Ship propeller

A technology for propellers and ships, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of the large volume of the steam boiler, the cooling problem of the combustion chamber, the heat loss of the combustion pipeline, etc. The effect of volume and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

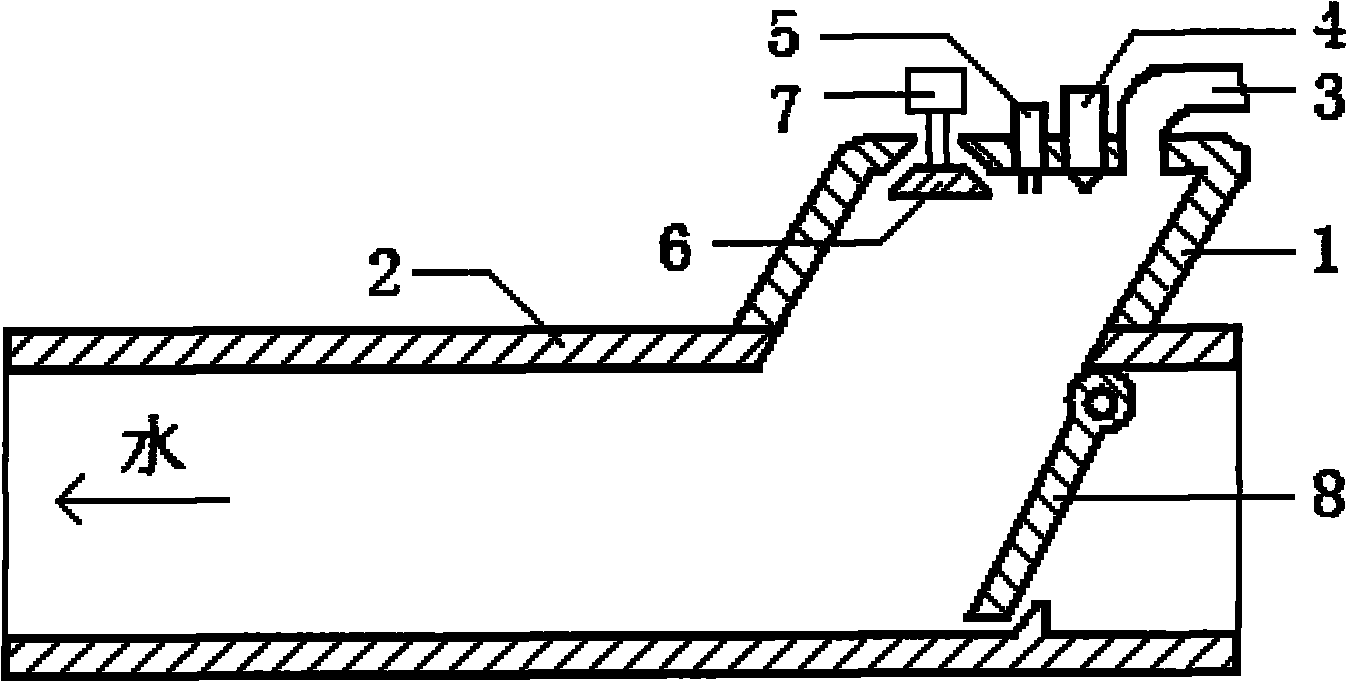

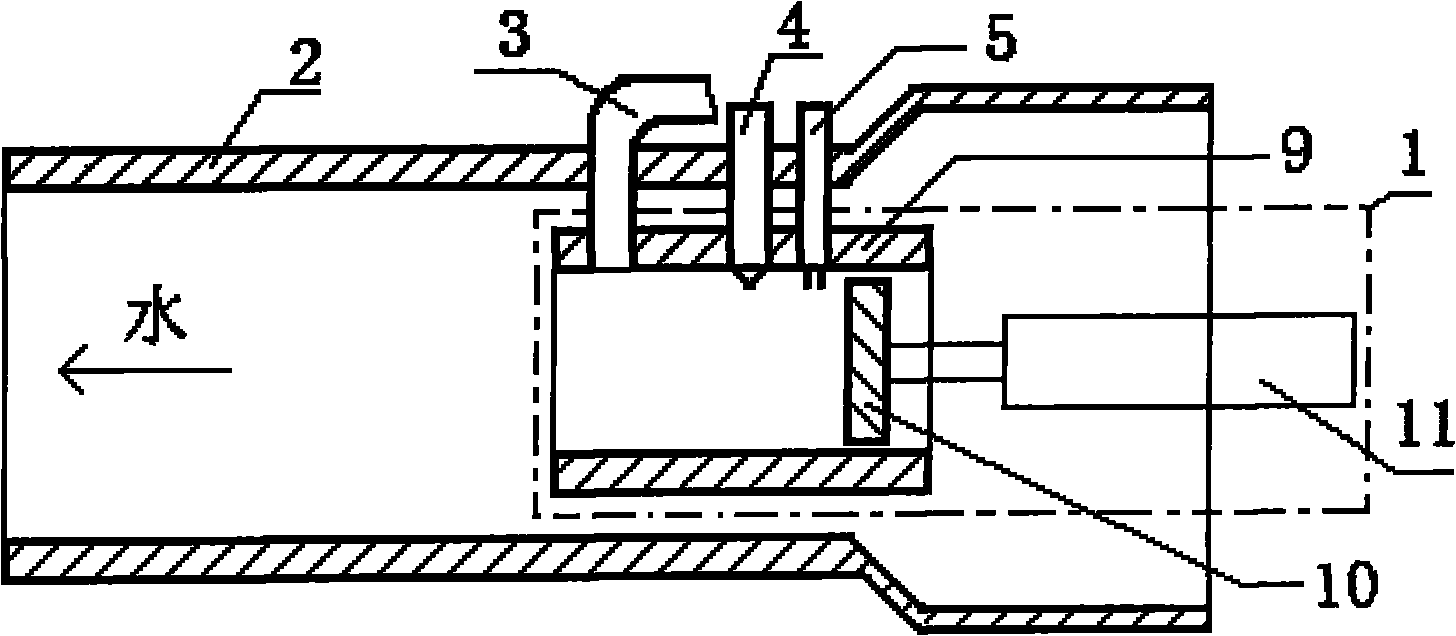

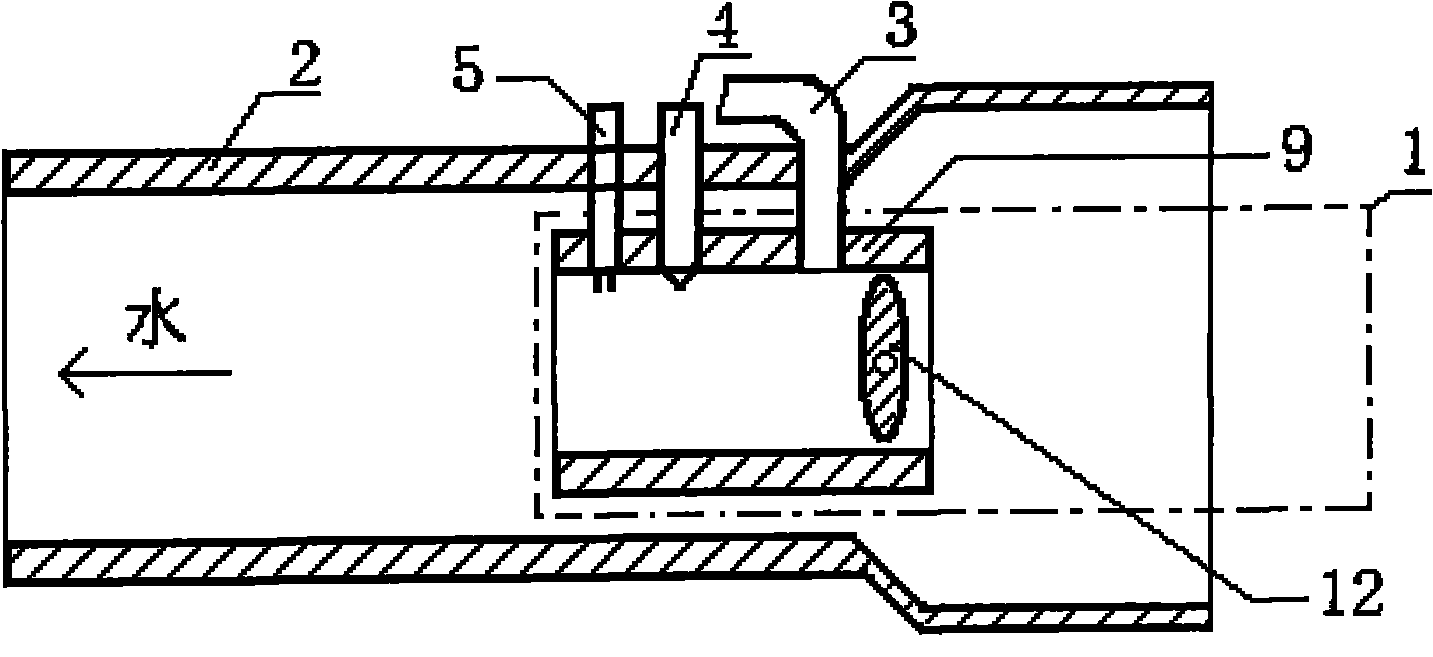

[0036] figure 1 The ship propeller shown is mainly composed of a cylinder 1 and a nozzle 2, the nozzle is connected to the lower end of the cylinder, the top of the cylinder is provided with a compressed air inlet 3, a fuel nozzle 4, an ignition device 5 and an exhaust valve 6, and the nozzle is provided with Swing check valve 8.

[0037] exist figure 1 In the specific embodiment shown, both the cylinder and the nozzle work in water, and the nozzle should be in a substantially horizontal state during installation, and the cylinder is located at the top of the nozzle; before the work, the cylinder and the nozzle are filled with water; Air valve 6, and fill the cylinder with fresh air through the cylinder compressed air inlet 3, and inject an appropriate amount of fuel into the cylinder at the same time, the fuel nozzle 4 should have an atomization function, so that the air and fuel can be fully mixed and meet the explosion requirements; After inflation and fuel injection, und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com