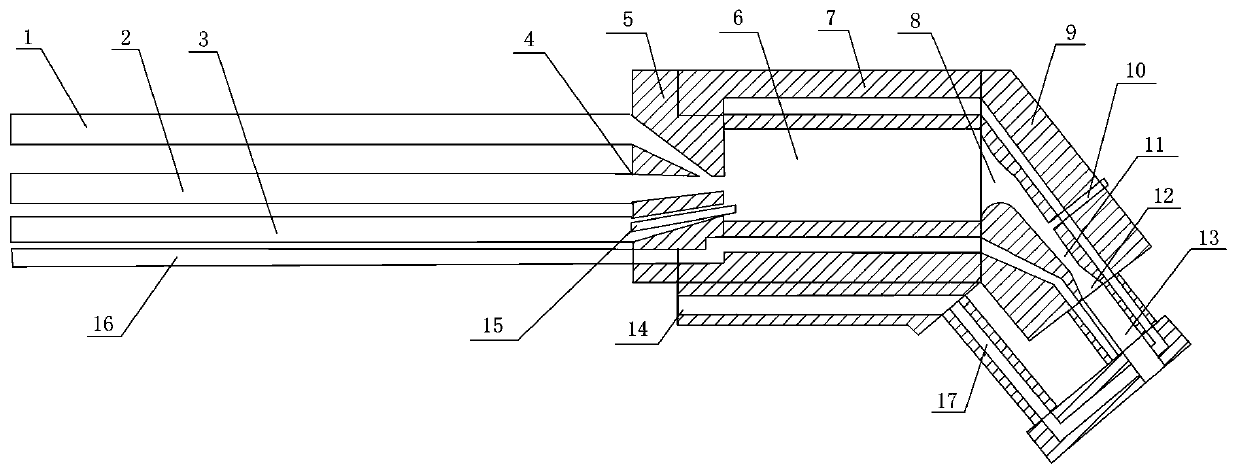

Liquid Fuel Bore Supersonic Flame Spray Gun

A technology of supersonic flame and liquid fuel, which is applied in fusion spraying, metal material coating technology, coating, etc., can solve the problems of low flame speed and failure to meet the requirements, and achieve increased flame speed, improved bonding strength, The effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further explained and illustrated:

[0020] see figure 1 , a supersonic flame spray gun with a liquid fuel inner hole, including a gun casing 7 and a gun barrel 17 in the gun casing, and also includes an oxygen delivery pipeline 1, a fuel delivery pipeline 2, an ignition line pipeline 3, a fuel injection nozzle 4, and a stabilizer 5 , combustion chamber 6, high temperature and high pressure gas converging section 8, elbow connector 9, powder feeding needle 10, gas compression throat 11, flame diffusion section 12, nozzle 13, water outlet 14 at the bottom of the combustion chamber, spark plug 15 and cooling water inlet The water pipeline 16; the combustion chamber 6 is located in the inside of the gun housing 7, the fuel injection nozzle 4 is arranged at the position where the fuel delivery pipeline 2 is connected with the stabilizer 5, and the spark plug 15 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com