Patents

Literature

37results about How to "Increased flame speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

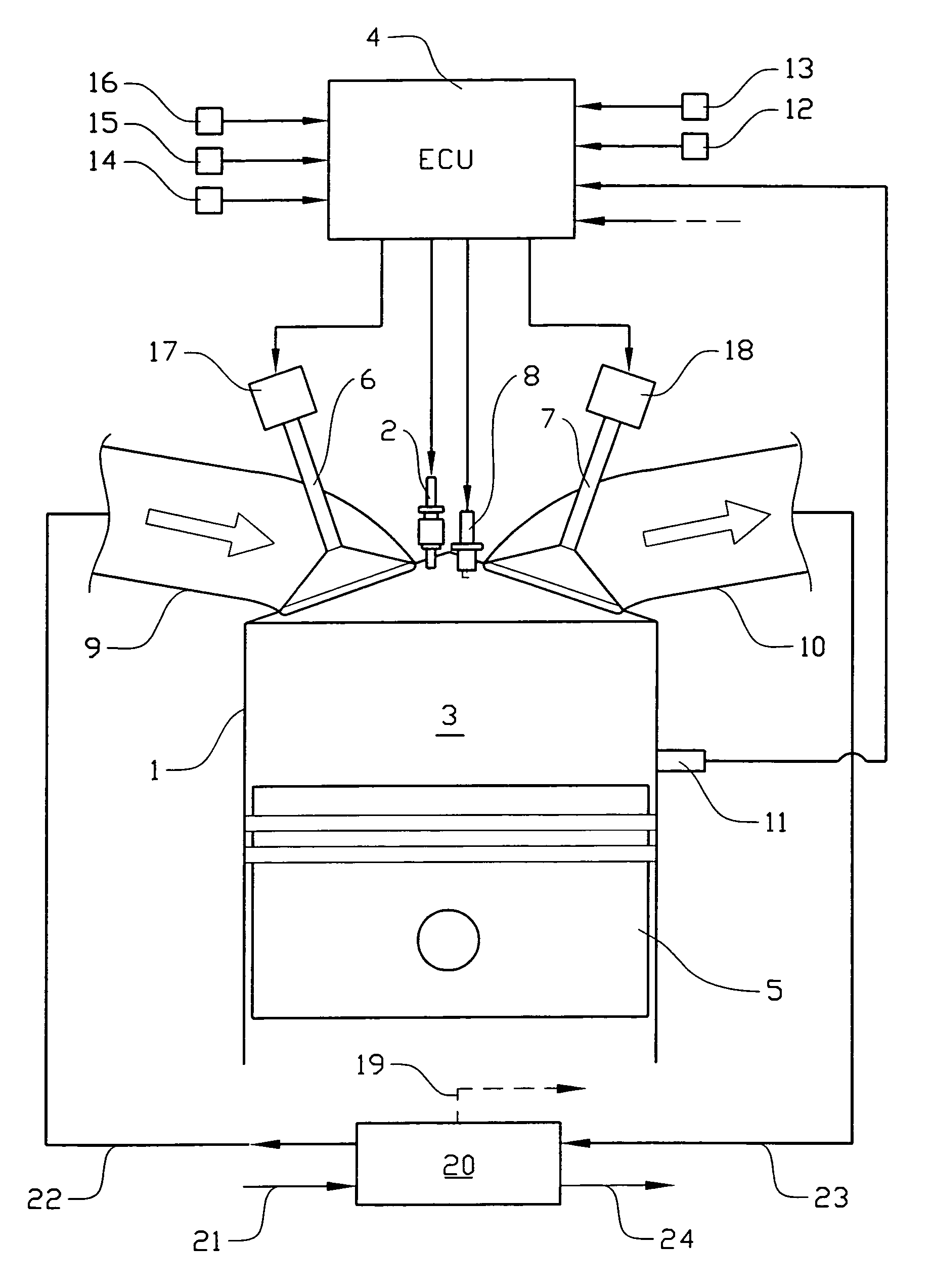

Internal combustion engine and method for auto-ignition operation of said engine

ActiveUS7194996B2Improve thermal efficiencyImprove flammabilityElectrical controlInternal combustion piston enginesCompression actionTop dead center

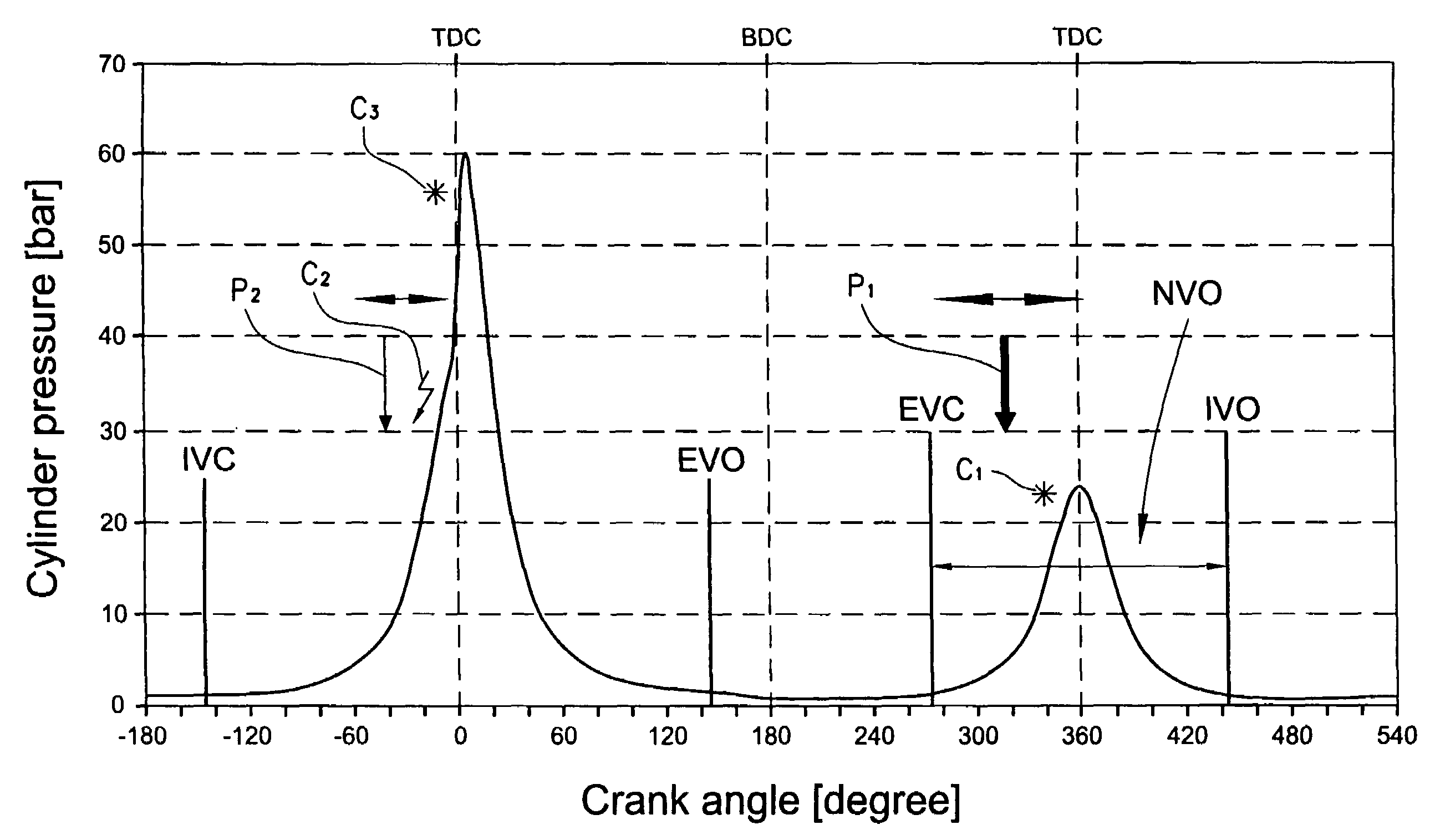

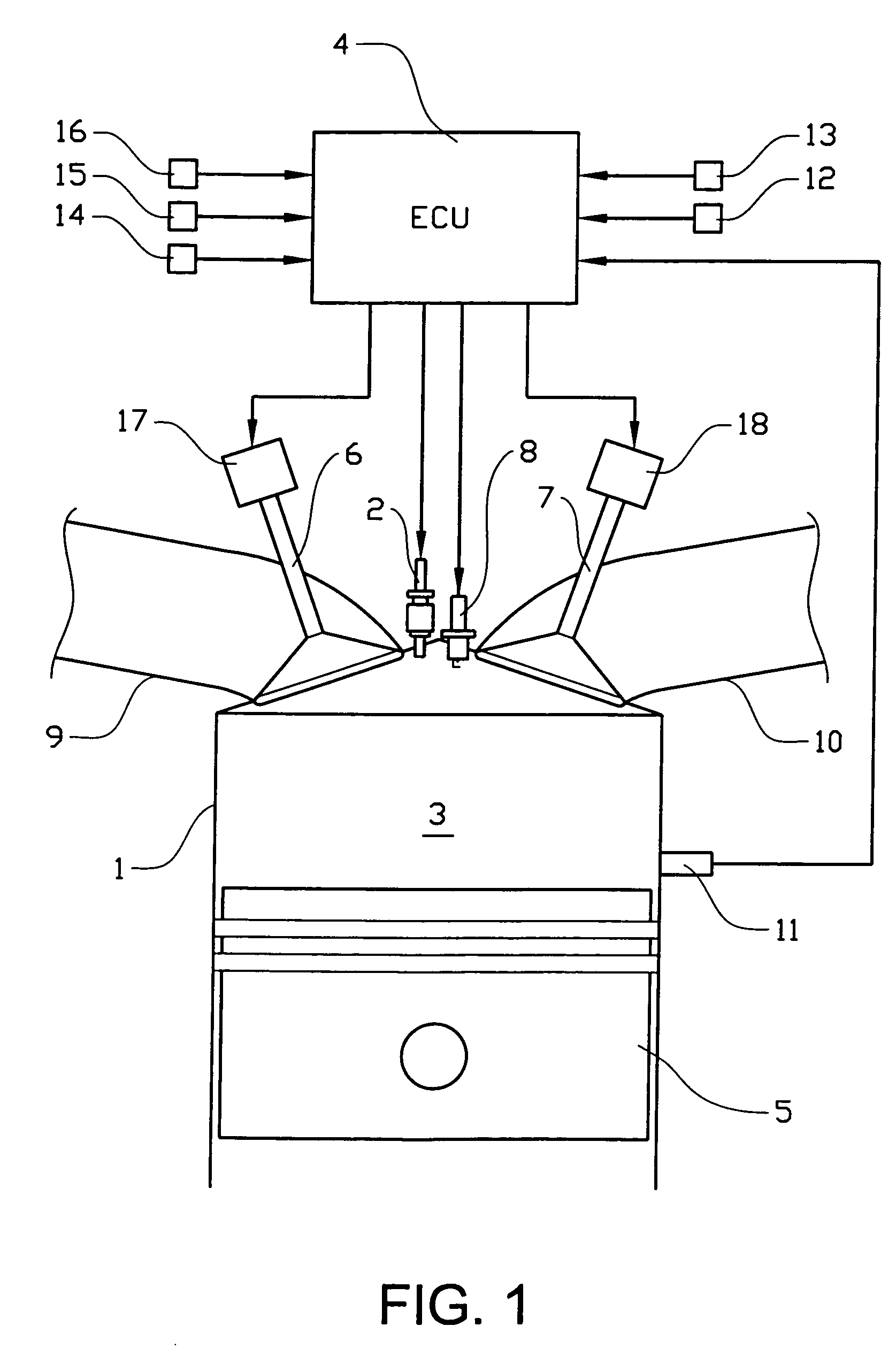

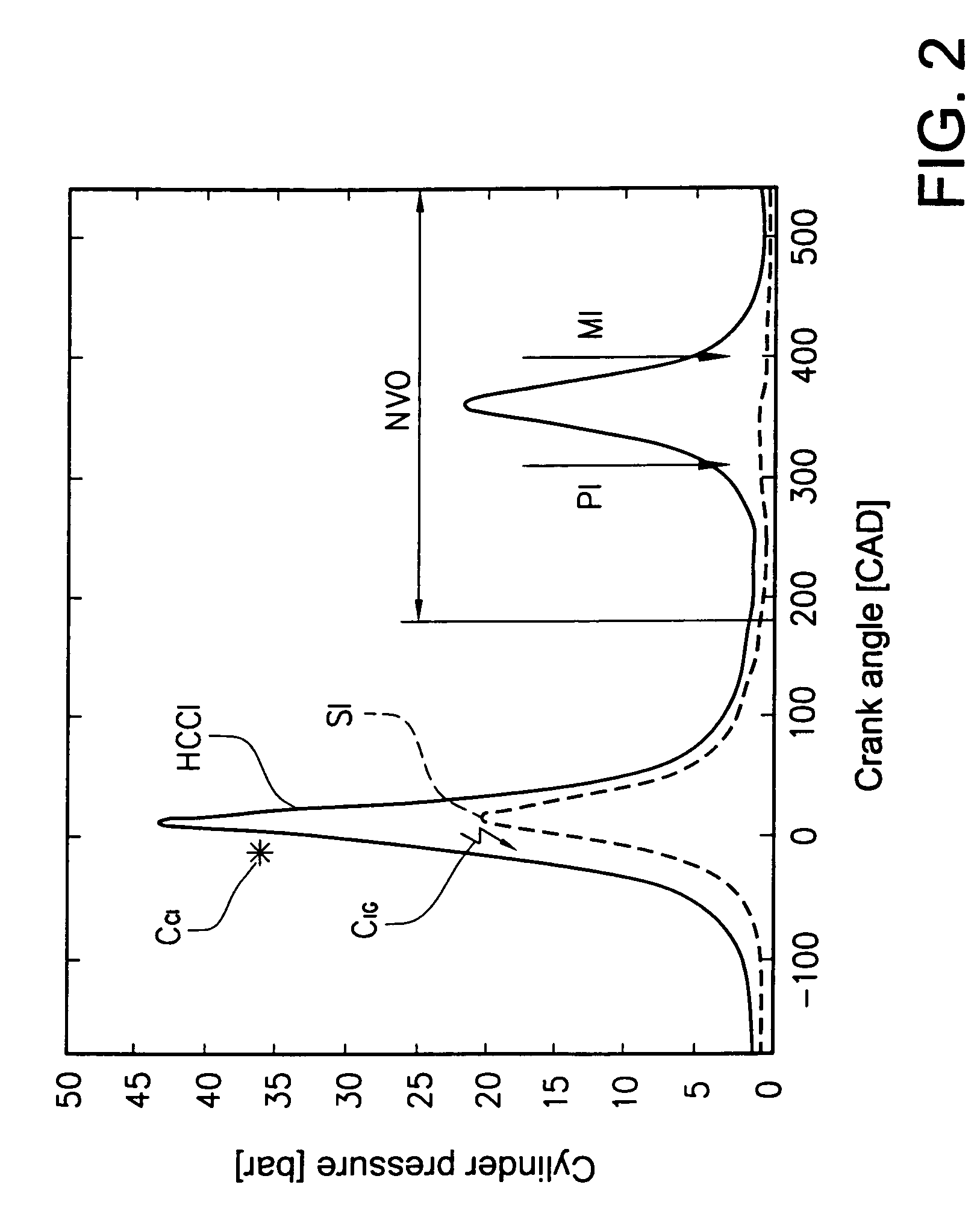

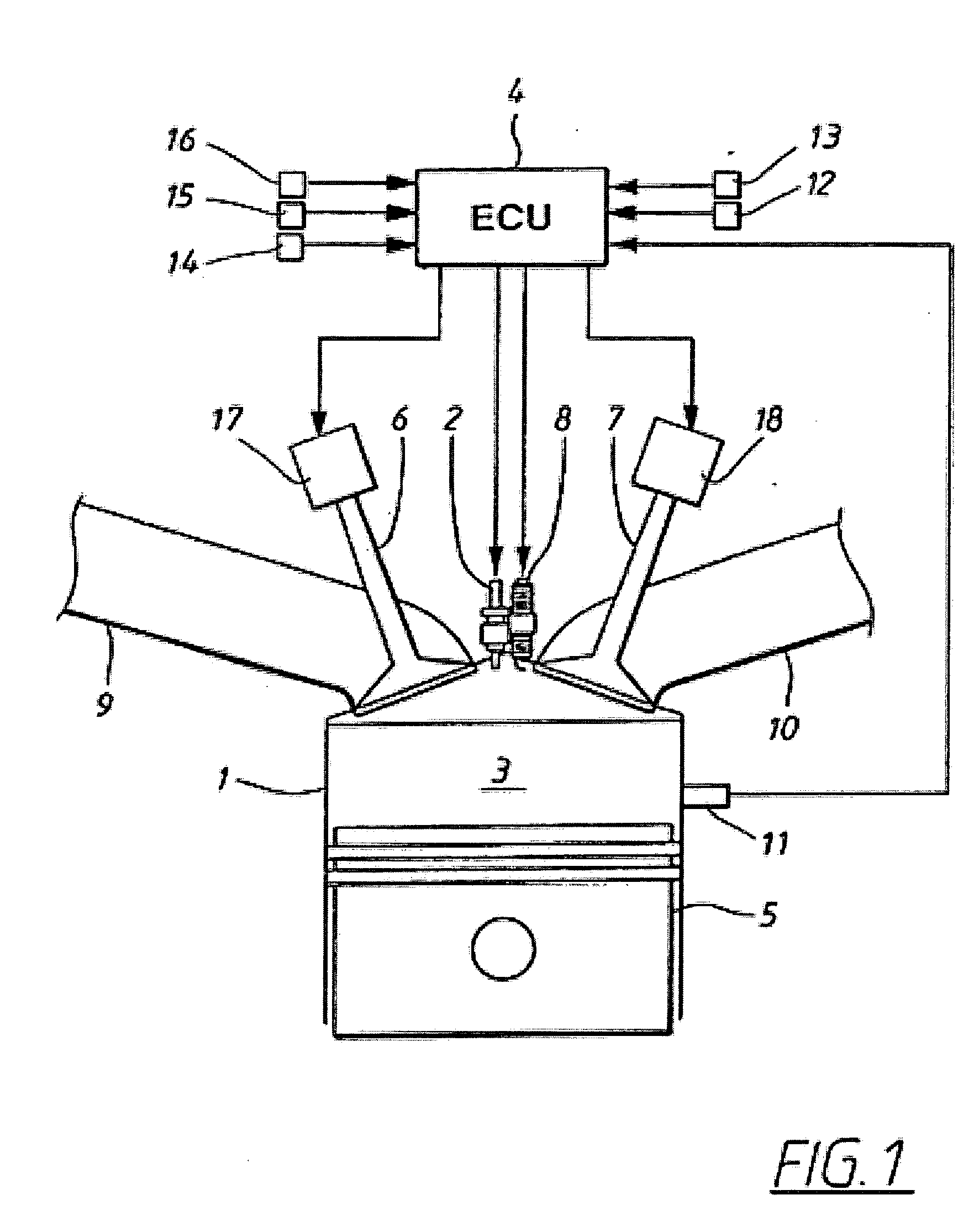

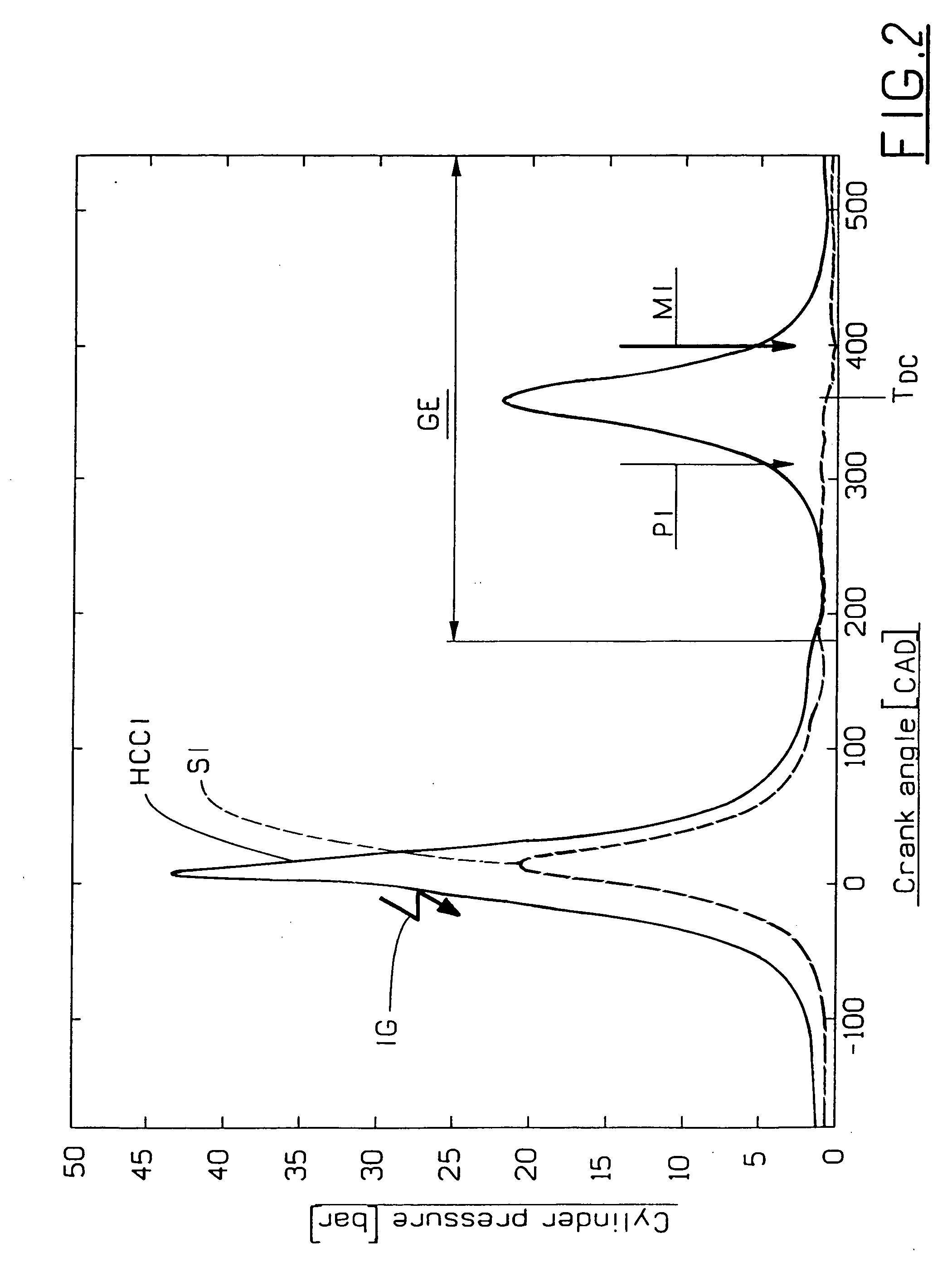

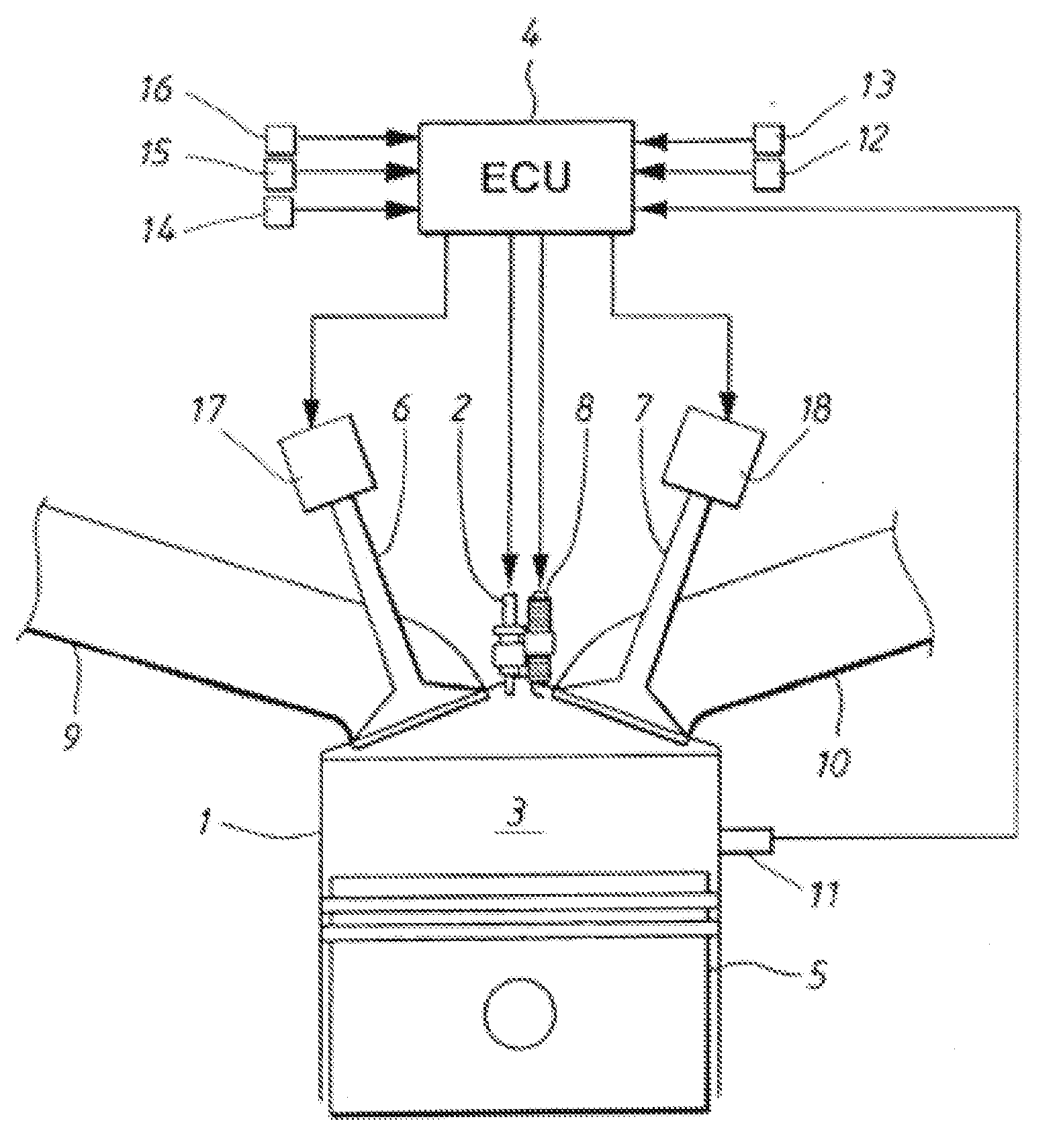

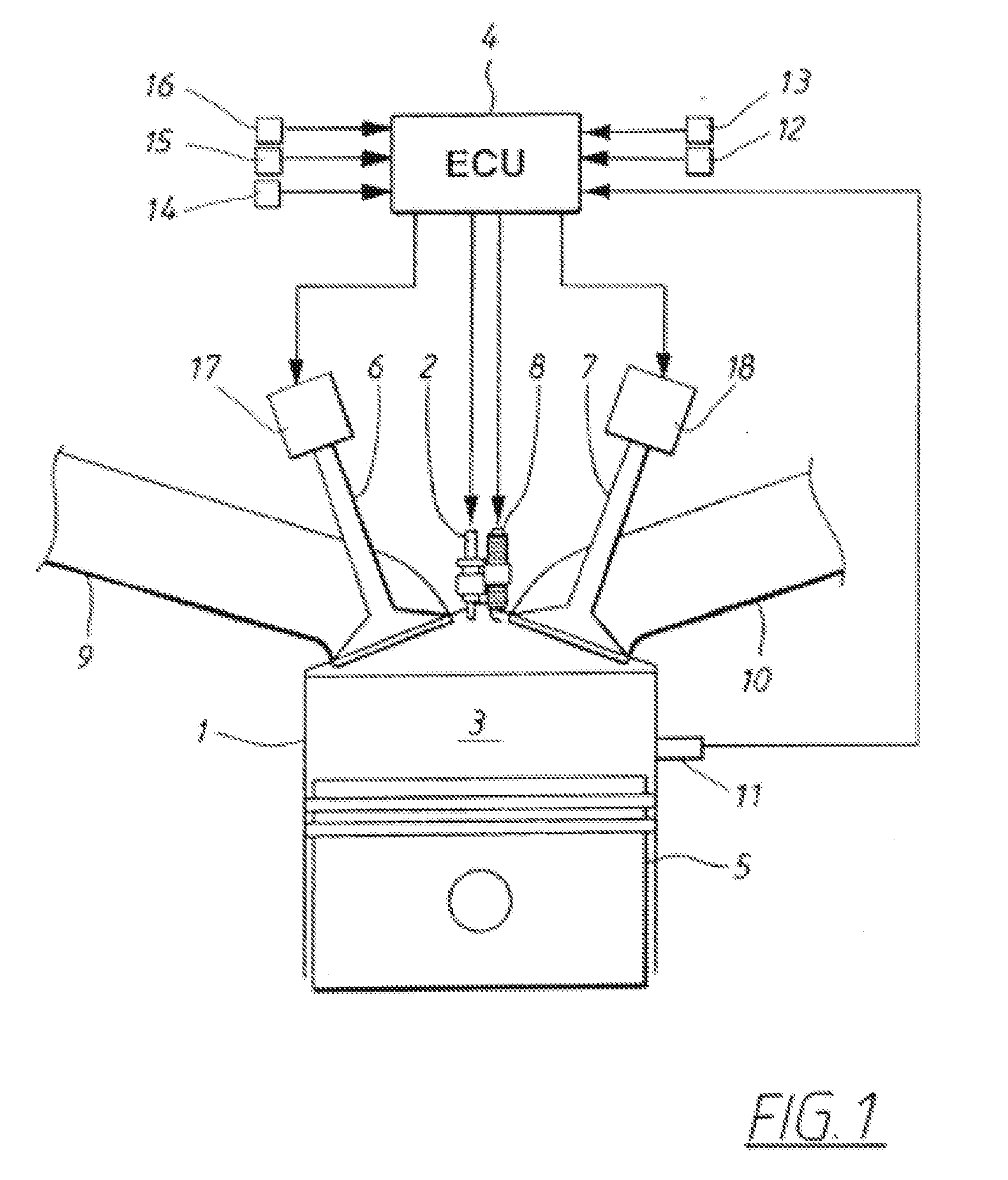

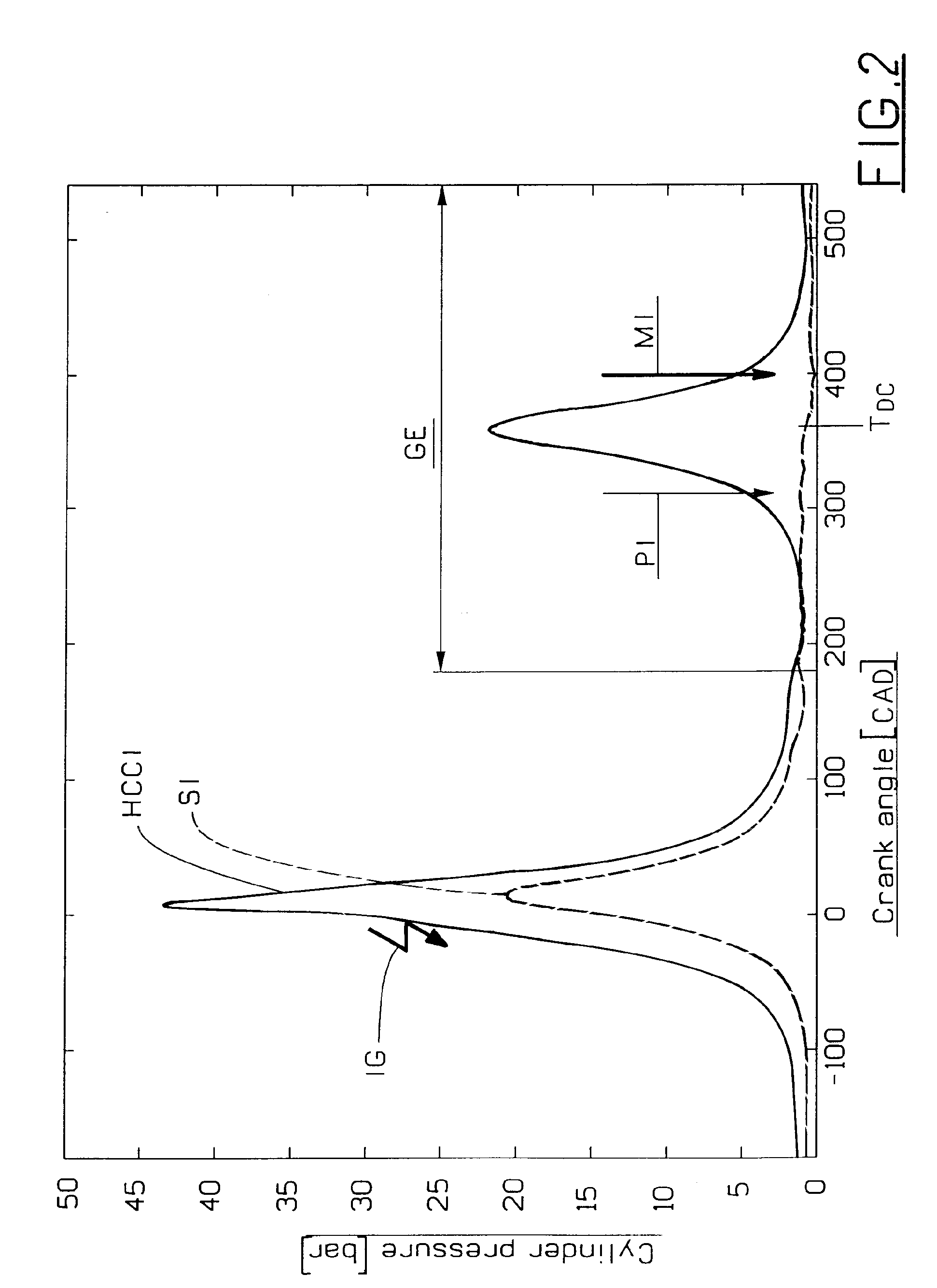

The invention relates to an internal combustion engine that can be operated in compression ignition mode, the engine comprising a fuel injector for each cylinder; a fuel injection controller for controlling fuel injection quantity and a piston in each cylinder whose compression action causes a mixture of air and fuel to be ignited. The engine is further provided with inlet and outlet valves and sensors for measuring various engine operating parameters. During compression ignition mode, the control unit controls the fuel injector to perform a first fuel injection before top dead center of the exhaust stroke during a period of negative valve overlap, and a second fuel injection during the piston compression stroke. The control unit may perform a switch between a first fuel injection strategy and at least one further fuel injection strategy in response to a change in load demand on the engine.

Owner:FORD GLOBAL TECH LLC

Method for auto-ignition operation and computer readable storage device for use with an internal combustion engine

ActiveUS20050211219A1Improve thermal efficiencyImprove flammabilityValve arrangementsElectrical controlCompression actionTop dead center

An internal combustion engine that can be operated in compression ignition mode, comprising a fuel injector (2) for each cylinder; a fuel injection control unit (4) for controlling fuel injection quantity and a piston (5) in each cylinder whose compression action causes a mixture of air and fuel to be ignited. The engine is further provided with inlet and outlet valves (6, 7) and sensors (12-16) for measuring various engine operating parameters, is disclosed. During compression ignition mode, the control unit controls the fuel injector to perform a first fuel injection before, and a second fuel injection after top dead center of the piston stroke during or after a negative valve overlap period. A method for operating the engine and a computer readable storage device (4) having stored therein data representing instructions executable by a computer to implement a compression ignition for an internal combustion engine is also described.

Owner:FORD GLOBAL TECH LLC

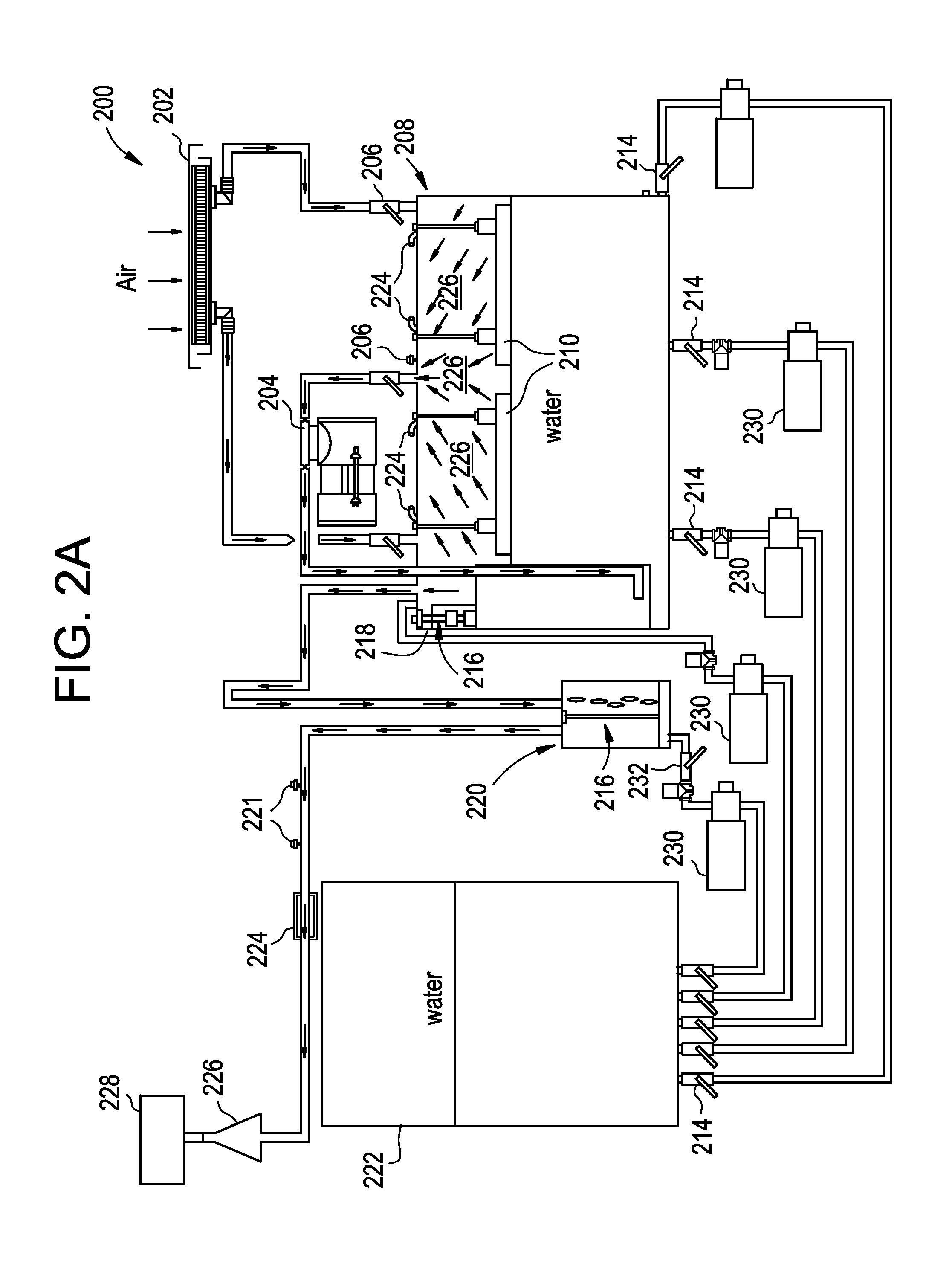

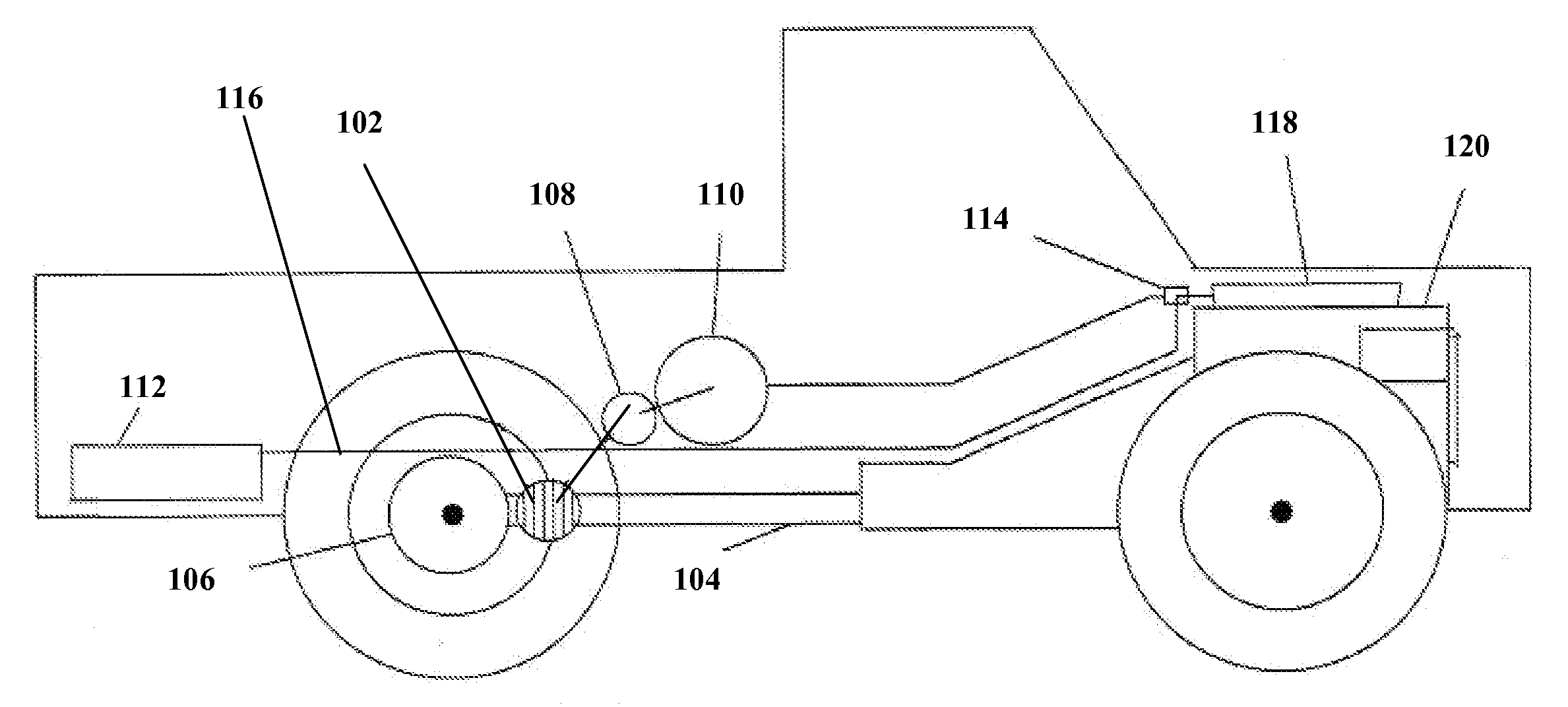

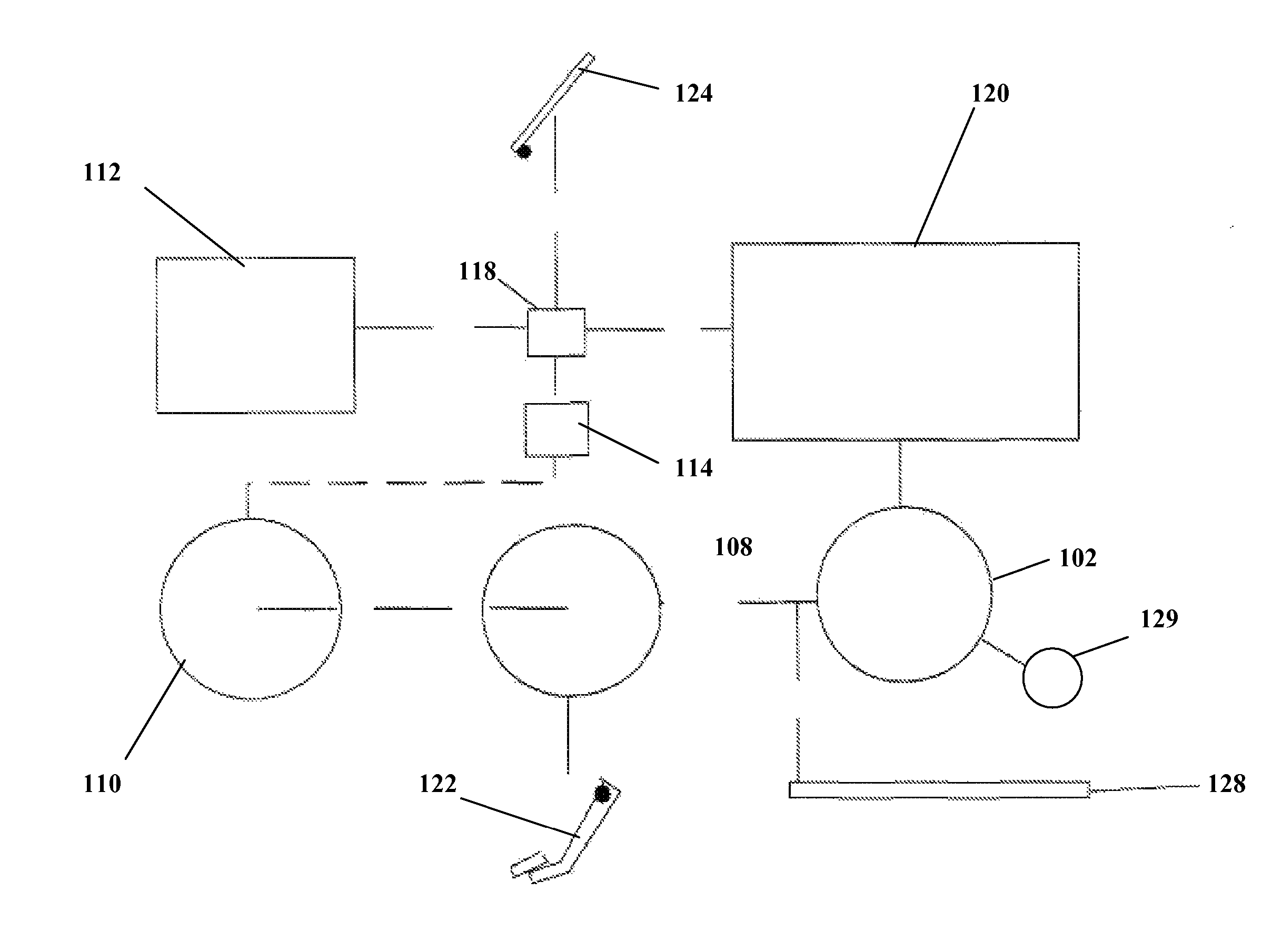

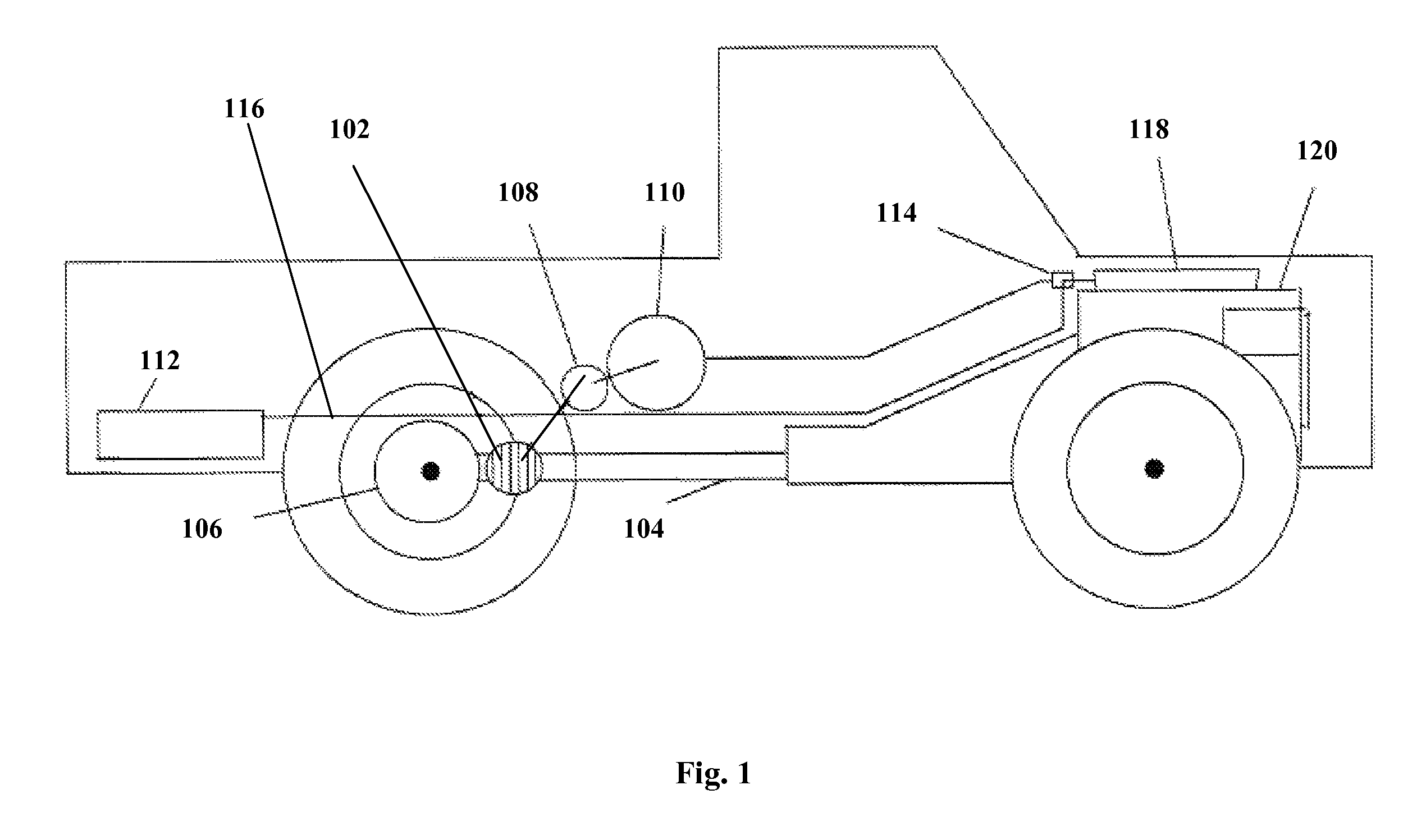

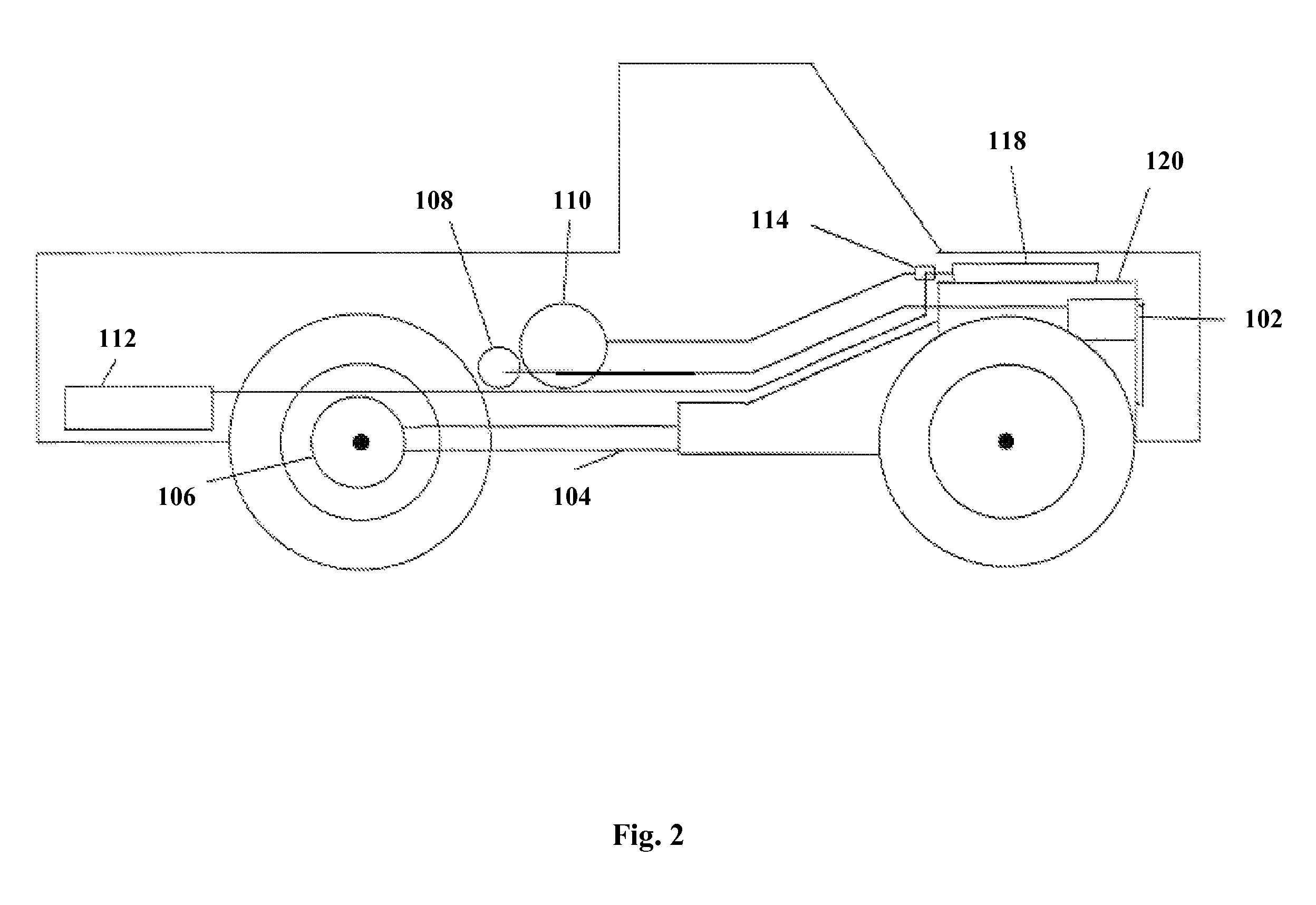

Energy conversion system for hydrogen generation and uses thereof

InactiveUS7753010B2Improve efficiencyEmission reductionAuxillary drivesElectrical controlHydrogenCombustion

The present invention relates to a system capable of using kinetic / inertial and renewable energy to generate hydrogen for use as a fuel in vehicles and other applications. In certain embodiments, this invention relates to a system in which hydrogen is generated during vehicle braking and which is operable with an internal combustion engine, and which can be retrofitted to vehicles with such an engine as well as to stationary combustion devices. Methods for generating hydrogen to power vehicles and vehicles utilizing the inventive technology are also provided. The present invention also relates to stationary devices, such as space heaters and water heaters, capable of generating hydrogen for use as a fuel additive therewith, and methods of generating hydrogen using such devices.

Owner:RUTLEDGE KEITH

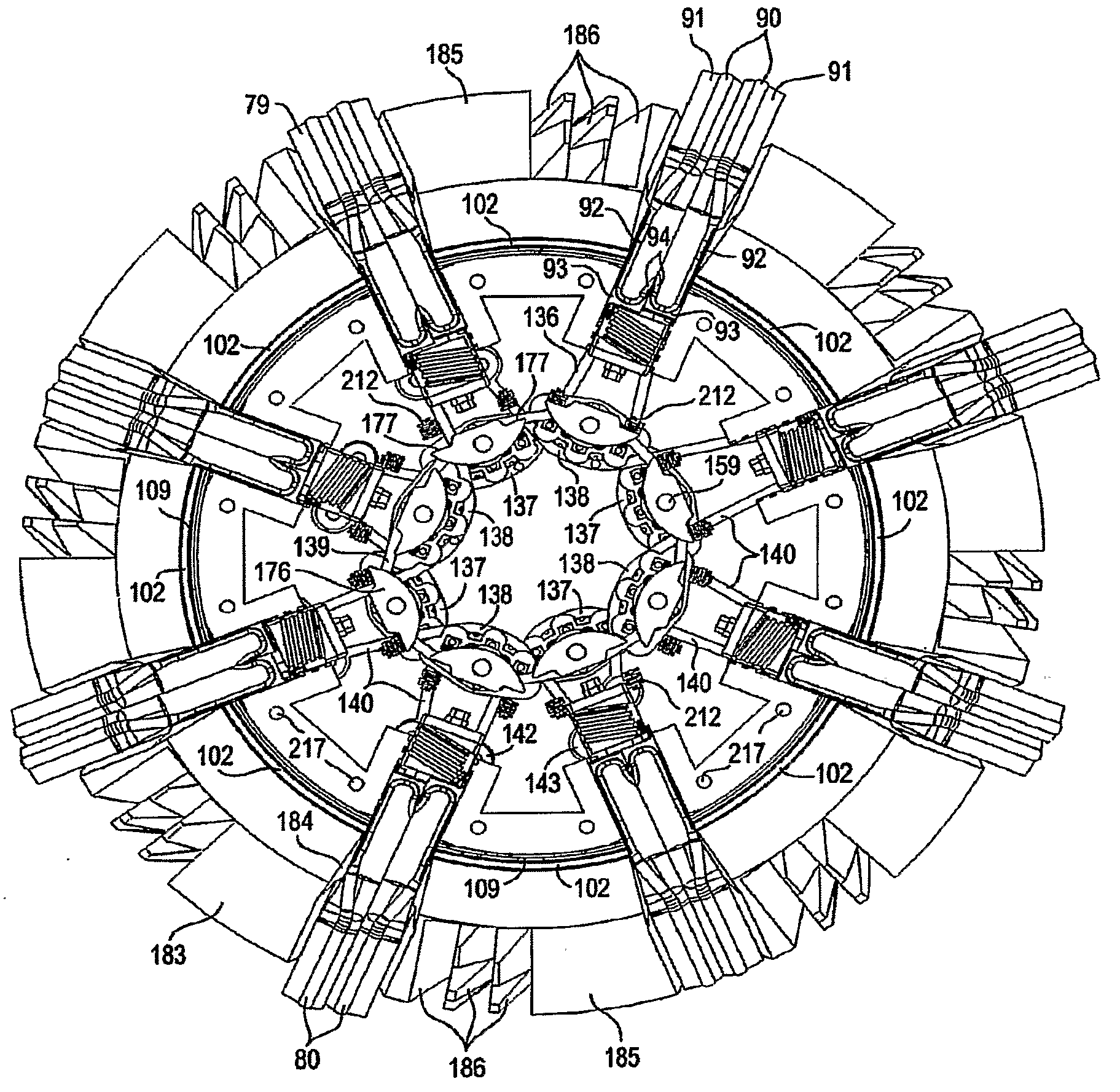

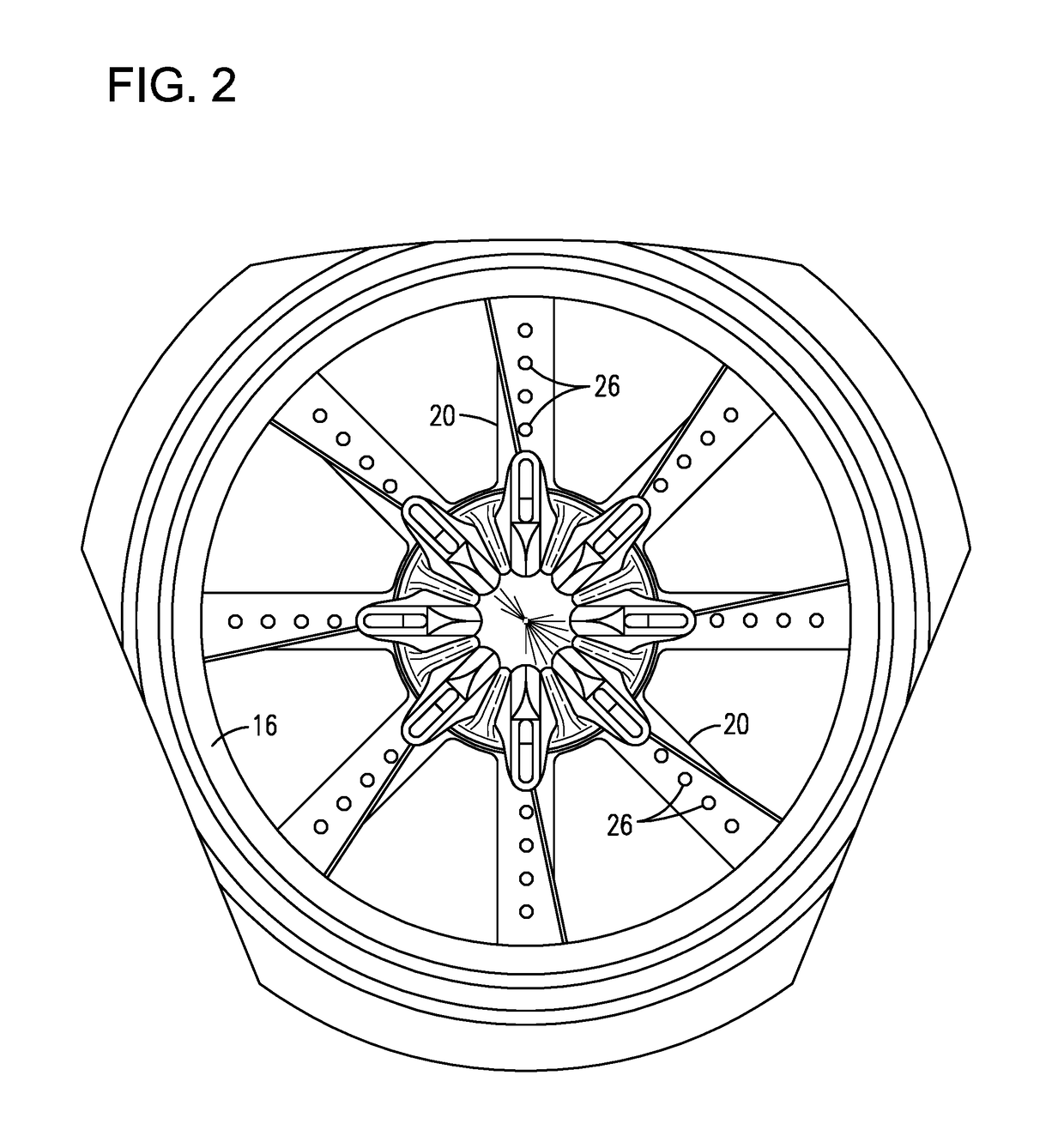

Hydrogen G-Cycle Rotary Internal Combustion Engine

ActiveUS20080247897A1High tensile strengthReduce frictionInternal combustion piston enginesOscillating piston enginesCombustion chamberThermal deformation

A hydrogen G-cycle rotary vane internal combustion engine has a sodium vapor chamber transferring excess combustion heat into combustion chambers. An active water cooling system captures heat from the engine housing stator, rotor, and sliding vanes and transfers it back into the combustion cycle by premixing it with hydrogen to reduce peak combustion temperature and with an early an late stage combustion chamber injection to help transfer heat from the sodium vapor chamber, to control chamber temperature, and to increase chamber vapor pressure. A combustion chamber sealing system includes axial seals between the rotor and the stator, vane face seals, and toggling split vane seals between the outer perimeters of the sliding vanes and the stator. Sliding vanes reciprocate laterally in and out of the rotor assisted by a vane belting system. A thermal barrier coating minimizes heat transfer and thermal deformation. Solid lubricants provide high temperature lubrication and durability.

Owner:PRIME MOVER INT

Method for Auto-Ignition Operation and Computer Readable Storage Device for Use with an Internal Combustion Engine

InactiveUS20060241848A1Improve thermal efficiencyImprove flammabilityAnalogue computers for vehiclesValve arrangementsCompression actionTop dead center

An internal combustion engine that can be operated in compression ignition mode, comprising a fuel injector (2) for each cylinder; a fuel injection control unit (4) for controlling fuel injection quantity and a piston (5) in each cylinder whose compression action causes a mixture of air and fuel to be ignited. The engine is further provided with inlet and outlet valves (6, 7) and sensors (12-16) for measuring various engine operating parameters, is disclosed. During compression ignition mode, the control unit controls the fuel injector to perform a first fuel injection before, and a second fuel injection after top dead center of the piston stroke during or after a negative valve overlap period. A method for operating the engine and a computer readable storage device (4) having stored therein data representing instructions executable by a computer to implement a compression ignition for an internal combustion engine is also described.

Owner:FORD GLOBAL TECH LLC

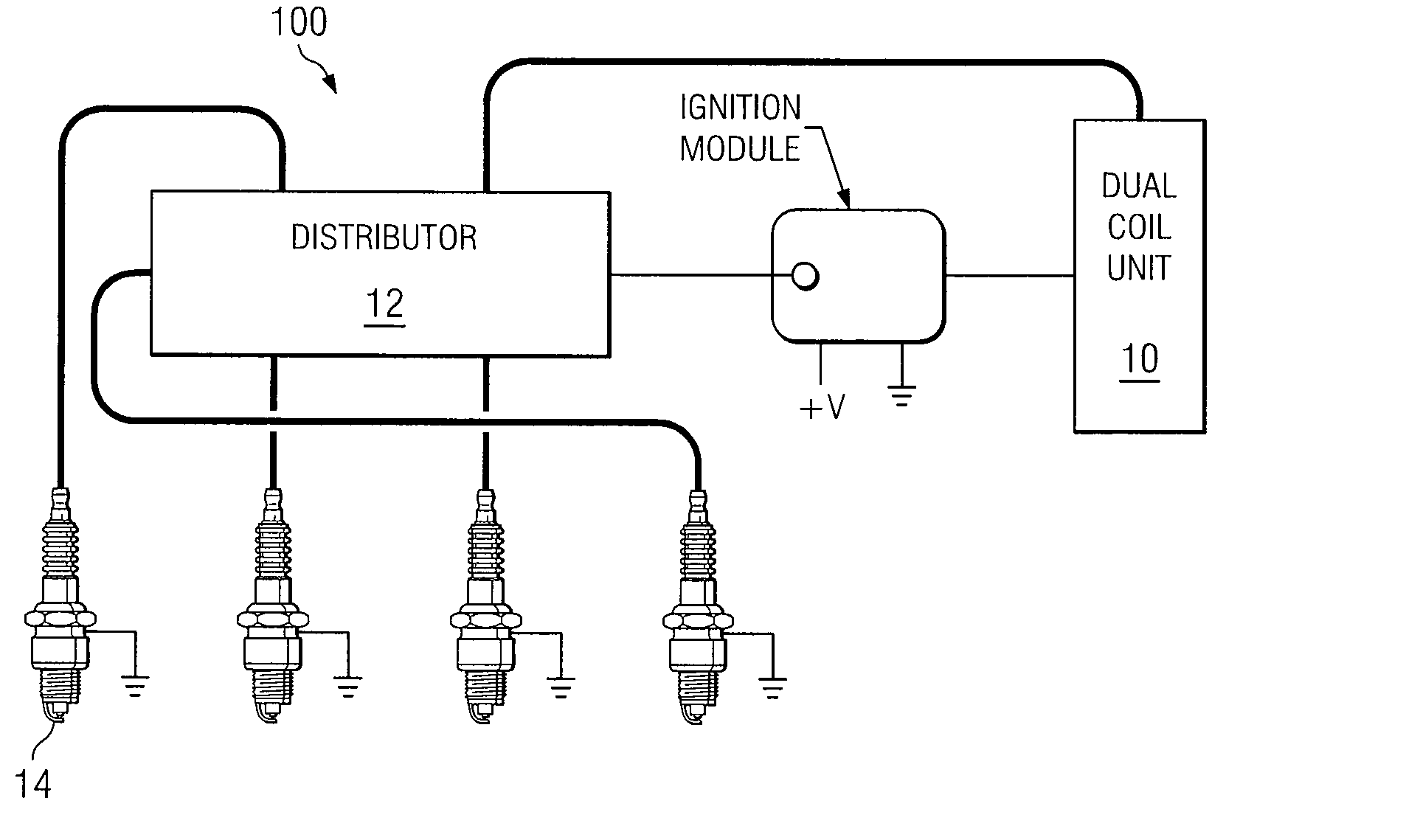

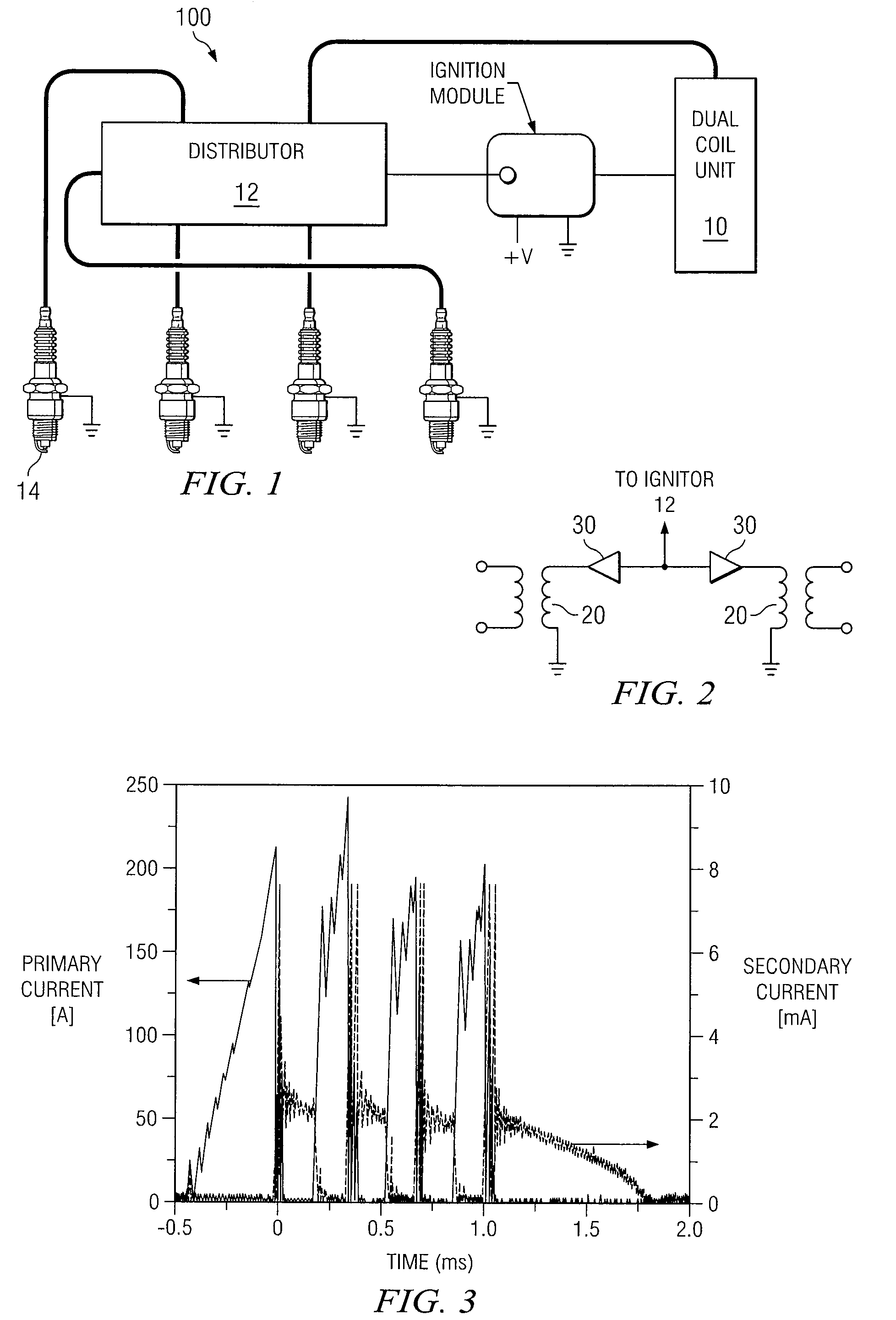

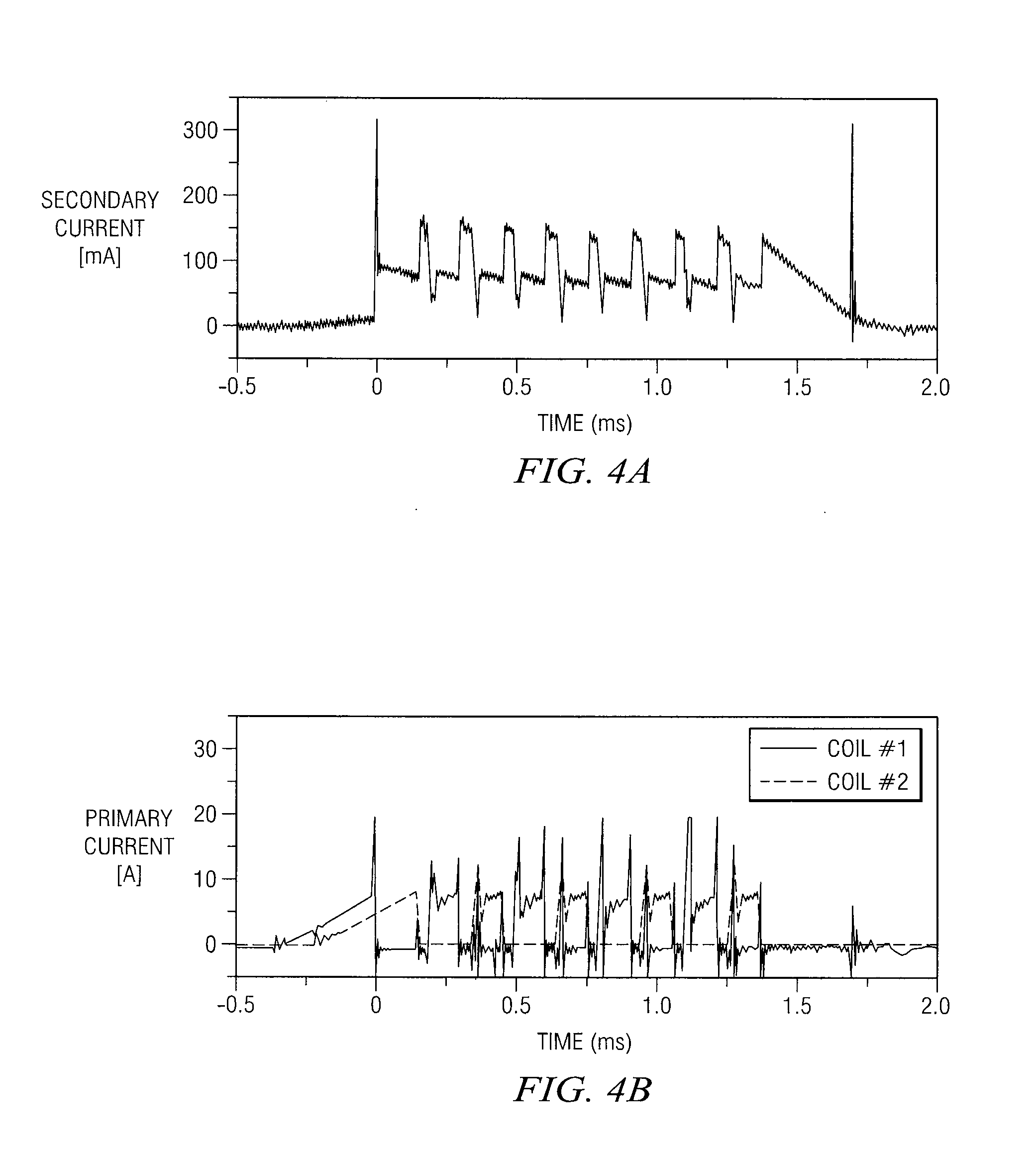

Dual coil ignition circuit for spark ignited engine

InactiveUS20090126710A1Improve flammabilityImprove thermal efficiencyTransformersMachines/enginesDual coilSingle pair

An electrical circuit for extending the duration of the spark provided by a spark plug. Instead of a single coil (and a single pair of windings), a dual coil unit is used. The dual coil unit may be operated in a “multi-strike” mode in which the discharge of each coil is shortened and offset from that of the other coil. This provides an effective spark for an extended duration.

Owner:SOUTHWEST RES INST

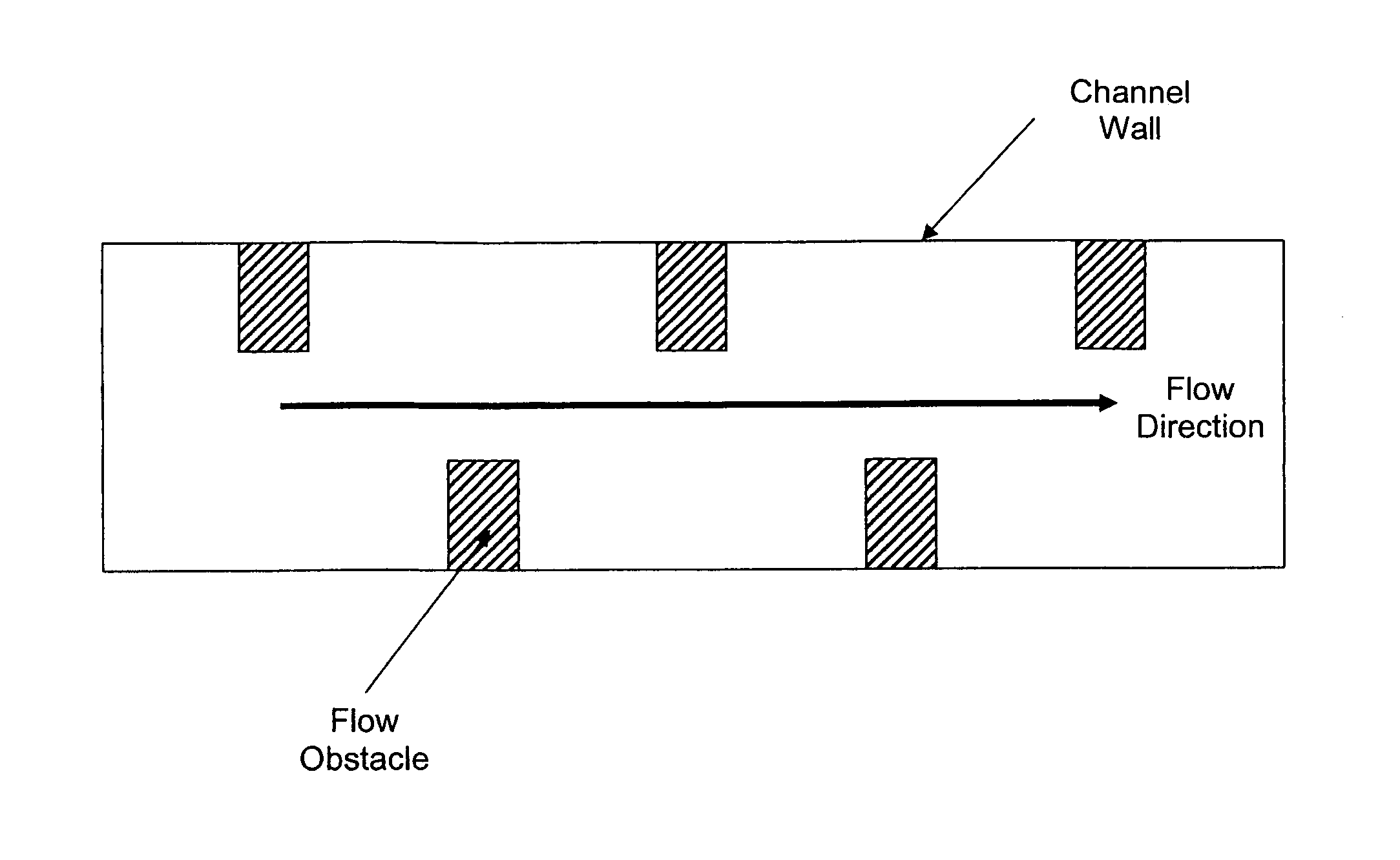

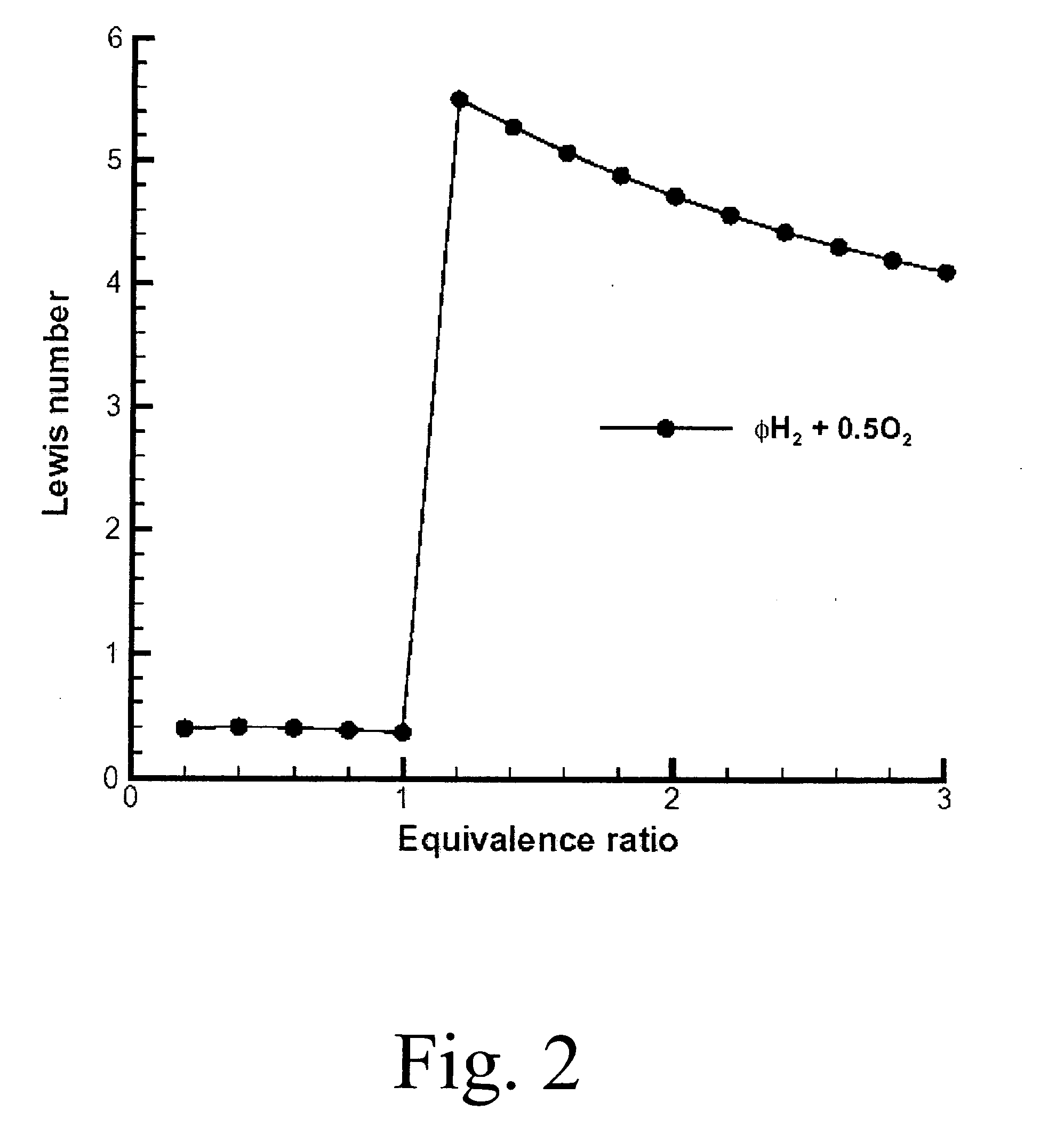

Detonation safety in microchannels

InactiveUS20060035182A1Increased flame speedProcess control/regulationFuel lightersInherent safetyFlame propagation

The proper sizing of microchannel dimensions and the management of internal features offer the possibility of inherently safe operation within the flammable limits of a combustible fluid stream while preserving the largest-possible flow dimensions for industrial-scale process capacity. Specifically, the microchannel dimensions need not be restricted to gap distances below the quenching distance to be operated safely. Microchannel performance can be engineered to provide adequate heat transfer for flame propagation. However, it is essential to maintain flame characteristics in such a manner that it cannot transition to a detonation flame front. A detonation takes place when the combustion wave propagates at supersonic speeds at the existing local temperature and pressure conditions in the system. It results in a much larger energy release over a much smaller period of time as compared to a laminar flame or deflagration, the later of which is a combustion wave propagating at subsonic speed. Detonations can be potentially highly destructive and very hazardous and therefore should be avoided for most industrial applications.

Owner:VELOCYS CORPORATION

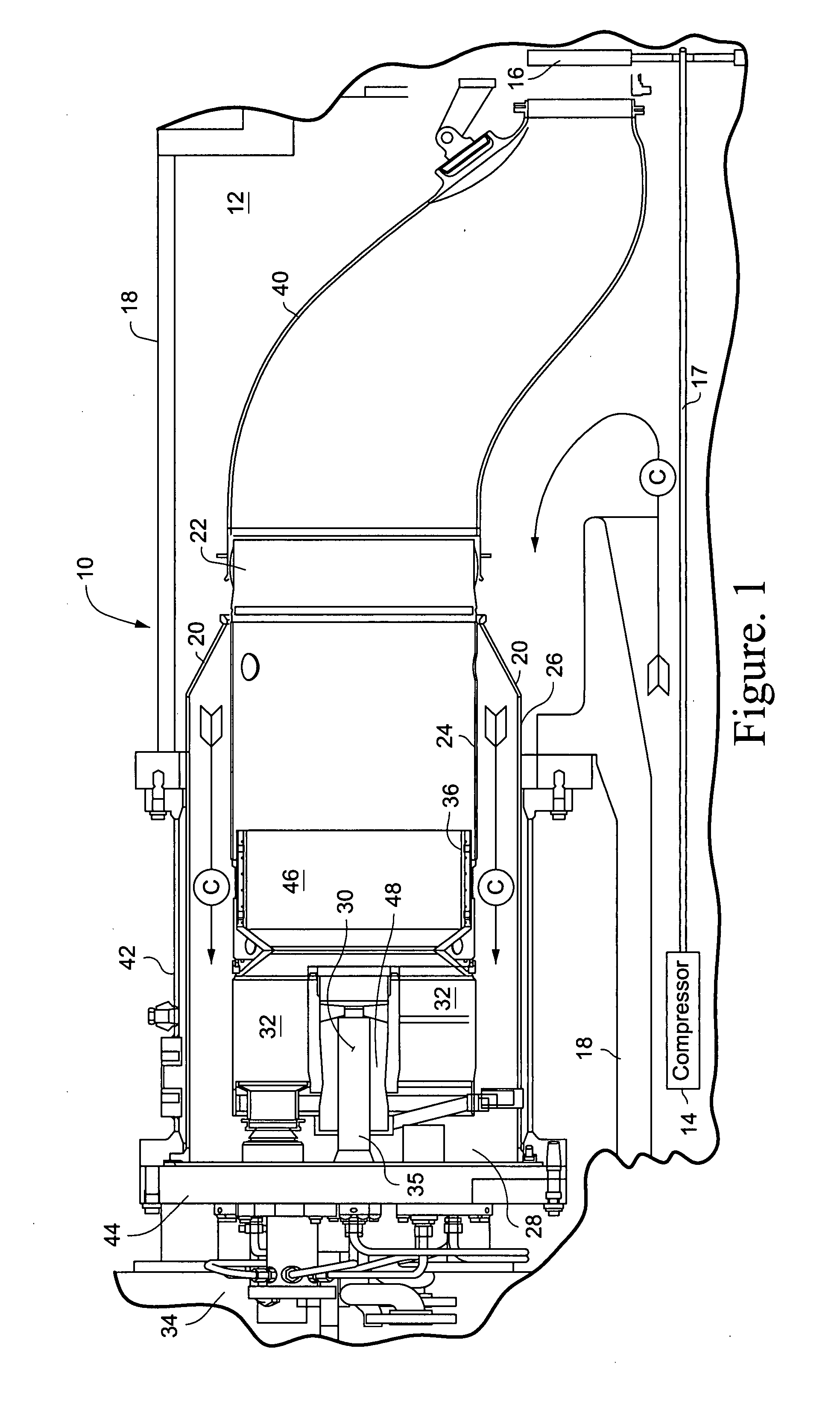

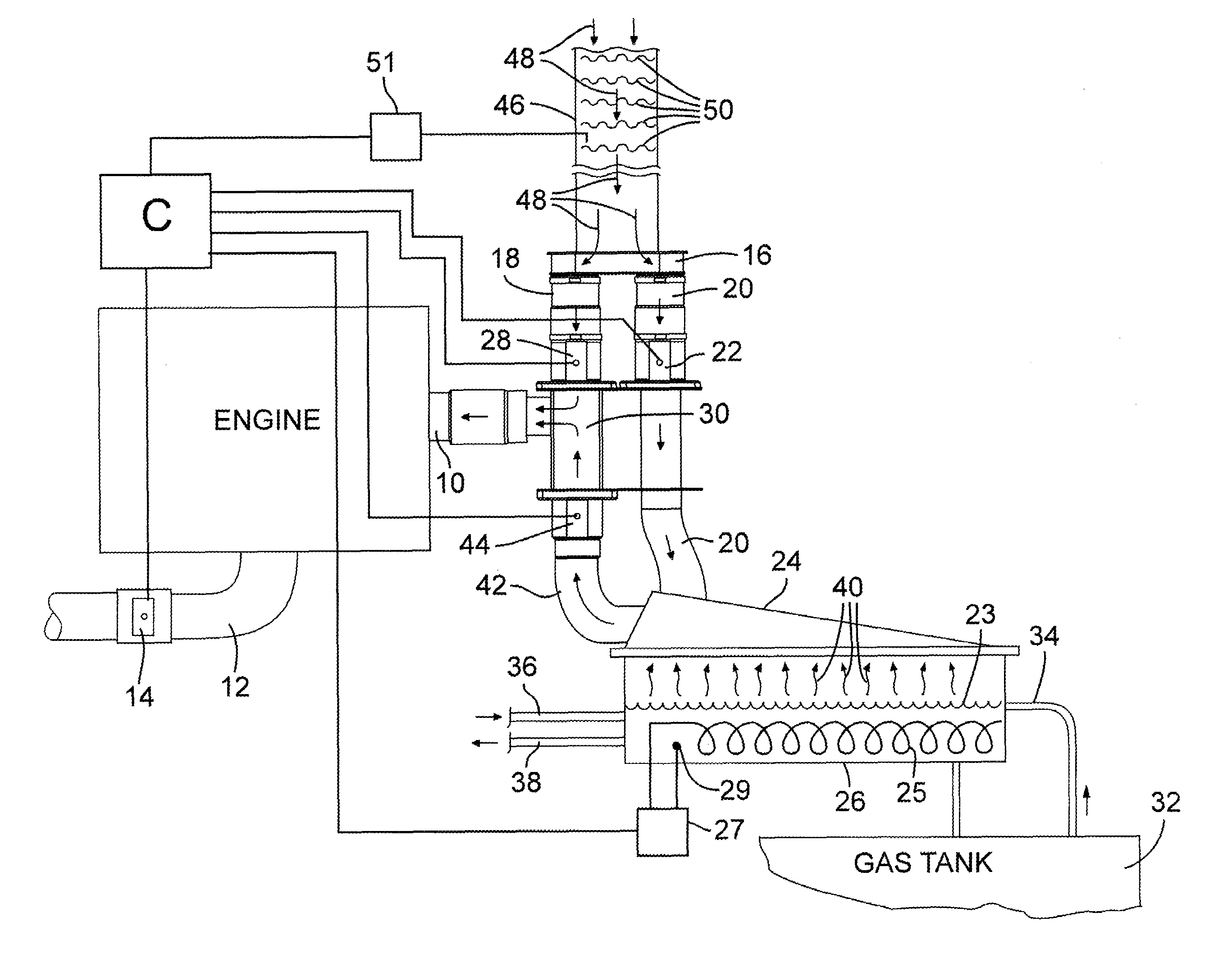

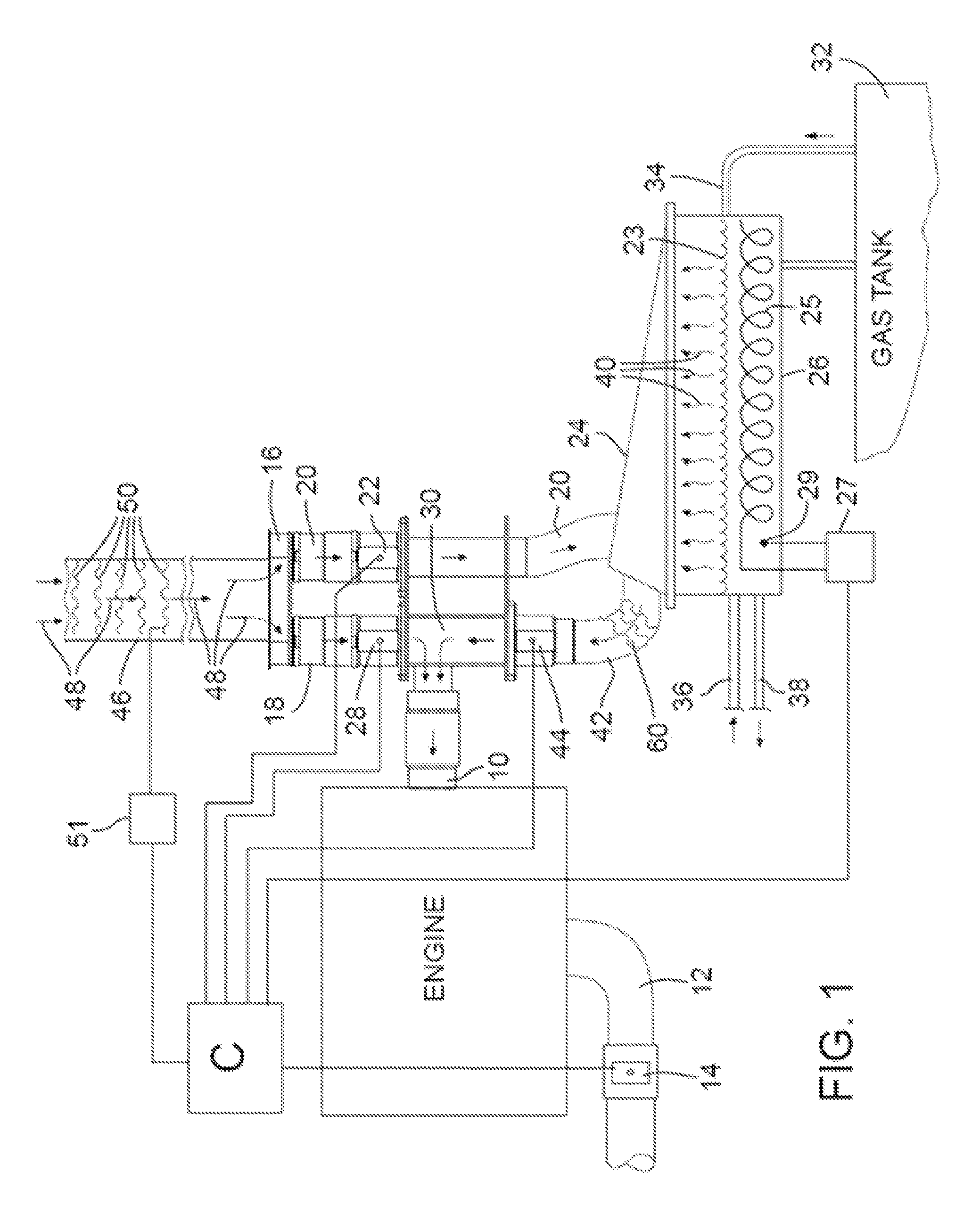

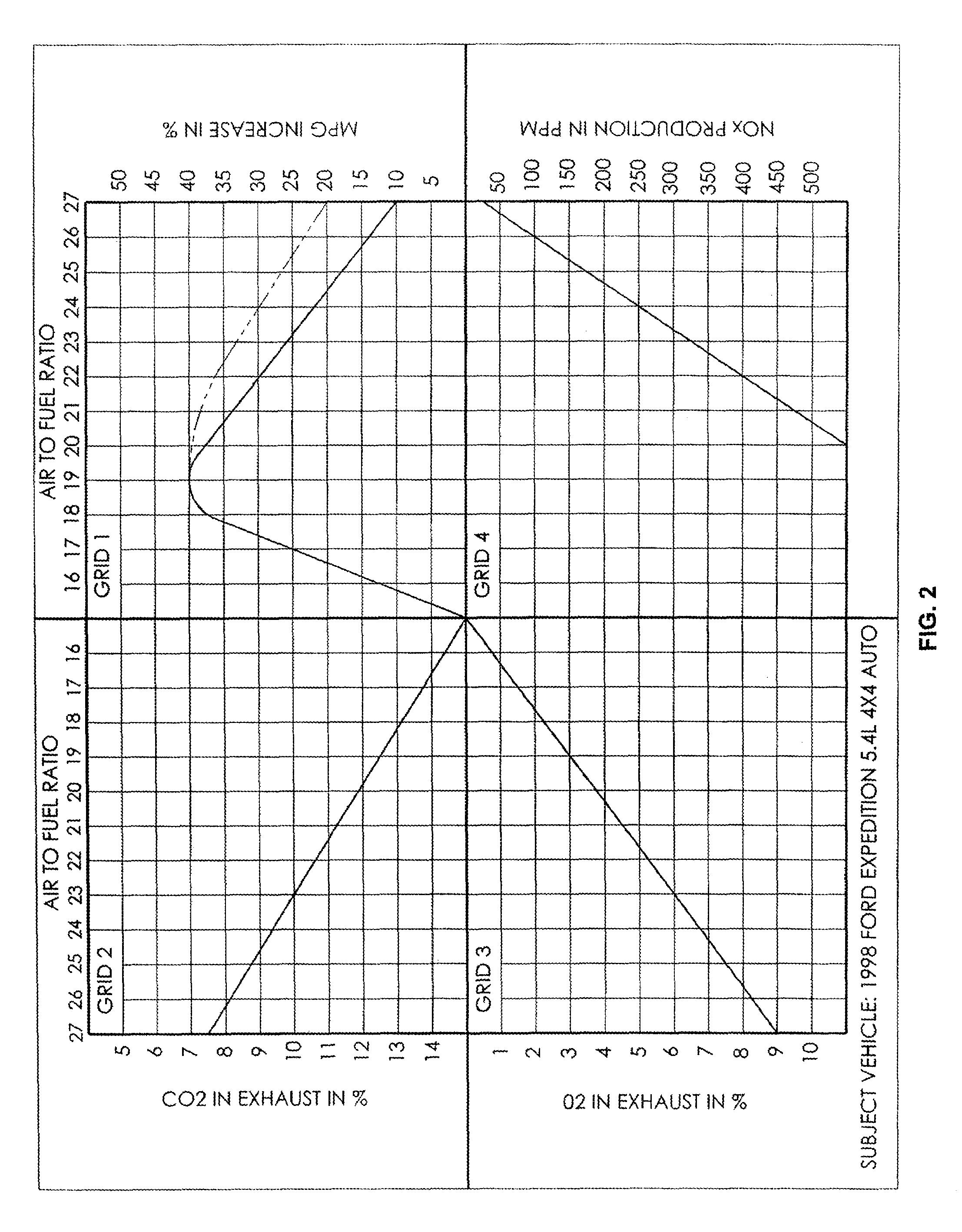

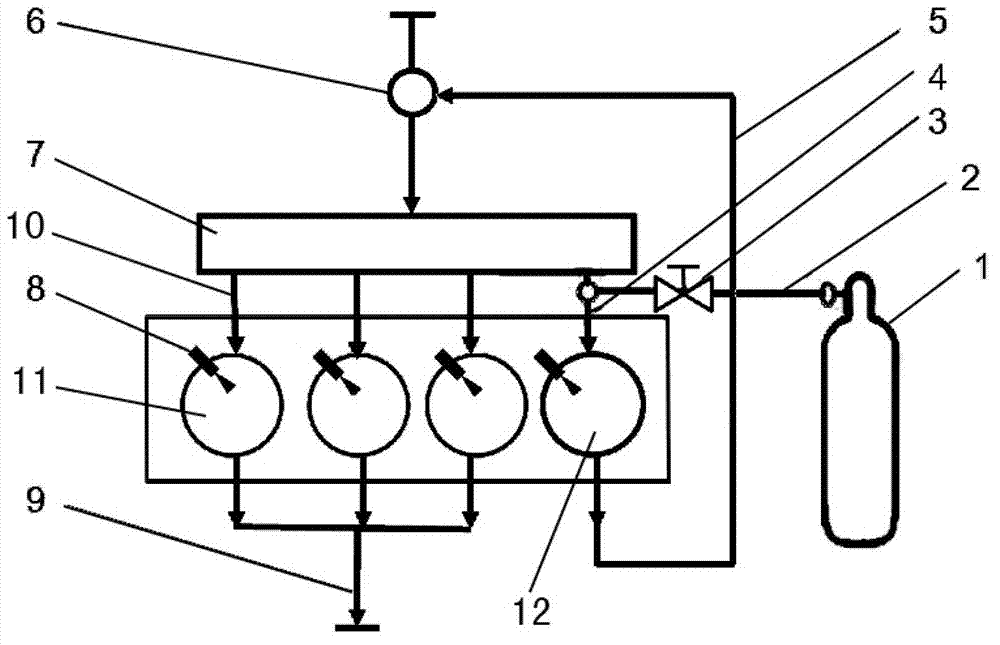

Hydrogen/oxygen on-demand system, high speed efficient hydrogen reactor system and methods therefor

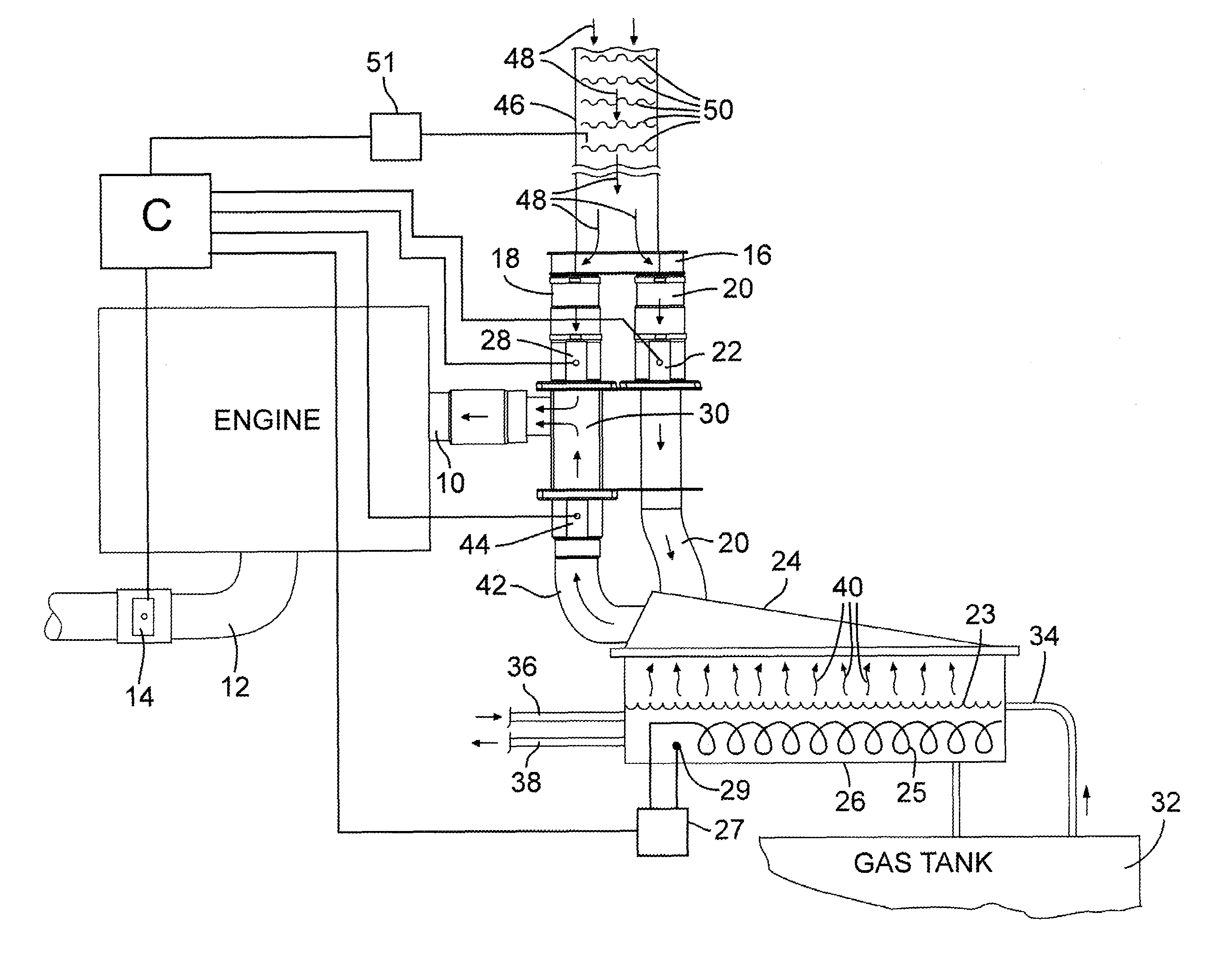

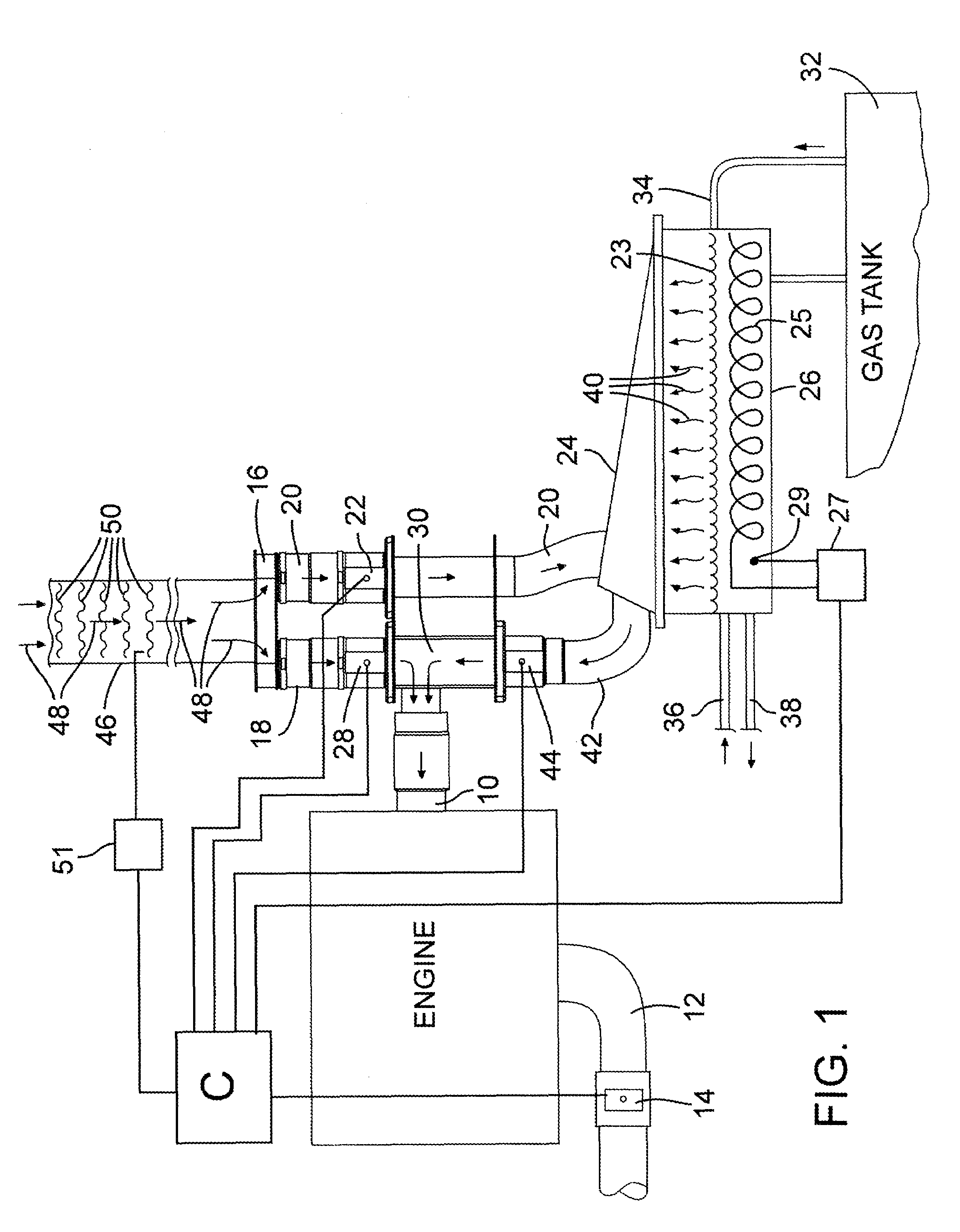

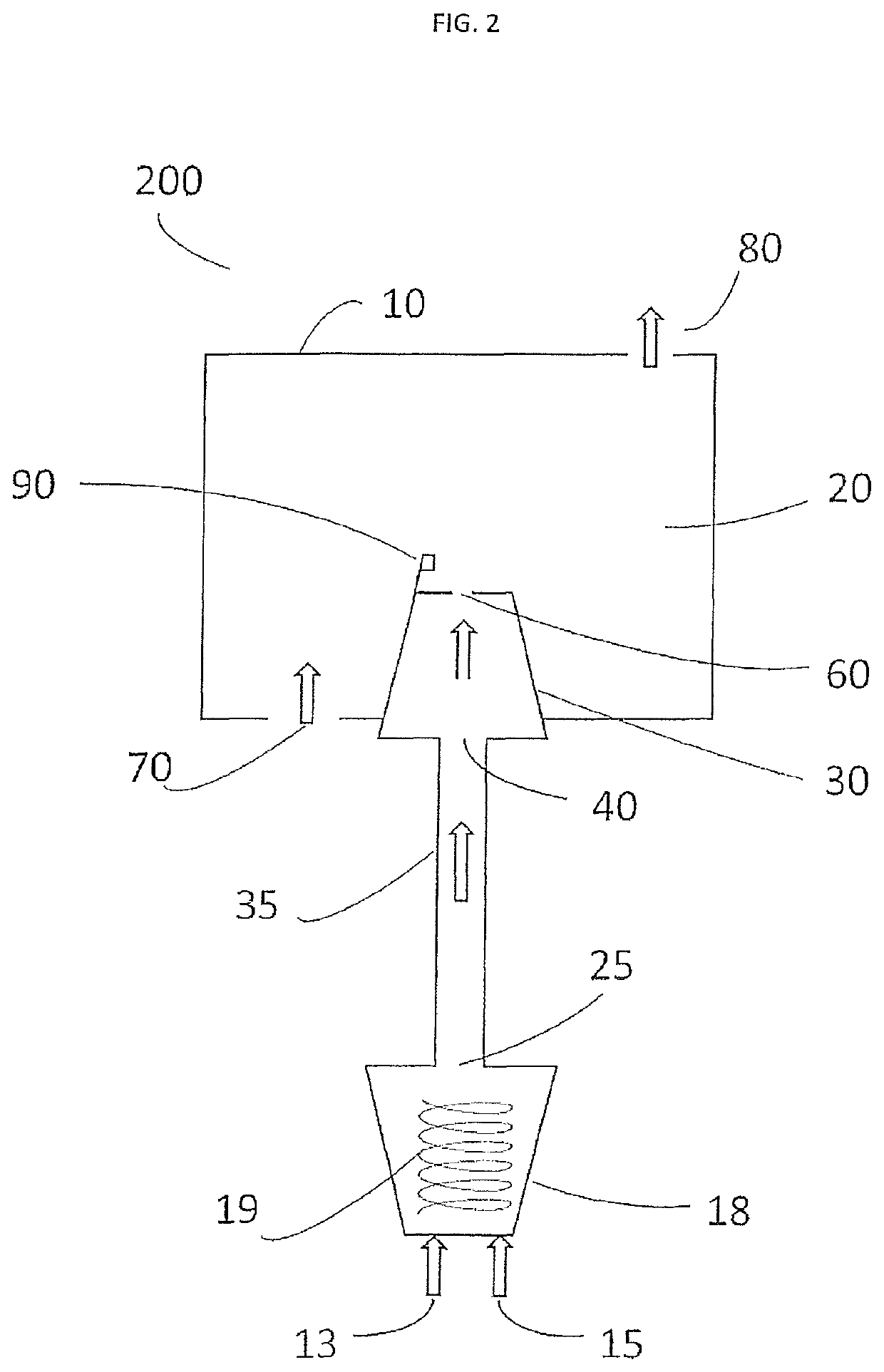

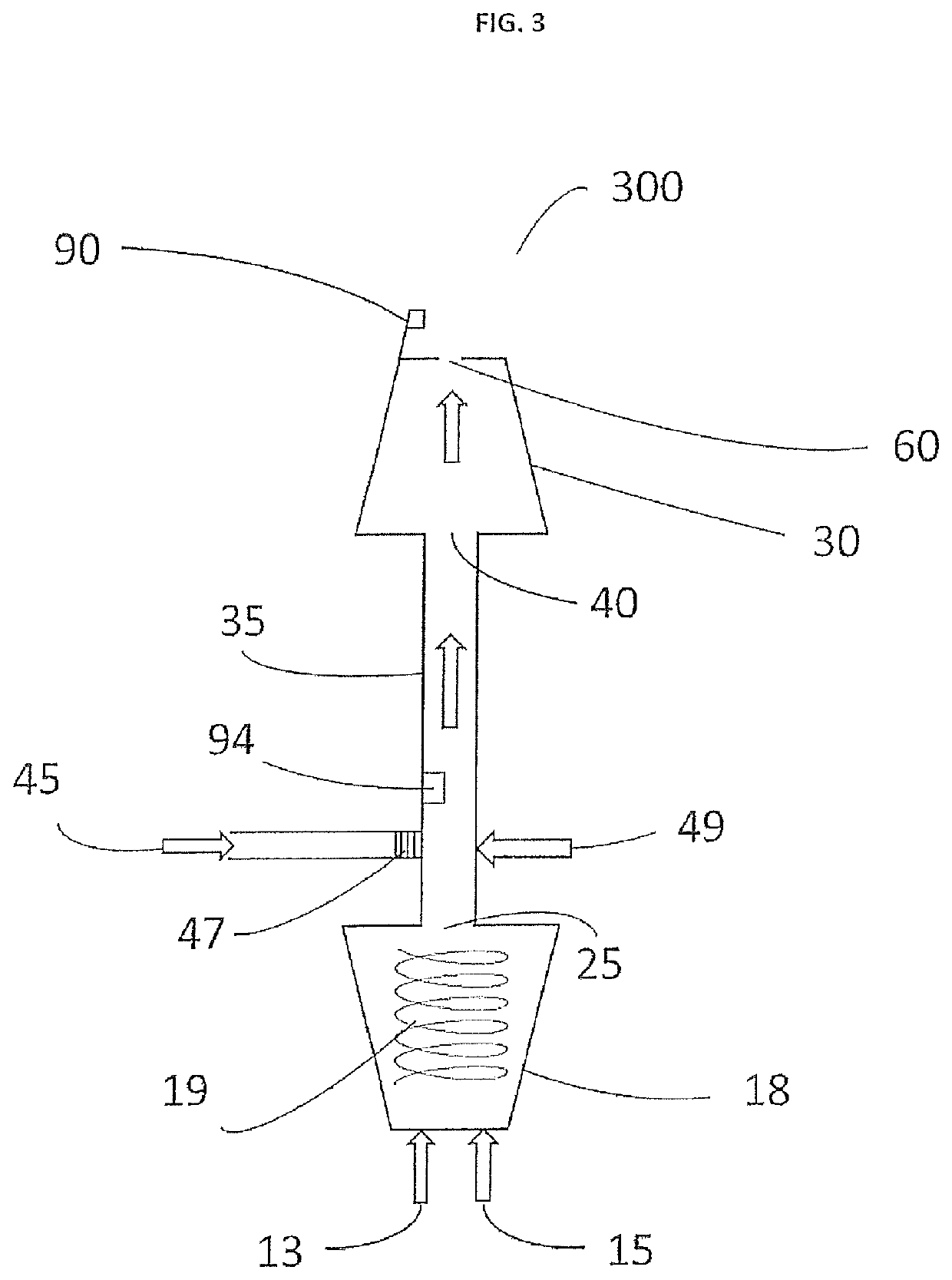

ActiveUS20150159284A1Emission reductionReduce NOx emissionsCellsInternal combustion piston enginesHydrogenReactor system

A system for improving efficiency in which water or aqueous solution is broken into its core molecules of hydrogen and oxygen using a 12 volt power source, and of which this gas vapor can improve the efficiency of an engine of a vehicle in a catalytic fashion once combining with a fossil fuel, and includes a reactor housing containing at least one reactor unit having electrodes slotted in an insulated container, a solution supply system that regulates the aqueous solution in the system; and an air handling system that regulates the decomposed hydrogen and oxygen gas in the system. The reactor unit being immersed in an liquid or aqueous solution produces hydrogen and oxygen through electrolysis.

Owner:PACKER DAVID

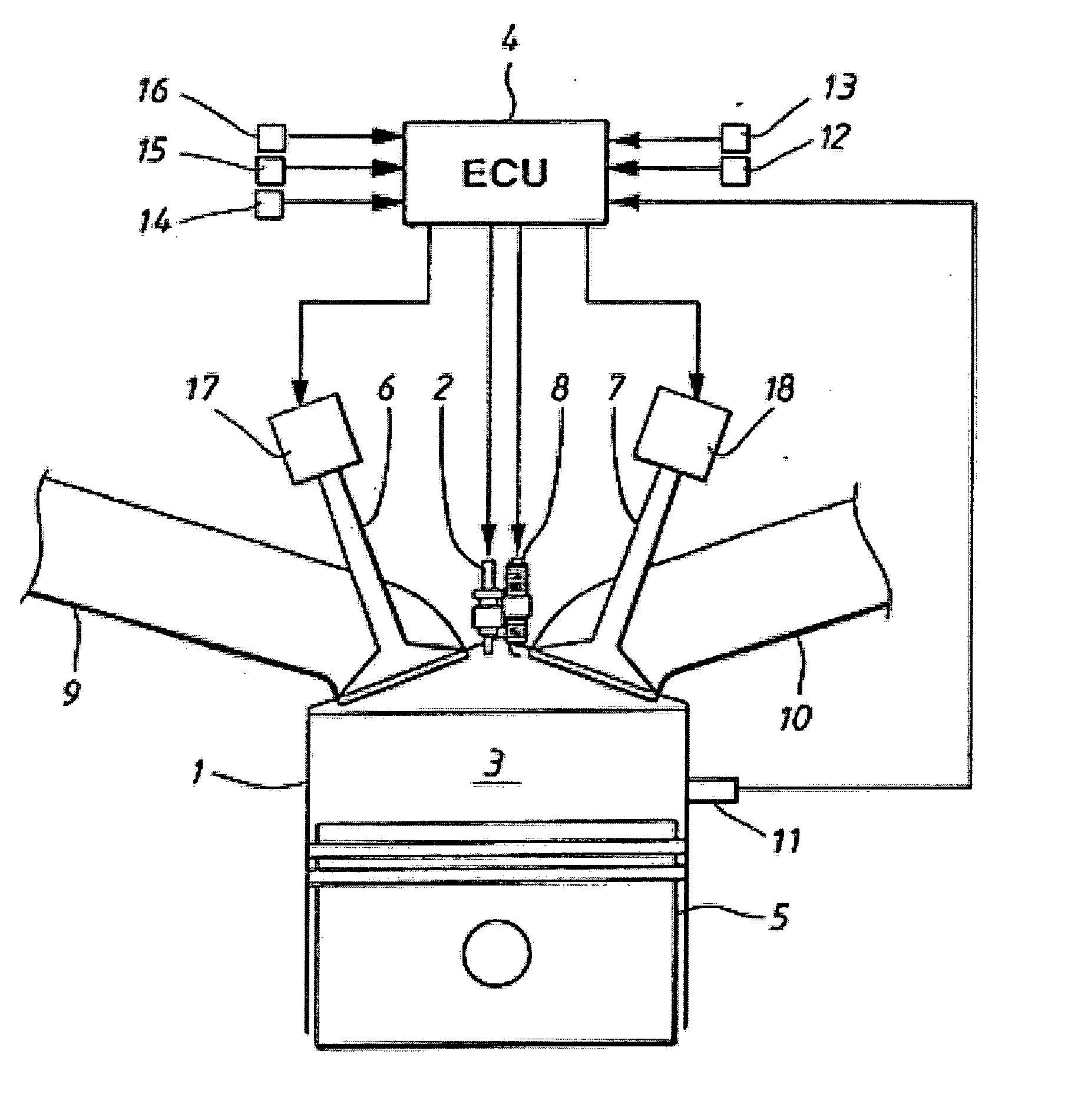

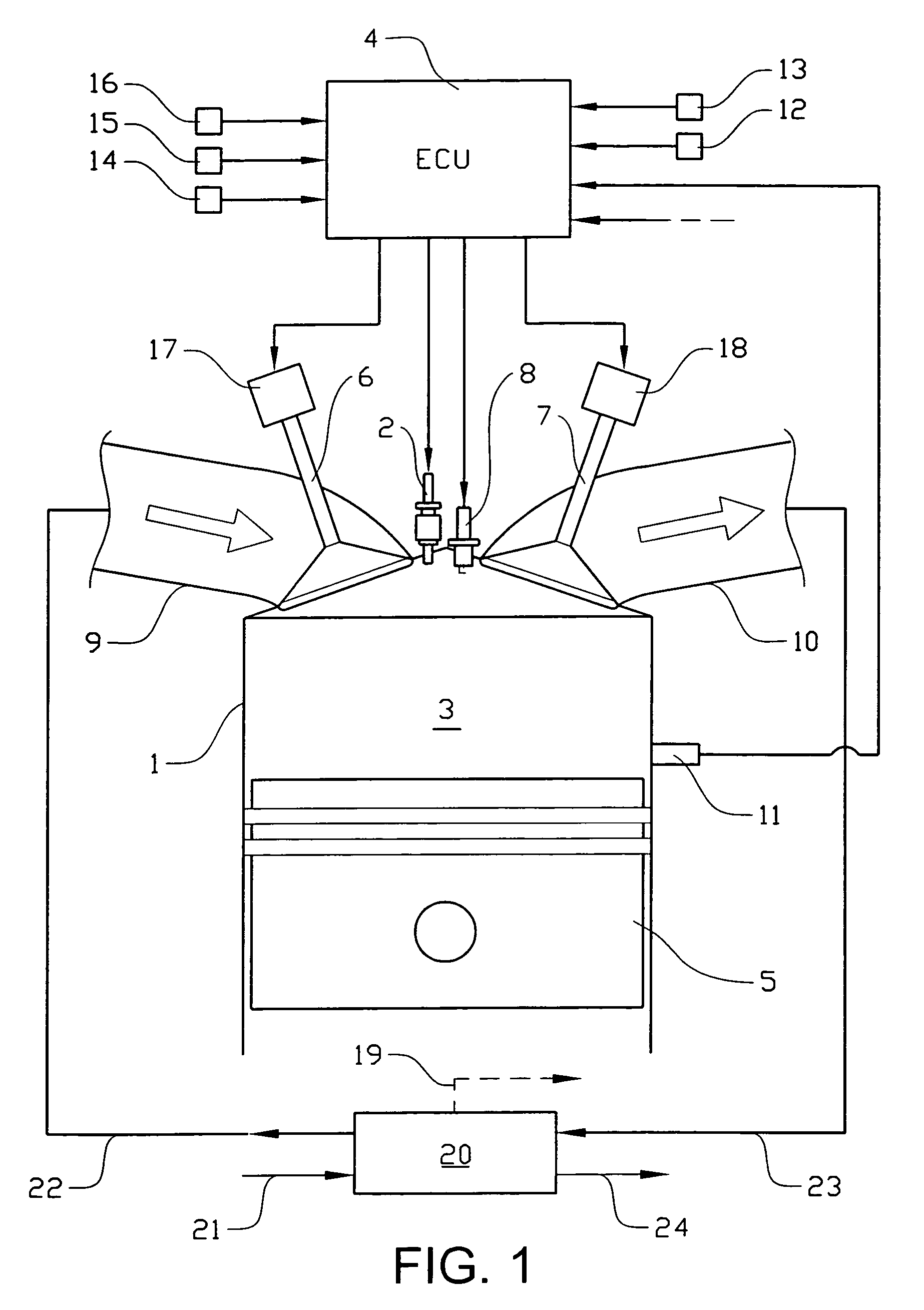

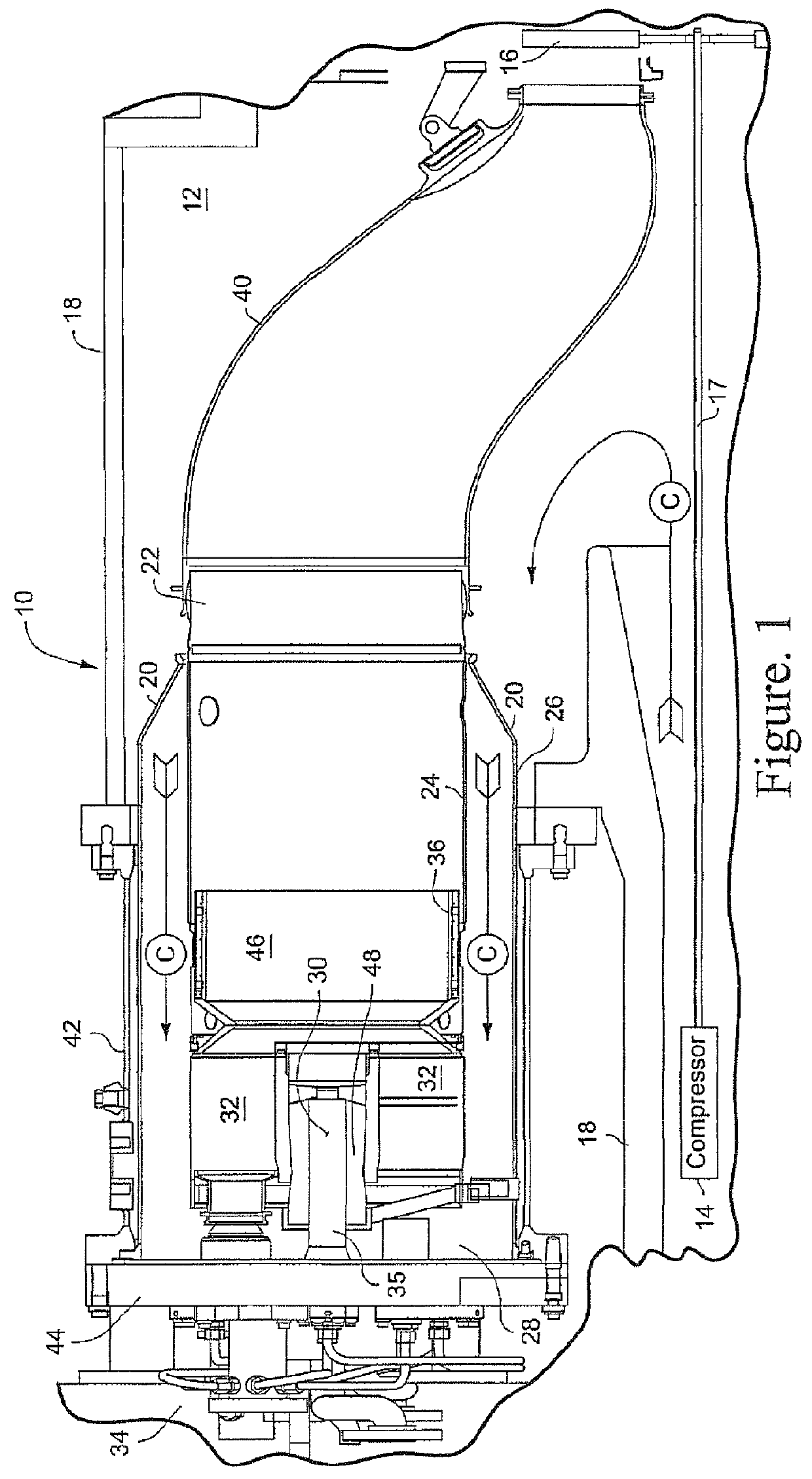

Internal combustion engine and method for performing a mode switch in said engine

ActiveUS7357103B2Improve thermal efficiencyImprove flammabilityValve arrangementsElectrical controlExternal combustion engineMode switch

The invention relates to an internal combustion engine provided with at least one cylinder and comprising a fuel injection system, an intake air charging system for supplying air under pressure to an air intake manifold, a controller for controlling the fuel injection system, a spark ignition system and the intake air charger. The control unit is adapted to switch the engine from a first combustion mode using a higher manifold pressure to a second combustion mode using a lower manifold pressure, and further adapted to control the intake air charging system to cause a surge in the intake air, in order to evacuate the higher manifold pressure. The invention further relates to a method for controlling the internal combustion engine and a vehicle provided with such an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

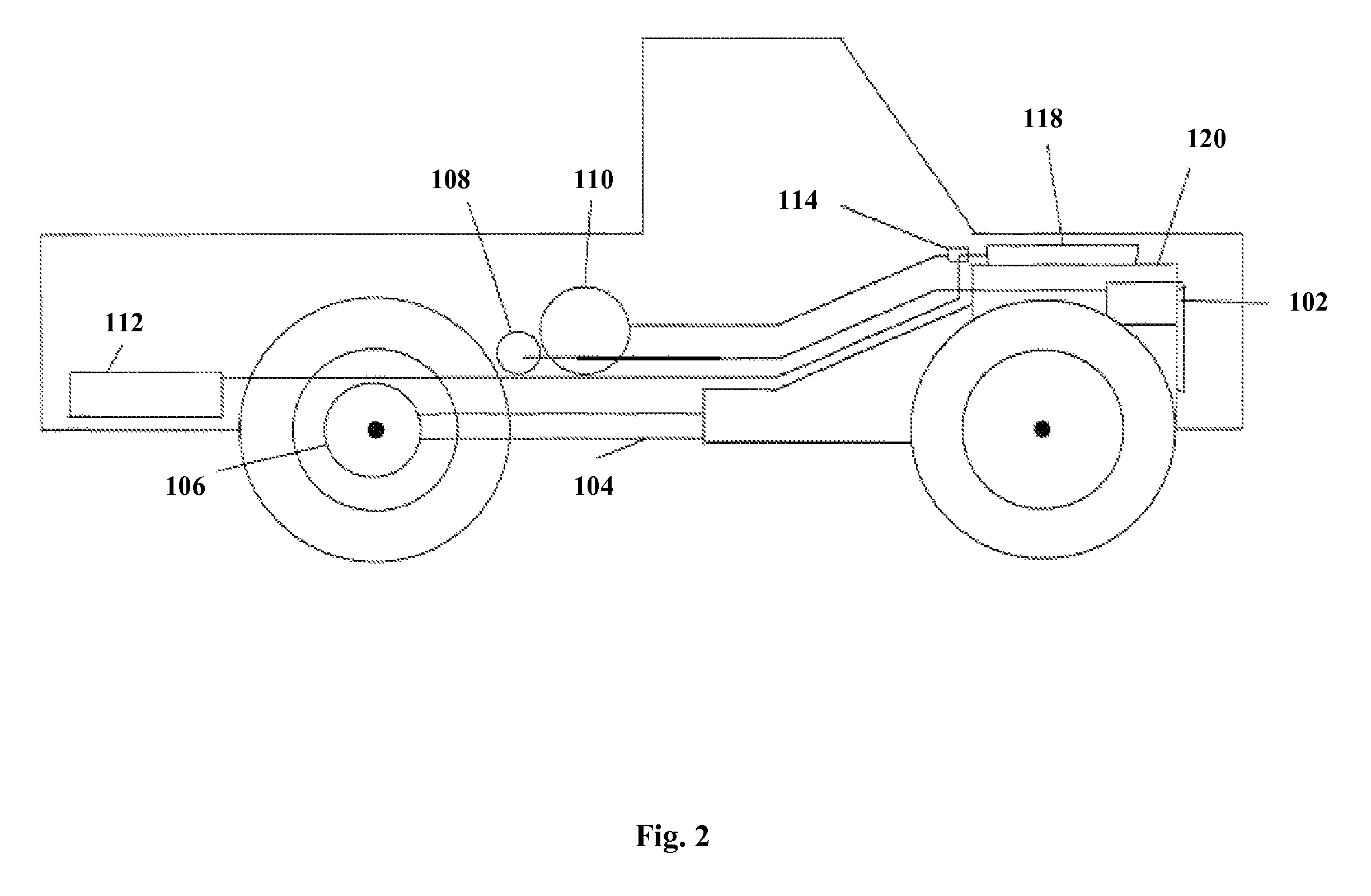

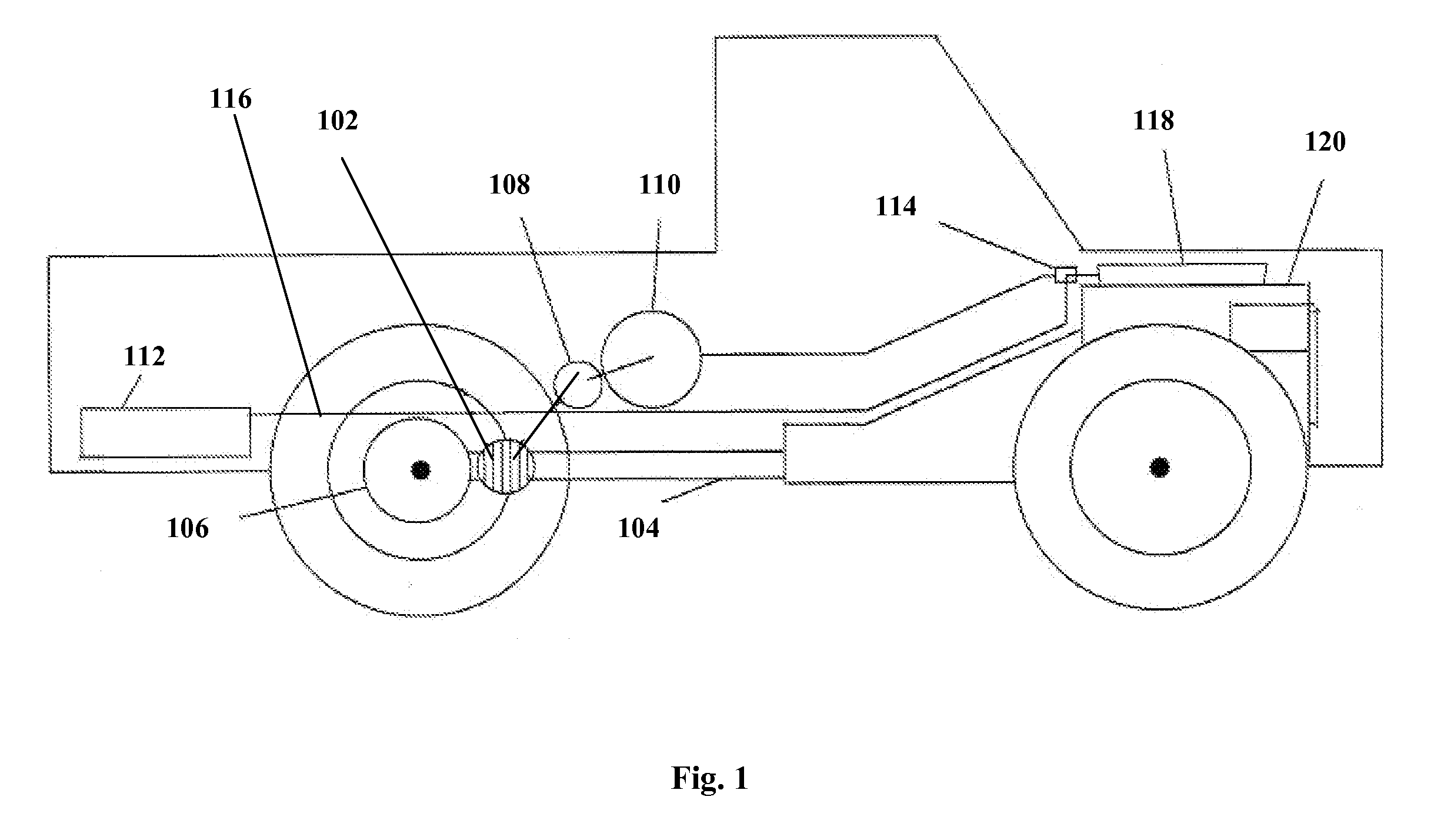

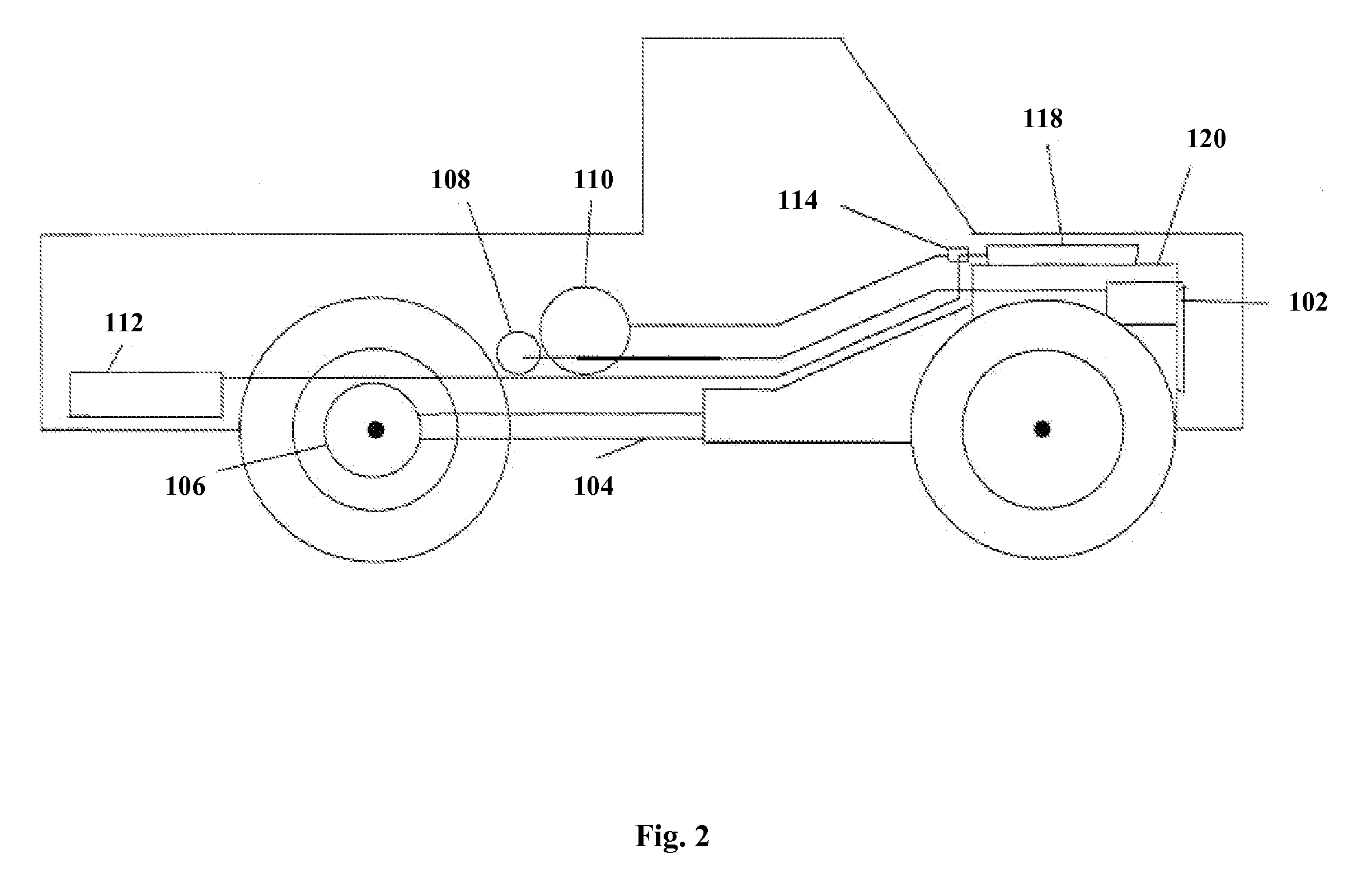

Energy Conversion System For Hydrogen Generation And Uses Thereof

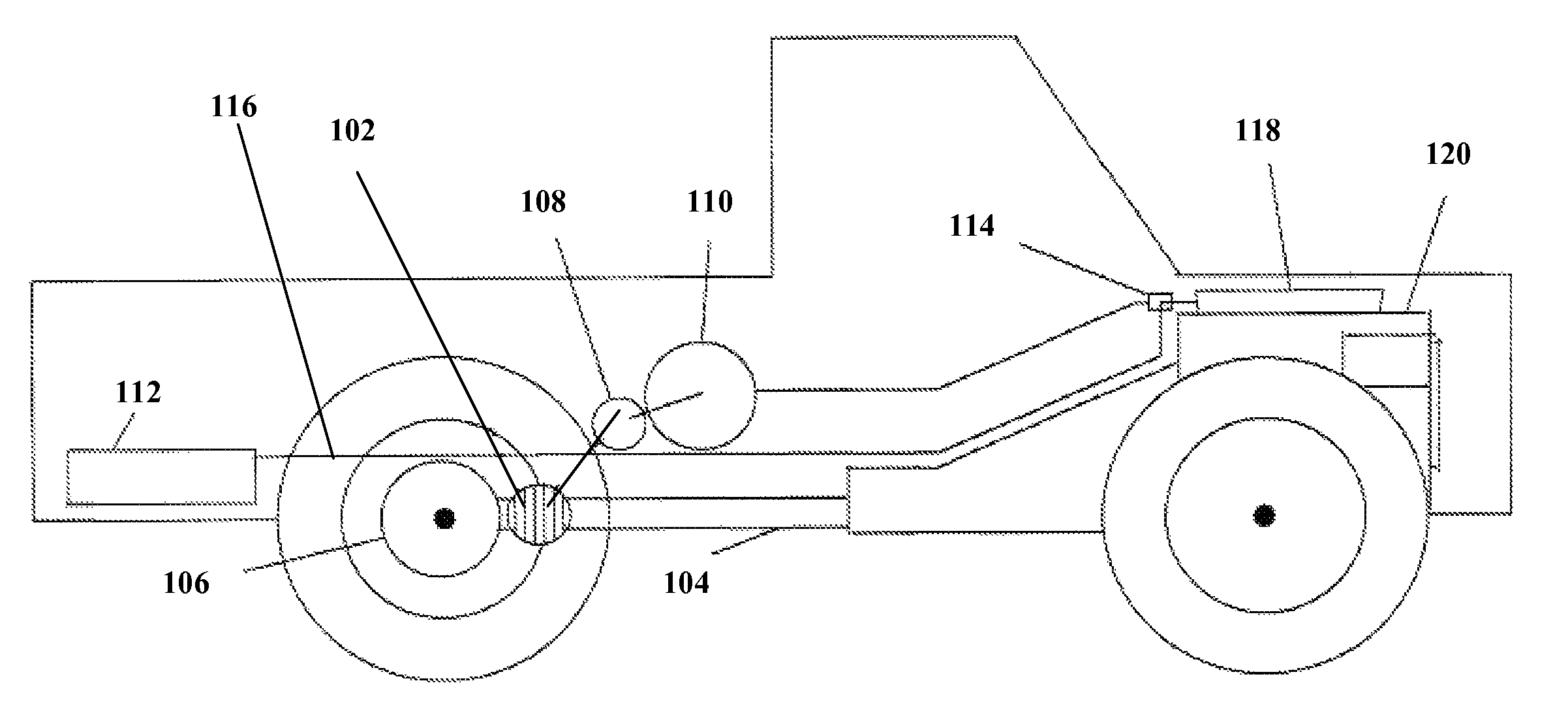

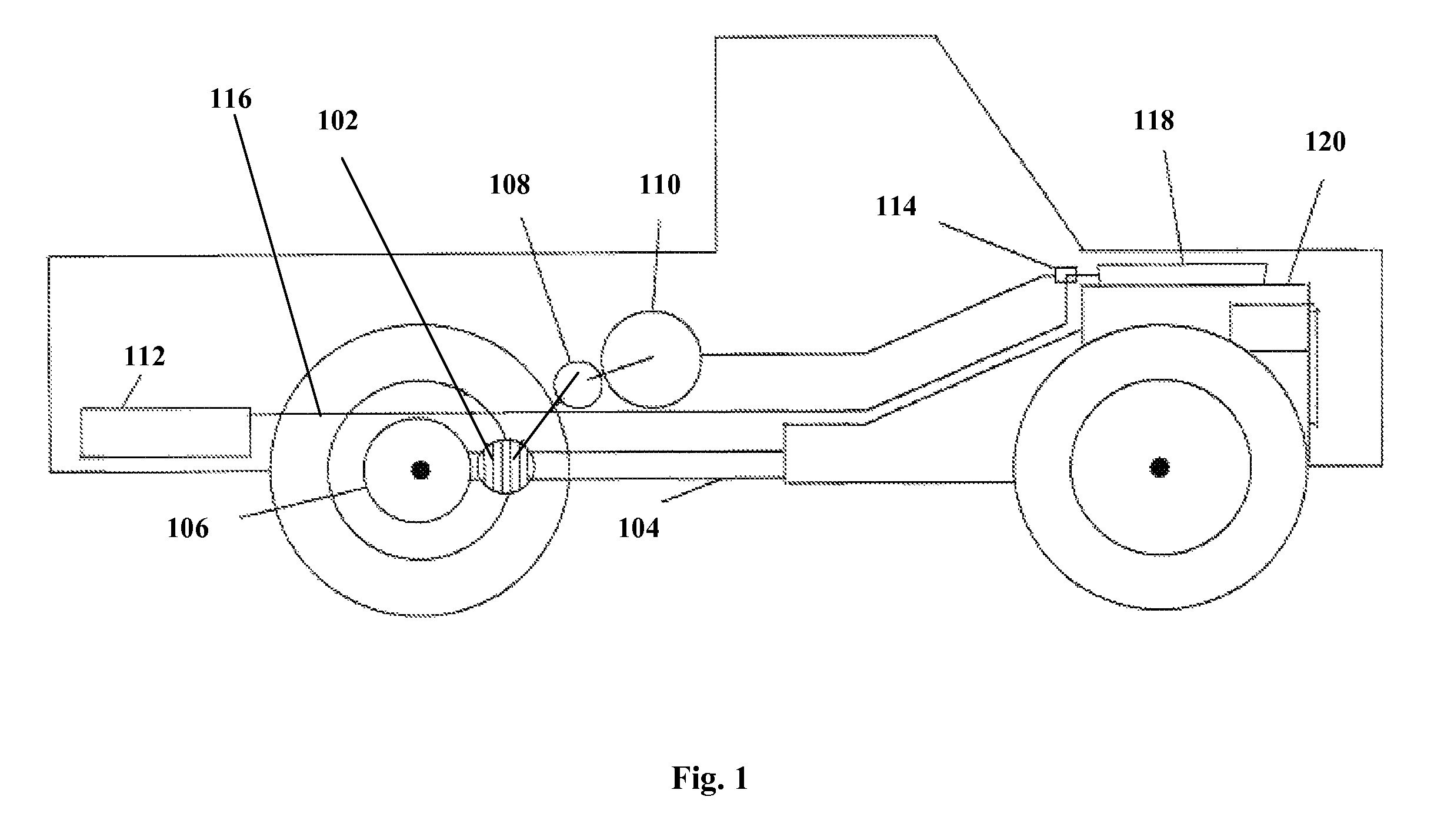

InactiveUS20070169723A1Improve efficiencyLow pollutant emissionAuxillary drivesElectrical controlExternal combustion engineInternal combustion engine

The present invention relates to a system capable of using kinetic / inertial and renewable energy to generate hydrogen for use as a fuel in vehicles and other applications. In certain embodiments, this invention relates to a system in which hydrogen is generated during vehicle braking and which is operable with an internal combustion engine, and which can be retrofitted to vehicles with such an engine as well as to stationary combustion devices. Methods for generating hydrogen to power vehicles and vehicles utilizing the inventive technology are also provided. The present invention also relates to stationary devices, such as space heaters and water heaters, capable of generating hydrogen for use as a fuel additive therewith, and methods of generating hydrogen using such devices.

Owner:RUTLEDGE KEITH

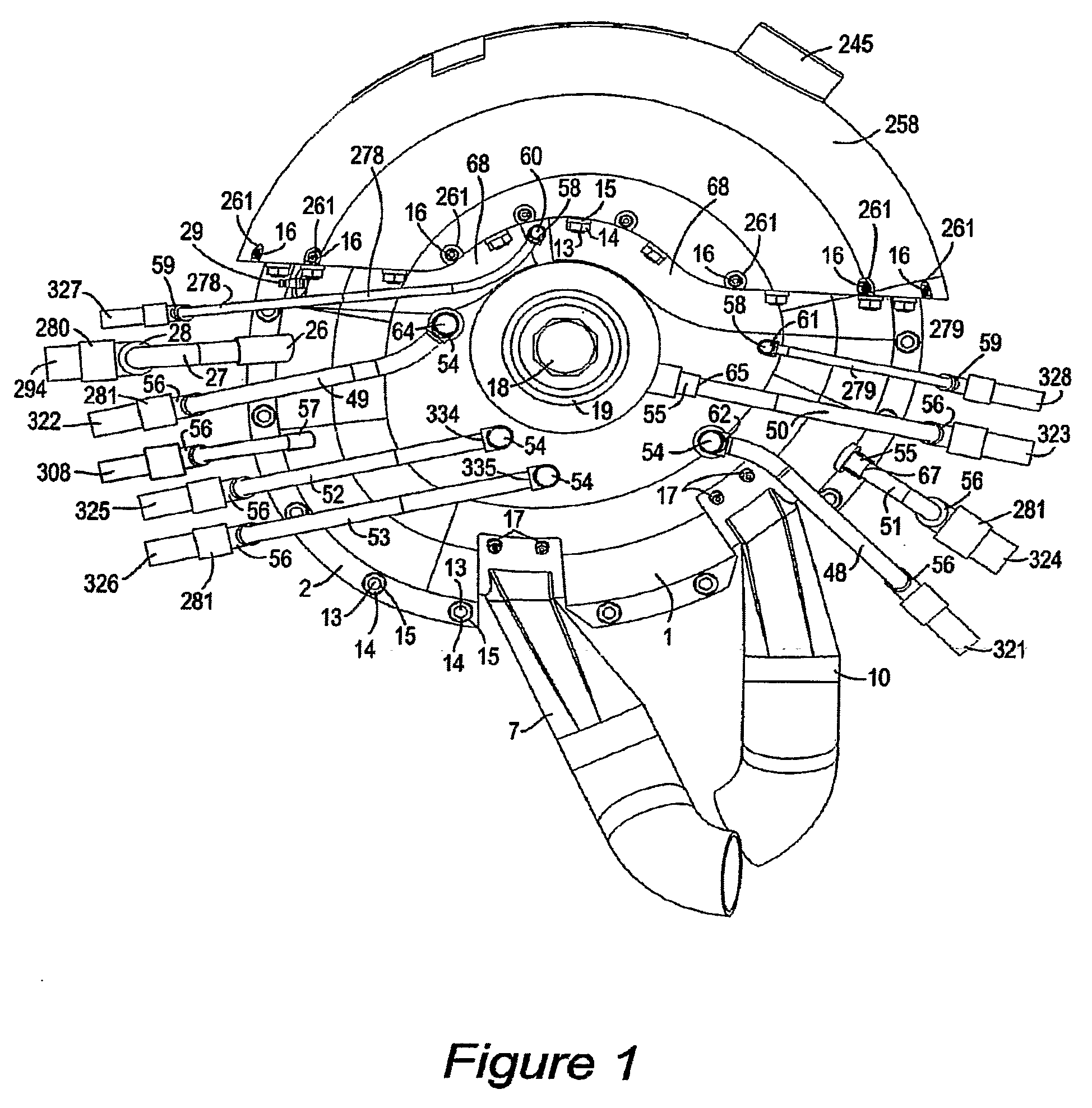

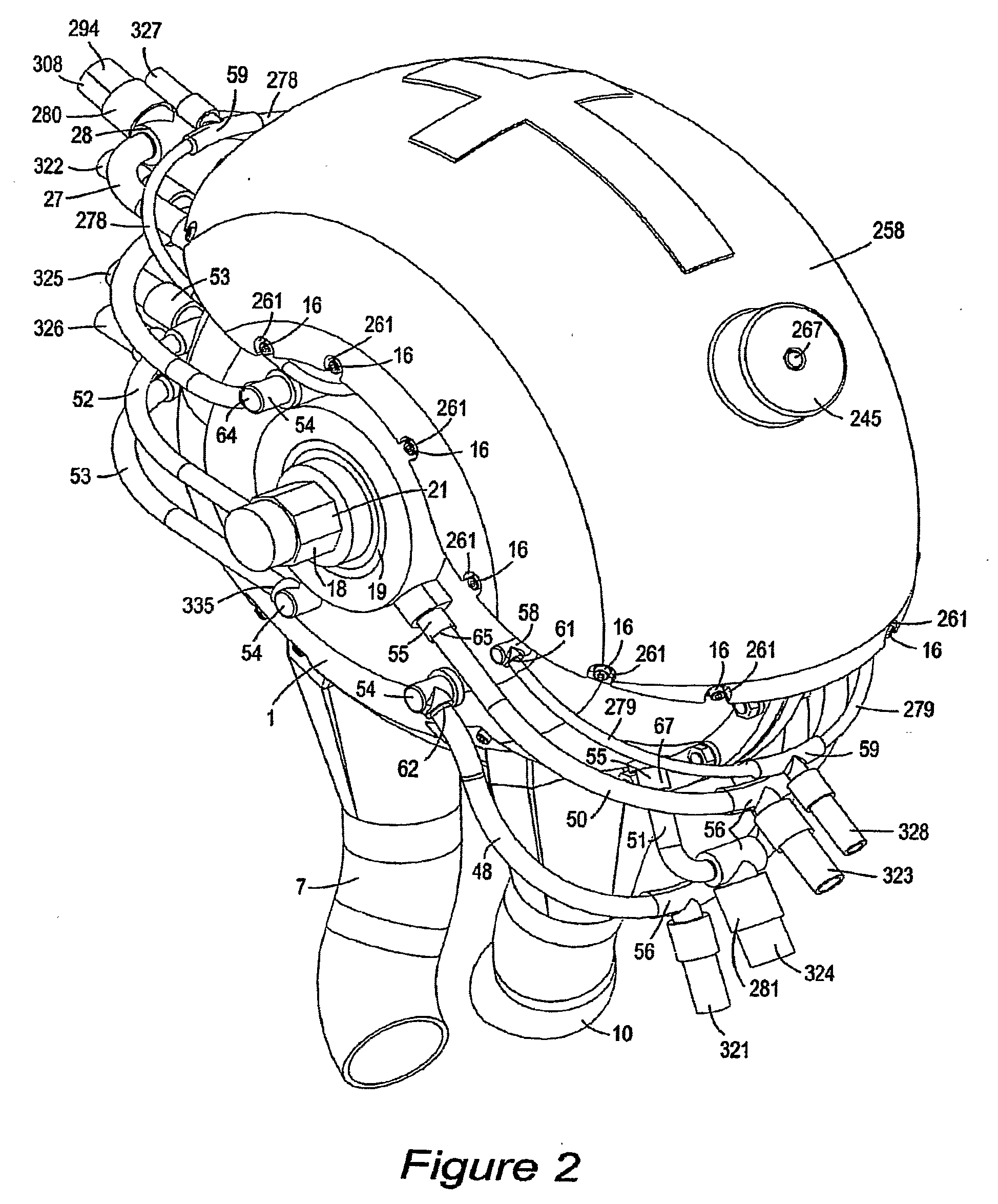

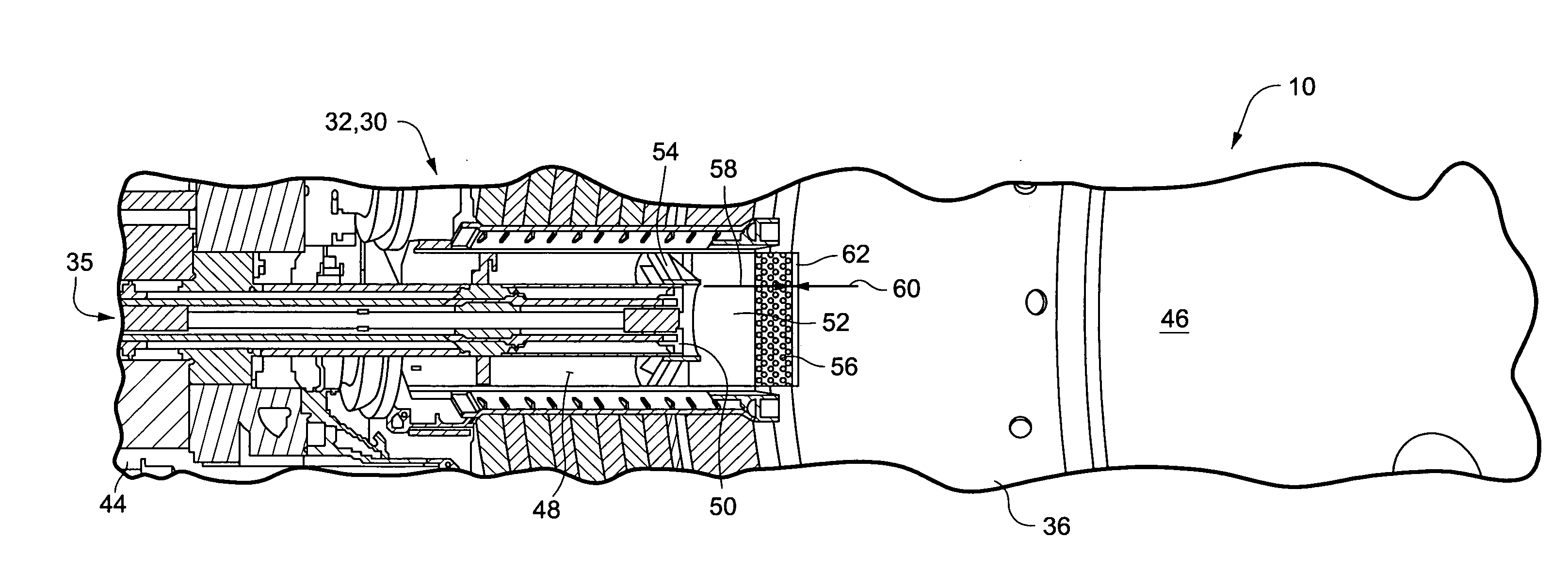

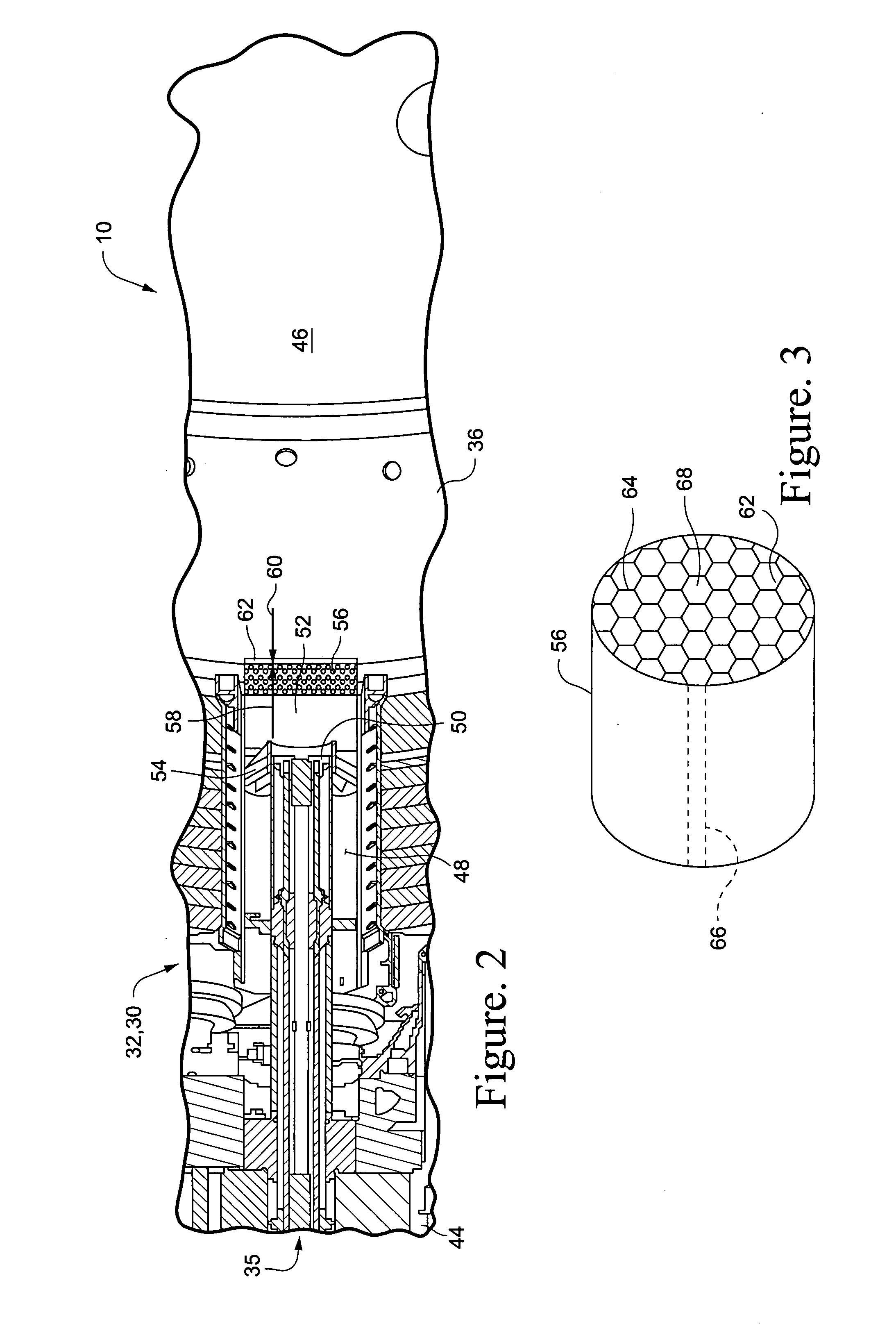

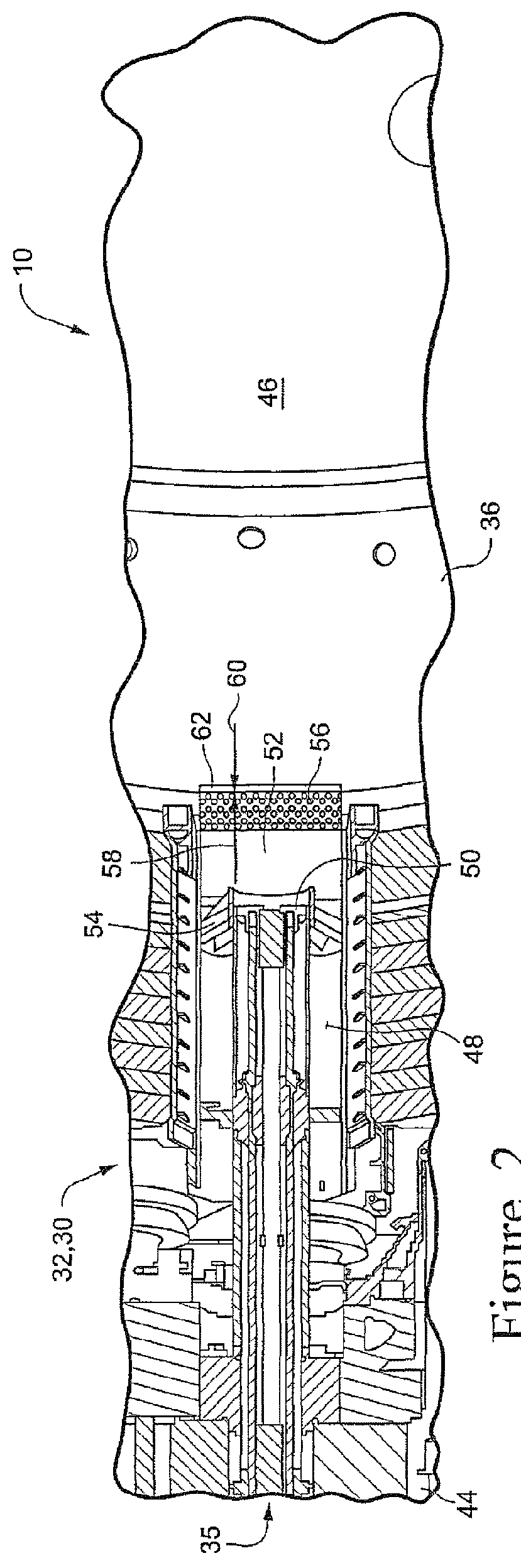

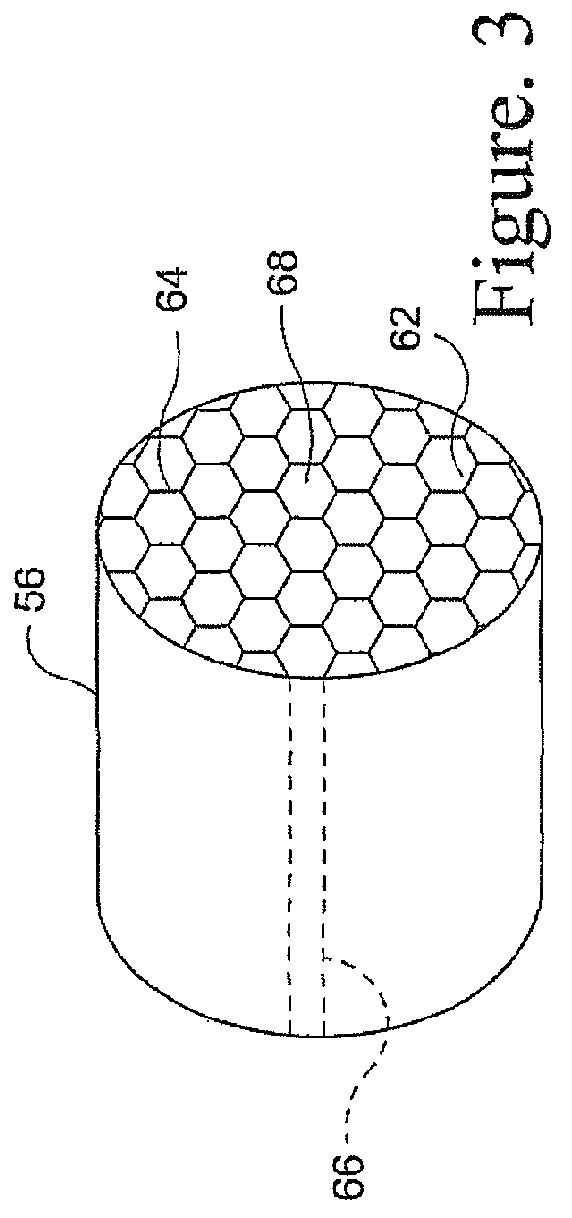

Method and system for porous flame holder for hydrogen and syngas combustion

InactiveUS20080276618A1High speedIncreased flame speedContinuous combustion chamberGas turbine plantsSyngasCombustor

A mixing region of a fuel nozzle assembly for a combustor in a gas turbine, the assembly including: a gaseous fuel nozzle having a center axis and extending along the center axis, the fuel nozzle including a gaseous fuel passage and a fuel nozzle at a distal end of the passage; an air tube concentric with the fuel nozzle and defining an air passage between the air tube and the fuel nozzle, wherein the air tube includes a distal section extending axially beyond the fuel injection nozzle; a first fuel-air mixing zone defined by and inside the distal section of the air tube, wherein said first fuel-air mixing zone is downstream of the fuel injection nozzle; a flame holder comprising a porous structure with thermal barrier coating and micro swirlers and defining a downstream end of the first fuel-air mixing zone, wherein fuel and air from the first fuel-air mixing zone pass through the porous structure of the flame holder and into a combustion zone of the combustor.

Owner:GENERAL ELECTRIC CO

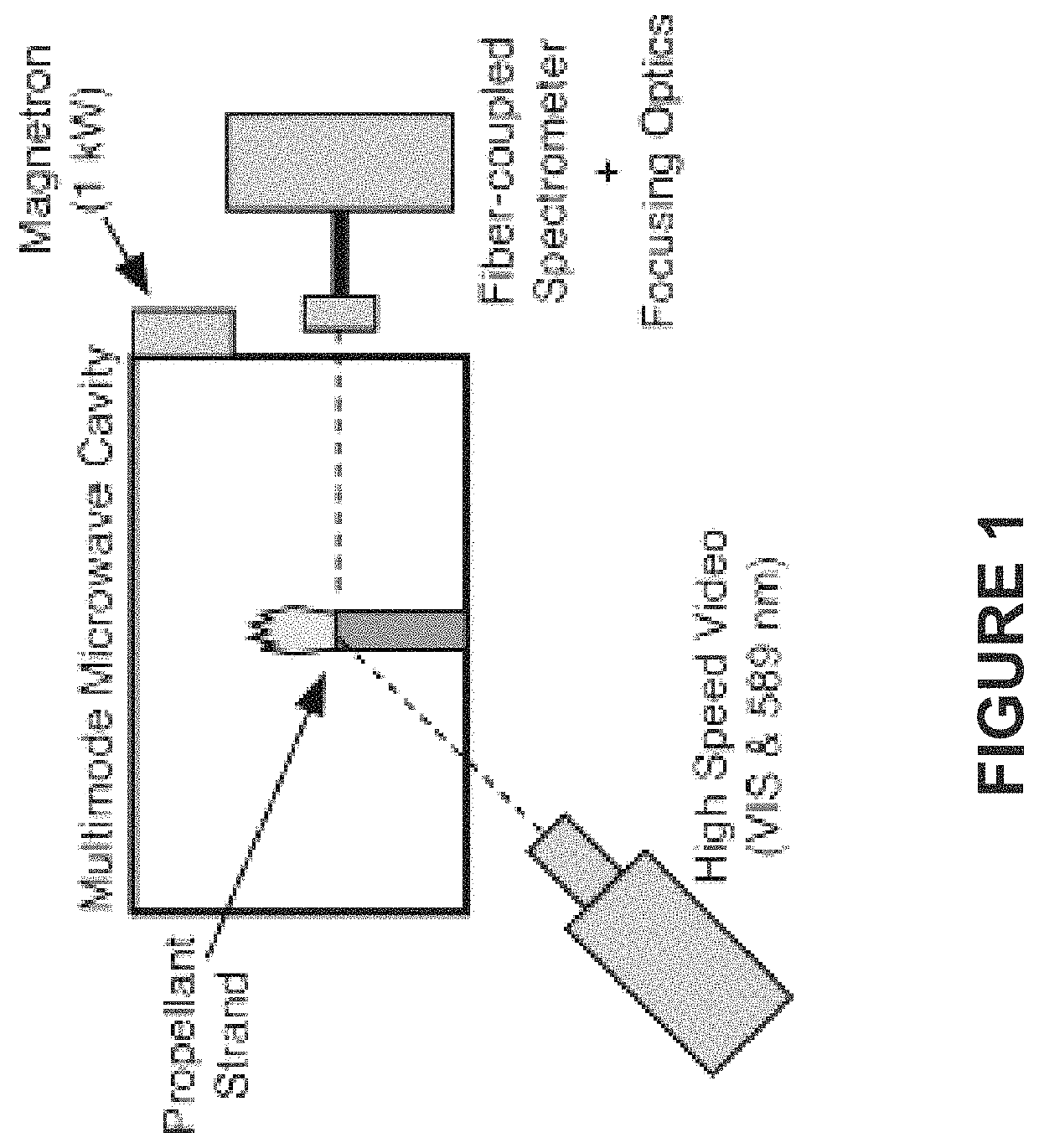

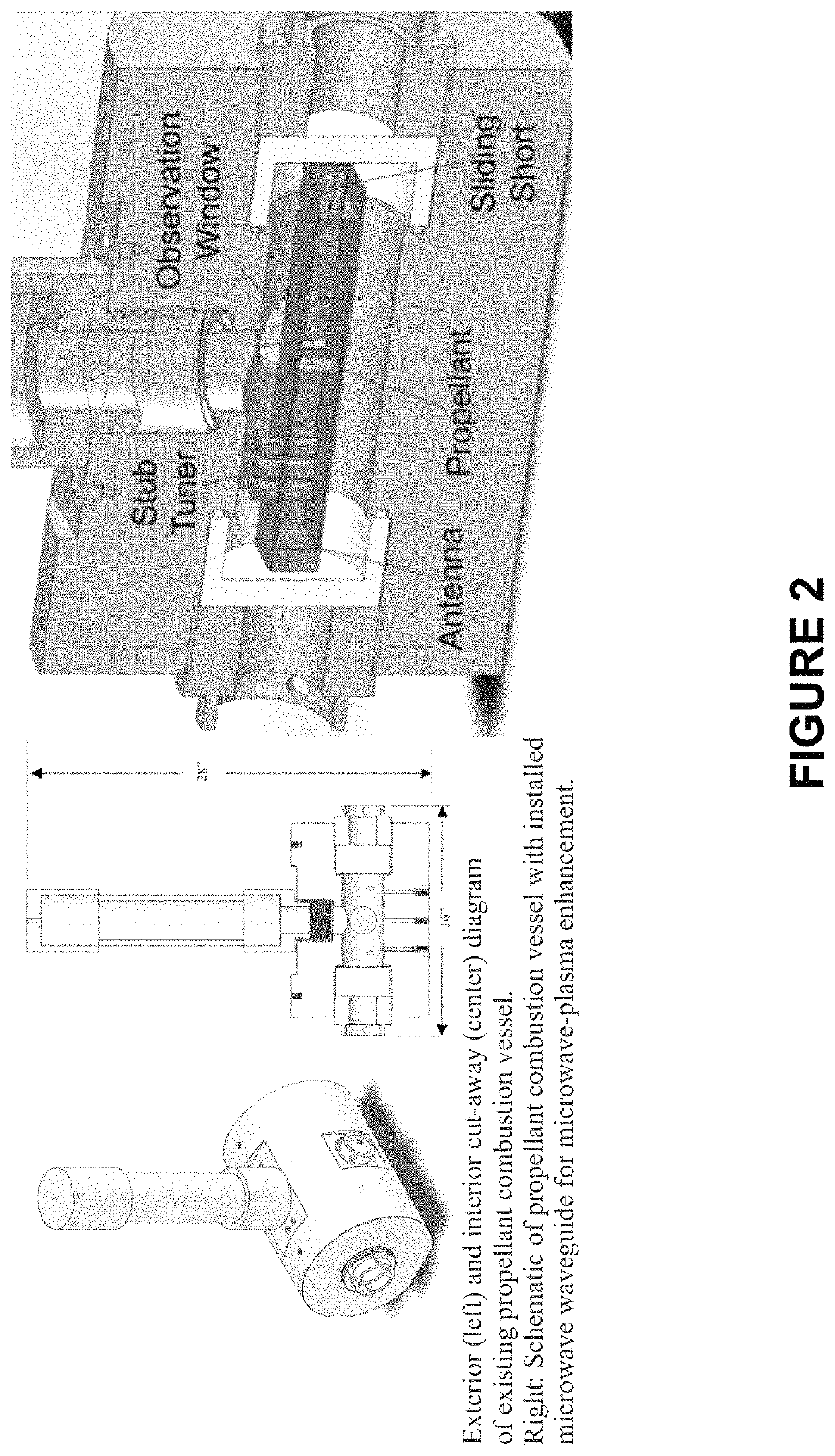

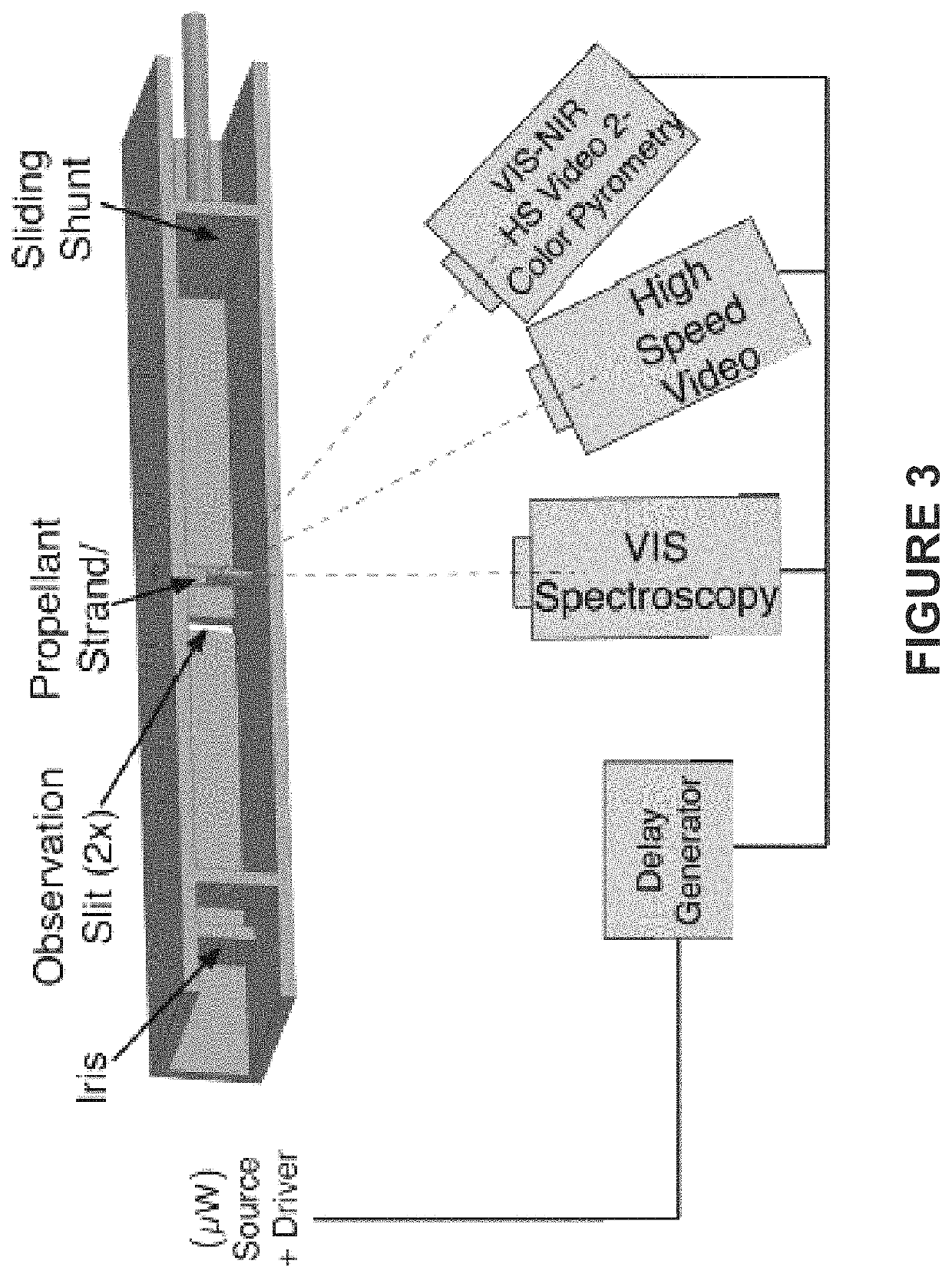

Microwave flame enhancement of energetic material combustion

ActiveUS11041464B1Promote combustionIncrease burn rateExplosive working-up apparatusRocket engine plantsControl powerEngineering

Apparatus, systems, and methods for enhancing solid propellant performance include seeding combusting energetic material, including solid propellant, with microwave energy at a controlled power and duration.

Owner:IOWA STATE UNIV RES FOUND

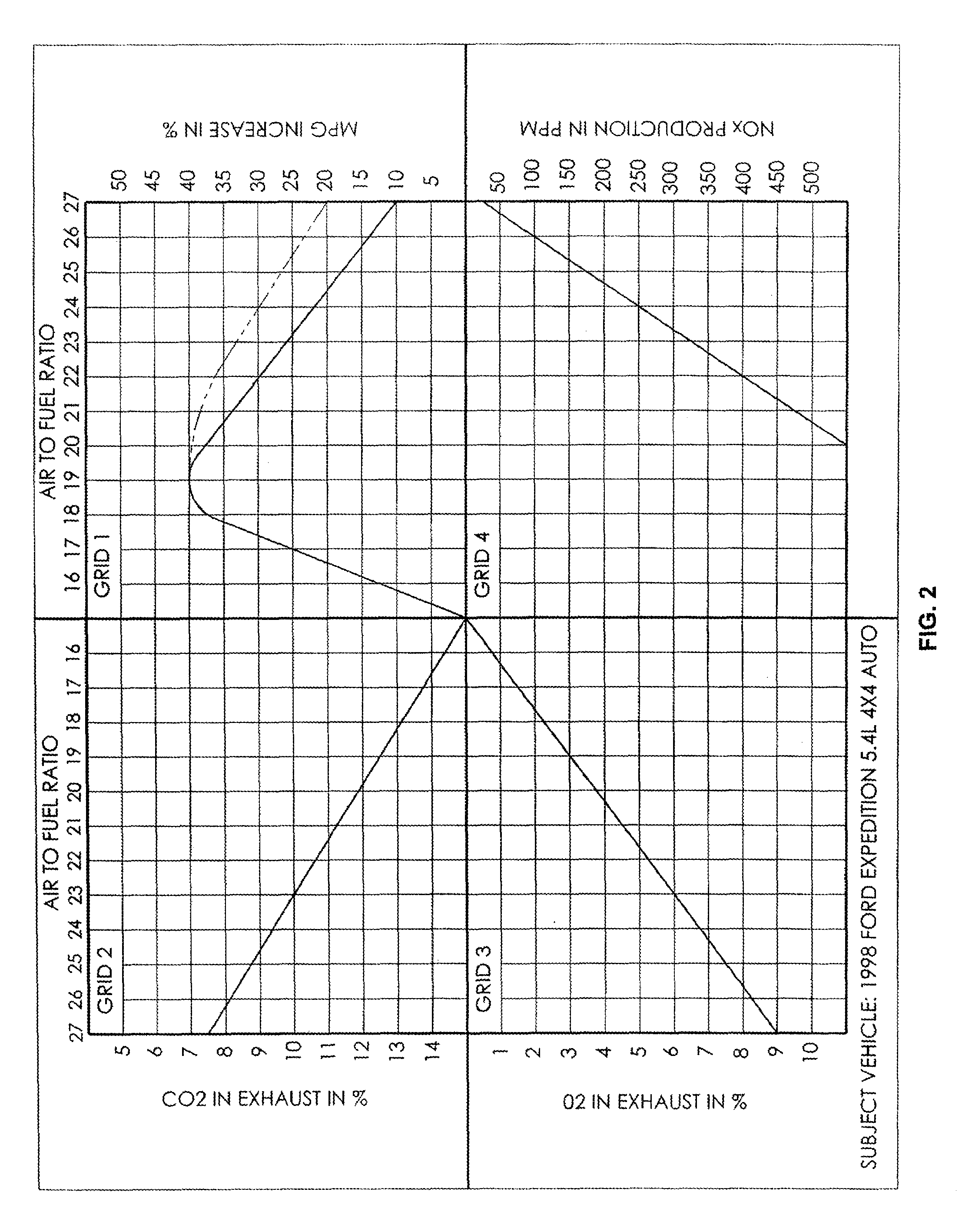

System for improving fuel utilization

InactiveUS7631637B2Improve engine performanceAvoid condensationInternal combustion piston enginesGaseous engine fuelsFractionationLiquid fuel

A vapor fuel air mixture supply system for a combustion engine, whereby the mixture of air and fuel vapor is elevated in temperature prior to combustion. The liquid fuel may be vaporized in a fractionation process and further heated to enhance flame speed combustion and improve efficiency of the system.

Owner:VAPOR FUEL TECH

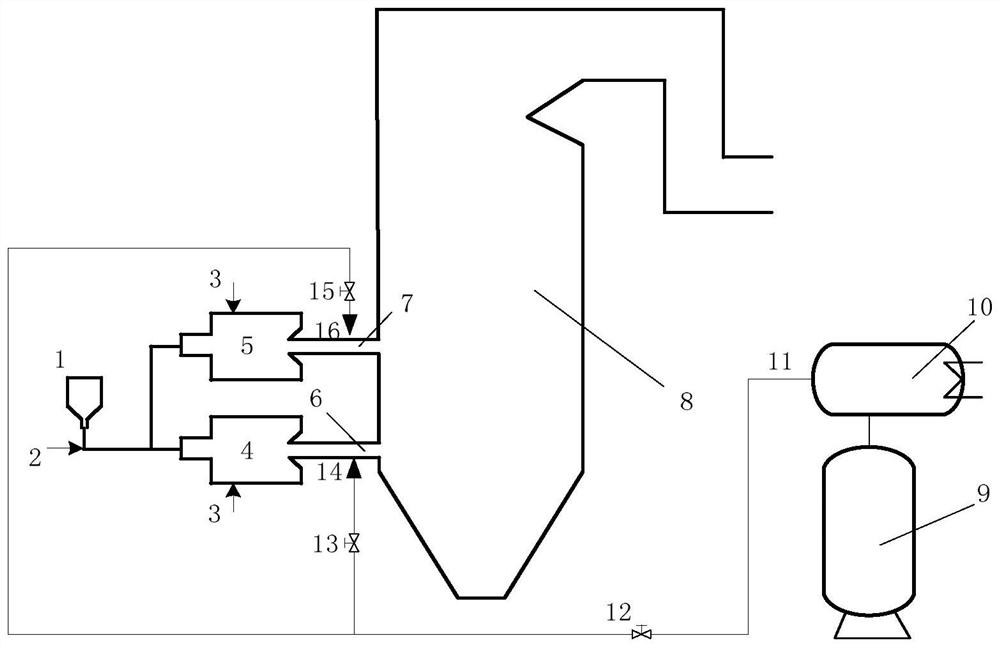

Pulverized coal and ammonia mixed fuel pre-pyrolysis combustion system and method

PendingCN113154369ALow costStable sourceNon-combustible gases/liquids supplyLump/pulverulent fuel preparationCombustion systemNitrogen oxides

The invention discloses a pulverized coal and ammonia mixed fuel pre-pyrolysis combustion system and method. The system comprises a boiler, each layer of combustor of the boiler communicates with a pyrolysis furnace through a transition flue, pulverized coal and primary air are mixed and then communicate with an inlet of each pyrolysis furnace in multiple paths, and secondary air tangentially communicates with each pyrolysis furnace. An outlet of a liquid ammonia storage tank communicates with a liquid ammonia inlet of an evaporator, ammonia gas at an ammonia gas outlet of the evaporator is divided into a plurality of ammonia gas branches to communicate with ammonia nozzles of transition flues after passing through an ammonia gas main pipeline, a main regulating valve is arranged on the ammonia gas main pipeline, and a regulating valve is arranged on each ammonia gas branch. The invention further discloses a working method of the system. The pulverized coal and ammonia mixed fuel pre-pyrolysis combustion system and method have the advantages of large-proportion ammonia blending combustion and low nitrogen oxide emission.

Owner:XIAN THERMAL POWER RES INST CO LTD

Energy conversion system for hydrogen generation and uses thereof

InactiveUS7765961B2Improve efficiencyEmission reductionAuxillary drivesElectrodynamic brake systemsCombustionHydrogen

Systems capable of using kinetic / inertial and renewable energy to generate hydrogen for use as a fuel in vehicles and other applications are provided, including systems in which hydrogen is generated during vehicle braking and which is operable with an internal combustion engine, and which can be retrofitted to vehicles with such an engine as well as to stationary combustion devices. Methods for generating hydrogen to power vehicles and vehicles utilizing the inventive technology, stationary devices, such as space heaters and water heaters, capable of generating hydrogen for use as a fuel additive therewith, and methods of generating hydrogen using such devices are also provided.

Owner:RUTLEDGE KEITH

Fuel composition and its use

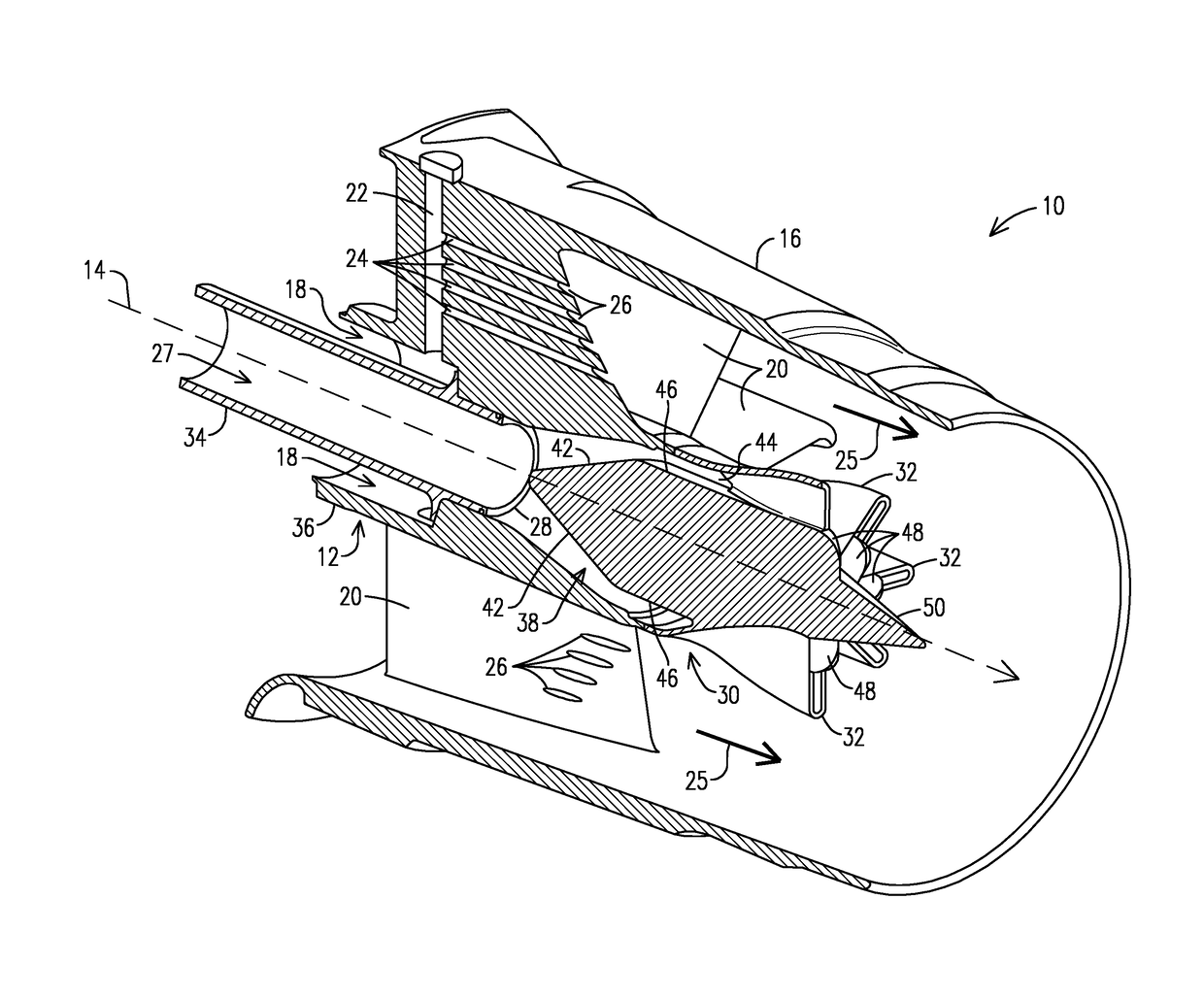

InactiveUS20110308140A1Increased flame speedSolid fuelsLiquid carbonaceous fuelsGasolineInternal combustion engine

A method for increasing flamespeed of an internal combustion engine by burning a certain gasoline composition is provided. The gasoline composition contains (a) a major amount of a mixture of hydrocarbons in the gasoline boiling range and (b) a minor amount of at least one hydrocarbon having 5 to 12 carbon atoms and containing at least one cyclopropyl group and at least one acetylenic group.

Owner:SHELL OIL CO

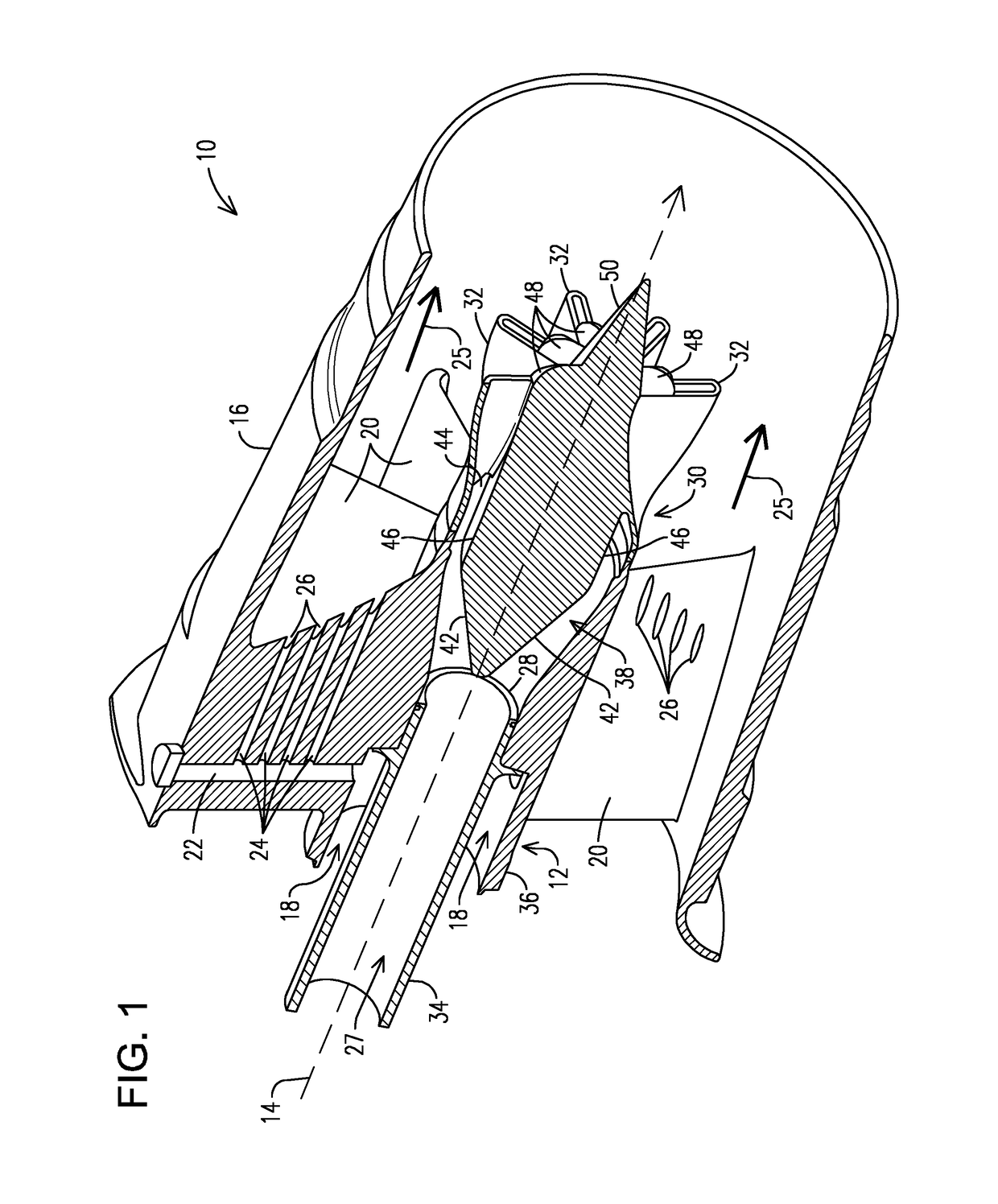

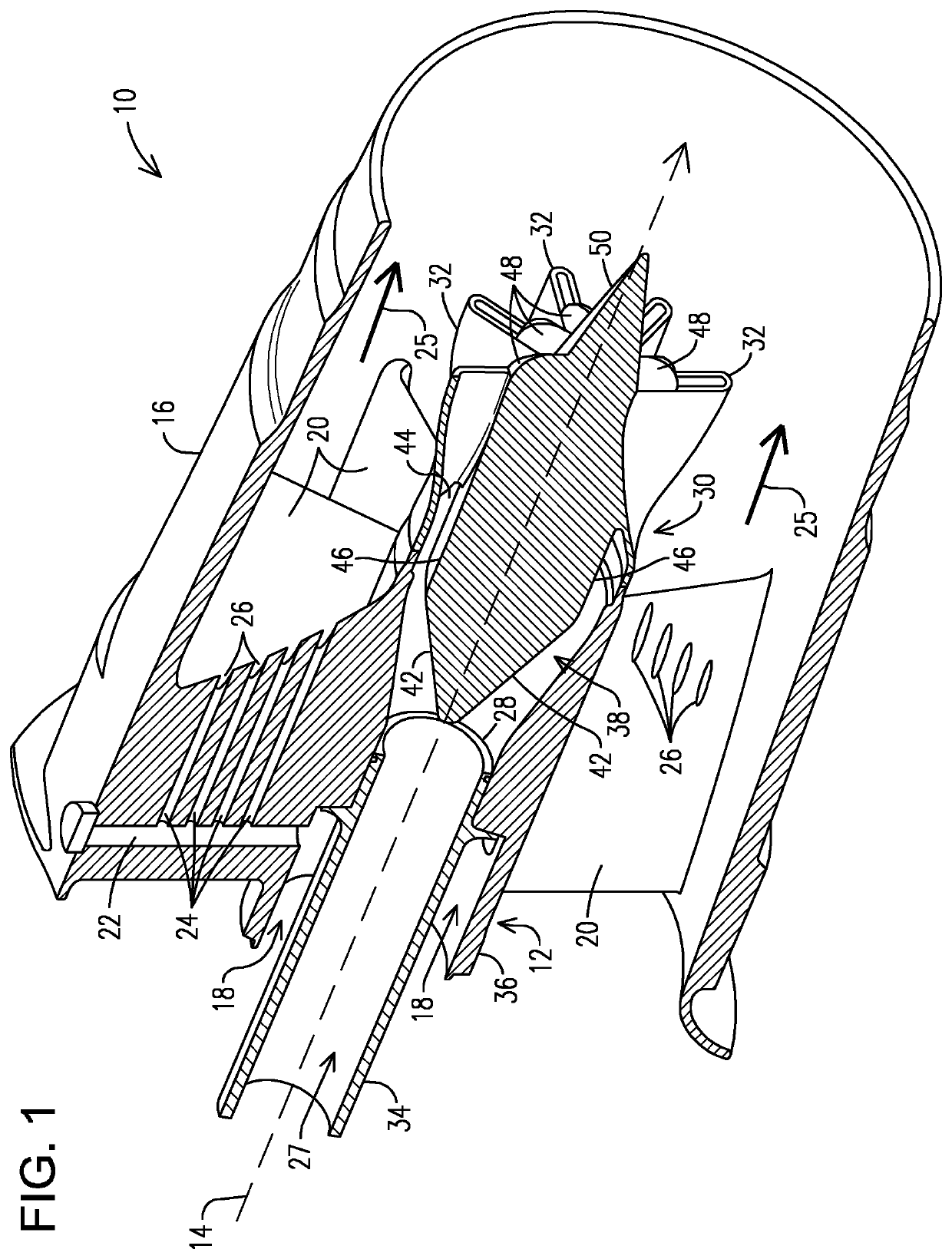

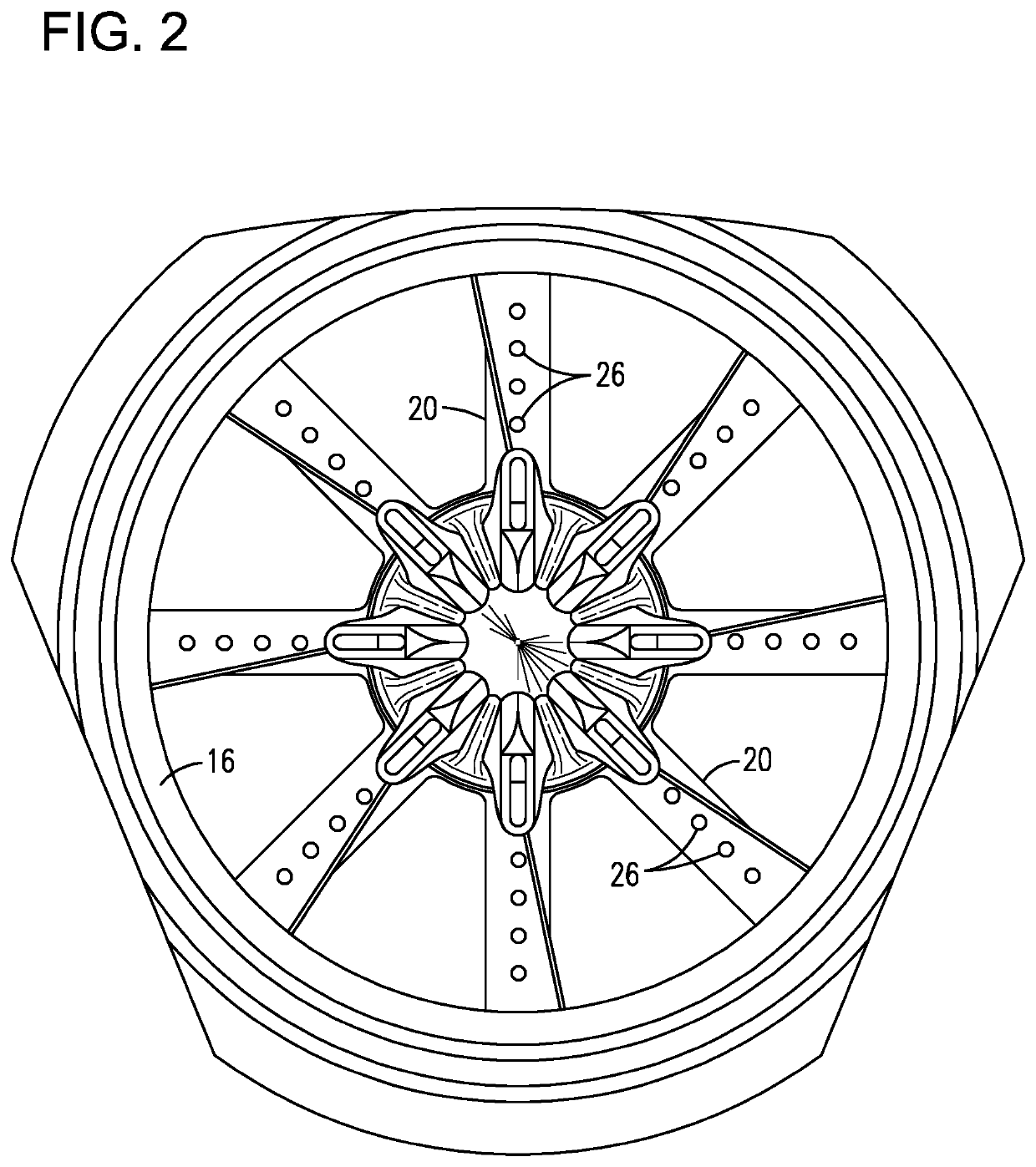

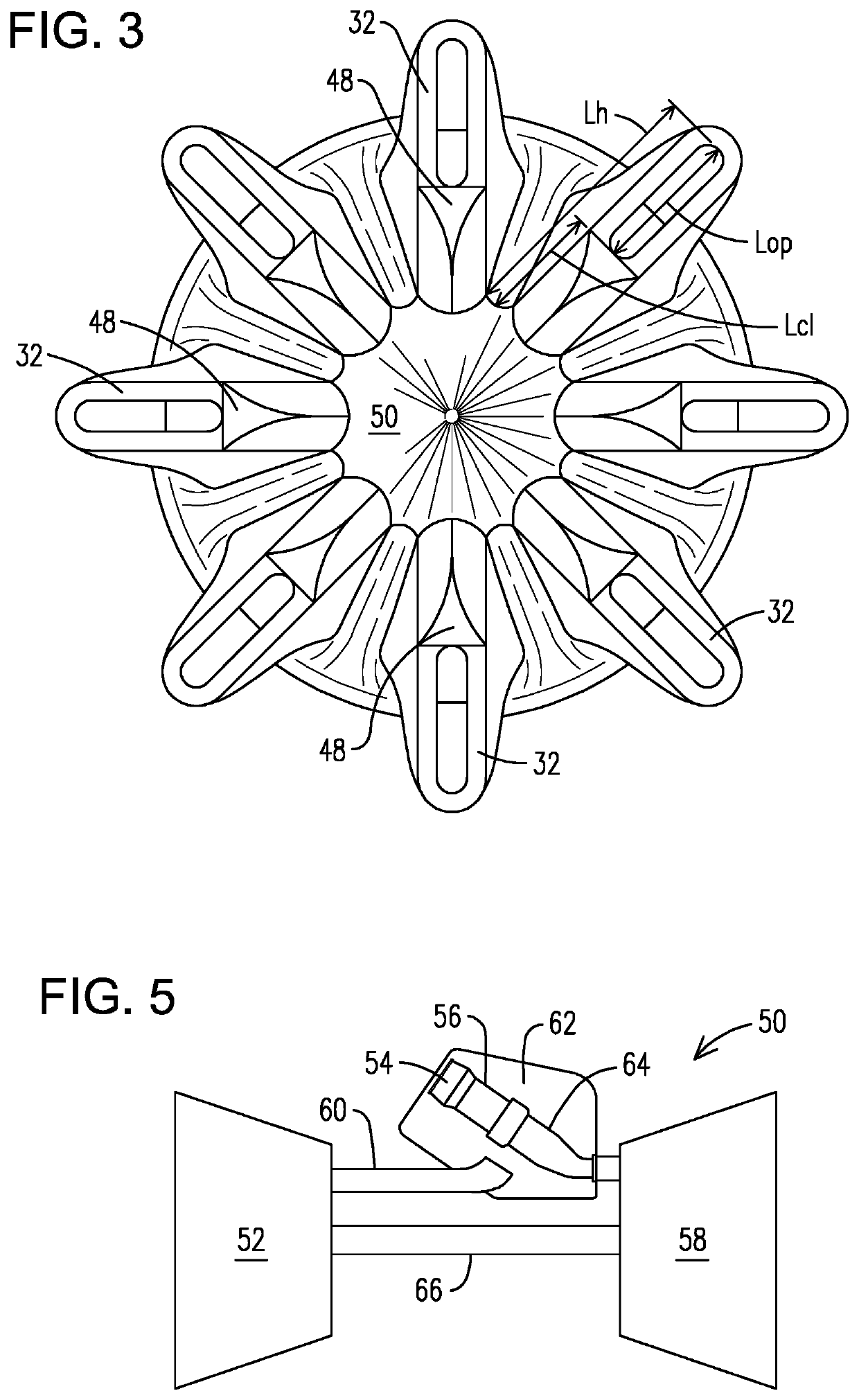

Fuel injector including a lobed mixer and vanes for injecting alternate fuels in a gas turbine

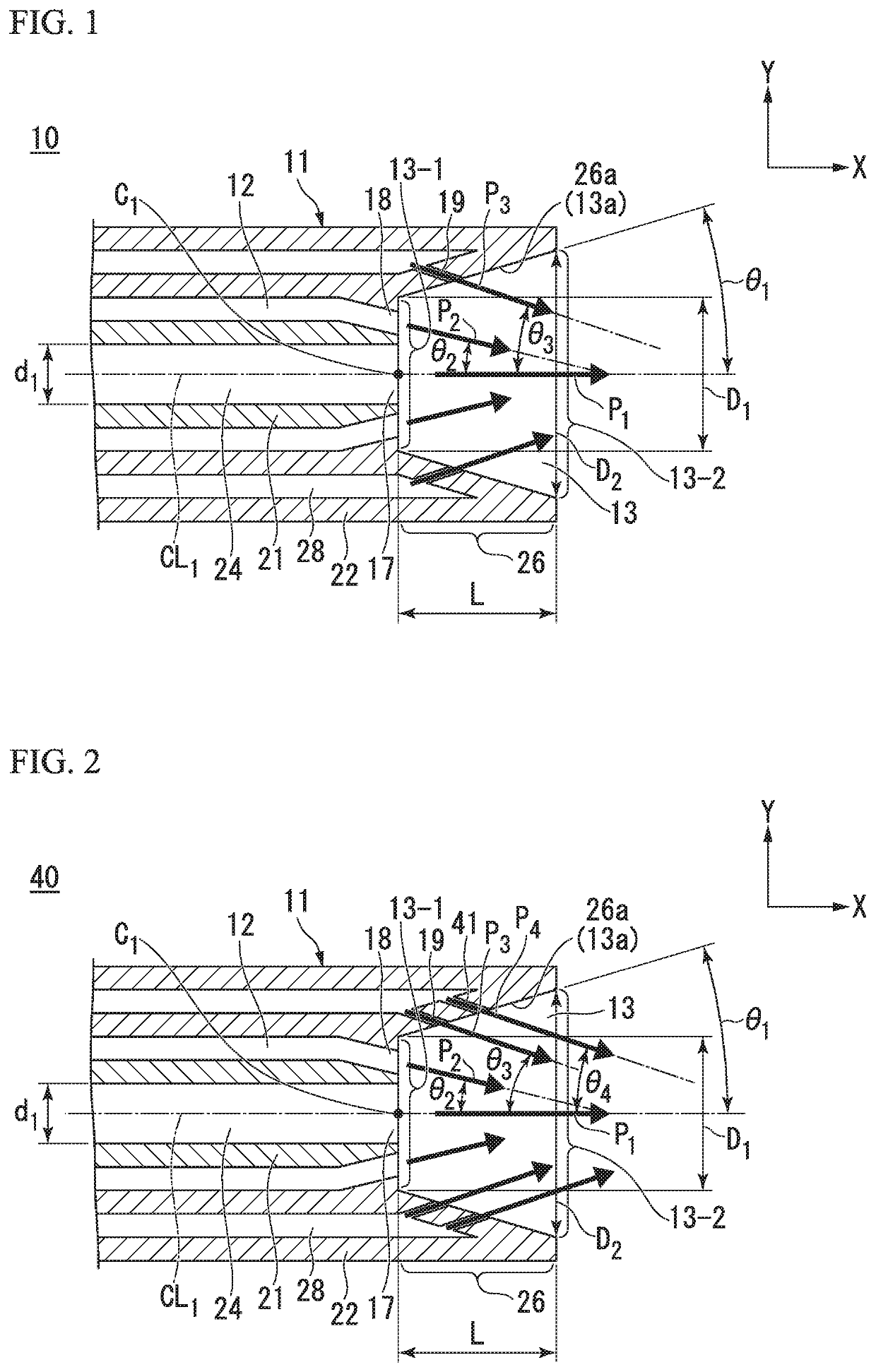

ActiveUS20170363291A1Increase heightIncreased flame speedContinuous combustion chamberGaseous fuel burnerEngineeringGas turbines

A fuel injector for injecting alternate fuels having a different energy density in a gas turbine is provided. A first fuel supply channel (18) may be fluidly coupled to a radial passage (22) in a plurality of vanes (20) that branches into passages (24) (e.g., axial passages) to inject a first fuel without jet in cross-flow injection. This may be effective to reduce flashback in fuels having a relatively high flame speed. A mixer (30) with lobes (32) for injection of a second fuel may be arranged at the downstream end of a fuel delivery tube (12). A fuel-routing structure (38) may be configured to route the second fuel within a respective lobe so that fuel injection of the second fuel takes place radially outwardly relative to a central region of the mixer. This may be conducive to an improved (e.g., a relatively more uniform) mixing of air and fuel.

Owner:SIEMENS ENERGY INC

Fuel for internal combustion-powered tools

InactiveUS6896794B2Improve combustionIncreased flame speedGaseous fuelsLiquid carbonaceous fuelsCombustible gasEngineering

A fuel for internal combustion-powered tools, especially for setting tools for fastening elements and based on a liquefied, combustible gas or gas mixture with a vapor pressure of 2 to 15 bar absolute at 20° C., and at least one combustible compound, which is soluble in the gas or gas mixture and is a liquid at 20° C. and atmospheric pressure, and which is used as an agent for improving the combustion behavior.

Owner:HILTI AG

Preparation method of nickel-based wear-resistant coating for nuclear second-stage pump bearing

InactiveCN102796980AHigh bonding strengthLower flame temperatureMolten spray coatingWear resistantBearing wear

The invention relates to the field of preparation of wear-resistant coatings, in particular to a preparation method of a nickel-based wear-resistant coating for a nuclear second-stage pump bearing, which solves the problem of difficulties in preparation of bearing wear-resistant coatings for a nuclear environment. The nickel-based wear-resistant coating for the nuclear second-stage pump bearing is prepared by spraying powder onto a matrix through a supersonic flame spraying technology. According to process parameters, the pressure of oxygen is 140 to 160psi; the pressure of propane is 80 to 100psi; the pressure of compressed air is 95 to 110psi; the flow of the oxygen is 340 to 370 standard cubic foot per hour (SCFH); the flow of the propane is 150 to 180SCFH; the flow of the compressed air is 880 to 920SCFH; powder feeding amount is 20 to 30g / min; and a spraying distance is 250 to 290mm. The wear-resistant coating prepared by the method is suitable for the nuclear second-stage pump bearing and has important application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method and system for porous flame holder for hydrogen and syngas combustion

InactiveUS8413445B2High speedIncreased flame speedContinuous combustion chamberGas turbine plantsSyngasCombustor

Owner:GENERAL ELECTRIC CO

Ammonia salt fuel system

InactiveUS20110197500A1Increase oxygen contentLow vapor pressureLiquid carbonaceous fuelsSolventAmmonia

Owner:GANLEY JASON C +1

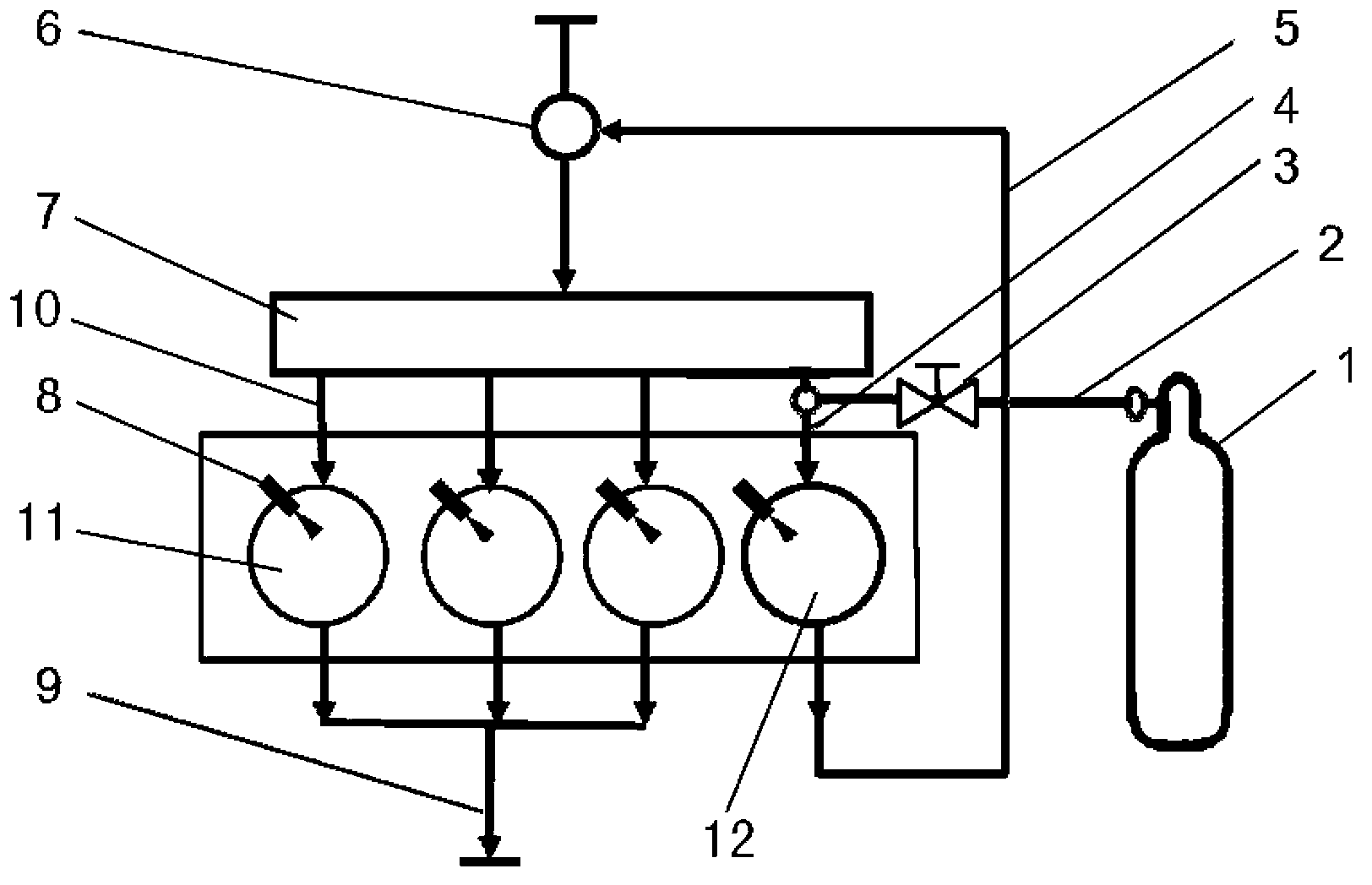

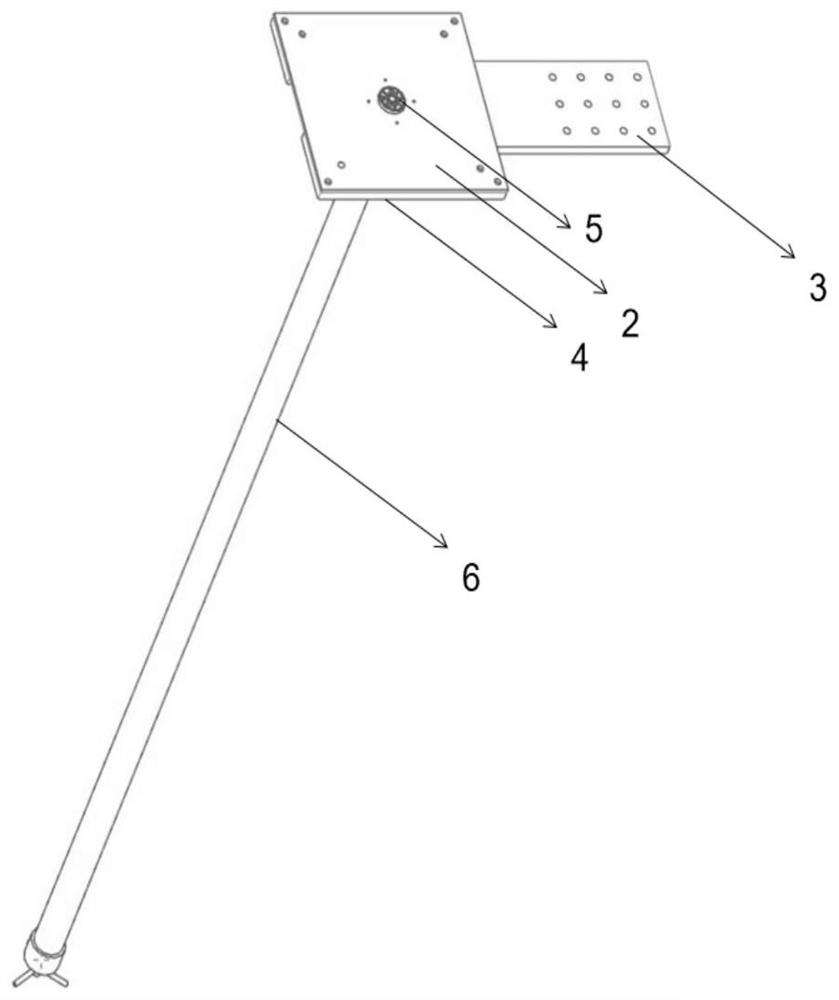

Low-temperature combustion method of internal-combustion engine with fuel reformation inside cylinders and system

ActiveCN103216316AEmission reductionIncreased flame speedInternal combustion piston enginesGaseous engine fuelsEquivalence ratioEmission standard

The invention relates to the internal-combustion engine technical field, in particular to a low-temperature combustion method of an internal-combustion engine with fuel reformation inside cylinders and system. High-cetane-number fuel is sprayed inside a rich burn air cylinder of a multi-cylinder engine to ignite rich burn combination gas of natural gas and air with a fuel-air equivalence ratio of 1.5-4.0, reformation combination gas which is rich in H2 and CO is generated after the natural gas is rich burned, and then after the reformation combination gas and the air are mixed to enter a lean burn air cylinder for combustion again, a lean burn mode of which the high-cetane-number fuel ignites the reformation combination gas is in the lean burn air cylinder, and a fuel-air equivalence ratio is less than 1. The low-temperature combustion method of the internal-combustion engine with the fuel reformation inside the cylinders and system has the advantages that compared with an existing ignition type natural gas engine, heat efficiency is increased by 30%, and the level of a diesel engine is achieved; emission can achieve an Euro 5 emission standard; use and production cost of the engine is greatly lower than the diesel engine in the same emission standard; and knocking is restrained and NOx is reduced in the process of heavy load, HC and CO emission is reduced in the process of small load, and meanwhile quantity of the required ignition high-cetane-number fuel is small.

Owner:TSINGHUA UNIV

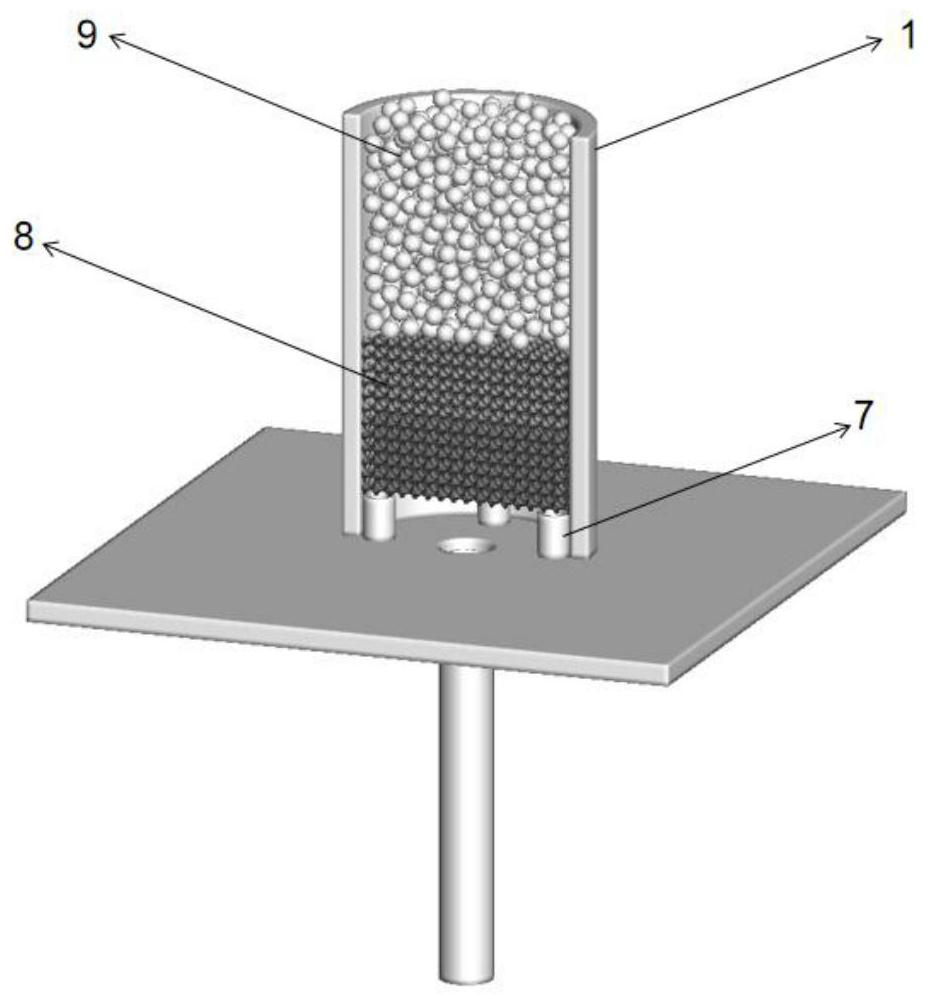

Novel wake flow combustor with random accumulation structure

PendingCN112128746ARapid coolingUniform temperature distributionPulverulent fuel combustion burnersGaseous fuel burnerTemperingPorous medium

The invention discloses a novel wake flow combustor with a random accumulation structure. The novel wake flow combustor comprises a combustion cavity, the bottom of the combustion cavity is connectedwith a gas mixing pipeline, a gas backflow area, two layers of foamed ceramics and an accumulation chamber are sequentially arranged in the combustion cavity from bottom to top, a Raschig ring is arranged at the bottom in the combustion cavity, the two layers of foamed ceramic are supported through the Raschig ring, and the gas backflow area is formed; and silicon-containing aluminum oxide pelletsare randomly accumulated in the accumulation chamber to form a porous medium layer, the combustion rate is increased through the silicon-containing aluminum oxide pellets, and the tempering phenomenon in the combustion process is reduced.

Owner:JIANGSU UNIV

Low-temperature combustion method of internal-combustion engine with fuel reformation inside cylinders and system

ActiveCN103216316BEmission reductionIncreased flame speedInternal combustion piston enginesGaseous engine fuelsEquivalence ratioEmission standard

The invention relates to the internal-combustion engine technical field, in particular to a low-temperature combustion method of an internal-combustion engine with fuel reformation inside cylinders and system. High-cetane-number fuel is sprayed inside a rich burn air cylinder of a multi-cylinder engine to ignite rich burn combination gas of natural gas and air with a fuel-air equivalence ratio of 1.5-4.0, reformation combination gas which is rich in H2 and CO is generated after the natural gas is rich burned, and then after the reformation combination gas and the air are mixed to enter a lean burn air cylinder for combustion again, a lean burn mode of which the high-cetane-number fuel ignites the reformation combination gas is in the lean burn air cylinder, and a fuel-air equivalence ratio is less than 1. The low-temperature combustion method of the internal-combustion engine with the fuel reformation inside the cylinders and system has the advantages that compared with an existing ignition type natural gas engine, heat efficiency is increased by 30%, and the level of a diesel engine is achieved; emission can achieve an Euro 5 emission standard; use and production cost of the engine is greatly lower than the diesel engine in the same emission standard; and knocking is restrained and NOx is reduced in the process of heavy load, HC and CO emission is reduced in the process of small load, and meanwhile quantity of the required ignition high-cetane-number fuel is small.

Owner:TSINGHUA UNIV

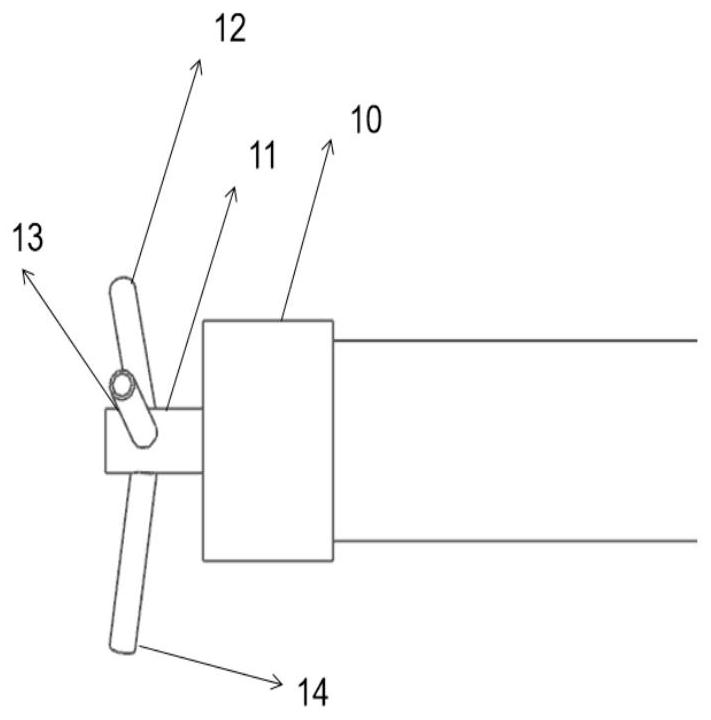

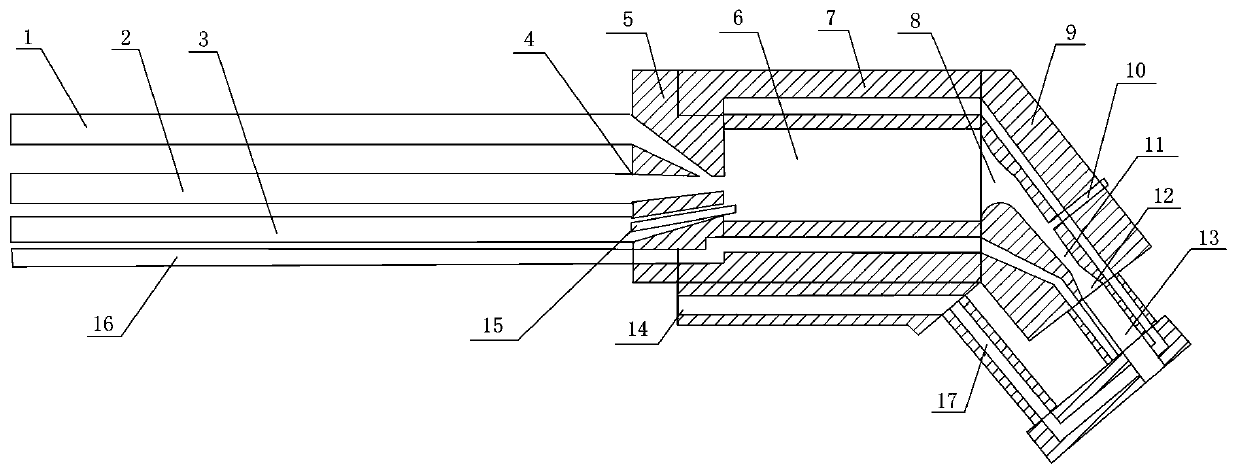

Liquid Fuel Bore Supersonic Flame Spray Gun

ActiveCN106591764BHigh bonding strengthIncrease temperatureMolten spray coatingCombustion chamberInjector nozzle

The invention discloses a liquid fuel inner hole supersonic flame spray gun, which comprises a gun shell, a gun barrel, an oxygen delivery pipeline, a fuel delivery pipeline, an ignition line pipeline, a fuel injection nozzle, a stabilizer, a combustion chamber, a high temperature and high pressure gas convergence section, Elbow connector, powder feeding needle, gas compression throat, flame diffusion section, nozzle, water outlet at the bottom of the combustion chamber, spark plug and cooling water inlet pipe; The position where the stabilizer is connected, the spark plug is set at the position where the ignition line pipe is connected to the stabilizer, one end of the combustion chamber is provided with a stabilizer, and the other end is provided with an elbow connector, and the combustion chamber and the elbow connector are connected. The pipeline consists of a high-temperature and high-pressure gas converging section, a gas compression throat, and a flame diffusion section in sequence. The nozzle is set at the end of the flame diffusion section; the powder feeding port is located in the middle of the elbow connector. The invention can effectively increase flame speed, improve coating bonding strength and reduce porosity.

Owner:ZHENGZHOU LIJIA THERMAL SPRAYING MACHINERY CO LTD

Fuel injector including a lobed mixer and vanes for injecting alternate fuels in a gas turbine

ActiveUS10704786B2Increase heightIncreased flame speedContinuous combustion chamberGaseous fuel burnerAlternative fuelsMechanics

A fuel injector for injecting alternate fuels having a different energy density in a gas turbine is provided. A first fuel supply channel (18) may be fluidly coupled to a radial passage (22) in a plurality of vanes (20) that branches into passages (24) (e.g., axial passages) to inject a first fuel without jet in cross-flow injection. This may be effective to reduce flashback in fuels having a relatively high flame speed. A mixer (30) with lobes (32) for injection of a second fuel may be arranged at the downstream end of a fuel delivery tube (12). A fuel-routing structure (38) may be configured to route the second fuel within a respective lobe so that fuel injection of the second fuel takes place radially outwardly relative to a central region of the mixer. This may be conducive to an improved (e.g., a relatively more uniform) mixing of air and fuel.

Owner:SIEMENS ENERGY INC

System for improving fuel utilization

InactiveUS20070277791A1Improve engine performanceAvoid condensationInternal combustion piston enginesGaseous engine fuelsFractionationLiquid fuel

A vapor fuel air mixture supply system for a combustion engine, whereby the mixture of air and fuel vapor is elevated in temperature prior to combustion. The liquid fuel may be vaporized in a fractionation process and further heated to enhance flame speed combustion and improve efficiency of the system.

Owner:VAPOR FUEL TECH

Apparatus and method for operating a gas-fired burner on liquid fuels

ActiveUS10738996B1Increased flame speedMore expensiveLiquid fuel feeder/distributionHydrogenCatalytic reformingDiffusion flame

A gas-fired burner adapted for use on a liquid fuel. A method for essentially smokeless start-up and steady state operation of a gas-fired burner on a liquid fuel. The apparatus integrates a catalytic liquid fuel reformer with a flame burner designed for operation on a gaseous fuel of high Wobbe Index, e.g., natural gas. The method involves reacting a mixture of a liquid fuel and oxidant in a catalytic reformer to obtain a gaseous reformate having a low Wobbe Index; and thereafter combusting the gaseous reformate, optionally augmented with liquid co-fuel and oxidant, in the gas-fired burner under diffusion flame conditions. The invention allows commercial gas-fired appliances to be operated on a liquid fuel, thereby offering advantages in logistics and camp operations.

Owner:PRECISION COMBUSTION

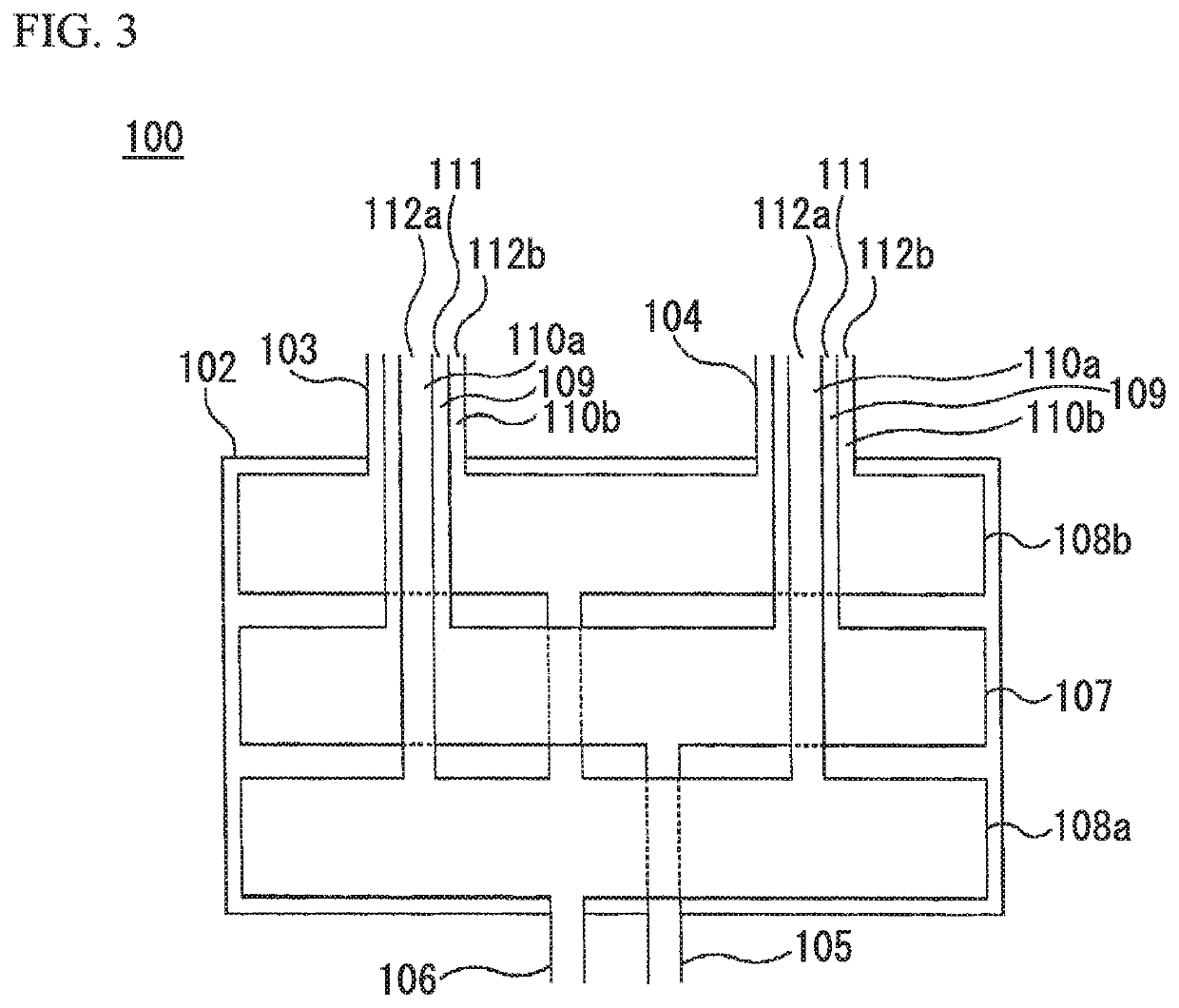

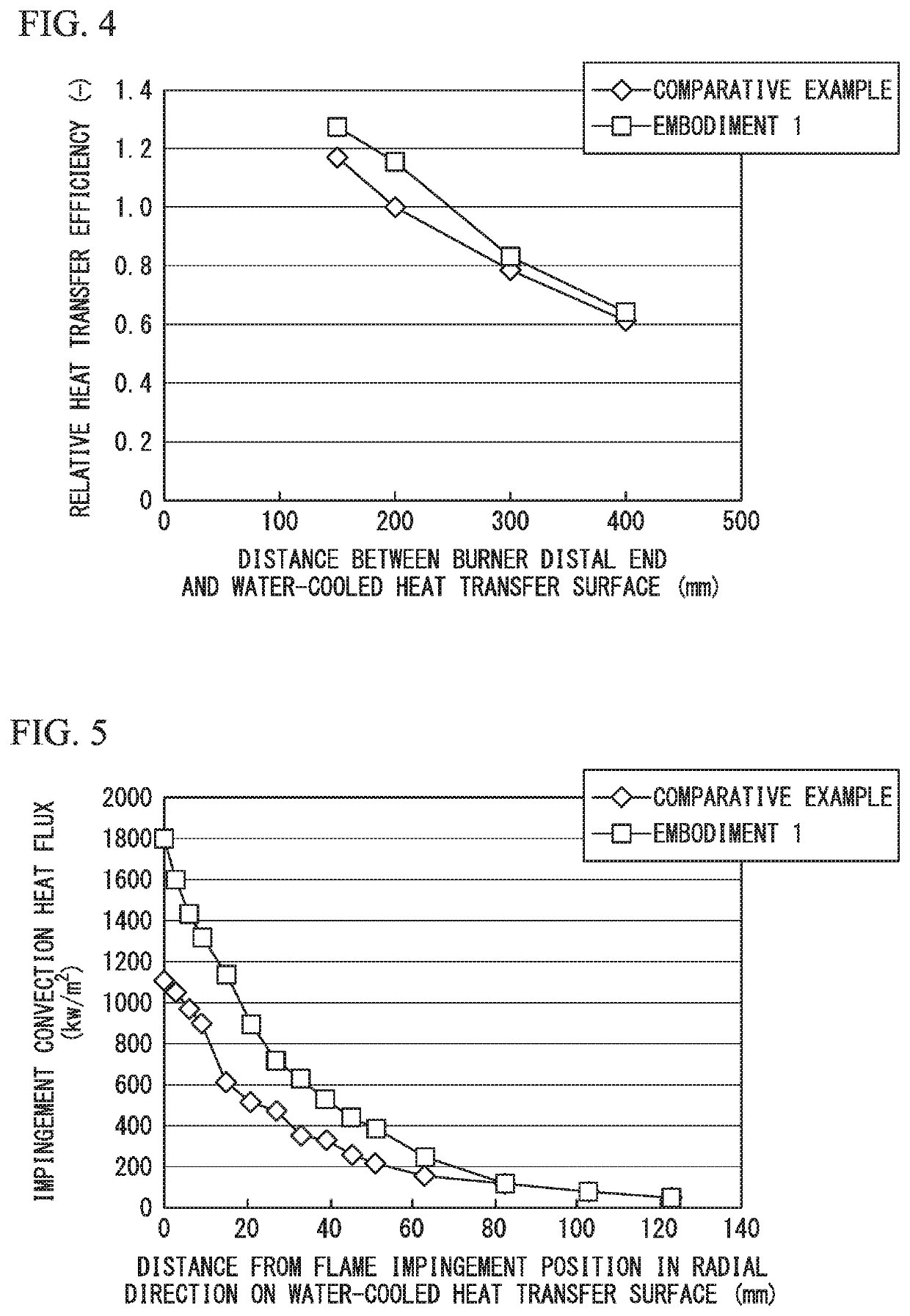

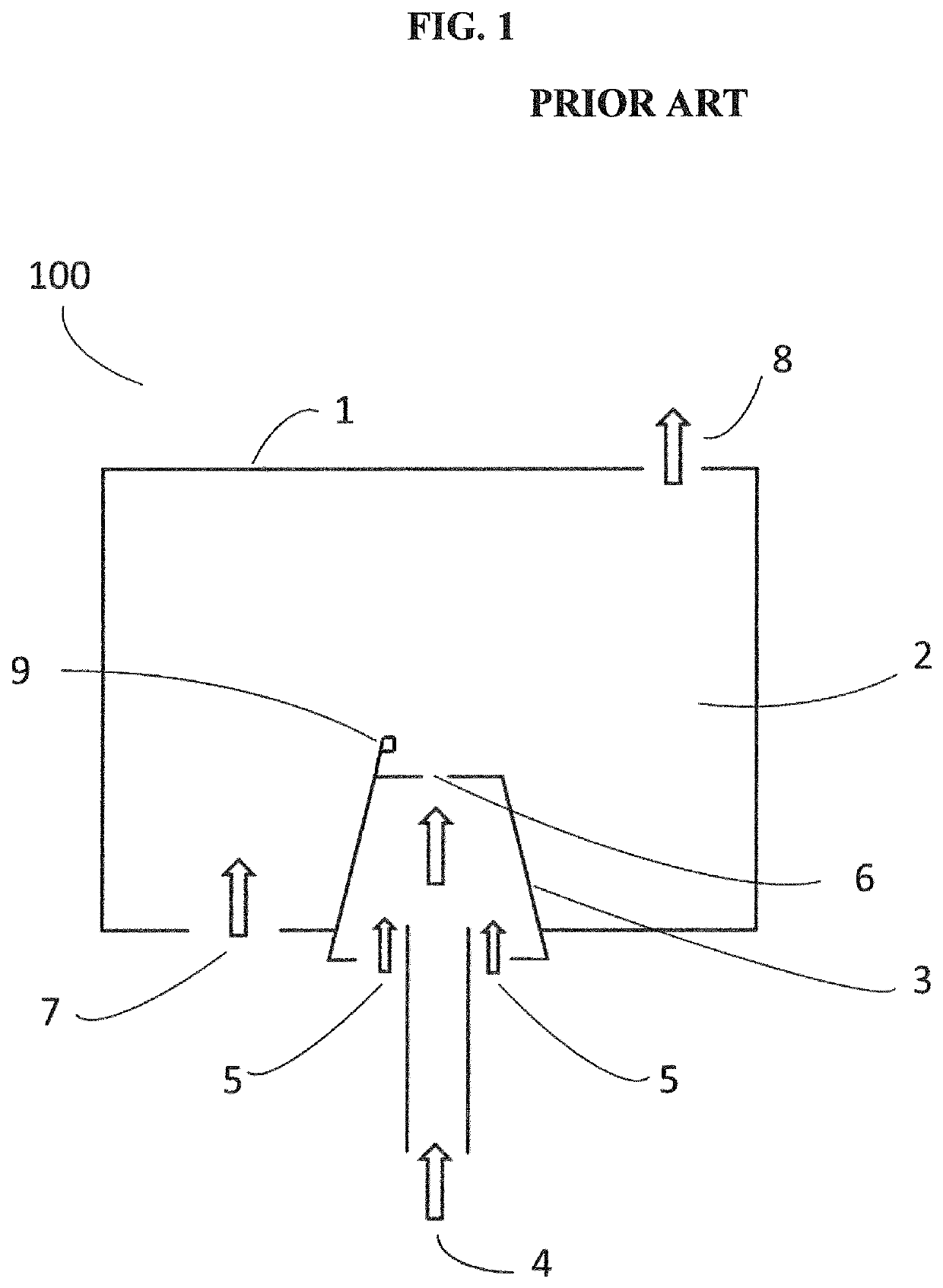

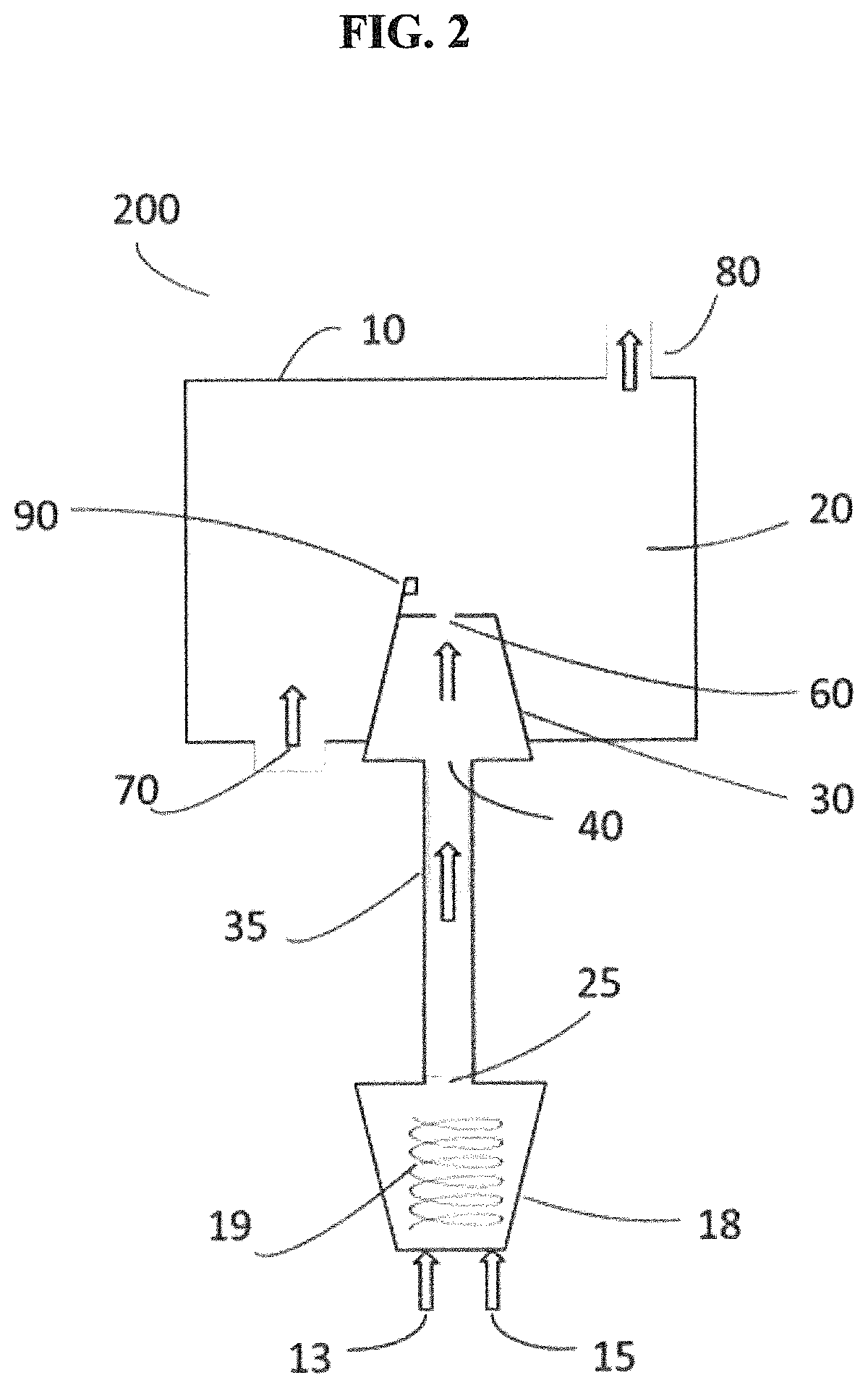

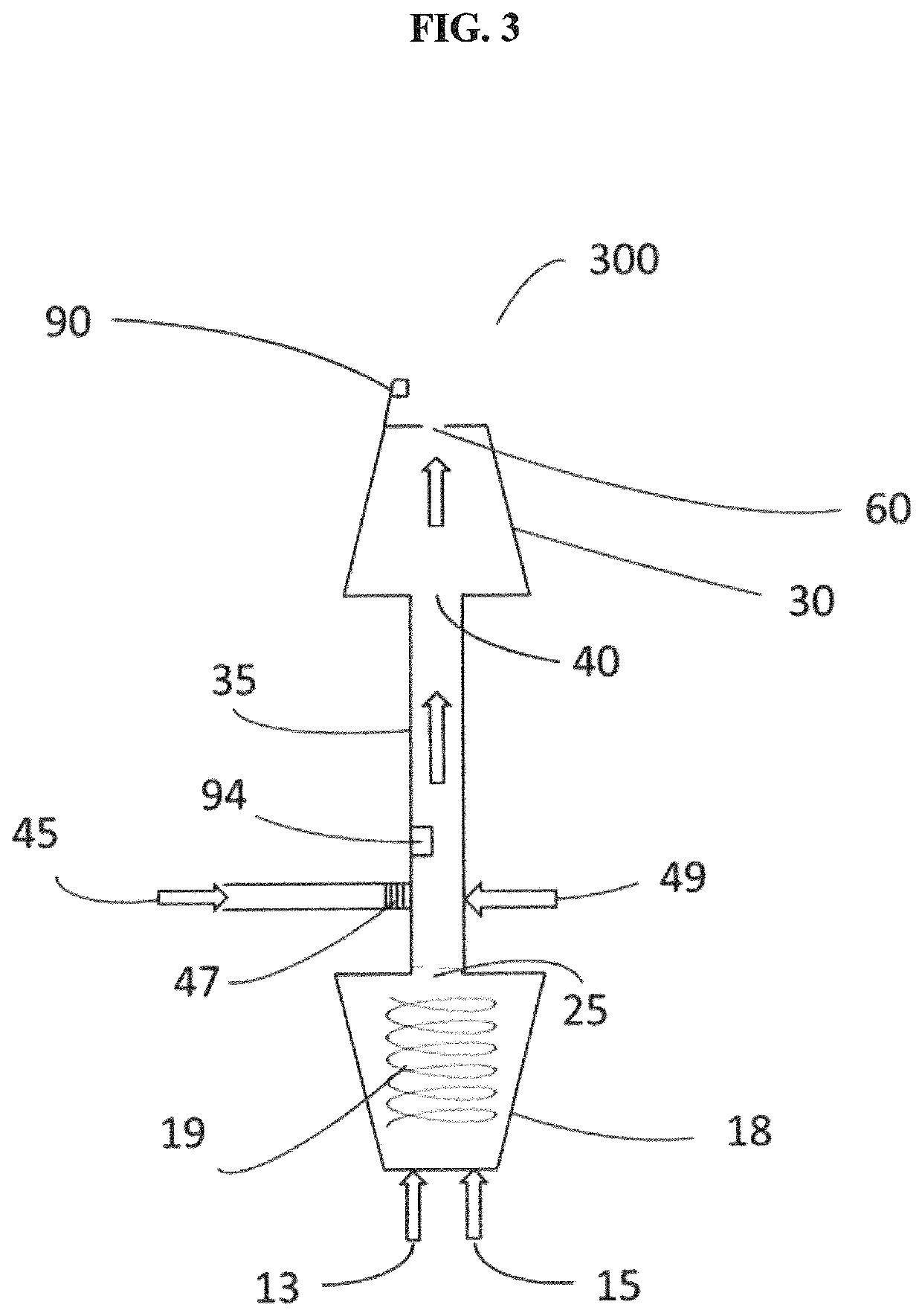

Gas fuel burner and method for heating with gas fuel burner

ActiveUS10677459B2Prevent oxidationIncreased flame speedGaseous fuel burnerThermodynamicsCombustion chamber

The gas fuel burner of the present invention has: a first oxidation agent discharge port that is disposed in the center of a first circular face constituting a combustion chamber having a truncated cone shape that expands from the basal end toward the distal end of a burner body and that discharges a first oxidation agent in the direction that the center axis of the burner body extends; a gas fuel discharge port that is disposed on the outside of the first oxidation agent discharge port and that discharges gas fuel in a direction intersecting the direction that the center axis extends; and a second oxidation agent discharge port that is disposed on a side face of the combustion chamber and that discharges a second oxidation agent in a direction intersecting the direction that the center axis extends.

Owner:NIPPON SANSO CORP

Apparatus and method for operating a gas-fired burner on liquid fuels

ActiveUS11022318B1High flame speedLess safe to handleFuel supply regulationLiquid fuel feeder/distributionChemistryProcess engineering

A gas-fired burner adapted for use on a liquid fuel. A method for essentially smokeless start-up and steady state operation of a gas-fired burner on a liquid fuel. The apparatus integrates a catalytic liquid fuel reformer with a flame burner designed for operation on a gaseous fuel of high Wobbe Index, e.g., natural gas. The method involves reacting a mixture of a liquid fuel and oxidant in a catalytic reformer to obtain a gaseous reformate having a low Wobbe Index; and thereafter combusting the gaseous reformate, optionally augmented with liquid co-fuel and oxidant, in the gas-fired burner under diffusion flame conditions. The invention allows commercial gas-fired appliances to be operated on a liquid fuel, thereby offering advantages in logistics and camp operations.

Owner:PRECISION COMBUSTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com