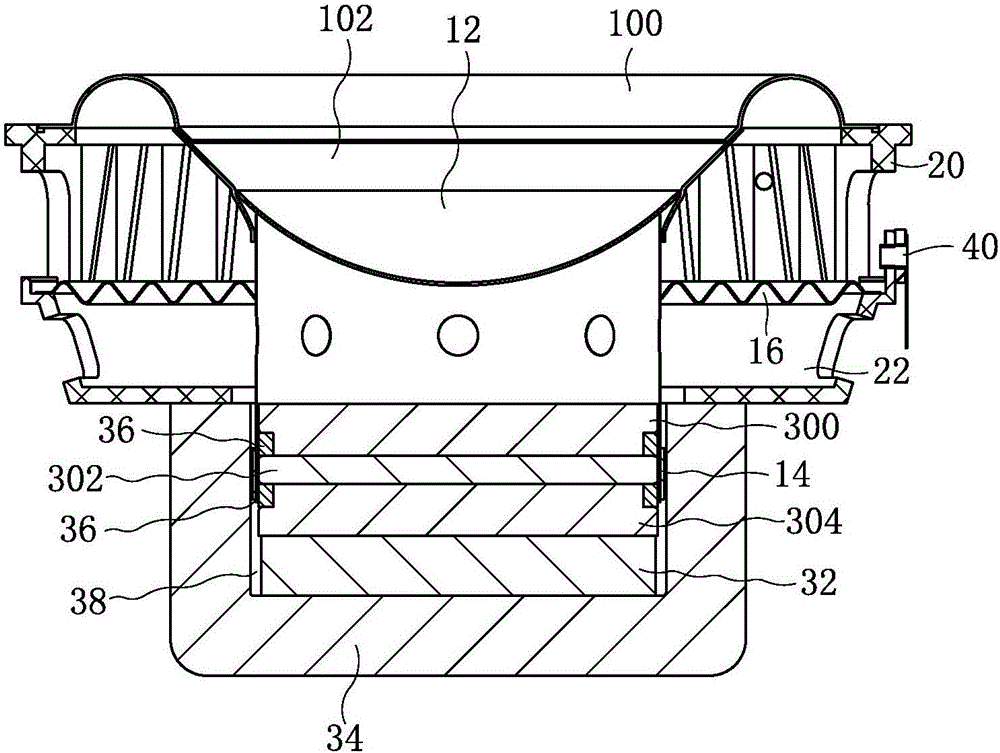

Loudspeaker

InactiveCN106028240AReduce low frequency distortionImprove acoustic performanceElectrical transducersLoudspeakersWooferLinearity

The invention discloses a loudspeaker, and relates to the technical field of an electroacoustic product. The loudspeaker comprises a basin frame, and a vibration system and a magnetic circuit system which are fixed on the basin frame. The magnetic circuit system comprises a magnetic conductive component, and a magnet and washers which are fixed on the magnetic conductive component in sequence. Magnetic gaps are formed between the magnetic conductive component, and the magnet and the washers. Grooves are arranged at locations on the washers corresponding to the magnetic gaps. The grooves are closed circular grooves which stretch along the peripheries of the washers. According to the loudspeaker provided by the invention, the technical problem that in the prior art, the distortion of a bass loudspeaker is high under a high power is solved. According to the loudspeaker, the magnetic fields are distributed evenly; the linearity of a BL is high; the distortion is low; the acoustic performance is high; moreover, the production difficulty is low; and the production efficiency is high.

Owner:GOERTEK INC

Novel planar cathode for vacuum magnetron sputtering

InactiveCN108728811AImprove cooling effectEasy to adjustVacuum evaporation coatingSputtering coatingSputteringAir pump

The invention discloses a novel planar cathode for vacuum magnetron sputtering. The novel planar cathode includes a cathode shield, a protective pedestal is disposed at the middle part inside the cathode shield, the lower surface of the cathode shield is in bolted connection with a copper backboard, fixed magnets and electromagnetic plates are evenly connected between the upper surface of the copper backboard and the protective pedestal, cooling liquid in a cooling liquid holding box can be extracted into a cooling pipeline through a water pump, the cooling pipeline can be used for heat dissipation of a target material and the inside of the cathode shield, after heat absorption, heat of the cooling liquid can be dissipated through a radiating pipe, also gas can be extracted into a condenser through an air pump, and a rheostat is employed to adjust the magnetic force of an electromagnetic plate. The novel planar cathode for vacuum magnetron sputtering provided by the invention has the characteristics of simple structure and convenient operation, not only enables more convenient device installation, but also achieves better cooling effect, and can adjust the magnetic force more conveniently.

Owner:镇江市德利克真空设备科技有限公司

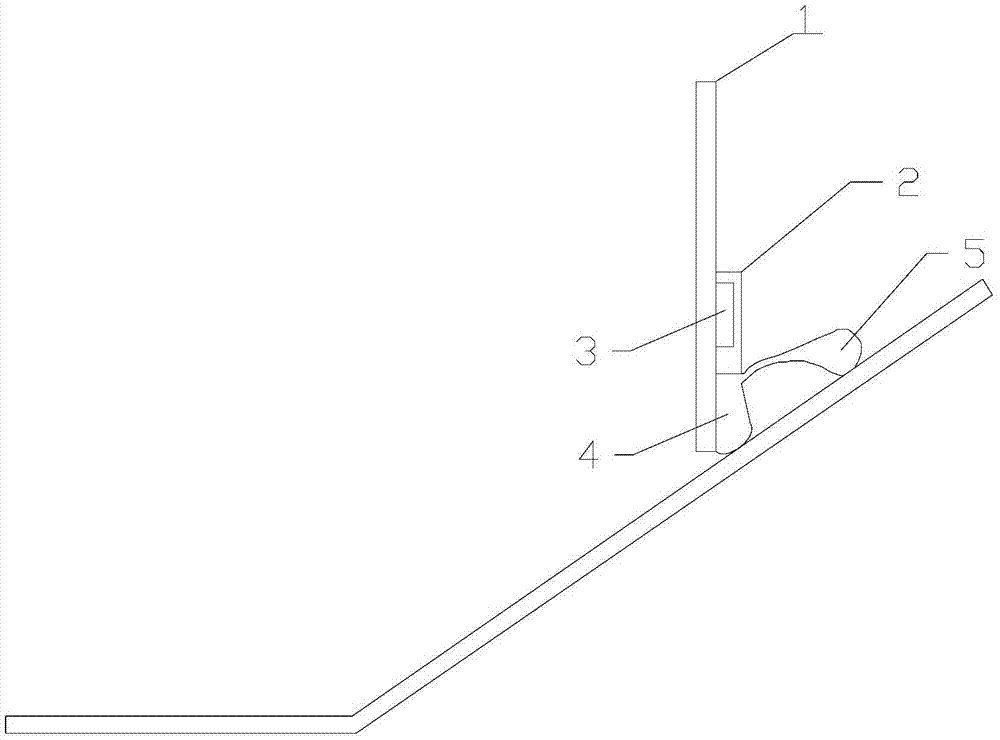

Magnetic fixing type anti-overflow skirt board mechanism

InactiveCN107200198ASimple structureEasy to install and disassembleConveyorsElectrical and Electronics engineeringLeather belt

The invention discloses a magnetic fixing type anti-overflow skirt board mechanism. The magnetic fixing type anti-overflow skirt board mechanism comprises a guide slot side plate and an anti-overflow skirt board, wherein the guide slot side plate is positioned above a conveyor belt; the anti-overflow skirt board is arranged on the guide slot side plate; and the lower end of the anti-overflow skirt board tightly fits to the conveyor belt. The magnetic fixing type anti-overflow skirt board mechanism is characterized by further comprising a magnetic body which is arranged on the anti-overflow skirt board, wherein magnetic force generated by the magnetic body is used for adsorbing the anti-overflow skirt board onto the guide slot side plate. According to the technical scheme adopted by the invention, the magnetic body is fixedly connected with the anti-overflow skirt board or is embedded into the anti-overflow skit board or the magnetic body is directly vulcanized into a rubber board of the anti-overflow skit board for being adsorbed and fixed through magnetic force; structures such as a bolt clamp does not need to be arranged on the guide slot side plate, so that the structure of the guide slot is simplified; and moreover, the mounting process and the dismounting process of the anti-overflow skit board are simple, and are high in efficiency.

Owner:MARTIN ENG KUNSHAN

Variable valve timing system

InactiveCN106837456AAvoid CatonAvoid setbacksValve arrangementsMachines/enginesVariable valve timingCamshaft

The invention provides a variable valve timing system, which comprises an electromagnet, a hydraulic valve and a camshaft adjuster, wherein the electromagnet comprises a valve core assembly, a substrate, a magnetic-isolating inner cover and an electromagnetic coil part which are coaxially arranged; the electromagnetic coil part comprises a skeleton and a coil; the skeleton sleeves the outside of the magnetic-isolating inner cover; the coil is wound on the skeleton; the valve core assembly and the substrate are arranged in the magnetic-isolating inner cover along the axial direction; the valve core assembly comprises a valve core and a post rod connected to the valve core; a conical part with an outer conical surface is arranged at one end, close to the valve core, of the substrate, and an accommodating part for accommodating the valve core is arranged at the end; a guide through hole is also arranged in the axis of the substrate; and the post rod is arranged in the guide through hole in a sliding manner. The variable valve timing system provided by the invention is stable in operation and high in reliability.

Owner:JIANGSU HAILONG ELECTRICAL APPLIANCE

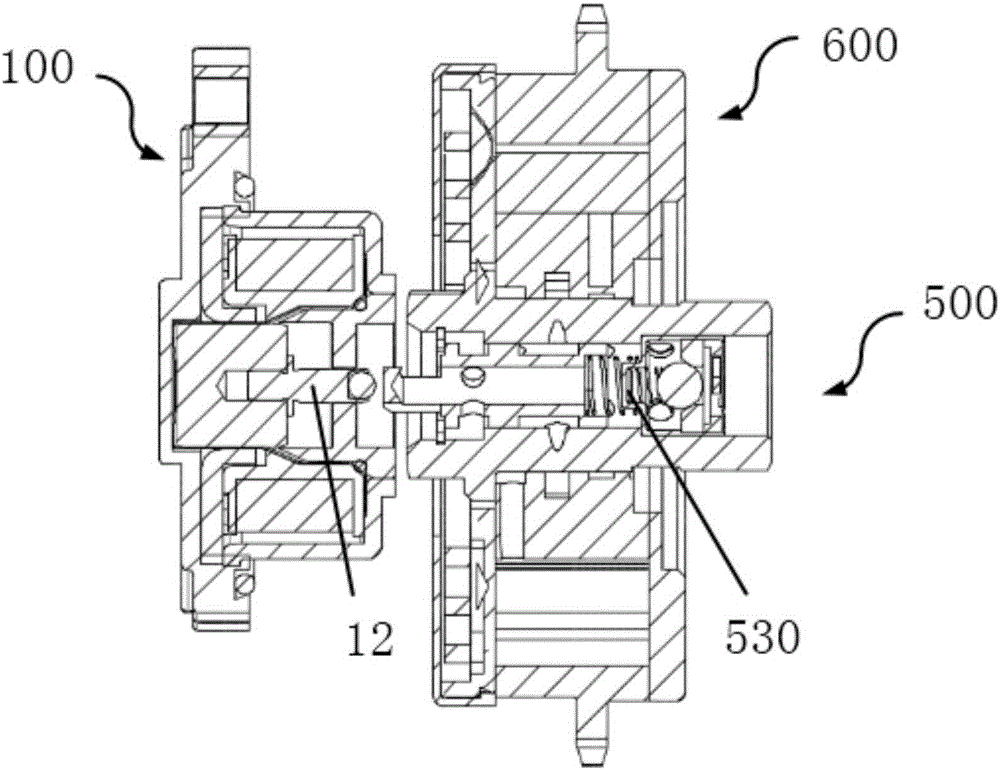

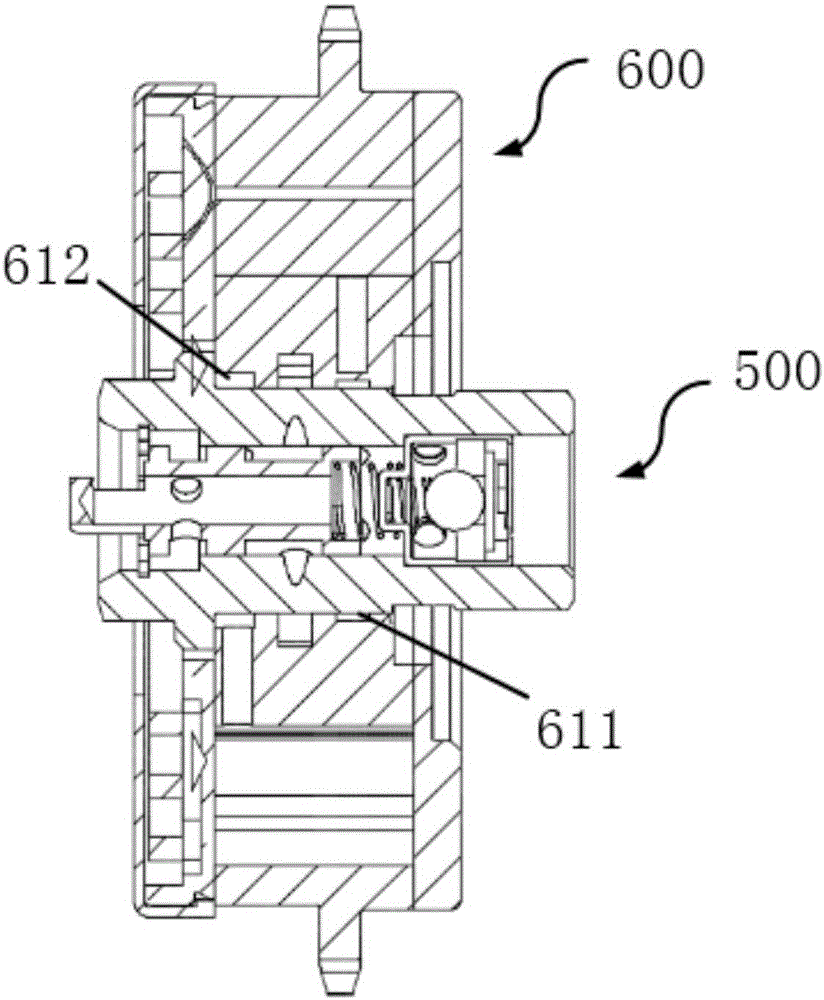

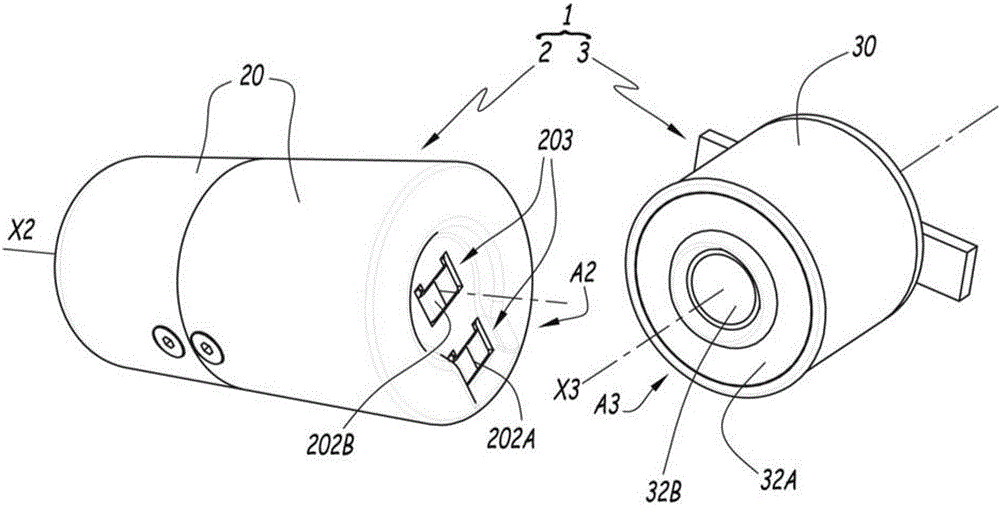

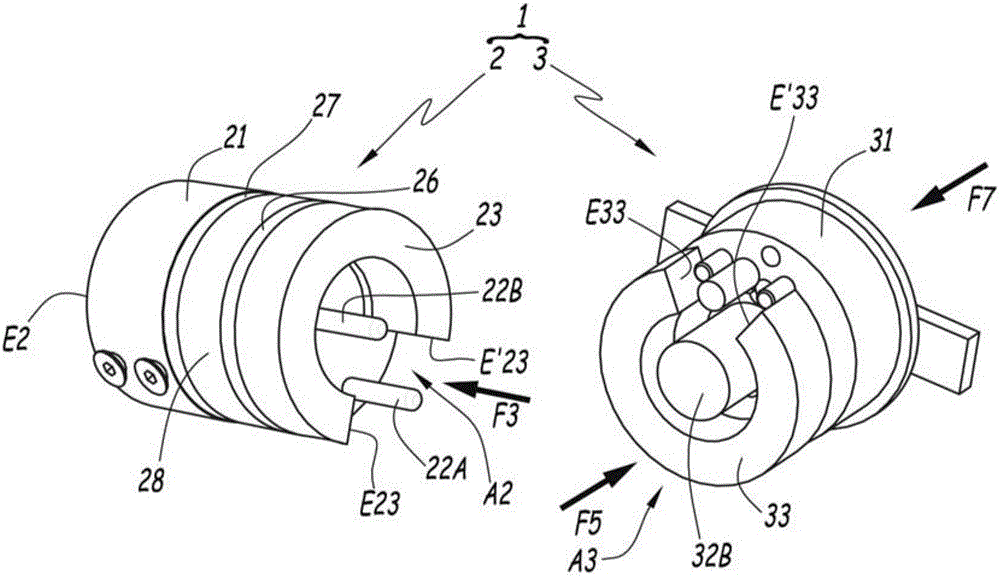

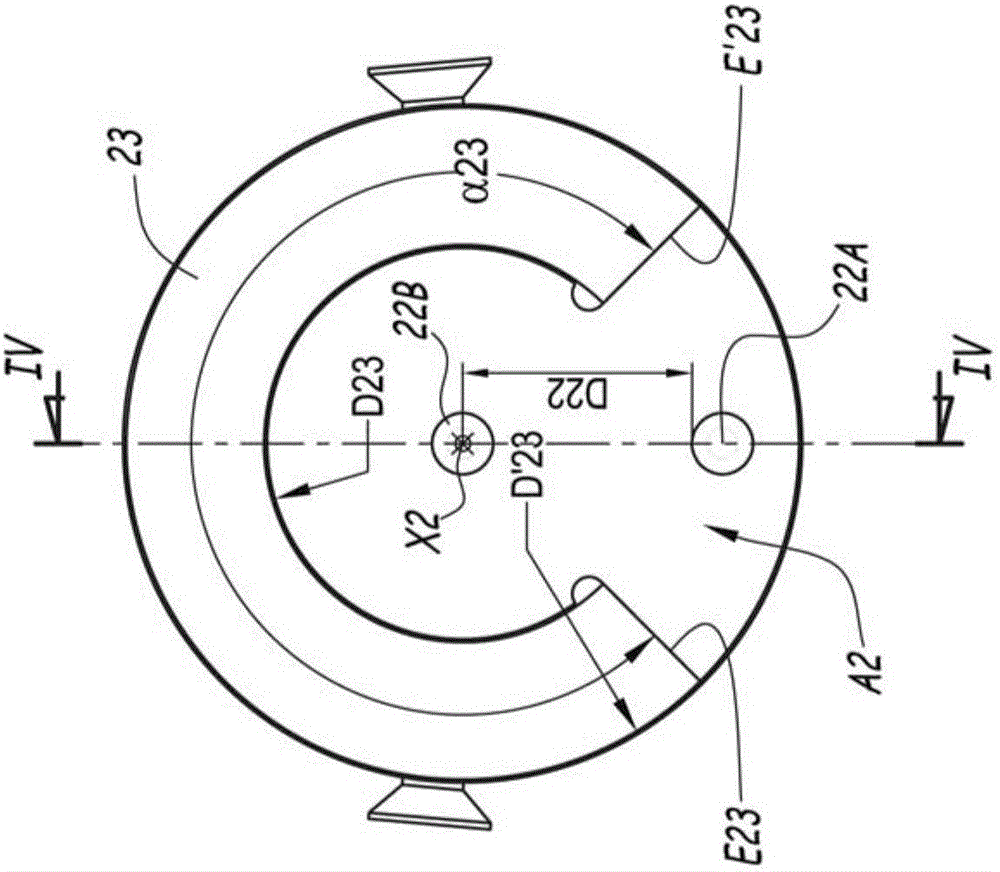

Electric connector set

ActiveCN105684229ASmall sizeSave materialEngagement/disengagement of coupling partsPermanent magnetsMagnetic tension forceElectricity

The invention relates to an electric power outlet unit (1) which comprises an electric junction socket (2) and an electric plug (3) which is suitable for detachably connecting with the socket (2) electrically. The socket (2) comprises at least one first contact and a second contact (22A,22B). The contacts respectively have a first concentric contact and a second concentric tracks (32A,32B) of the plug (3). The contacts (22A,22B) are movable between a first position where the contacts are retracted to inside of the socket (2) and a second position where the contacts are projected from the socket (2). The socket (2) is provided with a first magnetic element (23) which is suitable for connecting with a second magnetic element (33) which is mounted on the plug (3), thereby generating a magnetic force. The magnetic force is suitable for positioning and keeping the plug relative to the socket (2) and is used for moving the contacts (22A,22B) to the second position, thereby establishing electric contact between an electric track (32B) and the contacts (22A,22B). The first magnetic element (23) has an annular shape and furthermore the first electric track is made a material which is suitable for guiding the magnetic field that is generated by the magnetic elements (23,33) in a process of connecting the plug (3) with the socket (2).

Owner:SCHNEIDER ELECTRIC IND SAS

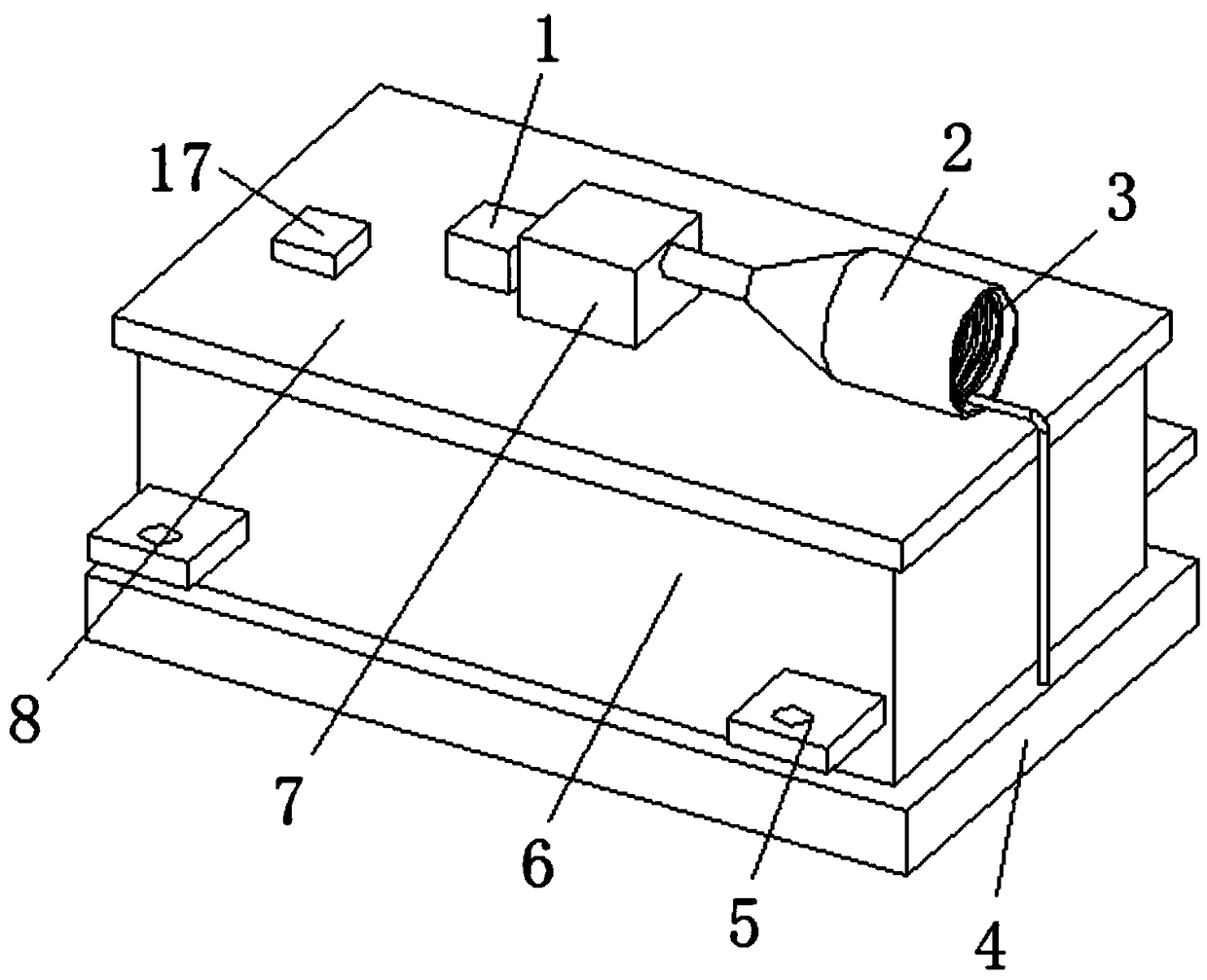

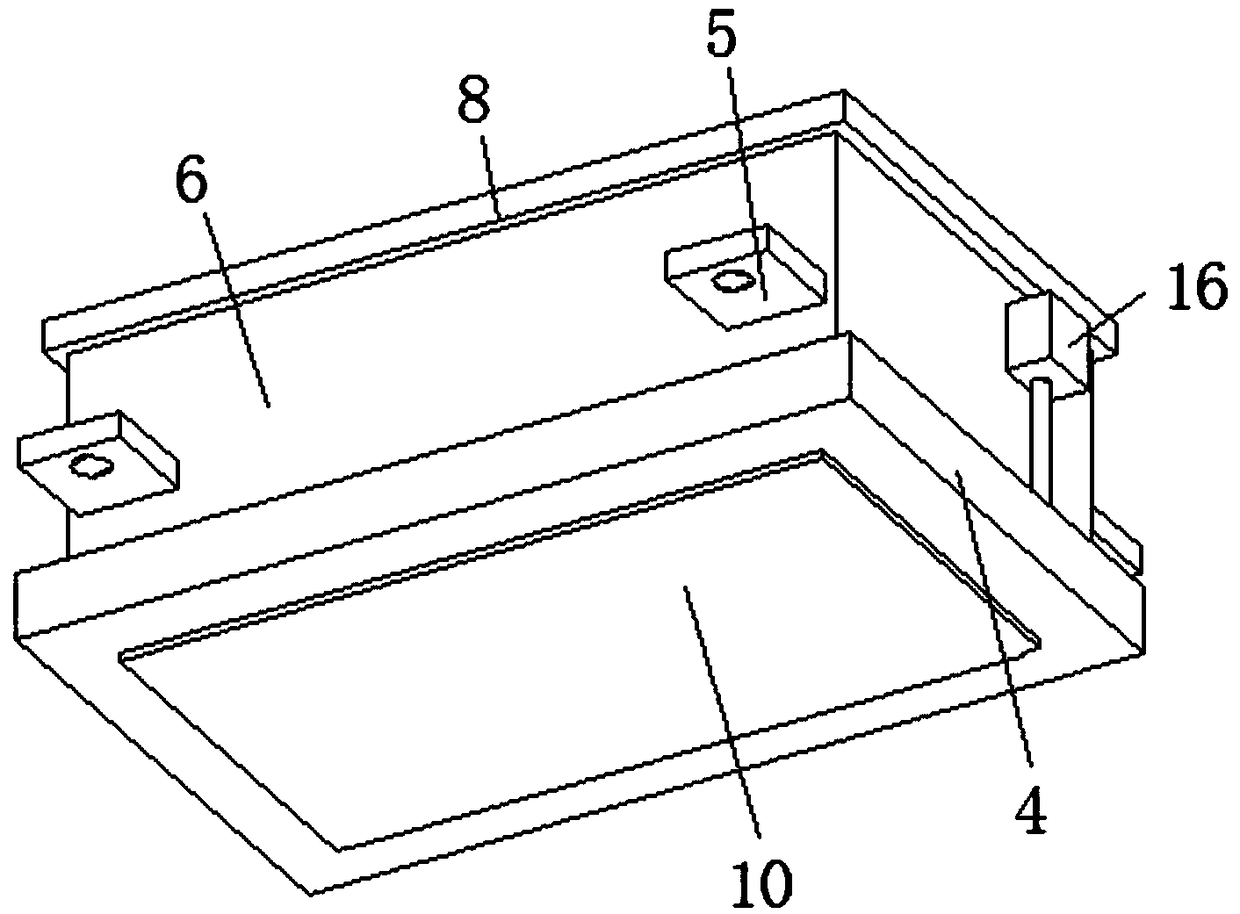

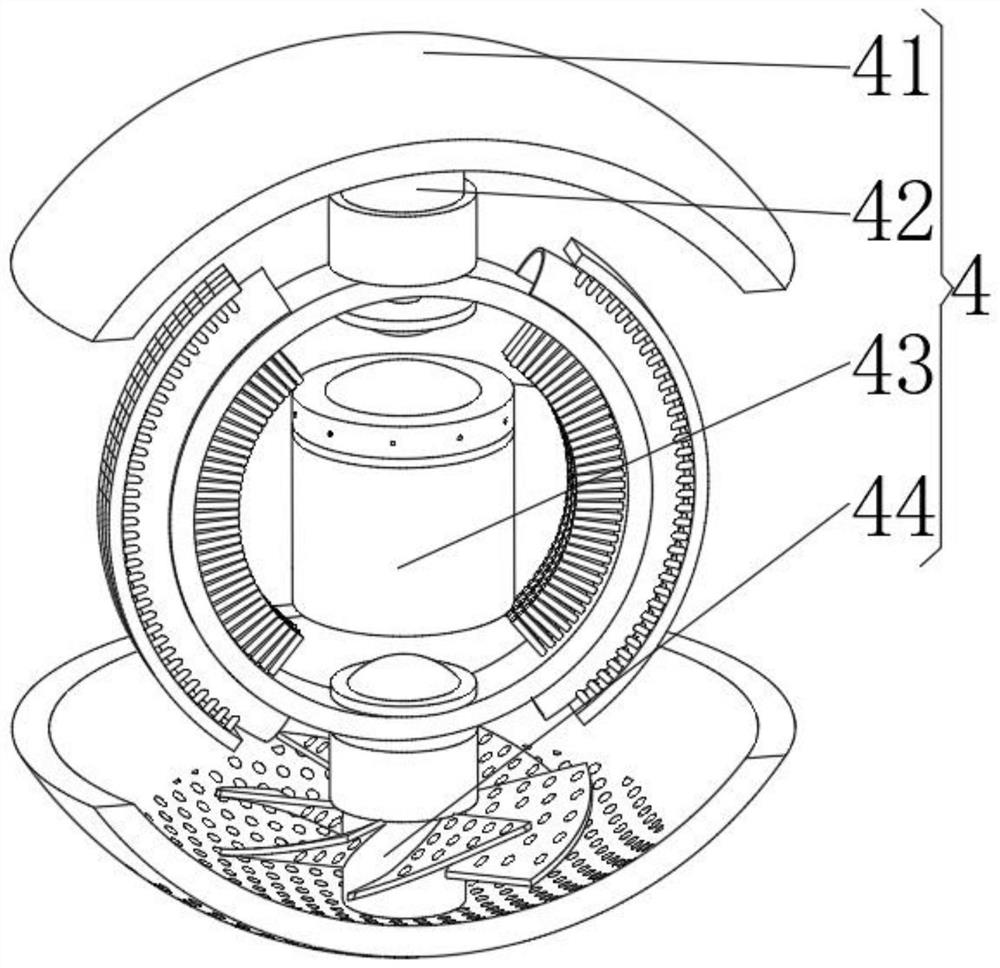

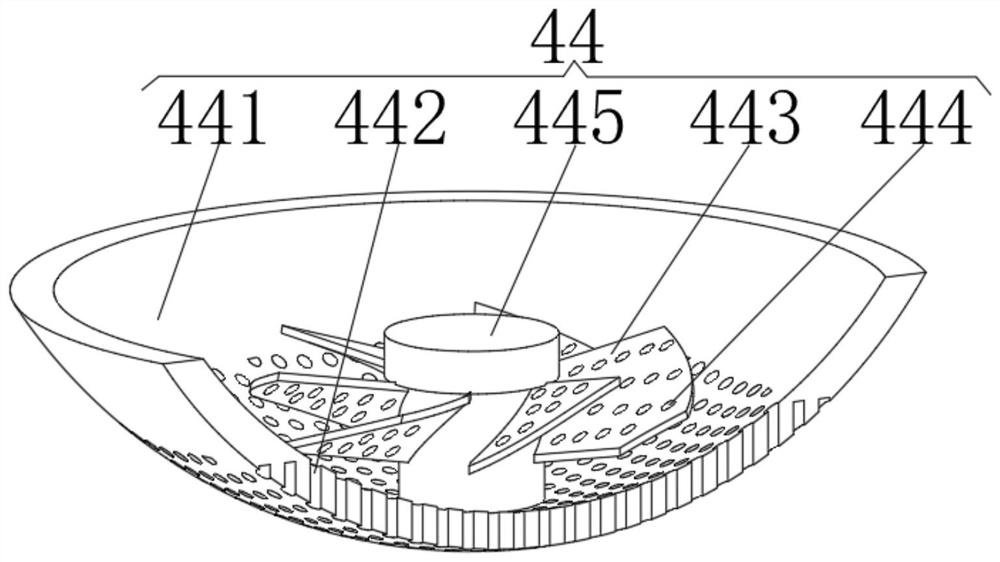

Intelligent overflow waste recovery device for injection mold

InactiveCN113199702AAvoid stickingEnsure thoroughnessPlastic recyclingBlade plateEnvironmental engineering

The invention discloses an intelligent overflow waste recovery device for an injection mold. Specifically, the intelligent overflow waste recovery device comprises a waste recovery mechanism; the waste recovery mechanism comprises a top cover and a transmission mechanism, the top cover is provided with a spherical plate body, the transmission mechanism is mounted at the bottom of the recovery mechanism, the transmission mechanism comprises an isolation bottom plate and an airflow fan blade, and the isolation bottom plate is provided with a main plate body and filtering air holes formed in the surface of the main plate body; and the airflow fan blade is provided with an inclined blade plate, through holes formed in the surface of the inclined blade plate and a T-shaped rotating column installed on the inner surface of the inclined blade plate. The invention relates to the technical field of injection molds. Airflow is guided through the airflow fan blade and is gathered for flowing, overflowing waste is impacted, guided and slowed down through the radian of the airflow fan blade, splashing of the overflowing waste is avoided, meanwhile, gathering of the airflow is matched with the filtering air holes and the through holes, the overflowing waste is cut off and separated, subsequent collection and secondary processing are facilitated, and raw materials are economically utilized.

Owner:丁兵兵

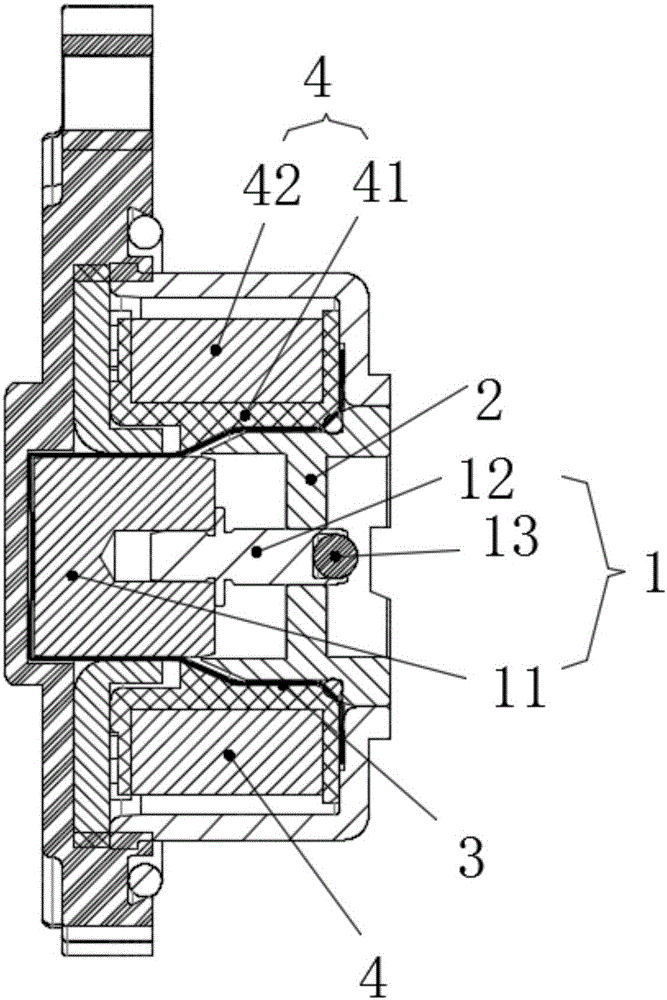

Electromagnetic mold clamping mechanism of injection molding machine

The invention provides an electromagnetic mold clamping mechanism of an injection molding machine, comprising a head plate, a secondary plate and an end plate which are sequentially arranged in parallel, wherein a magnetic plate is arranged between the secondary plate and the end plate; the magnetic plate is fixedly connected with the head plate through a pulling rod; a mold moving mechanism is arranged between the magnetic plate and the end plate; a mold adjusting column is arranged on the back of the secondary plate; the mold adjusting column is connected with a mold adjusting mechanism after penetrating through the central hole of the magnetic plate and the center of the end plate; the plane of the tail end of the magnetic plate is provided with the center hole, and is also equally provided with a plurality of magnetic poles in lines and rows; coils on the magnetic poles generate magnetic force after positively charging; the magnetic force tensions the end plate and the magnetic plate; and the coils on the magnetic poles do not generate the magnetic force to external parts after negatively charging. The mechanism has the advantages that: 1, the end plate can be equally absorbed on the magnetic plate; 2, the mechanism can strengthen the close attach between the magnetic plate and the end plate so as to ensure size and stability of mold clamping force; 3, the mechanism is energy-saving; 4, the mechanism is safe; and 5, the gap delta between the magnetic plate and the end plate is ensured.

Owner:NINGBO HAITIAN HUAYUAN MACHINERY

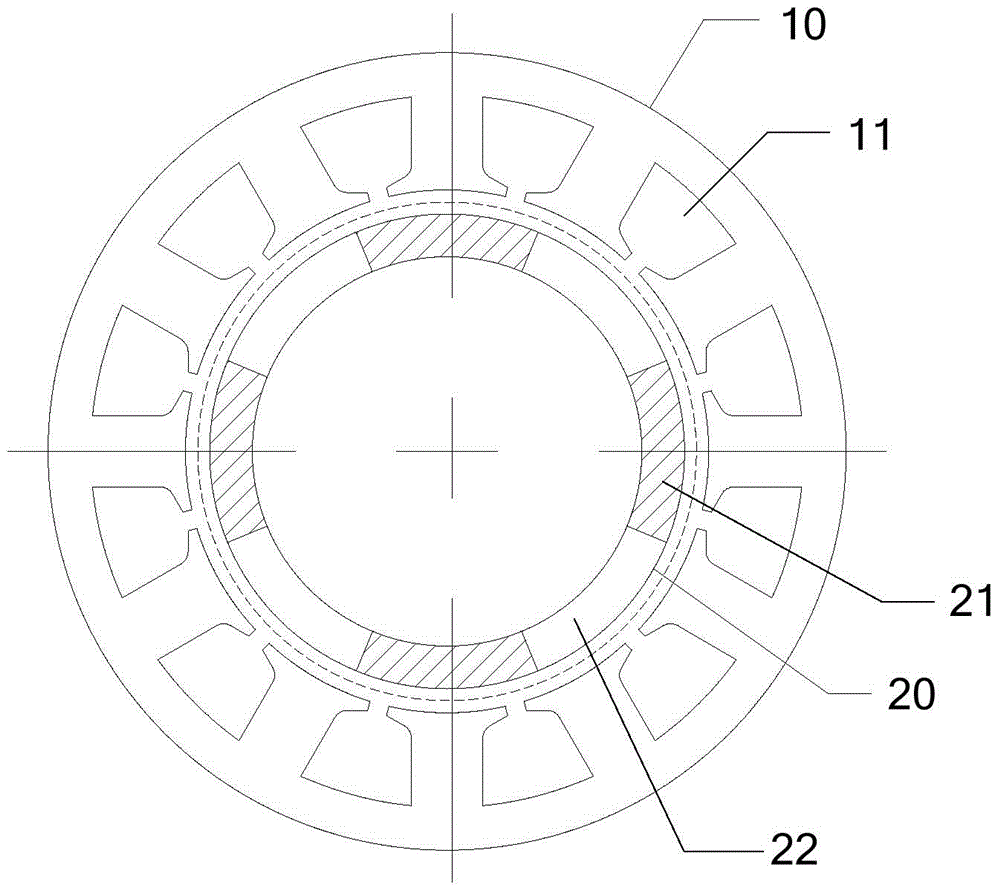

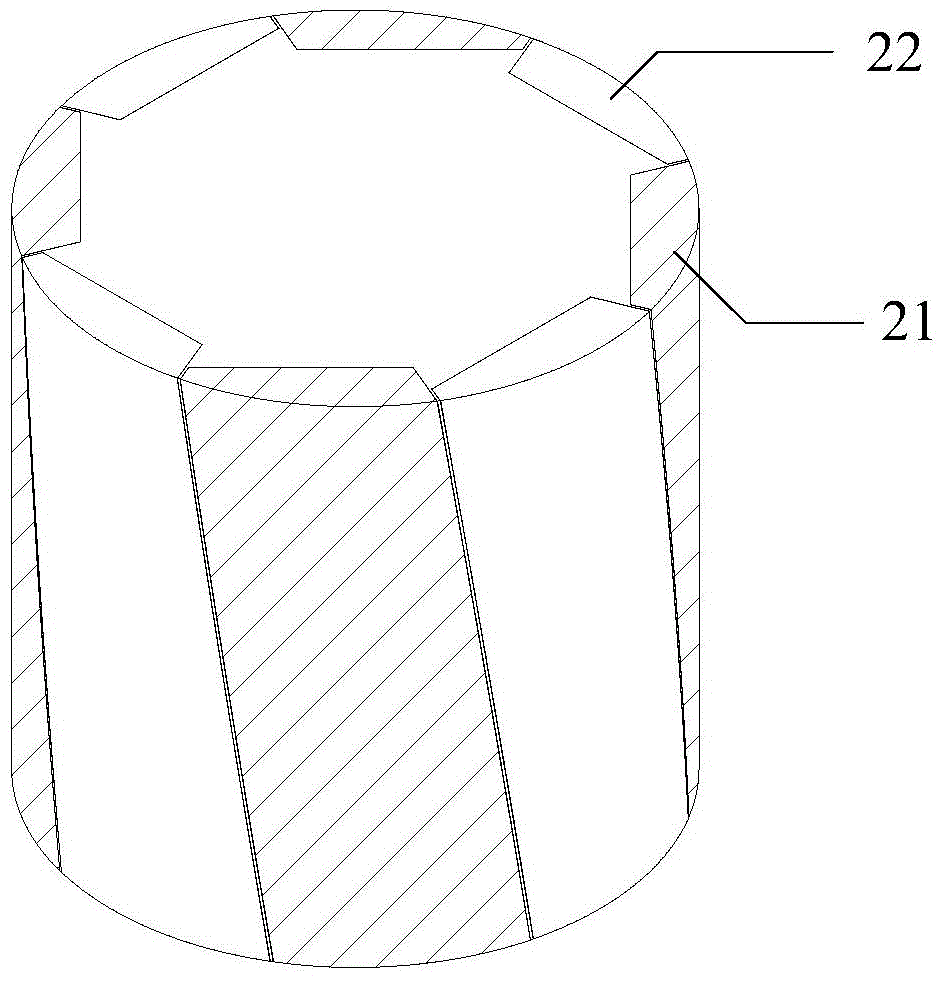

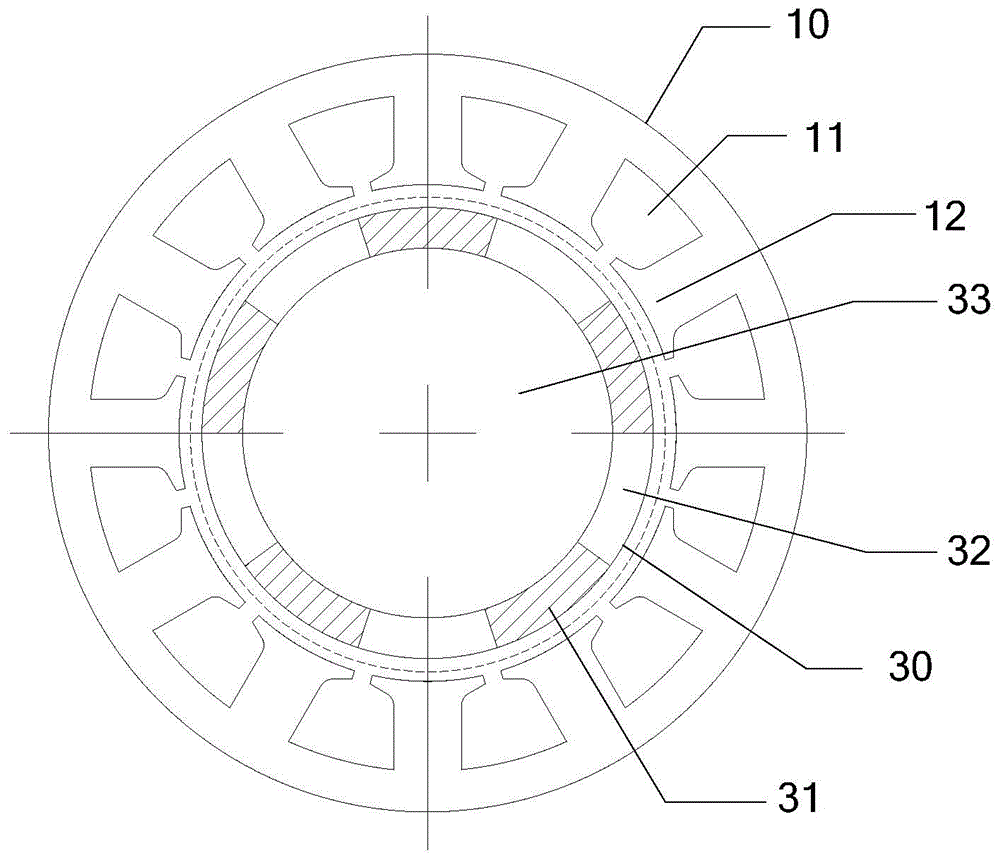

Permanent magnet synchronous motor

InactiveCN104578653AMeet the requirement of low cogging torqueUniform magnetic forceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsDistribution characteristicPermanent magnet synchronous motor

The invention provides a permanent magnet synchronous motor. The permanent magnet synchronous motor adopts a scheme of twelve slots and ten poles, wherein twelve-slot stators are arranged on the outer sides of ten-pole rotors; from the distribution characteristics of the twelve-slot stators and the ten-pole rotors, in the ten-pole rotors, the total quantities of the stator slots corresponding to permanent magnets with the outer rings as south pole and the stator slots corresponding to the permanent magnets with the outer rings as north pole are both six, so that the ten-pole rotors realize the situation that at any moment, the magnetic forces of the permanent magnets with the outer rings as the south pole and the permanent magnets with the outer rings as the north pole are basically identical, the magnetic force of the ten-pole rotor is distributed uniformly in the rotating process, and the cogging torque can be greatly reduced. Therefore, the twelve-slot ten-pole permanent magnet synchronous motor provided by the invention can greatly reduce the cogging torque, and meets the low cogging torque requirement on the permanent magnet synchronous motor in the actual application process under the situation that the production technology and the production cost are basically invariable.

Owner:大工科技(上海)有限公司

Hydrogen-oxygen mixed gas integrated generator

ActiveCN104294309BEven by forceUniform magnetic forceCellsChemical industryFlame arresterHigh energy

The invention provides an oxy-hydrogen mixed gas integrated generating device. The common problems of the existing oxy-hydrogen generators, such as high price, low gas yield, high energy consumption and incomplete safety setting, are solved. The invention has the technical main points that at least one closed electrolysed water generator is adopted, an oxy-hydrogen mixed gas dry and wet combined flame arrester of an identical structure is adopted, a hydrogen output and an oxygen output of the electrolysed water generator are respectively connected with gas inlets of hydrogen and oxygen liquid storing and gas filtering tanks, and an electrolyte circulating input and an electrolyte circulating output of the electrolysed water generator are connected with a heat exchanger and a heat radiator after being connected with an electrolyte circulating pump through filters. The oxy-hydrogen mixed gas integrated generating device is compact in structural arrangement and reasonable in design, has great pressure relief and explosion preventing properties and can effectively prevent oxy-hydrogen mixed gas backfire and explosion danger. Compared with the same class of products, the oxy-hydrogen mixed gas integrated generating device has the advantages of no gas leakage, no liquid leakage, no current leaking loss, energy conservation, safe and reliable use, high electrolysis efficiency, high gas yield, few heat losses and remarkable improvement on safe and continuous running efficiency.

Owner:刘枫

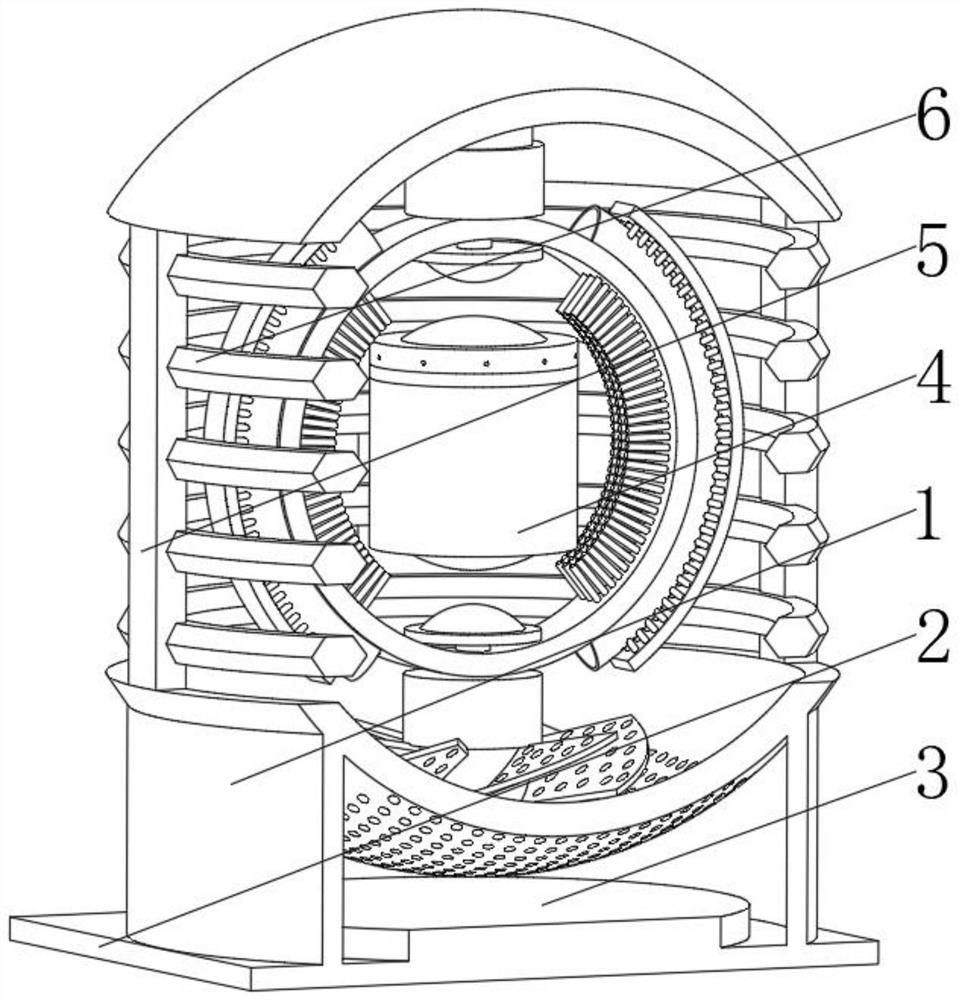

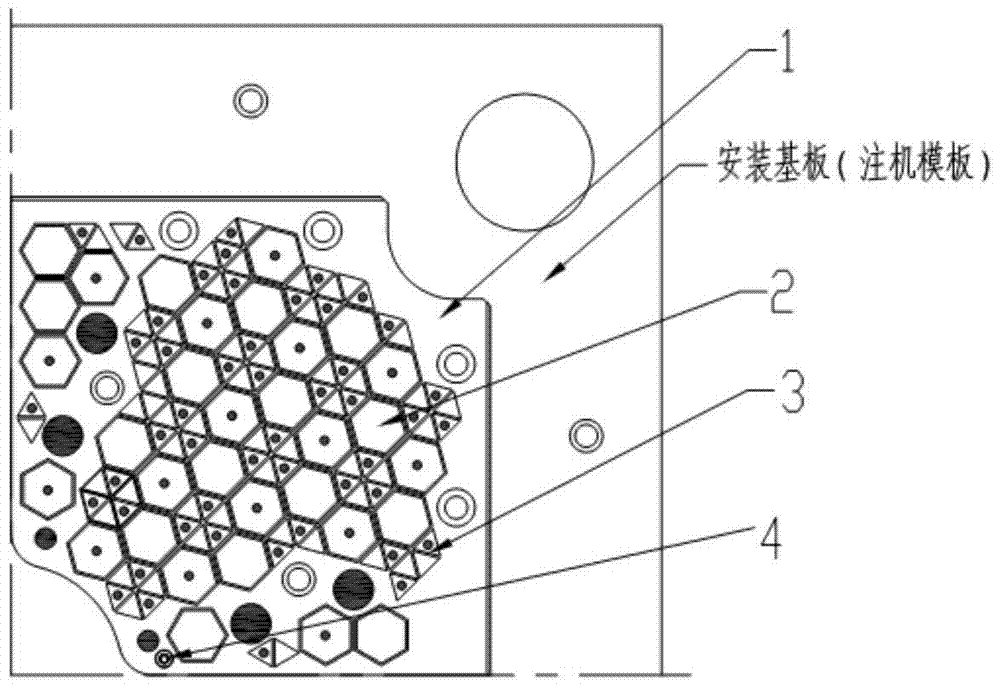

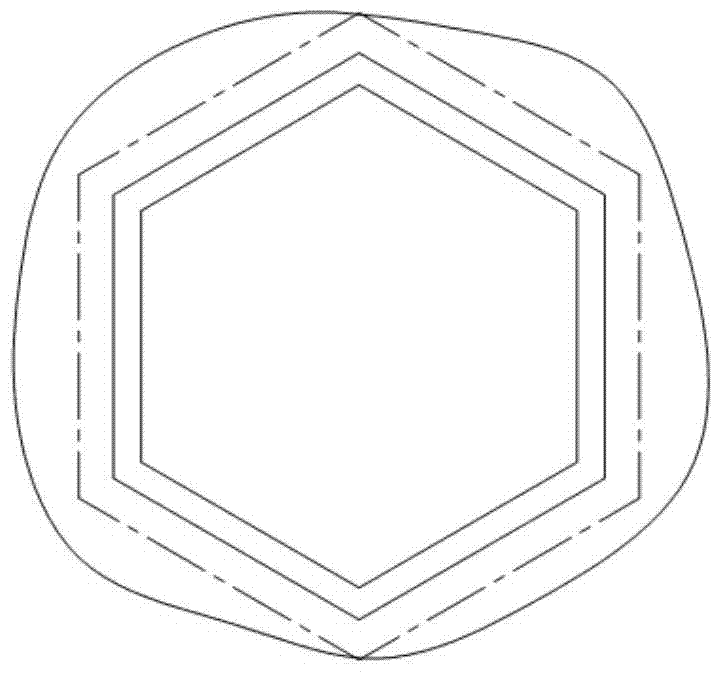

Honeycomb array structure mount type double-sided strong magnetic electric control permanent magnet template

The invention discloses an apiary array structure pasting type double-face strong-magnetism electric control permanent magnet template. The template is characterized in that first double-face strong-magnetism electric control permanent magnet systems (2) are each of an apiary unit structure and in a regular hexagon shape; second strong-magnetism electric control permanent magnet systems (3) are each of a rhombus structure, and every three rhombus units form one apiary unit structure in the regular hexagon shape; compounded reversible strong-magnetism permanent magnets (34) are formed by compounding reversible strong-magnetism permanent magnets (34a) and magnetic conductive materials (34b); the reversible strong-magnetism permanent magnets (34a) are coated with pulse coils (33); and the pole faces of the magnetic conductive materials (34b) are tightly attached to the inner pole faces of magnetic conductive base bodies (31). By the adoption of the template, space can be effectively used to the maximum degree, so that the effective attraction of the electric control permanent magnet template in the unit area is improved.

Owner:HUNAN QIANHAO ELECTRICAL & MECHANICAL TECH DEV

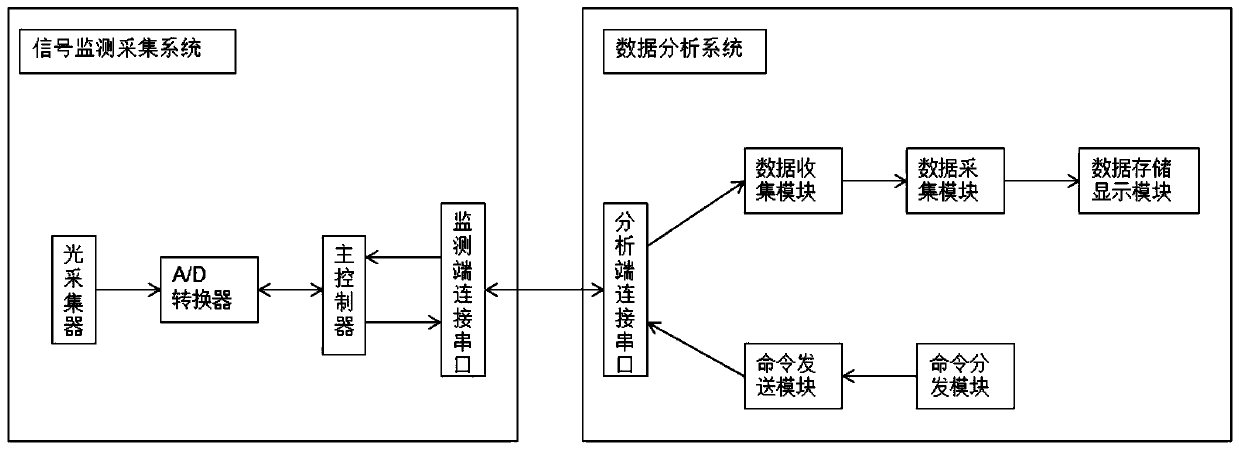

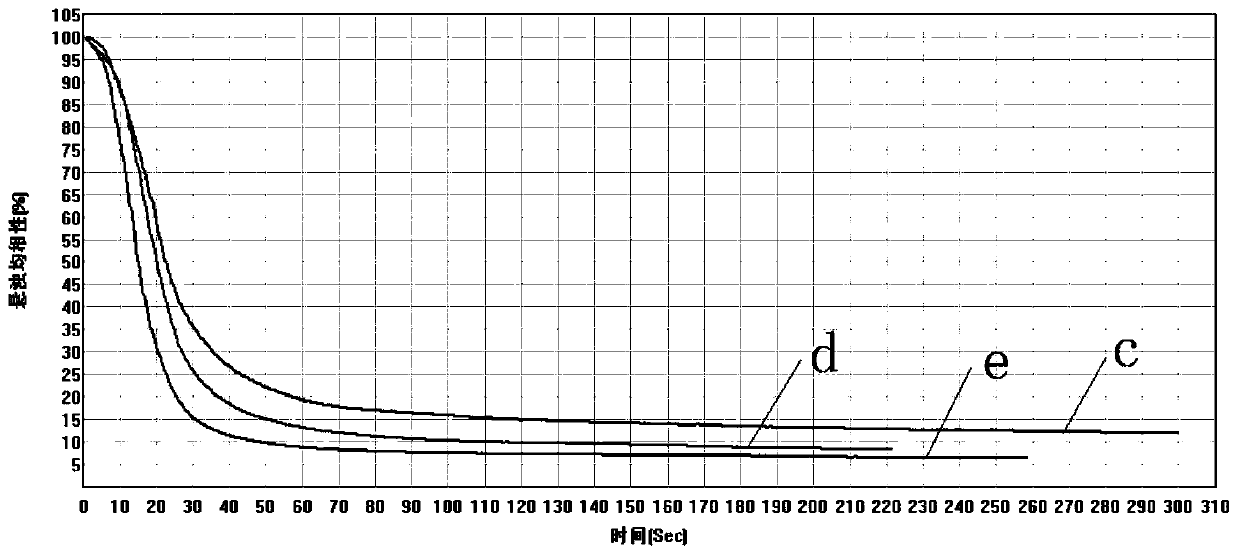

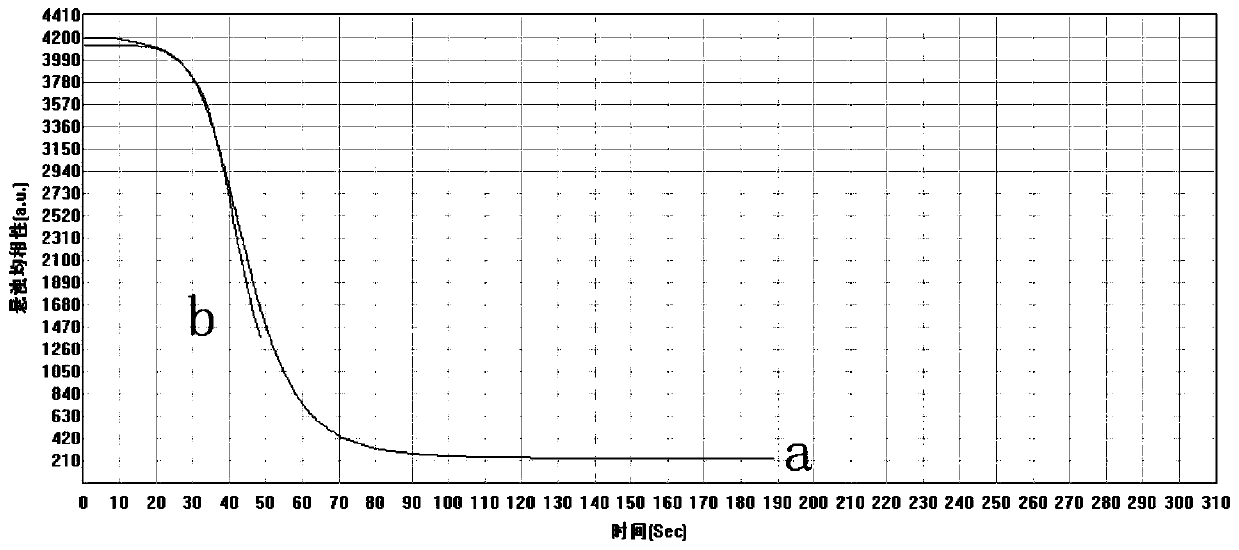

A visual magnetic separation method

ActiveCN108262157BInhibition of agglomerationUniform magnetic forceMagnetic separationCondensed matter physicsMaterials science

The invention belongs to the technical field of magnetic separation, and particularly relates to a visual magnetic separation method. The visual magnetic separation method can monitor of the permeability of a suspension according to the permeability change of the suspension, caused by magnetic separation, in real time in order to indirectly monitor the magnetic separation degree.

Owner:南京仁迈生物科技有限公司

Solenoid valves for controlling the brake pressure of the wheel brakes

ActiveCN109843667BImproved pressure regulation accuracyUniform magnetic forceOperating means/releasing devices for valvesABS control systemsSolenoid valveControl theory

The invention relates to a solenoid valve for controlling the brake pressure of the wheel brakes of a slip-regulating hydraulic brake system of a motor vehicle, which has a longitudinally movable manner at least partially arranged in a valve insert and cooperating with the valve seat An active valve element which, in the installed state, is loaded by a spring device with a force component acting in the opening direction relative to the valve seat and which can be actuated in the closing direction relative to the valve seat by means of an electromagnetic actuator, wherein the valve element Arranged between the armature and the valve seat and forming a contact surface on the valve element, the valve element is operatively connected to the armature on the contact surface, characterized in that the contact surface is designed such that between the central axis of the valve element and the contact surface There are non-right angles between them.

Owner:ROBERT BOSCH GMBH

A magnetized plate for uniformly magnetized magnetic adhesive strips

ActiveCN110415914BUniform magnetic forceIncrease distanceMagnetic bodiesMagnetic tension forceMagnetic tape

The invention discloses a uniform magnetizing plate for a magnetic rubber strip. The uniform magnetizing plate comprises a base; a rectangular through groove is formed in the upper end surface of thebase in the length direction of the base; a magnetizing line mounting core block is arranged in the rectangular through groove; two magnetizing line mounting through grooves parallel to each other areformed in the upper end surface of the magnetizing line mounting core block in the length direction of the magnetizing line mounting core block; magnetizing lines are arranged in the mounting throughgrooves; the two ends of each magnetizing line extend out to the outer sides of the two ends of the base and the magnetizing line mounting core block respectively; one ends, located on the outer sideof the tail end of the magnetizing line mounting core block, of the two magnetizing lines are connected together, and the two magnetizing lines are conducted at the connecting position; and a plurality of height adjusting mechanisms are arranged on the two side walls of the base in the length direction of the base. The height adjusting mechanisms are arranged, so that the purpose that a tractionpoint of a traction machine, the bottom wall of a slide way and the rubber strip are located on the same plane at a discharge point of a cooling device can be achieved; and the lower surface of the rubber strip slides completely against the bottom wall of the slide way, so that the magnetic rubber strip is uniform in magnetic force.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com