On demand hydrogen enhancement system for internal and external combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

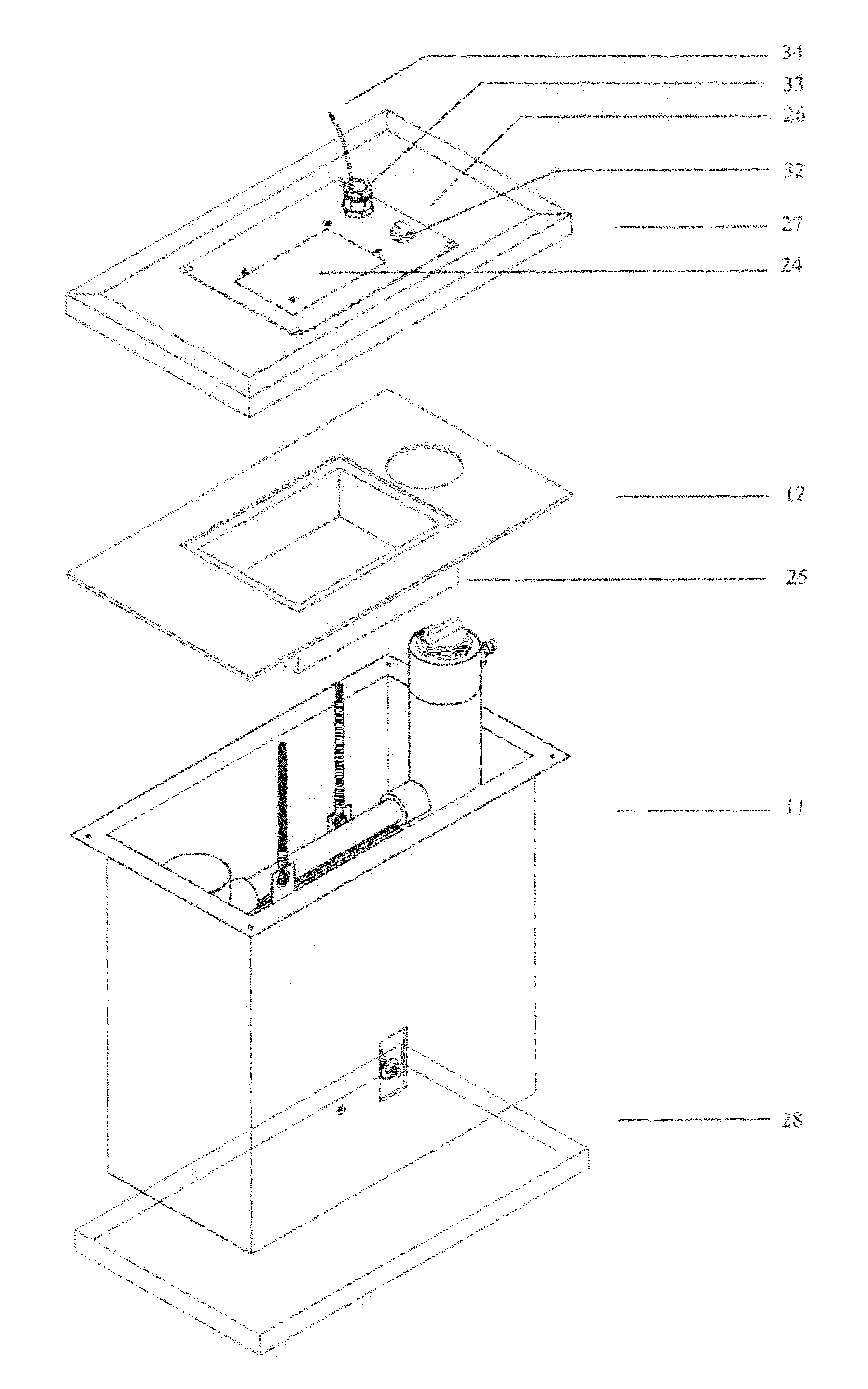

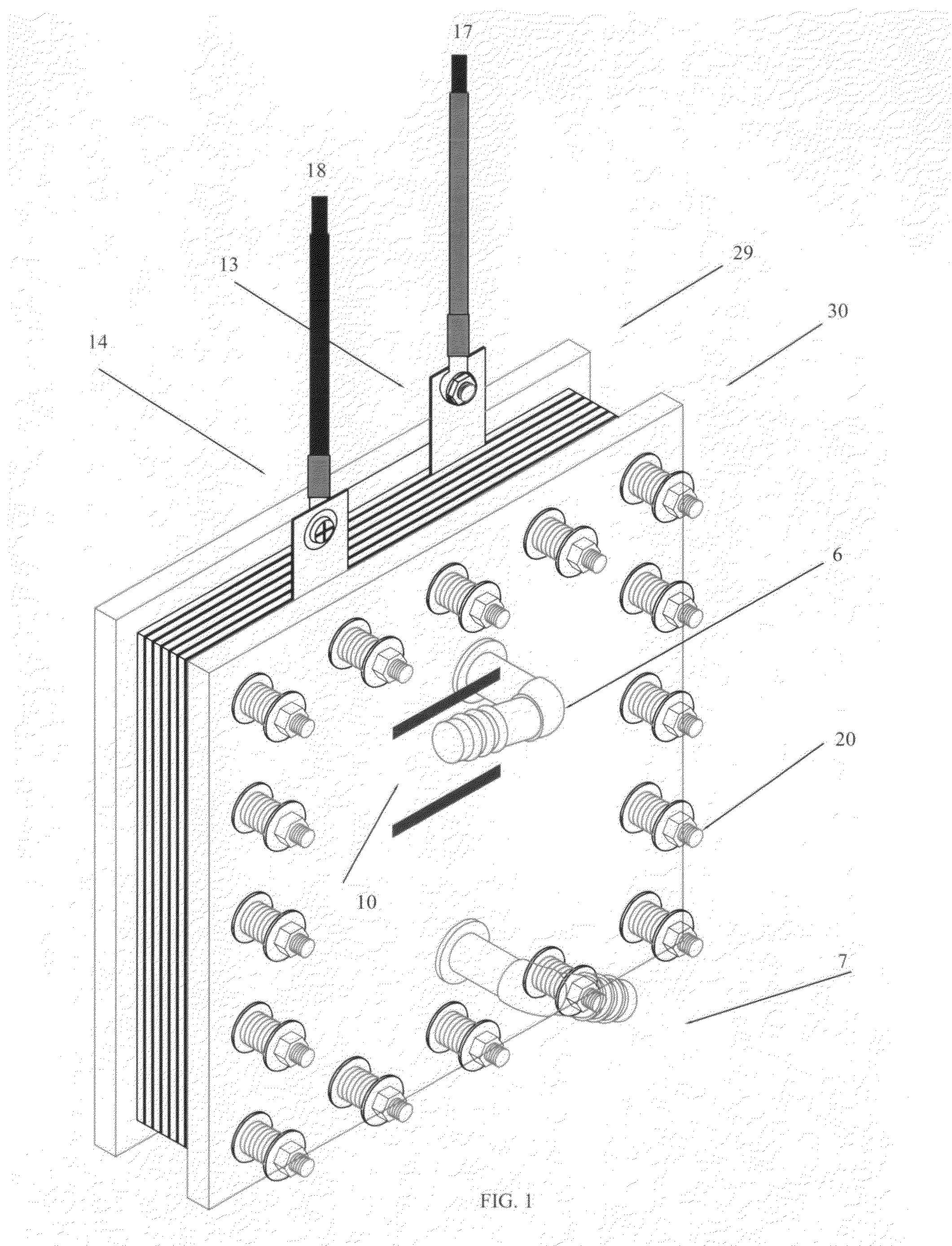

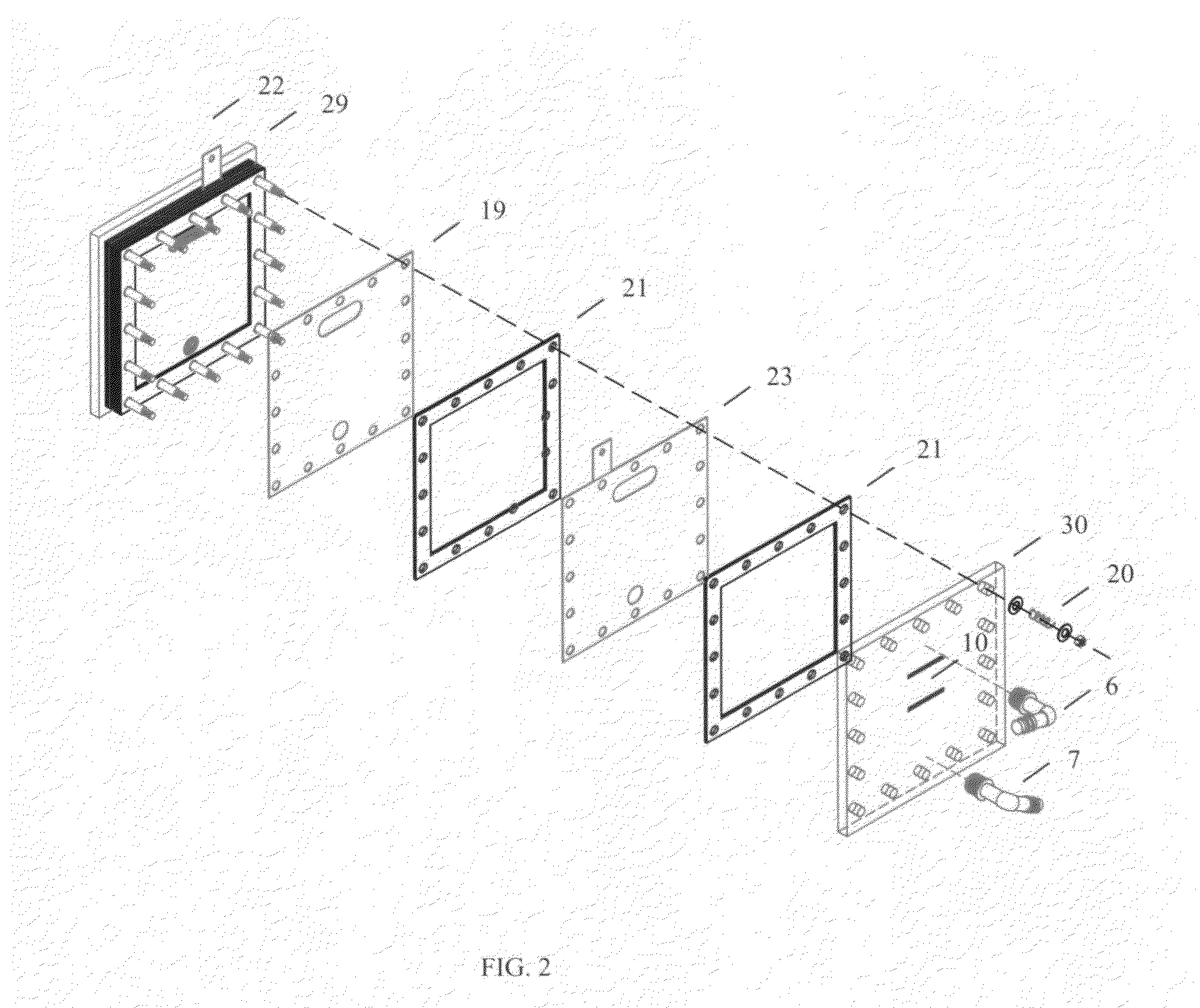

[0046]This invention is to develop a continuous non-pressurized water electrolyzer from clean water (not distil water) system use as catalyse for internal and external combustion engine. It can use with many types of fuel such as Ethanol, Methanol, Gasohol, Gasoline, Diesel, Bio Diesel, LPG, CNG, and LNG. This system can reduce fuel consumption, increase fuel efficiency, increase engine torque, reduce emissions, and reduce engine water temperature. This system has less heat loss it required no cooling fan and electrolytic solution circulation pump. Oxyhydrogen will produce on demand as the engine RPM. The controller unit will detect the signal frequency from alternator and use frequency modulation pulse width modulation (FMPWM) instead of amplitude modulation (AM) to control the electrolyzer. This circuit has current detector for automatic current control and over current protection. The on demand oxyhydrogen generator requires non pressured storage tank, electrolytic solution circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com