Patents

Literature

49results about How to "Less heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

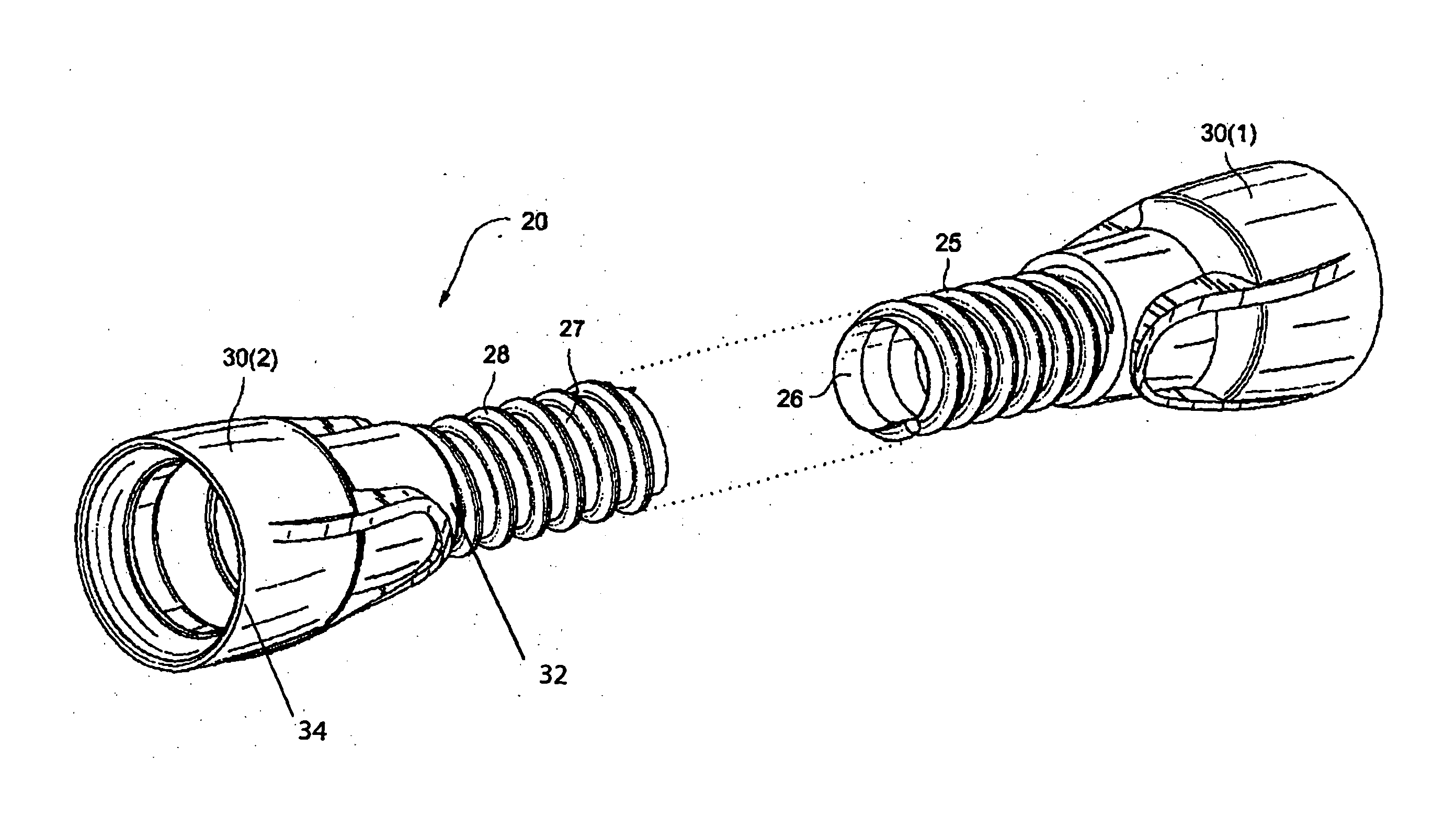

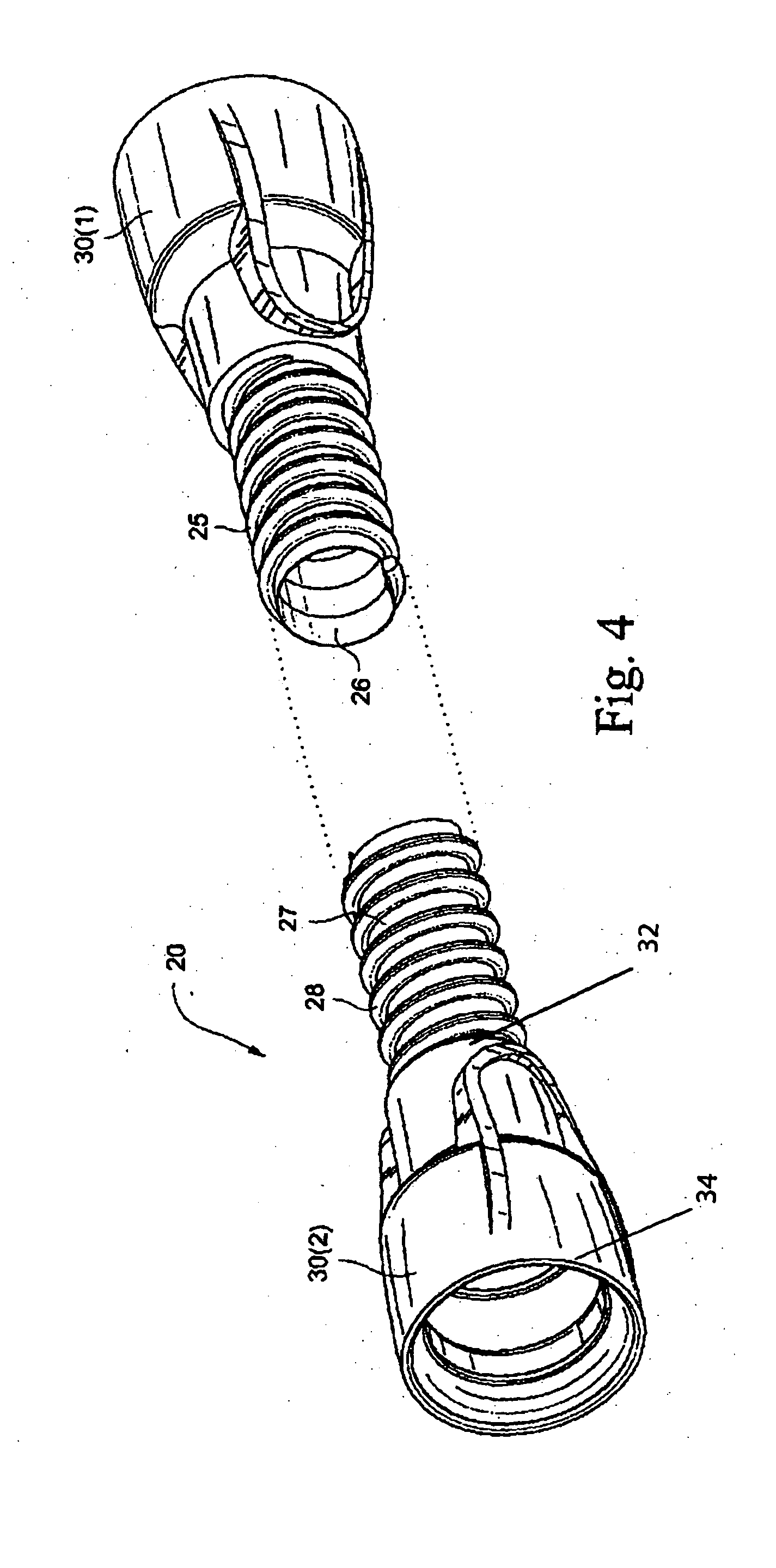

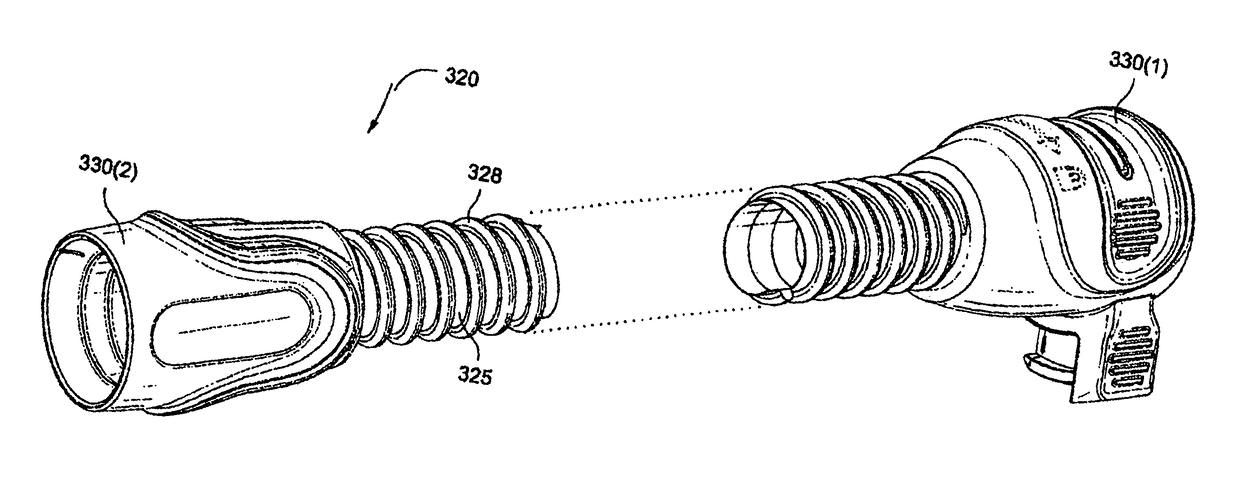

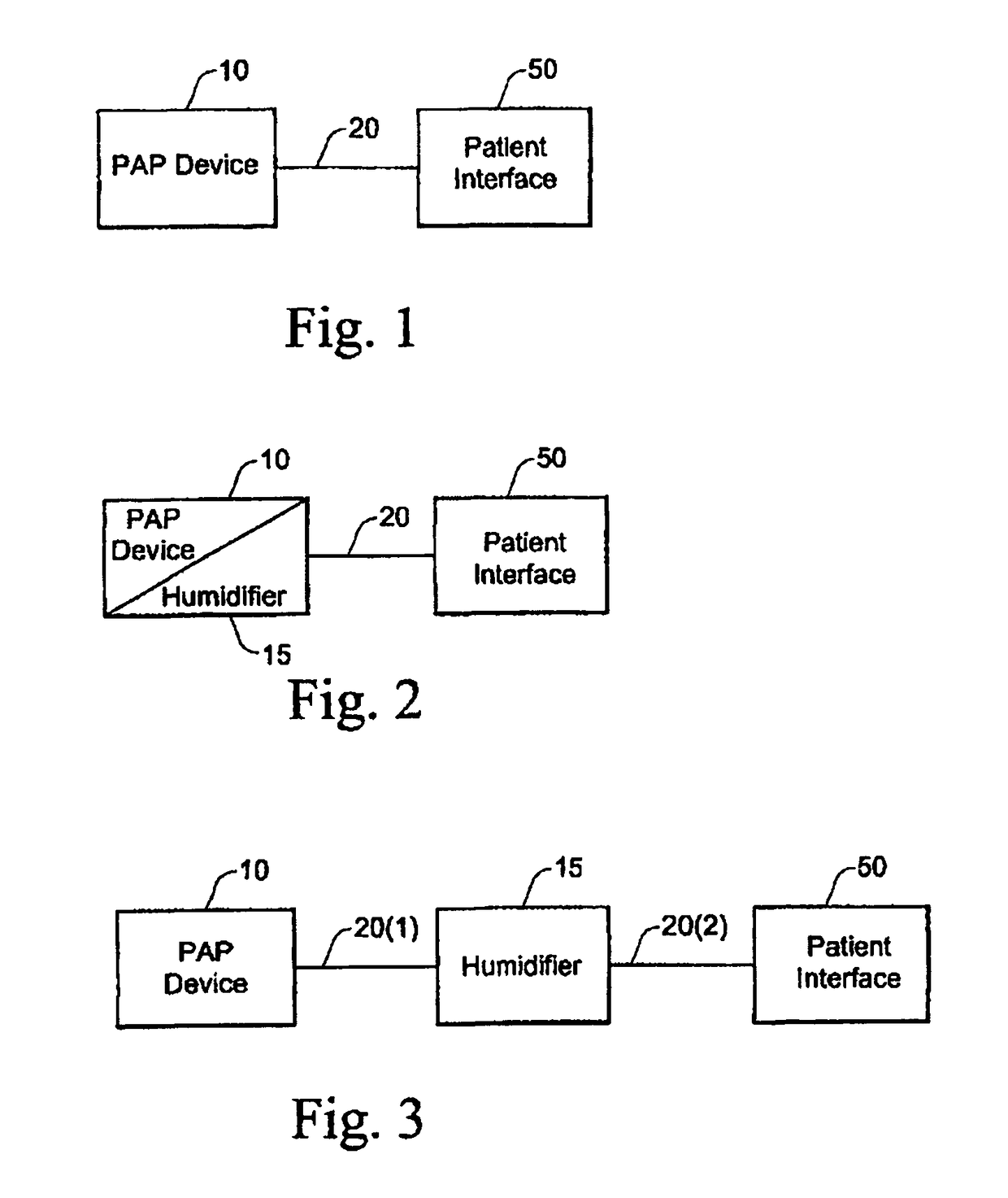

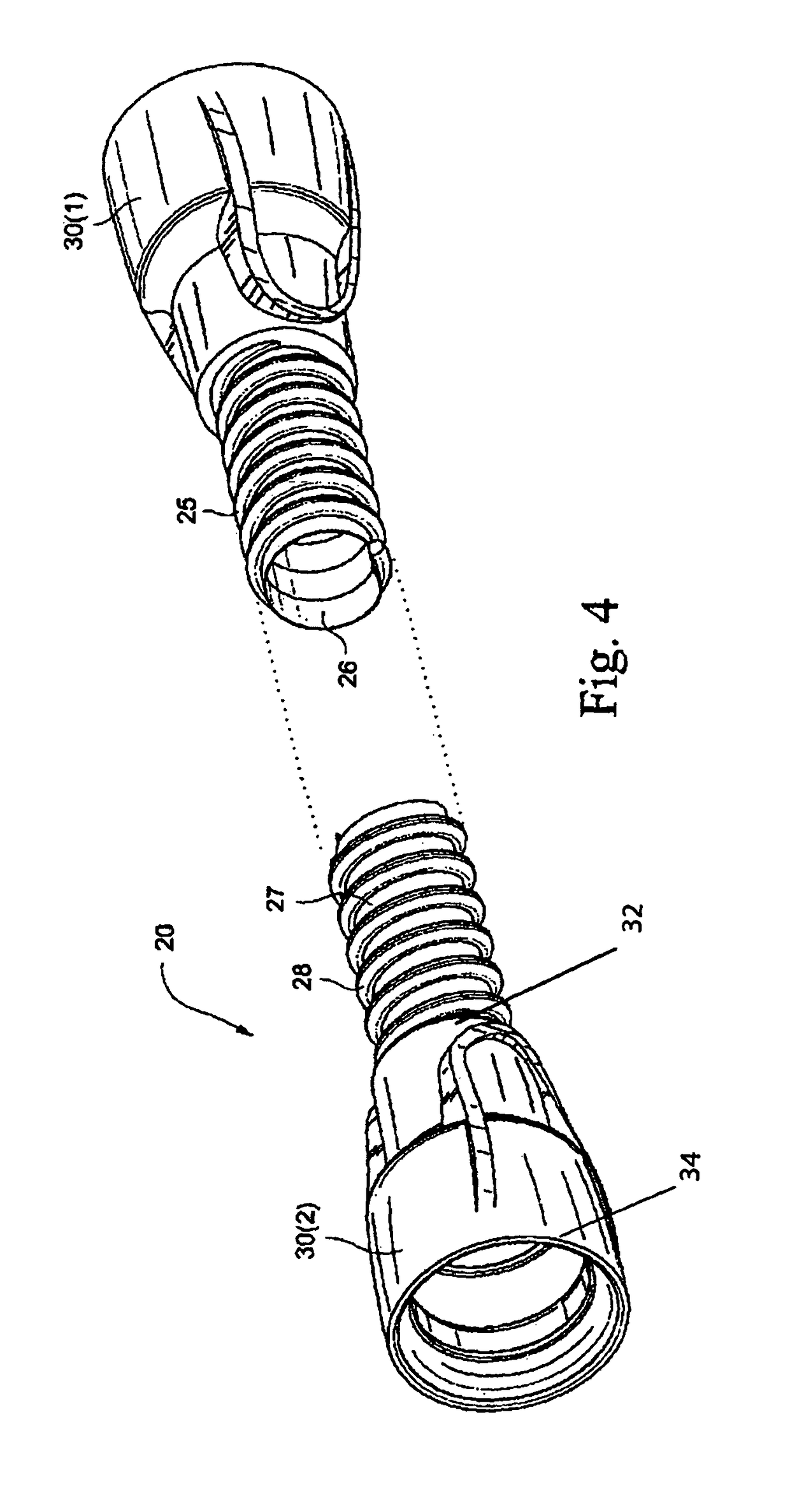

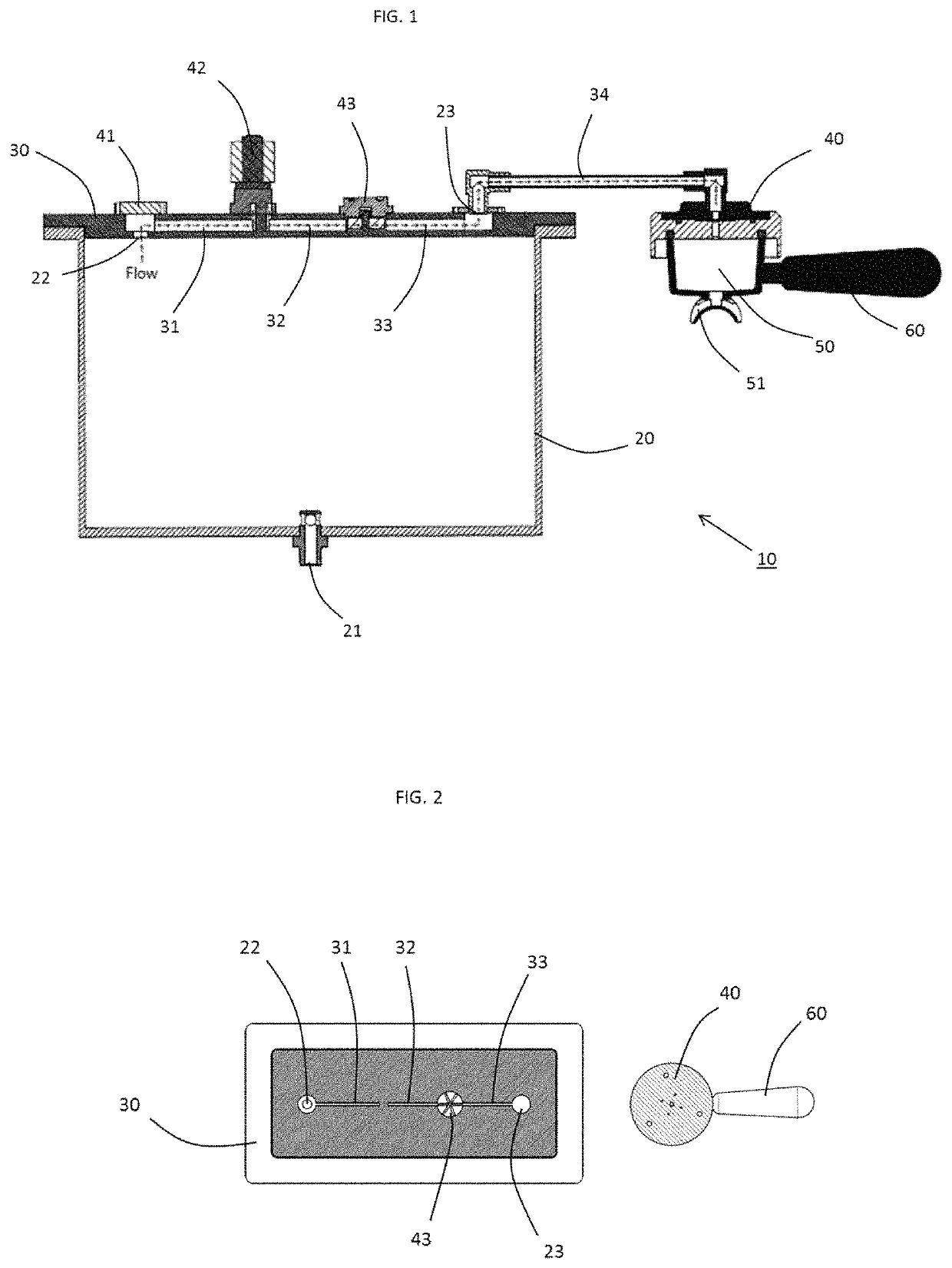

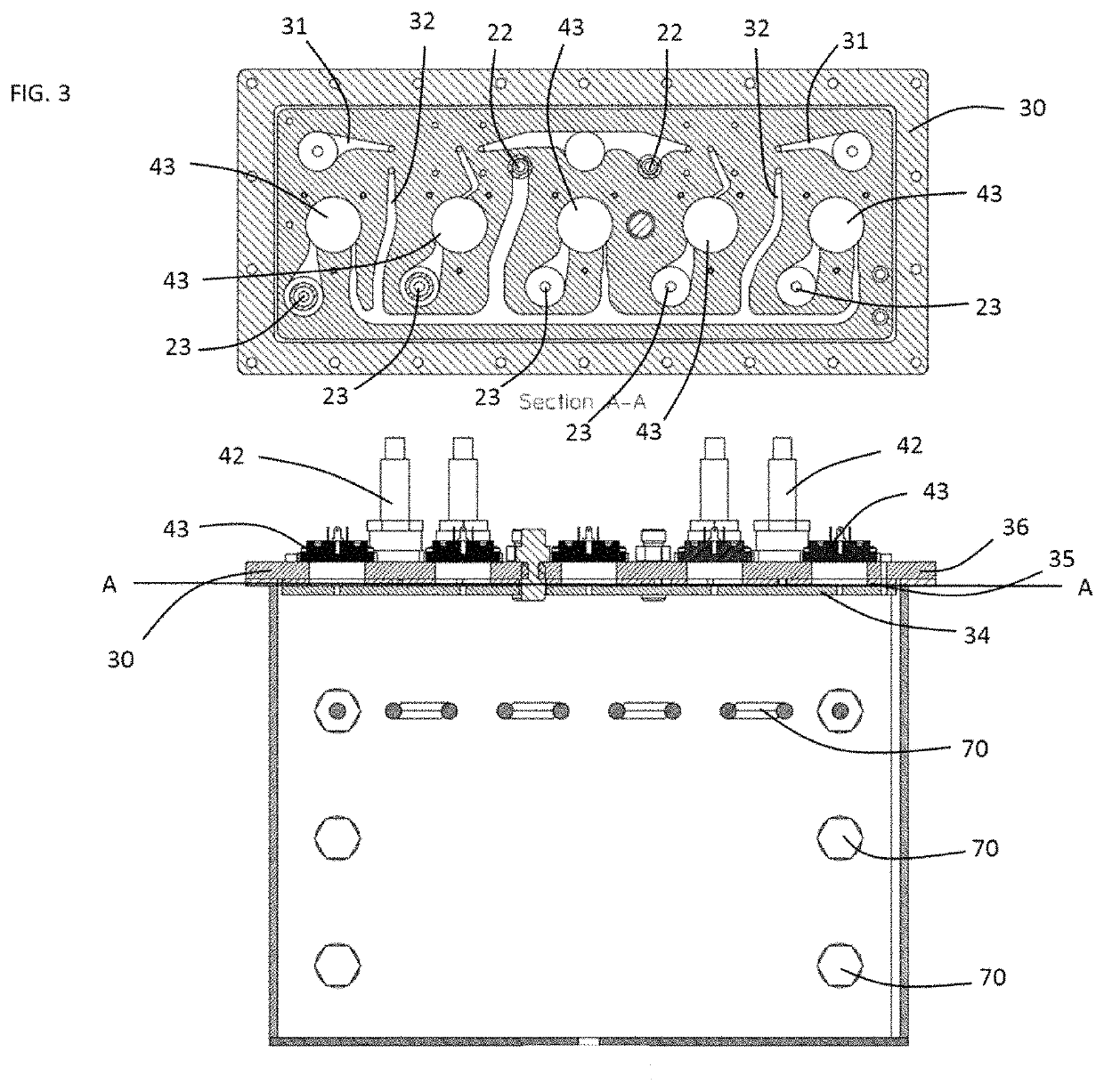

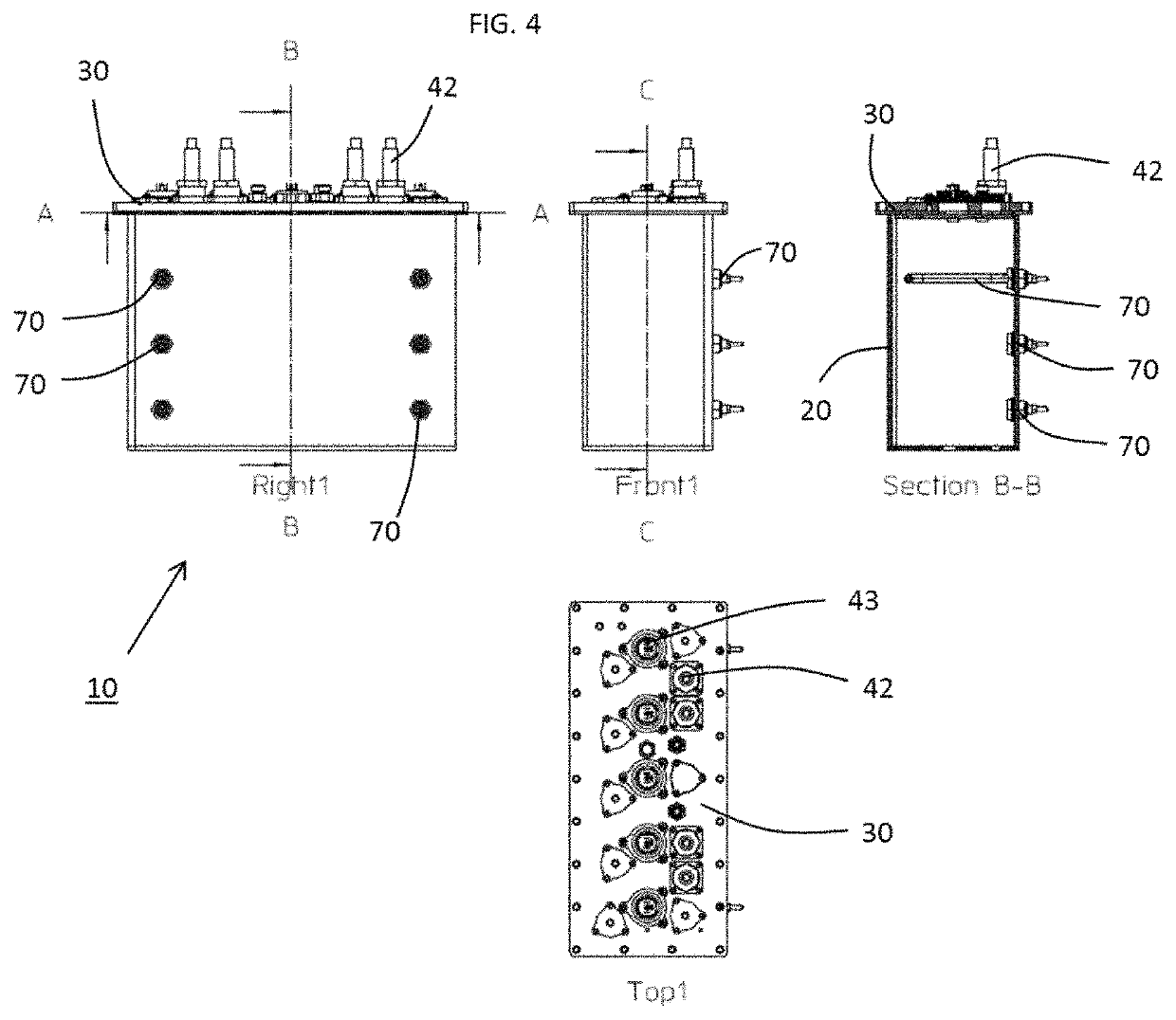

Cpap systems

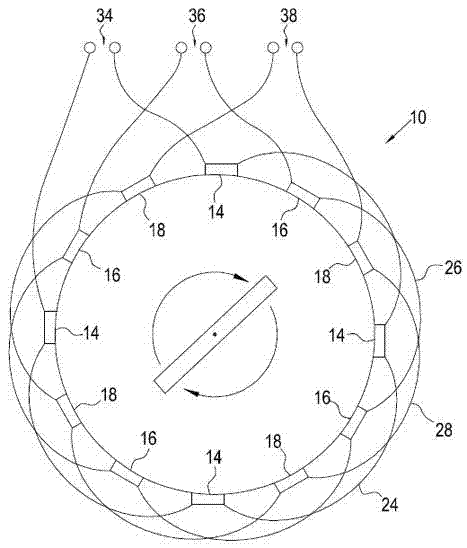

ActiveUS20120227738A1Small sizeEasy and quick connectionRespiratorsOperating means/releasing devices for valvesEngineeringElectrical impedance

A CPAP system includes a flow generator (10), a patient interface (50), an air delivery conduit (20) that interconnects the flow generator and the patient interface, wherein the air delivery conduit has an internal diameter of less than 19 mm. Preferably the air delivery conduit has an internal diameter of between about 10 mm and about 18 mm The CPAP system may also include a controller for compensating for pressure swings and / or increased impedance within the system. Preferably the blower includes a low inertia blower.

Owner:RESMED LTD

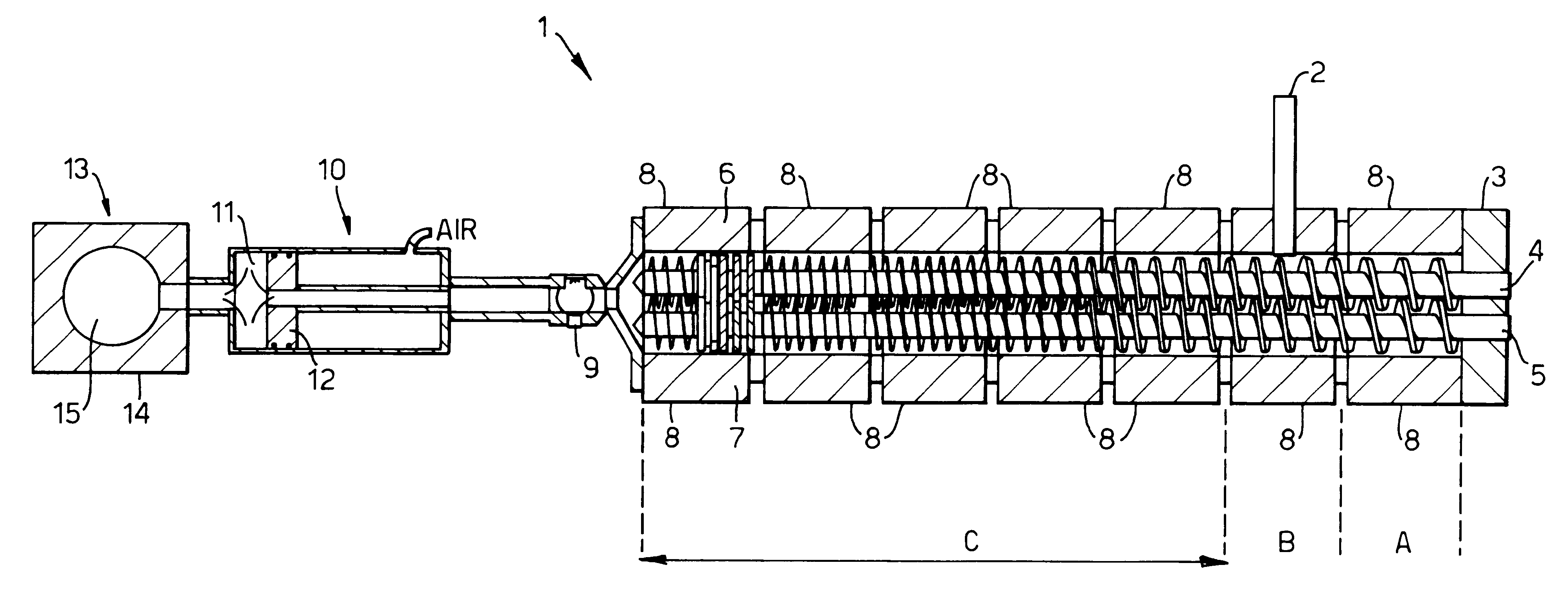

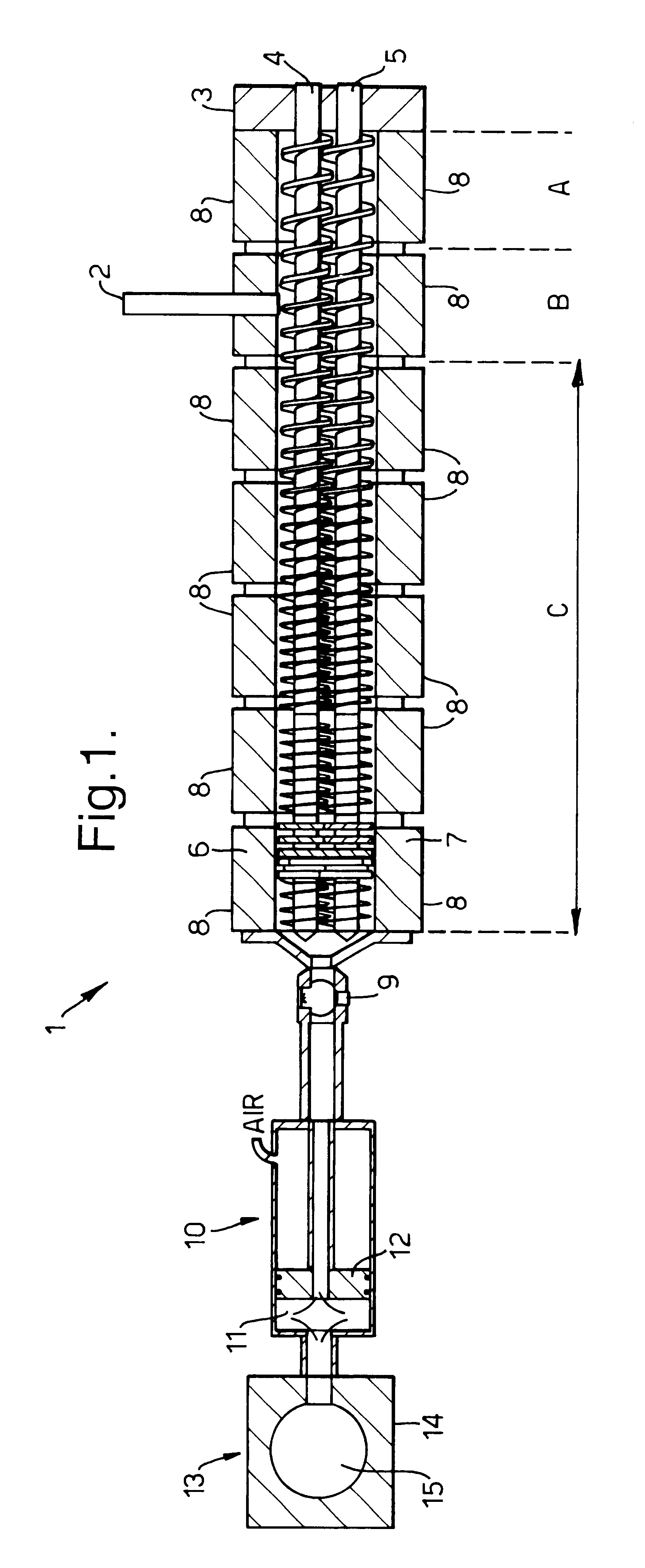

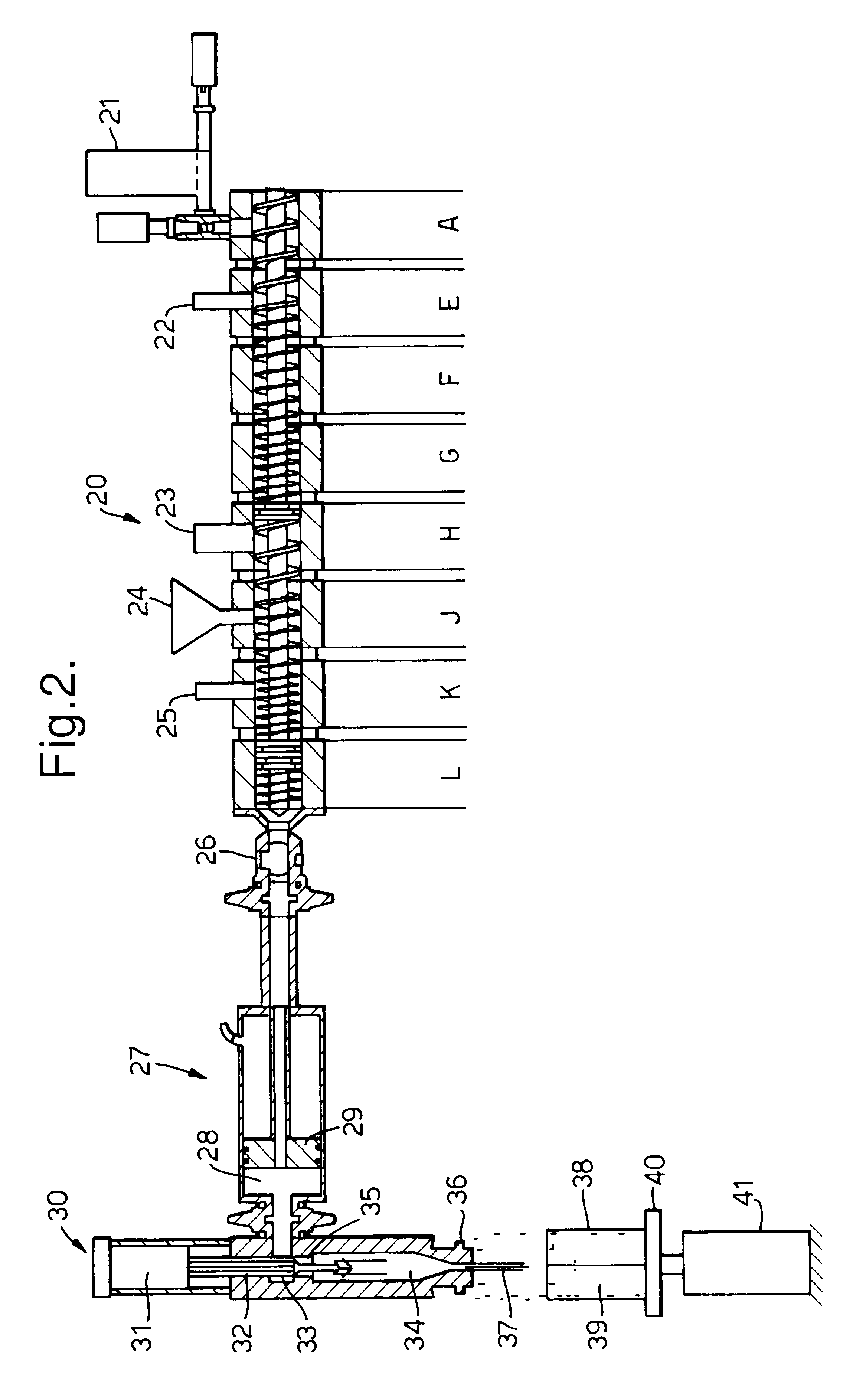

Process and apparatus for the production of a deodorant or antiperspirant composition

InactiveUS6338840B1Quicker and easy to control temperatureLess heat lossCosmetic preparationsToilet preparationsParticulatesActive agent

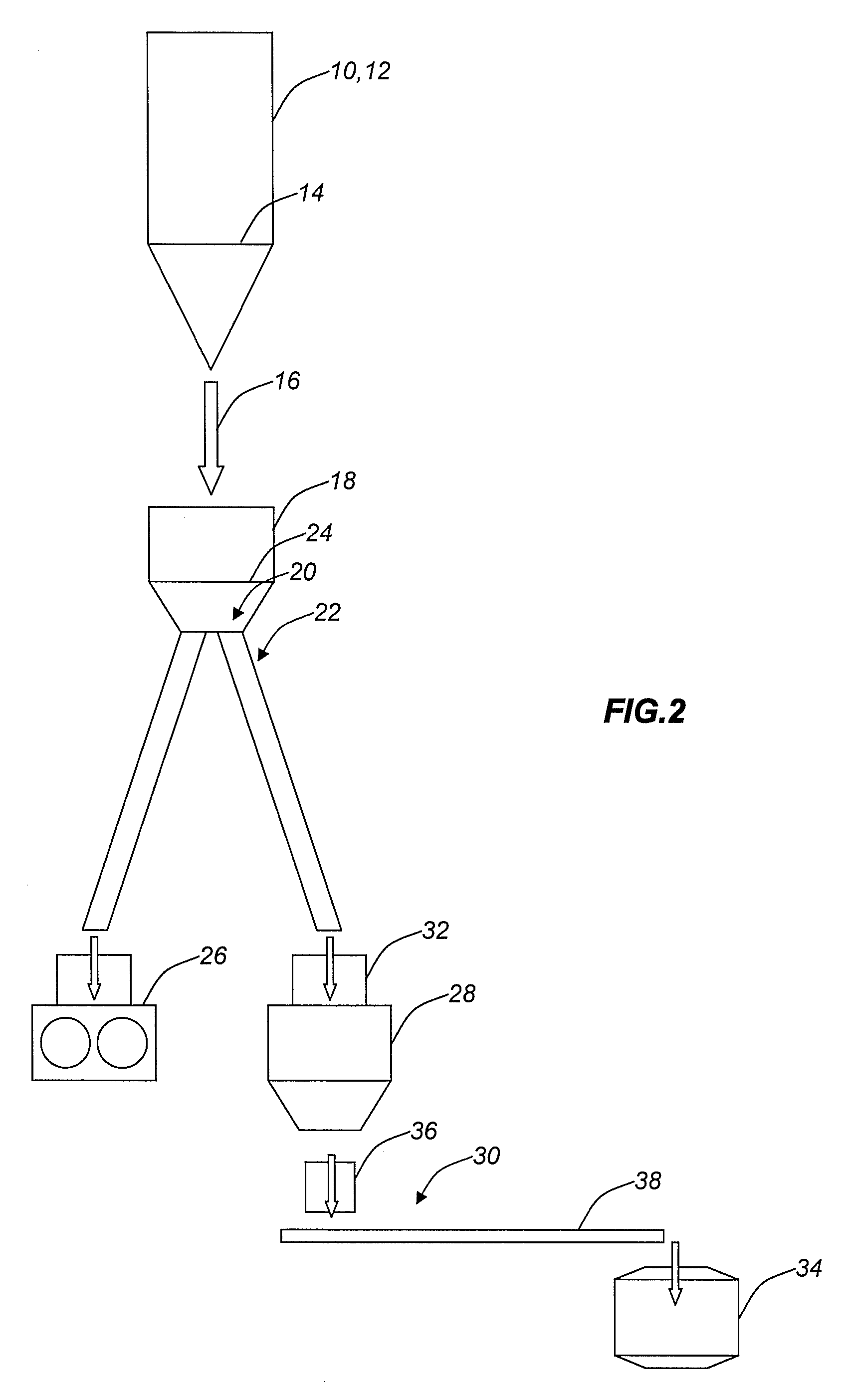

In a first aspect, a process for forming deodorant or antiperspirant sticks by continuously forming a mobile composition for dispensing into containers or molds at a rate matched with the rate at which it is dispensed, and in other aspects a process in which a mobile deodorant or antiperspirant composition is dispensed by injection molding, i.e. a process in which the deodorant or antiperspirant composition is dispensed under pressure. The composition at the time of injection moulding is preferably either in the vicinity of its regular set temperature, particularly in the range of about 0-3° C. below the regular set temperature and / or partially structured at the time of its delivery it into a container or mold. The deodorant or antiperspirant composition is preferably continuously produced in a screw extruder, especially a twin screw extruder, which is controlled to deliver the composition in a substantially semi-solid state, at a temperature close to its regular set temperature and is injected into the container or barrel at a pressure at the point of injection that is often greater than 15 psi. and in many instances from 200 to 400 psi in the injection head. Apparatus for forming deodorant or antiperspirant sticks by injection molding is also described. The combined process offers benefits for incorporating sensitive ingredients and ameliorating sedimentation of particulates such as particulate antiperspirant actives.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

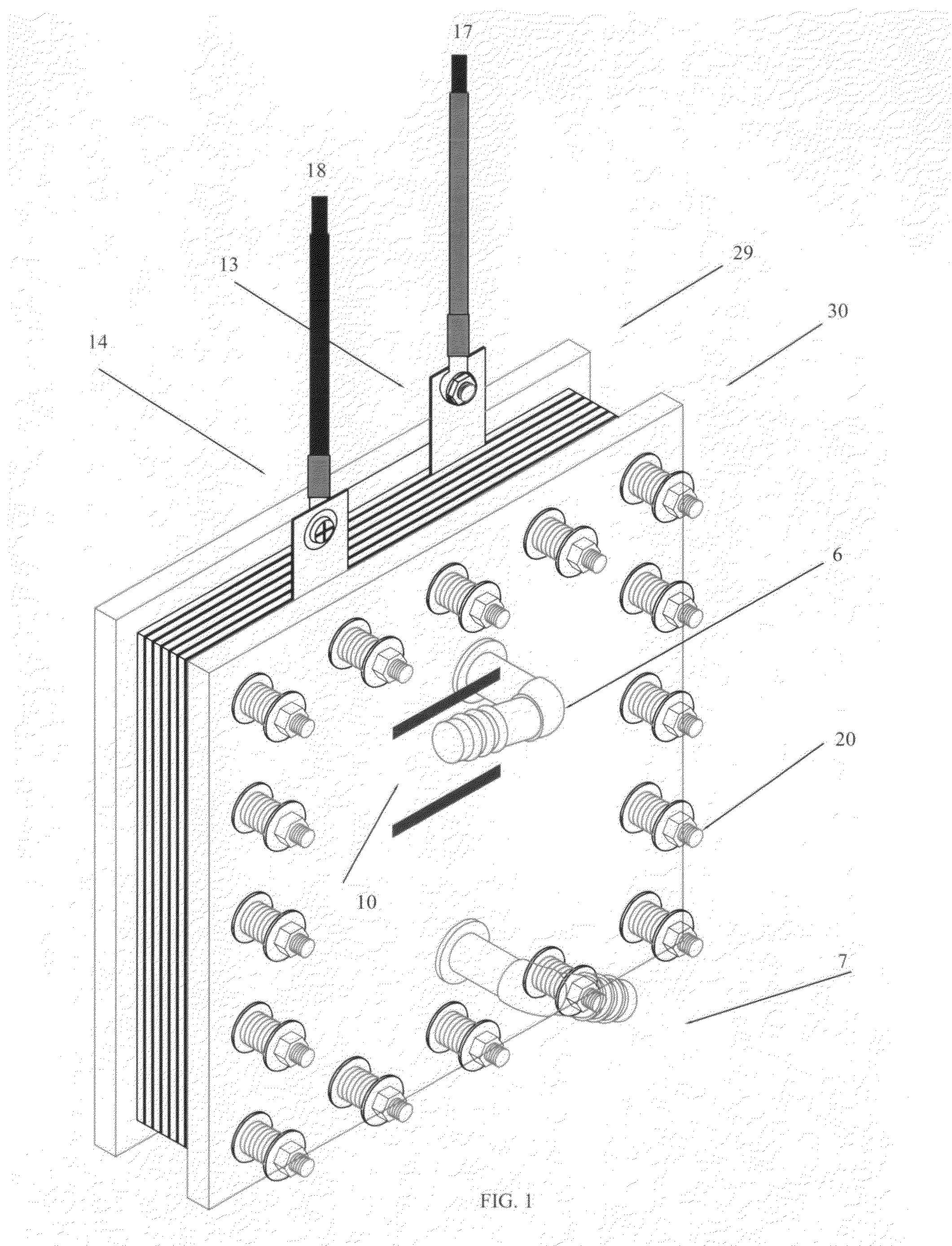

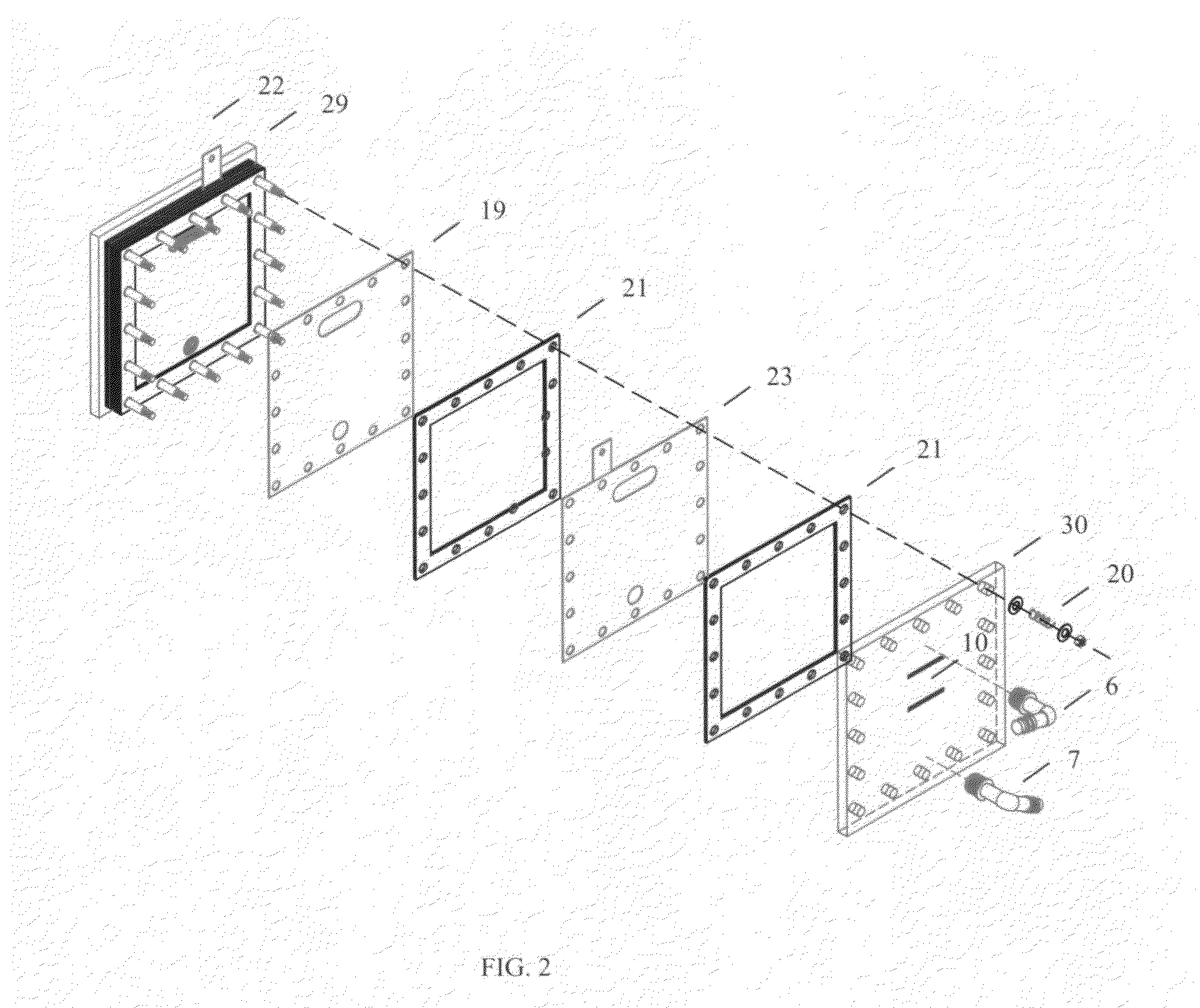

On demand hydrogen enhancement system for internal and external combustion engine

InactiveUS20100206721A1Increased flame speedImprove performanceCellsInternal combustion piston enginesExternal combustion engineInternal combustion engine

The objective of this invention, on demand hydrogen enhancement system for internal and external combustion engine, is to develop a continuous non pressurized water electrolyzer from clean water (not pure water or distil water) generator system. The mixed hydrogen gas and oxygen gas called “Oxyhydrogen”. Oxyhydrogen use as catalyse for internal and external combustion engine to increase fuel flame speed. It can use with variety fuels such as Ethanol, Methanol, Gasohol, Gasoline, Diesel, Bio Diesel, LPG, CNG, and LNG. This system can reduce fuel consumption, increase fuel efficiency, increase torque, reduce emissions, and reduce engine temperatures. The system required no cooling fan and electrolytic solution circulating pump. The system has less heat loss and very low electrical consumption. Oxyhydrogen will produce on demand as the engine RPM and load of generator. The control unit detects signal frequency from the alternator. Gas production rate low at low RPM and use less current and gas production will high at high RPM and use higher current. This can save lot of energy for the electrolysis process. In the past, water electrolysis use direct current (D.C.). In this invention the inventor uses D.C. with Frequency Modulate (FM) pulse width modulator (PWM) instead of Amplitude Modulator (AM) to control the electrolyzer (FMPWM). This circuit had current detector for automatic current adjustment and over current protection.

Owner:SNIDVONGS SURAVUT

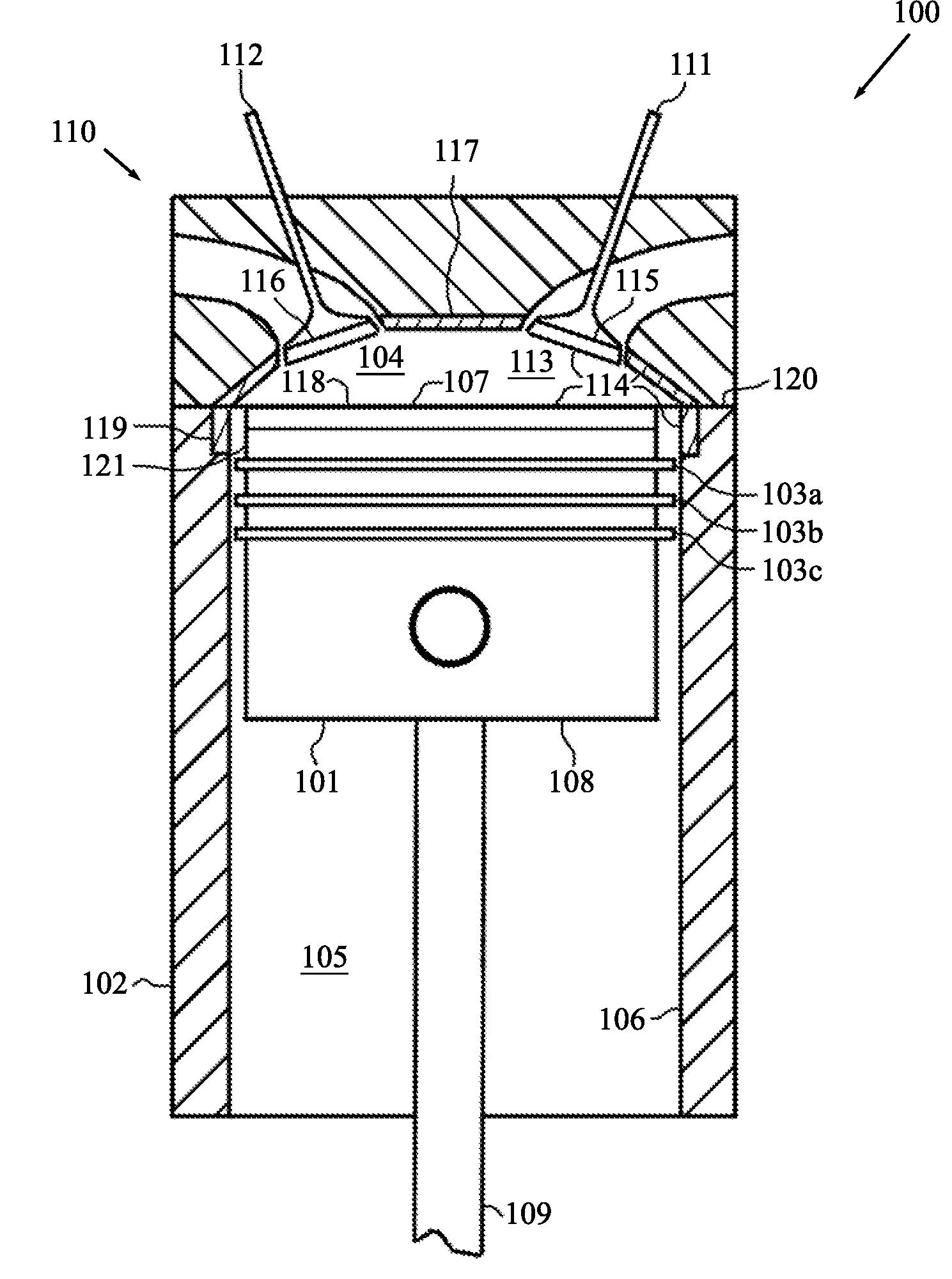

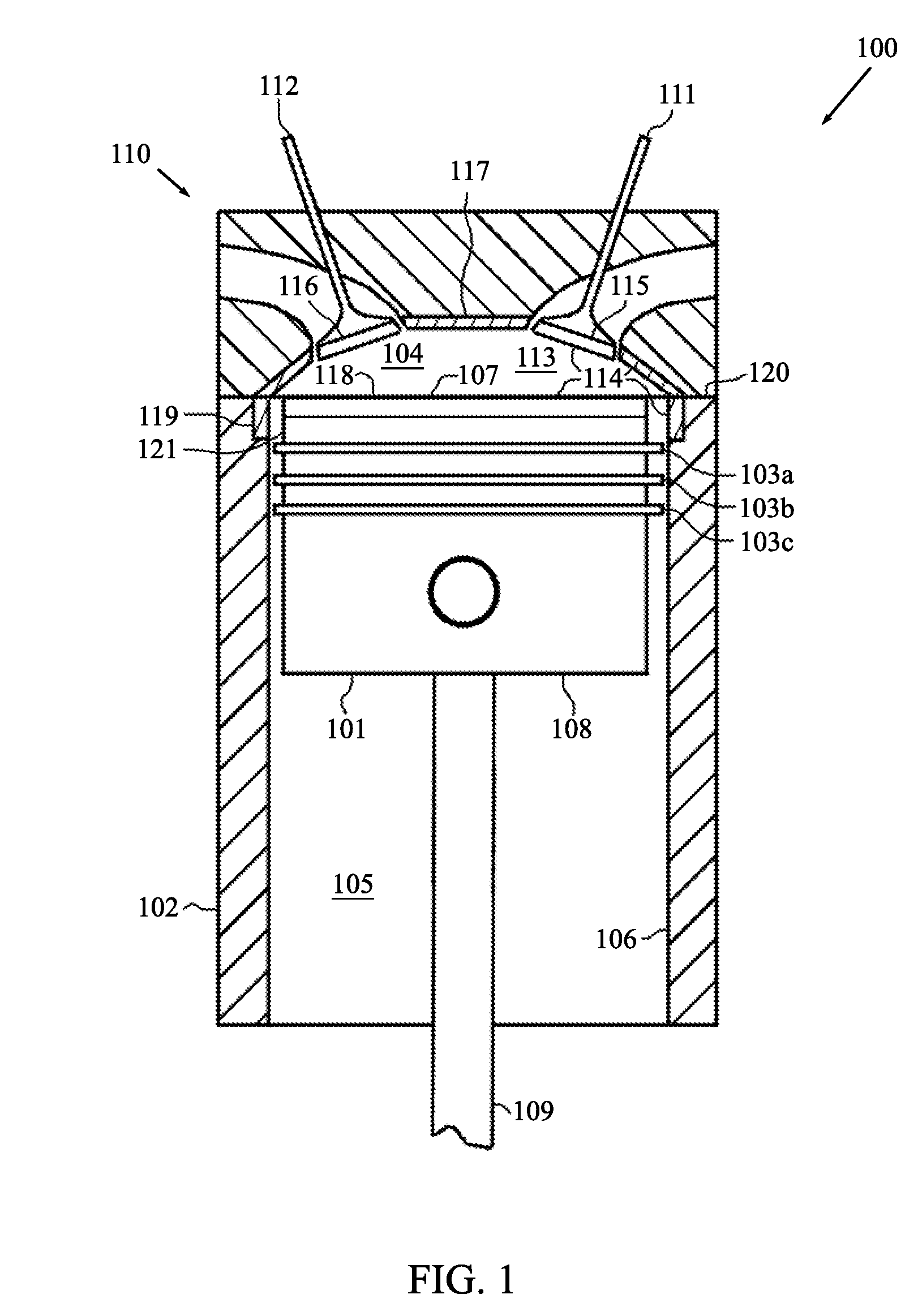

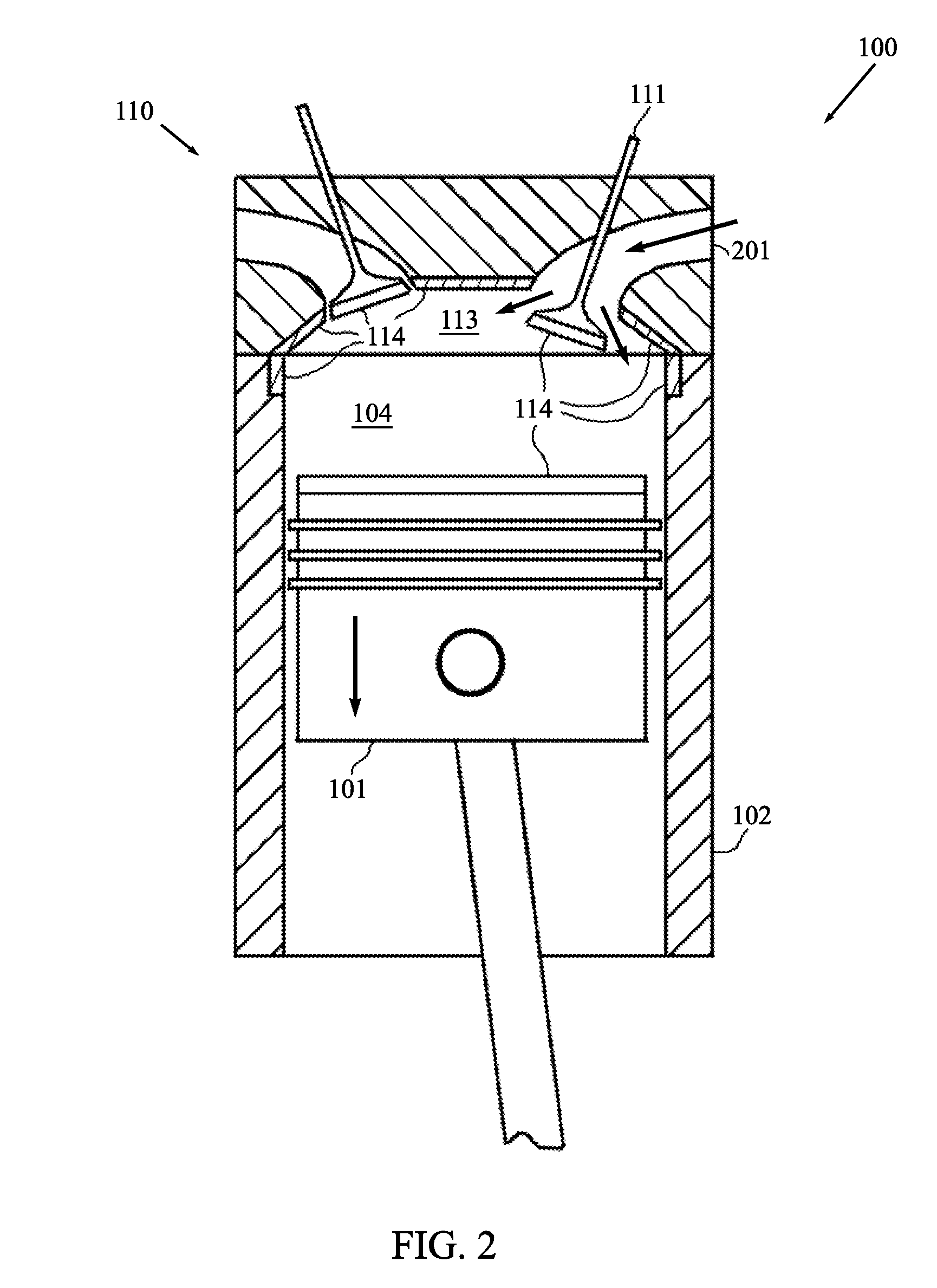

Low heat rejection high efficiency internal combustion engine

InactiveUS20090071434A1Improve efficiencyLow heat rejection rateCasingsInternal combustion piston enginesExternal combustion engineVariable valve timing

An internal combustion engine including a low thermal capacity, low thermal conductivity insulating liner is provided. The insulating liner may be positioned to line the combustion chamber and a portion of the cylinder wall. The insulating liner may comprise a high aspect morphology sintered ceramic material and may further include a surface coating. The internal combustion engine may be a four-stroke diesel engine with variable valve timing operating using an asymmetric cycle. Through the asymmetric cycle and insulative properties of the insulating liner, the heat loss of the disclosed internal combustion engine is significantly less than that of a similar conventional internal combustion engine, resulting in significant efficiency improvements.

Owner:DWIGHT ENGINE TECHNOLGIES

Blackbody furnace

InactiveUS6365877B1Improve cooling efficiencyReduce the temperatureRadiation pyrometryMuffle furnacesTemperature controlRoom temperature

A blackbody furnace, mainly comprising a radiation cavity, a thermally insulating layer, a heater, a housing, a temperature controller, an airflow controller and a high-pressure air source. Besides, a gas channel is provided at the bottom of the radiation cavity to conduct the interior of the furnace chamber with the exterior. In the process of lowering the temperature of the blackbody furnace, the airflow controller could be actuated by the temperature controller or by an operator. Therefore, the room-temperature high-pressure air will enter the radiation cavity through the gas channel to fast cool down the radiation cavity. Finally, heat air will be vented from an opening at the front end of the radiation cavity. The present invention utilizes forced convection to enhance the efficiency of heat dissipation to fast lower the temperature of the blackbody furnace.

Owner:IND TECH RES INST

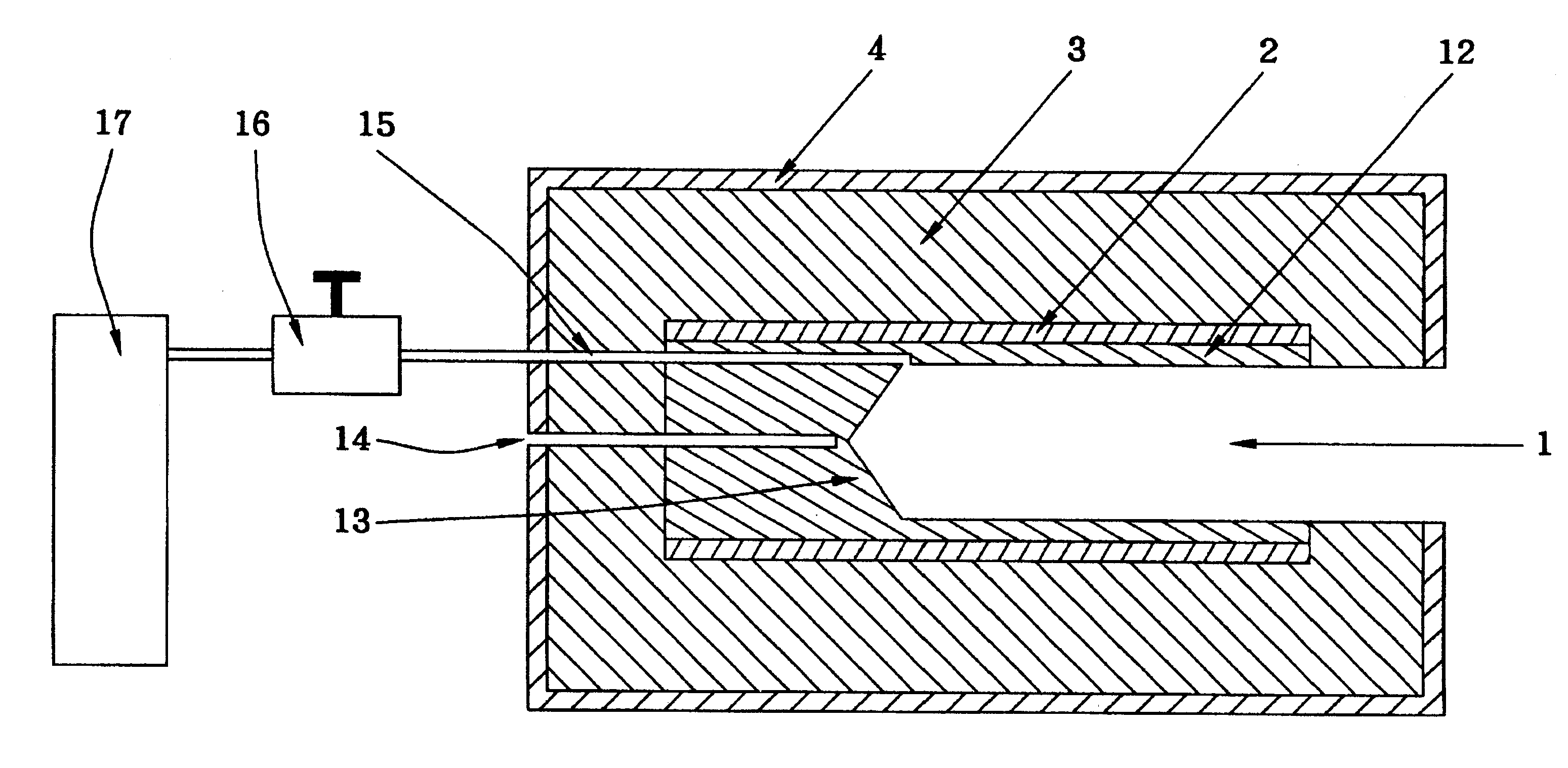

Mold temperature adjusting apparatus/method and mold temperature control unit

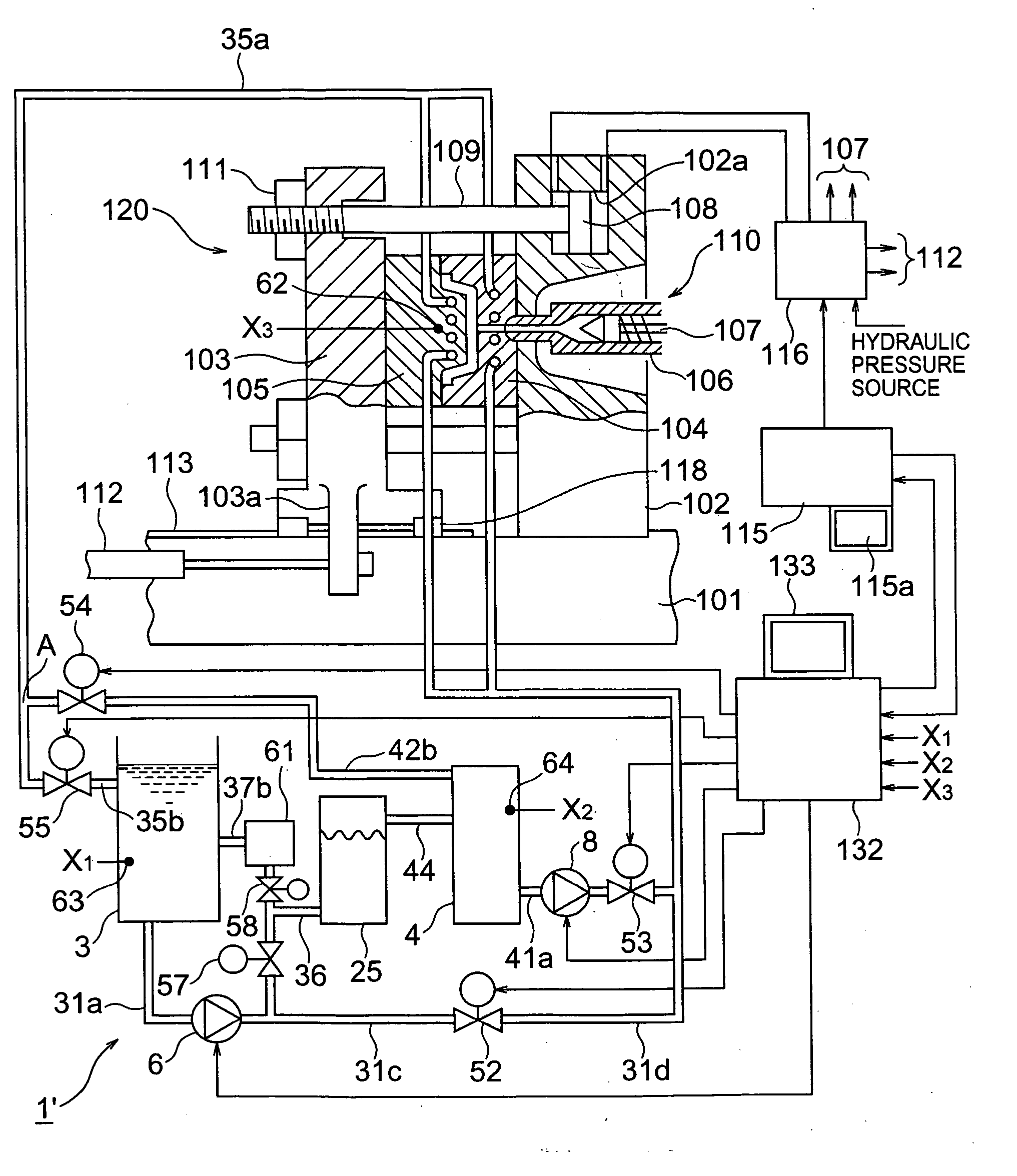

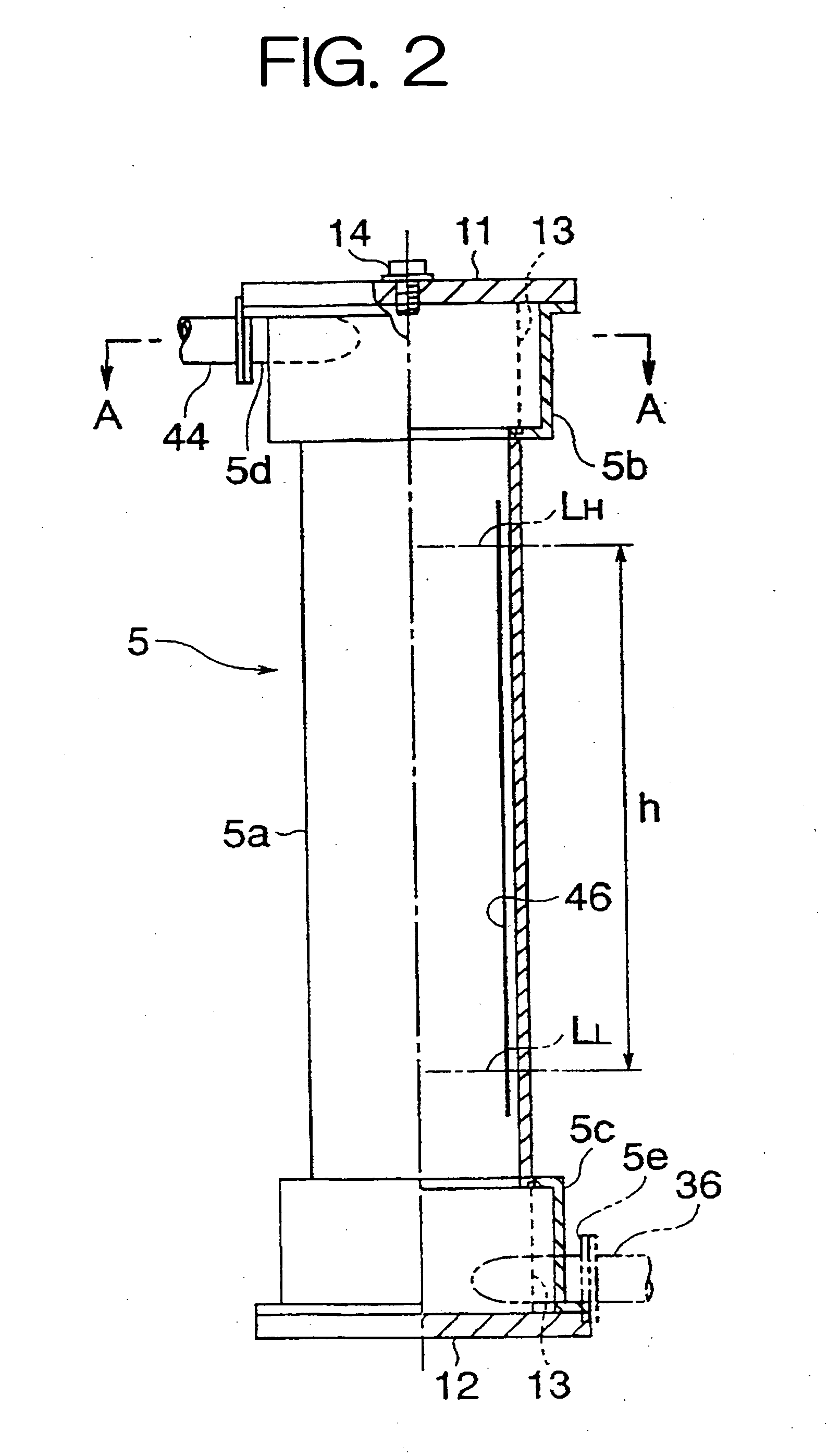

InactiveUS20050179157A1Mixing of fluid can be reducedReduce mixTemperature control without auxillary powerAuxillary shaping apparatusTemperature controlHeat transmission

A mold temperature adjusting apparatus is provided in which change-over timing of high temperature medium and low temperature medium is adjusted by a heat transmission delay in heating and cooling of a mold being taken into consideration, so that a cycle time of molding steps is shortened, a temperature deflection from a set temperature of the high temperature and low temperature medium is reduced, an energy loss is reduced and an optimal mold temperature for an injection step can be obtained. The mold temperature adjusting apparatus comprises a high temperature fluid tank and a low temperature fluid tank, a high temperature fluid supply system and a high temperature fluid return system between the mold and the high temperature fluid tank, a low temperature fluid supply system and a low temperature fluid return system between the mold and the low temperature fluid tank, a high temperature fluid by-pass system and a low temperature fluid by-pass system, a heat recovery tank connected to the high temperature fluid tank and a pressure adjusting means.

Owner:MITSUBISHI HEAVY IND LTD

Convection oven with turbo flow air nozzle to increase air flow and method of using same

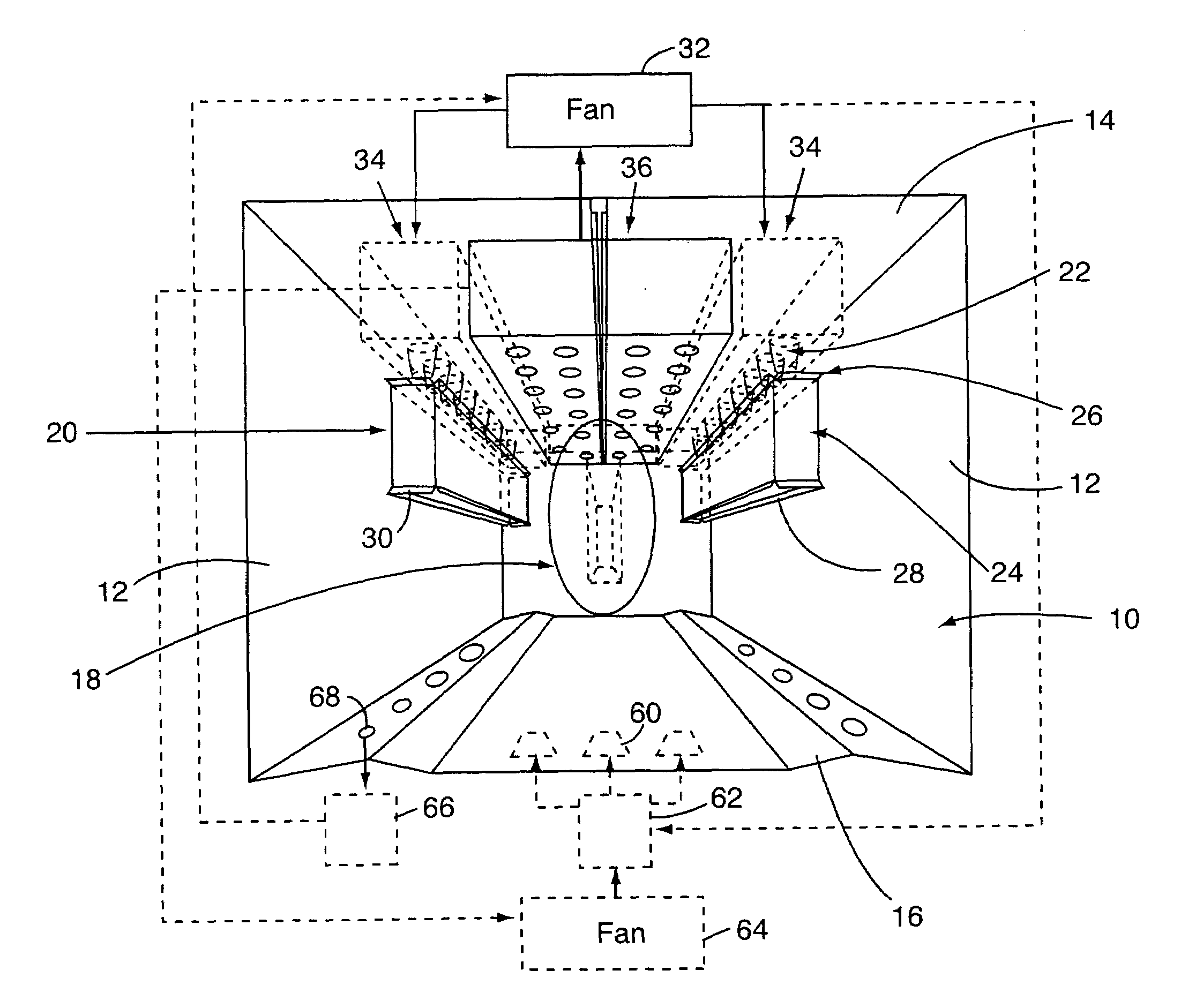

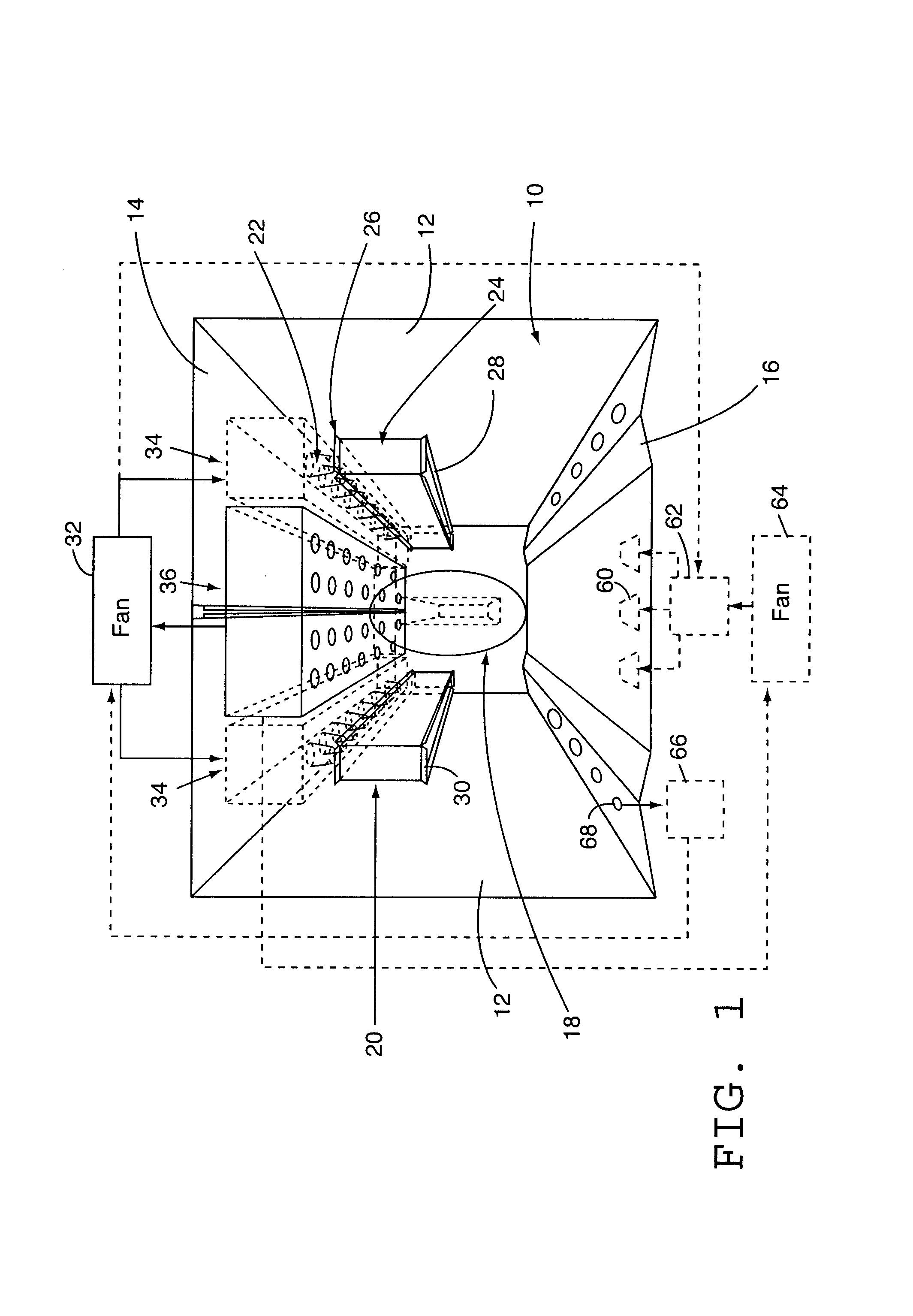

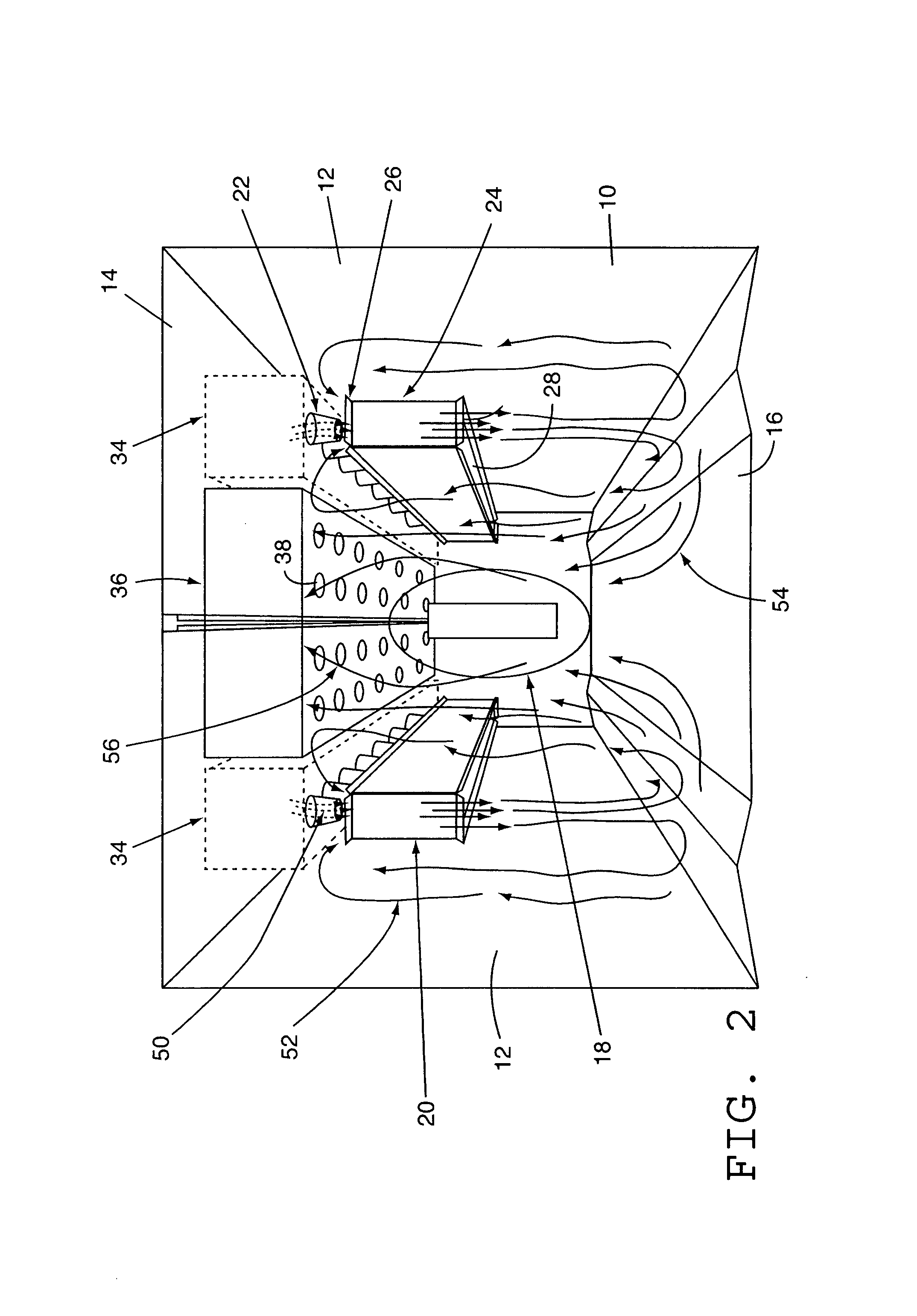

InactiveUS7264467B1Enhanced degree of air flowEasy to operateDrying solid materials with heatRotary drum furnacesAir entrainmentHigh velocity

A convection oven that achieves a substantially enhanced degree of air flow through the use of a special nozzle design. Turbo flow air nozzles create an air flow pattern to provide higher velocity airflow with a smaller fan size and ductwork. The turbo flow air nozzles include main supply nozzles that direct high velocity air through air entrainment and mixing sections that entrain air from the oven interior to generate the increased air flow in a heat transfer zone of the oven. Appropriate ductwork is provided to direct air from a fan or fans to the supply nozzles to generate a high velocity air flow therethrough.

Owner:INT THERMAL SYST

CPAP systems

ActiveUS9802015B2Small sizeQuickly and easily connectedRespiratorsMedical devicesCatheterEngineering

A CPAP system includes a flow generator (10), a patient interface (50), an air delivery conduit (20) that interconnects the flow generator and the patient interface, wherein the air delivery conduit has an internal diameter of less than 19 mm. Preferably the air delivery conduit has an internal diameter of between about 10 mm and about 18 mm. The CPAP system may also include a controller for compensating for pressure swings and / or increased impedance within the system. Preferably the blower includes a low inertia blower.

Owner:RESMED LTD

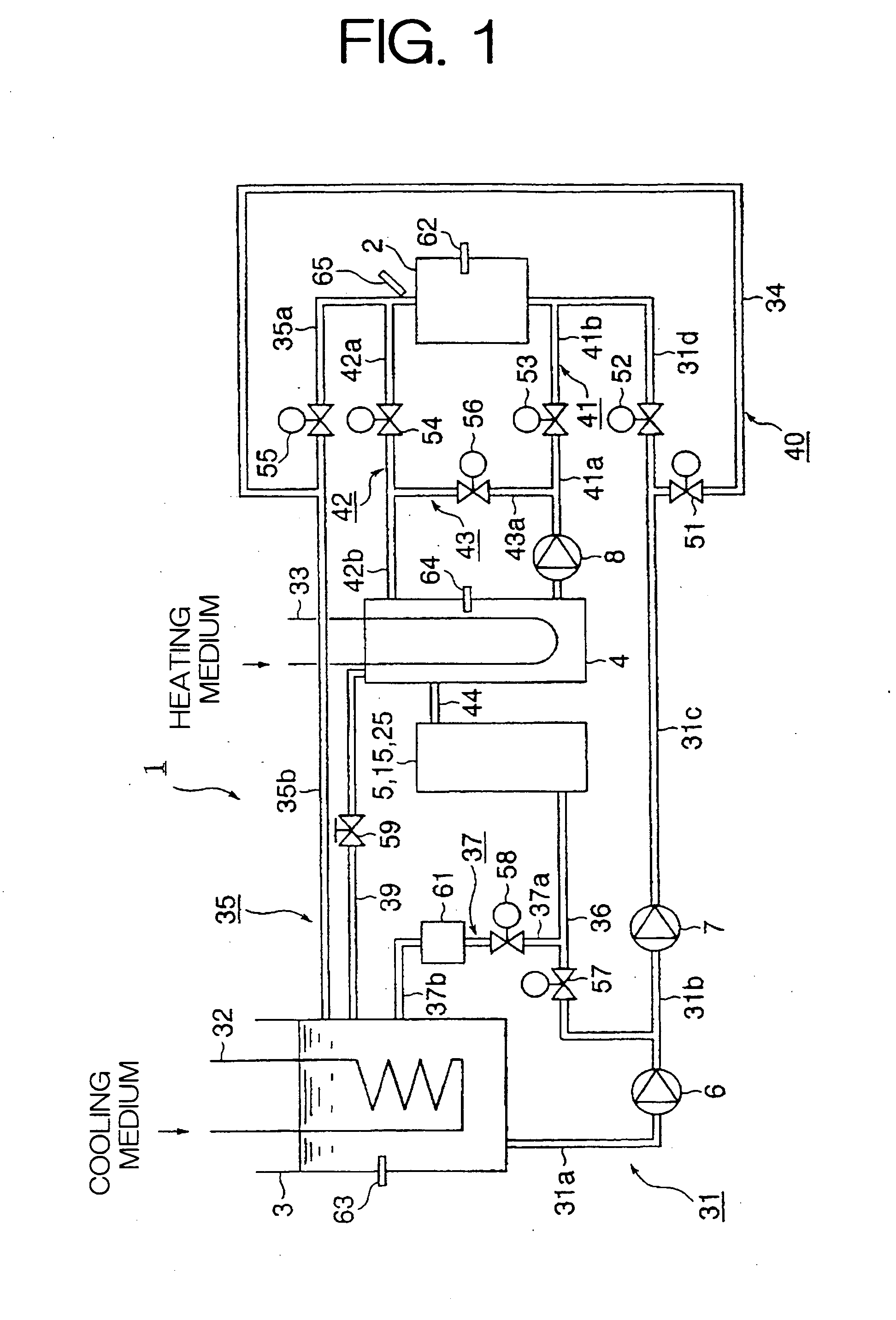

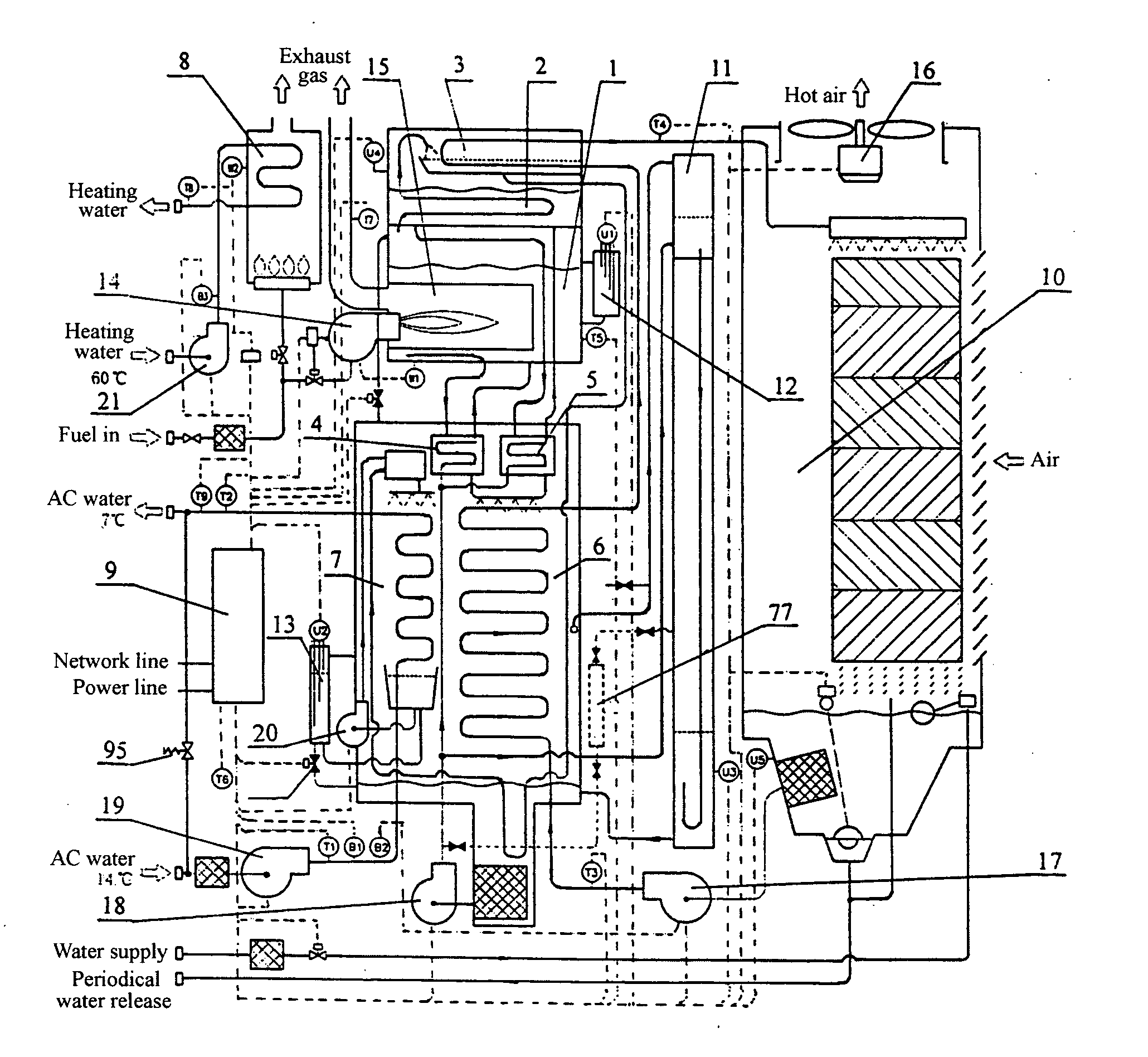

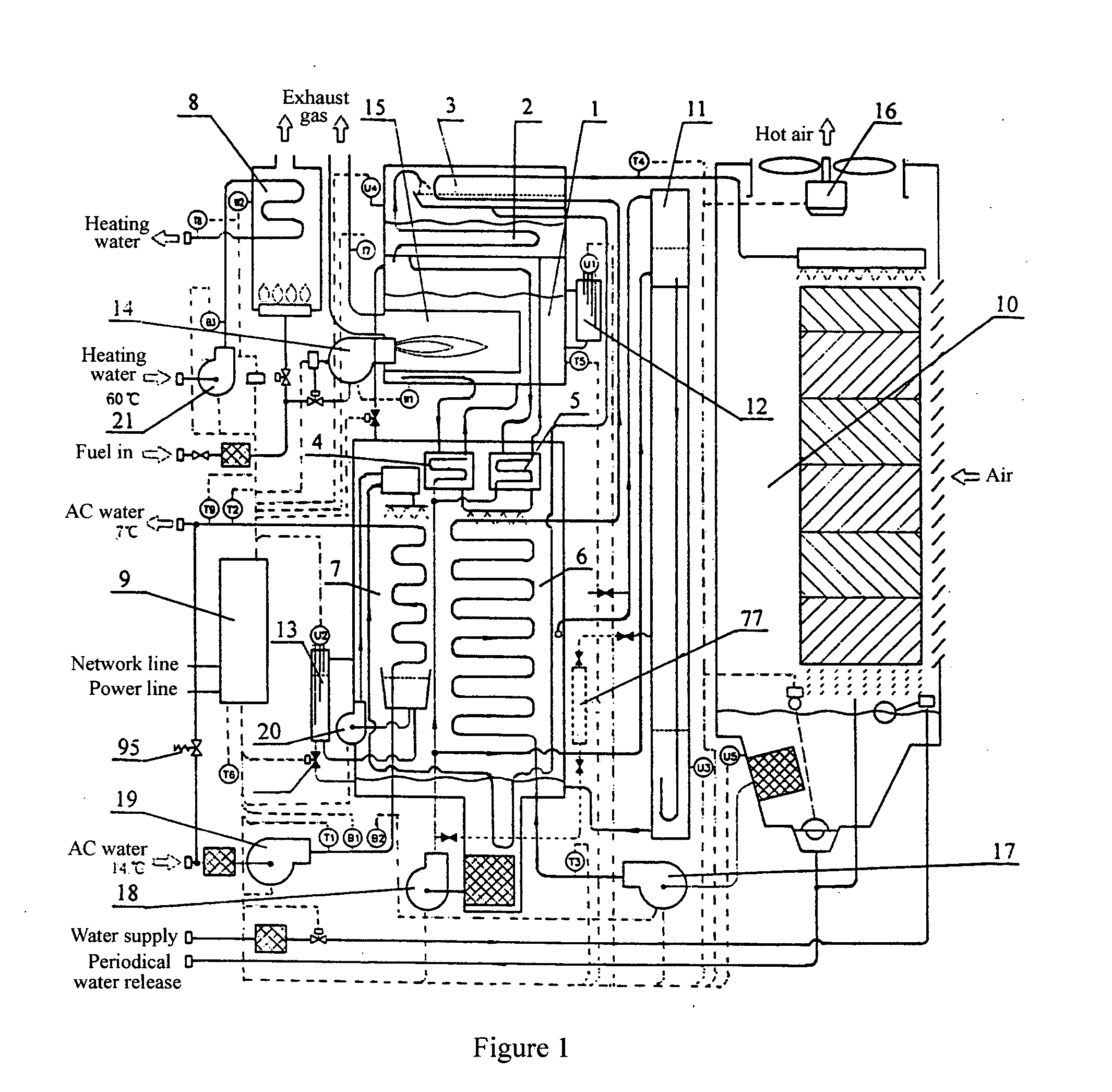

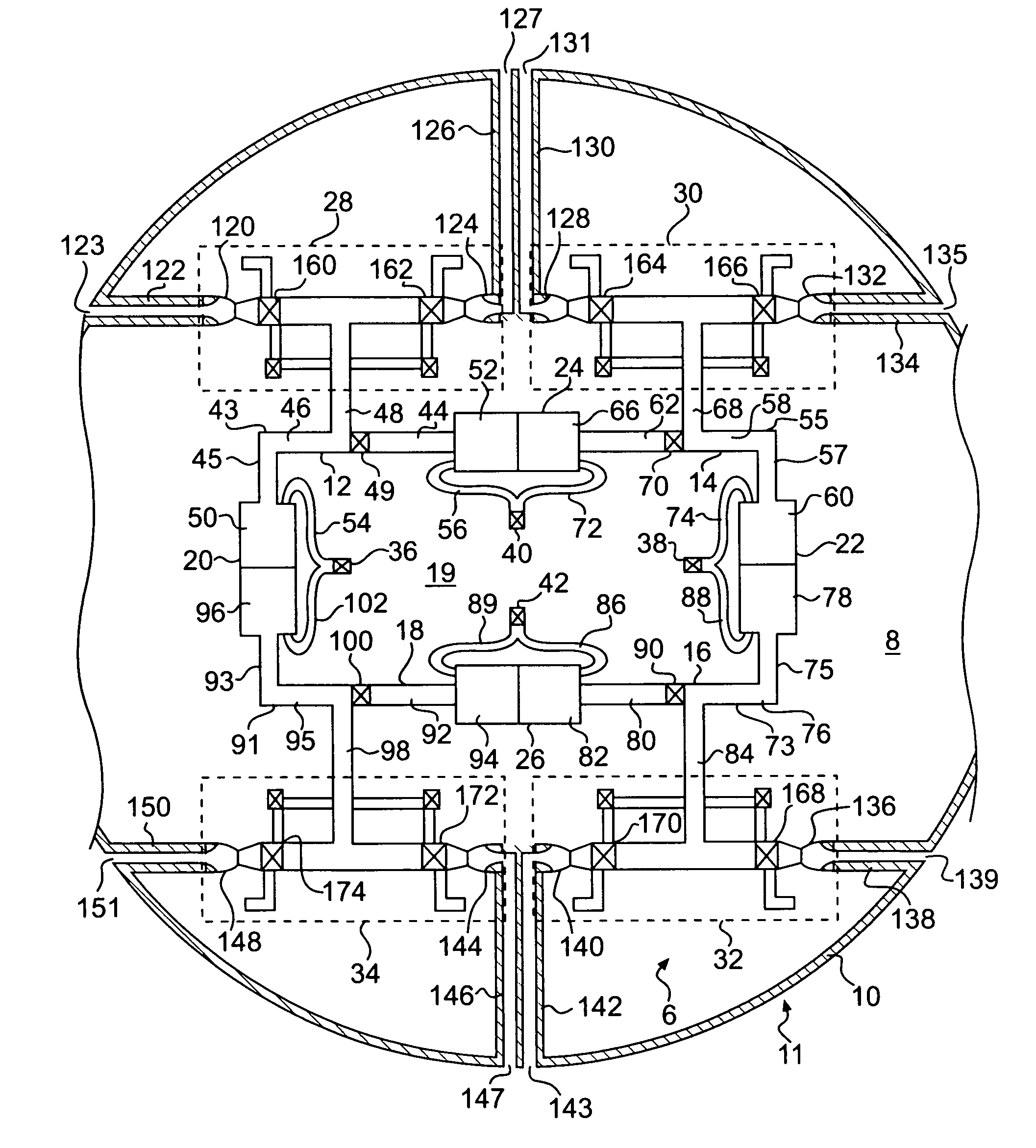

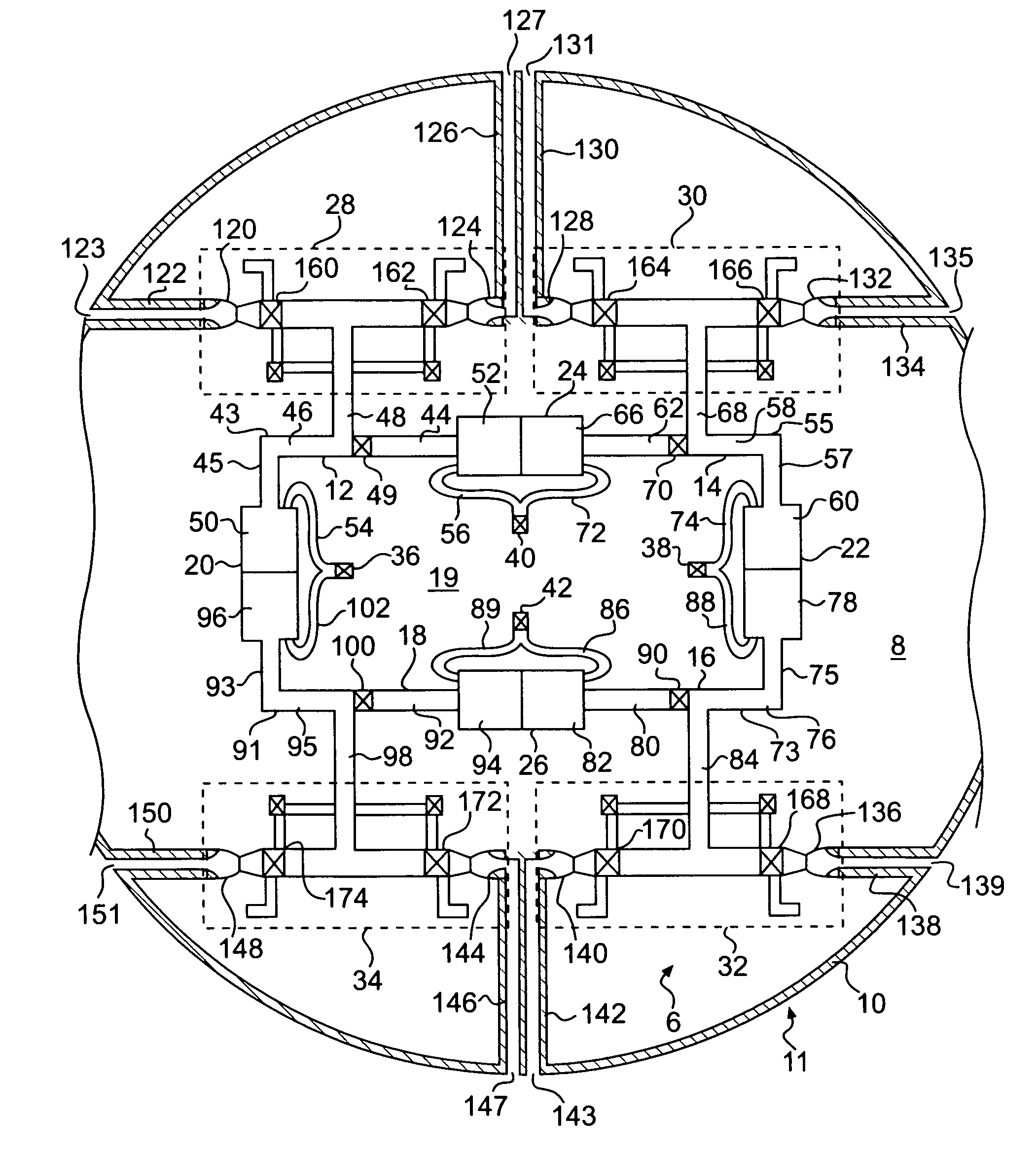

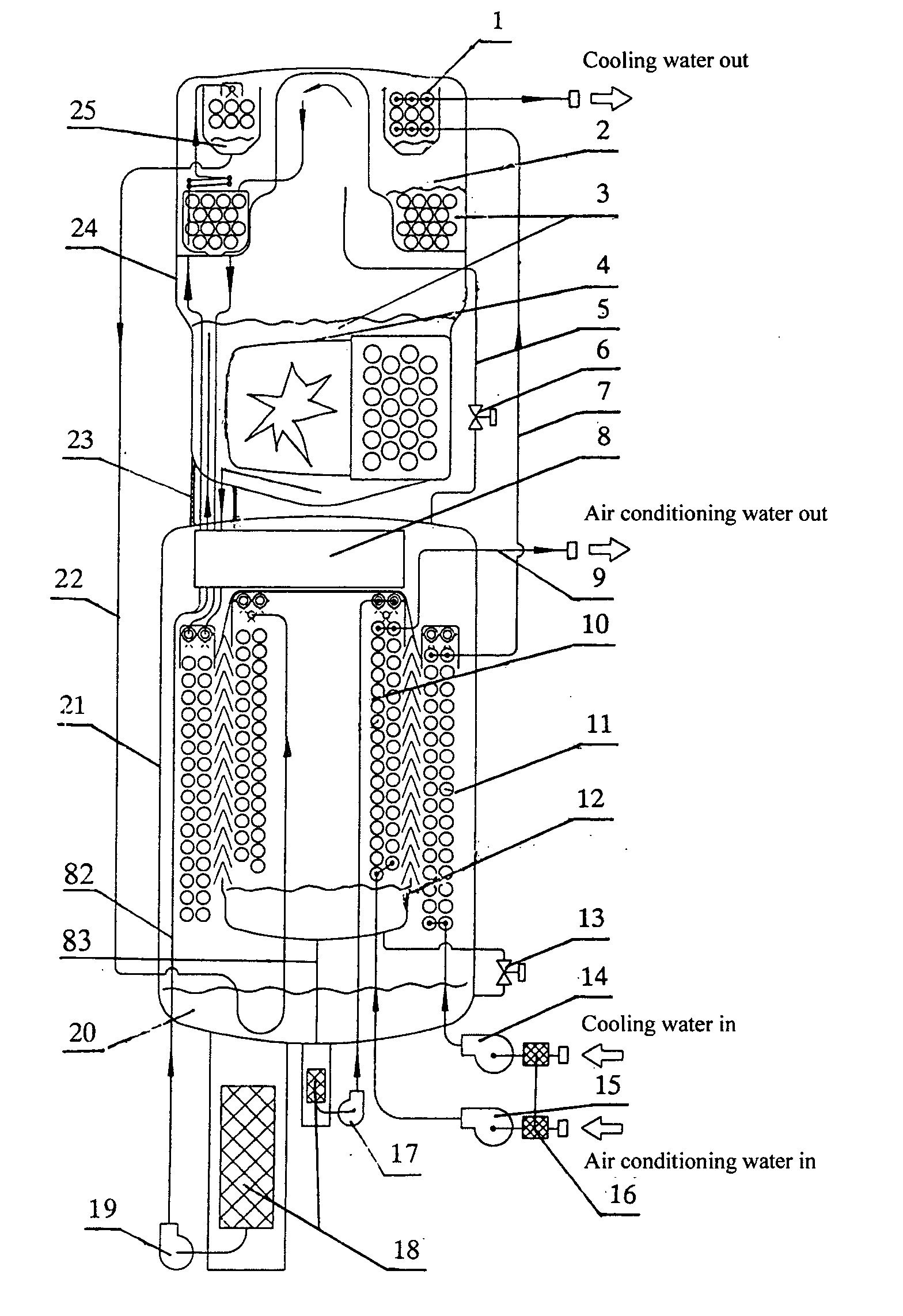

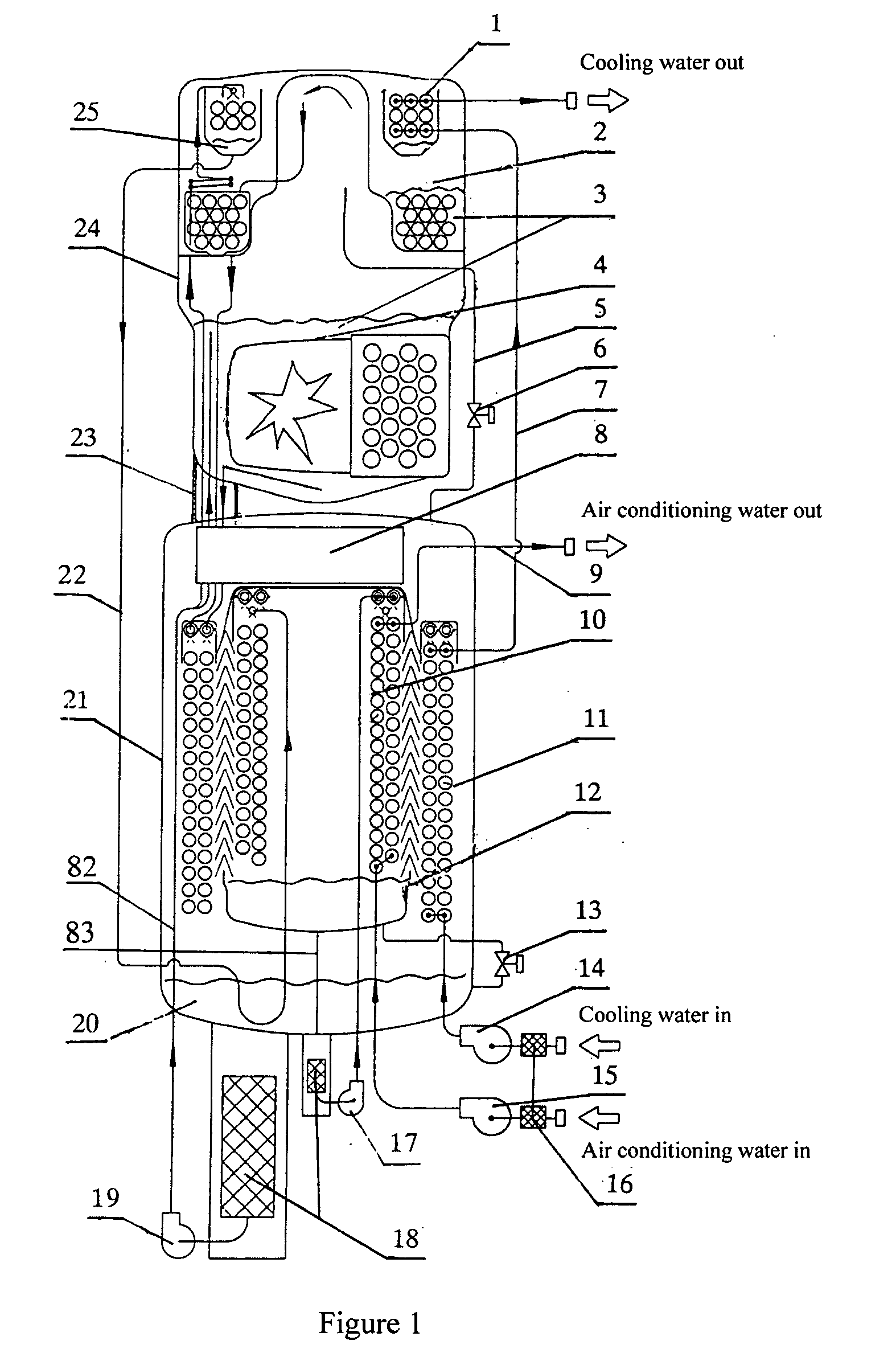

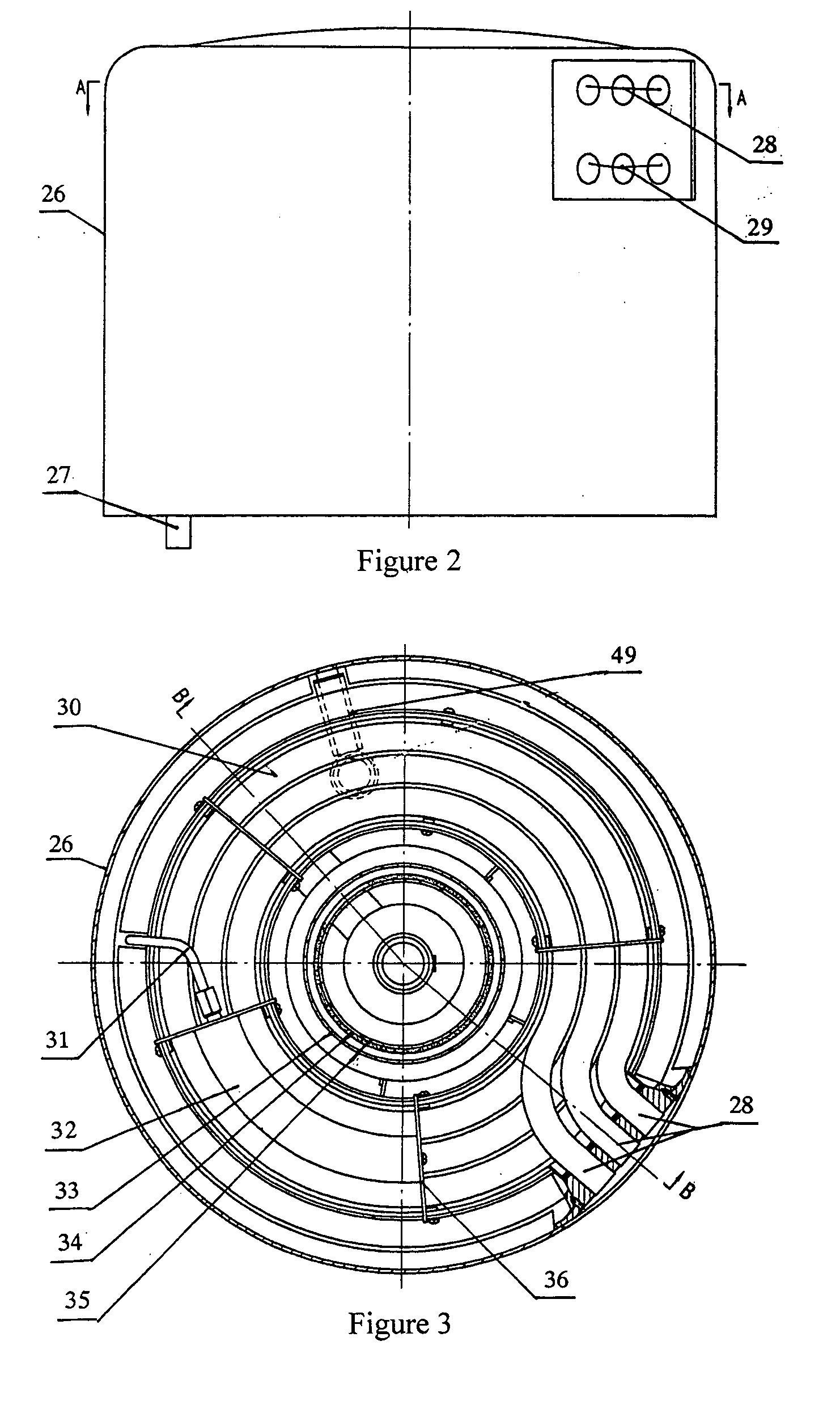

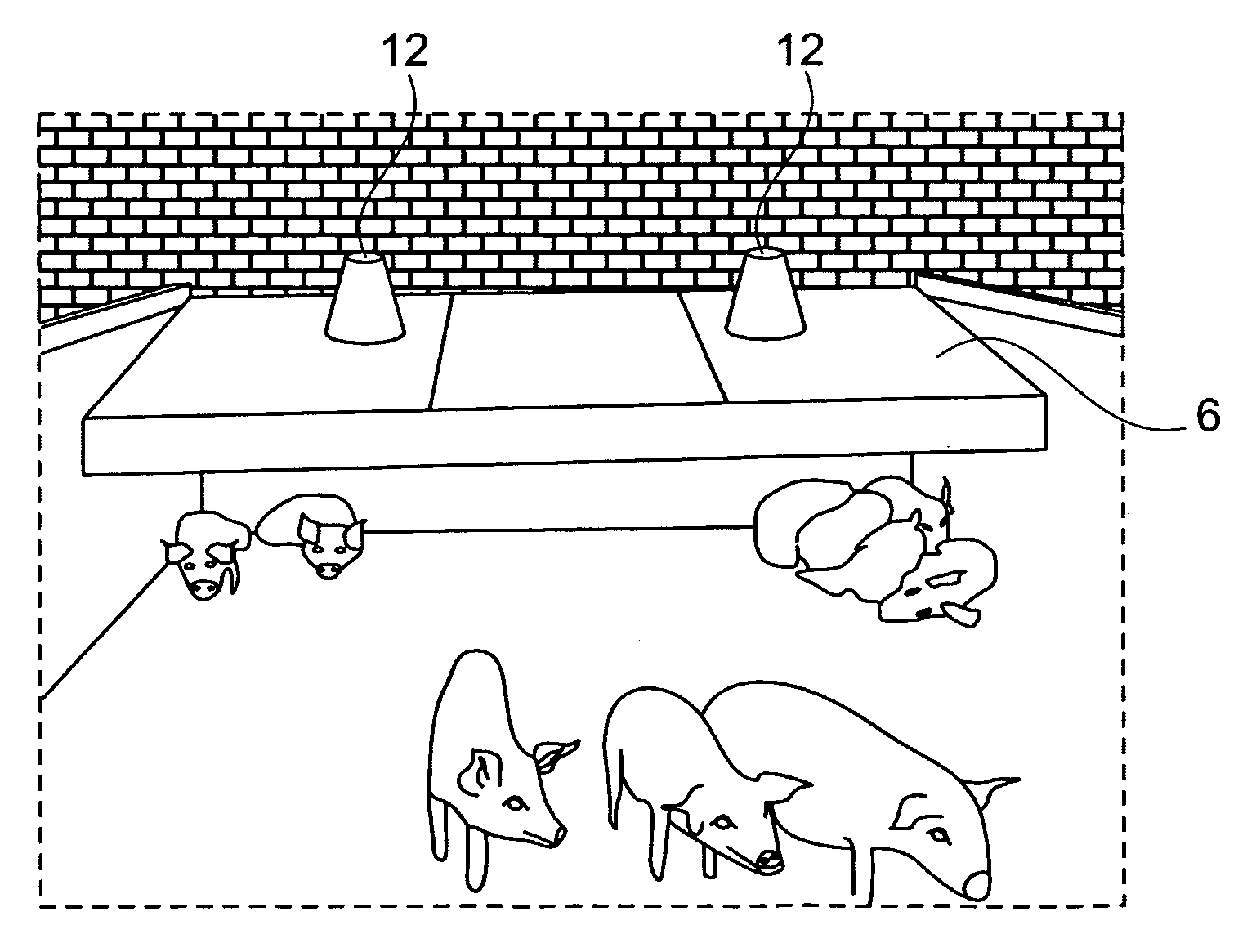

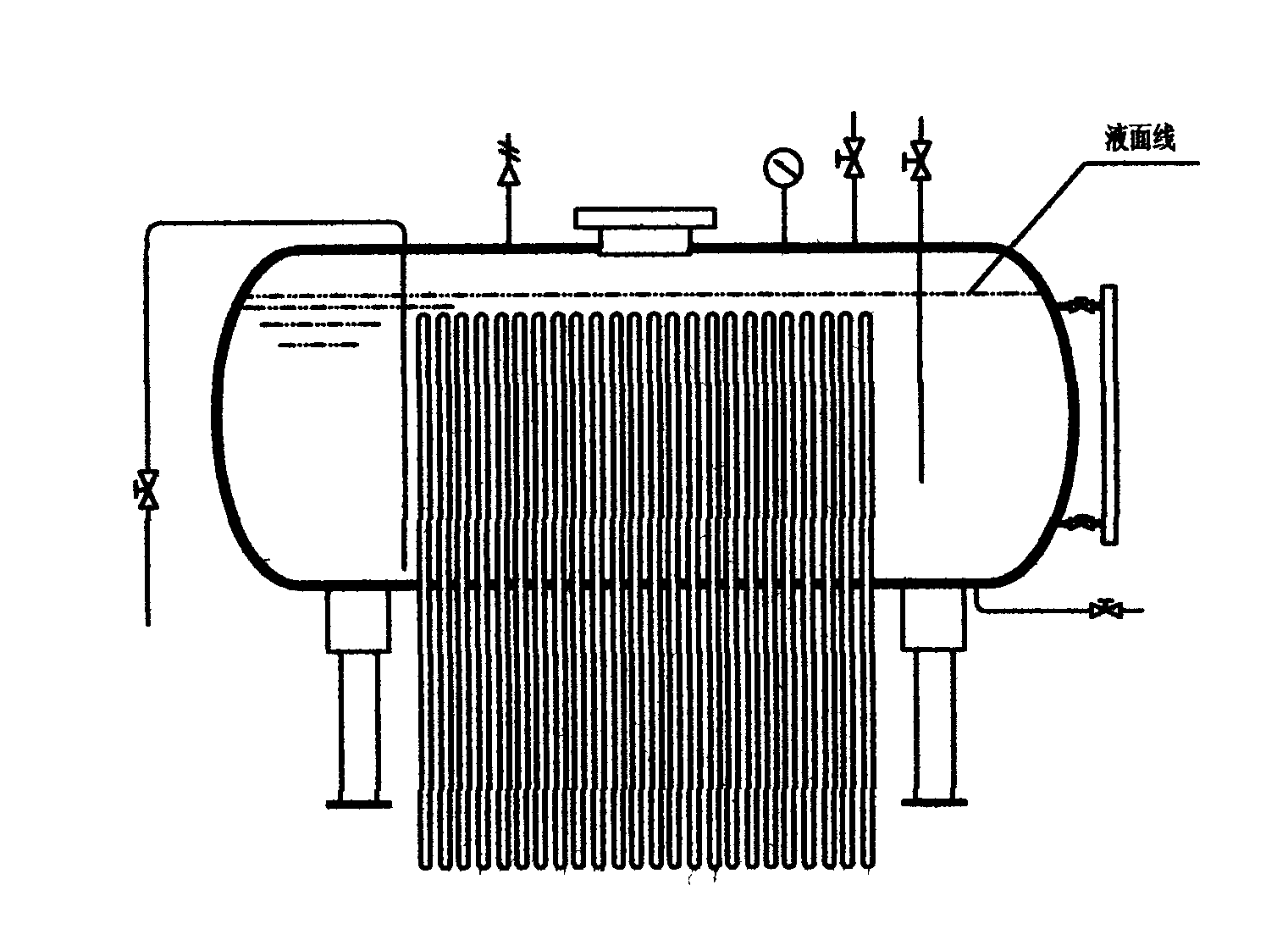

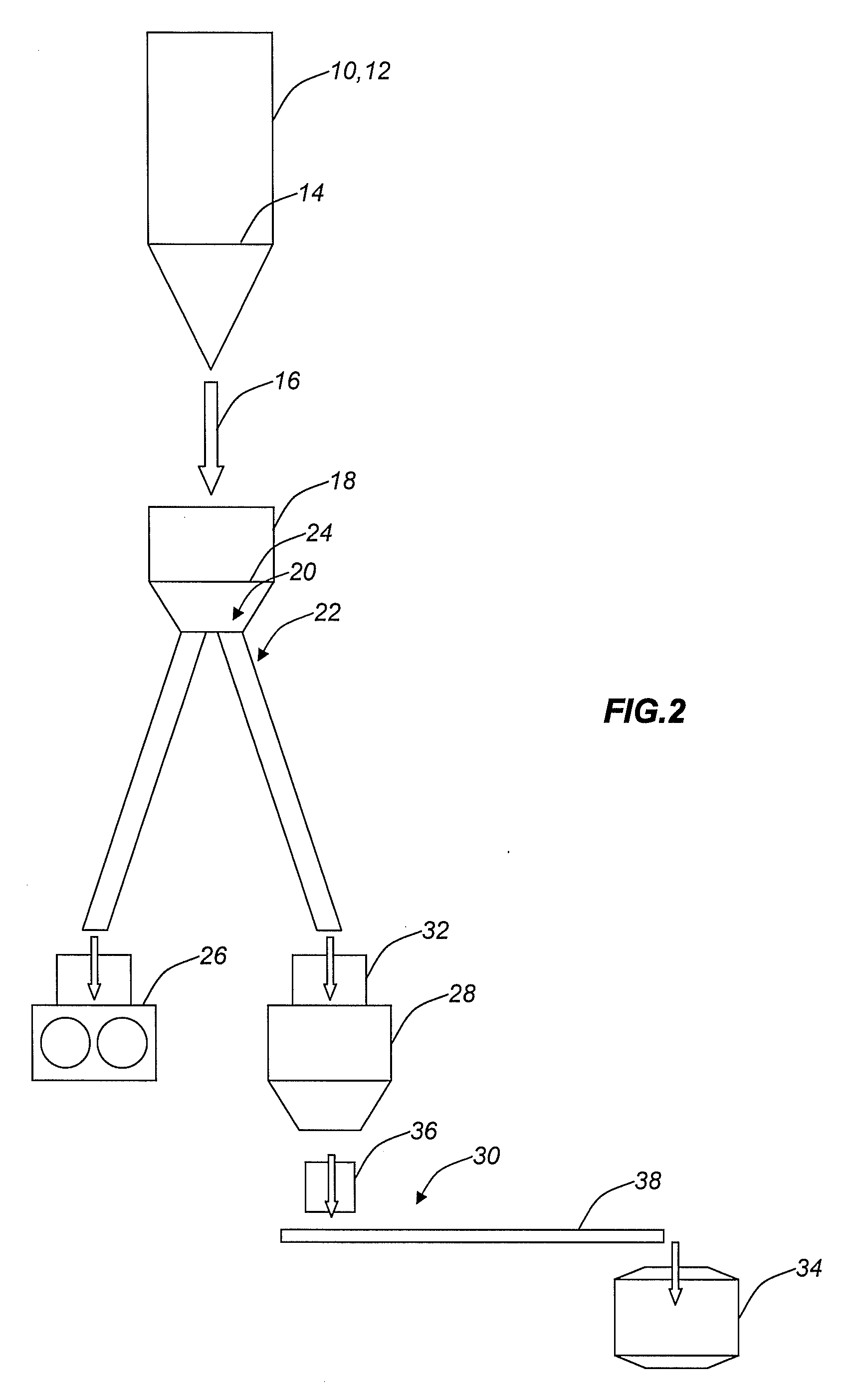

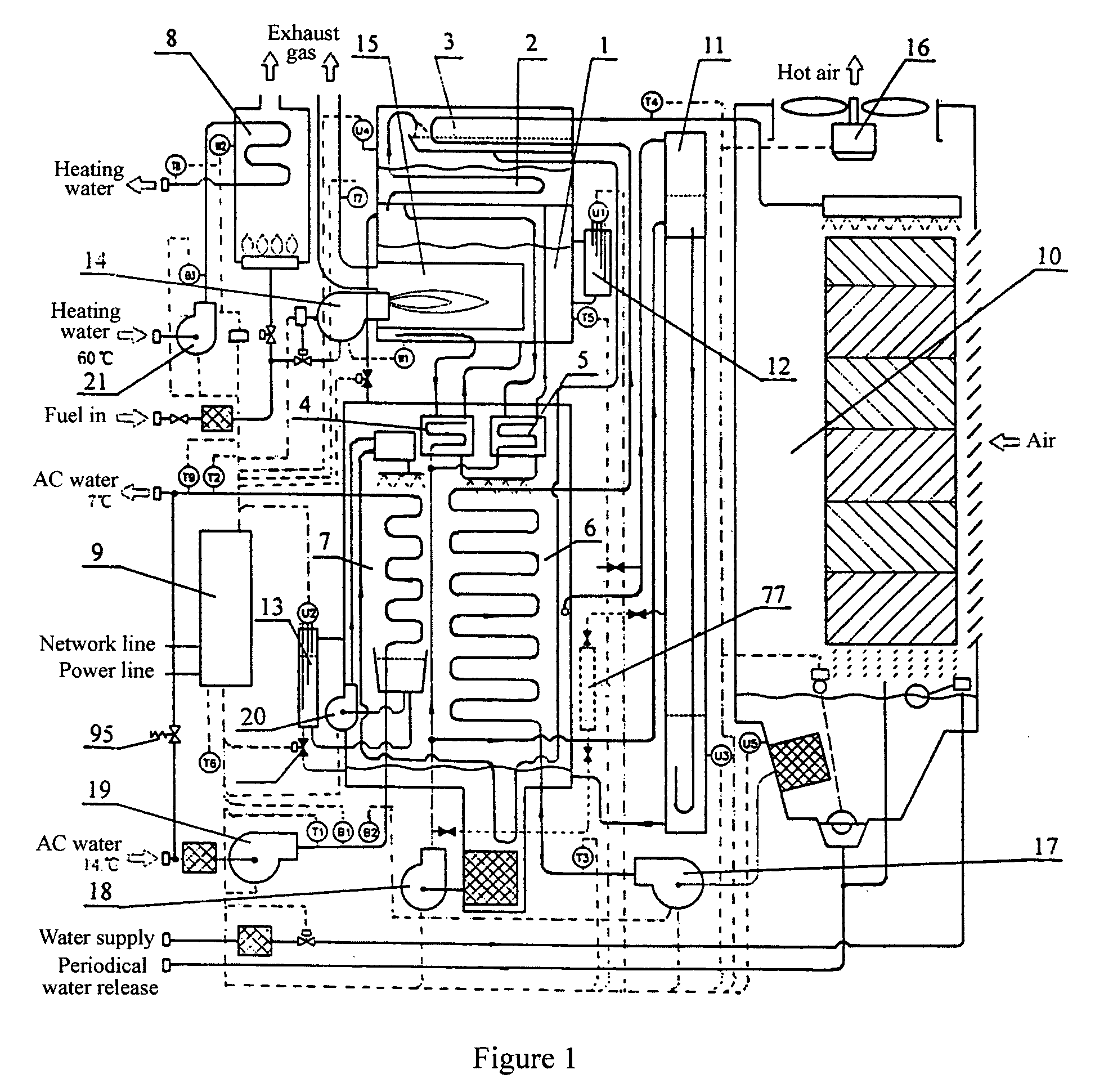

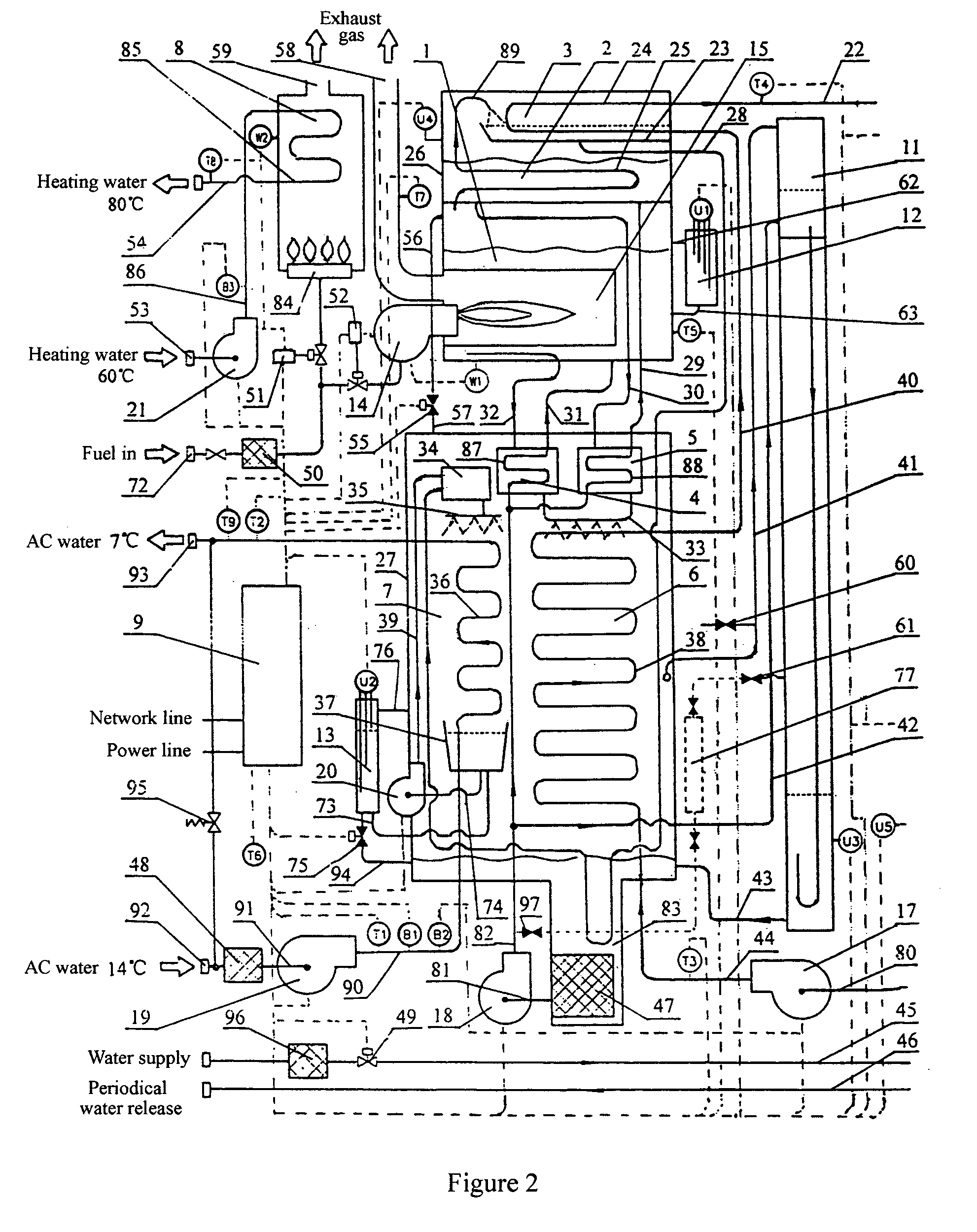

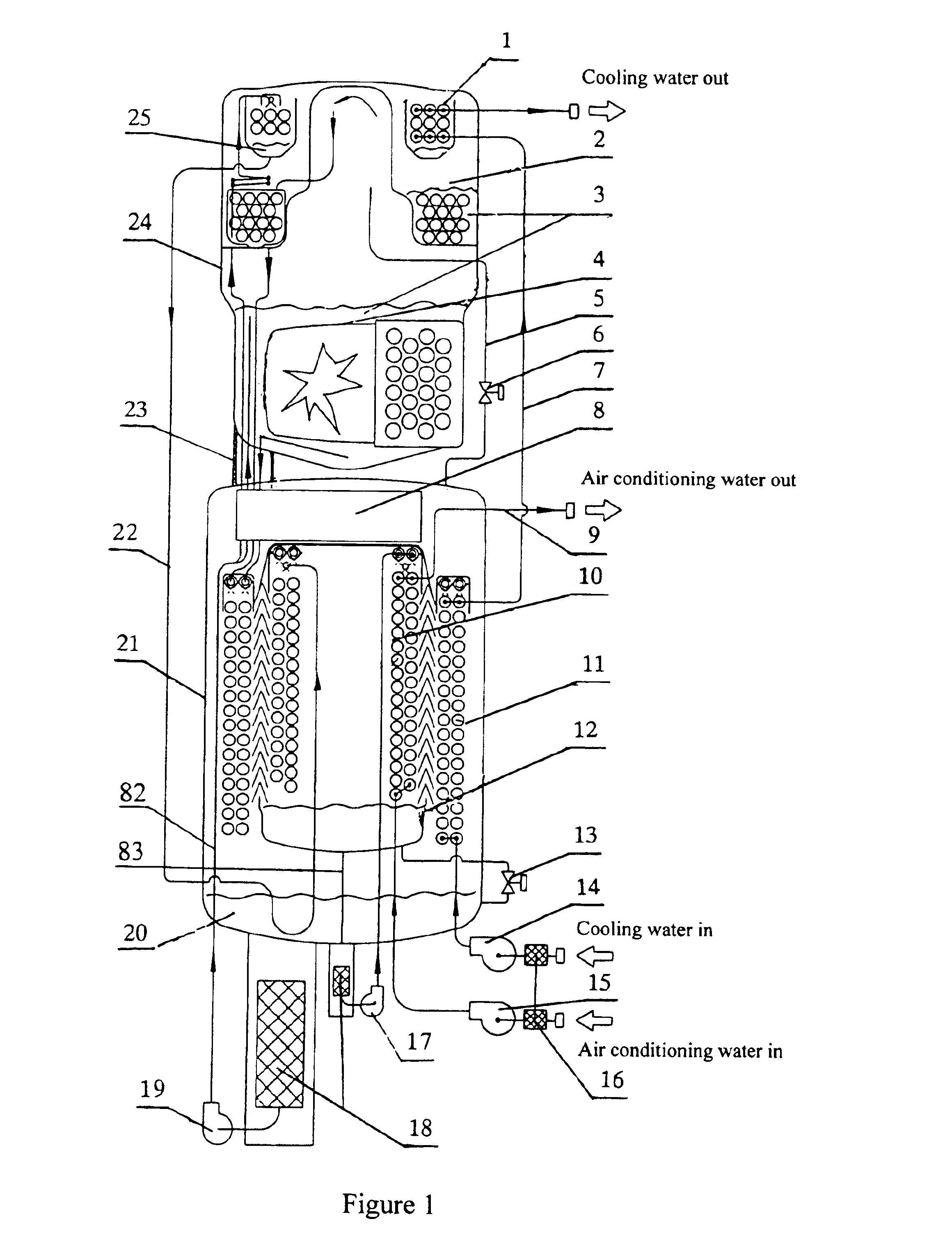

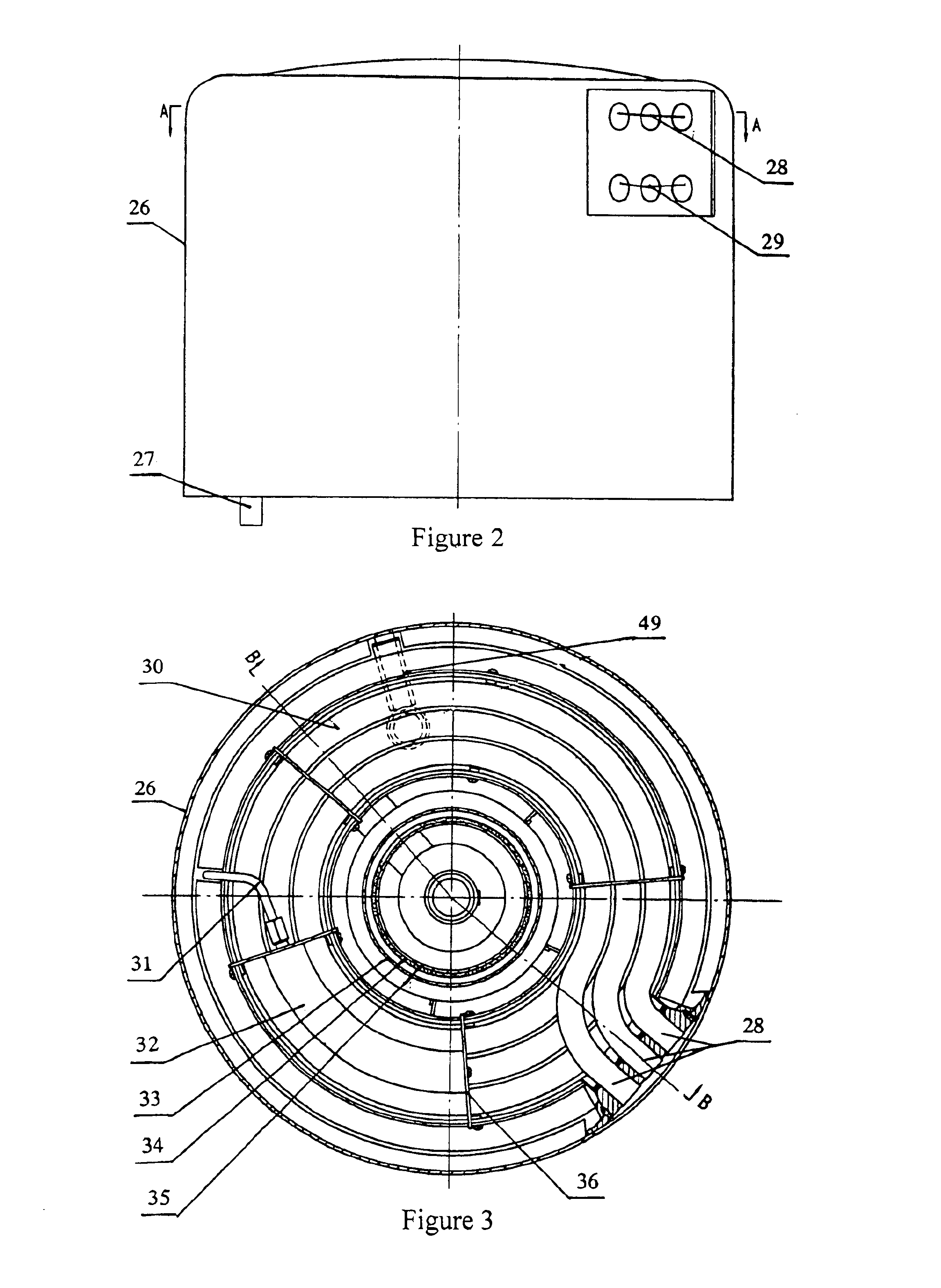

Absorption-type air conditioner system

ActiveUS20050016204A1Compact structureFew external welding seamBoilers/analysersEnergy efficient heating/coolingAir cycleLithium bromide

An absorption-type air conditioner system using lithium bromide solution as absorbent is provided, which has a small volume and compact structure. The system includes upper vessel 26, lower vessel 27, cooling heat exchanger 10, self-induced air circulation device 11, outdoor system controller 9 and water heater 8. Upper vessel 26 includes high temperature generator 1, low temperature generator 2 and condenser 3. The lower vessel 27 includes high temperature heat exchanger 4, low temperature heat exchanger 5, evaporator 7 and absorber 6. Upper vessel 26 is connected to lower vessel 27 by refrigerant water outlet pipe 28, LTG dilute solution inlet pipe 29, LTG concentrate solution outlet pipe 30, HTG dilute solution inlet pipe 31, HTG concentrate solution outlet pipe 32, HTG steam outlet pipe 56, heating steam switch valve 55 and HTG steam inlet pipe 57. The system is an ideal central air conditioner system for large houses.

Owner:ZHANG YUE

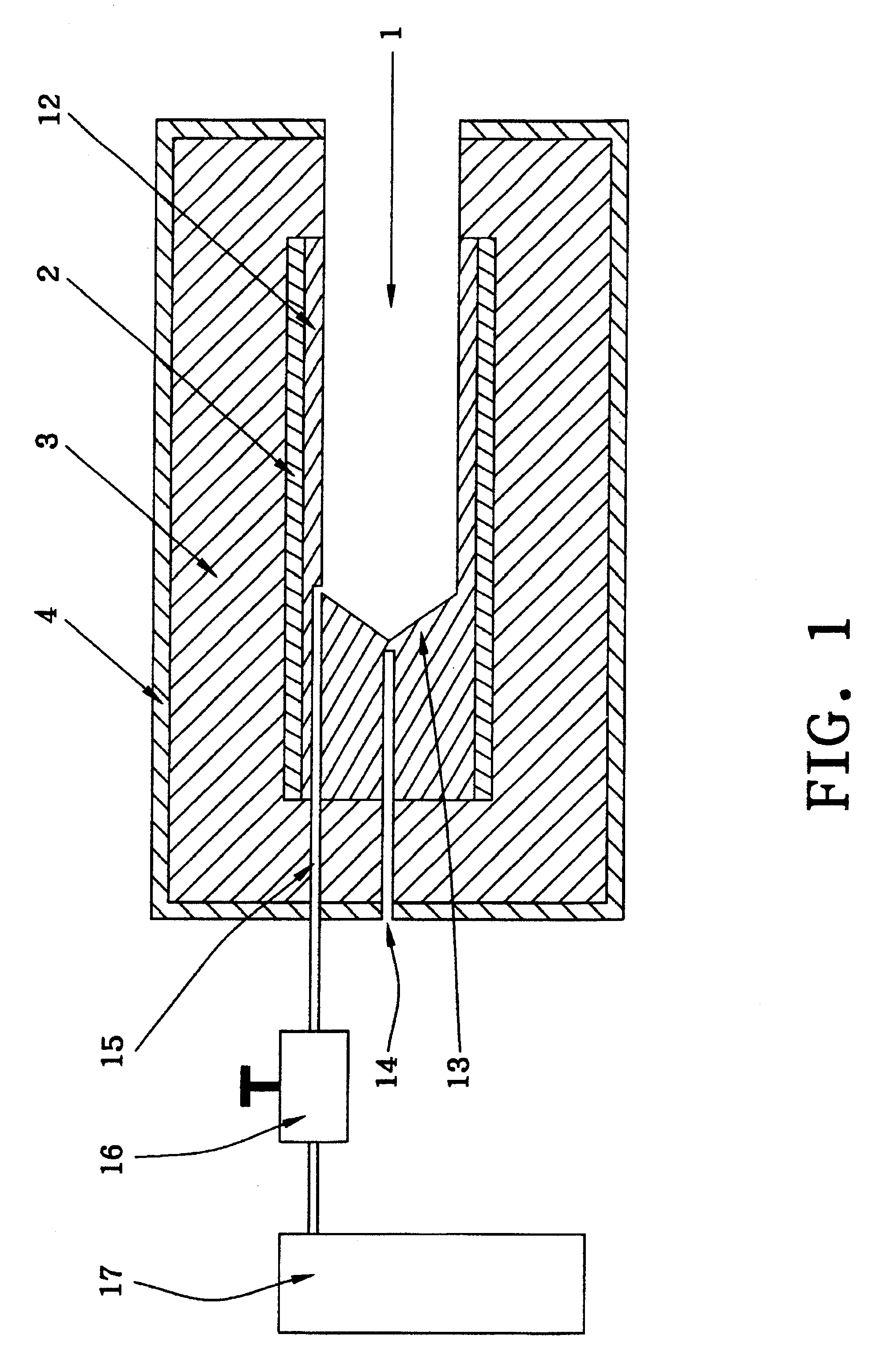

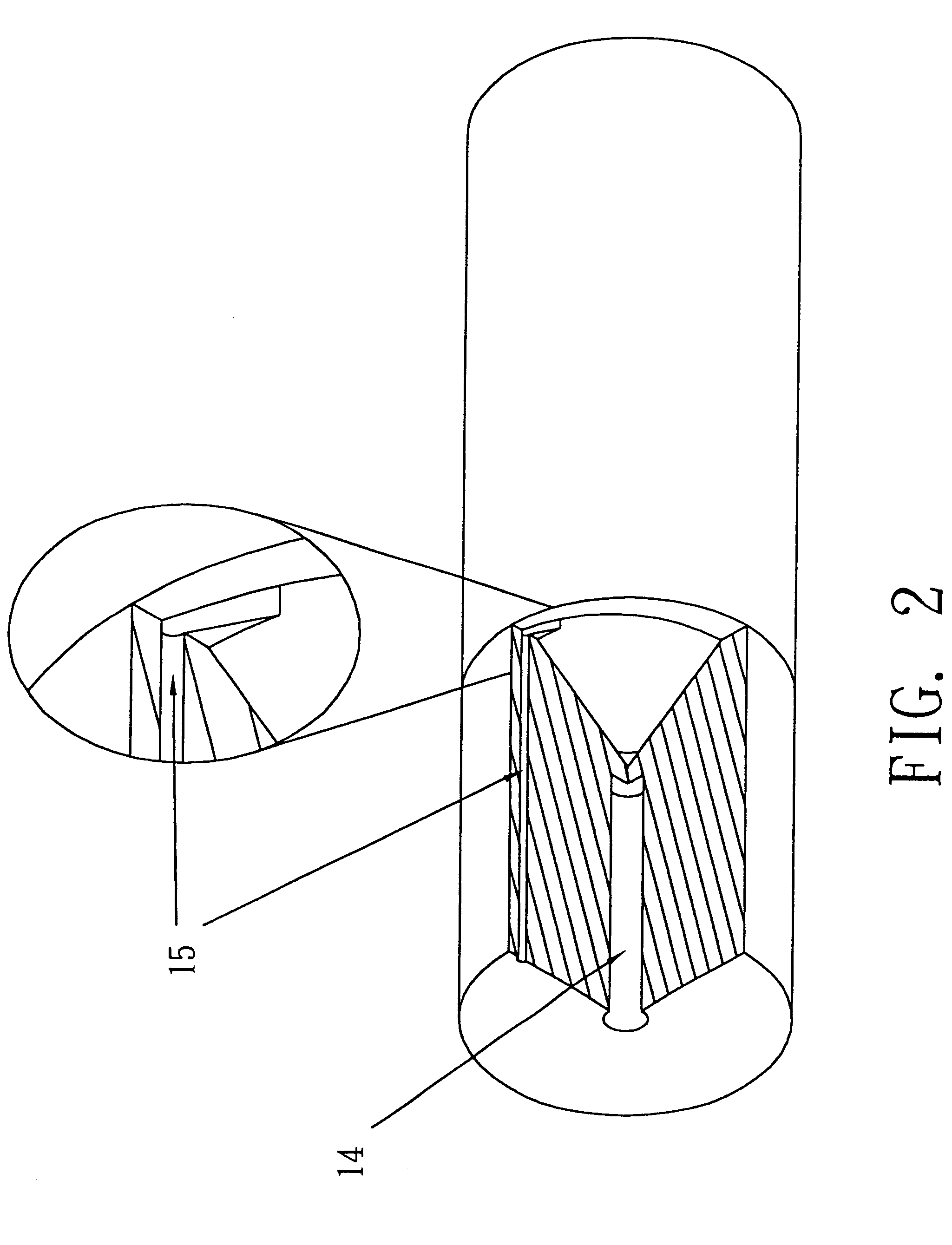

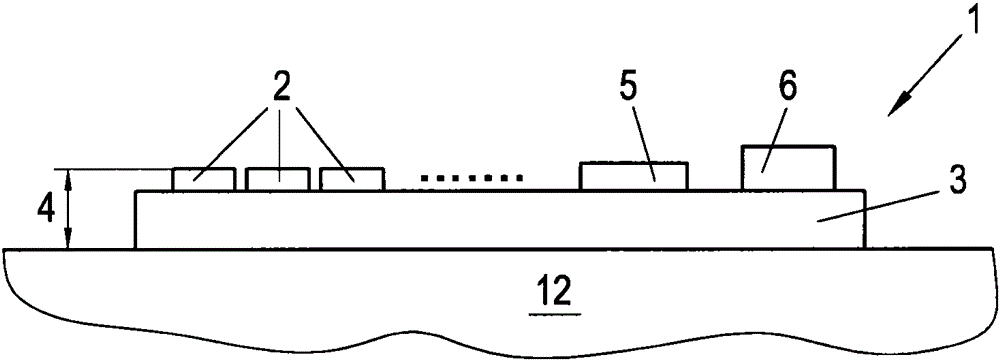

Ship propeller

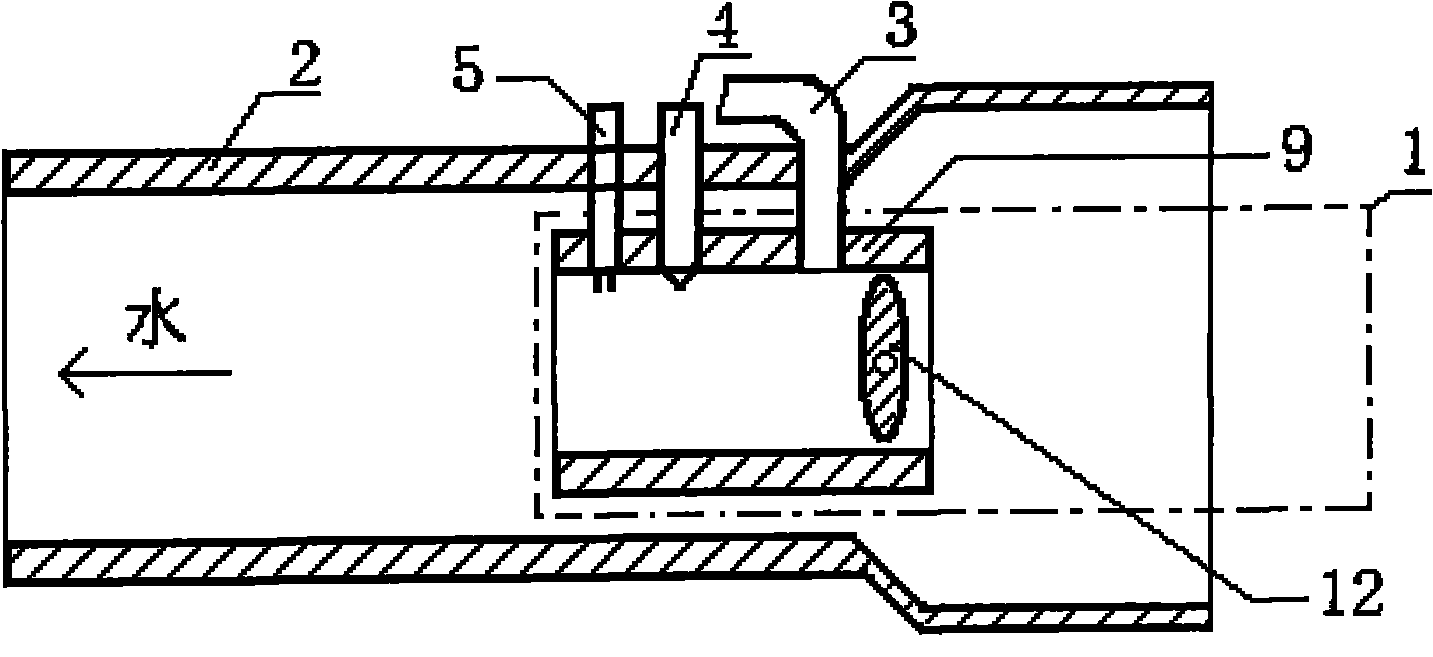

InactiveCN101927823ALess heat lossRealize integrationPropulsive elementsModular compositionHigh energy

The invention discloses a ship propeller which mainly comprises a cylinder and a jet pipe, wherein the cylinder is provided with a compressed air inlet, a fuel nozzle and an ignition unit. The ship propeller is characterized in that both the cylinder (1) and the jet pipe (2) of the propeller work in water, compressed air and fuel are respectively introduced into the cylinder through the compressed air inlet (3) and the fuel nozzle (4) and are subject to burning explosion under the action of an ignition unit (5), and burning explosion products directly jet out a water column in the jet pipe (2) so as to generate a thrust force based on the reactive force. Compared with the known ship propelling system, the propeller uses the cylinder part as the power unit, uses the jet pipe part as the propelling unit and realizes the integration of the power unit and the propelling unit, thereby having the advantages of high propelling efficiency, high energy utilization efficiency, high economical efficiency, simple structure and high operational reliability. The invention includes multiple implementation schemes, can realize the ultra high-power propulsion by modular combination and is applicable to various ships.

Owner:李江平 +1

Post boost control power assembly

InactiveUS7875838B1Minimal heat lossLess heat lossCosmonautic vehiclesDirection controllersControl powerEngineering

A tubular distributor in a missile having a right-angled hollow tubular first section, the right-angled hollow tubular first section having a first leg and a second leg, a straight hollow tubular second section, an end of the first leg of the right-angled hollow tubular first section perpendicularly connected to a first end of the hollow tubular second section, a straight hollow tubular third section, a first end of the hollow tubular third section perpendicularly connected to the first end of the straight hollow tubular second section, and a close / open valve positioned within the straight hollow tubular third section, the close / open valve positioned between a gas generator and the straight hollow tubular second section.

Owner:NAVY U S NAVY AS REPRESENTED BY THE SEC OF THE

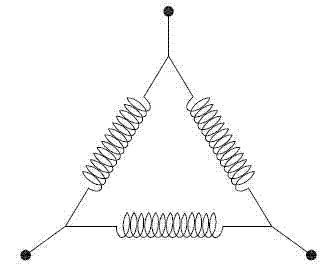

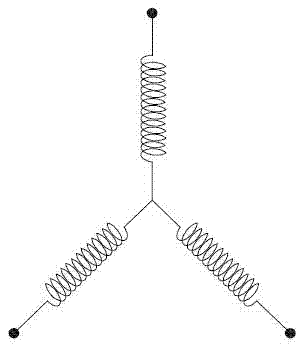

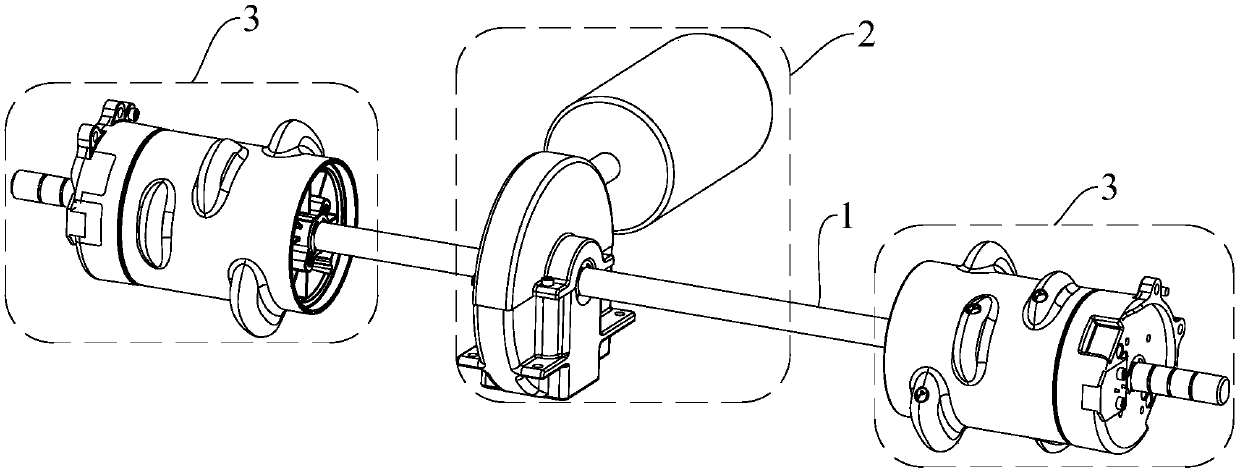

electric motor

InactiveCN102263469AReduced Capacitor RequirementsMeet Torque DemandsWindingsAC motor controlControl theoryElectric motor

An electric motor arrangement comprising an electric motor having a rotor, a stator, a first coil set and a second coil set. The first coil set is arranged to form a first sub motor with a control device being arranged to control current in the first coil set to generate a first torque on the rotor. The second coil set is arranged to form a second sub motor with the control device being arranged to control current in the second coil set to generate a second torque on the rotor. The first sub motor is arranged to have a first torque efficiency profile and the second sub motor is arranged to have a second torque efficiency profile. A controller is provided to determine a first torque value generated by the first sub motor and a second torque value generated by the second sub motor in response to a requested torque demand based on a required torque efficiency profile for the electric motor.

Owner:PROTEAN ELECTRIC LIMITED

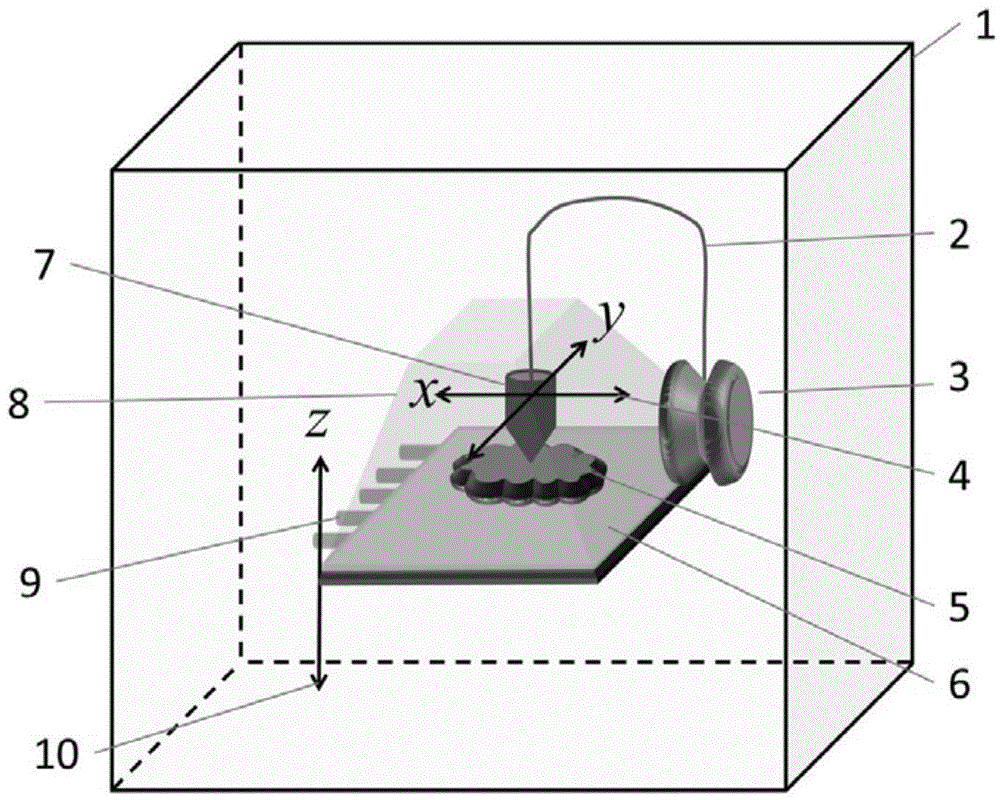

Metal part melting, extruding and quick-forming system and implementing method thereof

The invention discloses a metal part melting, extruding and quick-forming system and an implementing method thereof. The metal part melting, extruding and quick-forming system comprises a closed tank, a vacuum system and a gas flow control system, and a printing mechanism, a baseplate, a bobbin and a motion control system are arranged in the closed tank, wherein the bobbin is used for storing metal wires / strips, the printing mechanism comprises a crucible used for melting metal and an extruding nozzle, the baseplate is provided with heating pipes, a heat insulation device and a heatproof cover, the heatproof cover wraps the printing mechanism, and the motion control system is respectively connected with the printing mechanism and the baseplate. Metal is melted by independent heating and is extruded and formed; excellent performance of the metal is effectively combined with melting and extruding which is a low-cost and high-efficiency forming manner, so that the metal part melting, extruding and quick-forming system is low in forming cost, high in forming efficiency and applicable to massive popularization and application.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

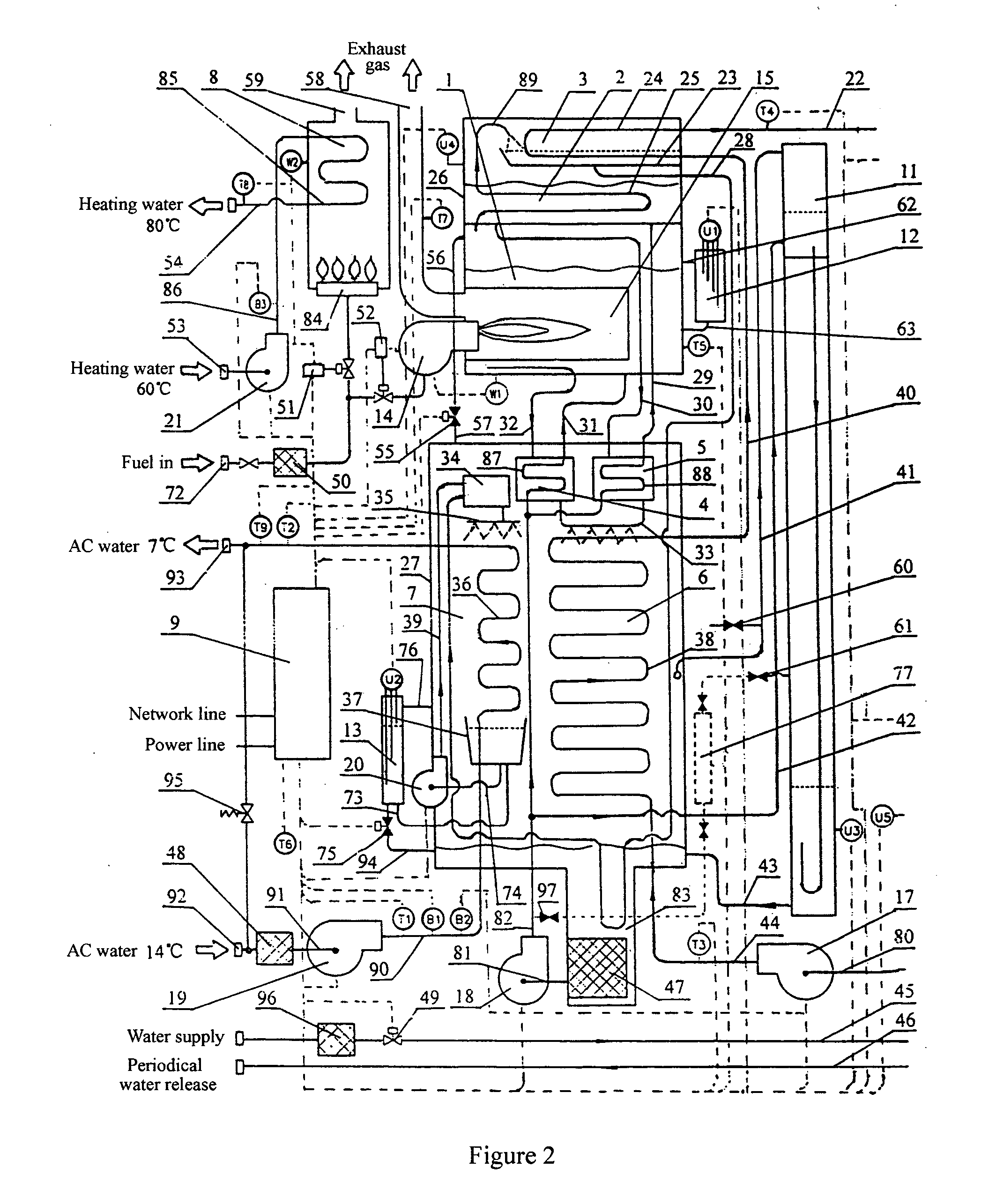

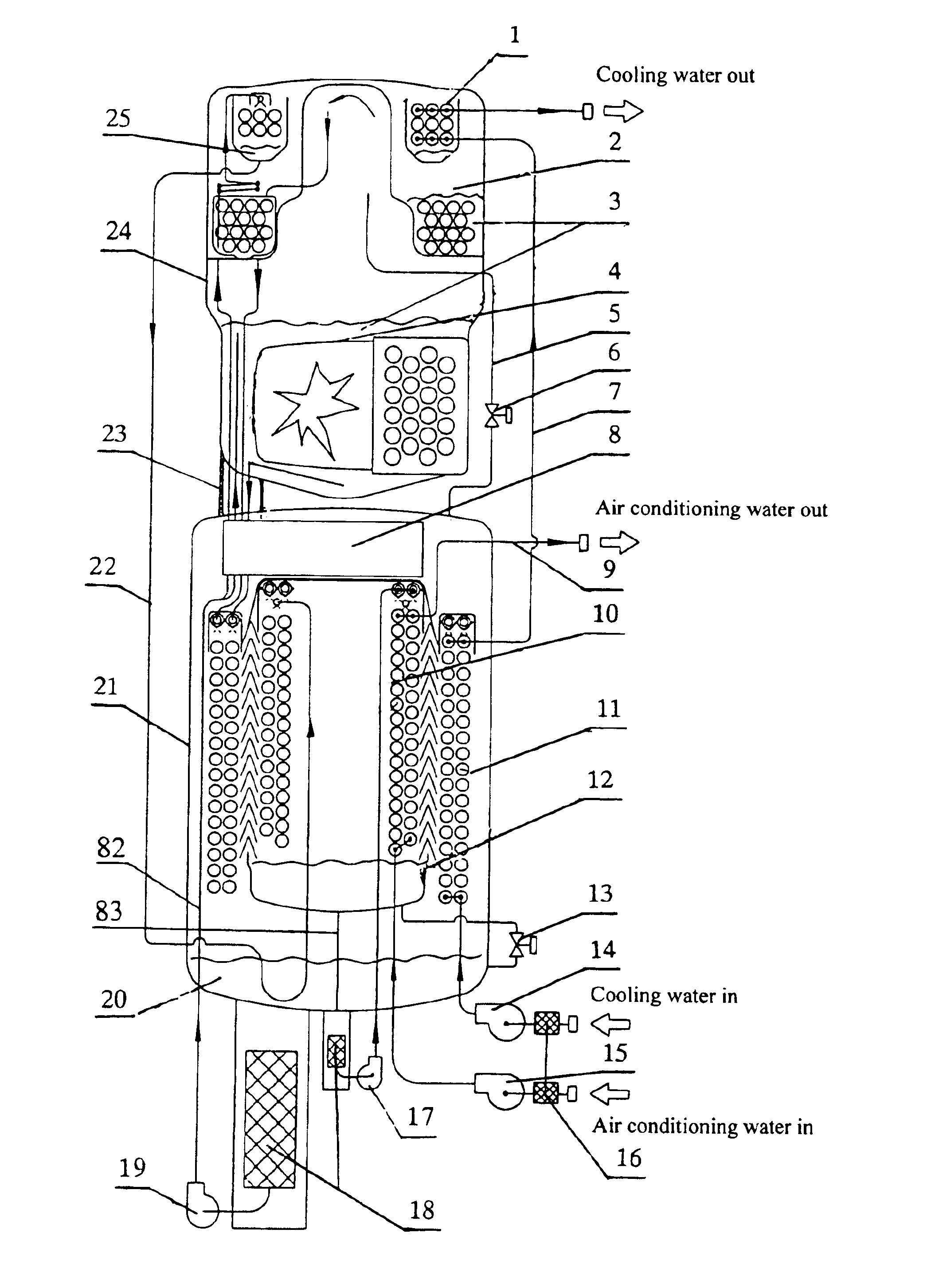

Absorption-type air conditioner core structure

ActiveUS20040177645A1Compact structureFew external welding seamBoilers/analysersEnergy efficient heating/coolingLithium bromideEngineering

An absorption-type air conditioner core structure is provided, which uses lithium bromide solution as absorbent and has a small volume and compact structure. The air conditioner core structure includes an upper vessel (24) and a lower vessel (21). The upper vessel and lower vessel are connected by a refrigerant water pipe (22), a cooling water pipe (7), a heating steam pipe (5), two concentrate solution pipes (27, 58) and two dilute solution pipes (46, 52). The concentrate solution and dilute solution pipes are disposed within a solution pipe protecting cover (23) which connects to both vessels. Because of its compact structure, small volume, fewer welding seams, high level of vacuum, and having the heat exchange pipes (30, 39, 61, 73) of the condenser 1, low temperature generator 2, evaporator 10 and absorber 11 all made of helical copper pipes, the air conditioner core structure has high heat exchange efficiency.

Owner:ZHANG YUE

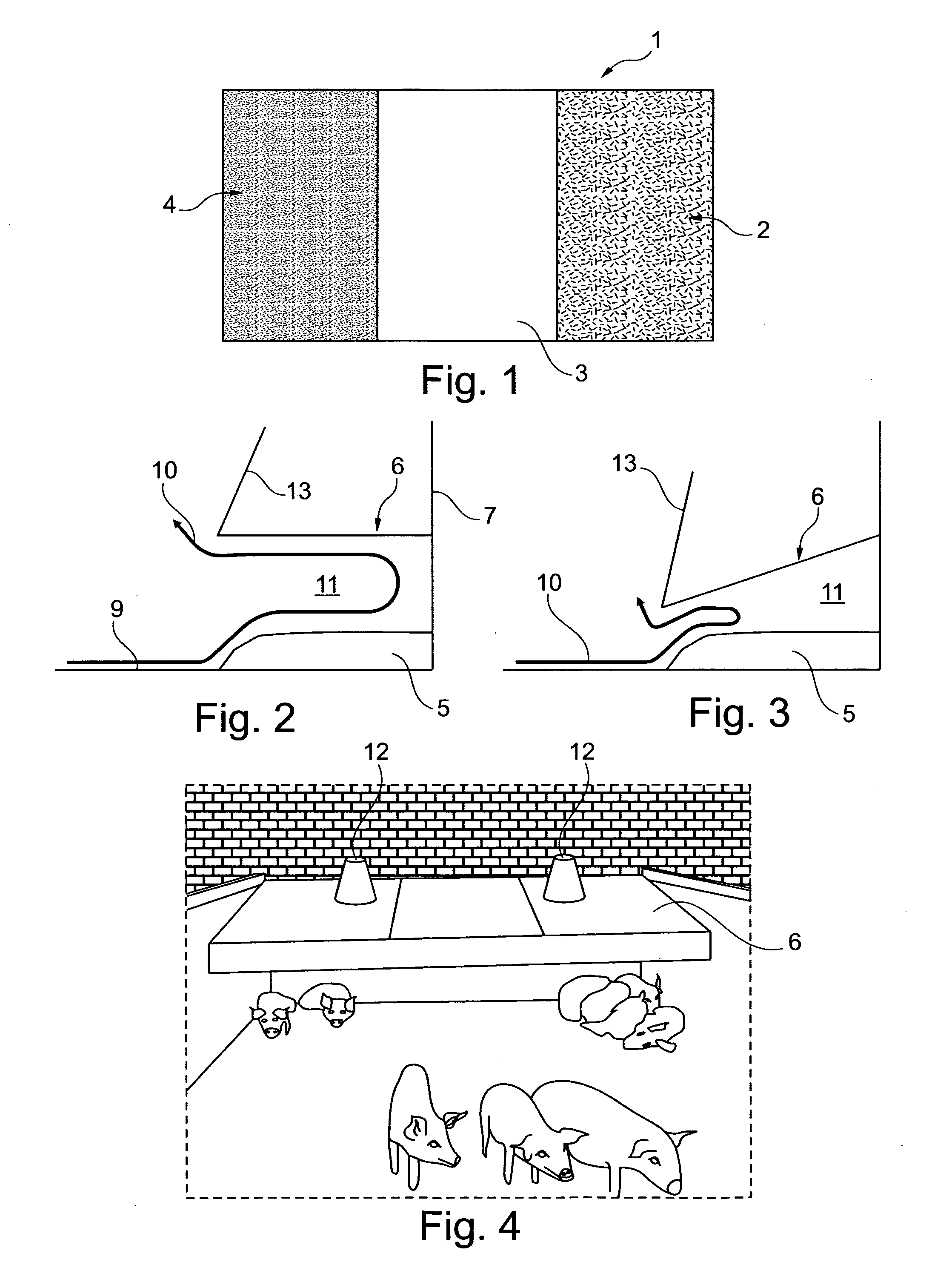

Intelligent Climate Control in Domestic Animal Stables

InactiveUS20120125264A1Weak thermal movementLess heat lossAnimal housingOther apparatusFeed consumptionEngineering

It is a problem in stables when the animals have a behaviour different from the intended. The behaviour is changed if the animals are too hot or too cold. The air temperature is not sufficient information as this lacks information about air speed, feed consumption by the animals, animal activity and health condition of the animals. Measuring the surface temperature of the animals by infrared sensors will contain all of the above factors. This surface temperature may be used for controlling heating, covering and cooling measures.

Owner:VENG NIELS SKOV

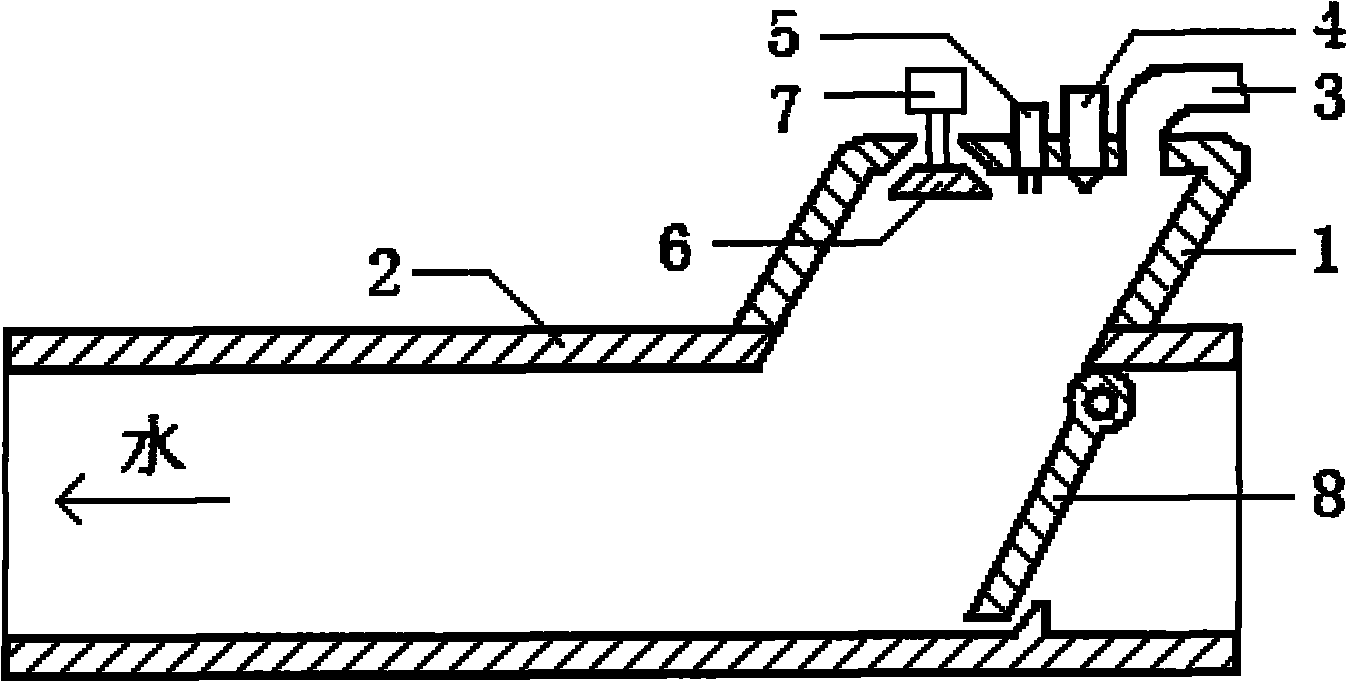

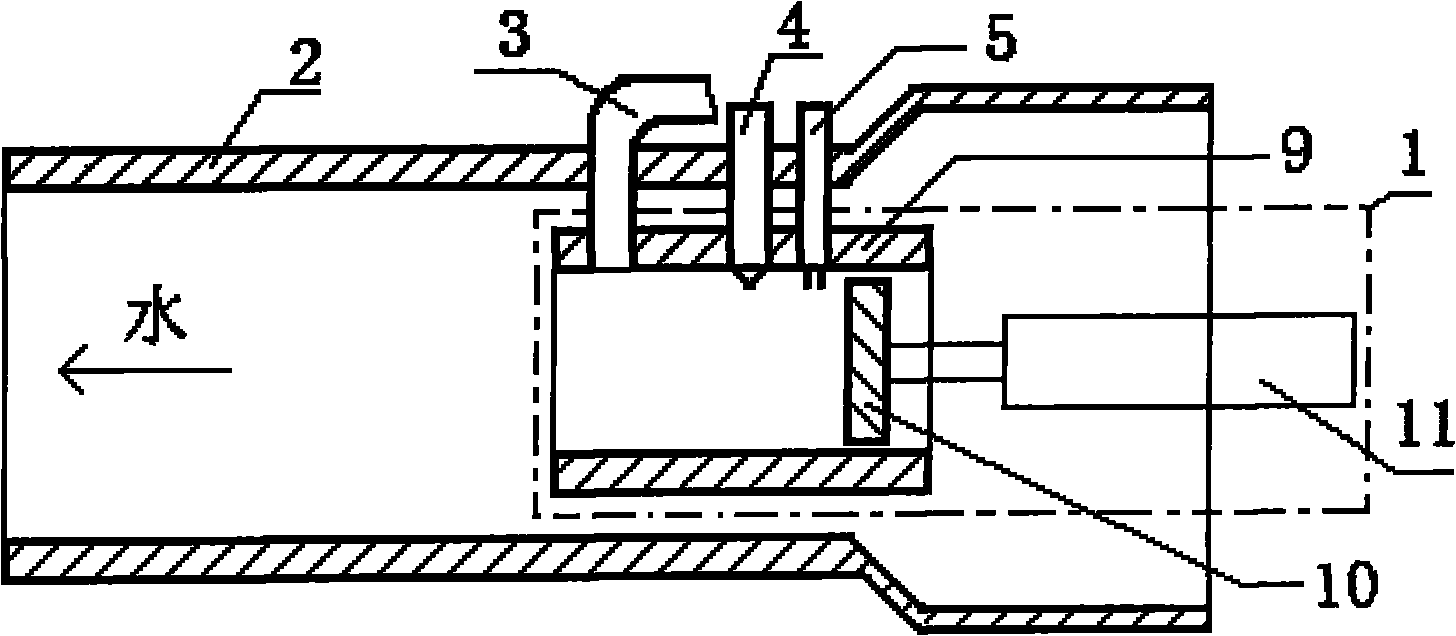

Novel heat distribution pipeline thermal insulation pipe pier system

InactiveCN105257953AEasy to operateLess heat lossThermal insulationPipe protection by thermal insulationPetroleumAerogel

Disclosed is a novel heat distribution pipeline thermal insulation pipe pier system in the technical field of petrochemical engineering. The novel heat distribution pipeline thermal insulation pipe pier system comprises a heat distribution pipeline, a steel plate, wedges, MQK nanometer aerogel layers, galvanized sheet iron, hydrophobic silicate cotton and a U-shaped steel band, wherein the steel plate is fixedly connected with a pipe pier; the first MQK nanometer aerogel layer is arranged on the upper surface of the steel plate; the second MQK nanometer aerogel layer is arranged in grooves of the upper surfaces of the wedges; the third MQK nanometer aerogel layer, the hydrophobic silicate cotton and the galvanized sheet iron sequentially wrap the outer surface of the heat distribution pipeline. A heat bridge between a high-temperature pipeline and the pipe pier can be completely cut off, the surface temperature and the heat flux of the pipe pier are substantially reduced, heat loss is remarkably reduced, and a large amount of heat energy is saved. The novel heat distribution pipeline thermal insulation pipe pier system is reasonable in design, simple in structure and applicable to the optimized design of the heat distribution pipeline thermal insulation system.

Owner:METROCOAT MATERIAL TECH SHANGHAI

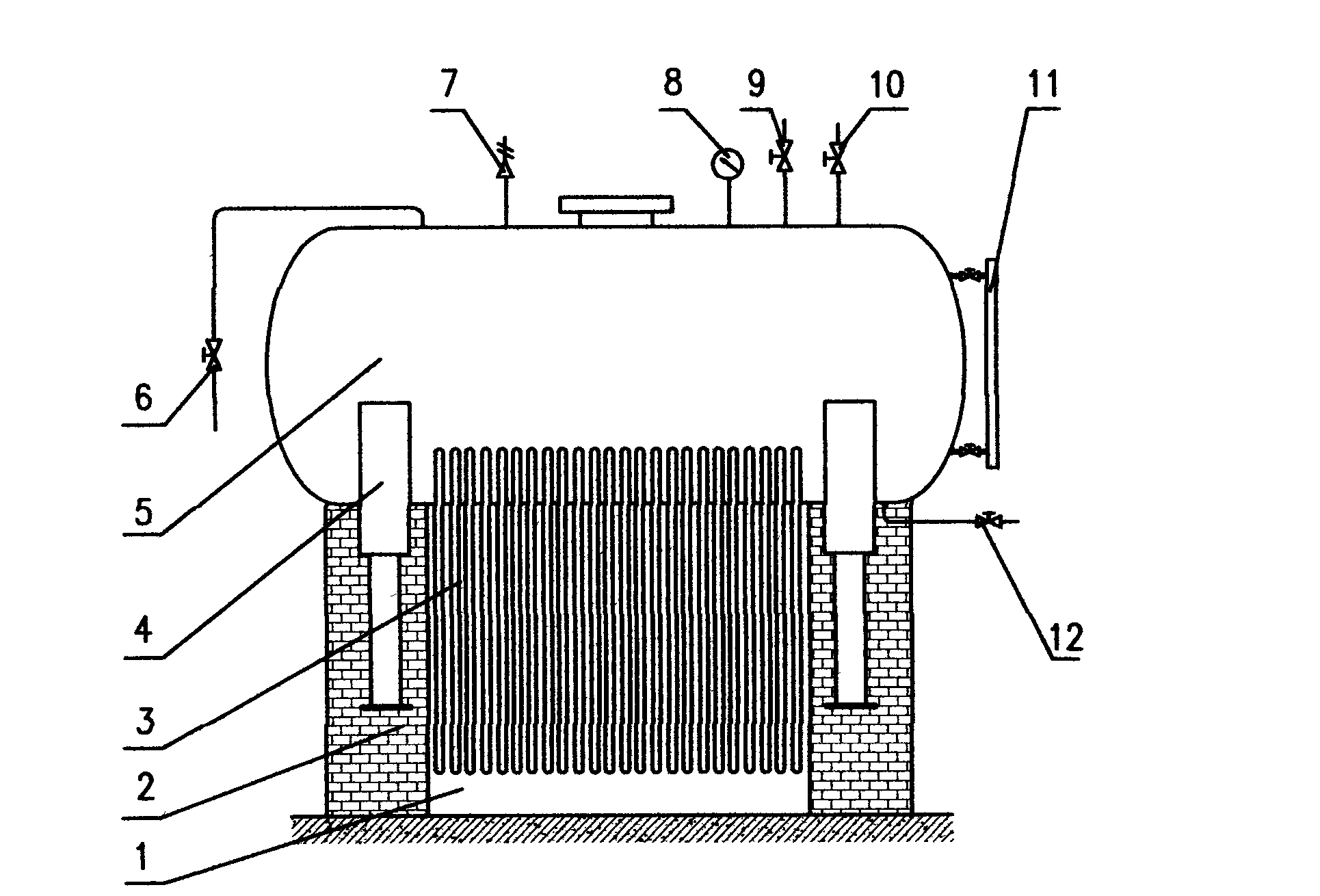

Heat-pipe type boiler/furnace/kiln flue-gas waste-heat recovery device

InactiveCN102322758ANo phase phenomenonWill not polluteIndirect heat exchangersInlet valveEngineering

The invention discloses a heat-pipe type boiler / furnace / kiln flue-gas waste-heat recovery device which externally consists of a cylindrical horizontal vessel and a heat pipe set, wherein the cylindrical horizontal vessel is provided with a support, supported on the outside of the top of a flue by the support, and respectively connected with a water inlet valve, a safety valve, a pressure gauge, a discharge valve, a water outlet valve, a liquid level meter and a blow-off valve by pipes; the heat pipe set is composed of a plurality of heat pipes which are arranged according to a certain rule, the upper half parts of the pipes stretch into the water in the horizontal vessel, and the lower half parts of the pipes are inserted in the flue, so that mediums in the pipes are heated by high-temperature flue gas in the flue so as to form a steam flow, the steam flow transfers heats to the upper half parts of the heat pipes in the process of upward movement and then transfers the heats to the water in the vessel, after the heats are released, the mediums are condensed into liquid, and then the liquid flows back to the lower half parts of the heat pipes, after the process is circulated repeatedly, the heats in the flue gas are collected and rapidly transferred to the vessel so as to heat the water in the vessel to a high temperature. The waste-heat recovery device disclosed by the invention is high in heat efficiency, less in heat-transfer loss, safe and reliable.

Owner:林世鸿

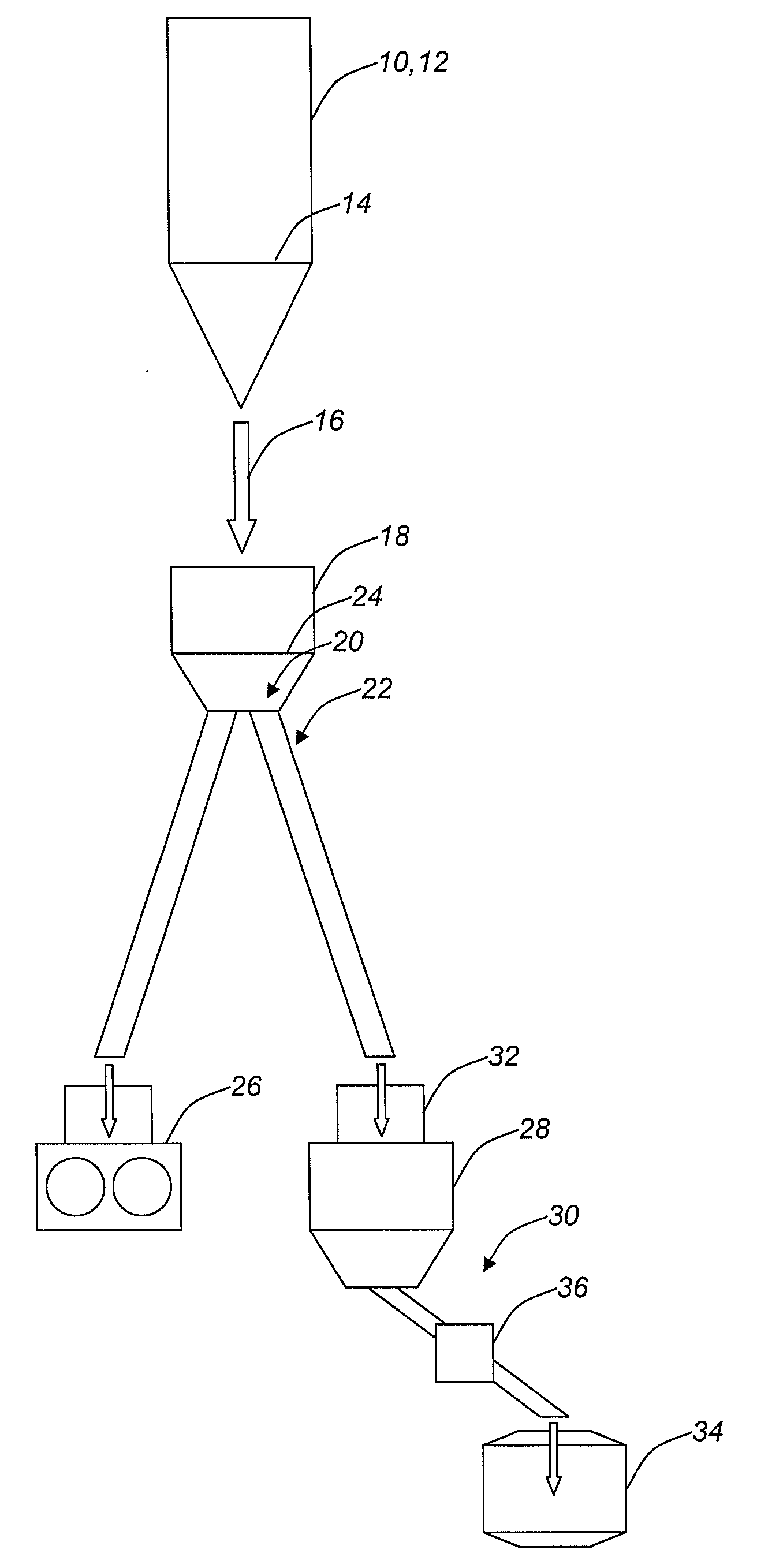

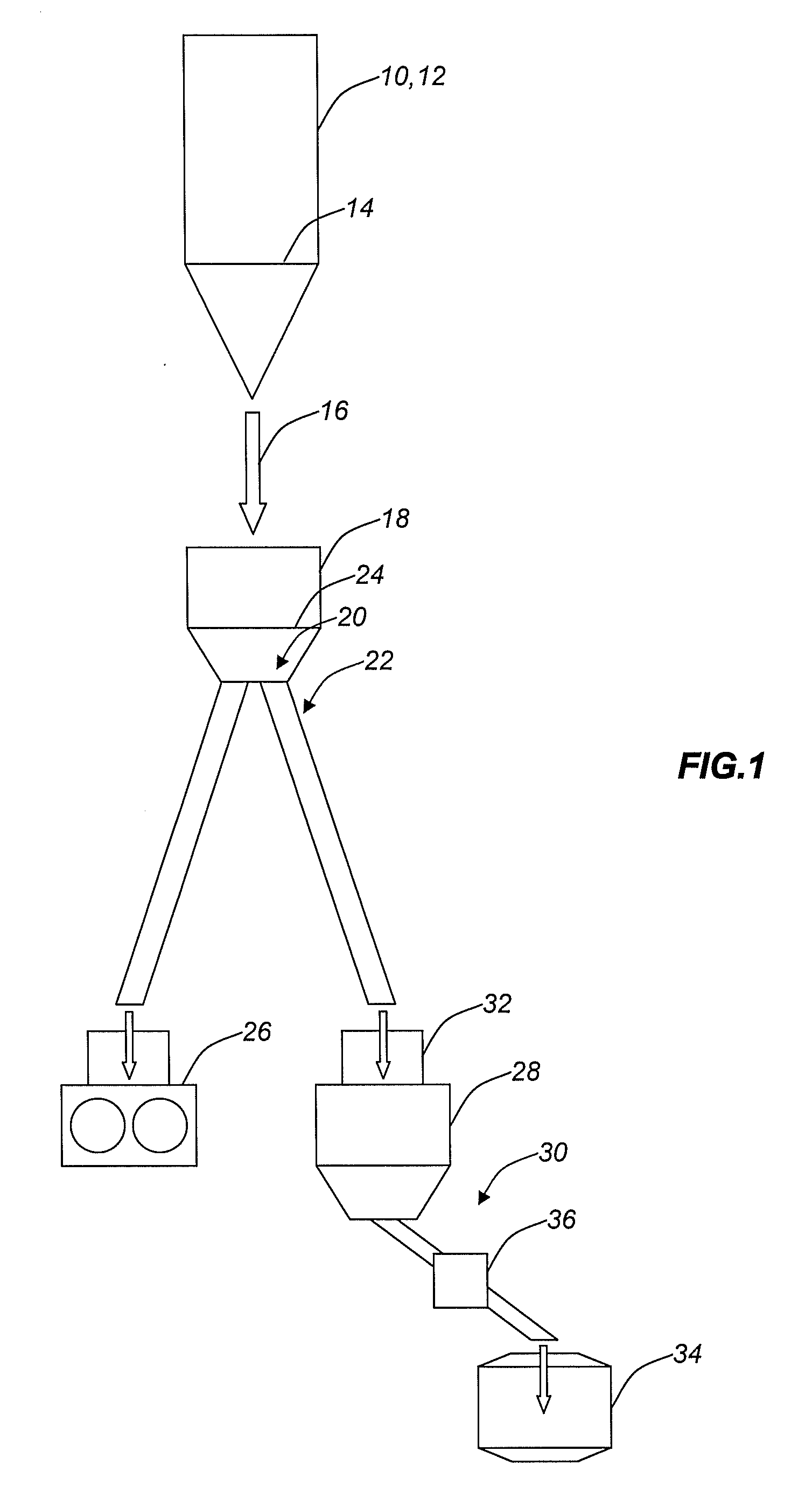

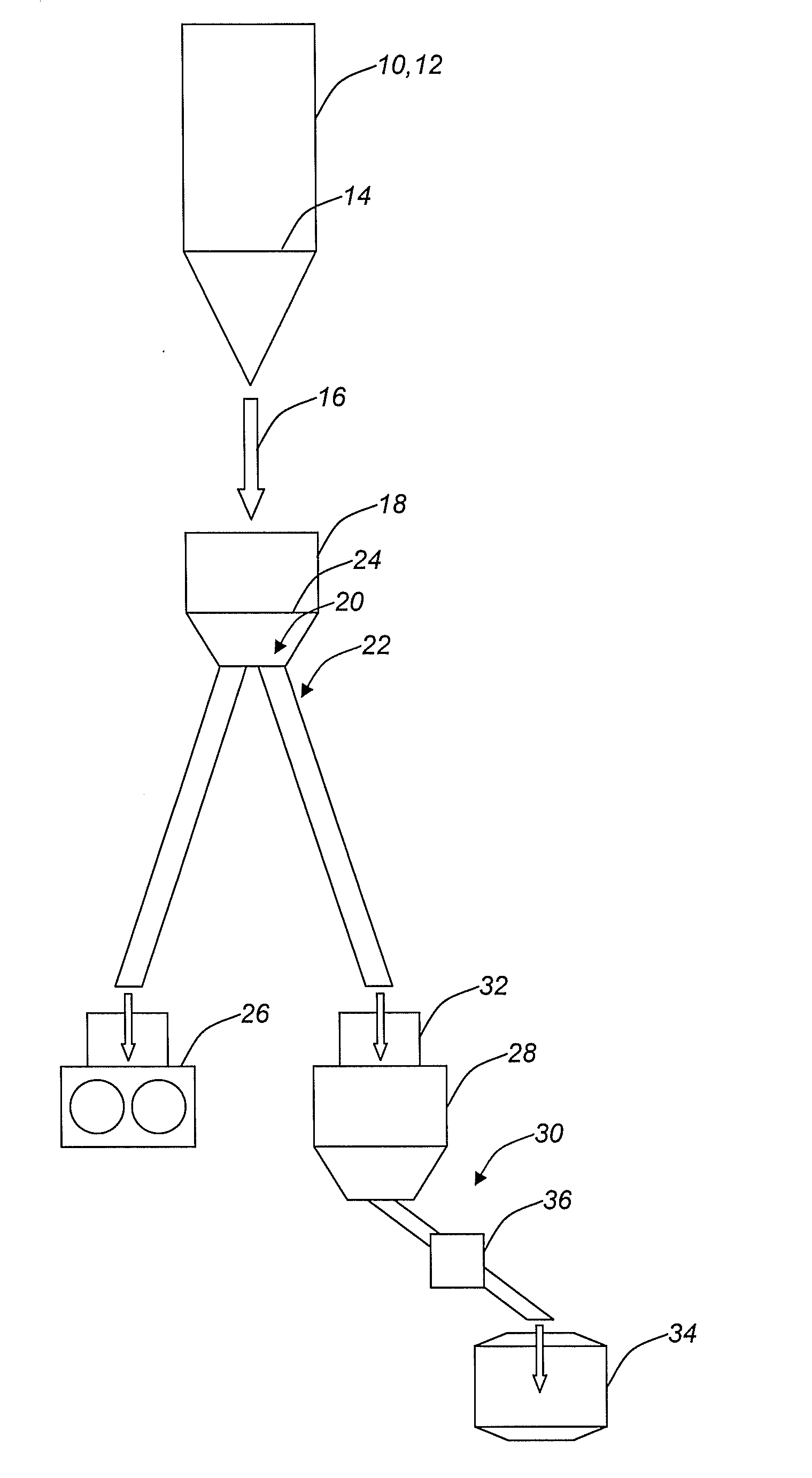

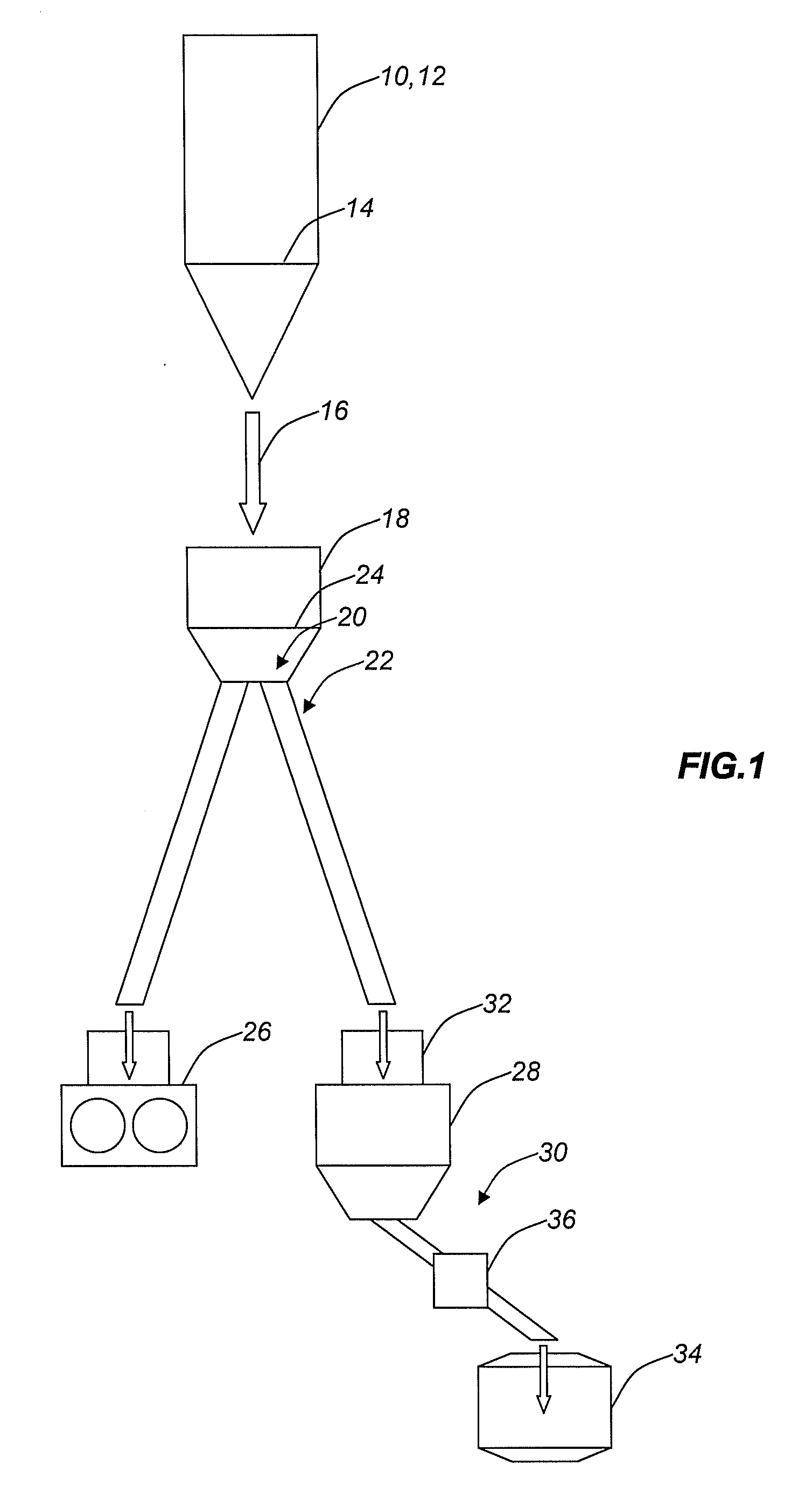

Method and system for the supply of hot direct reduced iron for multiple uses

ActiveUS20080236335A1Easy to operateLess heat lossBlast furnace detailsCharge manipulationMultiple useEngineering

The present invention relates generally to a method and system for the supply of a continuous stream of hot direct reduced iron (HDRI) from a direct reduction (DR) shaft furnace or direct reduced iron (DRI) reheating furnace to a point outside of the DR shaft furnace or DRI reheating furnace where the HDRI stream is split into at least two HDRI streams. The first HDRI stream is sent continuously to a hot briquetting plant by gravity in a closed duct system. The second HDRI stream is sent continuously to an adjacent melting furnace also by gravity in a closed duct system, with a surge bin and feeders, or by a combination of gravity in a closed duct system, also with a surge bin and feeders, and a generally horizontal charge conveyor. Optionally, a third HDRI stream is employed to continuously feed multiple hot transport vessels.

Owner:MIDREX TECH INC

Absorption-type air conditioner system

ActiveUS6904768B2Compact structureFew external welding seamBoilers/analysersEnergy efficient heating/coolingAir cycleLithium bromide

An absorption-type air conditioner system using lithium bromide solution as absorbent is provided, which has a small volume and compact structure. The system includes upper vessel 26, lower vessel 27, cooling heat exchanger 10, self-induced air circulation device 11, outdoor system controller 9 and water heater 8. Upper vessel 26 includes high temperature generator 1, low temperature generator 2 and condenser 3. The lower vessel 27 includes high temperature heat exchanger 4, low temperature heat exchanger 5, evaporator 7 and absorber 6. Upper vessel 26 is connected to lower vessel 27 by refrigerant water outlet pipe 28, LTG dilute solution inlet pipe 29, LTG concentrate solution outlet pipe 30, HTG dilute solution inlet pipe 31, HTG concentrate solution outlet pipe 32, HTG steam outlet pipe 56, heating steam switch valve 55 and HTG steam inlet pipe 57. The system is an ideal central air conditioner system for large houses.

Owner:ZHANG YUE

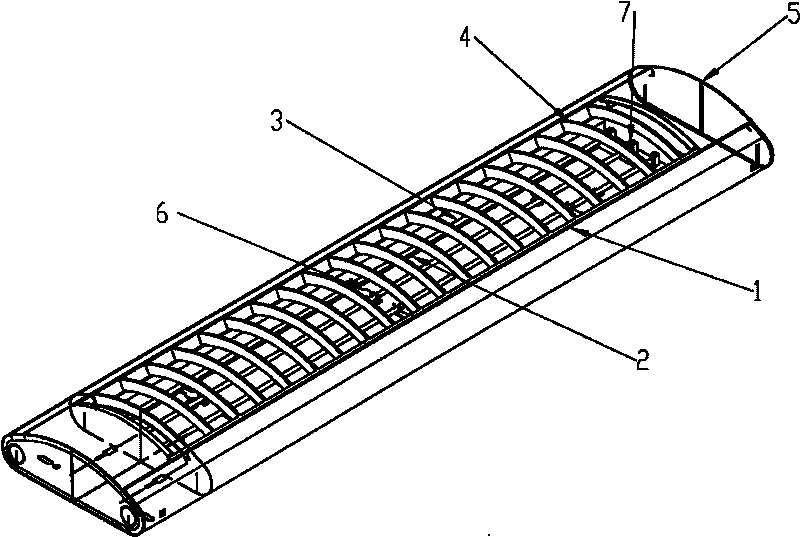

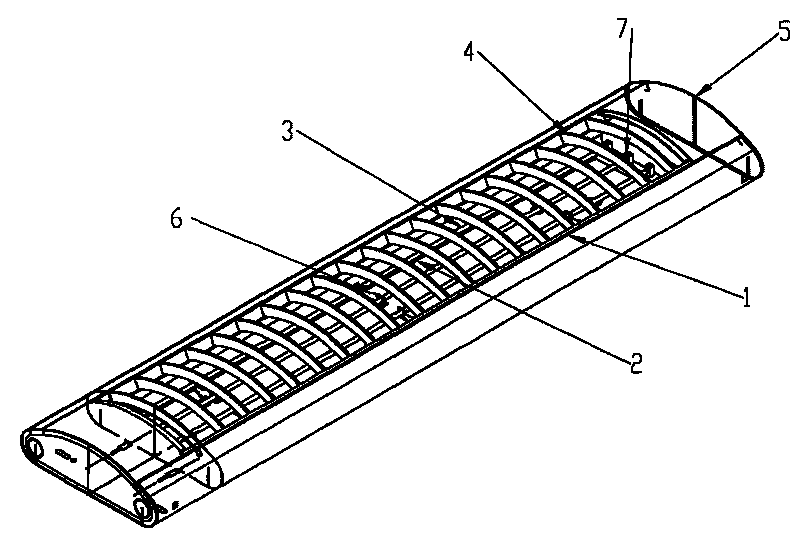

Cambered grille lamp with cold cathode tube

InactiveCN101706057AStable lighting parametersEasy to useElongate light sourcesElectric circuit arrangementsEffect lightCold cathode

The invention relates to a cambered grille lamp with a cold cathode tube, belonging to a lighting light fitting and comprising a light fitting chassis, a light fitting holder and a cambered grille. A cold cathode tube is fixed on a light reflecting plate of the light fitting chassis by a pipe clamp; and the wire connecting terminal of an inverter is connected with the electrode of the cold cathode tube. A U-type tube is adopted as the cold cathode tube. The double-U-type cold cathode tube is adopted as the tube, the service life of the cambered grille lamp can reach more than 60,000 hours; the cambered grille lamp can be frequently switched for not less than 1 million times; the power dissipation is small, the light decay is small and the tube wall temperature is low, thereby effectively reducing the heat loss caused by heating. The double-U-type cold cathode tube is cooperated with a one-to-two inverter to drive with double high voltages, thus the light-up parameters of the tube are more stable. The input voltage of the inverter is 220 V; compared with the traditional DC input inverters, the inverter does not need to transfer voltage, thereby facilitating family and office use.

Owner:YICHANG JINSEN OPTRONICS TECH +1

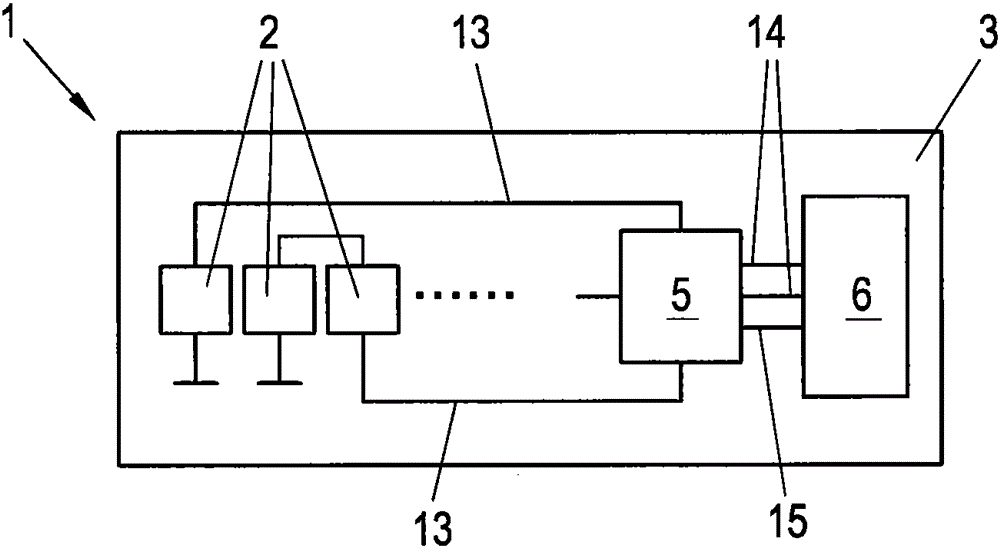

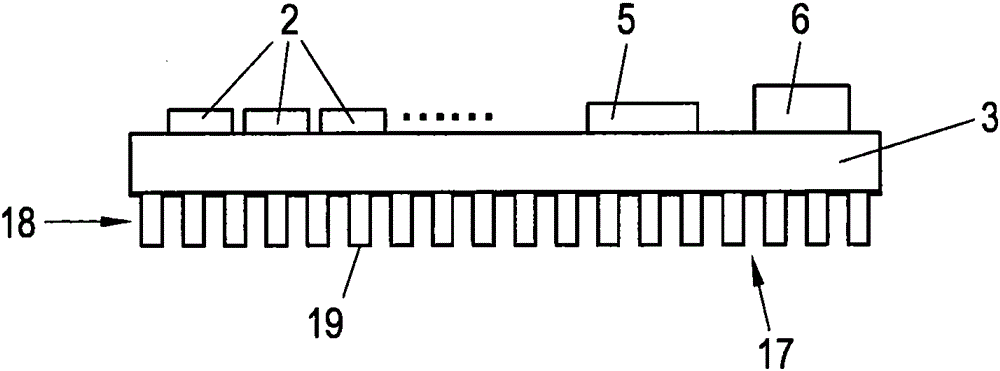

Light source and method for producing the light source

ActiveCN105103655AEasy to integrateReduce weightVehicle headlampsElectrical apparatusSurface mountingBuck converter

The invention relates to a light source (1) and a method for producing said light source, for integration in a headlight having a circuit board (3), on which at least one light diode (LED) (2) and a converter unit (5) for supplying power to the LED (2) are arranged, wherein the converter unit (5) and the at least one LED (2) are designed as surface-mounted components (surface-mounted device, SMD) and the converter unit (5) has one or a plurality of buck converters.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

Method for producing 400-500 MPa high-strength anti-seismic deformed steel bars by adopting non-heating low-temperature slitting and rolling

InactiveCN112090960ALess investmentReduce oxidation burnMetal rolling arrangementsEngineeringSteel bar

The invention relates to a method for producing 400-500 MPa high-strength anti-seismic deformed steel bars by adopting non-heating low-temperature slitting and rolling, comprising the following steps:S1, cutting square billets by a continuous casting machine at 850-1000 DEG C, feeding the square billets into a quick heat preservation roller way by means of a steel slitting device, feeding the square billets into an outlet roller way of a stepper heating furnace, feeding the square billets to a roughing rolling unit at about 800-900 DEG C, rolling rough-rolled intermediate billets by adoptinga slotless rolling hole shape by means of the roughing rolling unit, and cutting heads and removing tails by a flying shear; S2, feeding the rough-rolled intermediate square billets of about 780-870 DEG C into an intermediate rolling unit, rolling intermediate-rolled round billets by adopting an oval-round hole shape by means of the intermediate rolling unit, and then cutting heads and removing tails by a flying shear; and S3, feeding the intermediate-rolled round billets of about 870-1000 DEG C into a finish rolling unit for rolling, and rolling to a size close to that of a finished product by adopting a slitting hole shape by means of the finish rolling unit. According to the method, a non-heating low-temperature rolling technology is adopted, and steel billets do not need to be heated by a heating furnace in the non-heating low-temperature rolling technology, so that the investment of heating furnace devices and fuels is effectively saved, the energy consumption and the metal oxidation burning loss are reduced, and the production cost is reduced.

Owner:WISCODRI WUGANG ENG

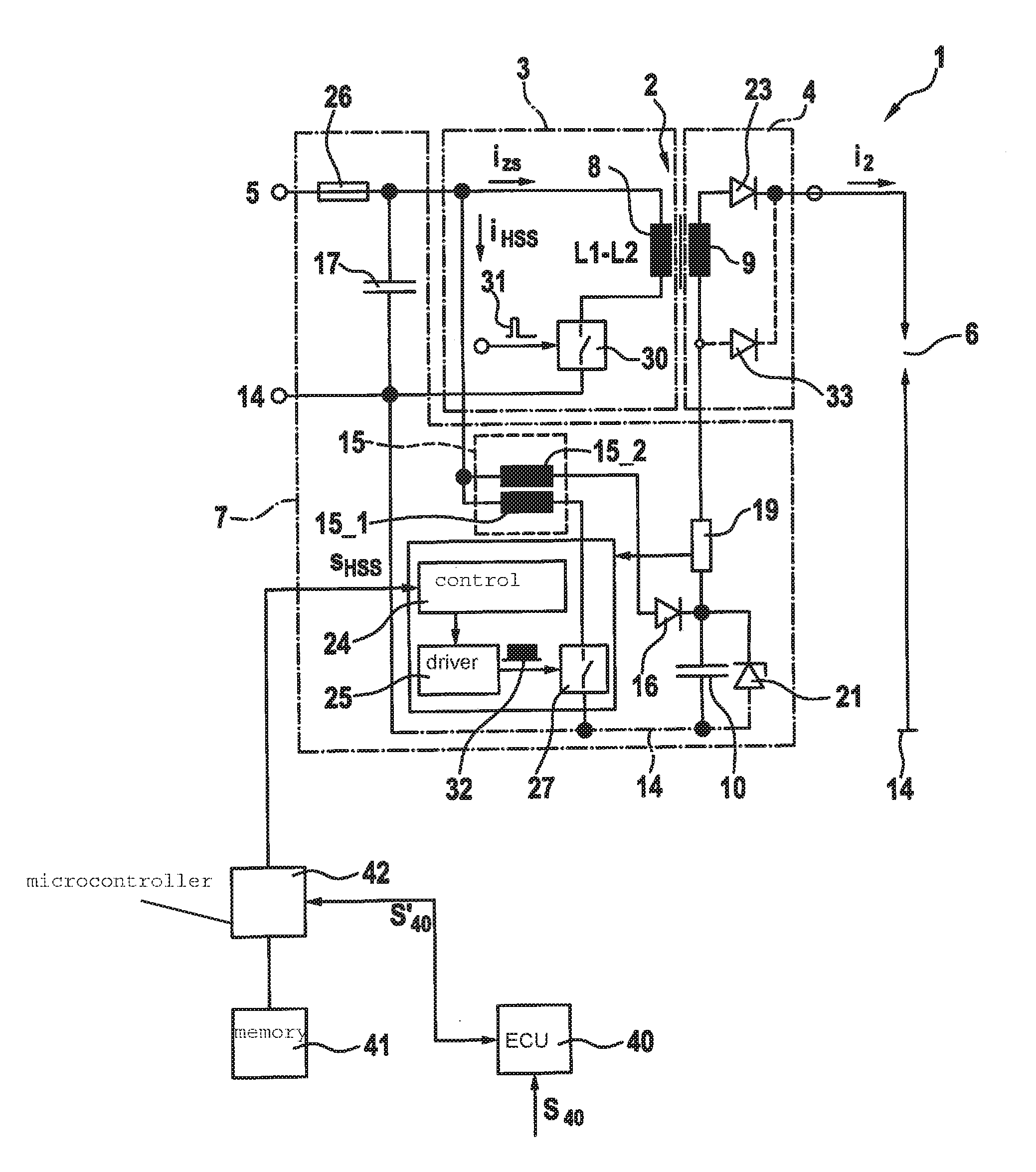

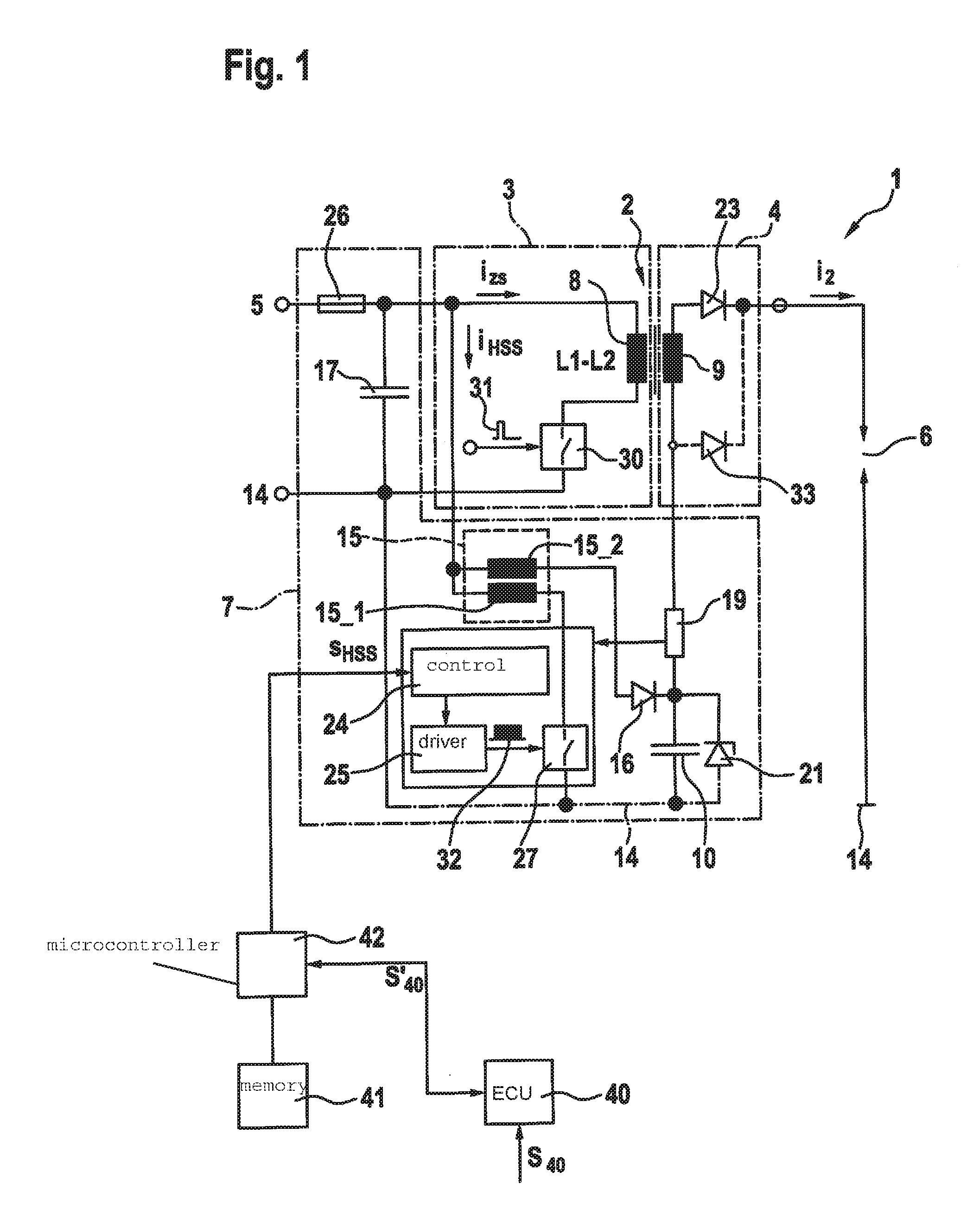

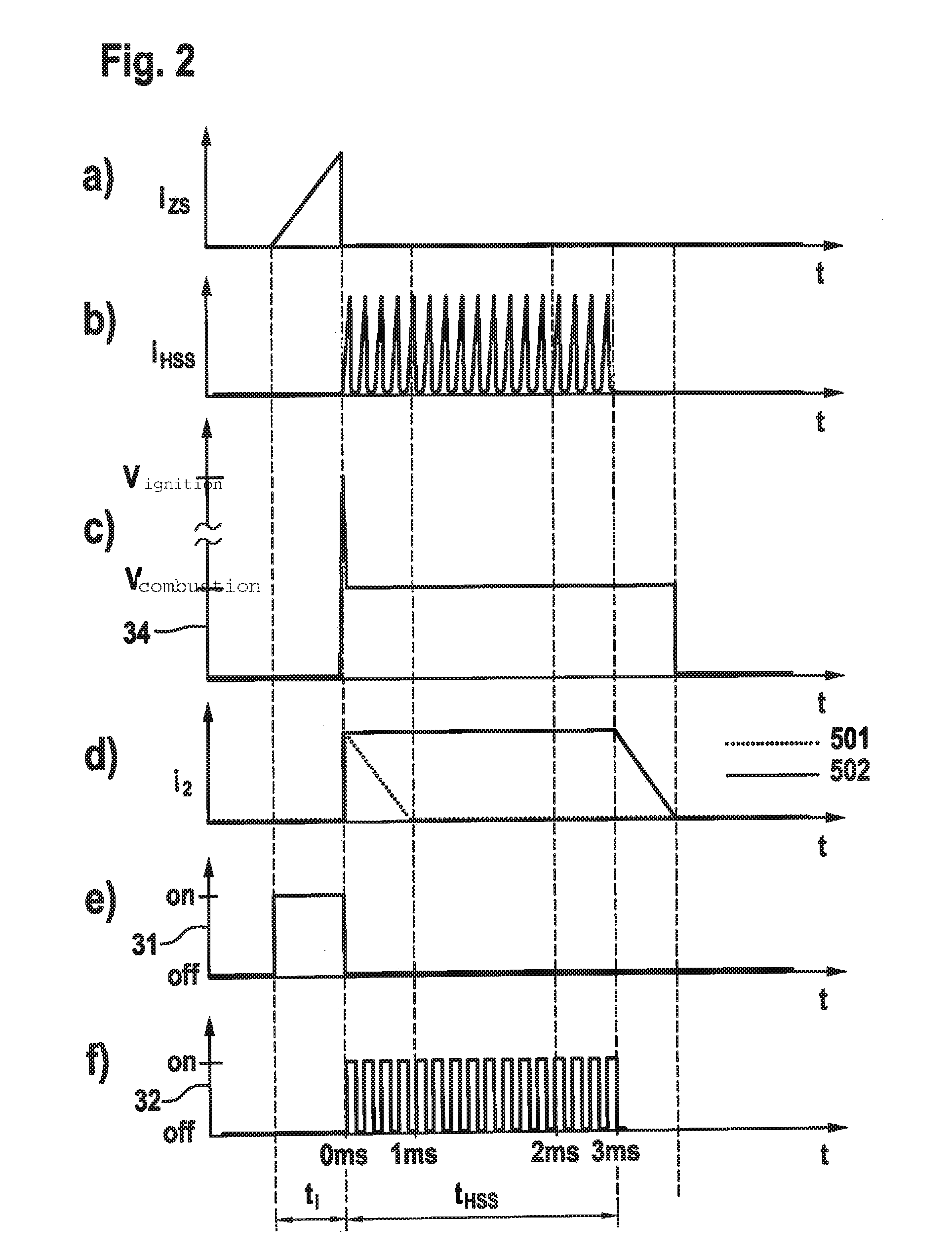

Ignition system and method for operating an ignition system

InactiveUS20160298591A1Cost-effectiveSimple mathematical operationMachines/enginesInstallations with induction energy storageVoltage generatorEngineering

A method is described for operating an ignition system for an internal combustion engine, including a primary voltage generator and a bypass, in particular, a boost converter for maintaining a spark generated with the aid of the primary voltage generator, the method includes an ascertainment of a modified energy requirement for an ignition spark, which is to be maintained with the aid of the bypass and a modification of the working mode of the bypass in response thereto.

Owner:ROBERT BOSCH GMBH

Method and system for the supply of hot direct reduced iron for multiple uses

ActiveUS7938882B2Reduce the overall heightLess heat lossCharge manipulationBlast furnace detailsMultiple useEngineering

Owner:MIDREX TECH INC

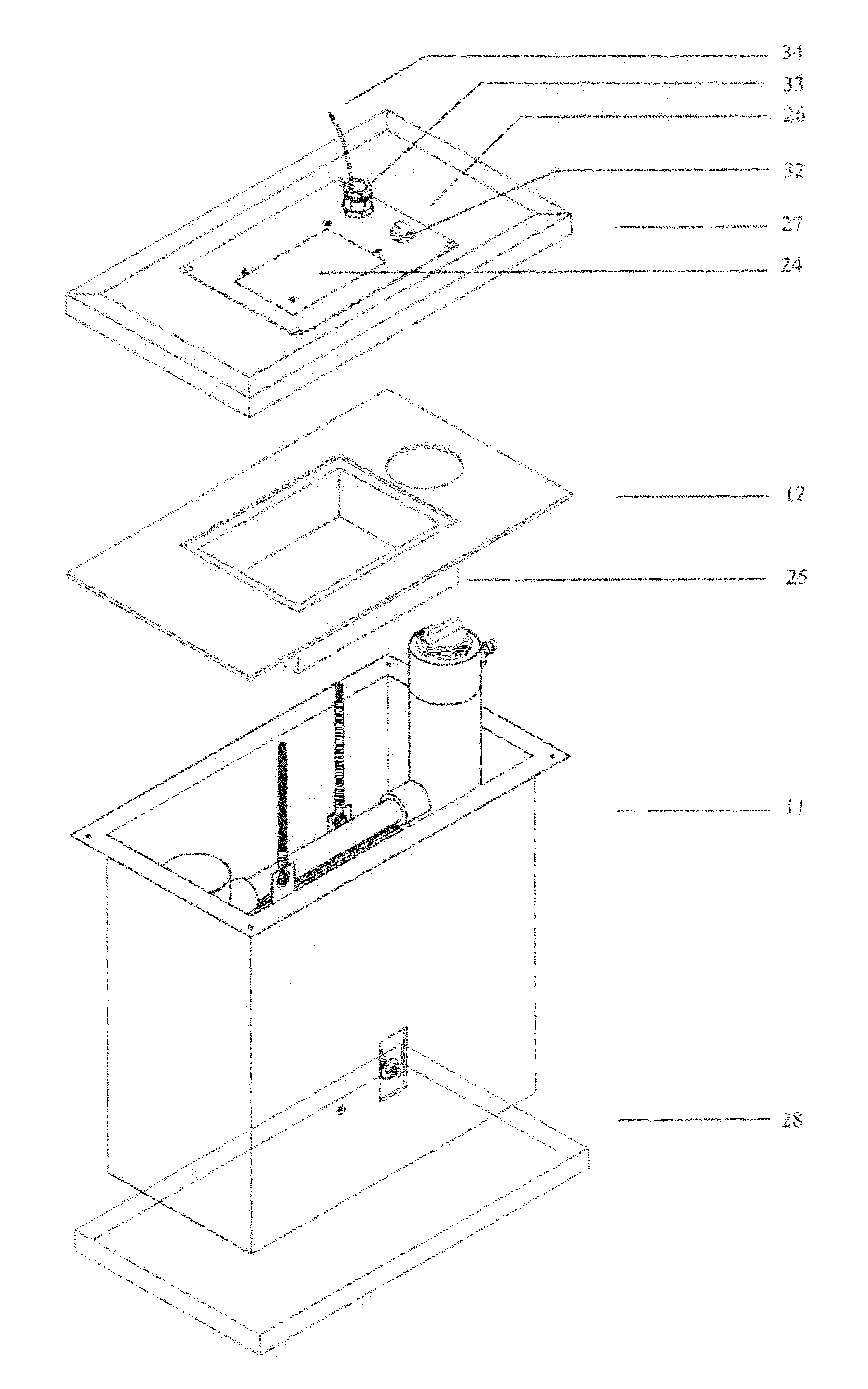

Desalinization Device and Method of Using the Same

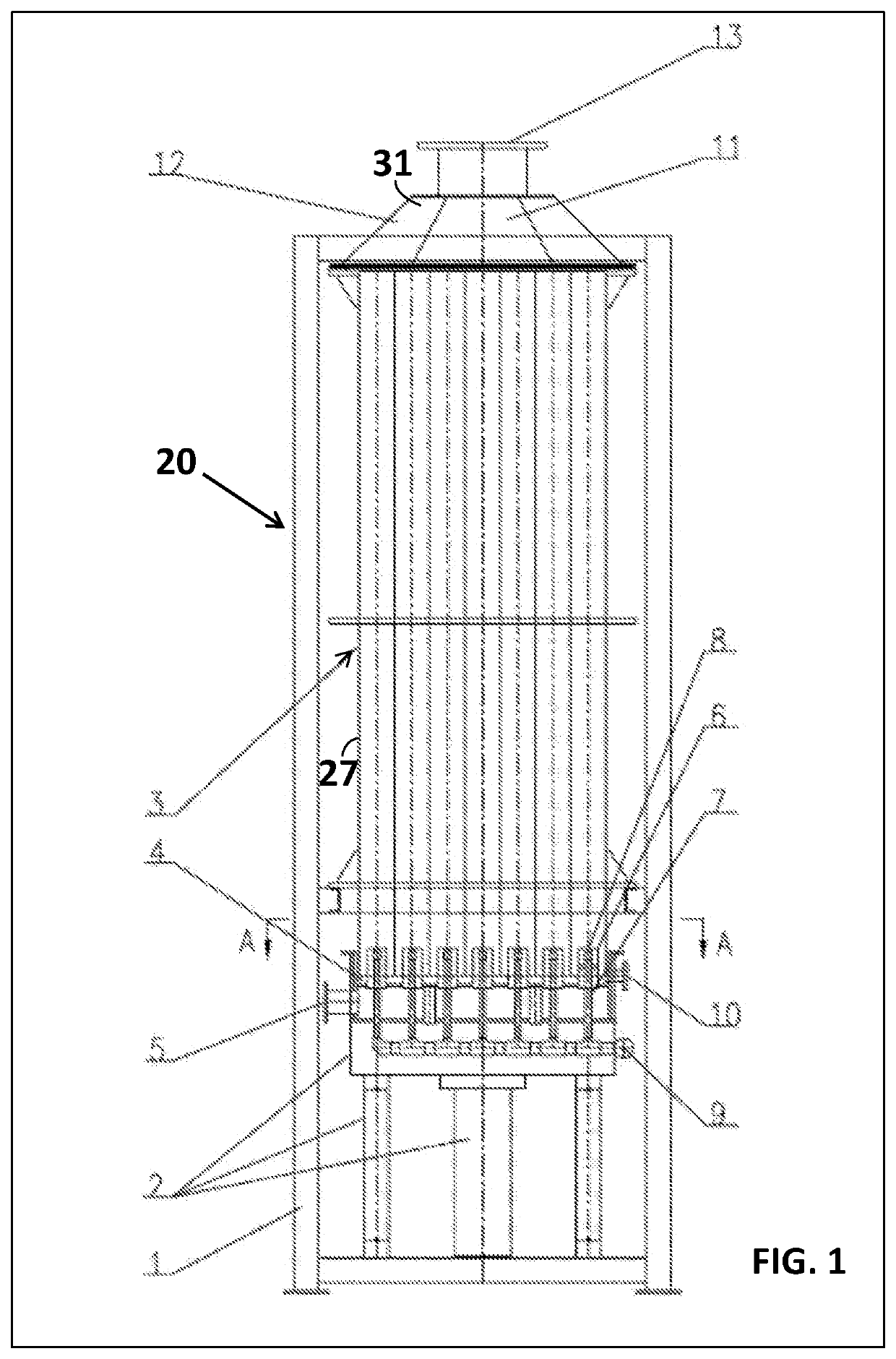

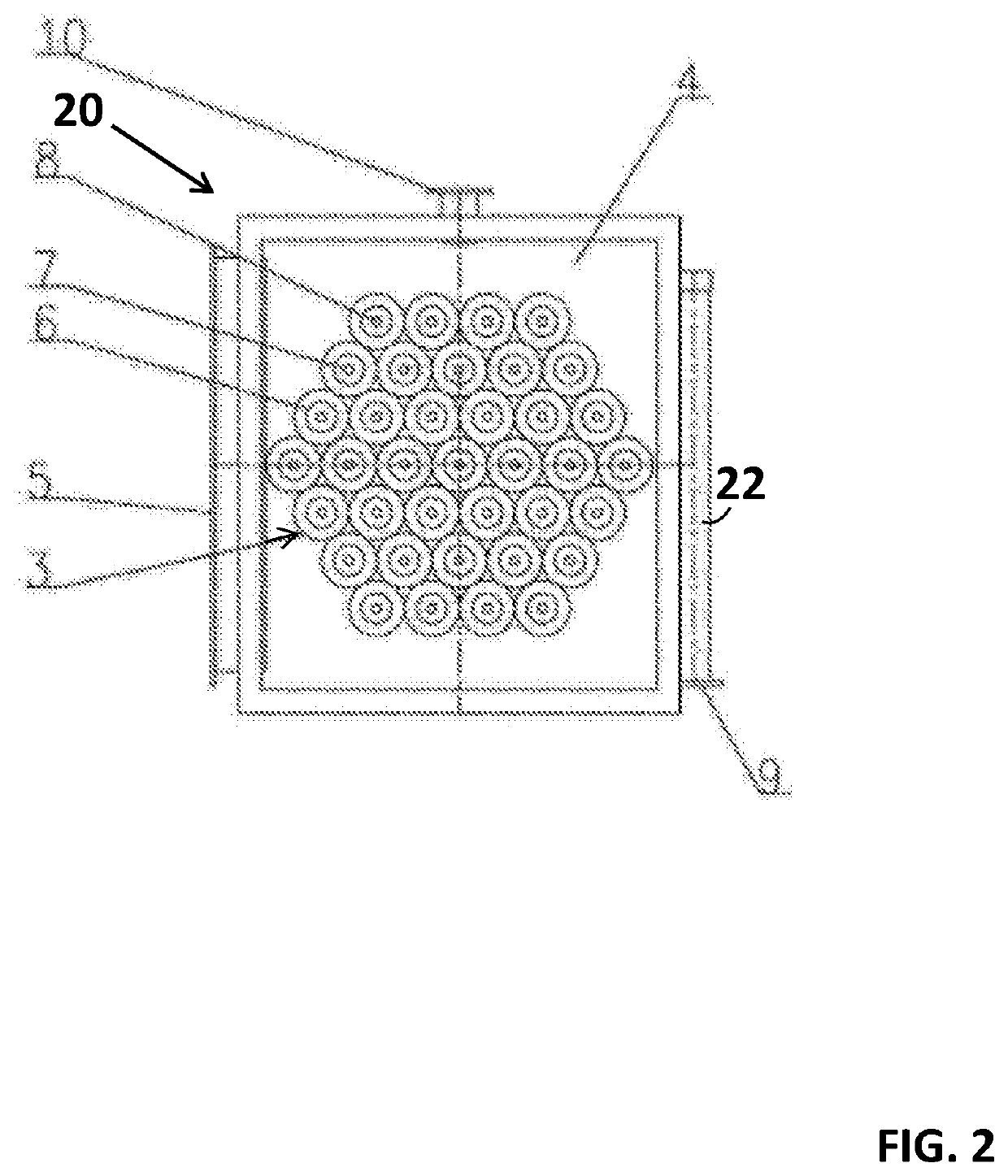

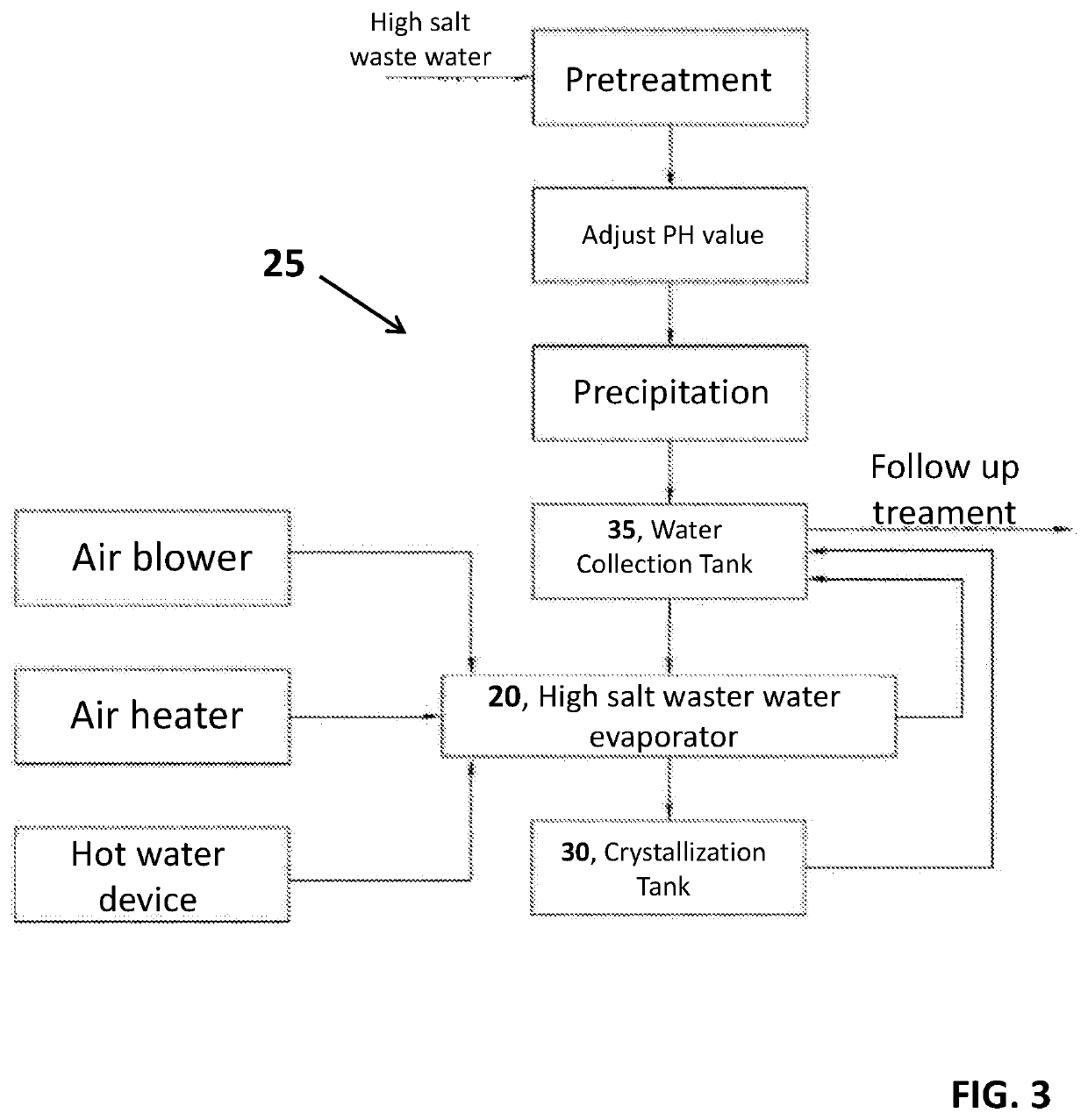

ActiveUS20200087167A1Improve processing efficiencySimple structureGeneral water supply conservationPaint waste treatmentDesalinationWastewater

The invention is a high-salt waste water air powered low temperature evaporating device and method of use. A tray is mounted on a lifting platform; an air inlet and a water inlet are on the tray. Air distributing pipes are arranged at the center of the nested column tubes (33). A groove (4) is installed at the top of the tray, and mounting points are accompanied by multiple nested column tubes (33). The nested column tubes (33) are connected with the air inlet. An atomizer is arranged inside the air distributing pipes; and the atomizer is connected with the water distributing pipes. Using air power evaporates concentrated waste water multiple times so that the salt in the wastewater reaches saturated concentration, and therefore, the wastewater temperature is reduced, salt is crystallized and separated out, liquid is continuously evaporated, and the wastewater can be completely treated.

Owner:LIU DEPEI

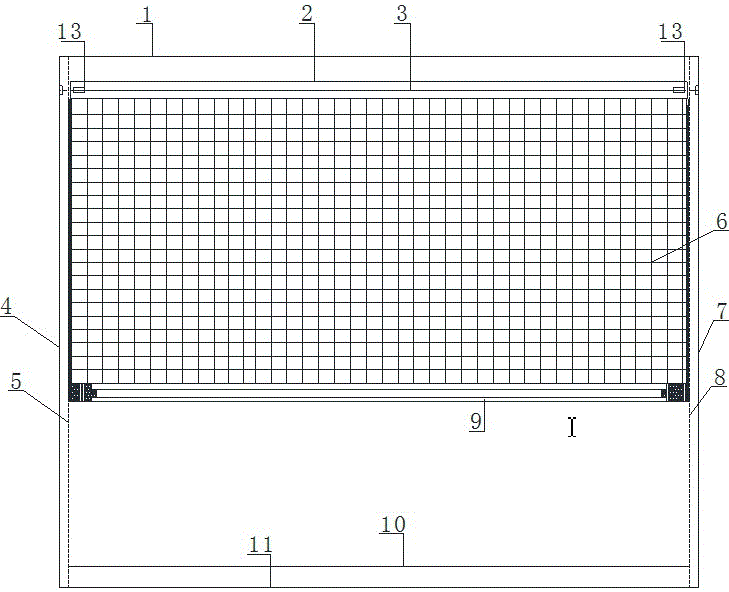

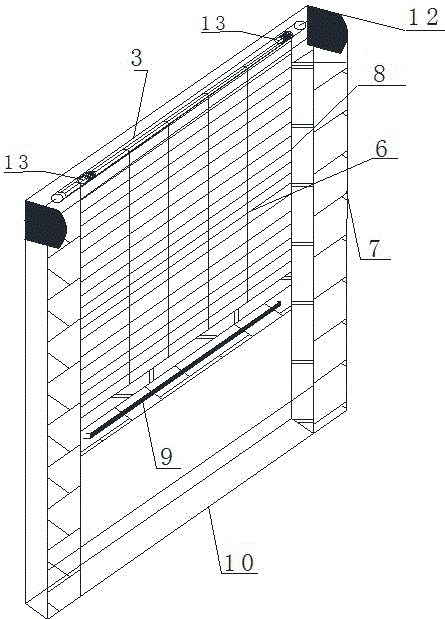

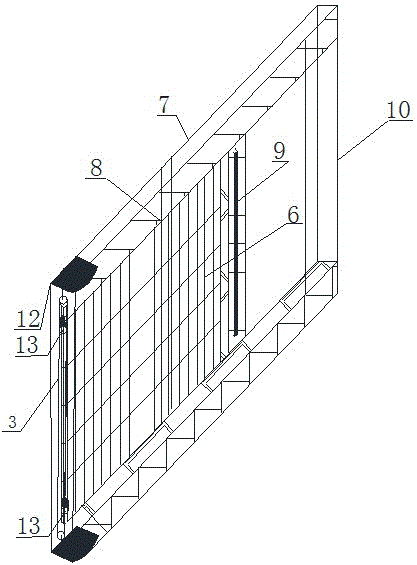

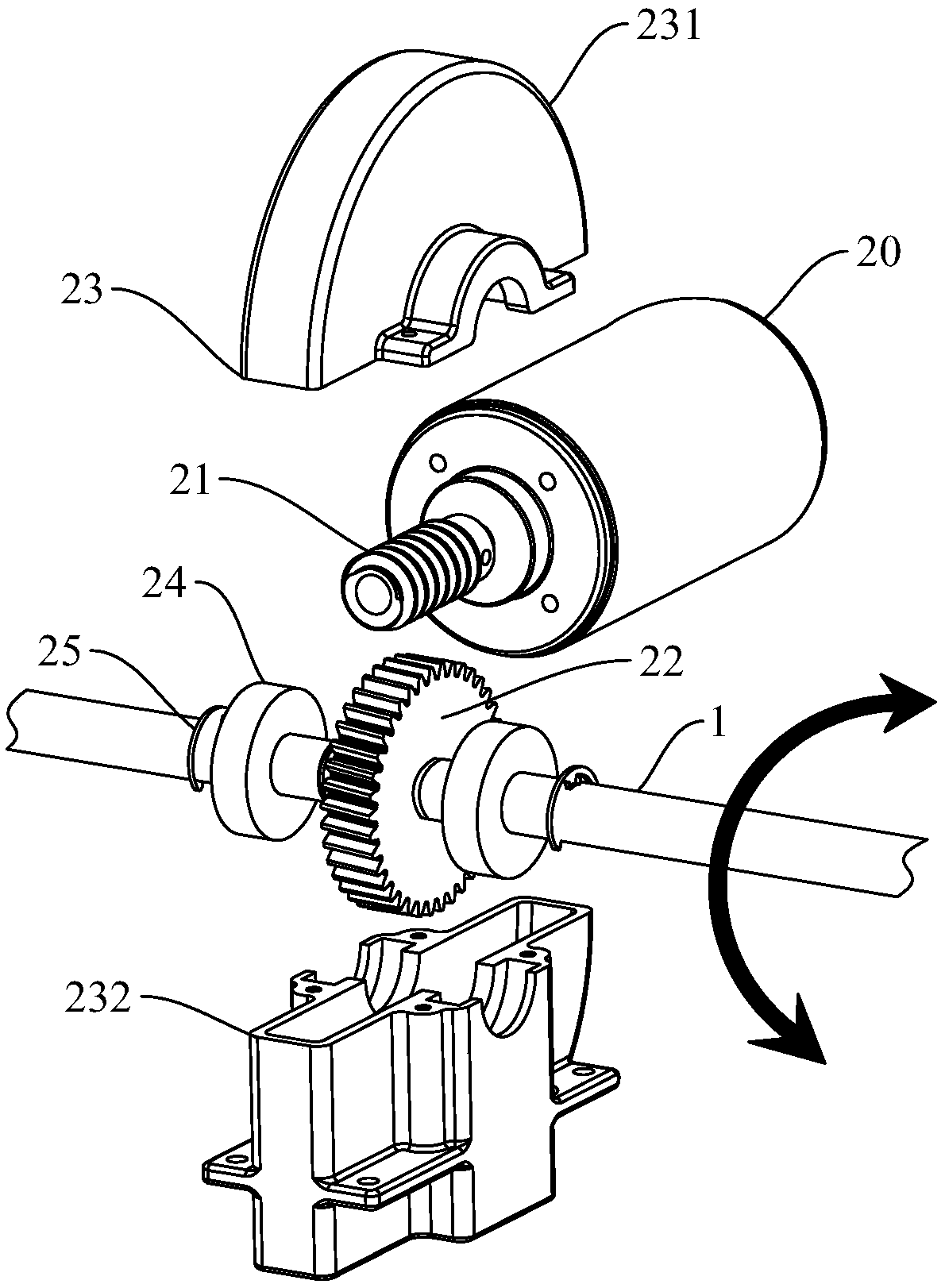

Solar energy-saving heat-insulating window capable of collecting heat and sheltering from sunshine

ActiveCN106351556ALower heat transfer coefficientLess heat lossSolar heating energyFireproof doorsLower borderRemote control

The invention provides a solar energy-saving heat-insulating window capable of collecting heat and sheltering from sunshine. A window frame of the heat-insulating window is located on the outer wall of a corresponding window, a heat-insulating shutter protecting tube is fixed in an upper border of the window frame, two rotating shafts connected with a heat-insulating shutter are arranged in the heat-insulating shutter protecting tube, and remote-control motors are arranged on the rotating shaft I and rotate to drive the rotating shaft II to rotate; a stainless steel solar heat collector is arranged slantwise downwards outside the upper border of the heat-insulating shutter protecting tube; the heat-insulating shutter moves vertically through a left guide rail and a right guide rail arranged in a left border and a right border of the window frame, a pulling bar with the identical width to that of the heat-insulating shutter is fixed at the tail end of the heat-insulating shutter, and the pulling bar is connected with a locating bar, fixed on the lower border, through magnetic buckles and plastic suckers. The heat-insulating window is simple in structure and high in seal property, further improves the heat-insulting property of doors and windows, can shelter from the sunshine and produce hot water by the aid of solar energy, is applicable to cold dispelling and sunstroke prevention for residents and is energy-saving.

Owner:TAIYUAN UNIV OF TECH

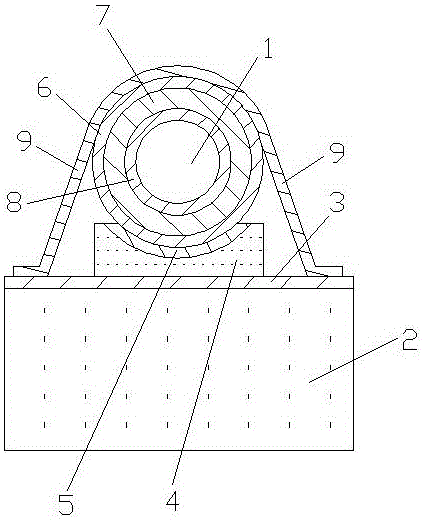

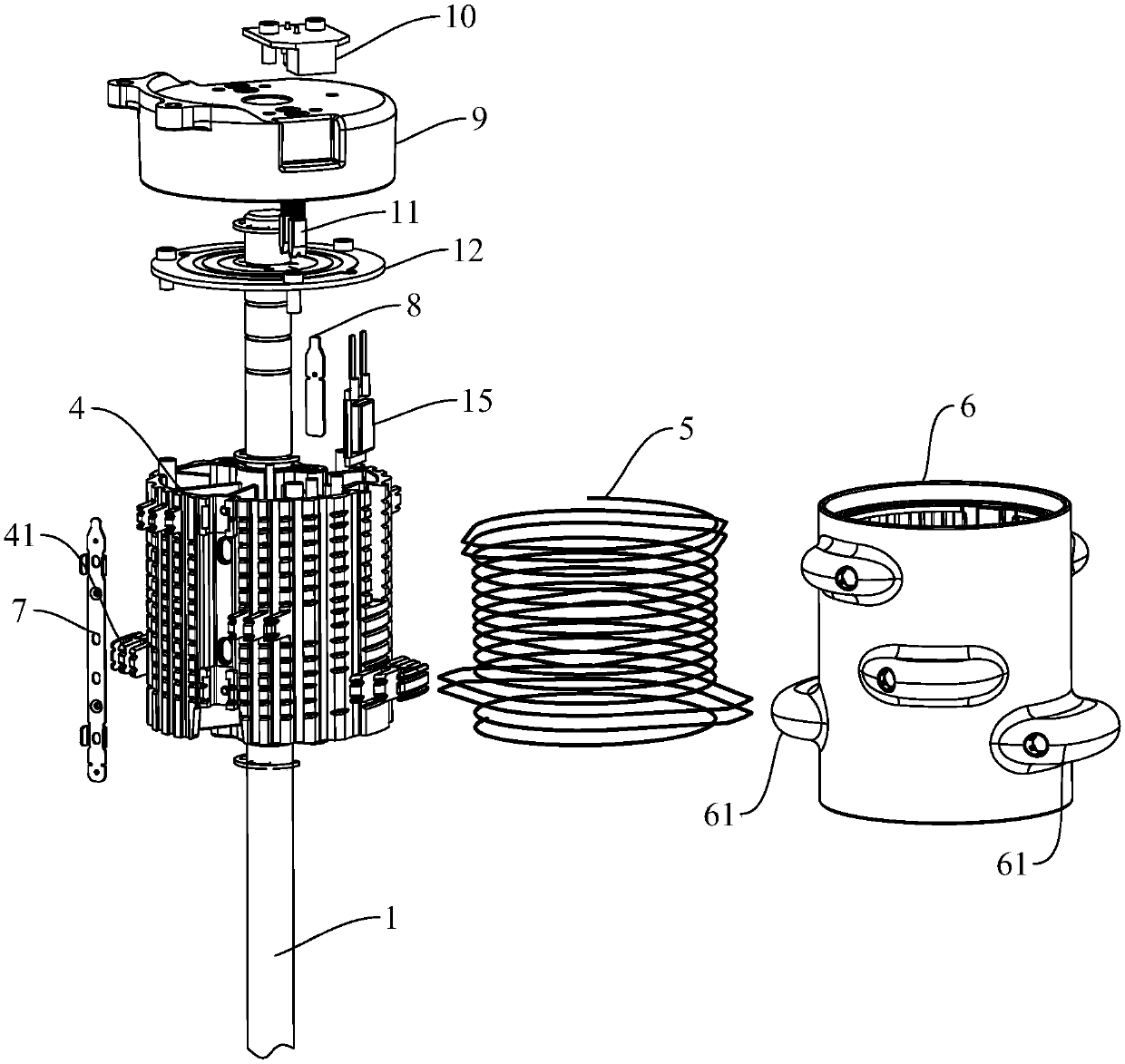

Heating unit and forming process thereof

PendingCN110811971ABarrier deliveryEasy to passDevices for pressing relfex pointsRoller massageThermodynamicsEngineering

The invention provides a heating unit which comprises an inner heat insulation casing, a heating wire, an outer heat conduction casing, an electric connection assembly and a power supply assembly, wherein the inner heat insulation casing is provided with a cylindrical outer peripheral surface; the outer heat conduction casing is fixedly arranged outside the inner heat insulation casing in a sleeving way; the electric connection assembly is fixed to the inner heat insulation casing; the power supply assembly is relatively fixed to the inner heat insulation casing; the heating wire is wound on the cylindrical outer peripheral surface of the inner heat insulation casing to form a cylindrical heating coil; the cylindrical heating coil is fixed between the inner heat insulation casing and the outer heat conduction casing; the two ends of the heating wire are connected with the electric connection assembly; and the electric connection assembly is connected with the power supply assembly. Theheating unit has the advantages that the heating surface of the heating unit is a space surface instead of a plane, so that the heating is uniform; by combining the heat insulation performance of theinner heat insulation casing and the heat conduction performance of the outer heat conduction casing, the heat can be prevented from being inwards transferred, so that the heat can be better outwardstransferred; the heat loss is little; the heating effect is good; and the heating power is greatly reduced.

Owner:SHANGHAI RONGTAI FITNESS TECH DEV CO LTD

Absorption-type air conditioner core structure

ActiveUS6820440B2Compact structureFew external welding seamBoilers/analysersEnergy efficient heating/coolingLithium bromideEngineering

An absorption-type air conditioner core structure is provided, which uses lithium bromide solution as absorbent and has a small volume and compact structure. The air conditioner core structure includes an upper vessel (24) and a lower vessel (21). The upper vessel and lower vessel are connected by a refrigerant water pipe (22), a cooling water pipe (7), a heating steam pipe (5), two concentrate solution pipes (27, 58) and two dilute solution pipes (46, 52). The concentrate solution and dilute solution pipes are disposed within a solution pipe protecting cover (23) which connects to both vessels. Because of its compact structure, small volume, fewer welding seams, high level of vacuum, and having the heat exchange pipes (30, 39, 61, 73) of the condenser 1, low temperature generator 2, evaporator 10 and absorber 11 all made of helical copper pipes, the air conditioner core structure has high heat exchange efficiency.

Owner:ZHANG YUE

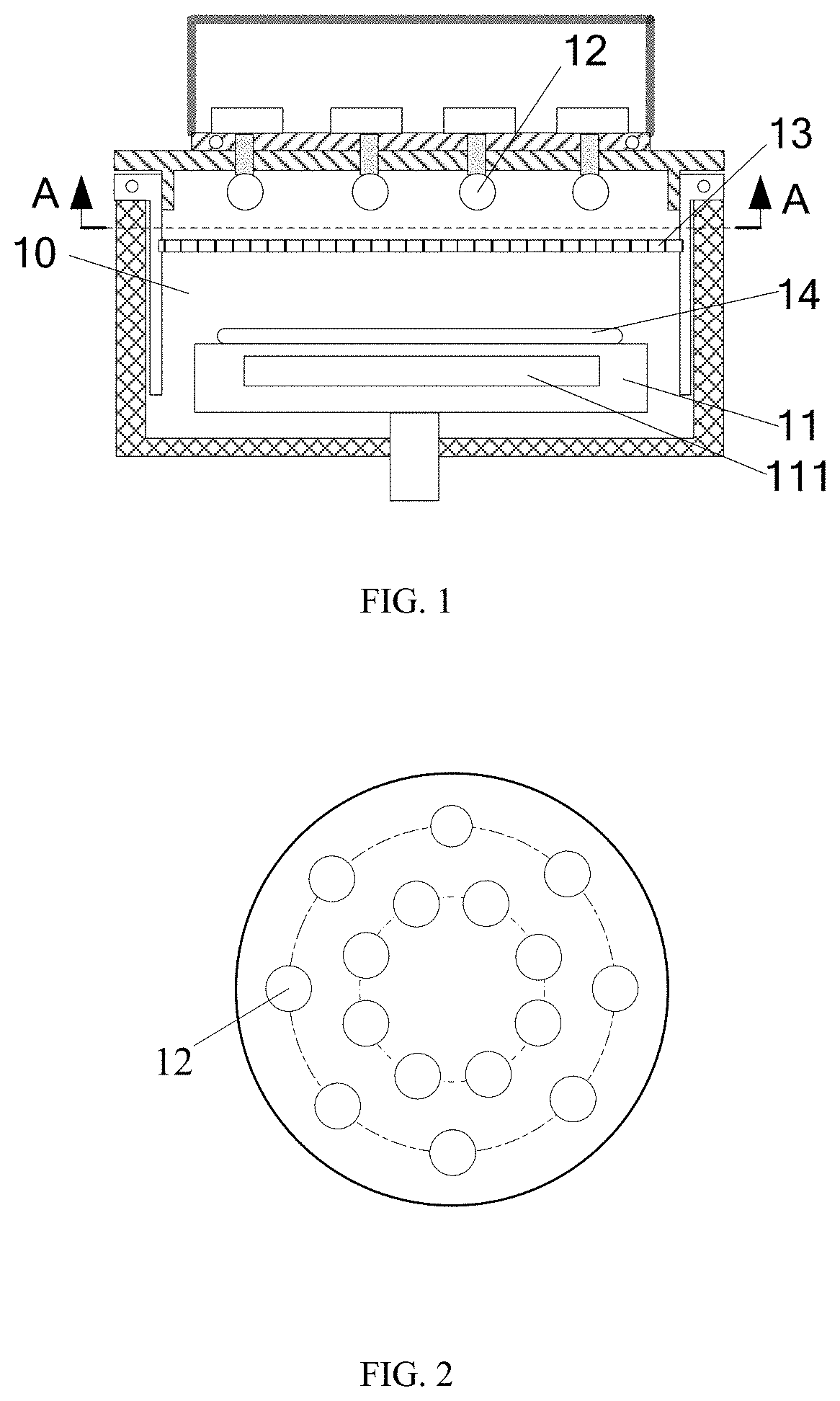

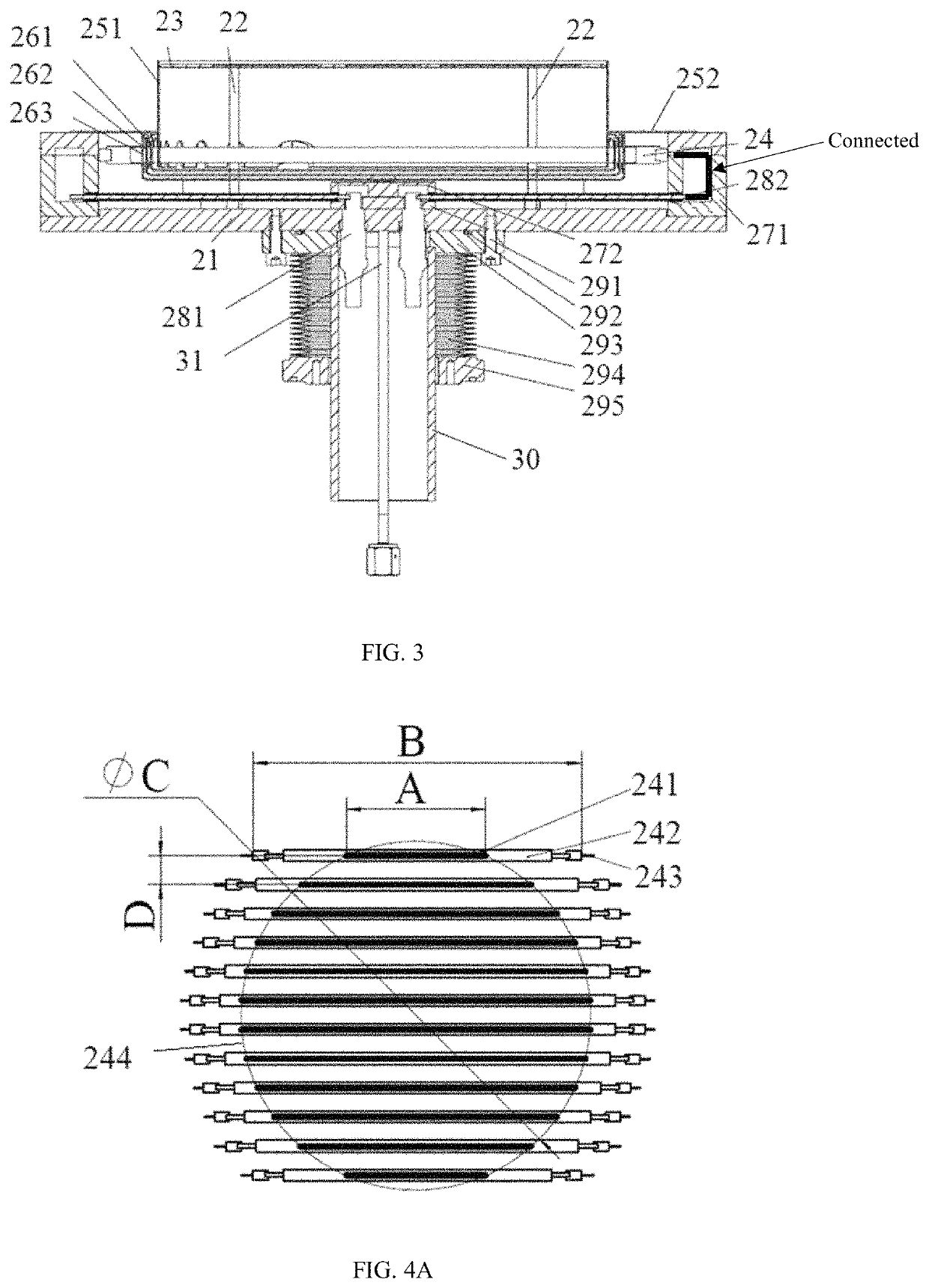

Heating device and heating chamber

ActiveUS10937672B2Reduce heat lossHeating fastVacuum evaporation coatingCharge supportsEngineeringBearing surface

A heating device and a heating chamber are provided, comprising a base plate (21), at least three supporting columns (22) and a heating assembly, where the at least three supporting columns are arranged vertically on the base plate and are distributed at intervals along a circumferential direction of the base plate Top ends of the at least three supporting columns form a bearing surface for supporting a to-be-heated member (23). The heating assembly includes a heating light tube (24) and a thermal radiation shielding assembly, where the heating light tube is disposed above the base plate and below the bearing surface. A projection of an effective heating area formed by uniform distribution of the heating light tube on the base plate covers a projection of the bearing surface on the base plate. The thermal radiation shielding assembly shields heat radiated by the heating light tube towards surroundings and bottom.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Apparatus for brewing and dispensing beverages

An apparatus for brewing and dispensing beverages such as coffee, said apparatus comprising a water tank comprising a water inlet configured for fresh water supply, and one or more heater elements, said apparatus comprising a water tank outlet, which is connected via a hot water channel to a water faucet a brewing chamber and a dispensing nozzle, wherein said hot water channel has at least one section forming a flow path for hot water, said at least one section of said hot water channel is configured such that it is in direct thermal contact with the periphery of said water tank along the entire length of said at least one section of said hot water channel, and such that said at least one section of said hot water channel extends substantially parallel to the periphery of said water tank.

Owner:STERLANDSK THEHUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com