Solenoid valve for controlling the brake pressure of a wheel brake

A wheel brake and brake pressure technology, which is applied in the direction of brakes, control valves, air release valves, brake components, etc., can solve problems such as pressure adjustment fluctuations, skewed contact surfaces, and influence on pressure adjustment accuracy, and achieve uniform force flow, Avoid the effect of tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

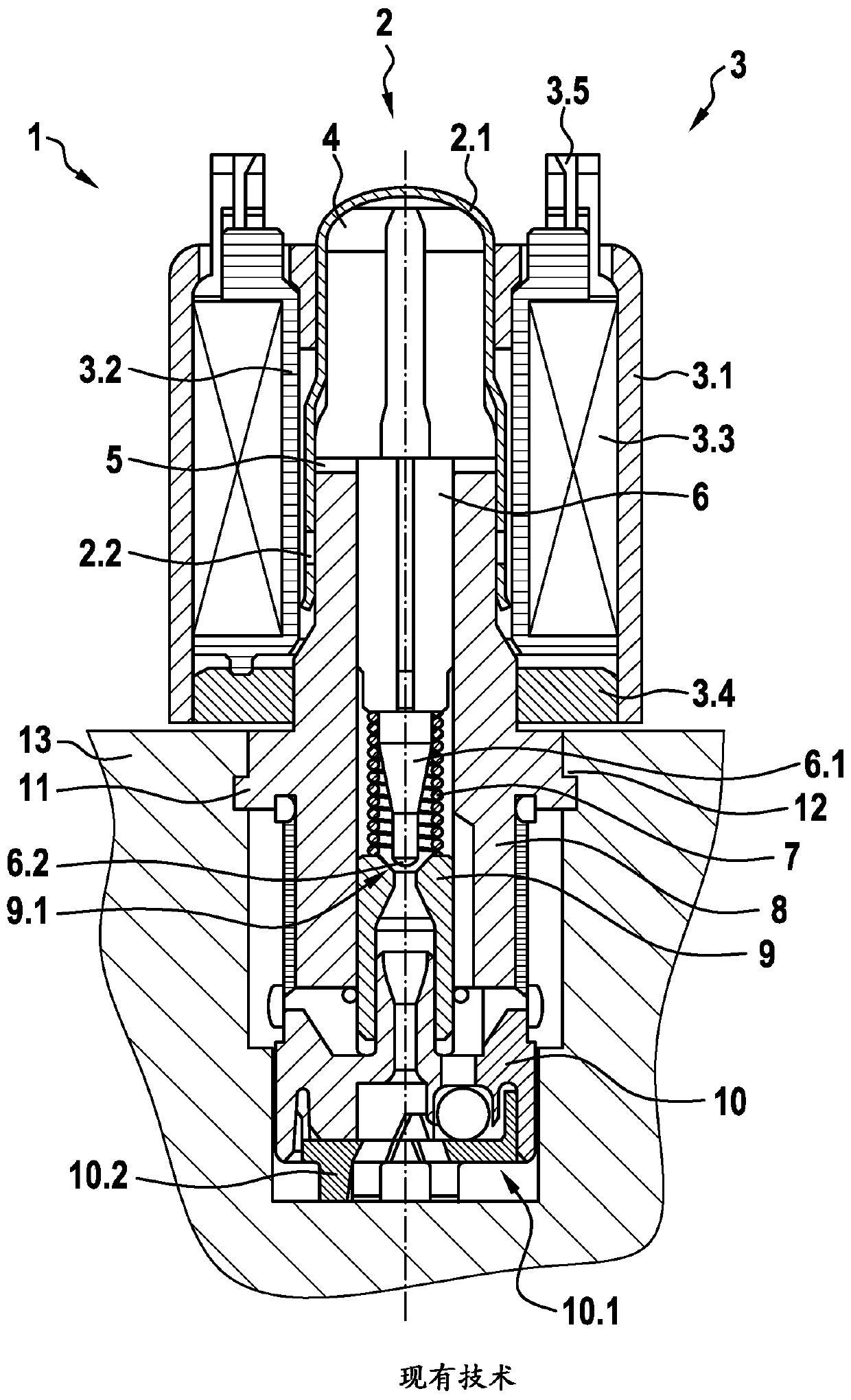

[0054] exist figure 1 A schematic cross-sectional view of a conventional solenoid valve is shown in . This has been described as prior art.

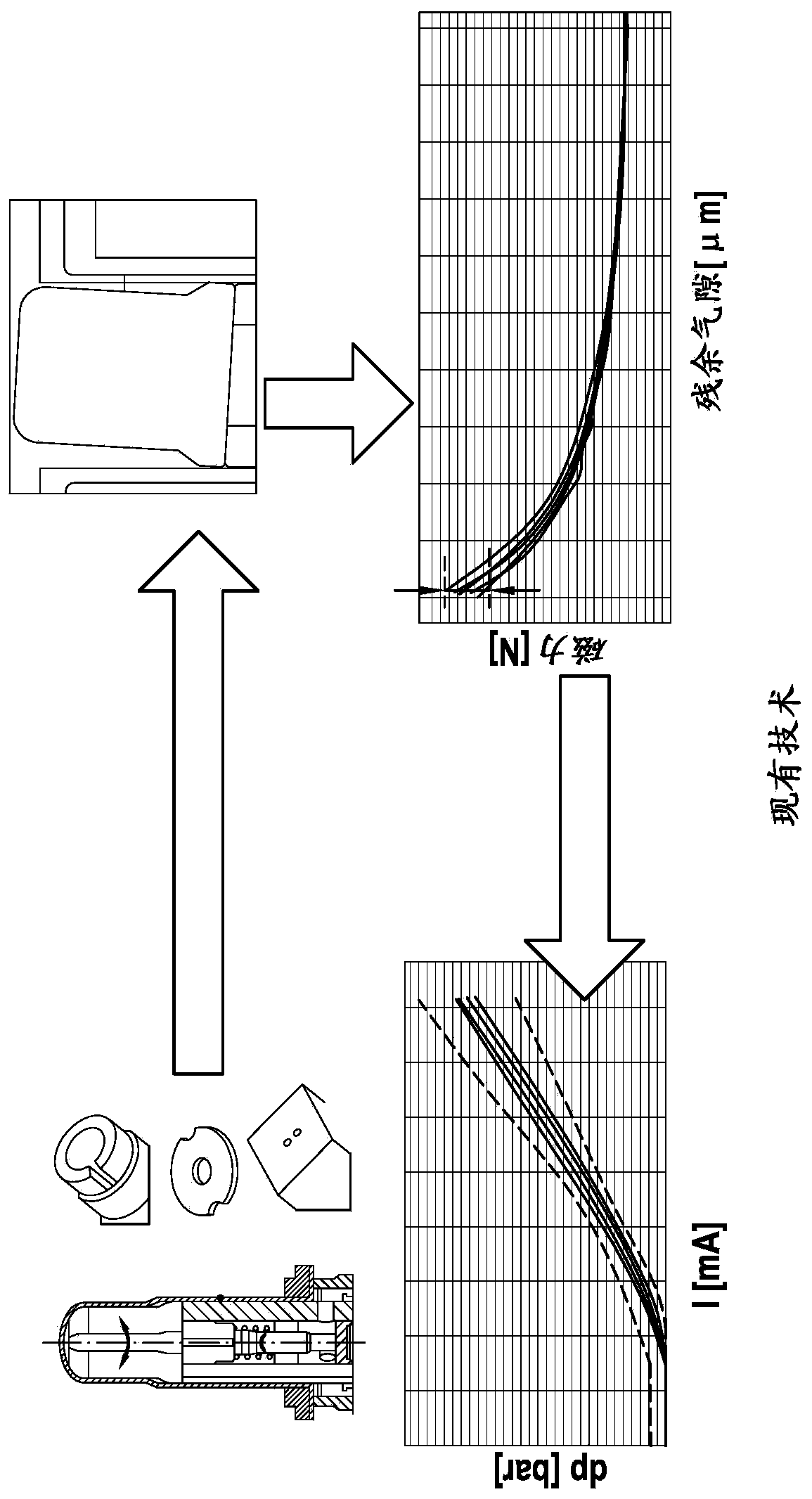

[0055] figure 2 The causal chain is also shown schematically. In this case, possible inaccuracies in the individual components are shown in the illustration in the upper left corner. One of these inaccuracies is the deformation of the valve components depending on the material and manufacturing. For example, such inaccuracies may lead to tipping or tipping of the armature relative to the valve insert. This is shown in the upper right corner of the drawing. Rotation of the armature and / or valve element results when the valve is used. This results in a varying tilted position of the armature, for example with respect to the valve seat. However, a varying tilted position of the armature results in a varying magnetic force acting on the armature. This is shown in the attached image on the bottom right. The varying magnetic force ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com