Novel heat distribution pipeline thermal insulation pipe pier system

A thermal pipeline, thermal insulation technology, applied in pipeline protection, pipeline protection through thermal insulation, thermal insulation, etc., can solve problems such as heat loss, and achieve the effects of reducing heat loss, easy operation, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

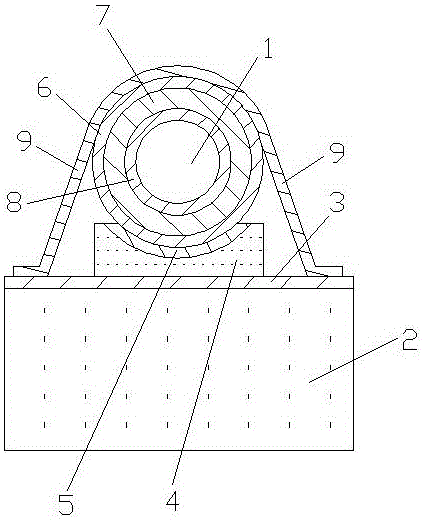

[0013] Such as figure 1 As shown, the present invention includes a thermal pipeline 1, a pipe pier, a steel plate 2, a first MQK nano-airgel layer 3, a casket 4, a second MQK nano-airgel layer 5, a galvanized iron sheet 6, and a hydrophobic silicate Cotton 7, the third MQK nano-airgel layer 8, U-shaped steel belt 9, the steel plate 2 and the pier are consolidated together, the first MQK nano-airgel layer 3 is arranged on the upper surface of the steel plate 2, and the peg 4 The expansion bolts are consolidated with the steel plate 2, the upper surface of the pebble 4 has arc-shaped grooves, the second MQK nano-airgel layer 5 is arranged in the groove on the upper surface of the pebble 4, and the third MQK nano-airgel layer 8, hydrophobic silicate cotton 7, and galvanized iron sheet 6 are sequentially wrapped on the outer surface of the thermal pipeline 1; the wrapped thermal pipeline 1 is placed in the groove on the upper surface of the pan 4 and passed U-shaped steel strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com