Closed Electrolyzed Water Generator

A closed water electrolysis and generator technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of gas leakage, unbalanced tension, gas leakage, etc., and achieve less thermal power loss, balanced magnetic field force, and electrolysis Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

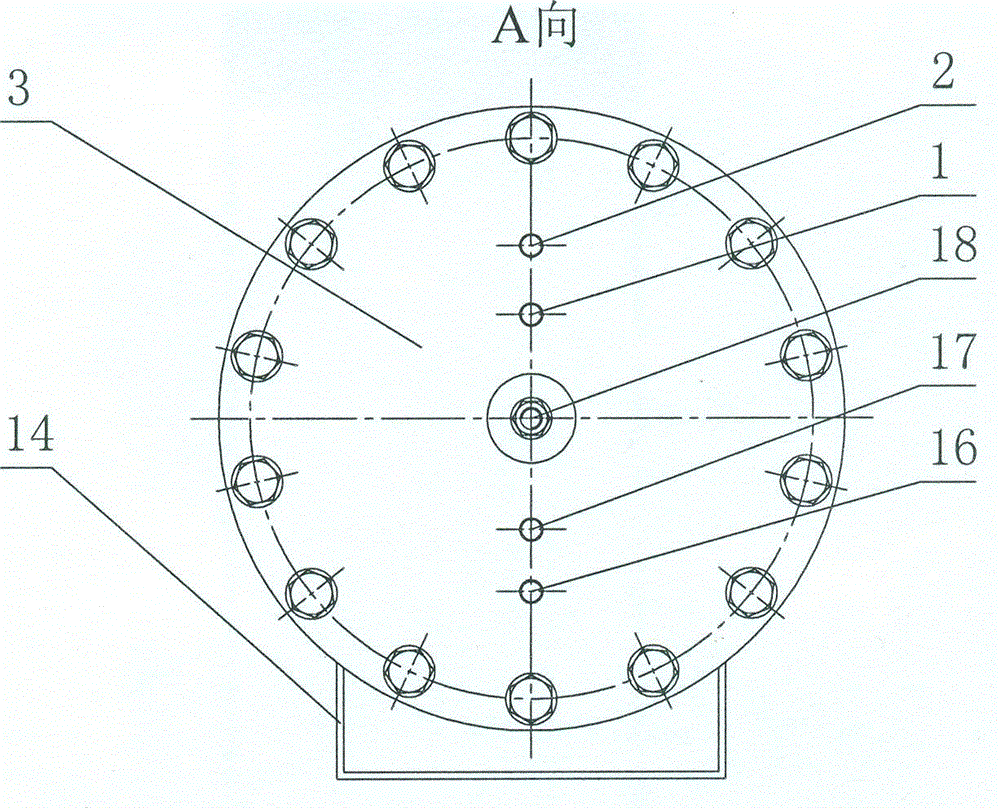

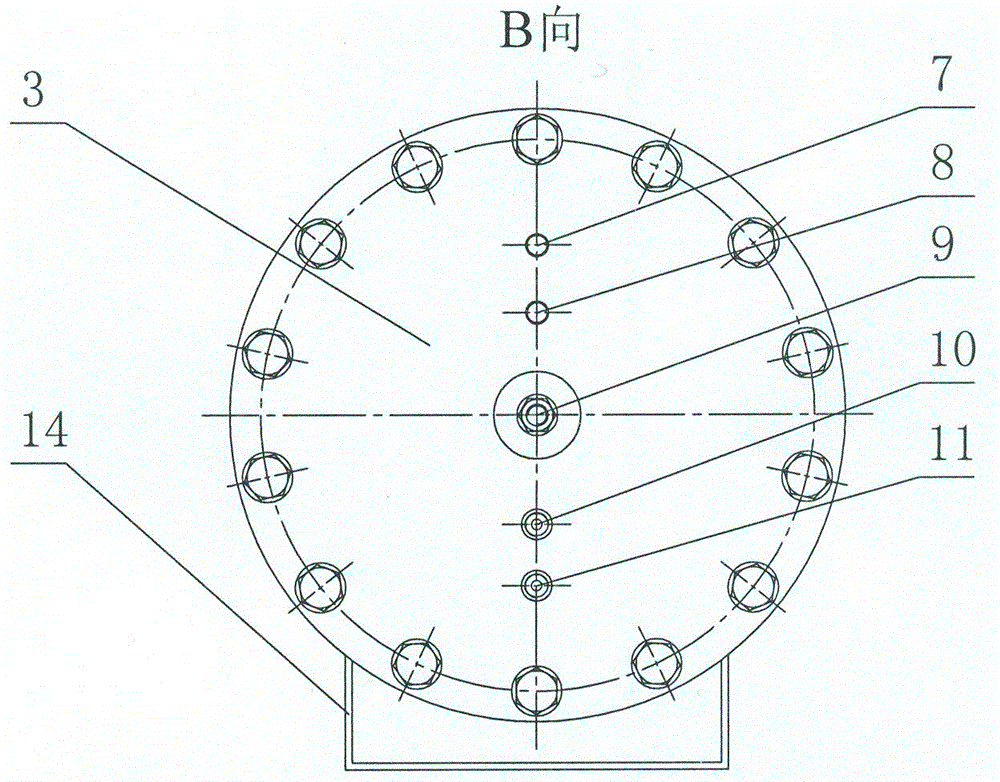

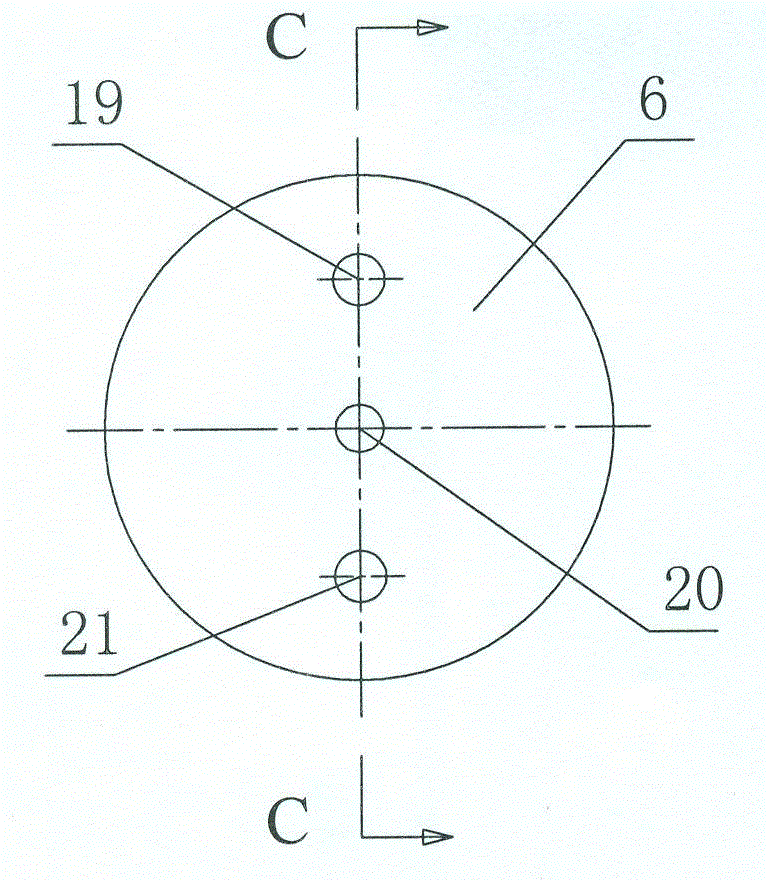

[0024] according to Figure 1-8The specific structure of the present invention will be described in detail. The airtight electrolyzed water generator comprises two heads 3 with positive power terminal 18 and negative power terminal 9 respectively, a cylinder 13 with flanges 4 at both ends, and an insulating press assembled in the cylinder 13. Cover 12, electrode connection claw 15, pole plate 6, insulating sealing rubber ring 5, and electrolyte circulation circuit and other parts. The cylinder body 13 is an insulating cylinder with two ends open, and is connected with the insulating frame (not shown in the figure) through the fixing seat 14 . In this embodiment, the cylindrical body 13 is made of hard non-metallic materials such as glass fiber reinforced plastics, and its specification, size and shape should be selected according to actual needs. The pole plate 6 adopts a brand-new structure in which the outer surface of the nickel-titanium alloy is coated with an iridium-ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com