Patents

Literature

35results about How to "Meet Torque Demands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

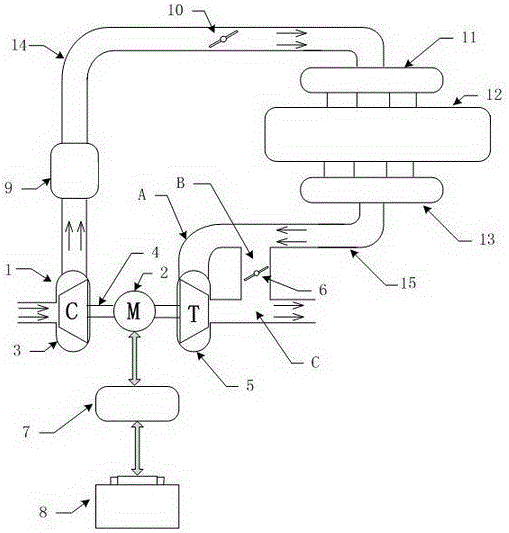

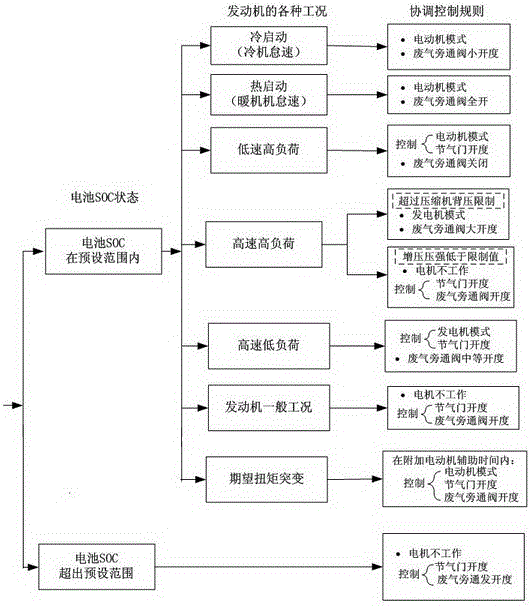

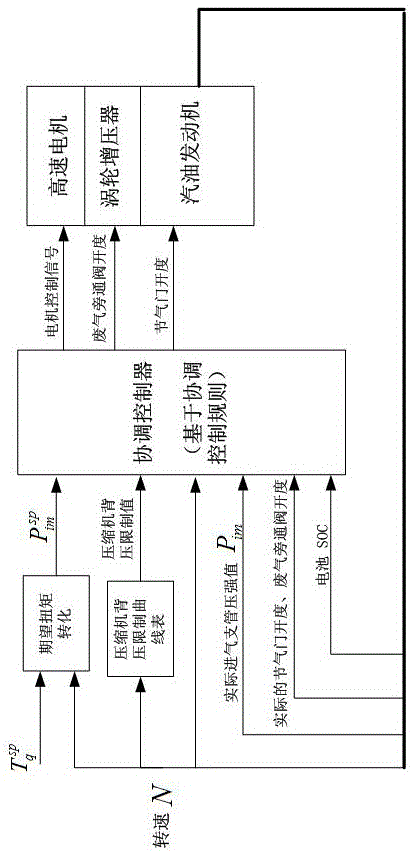

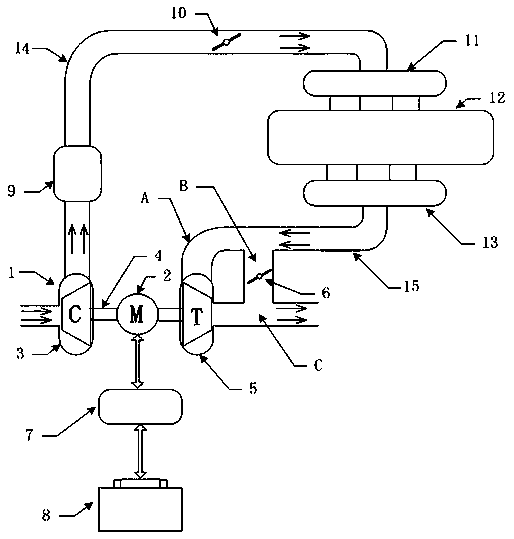

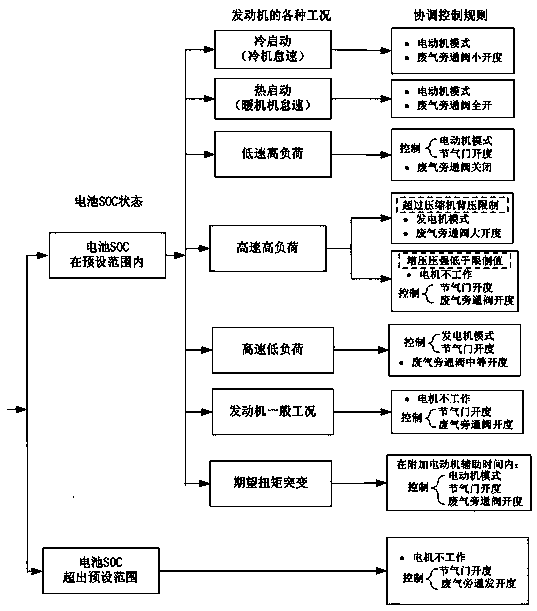

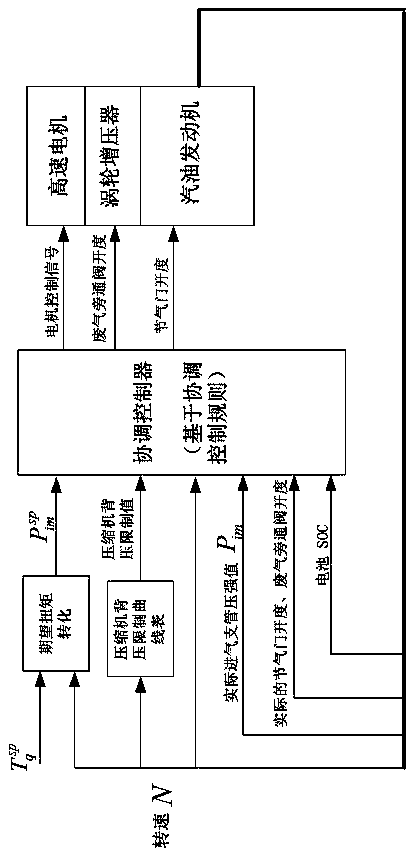

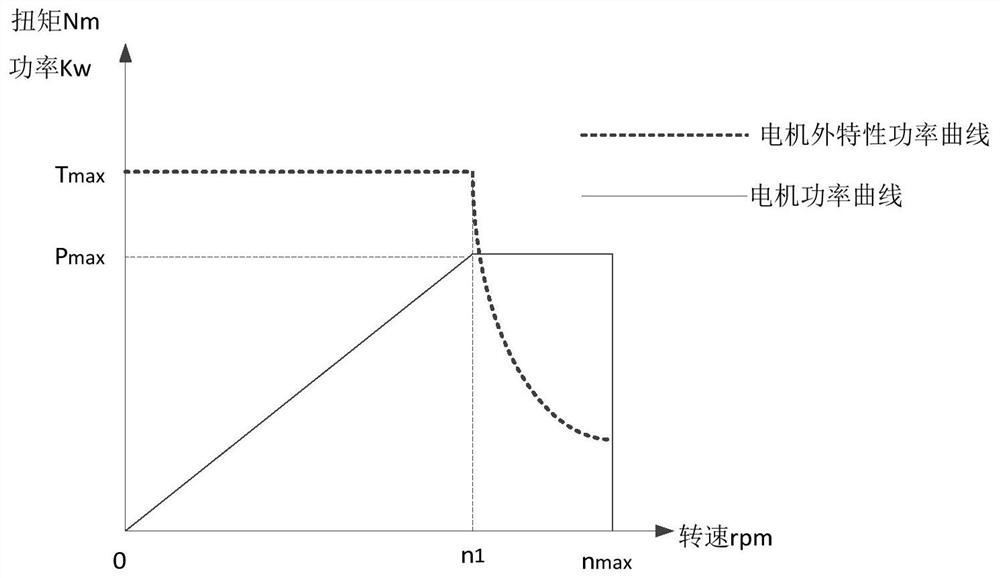

Electrically-aided turbocharging system and control method thereof

ActiveCN105927370AMeet Torque DemandsEasy to chargeElectrical controlInternal combustion piston enginesElectricityTurbocharger

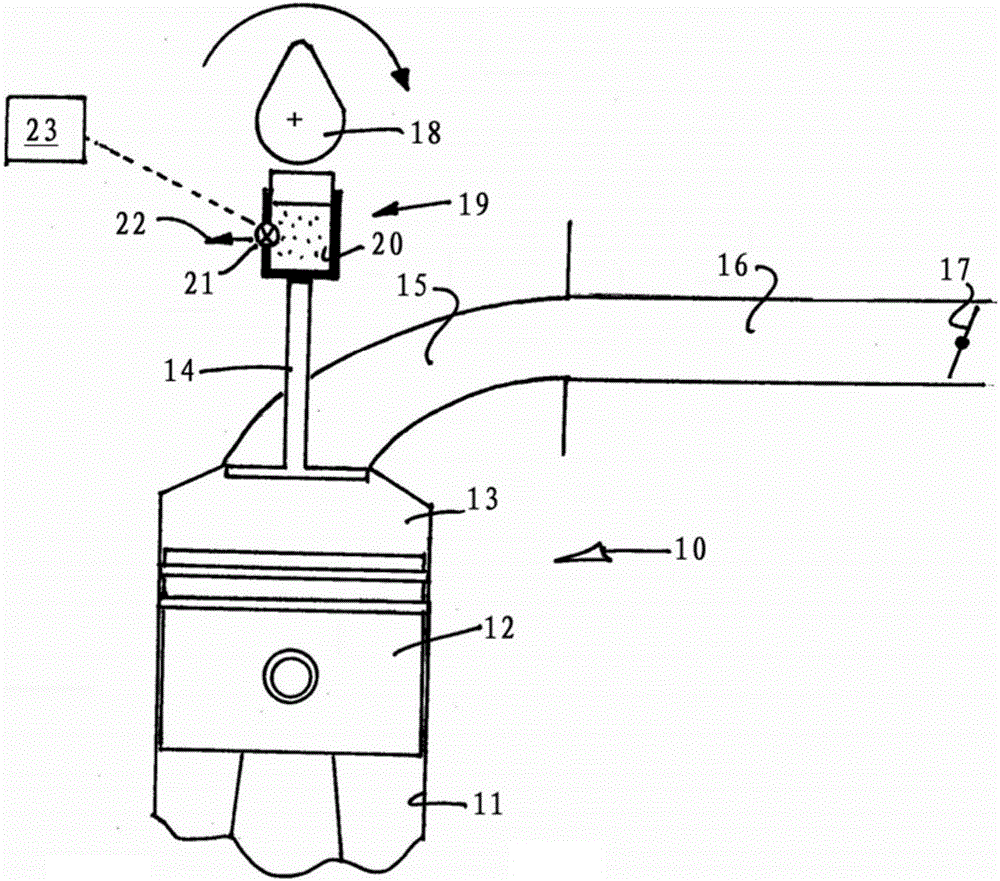

The invention discloses an electrically-aided turbocharging system, and belongs to the technical field of turbocharging. The invention aims at providing an optimized electrically-aided turbocharging system adequately utilizing a turbine body structure, and a control method thereof. One end of the electrically-aided turbocharger disclosed by the invention is installed at an inlet end of an intake channel, and the other end of the electrically-aided turbocharger is installed at an outlet end of an exhaust channel; the electrically-aided turbocharger is composed of an aiding high-speed motor, a compressor, a turbocharger rotary shaft, a turbine and a waste gas bypass valve device; an intercooler is installed on the intake channel; an intake branch pipe is connected to a tail end of the intake channel; an exhaust branch pipe is connected to an inlet end of the exhaust channel; a gasoline engine cylinder is directly connected between the intake branch pipe and the exhaust branch pipe; the exhaust channel behind the exhaust branch pipe is divided into a first passage and a second passage which are connected in parallel; and tail ends of the first passage and the second passage both communicate with an outlet pipeline. According to the electrically-aided turbocharging system disclosed by the invention, the high-speed motor is combined with the turbocharger with the waste gas bypass valve, thus the influence of waste gas turbocharging for the performance of a gasoline engine is furthest utilized.

Owner:JILIN UNIV

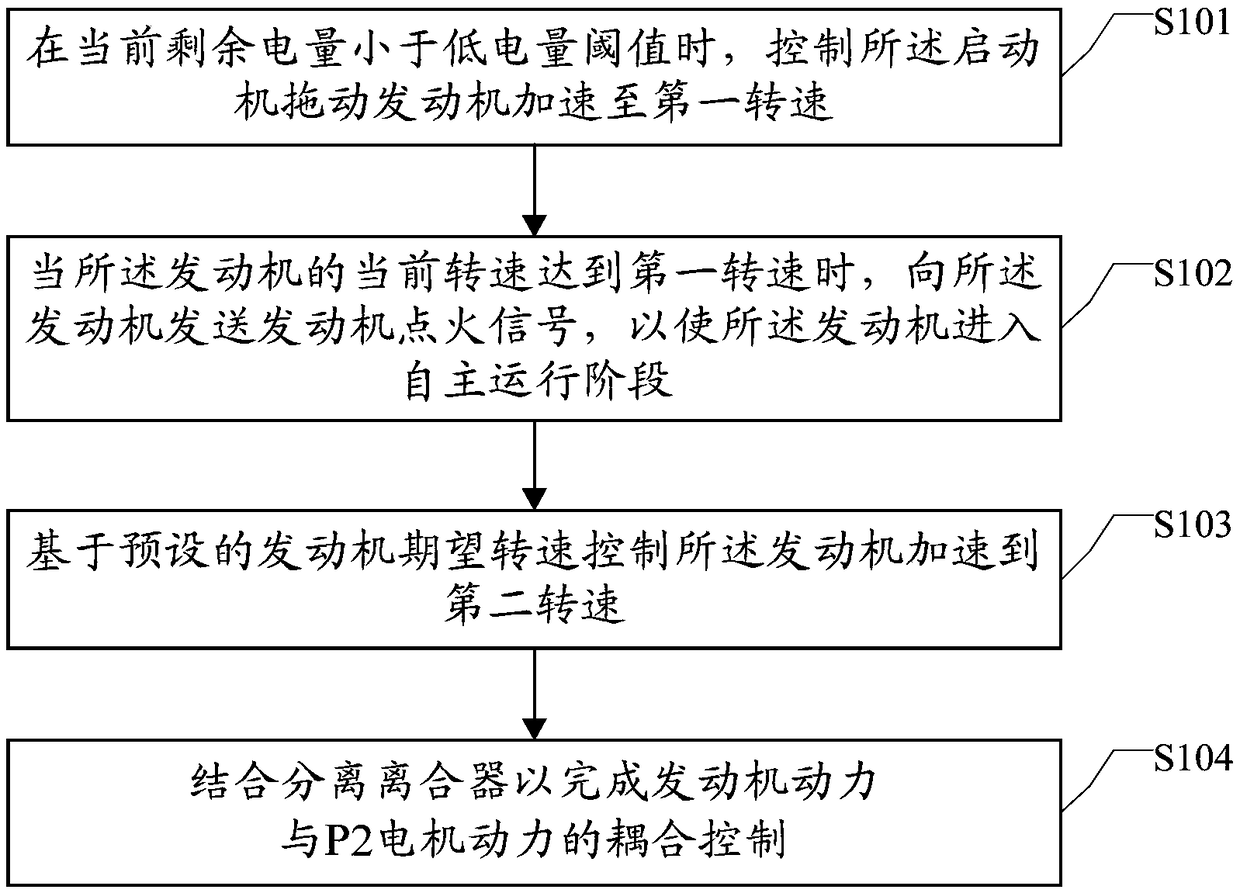

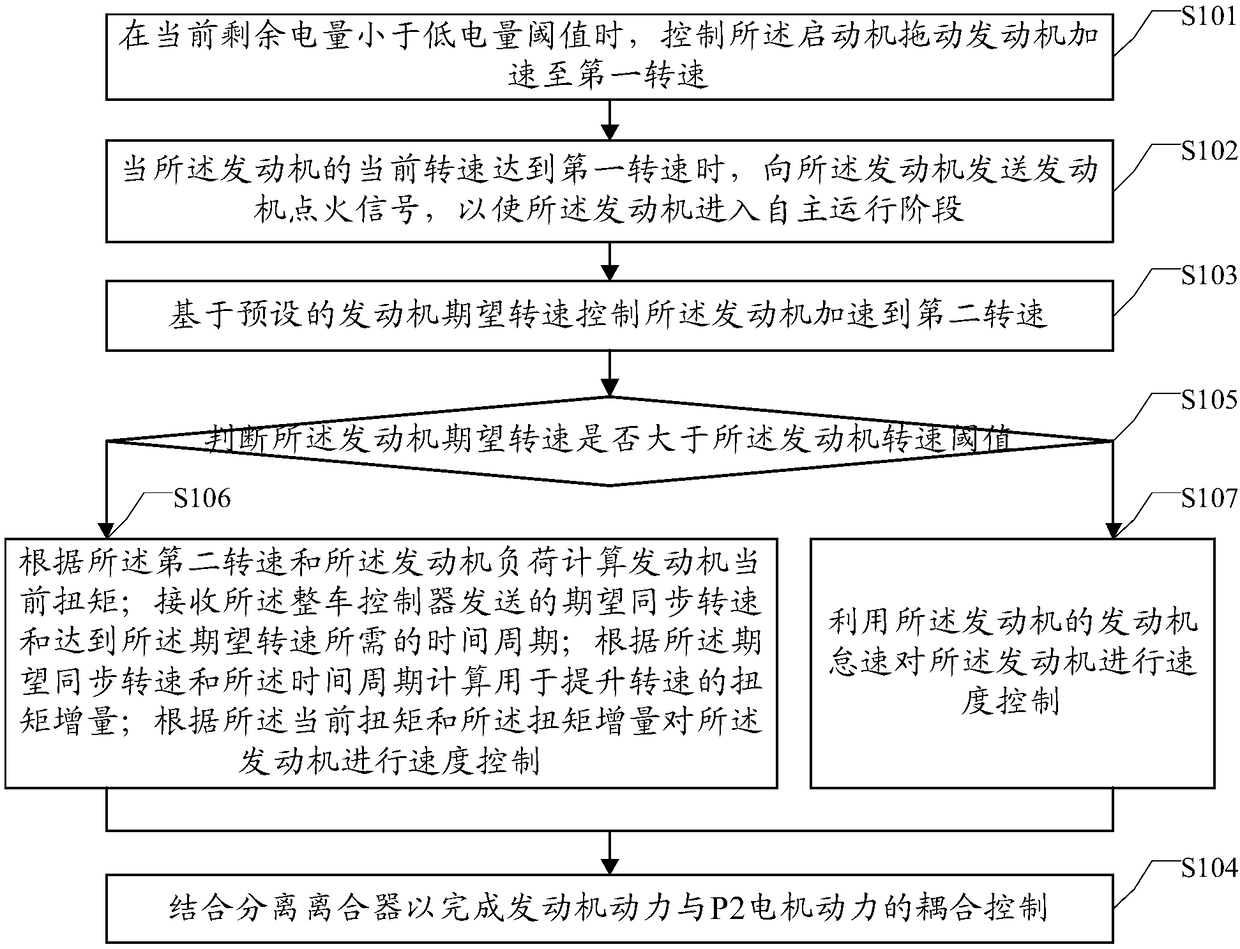

Starting control method and system

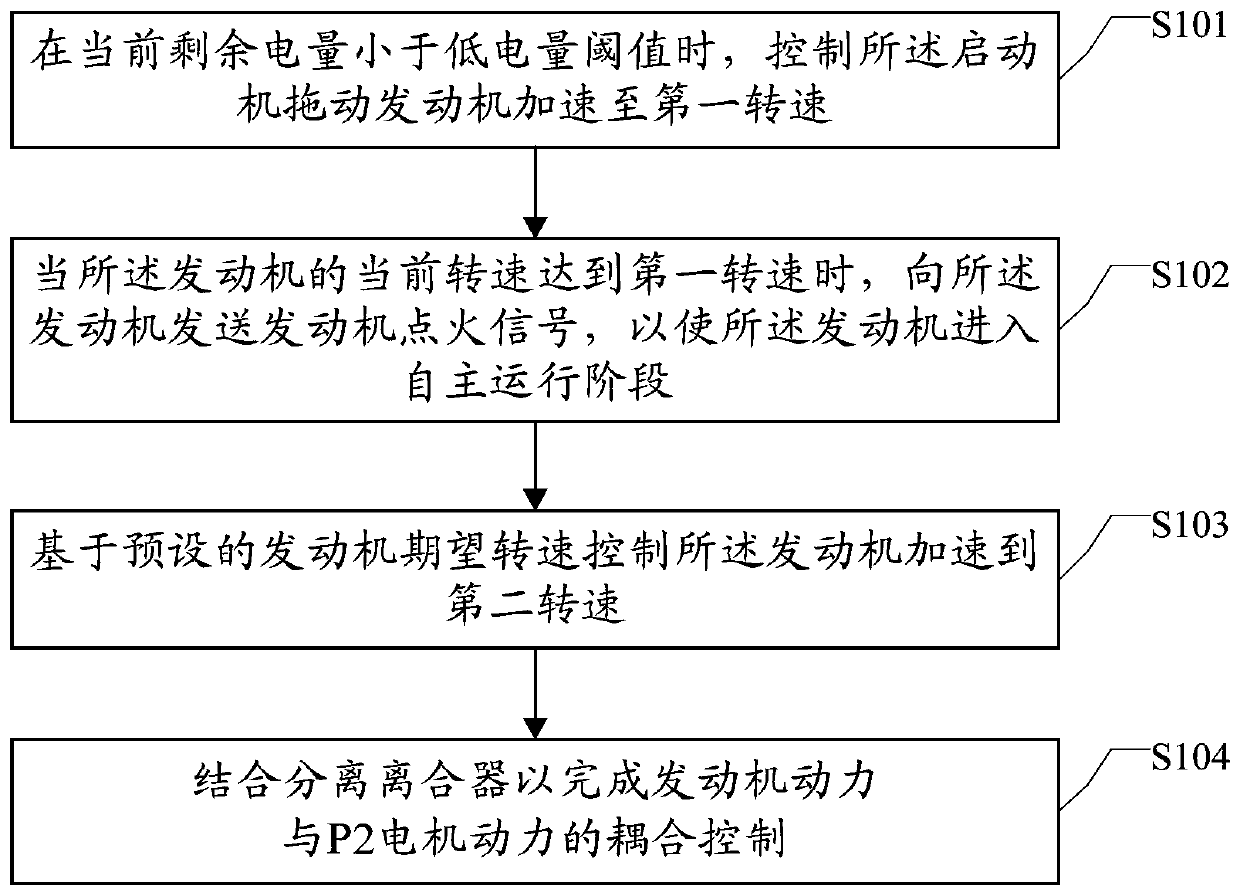

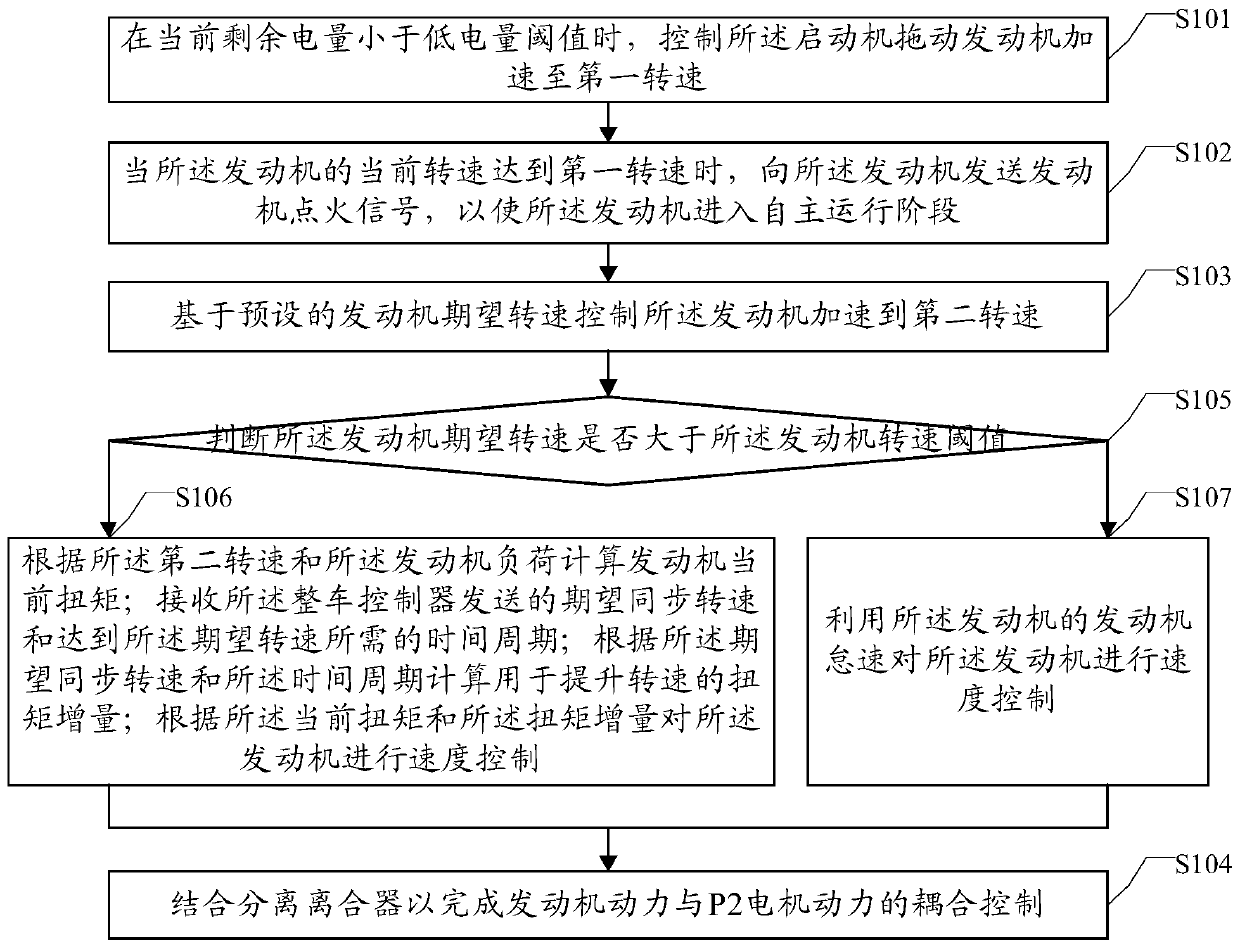

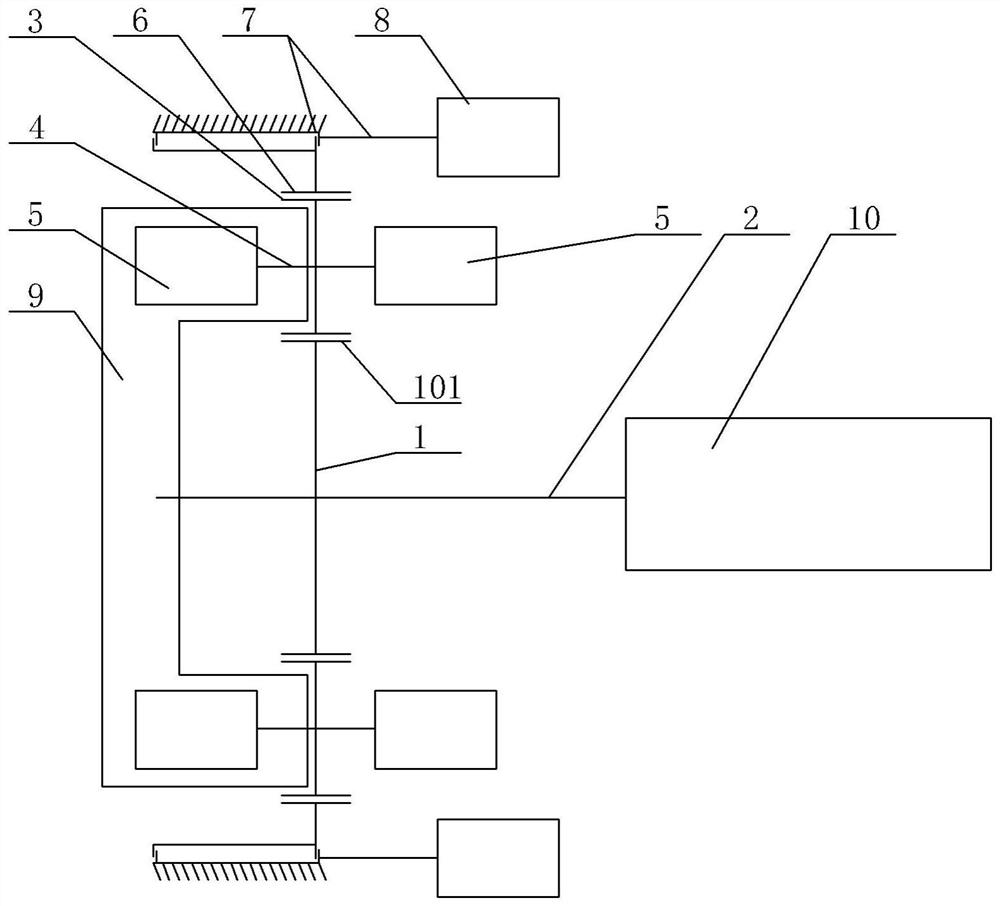

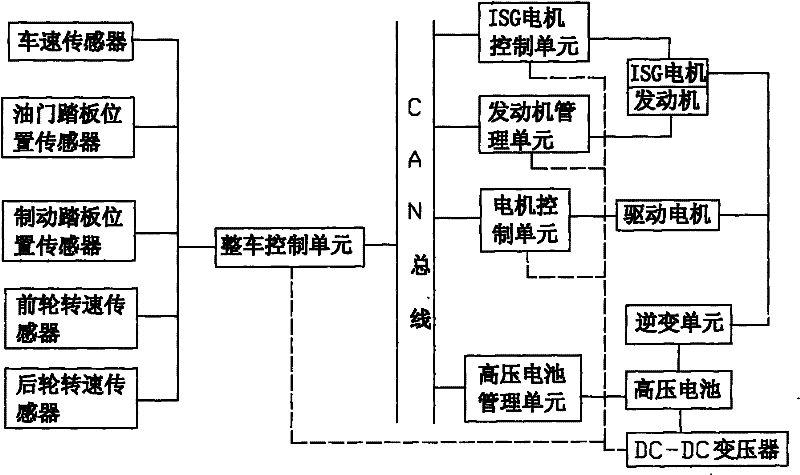

The embodiment of the invention provides a starting control method and system, and relates to the technical field of engine control. The starting control method comprises the following steps that whenthe current remaining electric quantity is smaller than a low electric quantity threshold value, a starter is controlled to drag an engine to accelerate to the first rotating speed; when the currentrotating speed of the engine reaches the first rotating speed, an engine ignition signal is sent to the engine, and thus the engine enters into the automatic operation stage; based on the preset engine expected rotating speed, the engine is controlled to accelerate to the second rotating speed; and when the engine reaches the second rotating speed, coupling control of the engine power and the P2 motor power is completed by combining with a separation clutch. By applying the scheme, when the engine in the shutdown state is started, the starter enables the engine to accelerate to the first rotating speed firstly, then the engine automatically operates and approaches to the engine expected rotating speed, and thus even if the remaining electric quantity of a vehicle is insufficient, the engine and a motor can still jointly provide torque to meet the vehicle acceleration torque requirements.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

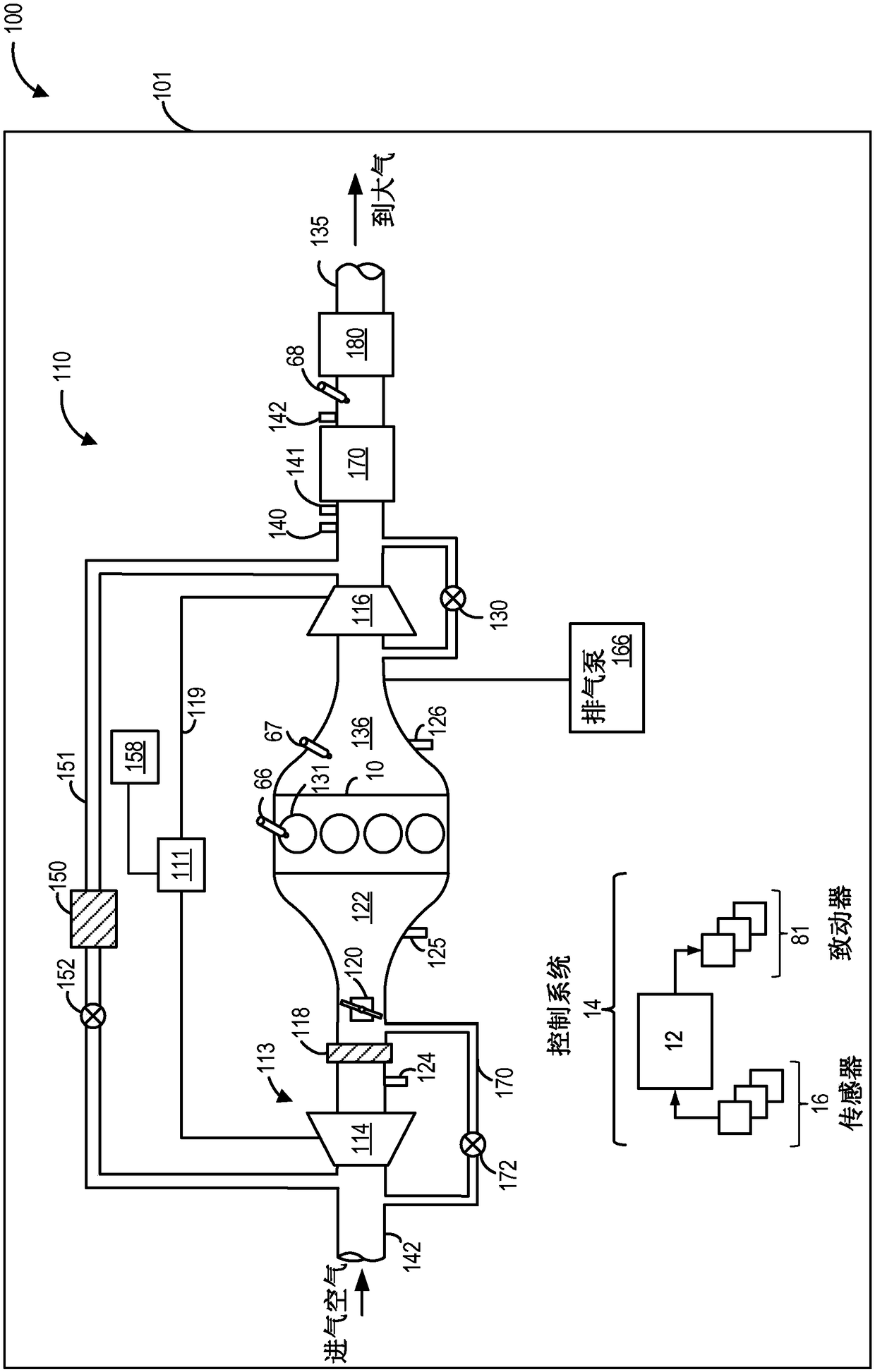

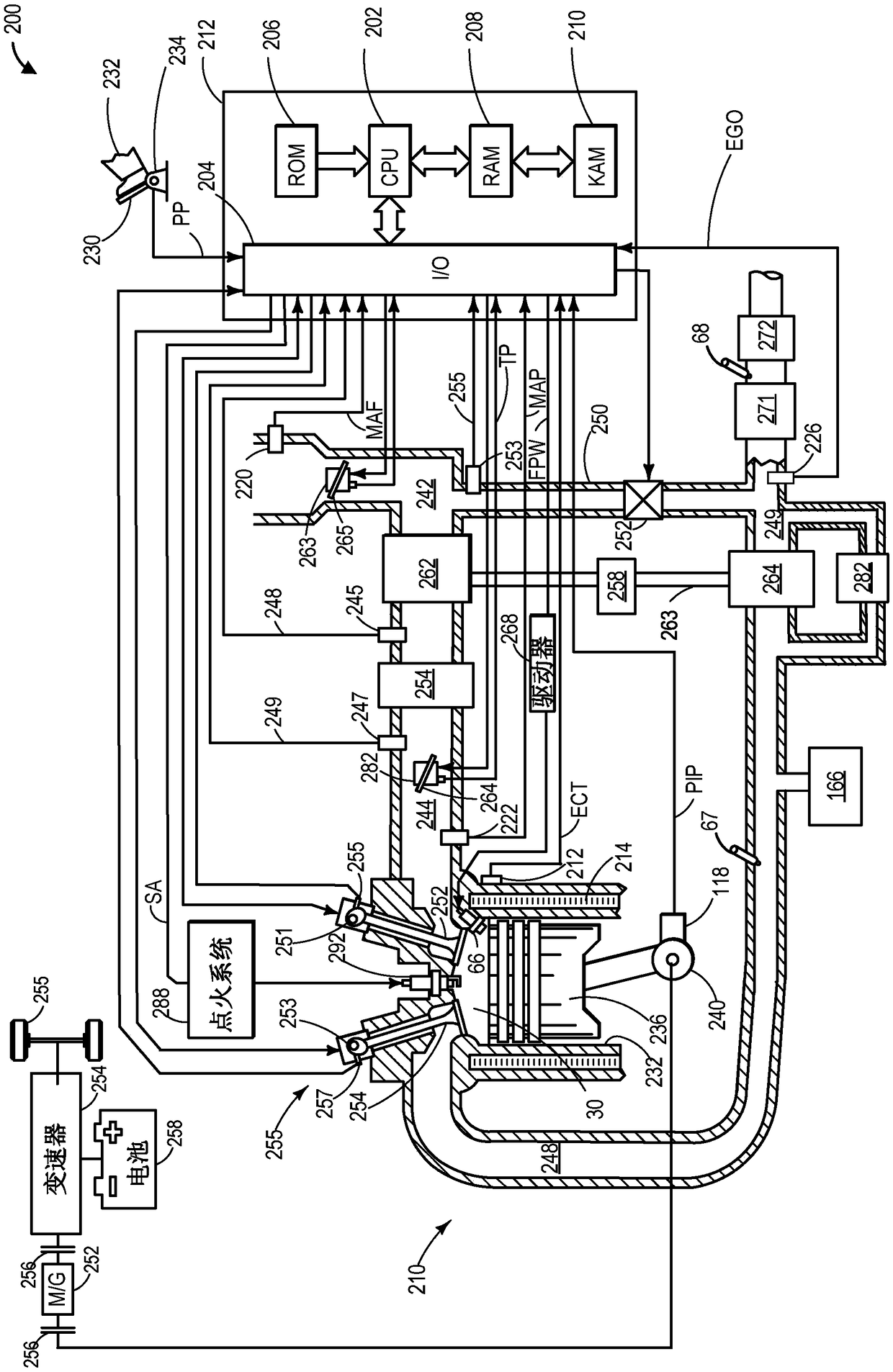

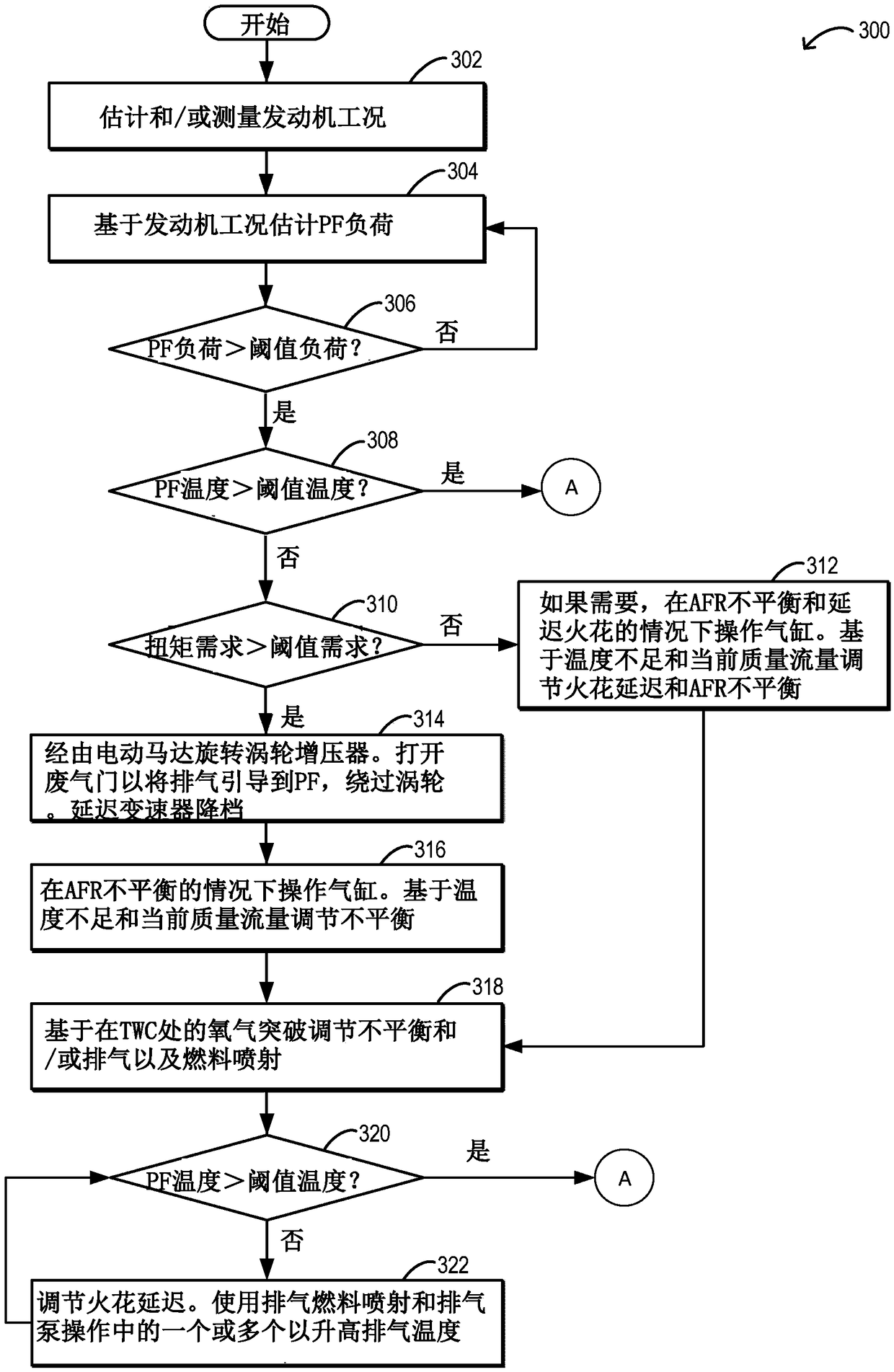

Method and system for particulate filter regeneration

PendingCN109306887APromote regenerationImprove emission performanceGas treatmentElectrical controlParticulatesTurbocharger

The present invention relates to a method and a system for particulate filter regulation. Methods and systems are provided for expediting exhaust particulate filter regeneration. In one example, an engine controller may generate an exotherm at the filter by operating engine cylinders with air-fuel imbalance while using electric assist to a turbocharger to meet a torque demand and raise an intake airflow to enhance the effect of the exotherm. Once heated, the filter may be regenerated by flowing extra air to the exhaust via an air pump and injecting extra fuel to an exhaust passage via an exhaust injector.

Owner:FORD GLOBAL TECH LLC

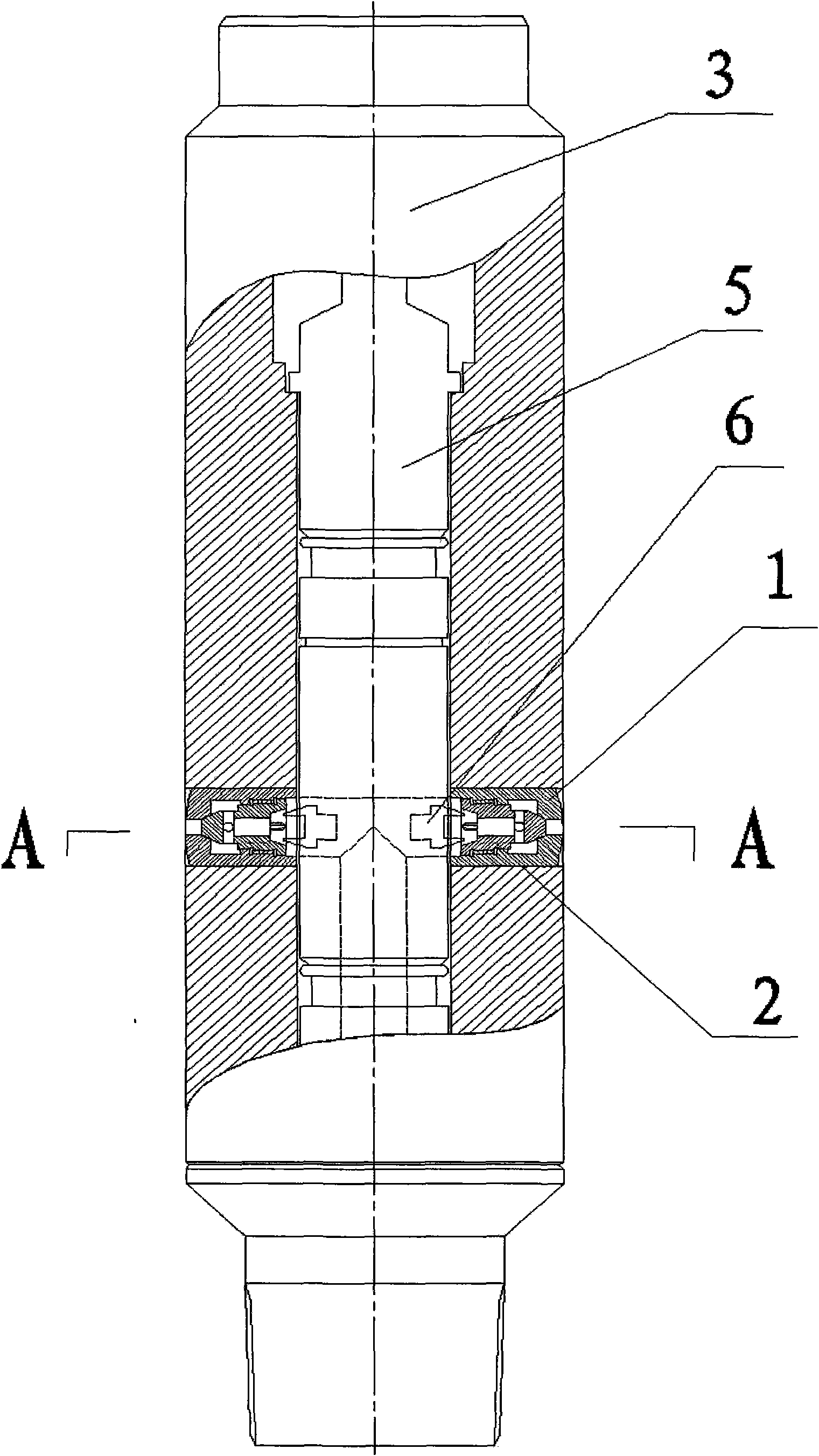

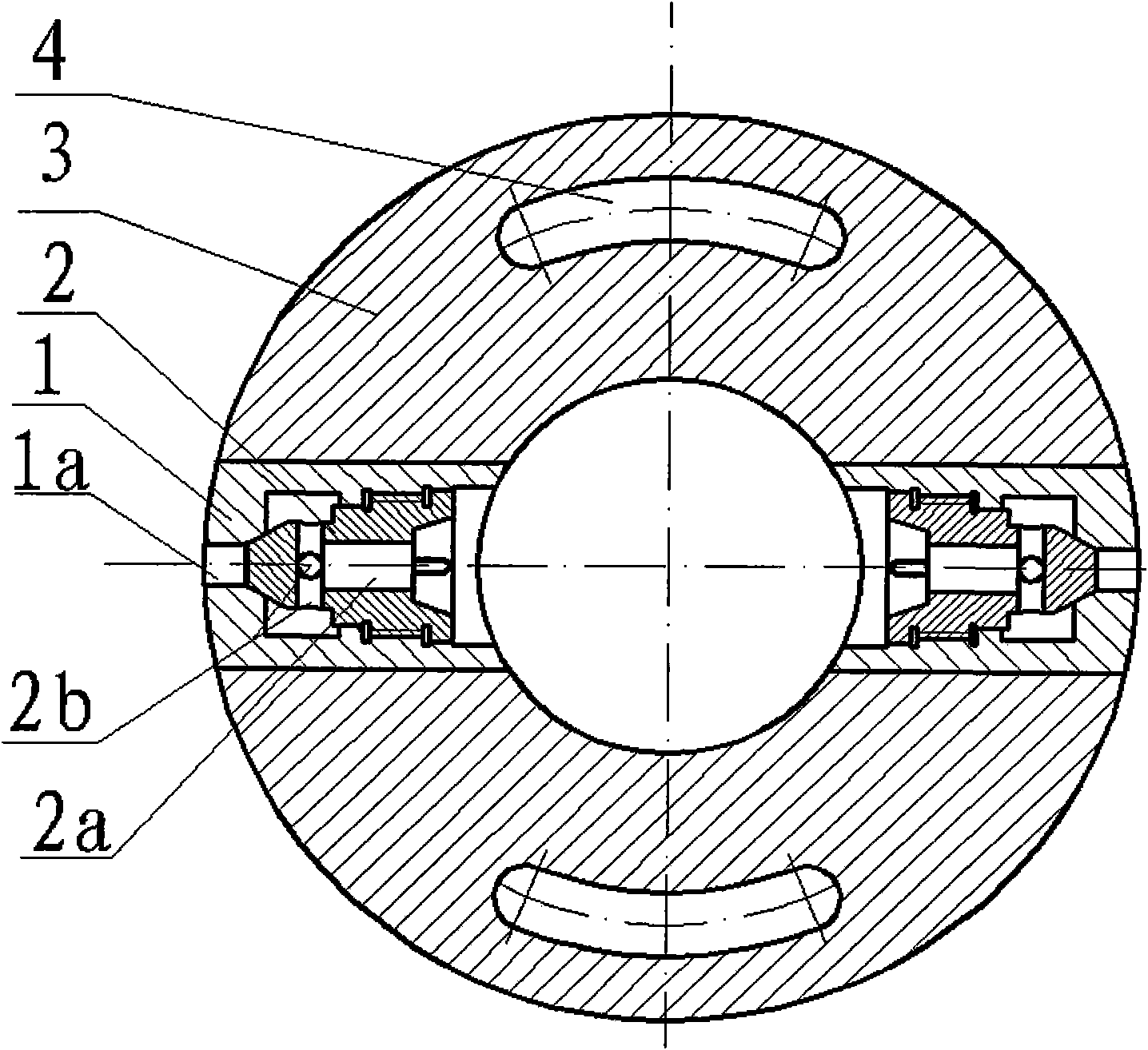

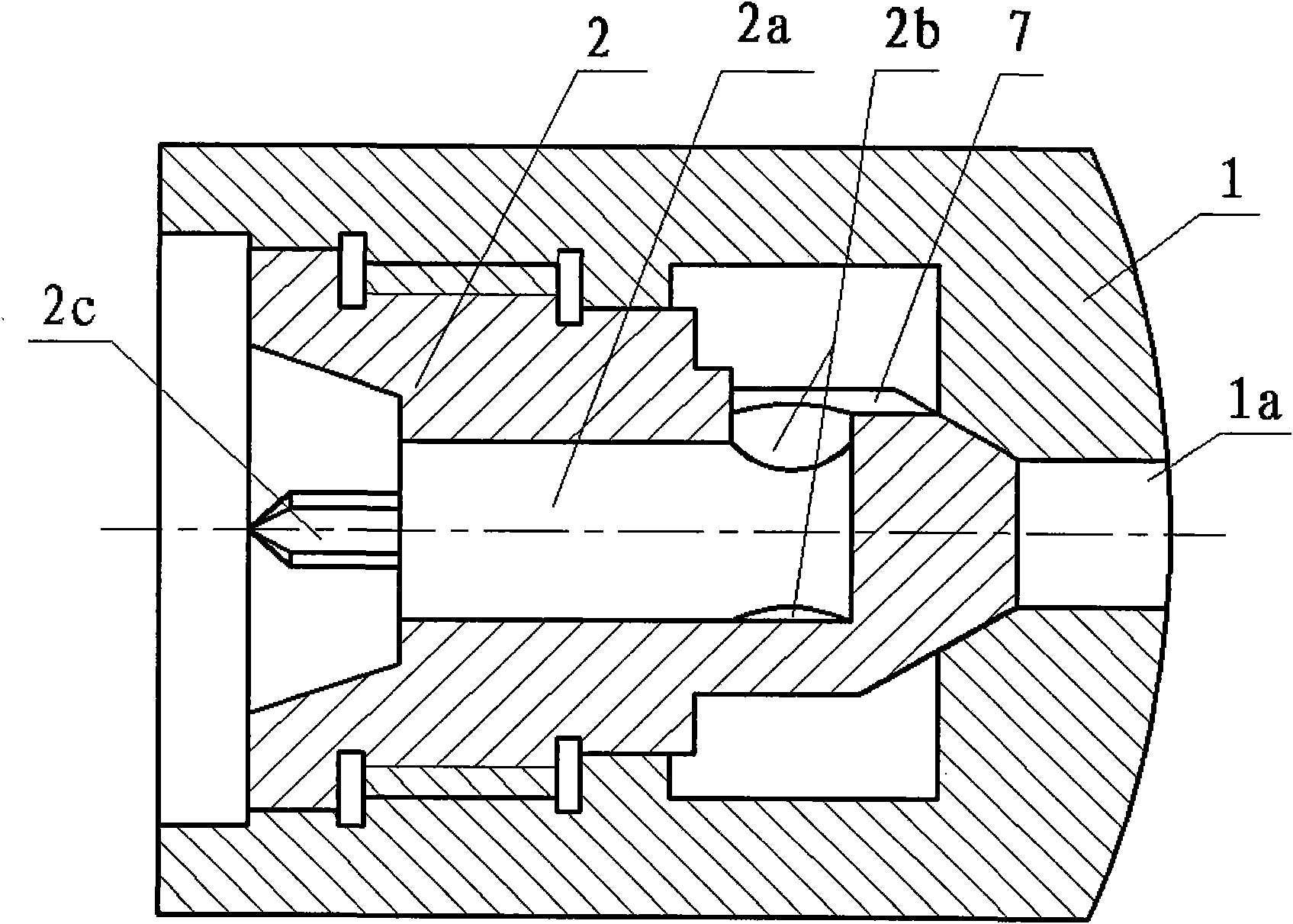

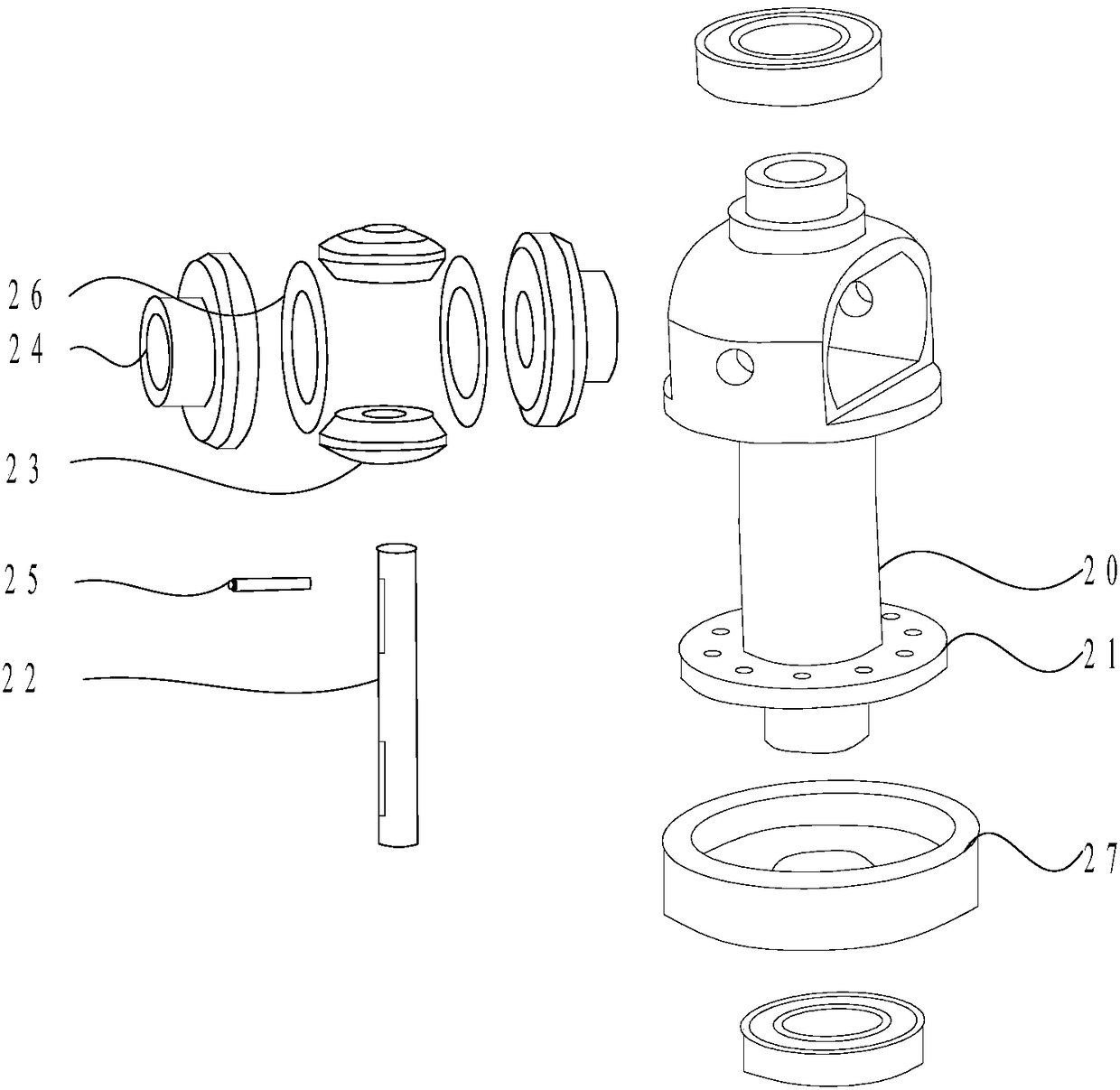

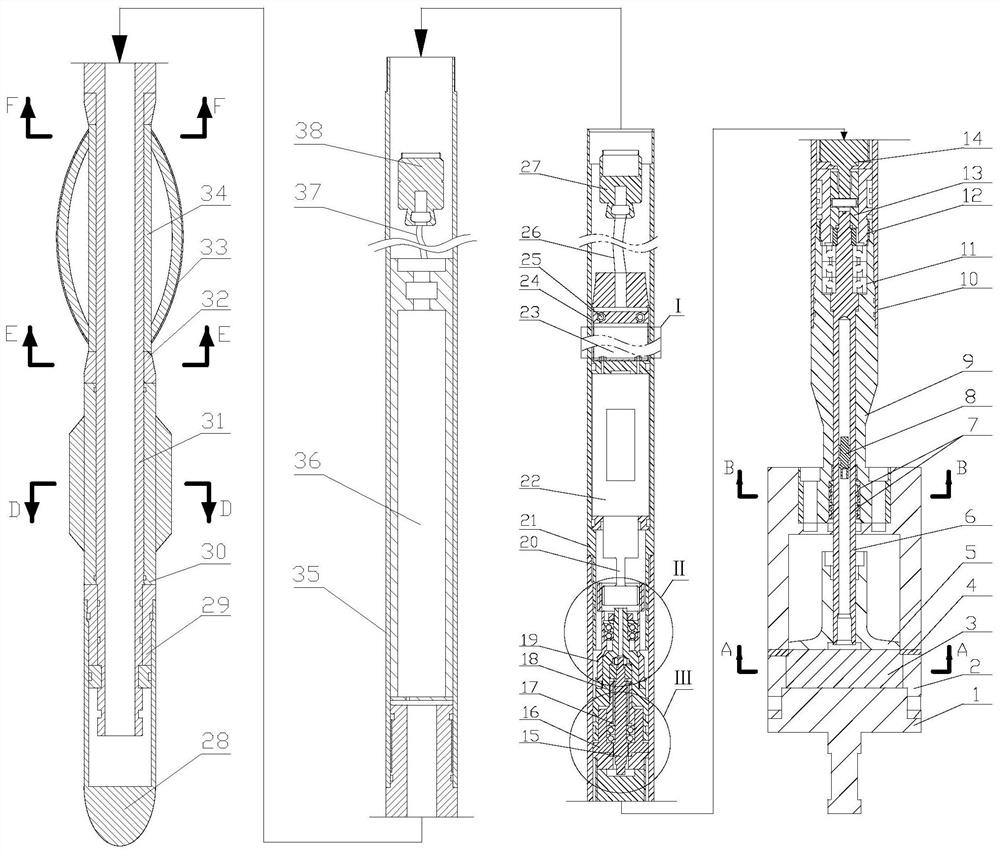

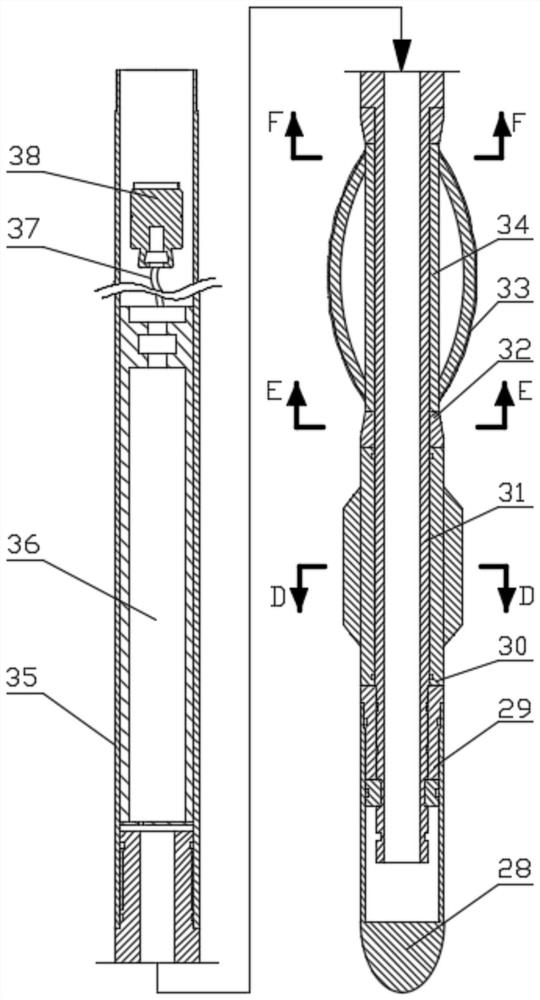

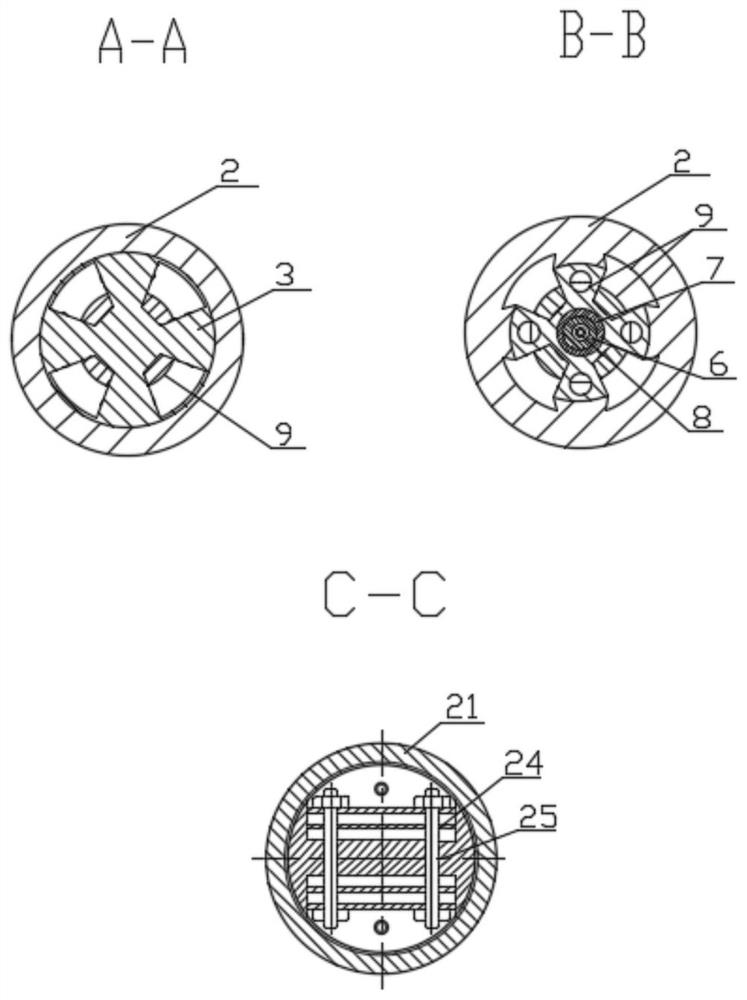

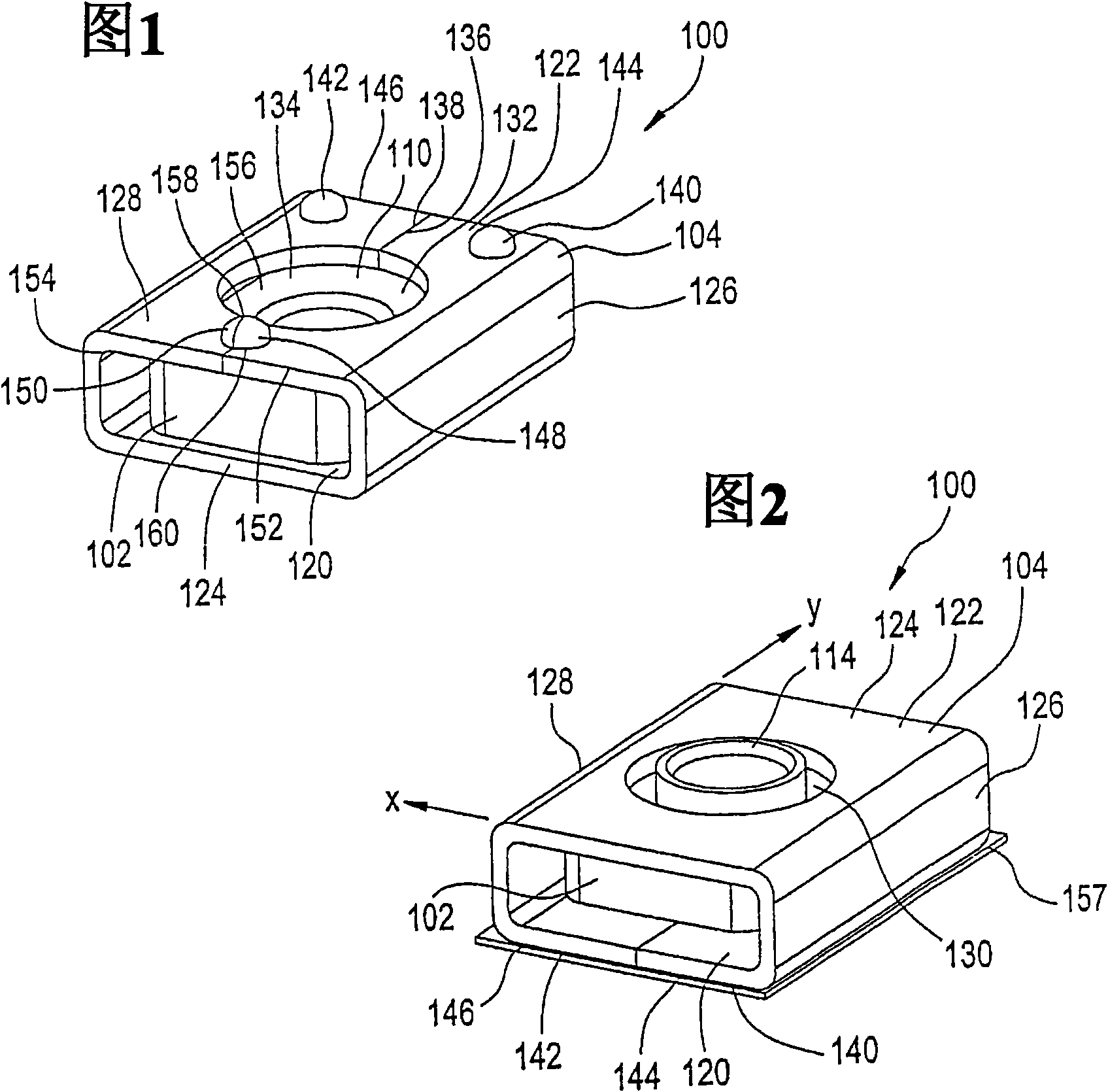

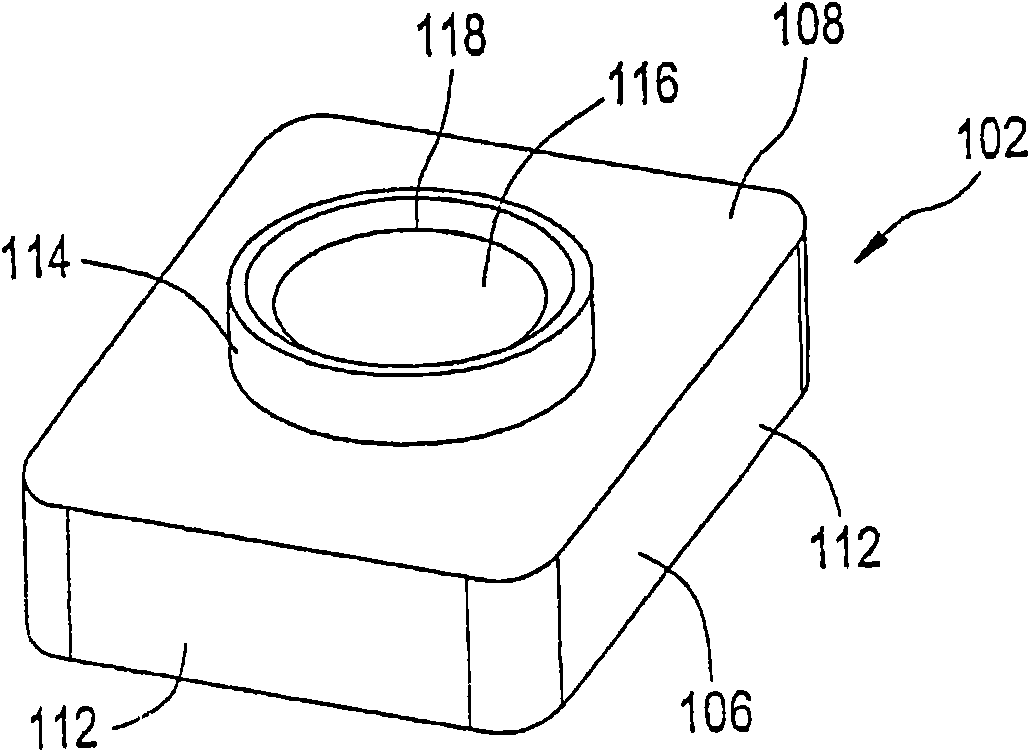

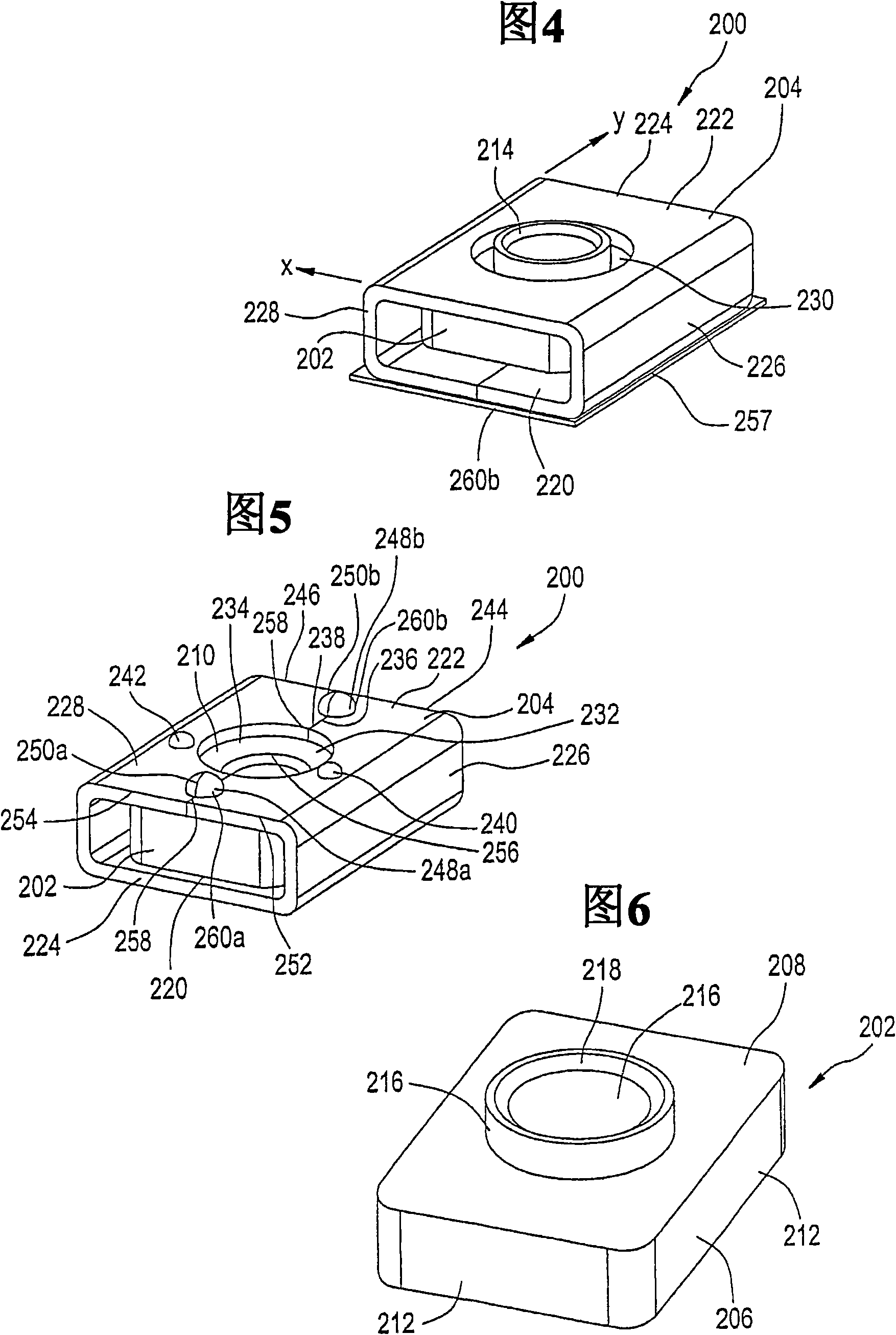

Adjustable water nozzle for oilfield water injection and water distributor with same

InactiveCN101936148ASmall drive torqueSimplified connection meshingFluid removalEngineeringDistributor

The invention discloses an adjustable water nozzle for oilfield water injection and a water distributor with the same, and belongs to the technical field of oilfield separate zone water injection. The adjustable water nozzle comprises a valve sleeve and a valve core, wherein the valve sleeve has a cavity structure and is provided with a water outlet hole; the valve sleeve is in threaded fit with the valve core; the valve core is in seal fit with the conical surface of the water outlet hole of the valve sleeve; the head of the valve core is provided with a side hole; a cavity is formed betweenthe valve sleeve and the valve core outside the side hole; a water inlet hole is formed in the valve core; and the tail part of the valve core is provided with a claw. The water distributor has a tube-shaped structure; the adjustable water nozzle is vertically arranged on the side of the water distributor and is communicated with the inner wall and the outer side of the water distributor; a bridge channel for water injection is formed in the wall of the water distributor; and a water nozzle adjuster for controlling the adjustable water nozzle is arranged in the water distributor. The adjustable water nozzle and the water distributor can accurately control water injection rate and are suitable to be popularized in the technical field of the oilfield separate zone water injection.

Owner:SOUTHWEST PETROLEUM UNIV

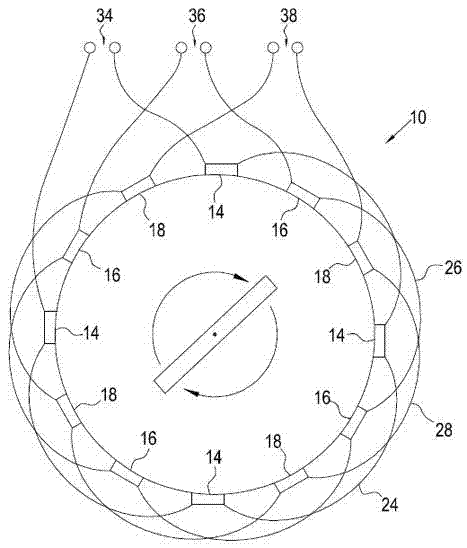

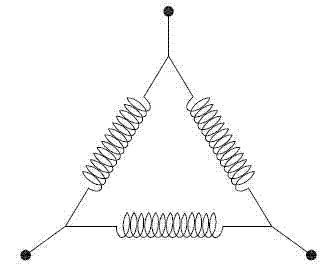

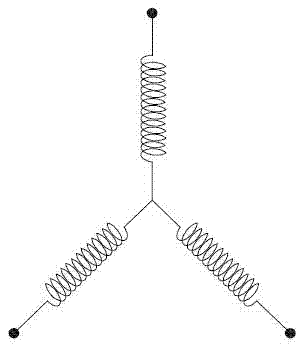

electric motor

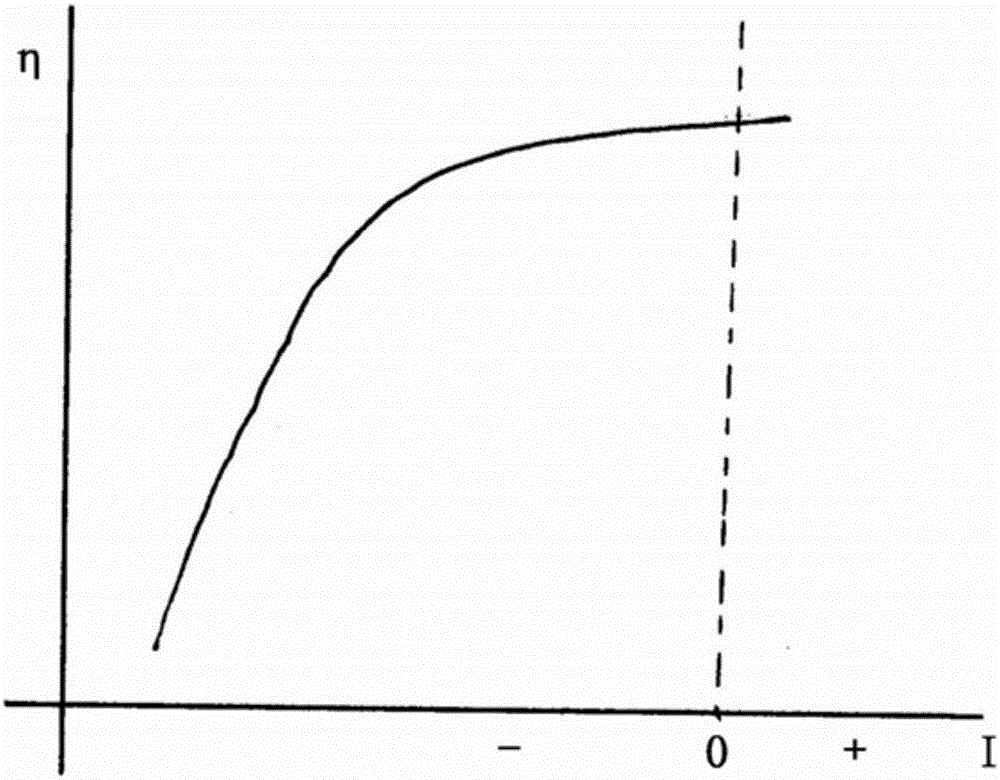

InactiveCN102263469AReduced Capacitor RequirementsMeet Torque DemandsWindingsAC motor controlControl theoryElectric motor

An electric motor arrangement comprising an electric motor having a rotor, a stator, a first coil set and a second coil set. The first coil set is arranged to form a first sub motor with a control device being arranged to control current in the first coil set to generate a first torque on the rotor. The second coil set is arranged to form a second sub motor with the control device being arranged to control current in the second coil set to generate a second torque on the rotor. The first sub motor is arranged to have a first torque efficiency profile and the second sub motor is arranged to have a second torque efficiency profile. A controller is provided to determine a first torque value generated by the first sub motor and a second torque value generated by the second sub motor in response to a requested torque demand based on a required torque efficiency profile for the electric motor.

Owner:PROTEAN ELECTRIC LIMITED

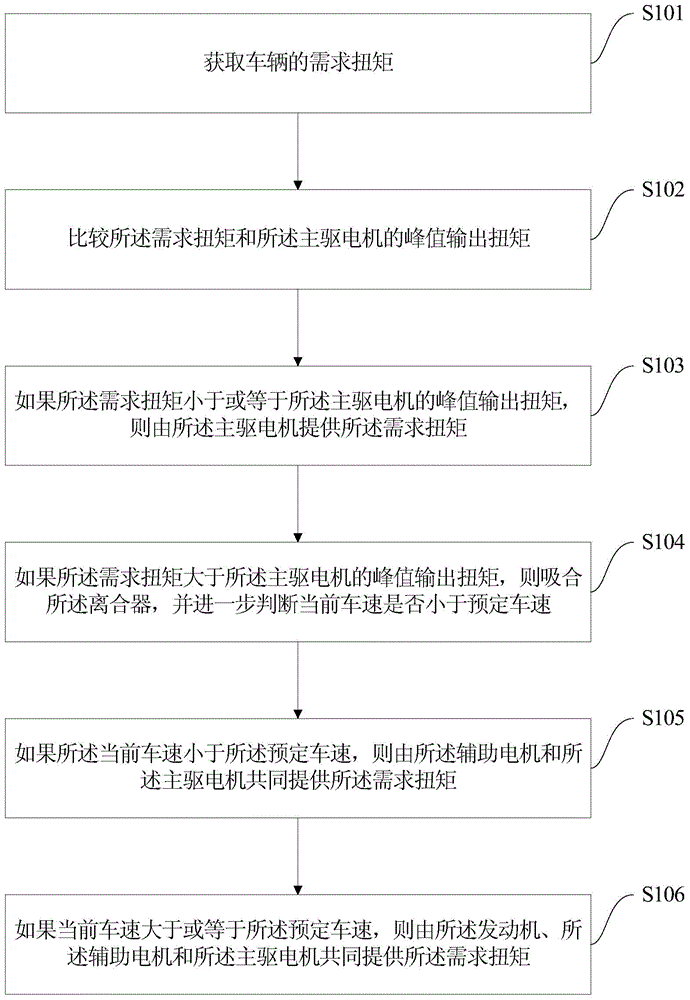

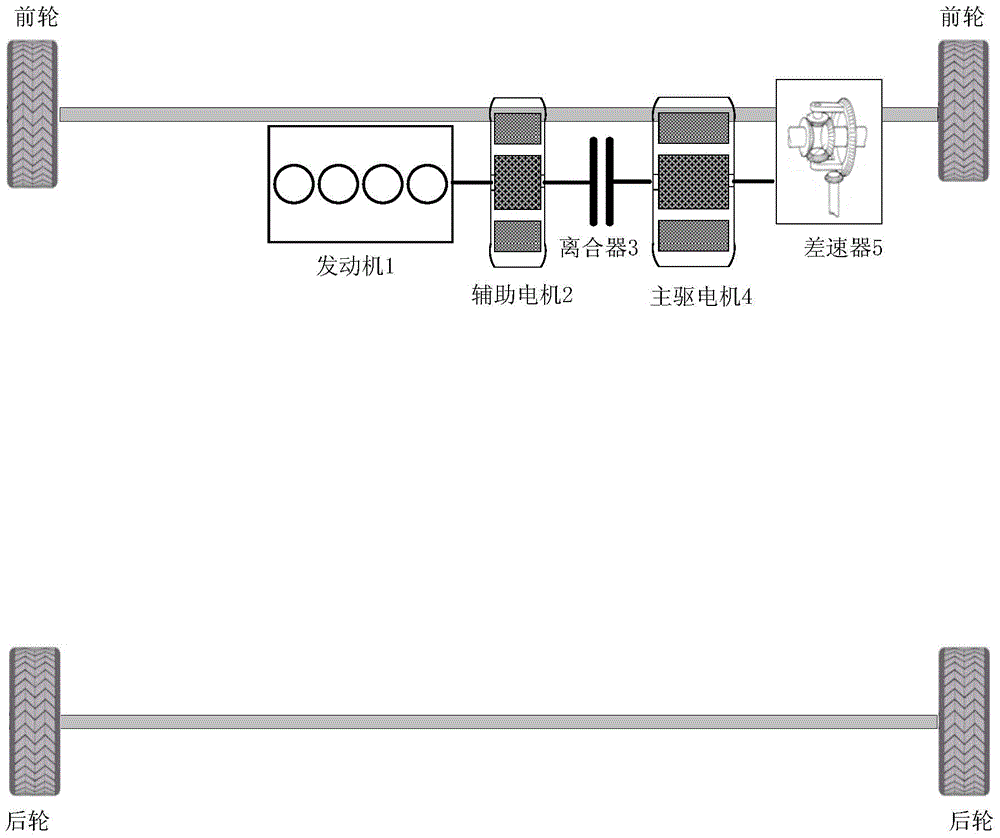

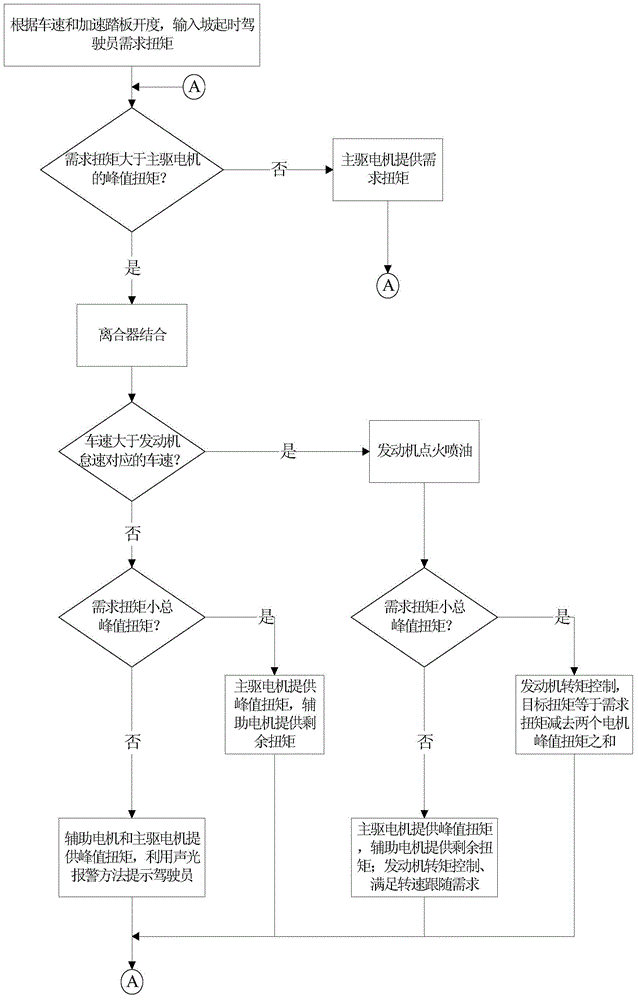

Hill starting control method, system of double-model HEV (Hybrid Electric Vehicle) and HEV

The invention provides a hill starting control method of a double-model HEV (Hybrid Electric Vehicle). The method comprises the steps of acquiring a demand torque of a vehicle; comparing a demand torque with a peak value output torque of a main drive motor; if the demand torque is less than or equal to the peak value output torque of the main drive motor, providing the demand torque by the main drive motor; if the demand torque is more than the peak value output torque of the main drive motor, attracting a clutch, and further judging whether the existing travel speed is less than the preset vehicle speed; if the existing vehicle speed is less than the preset vehicle speed, providing the demand torque by an auxiliary motor and the main drive motor; if the existing vehicle speed is greater than or equal to the preset vehicle speed, providing the demand torque by an engine, the auxiliary motor and the main drive motor. According to the hill starting control method of the double-model HEV provided by the invention, the stability of the vehicle can be ensured when the demand torque is larger (for example, the hill starting is carried out), and the power demand can be maximally met. The invention further provides a hill starting control system of the double-model HEV and an HEV.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

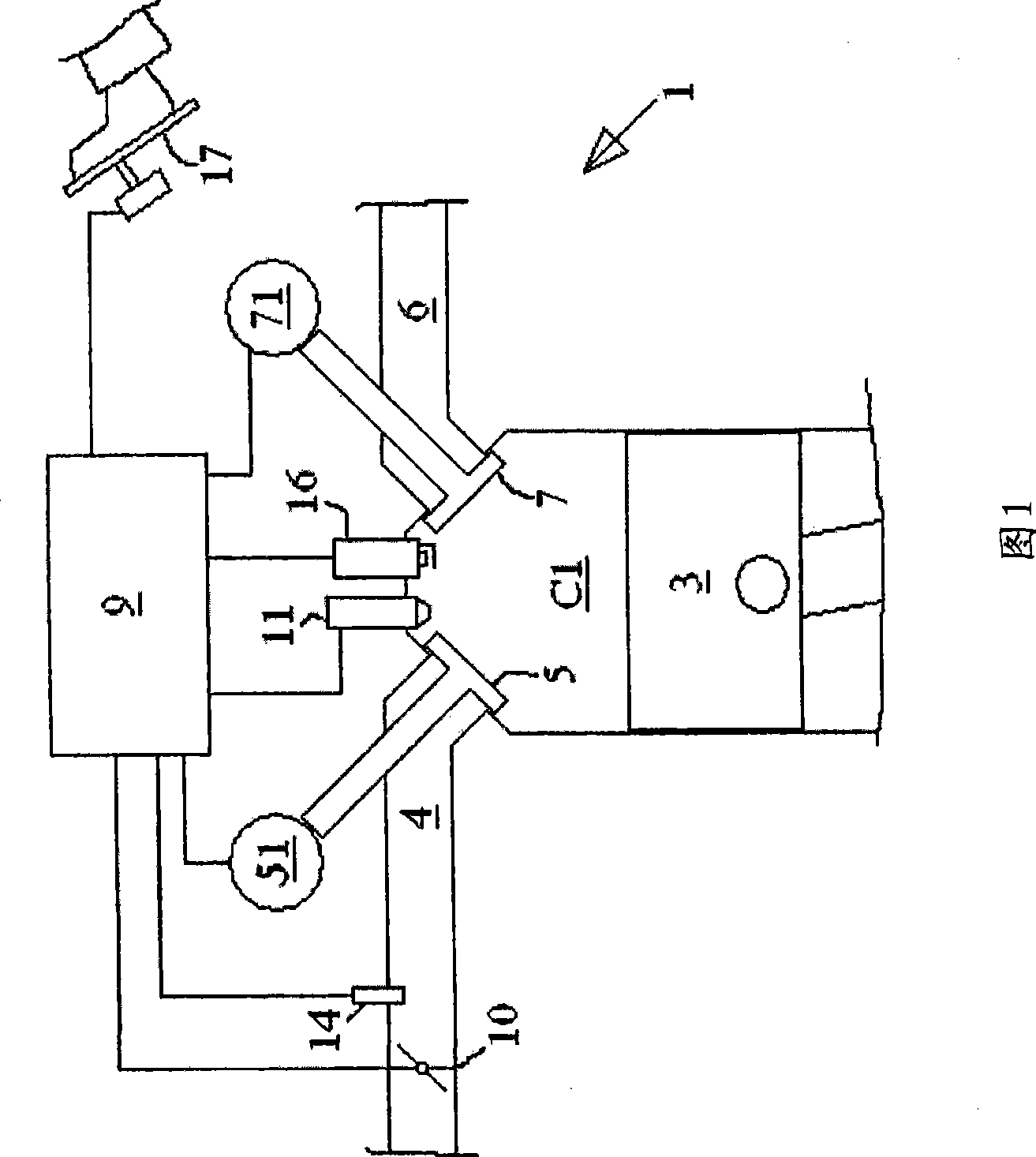

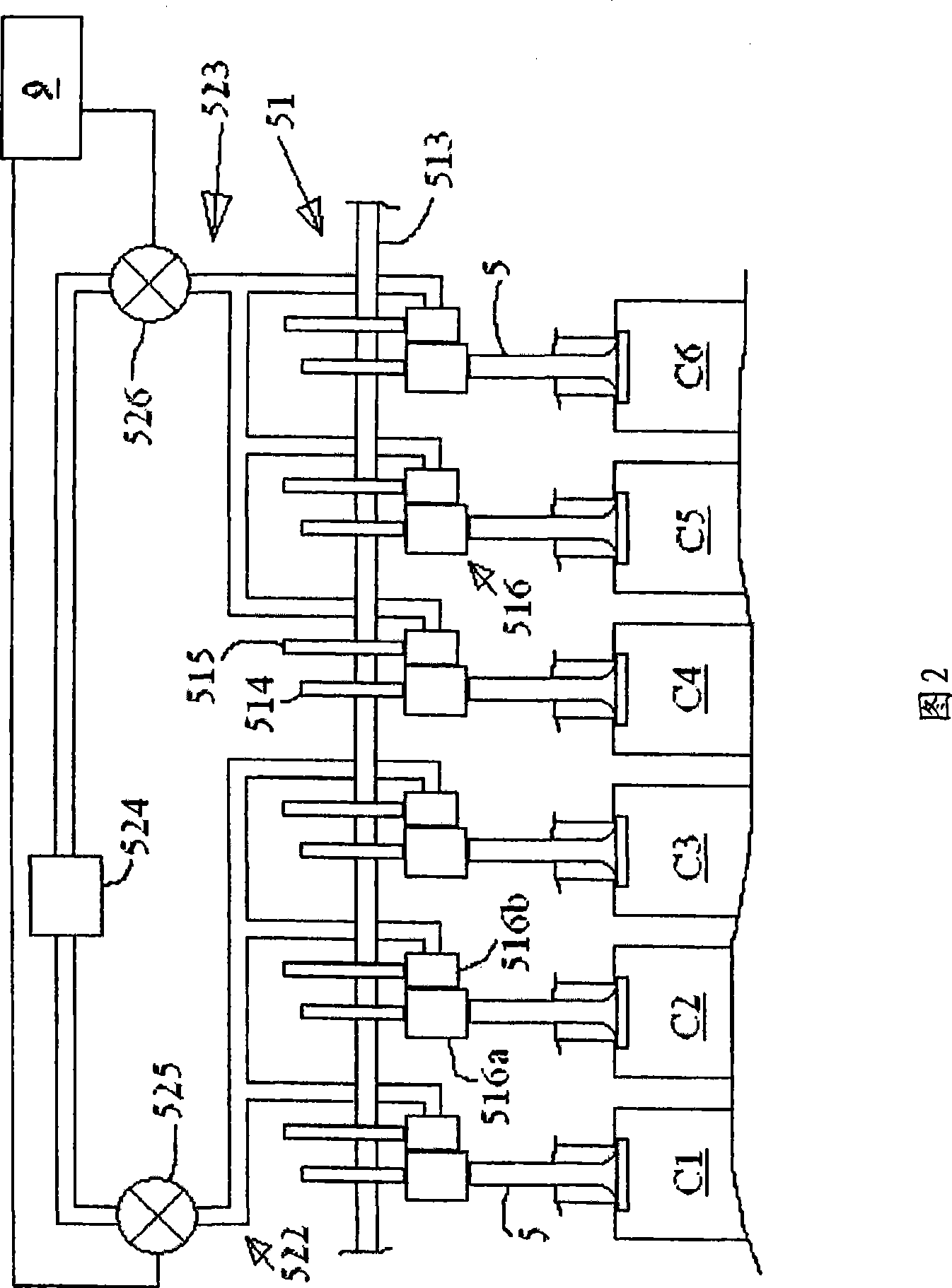

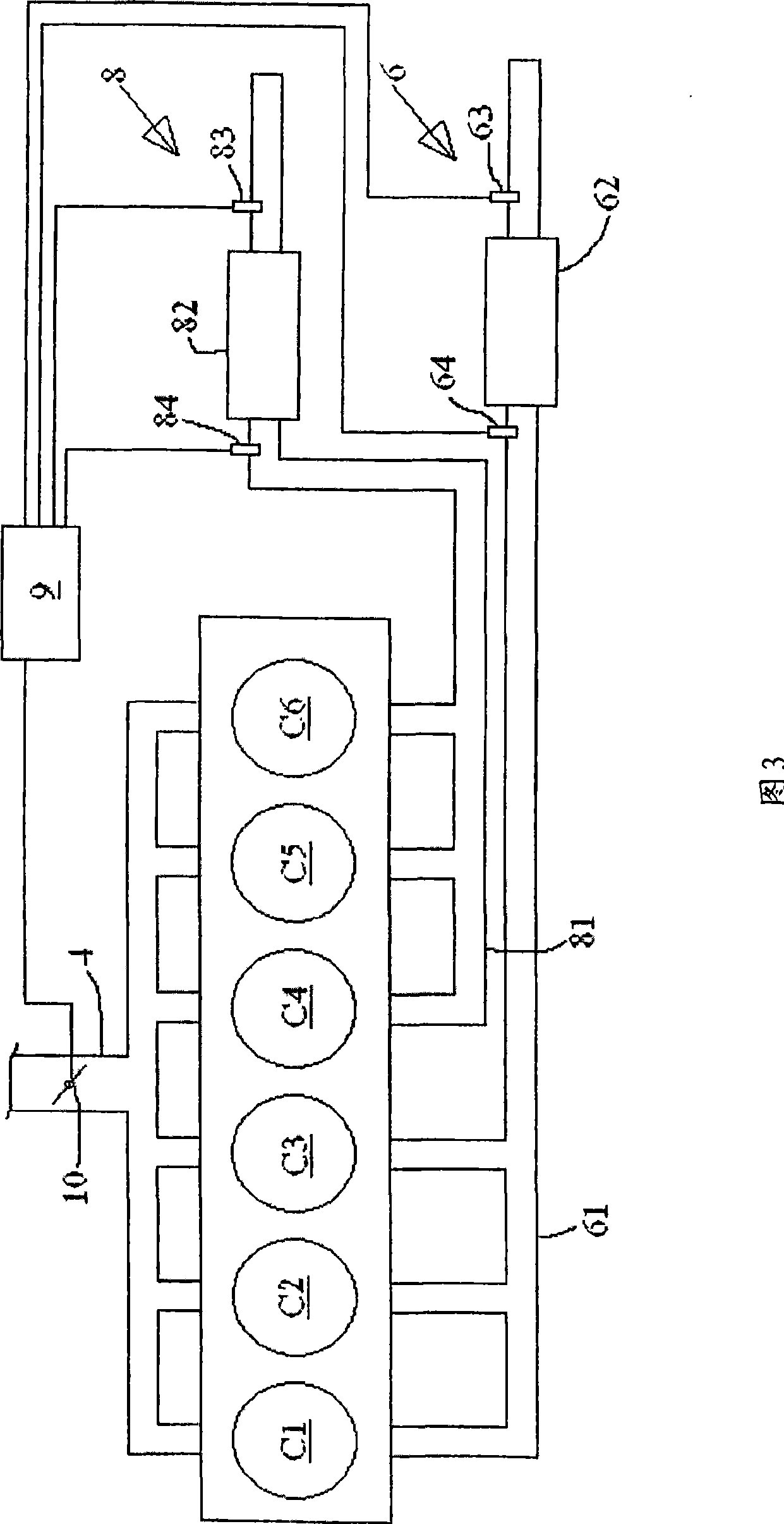

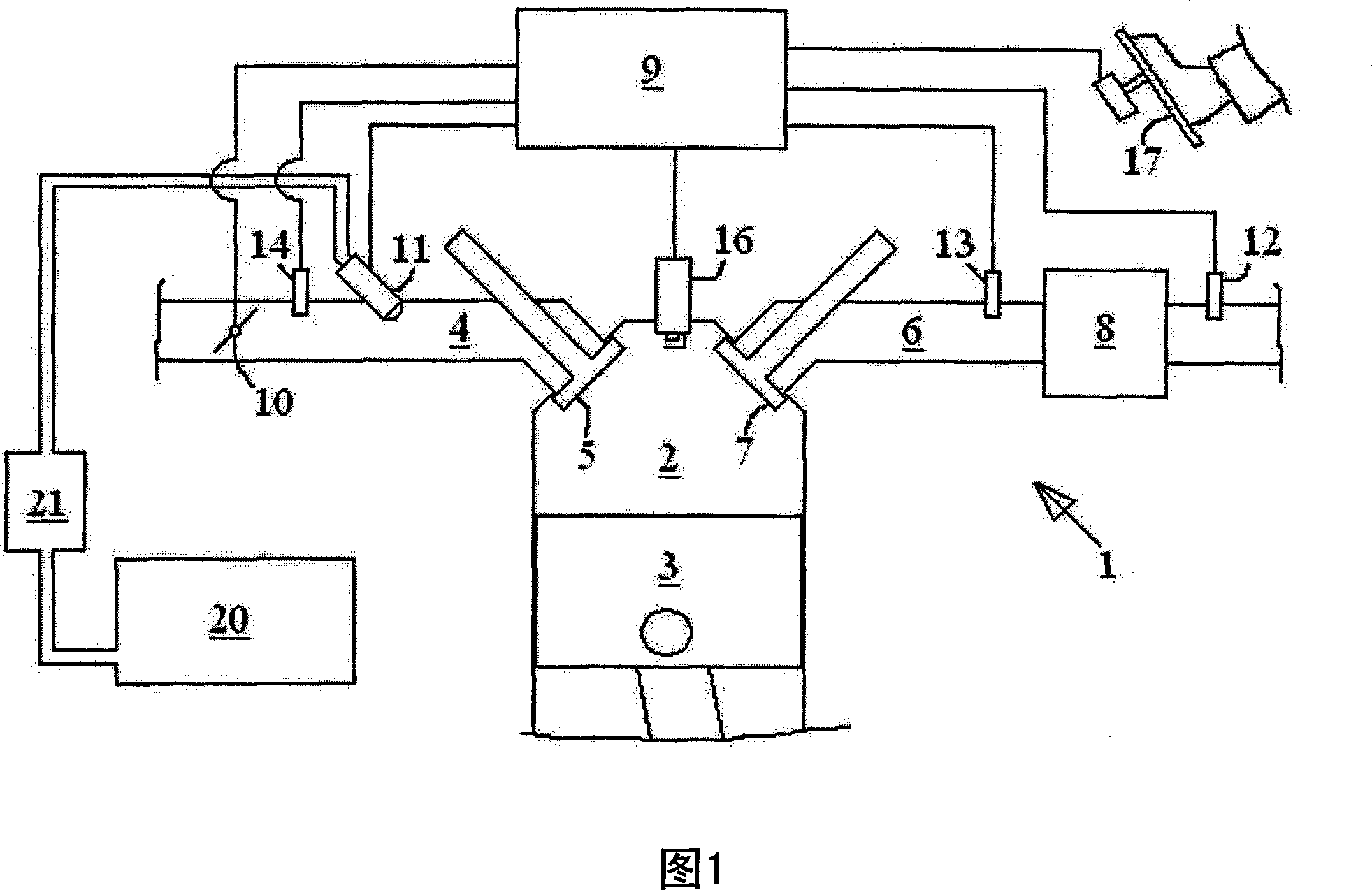

An internal combustion engine system, and a method in such an engine system

InactiveCN101440740AExpand the scope of operationReduce consumptionElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

The invention relates to an engine system, and a method in an engine system comprising an internal combustion engine having at least two cylinders (C1-C6) at each of which a piston (3), at least one inlet valve (5), at least one exhaust valve (7), and fuel injection means (11), for injection of fuel directly into the cylinder (C1-C6), are provided, the engine system also comprising an engine control unit (9). The engine control unit (9) is adapted to control the engine so as to operate in a homogenous charge compression ignition mode (HCCI) in at least one of the cylinders (C1-C3), and simultaneously operate in another ignition mode (SI) in at least one of the remaining cylinders (C4-C6).

Owner:FORD GLOBAL TECH LLC

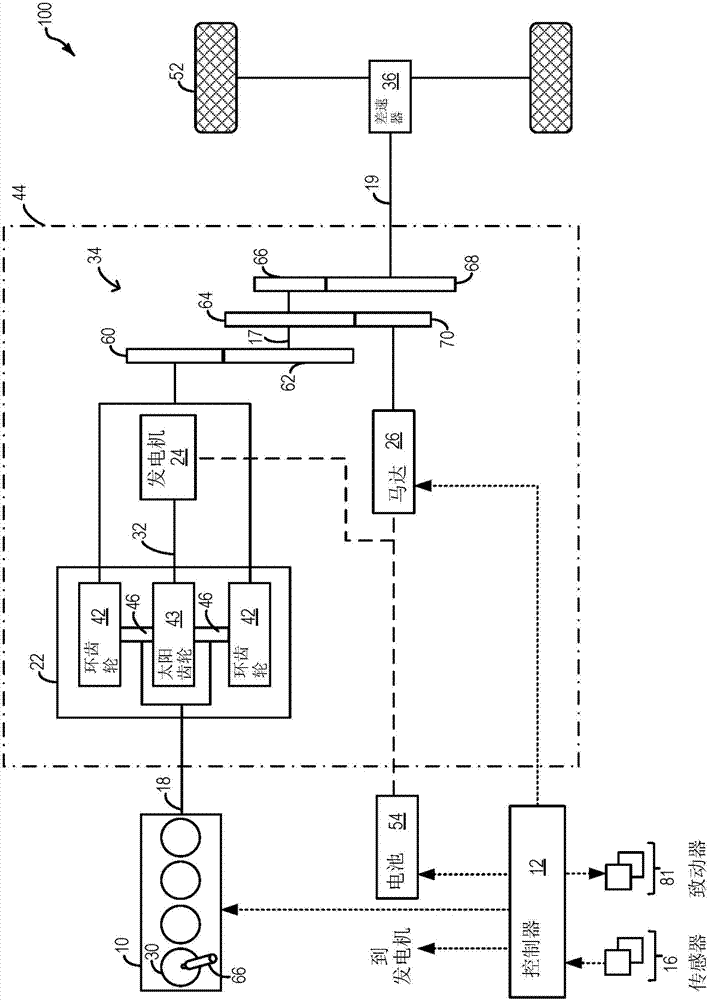

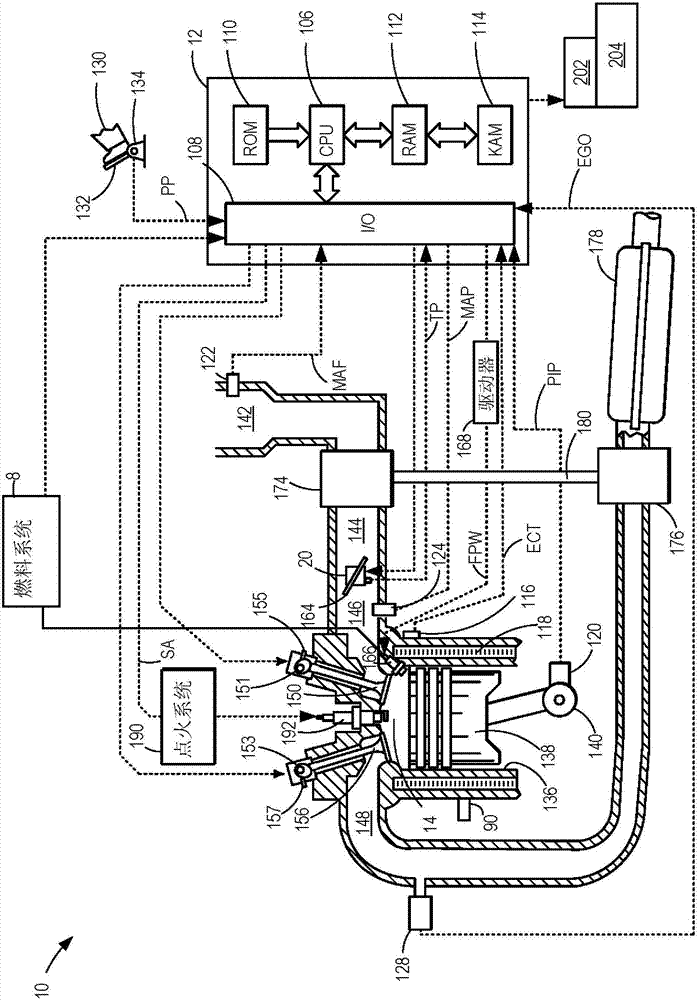

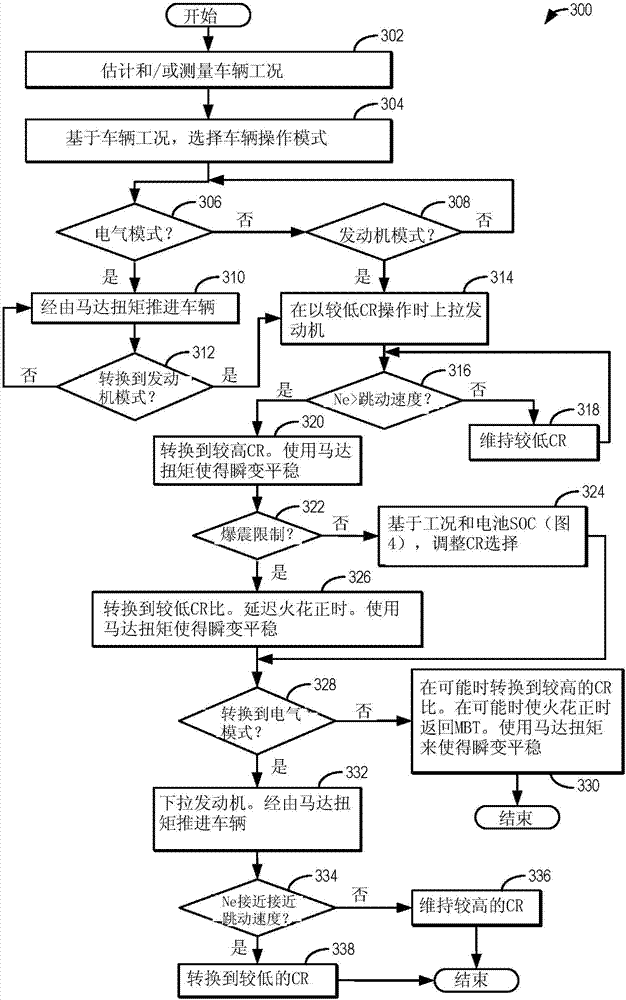

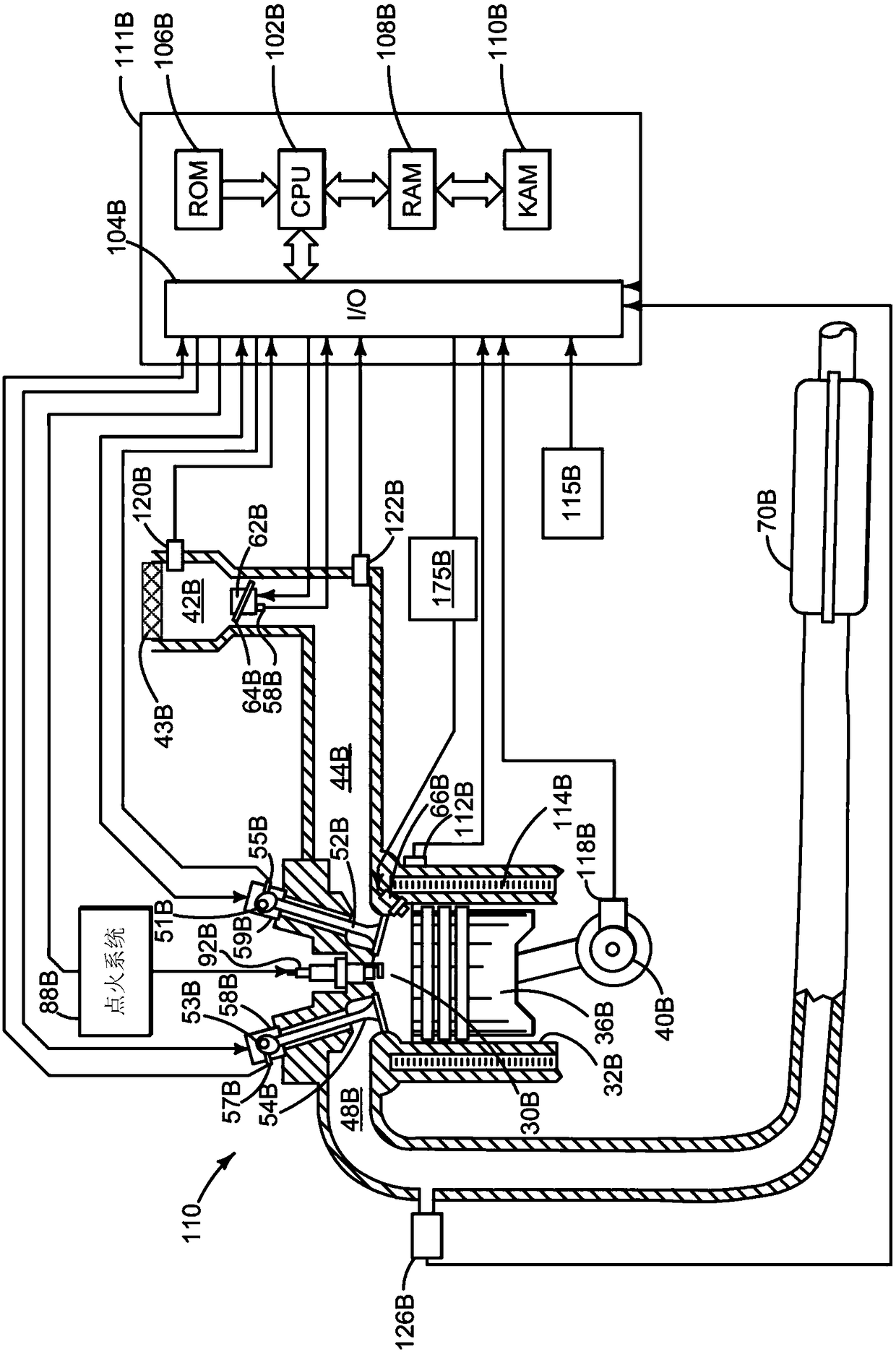

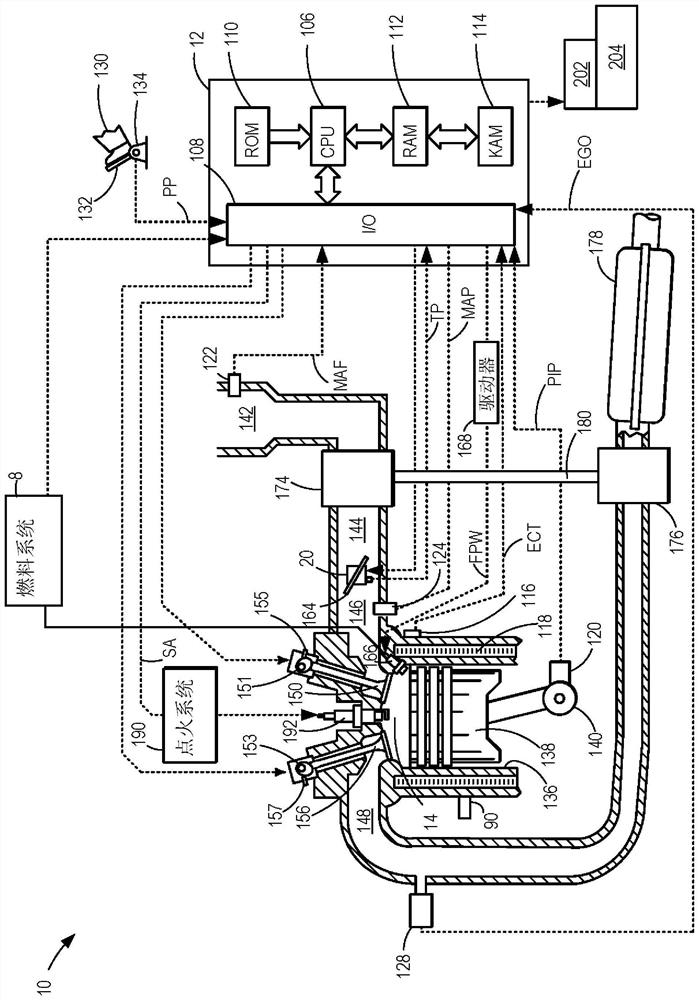

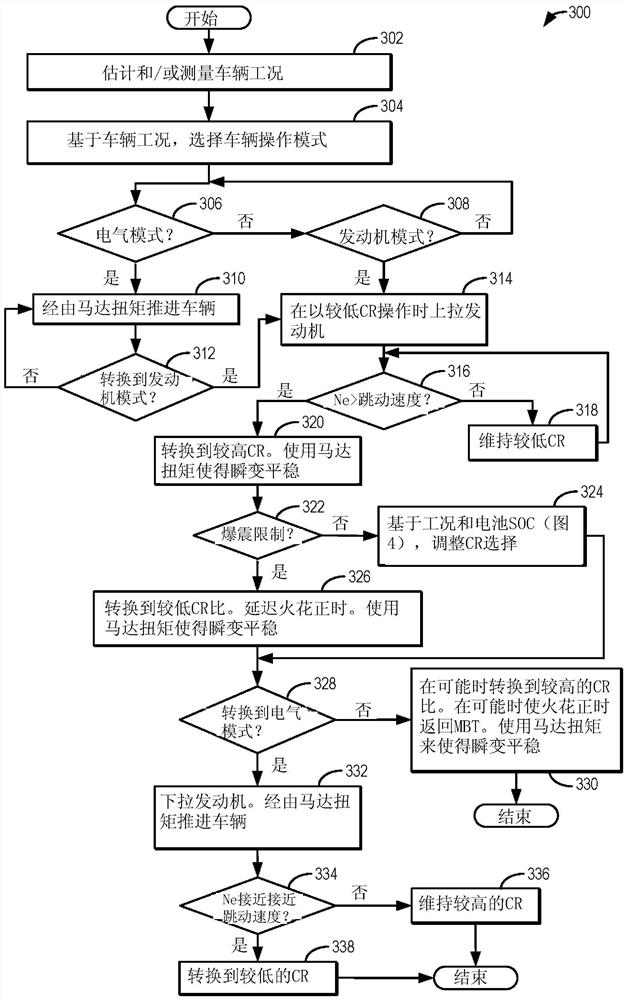

Method and system for engine control

ActiveCN107345500AMeet Torque DemandsReduce economic lossHybrid vehiclesElectrical controlLow speedHybrid vehicle

The invention relates to a method and system for engine control. Methods and systems are provided for synergizing the benefits of a variable compression ratio engine in a hybrid vehicle system. A vehicle controller may hold the engine in a lower compression ratio during engine pull-ups and pull-downs, in particular when passing through a low speed region where compression bobbles can occur. During engine operation, in response to a change in driver demand, the controller may opt to switch the compression ratio or maintain a current compression ratio while smoothing a torque deficit using motor torque, the selection based on fuel economy.

Owner:FORD GLOBAL TECH LLC

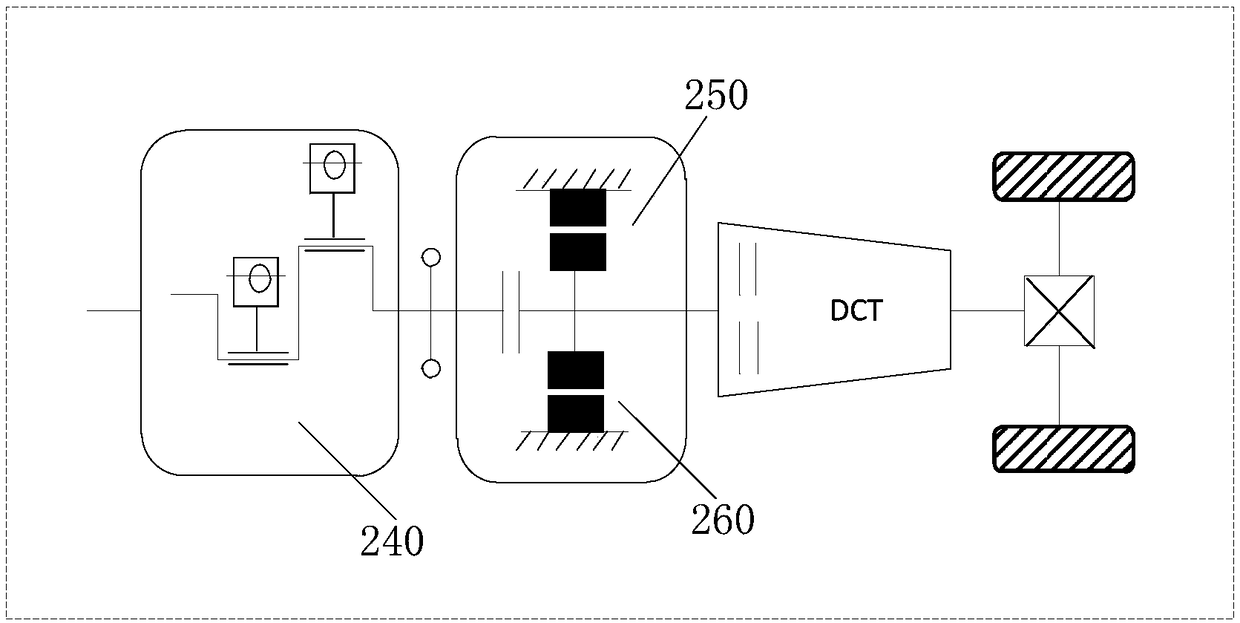

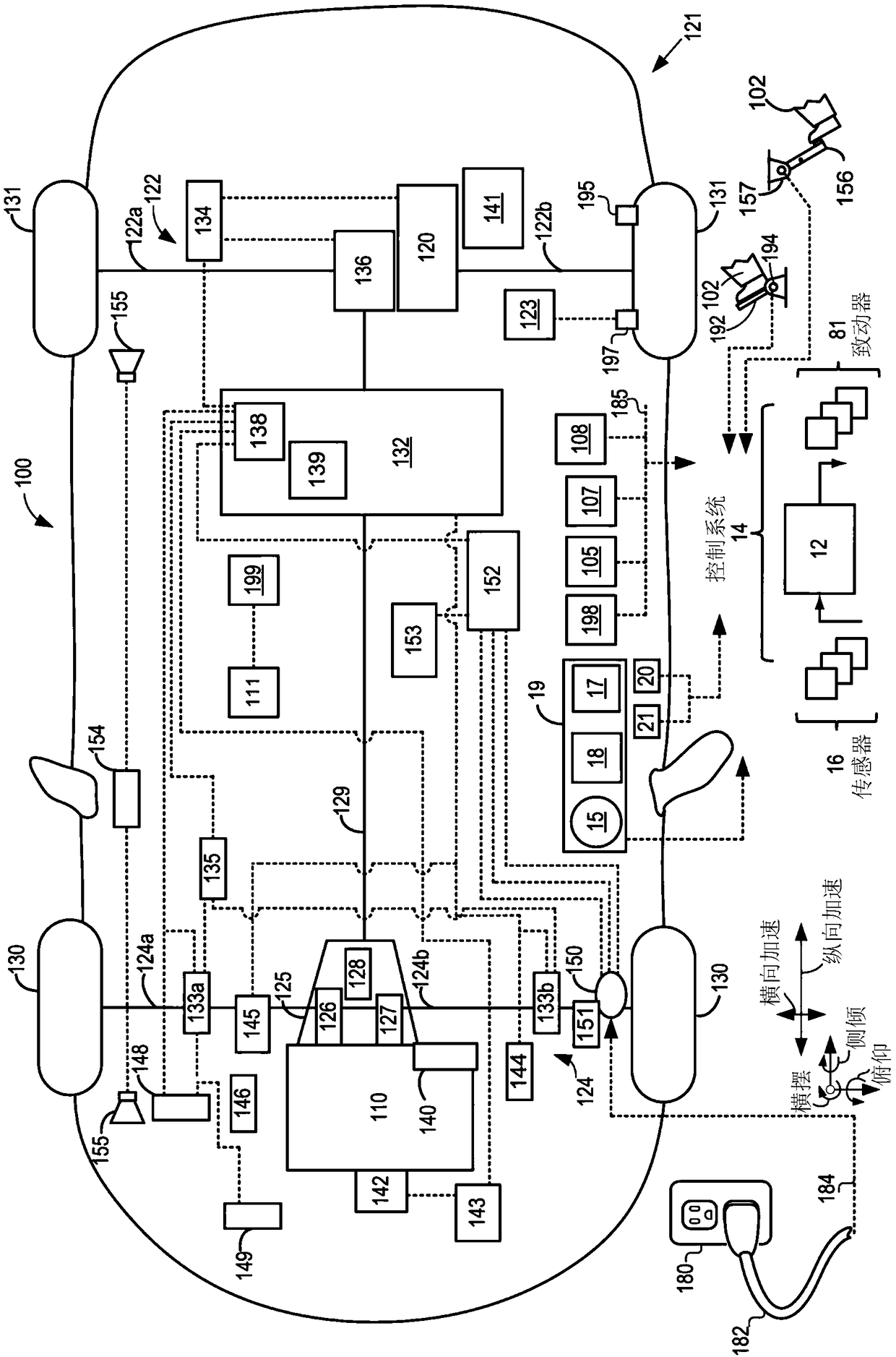

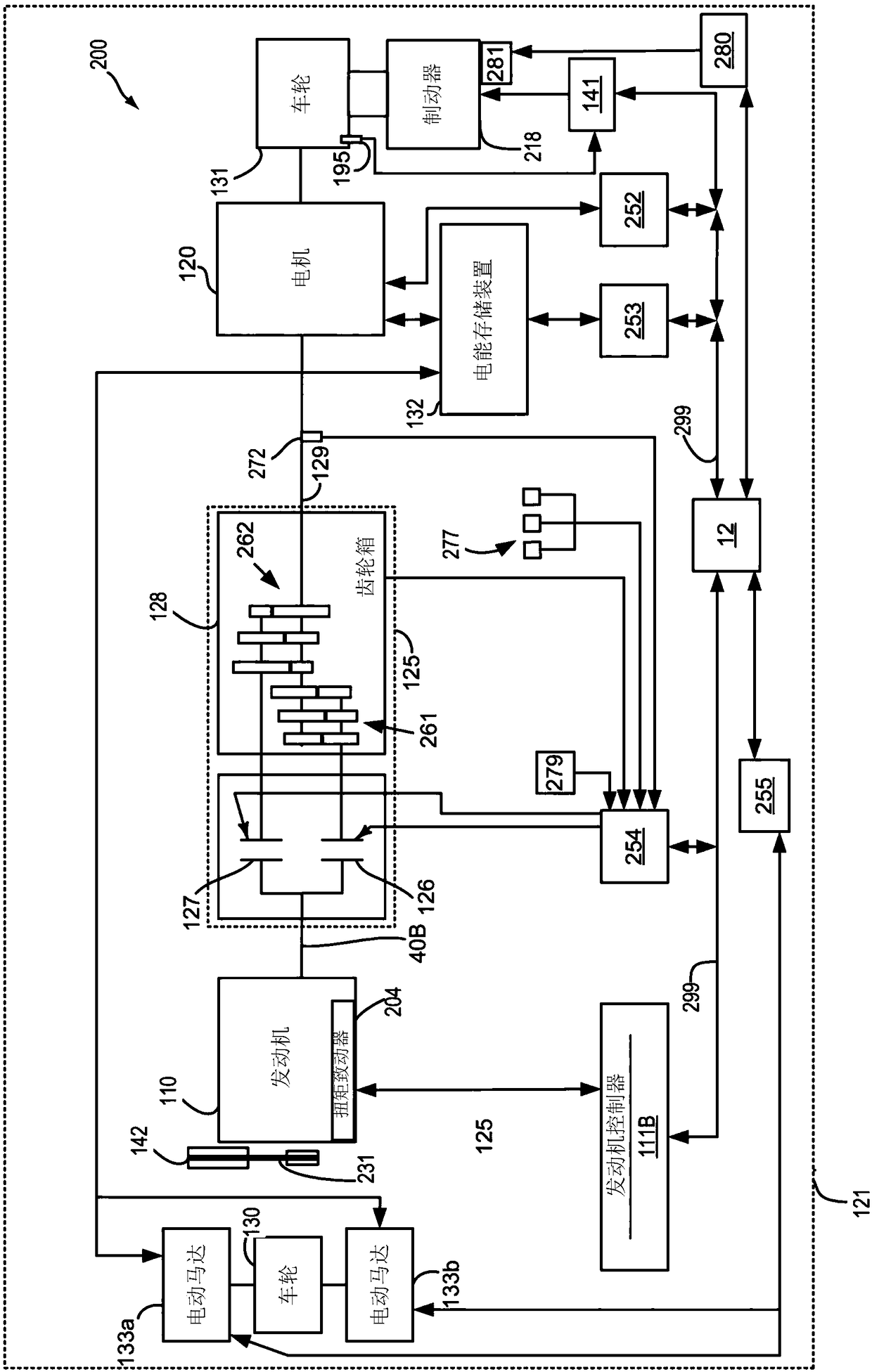

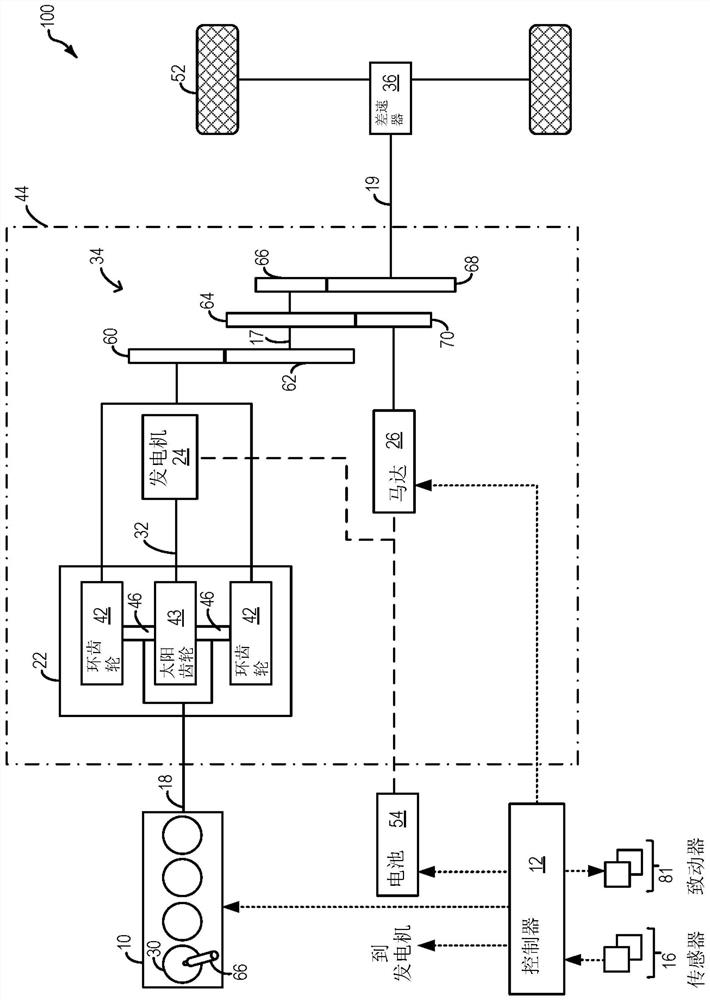

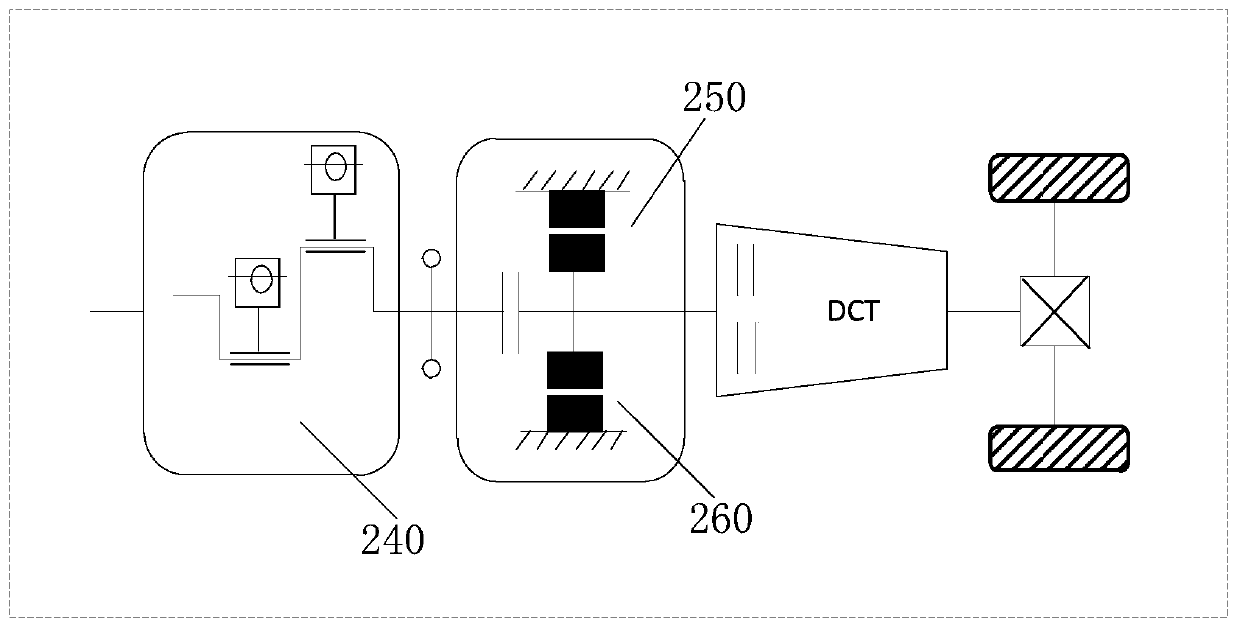

Systems and methods for meeting wheel torque demand in hybrid vehicle

ActiveCN108437975AOutput satisfiesOutput assist to meet wheel torque demand meetHybrid vehiclesVehicle sub-unit featuresDriver/operatorElectric machinery

The present invention discloses systems and methods for meeting wheel torque demand in a hybrid vehicle. The hybrid vehicle comprises an engine, a dual clutch transmission coupled to a driveline of the vehicle downstream of the engine, and an electric machine coupled to the driveline downstream of the dual clutch transmission. In one example, a method comprises transferring transmission input torque through a clutch of the dual clutch transmission controlled to a first capacity, and in response to a desired transmission input torque exceeding the capacity, increasing torque output of the electric machine coupled downstream of the dual clutch transmission to assist in meeting a wheel torque demand. In this way, a driver-requested increase in acceleration may be met under conditions where transmission input torque is limited by clutch capacity.

Owner:FORD GLOBAL TECH LLC

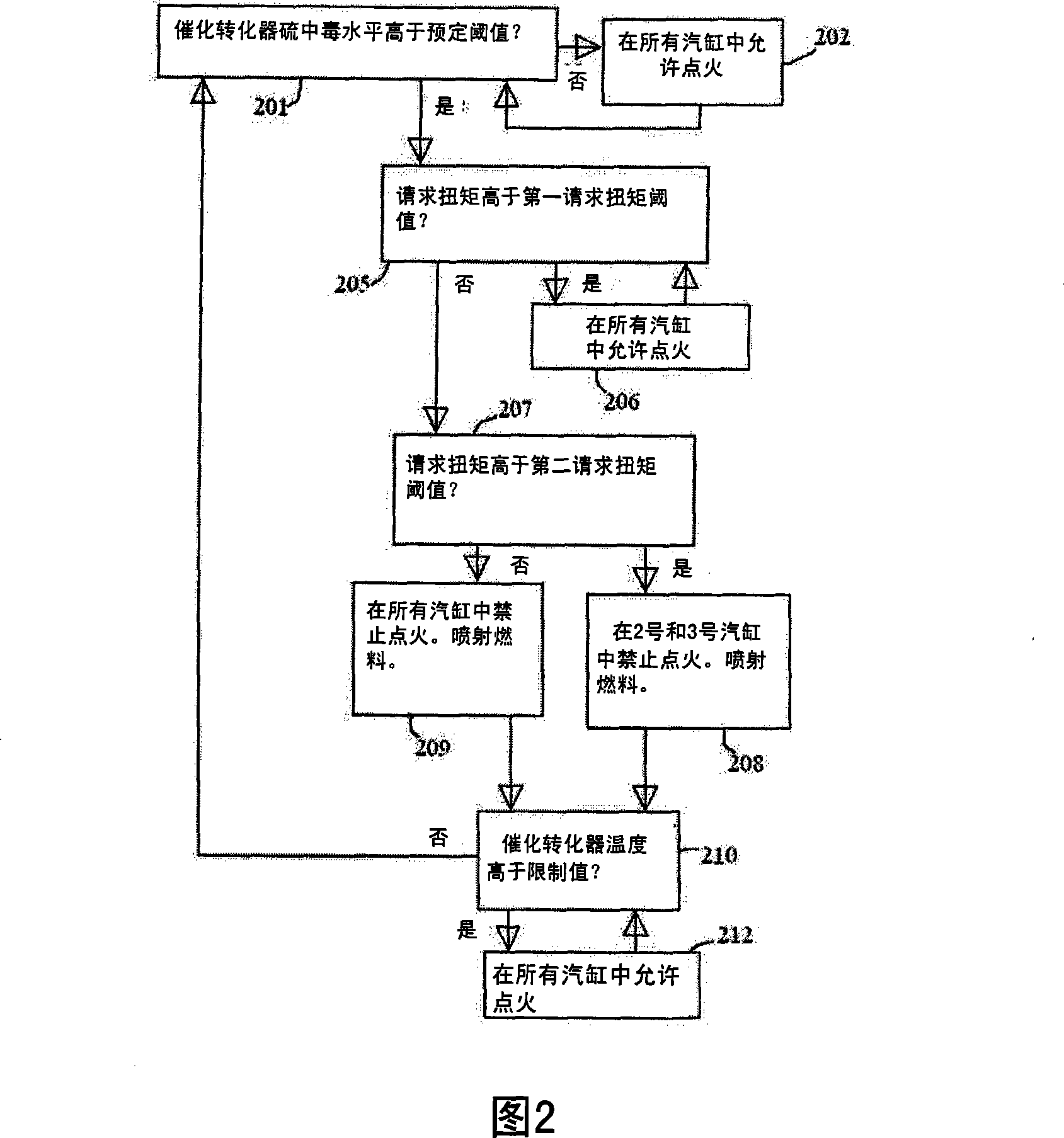

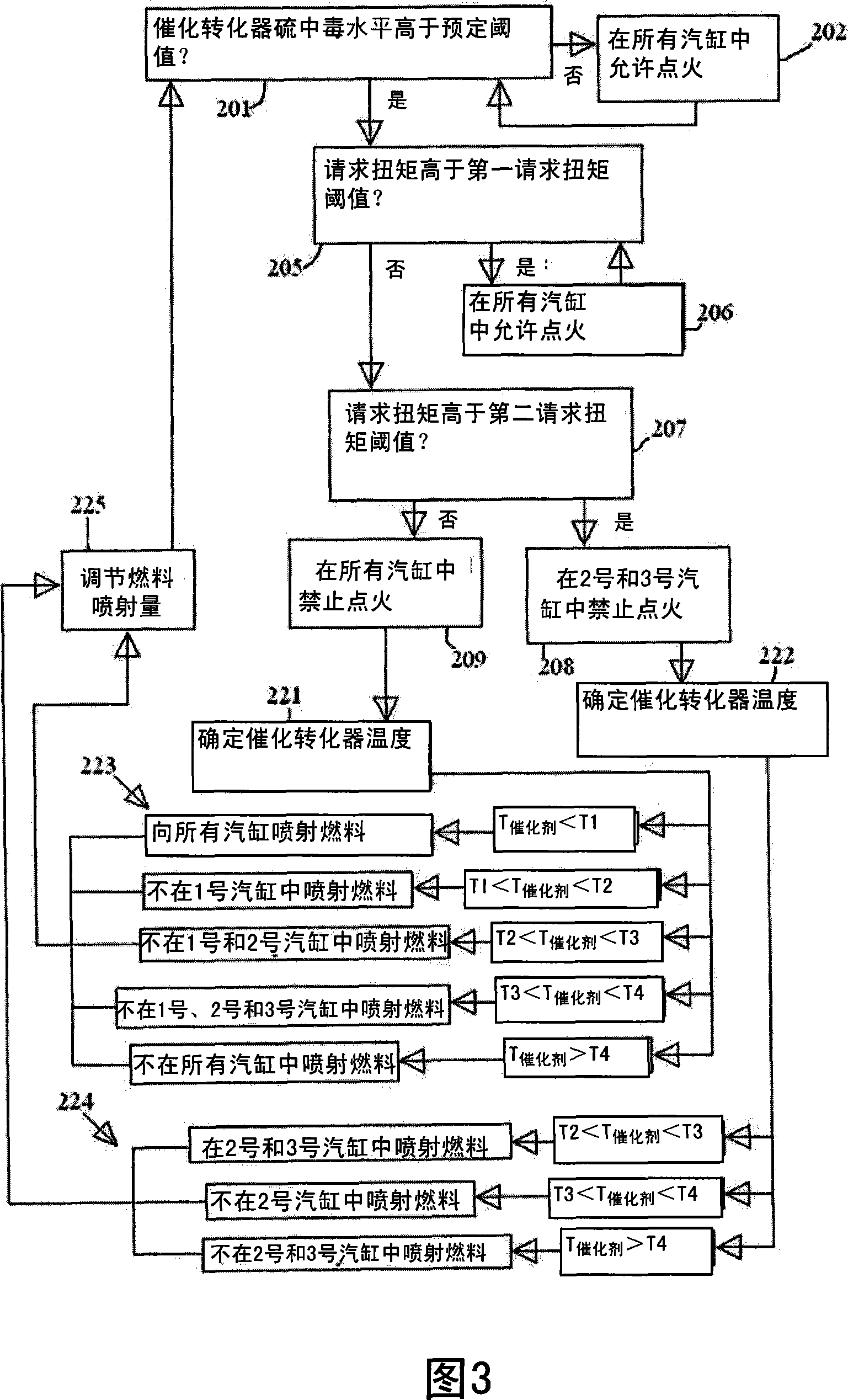

Exhaust gas treatment device regeneration inhibiting fuel combustion in engine cylinder

ActiveCN101205826AMinimize the risk of damageEfficient regenerationElectrical controlInternal combustion piston enginesCombustionExternal combustion engine

A method for an exhaust gas treatment device (8) in an engine system, and an engine system comprising an internal combustion engine with at least one cylinder (2) are presented. The engine system further comprises fuel injection means (11) and an exhaust gas treatment device (8). The method comprises performing a combustion inhibition exhaust gas treatment device regeneration (208, 209, 223, 224,225), comprising inhibiting combustion in at least one of the cylinders (2), and controlling the fuel injection means (11) so that fuel is allowed into at least one of the cylinders (2) in which combustion is inhibited.

Owner:VOLVO CAR CORP

Drive axle assembly of variable-speed electric vehicle

PendingCN108591399ASolve the following technical problemsLower performance requirementsGearingGearing detailsGear wheelElectric vehicle

The invention discloses a drive axle assembly of a variable-speed electric vehicle. The drive axle assembly comprises a transmission, a differential mechanism assembly and a clutch, wherein the transmission comprises a first shaft, a second shaft and a middle shaft, wherein the axis of the first shaft and the axis of the second shaft are located on the same straight line, the second shaft is inserted into the first shaft, the middle shaft is located below the first shaft and the second shaft, and a large gear of a reduction gear set on the middle shaft is connected with a primary reduction main gear of the second shaft; a second-stage speed reducing driven gear on the differential mechanism assembly is connected with a small gear of the speed reducing gear set on the middle shaft, and thefirst shaft is connected in an clutch internal gear of the clutch. According to the assembly, the structure is adopted by the drive axle assembly of the variable-speed electric vehicle, so that the using performance of the electric vehicle is effectively improved, so that the structure of the driving axle is compact, the driving axle can adapt to multiple road conditions, and the endurance mileageof the whole vehicle is increased.

Owner:保定市信达车桥配件制造有限公司

Torque modulation for internal combustion engine

InactiveCN105683559AMeet Torque DemandsAvoid incomplete combustionElectrical controlOutput powerExternal combustion engineEngineering

A method and apparatus for continually and rapidly adjusting the output torque of an engine according to a torque demand uses an active tappet to vary the instant air charge in a combustion chamber. The invention allows substantially efficient combustion throughout the engine operating map. Various methods of changing the charge of air are disclosed.

Owner:JAGUAR LAND ROVER LTD

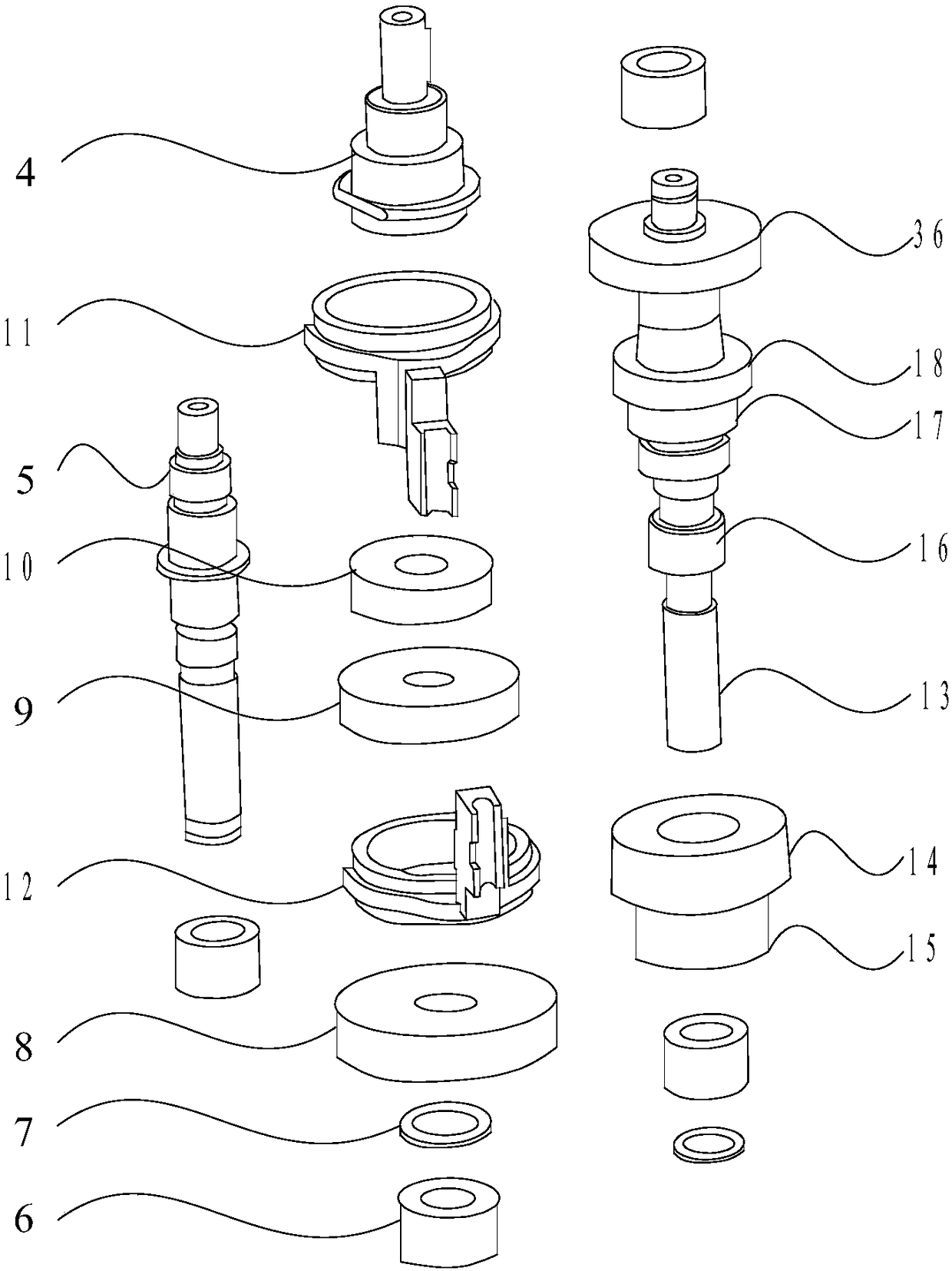

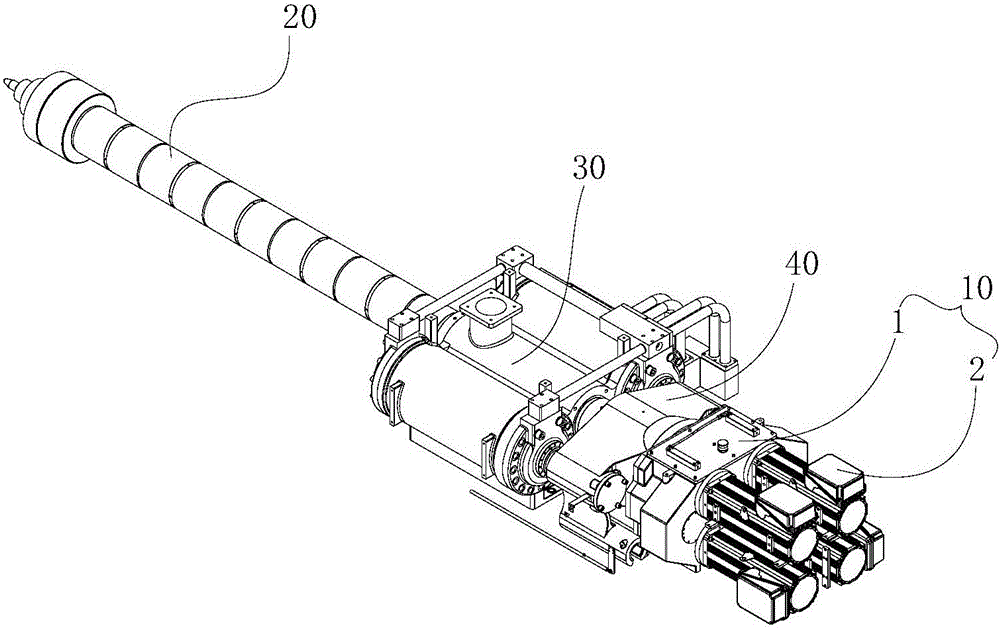

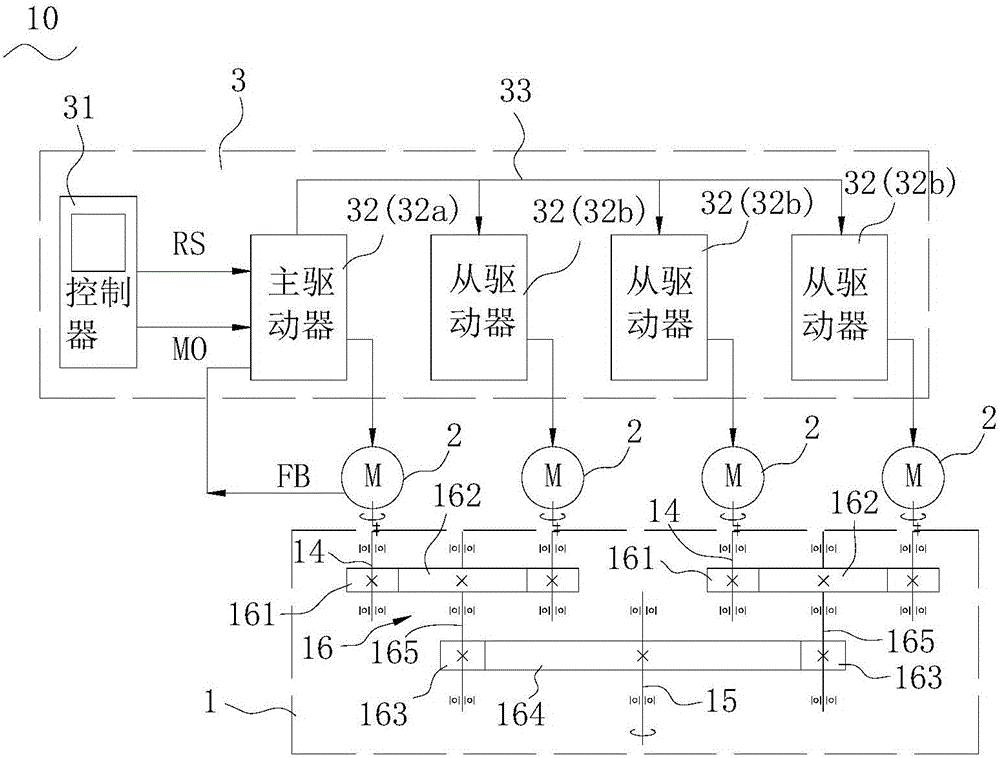

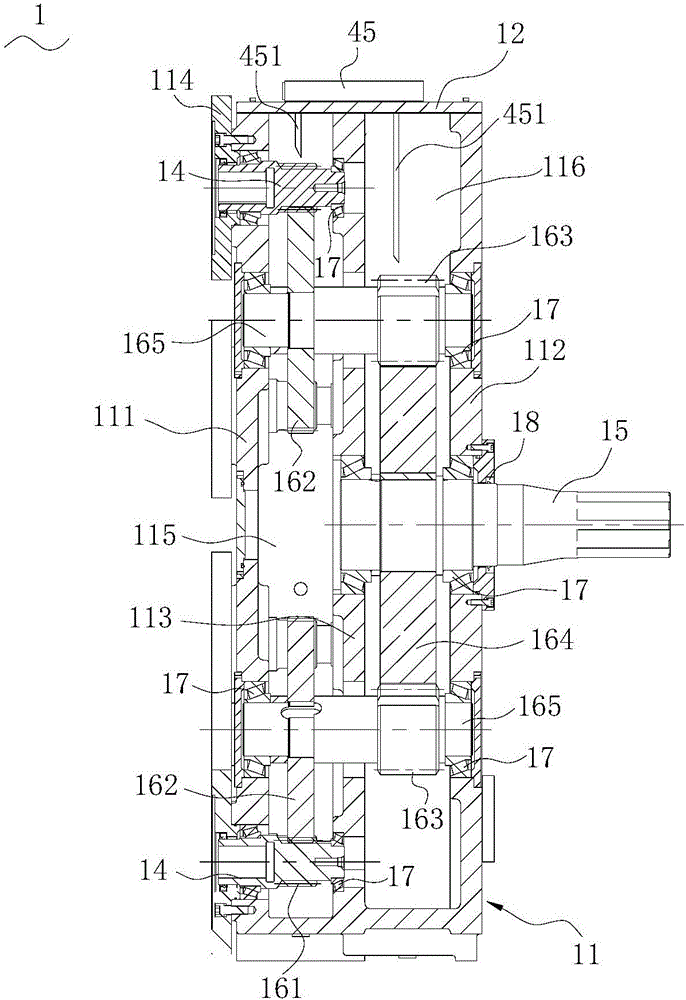

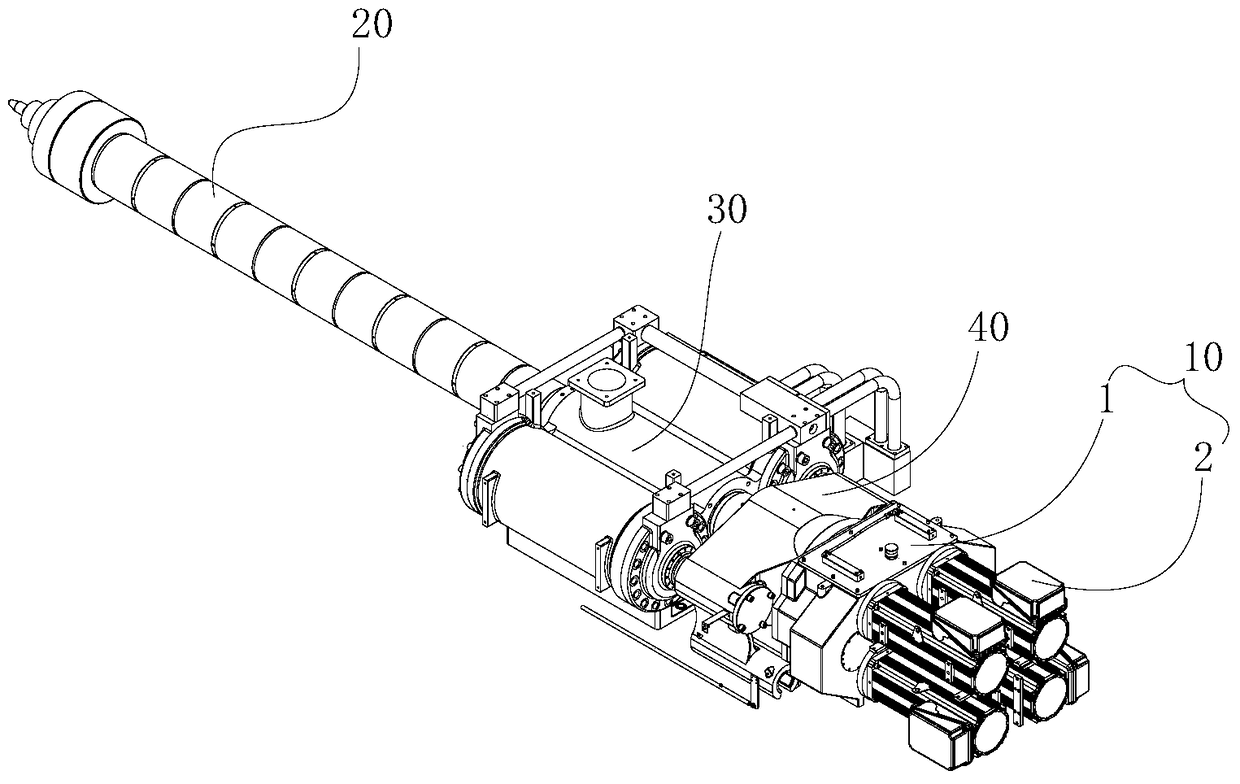

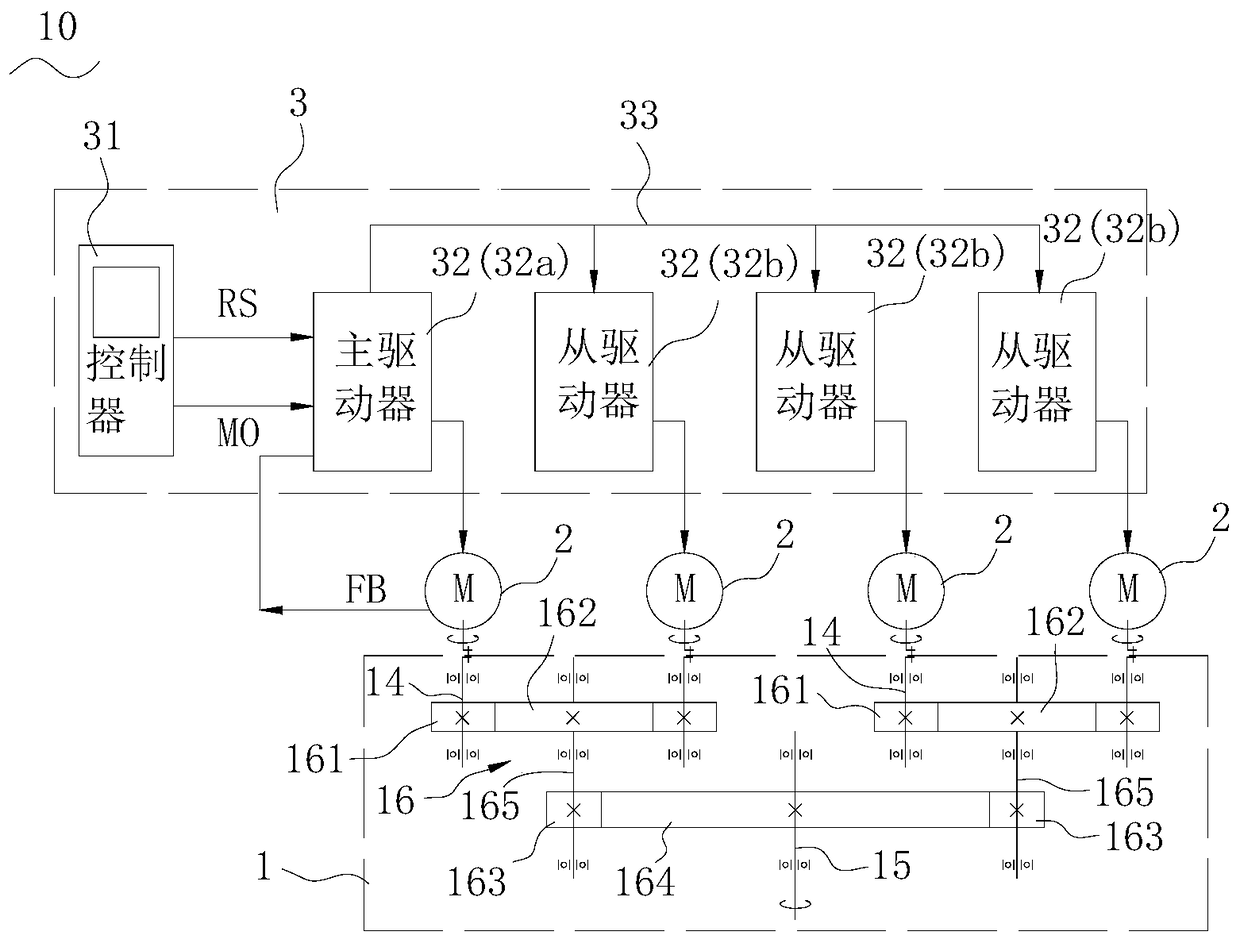

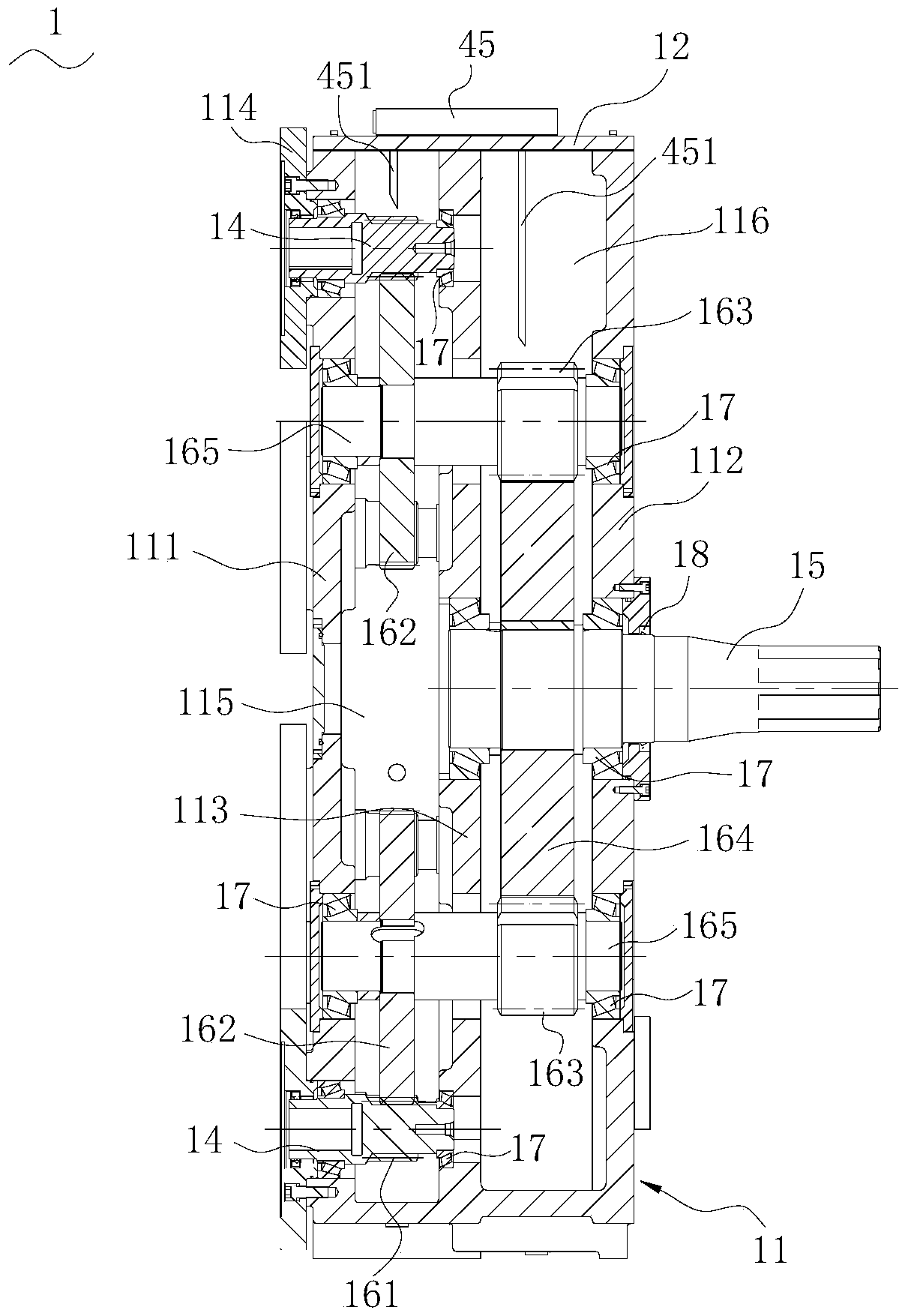

Driving device and injection molding machine provided with driving device

The invention provides a driving device and an injection molding machine provided with the driving device. The driving device comprises a speed reducer and a plurality of servo motors. The speed reducer is provided with a plurality of input shafts, an output shaft and a gear set. The gear set is connected between the input shafts and the output shaft and used for decelerating and synthesizing movement input of the input shafts and transmitting the movement input of the input shafts to the output shaft for single-shaft output. Output shafts of the servo motors are connected with the input shafts of the speed reducer correspondingly, so that movement input to the input shafts of the speed reducer is achieved. The driving device is used for driving a screw in a charge pipe assembly in the injection molding machine. According to the driving device and the injection molding machine provided with the driving device, the effect that input of the relatively-small-torque servo motors forms single large-torque output is achieved, and the torque requirement for screw driving of the large injection molding machine is met.

Owner:震雄机械(深圳)有限公司

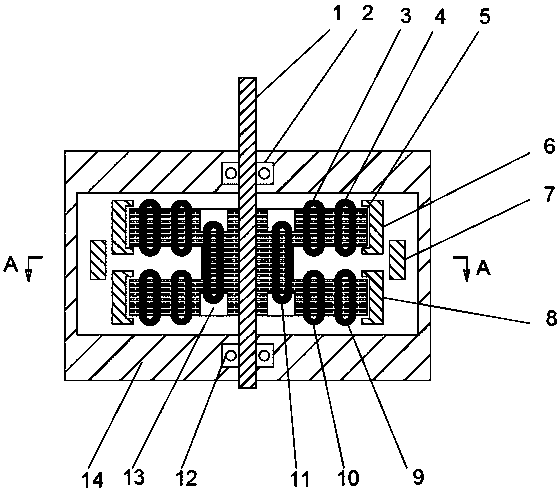

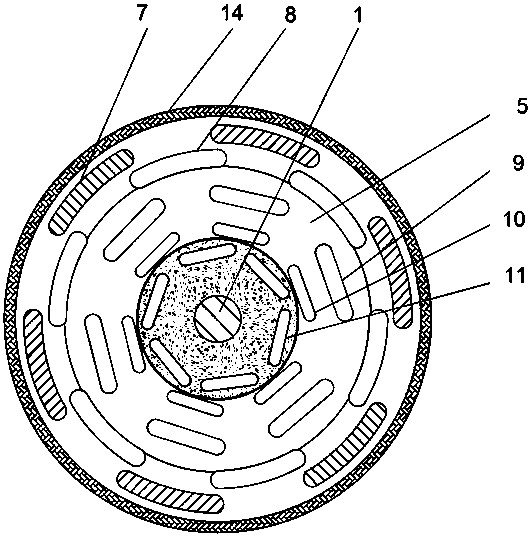

A high-torque motor for multi-rotor drones

ActiveCN107919748BIncrease effective torqueMeet torque demandsMagnetic circuit rotating partsMagnetic circuit stationary partsRotary wingVoltage

The invention discloses a high-torque motor for a multi-rotor unmanned aerial vehicle. The high-torque motor comprises a shell, a drive shaft, an electric brush and a commutator, wherein the commutator is in contact connection with the electric brush and is arranged on the drive shaft; a middle segment, located in the shell, of the drive shaft is fixedly sleeved with a rotor main body formed by superposing multiple silicon steel sheets; the rotor main body is provided with a winding group formed by multiple windings; and a corresponding permanent magnet group is arranged at the position, closeto the inner wall of the shell, on the outer circumference, employing the drive shaft as the circle center, of any layer of winding in the winding group. The magnetic field can be strengthened underthe condition of the same voltage supply through correspondingly adding the multiple windings and permanent magnets, thereby increasing the torque; and furthermore, multiple layers of windings are arranged along the direction of the drive shaft in a staggered manner, so that the problem of a dead angle in a gap between magnetic force and driving force can be solved and torque output is more linearand stable.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

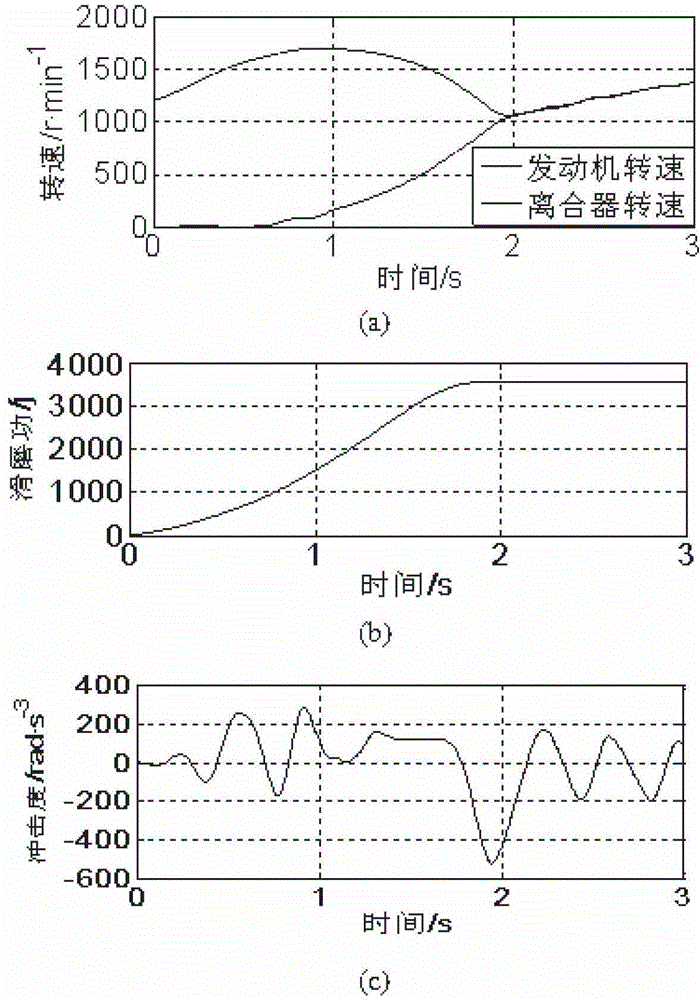

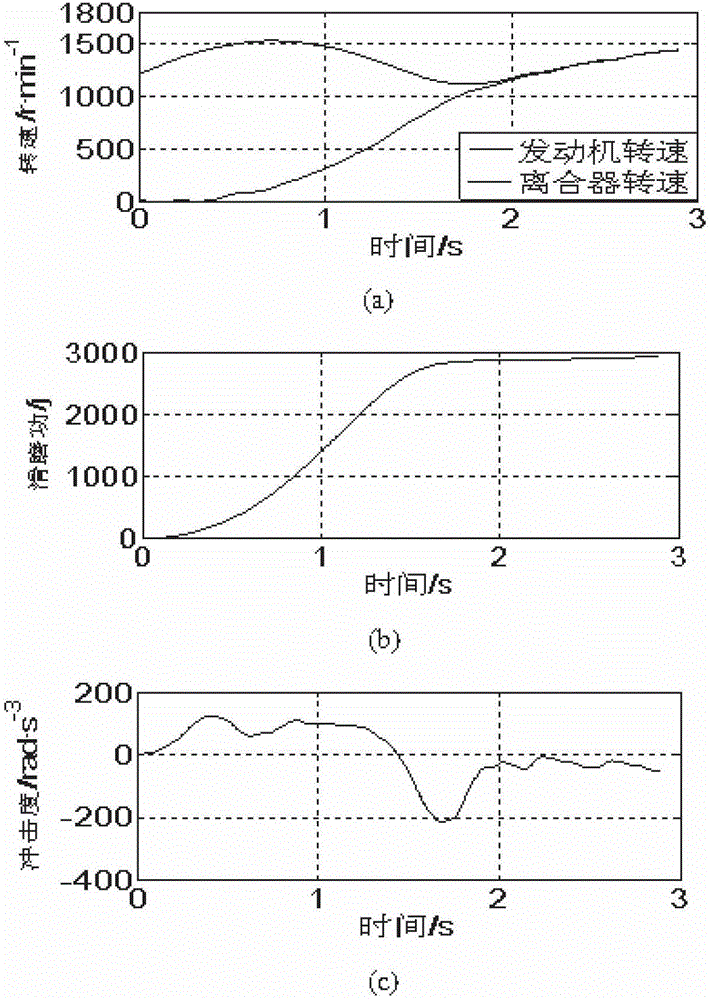

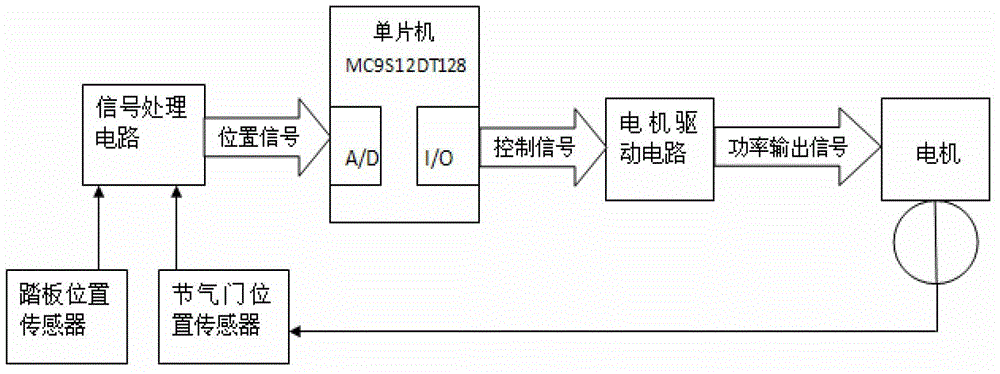

A vehicle starting control method for reducing fuel consumption

InactiveCN102910169BReduce shockReduce fuel consumptionInternal combustion piston enginesMicrocontrollerFriction torque

The invention relates to a vehicle starting-up control method, particularly relates to a vehicle starting-up control method capable of reducing oil consumption, and aims at solving the problems of over-high engine rotation speed, larger impact and increase of sliding friction work and oil consumption possibly caused by improper operation by a driver during starting up of the vehicle. According to the method, the relation between engine torque and clutch friction torque during starting up of a vehicle is analyzed and studied, an electronic throttle and a clutch position sensor are additionally arranged on a manual shift automobile, and an electronic throttle control system which uses a microprogrammed control unit as the control core, and uses the clutch release bearing position, the engine rotation speed and the rotation speed of a gearbox input shaft as the input signals is developed to coordinately control the engine torque and the clutch friction torque during the starting up of a vehicle so as to realize the comprehensive control of the impact and sliding friction work during starting up of the vehicle and improve the oil economy and riding comfort during the starting up of the vehicle.

Owner:BEIJING UNIV OF TECH

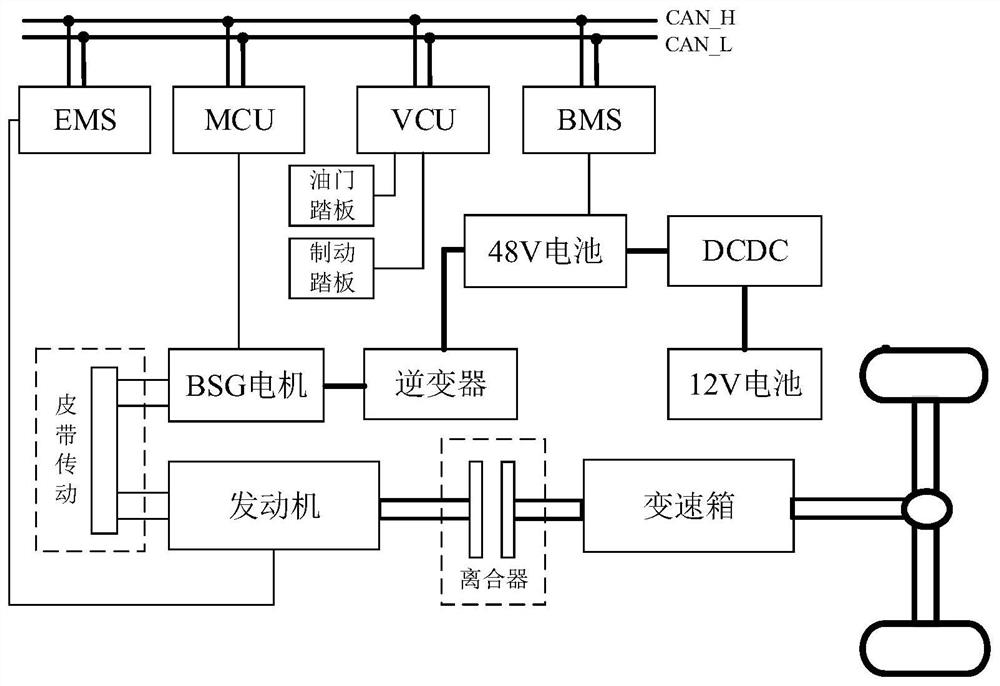

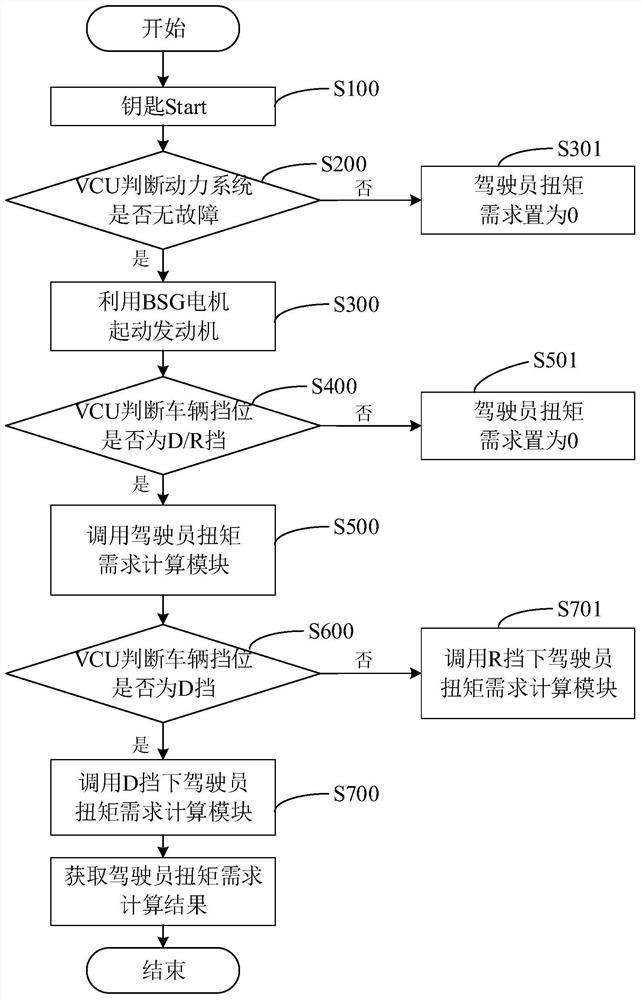

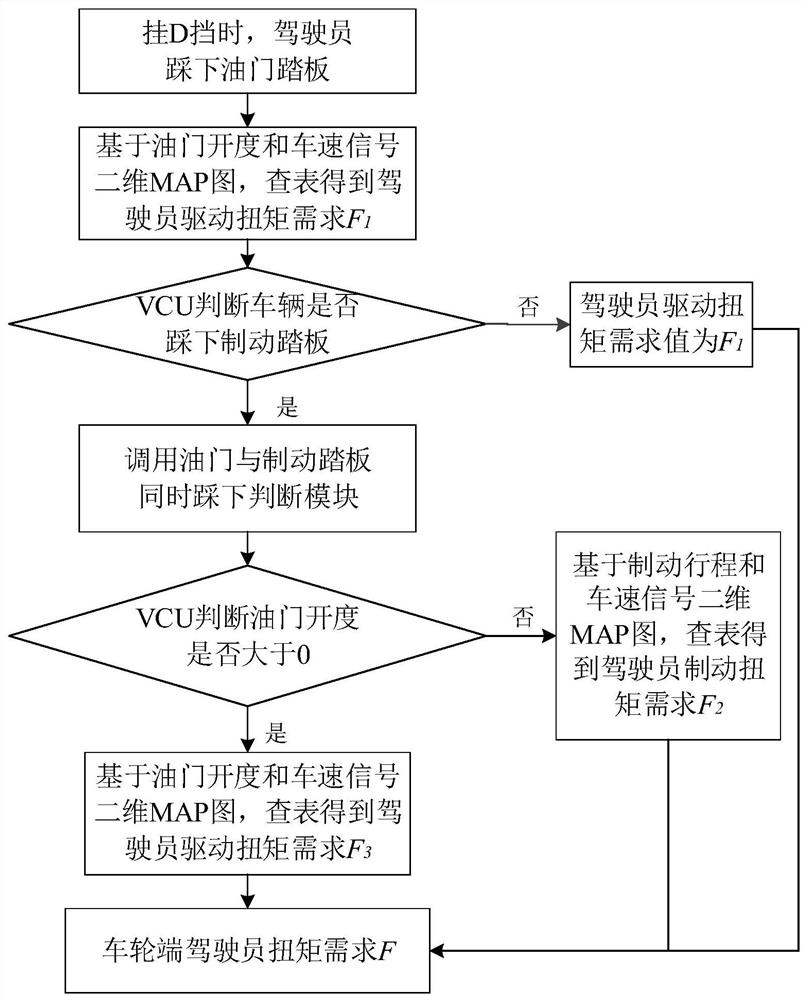

Calculation method, storage medium and vehicle for driver's torque demand of mild hybrid power system

The invention relates to the technical field of vehicle power control, in particular to a method for calculating driver torque demand of a mild hybrid system, a storage medium and a vehicle. In the method for calculating the torque demand of the driver of the mild hybrid system, firstly, it is judged whether the power system is fault-free, and if the power system is fault-free, the engine is started; it is judged whether the vehicle gear is in the D gear or the R gear; if the vehicle gear is in the D gear or R gear, the driver’s torque demand calculation module is called to output the calculation result of the driver’s torque demand. This method can accurately and effectively calculate the torque demand of the driver of the power system, meet the driving demand of the driver, and improve the vehicle control performance . The computer-readable storage medium can realize the above method, and accurately and effectively calculate the torque demand of the driver of the power system. The vehicle can realize the above method, meet the driving needs of the driver, and improve the control performance of the whole vehicle.

Owner:CHINA FIRST AUTOMOBILE

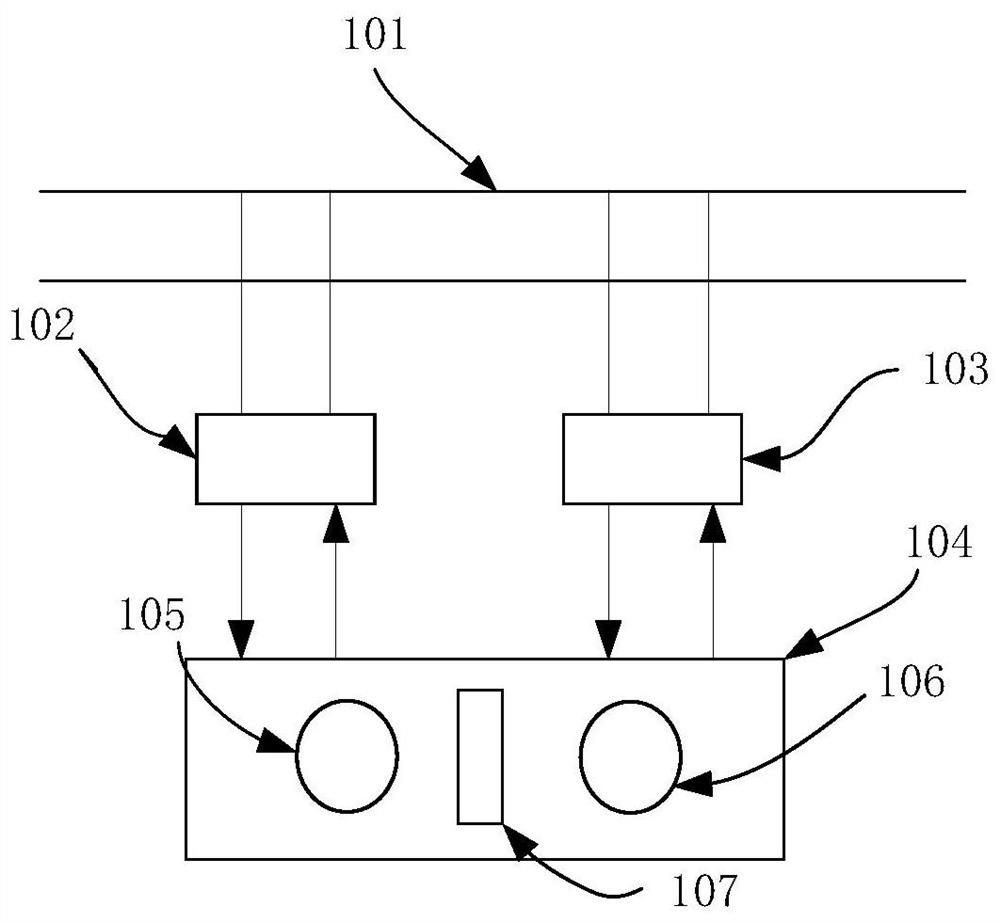

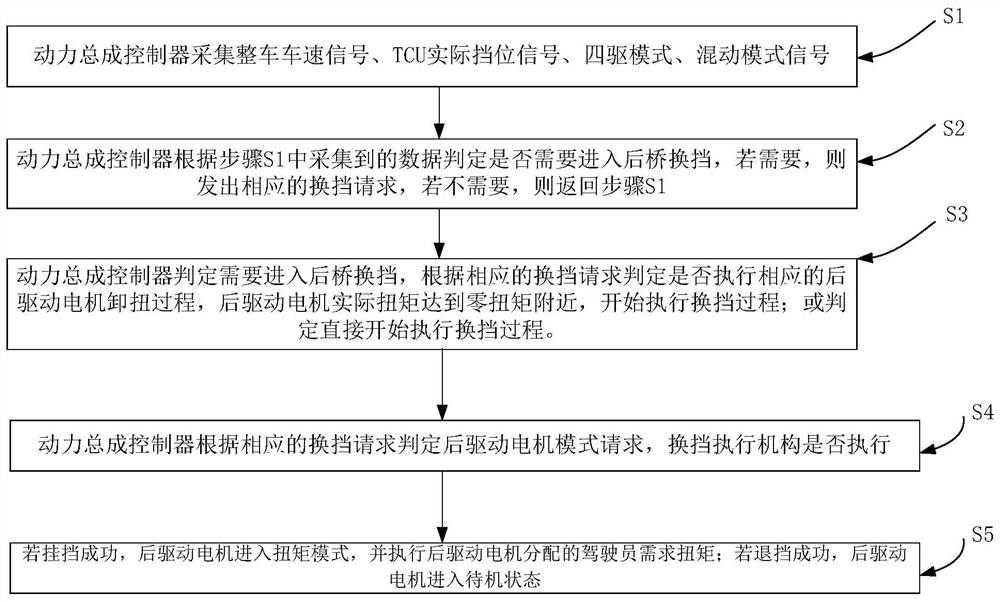

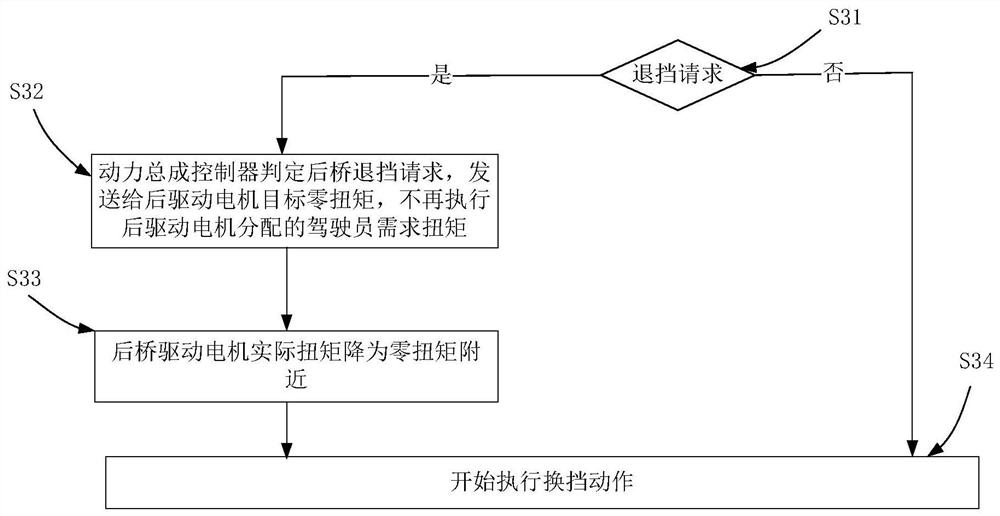

Method for Controlling Rear Axle Clutch of Hybrid Electric Vehicle

ActiveCN112303223BExtended service lifeMeet Torque DemandsGearing controlClutch controlElectric machinery

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method and system for engine control

ActiveCN107345500BMeet Torque DemandsReduce economic lossHybrid vehiclesElectrical controlLow speedControl theory

The present invention relates to methods and systems for engine control. Methods and systems are provided for enhancing the benefits of variable compression ratio engines in hybrid vehicle systems. During engine pull-up and pull-down, the vehicle controller may maintain the engine at a lower compression ratio, especially when passing through low speed regions where compression bounce can occur. During engine operation, in response to changes in driver demand, the controller may choose to switch the compression ratio or maintain the current compression ratio while using motor torque to smooth undertorque, the selection being based on fuel economy.

Owner:FORD GLOBAL TECH LLC

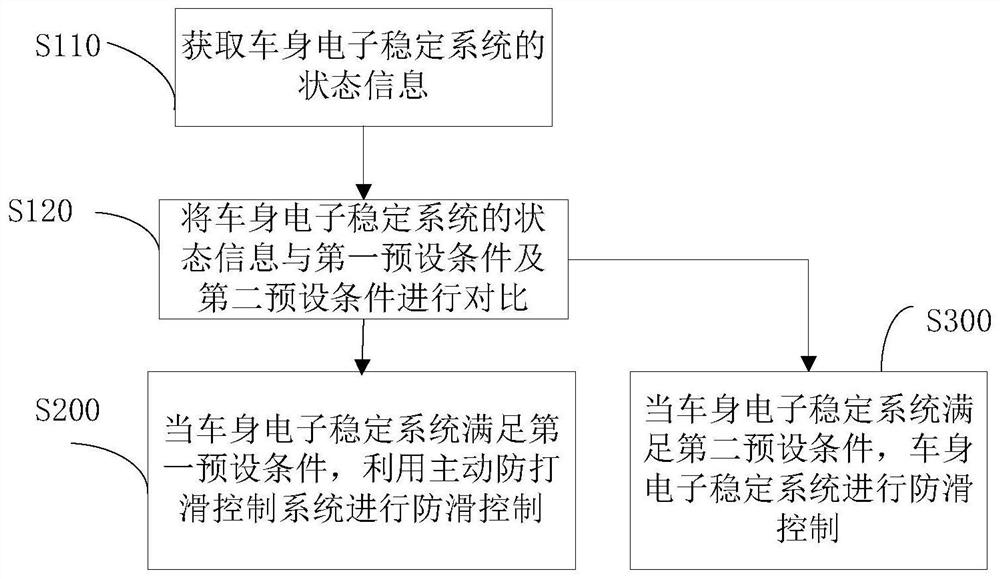

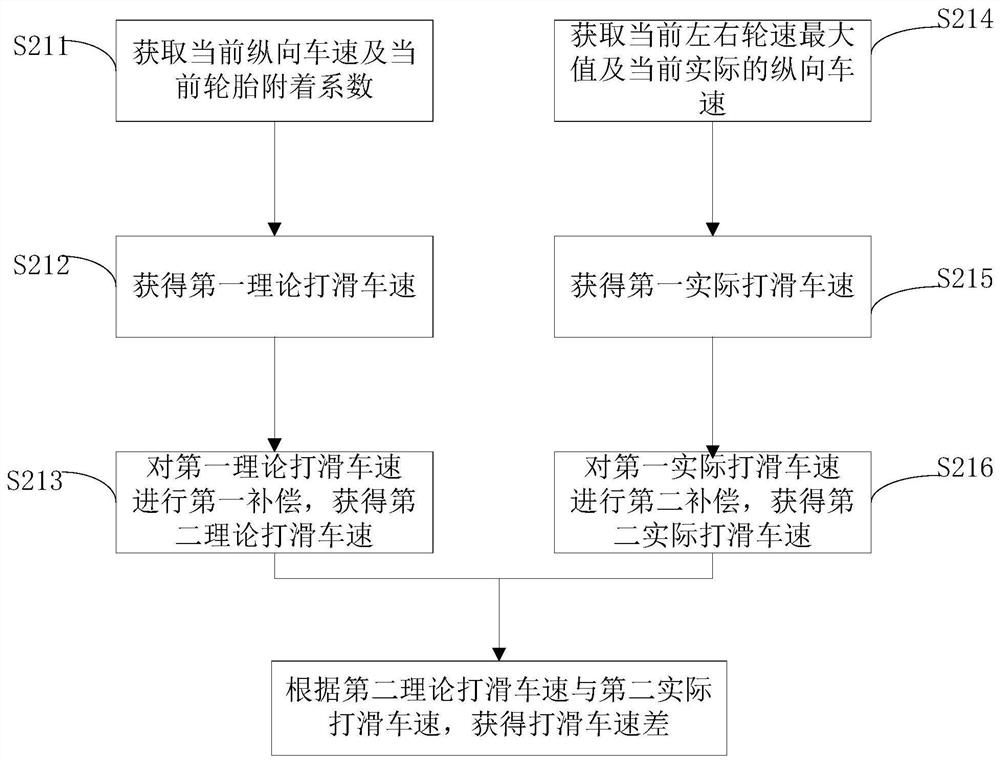

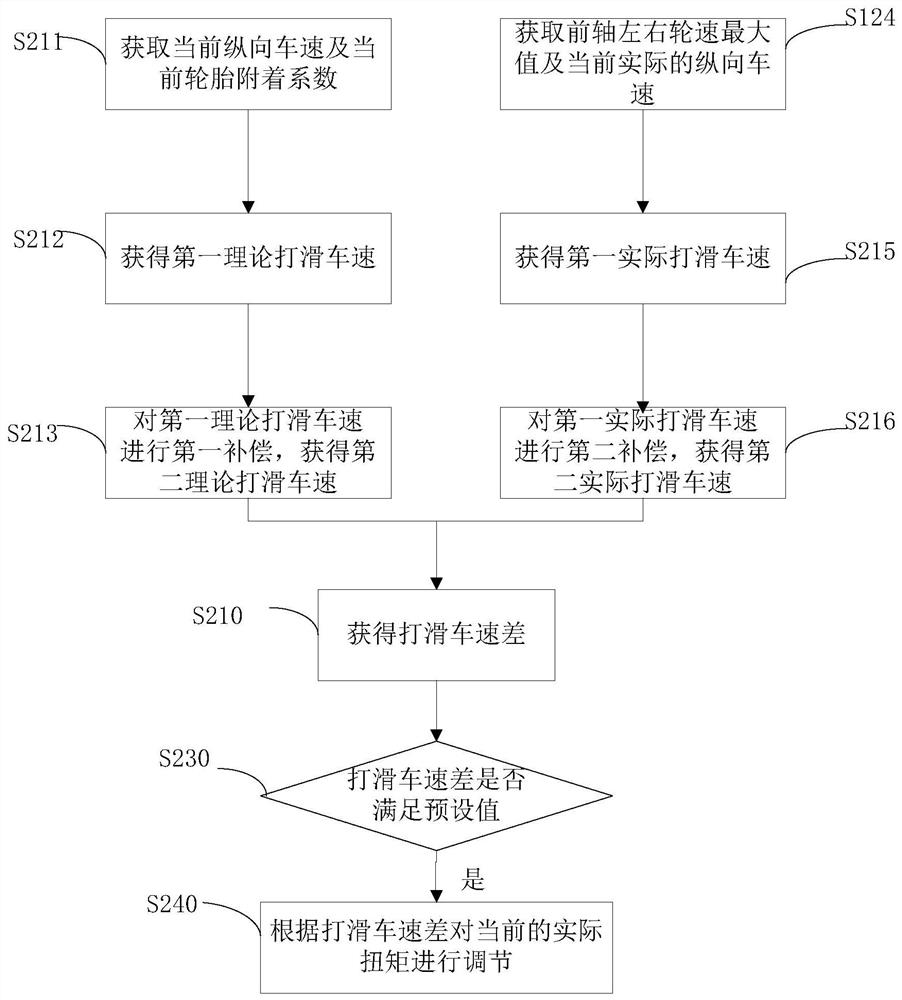

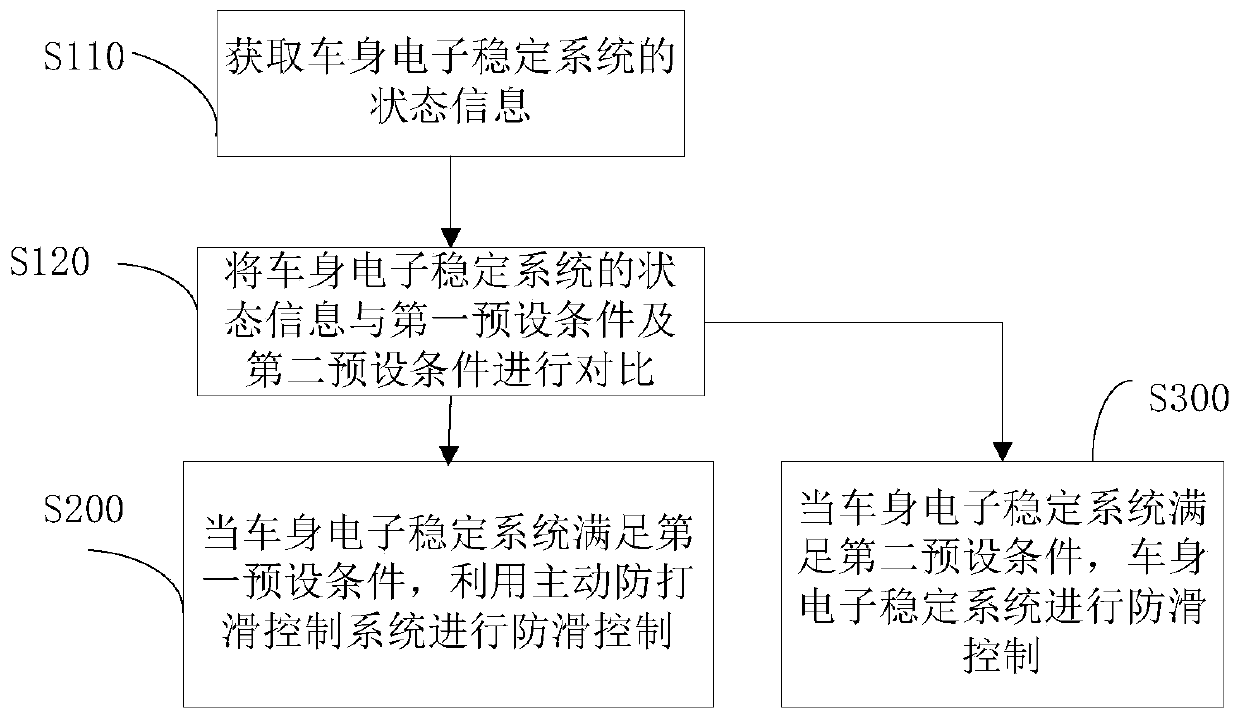

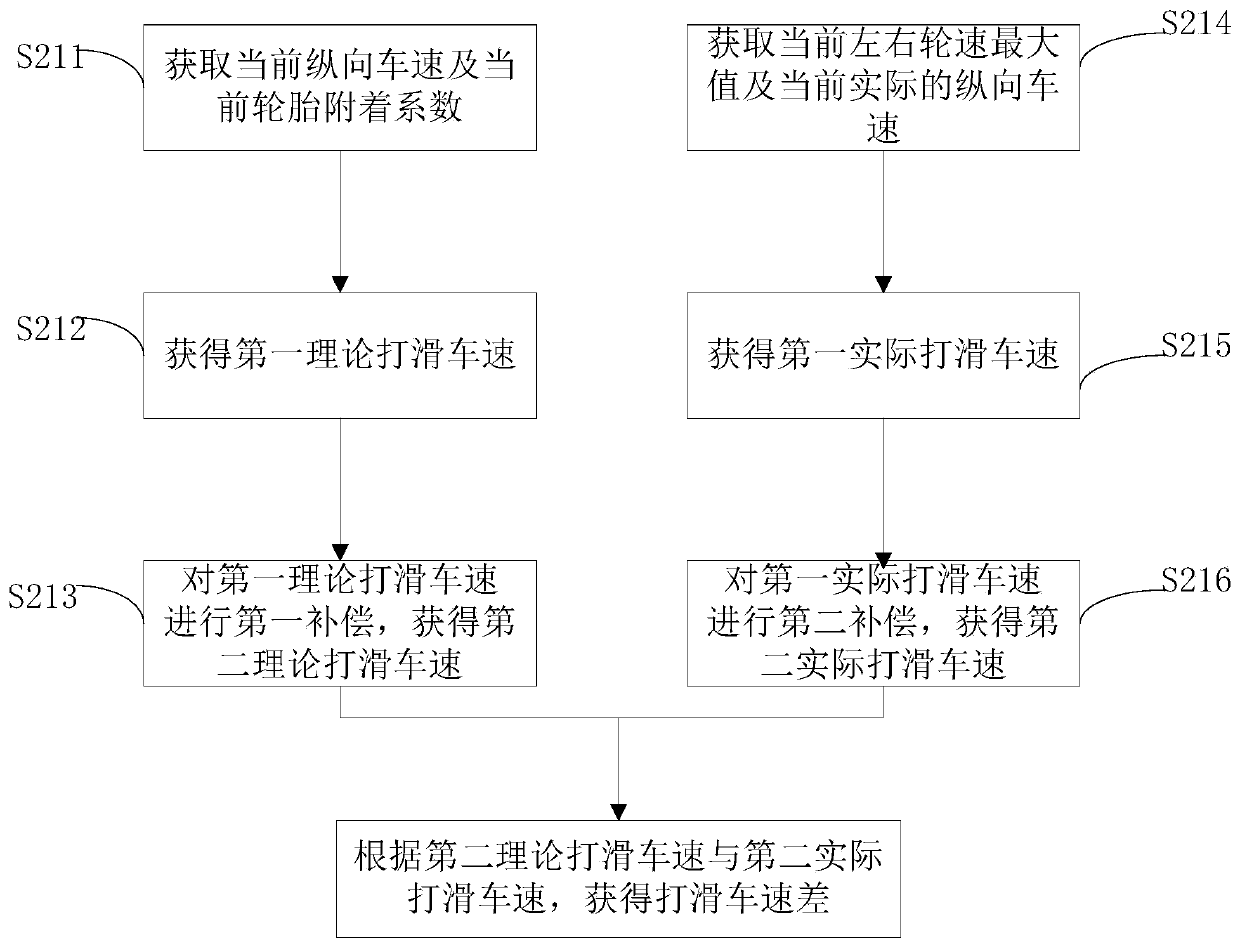

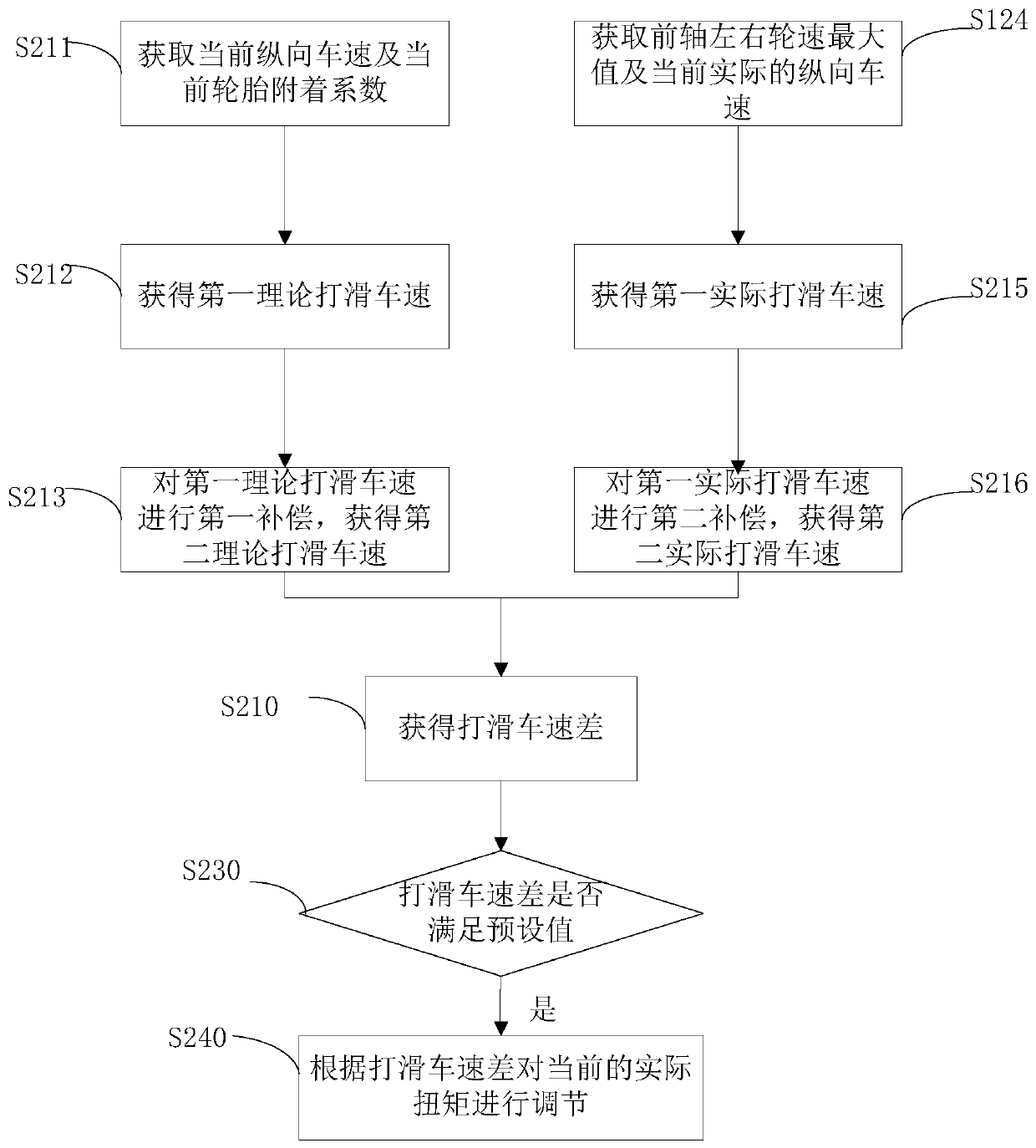

Anti-skid control method and system

The invention discloses an anti-skid control method, which is applied to an anti-skid control system. The system includes an electronic stability system of a vehicle body and an active anti-skid control system. The method includes: acquiring state information of the electronic stability system of a vehicle body; Information comparison between the first preset condition and the second preset condition; when the first preset condition is met, the active anti-skid control system is used for anti-skid control; when the second preset condition is met, the body electronic stability system is used for anti-skid control; active anti-skid The anti-slip control of the control system includes: acquiring the slipping vehicle speed difference; comparing the slipping vehicle speed difference with a preset value; and adjusting the actual torque according to the slipping vehicle speed difference when the preset value is not satisfied. The invention does not affect ESP, adds an active anti-skid control system, and drives safer. The active anti-skid control system directly calculates and distributes torque for faster response. By adding mode compensation, the skidding speed calculation is more accurate. The invention discloses an antiskid control system.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

A startup control method and system

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Planetary gear electrically-driven force joining device

PendingCN112709790ASmall installation space requirementRealize multi-dynamic couplingGearboxesToothed gearingsElectric machineGear wheel

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

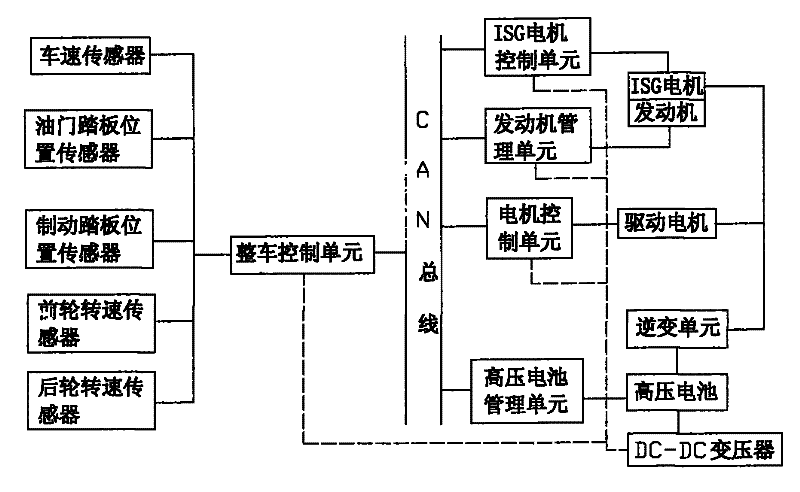

Four-wheel driven hybrid vehicle driving system and driving management method thereof

ActiveCN101570131BGuaranteed safe electricityMeet Torque DemandsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDriver/operatorDrive motor

Owner:CHERY AUTOMOBILE CO LTD

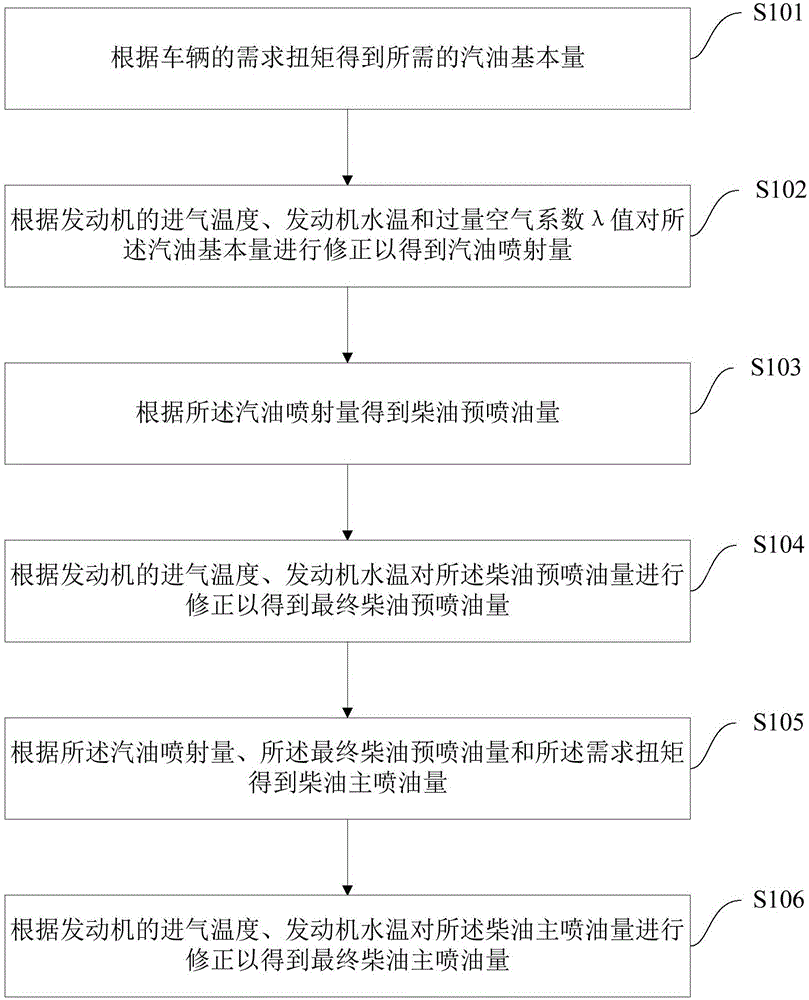

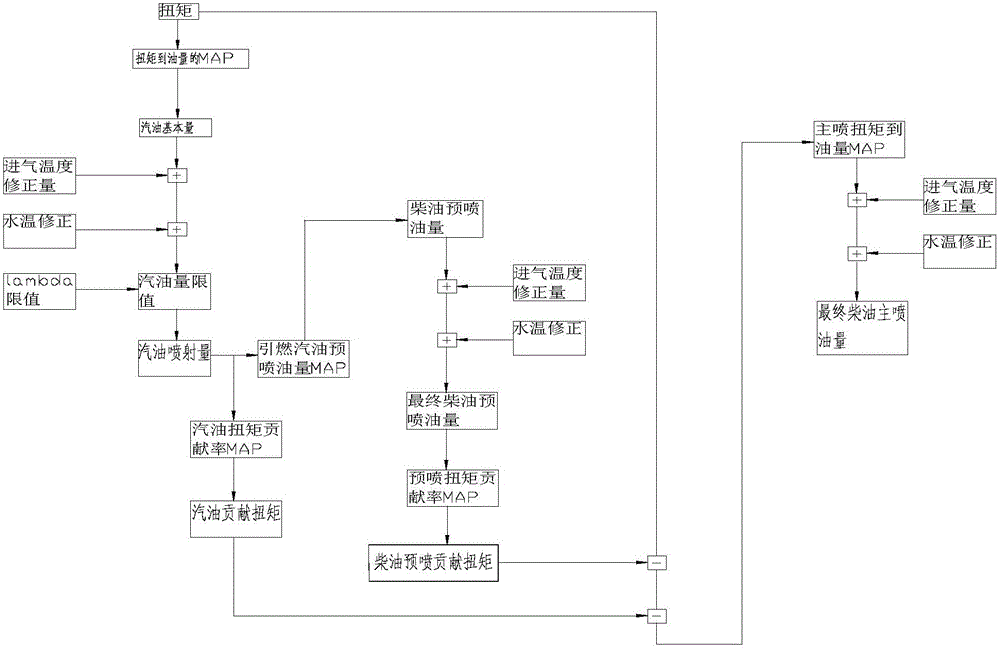

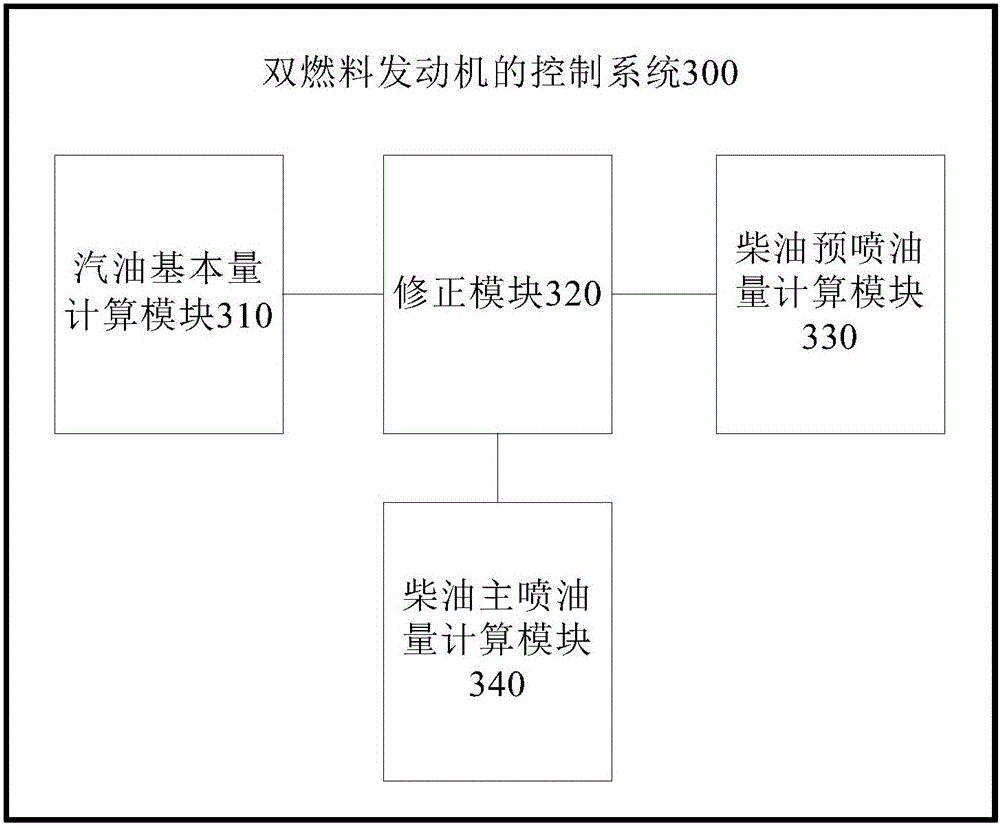

Control method and system for dual-fuel engine

ActiveCN104033257BImprove work efficiencyMeet Torque DemandsEngine controllersMachines/enginesControl systemGasoline

Owner:GREAT WALL MOTOR CO LTD

Electrically assisted turbocharging system and control method thereof

ActiveCN105927370BMeet Torque DemandsEasy to chargeElectrical controlInternal combustion piston enginesElectricityElectric machine

The invention discloses an electrically-aided turbocharging system, and belongs to the technical field of turbocharging. The invention aims at providing an optimized electrically-aided turbocharging system adequately utilizing a turbine body structure, and a control method thereof. One end of the electrically-aided turbocharger disclosed by the invention is installed at an inlet end of an intake channel, and the other end of the electrically-aided turbocharger is installed at an outlet end of an exhaust channel; the electrically-aided turbocharger is composed of an aiding high-speed motor, a compressor, a turbocharger rotary shaft, a turbine and a waste gas bypass valve device; an intercooler is installed on the intake channel; an intake branch pipe is connected to a tail end of the intake channel; an exhaust branch pipe is connected to an inlet end of the exhaust channel; a gasoline engine cylinder is directly connected between the intake branch pipe and the exhaust branch pipe; the exhaust channel behind the exhaust branch pipe is divided into a first passage and a second passage which are connected in parallel; and tail ends of the first passage and the second passage both communicate with an outlet pipeline. According to the electrically-aided turbocharging system disclosed by the invention, the high-speed motor is combined with the turbocharger with the waste gas bypass valve, thus the influence of waste gas turbocharging for the performance of a gasoline engine is furthest utilized.

Owner:JILIN UNIV

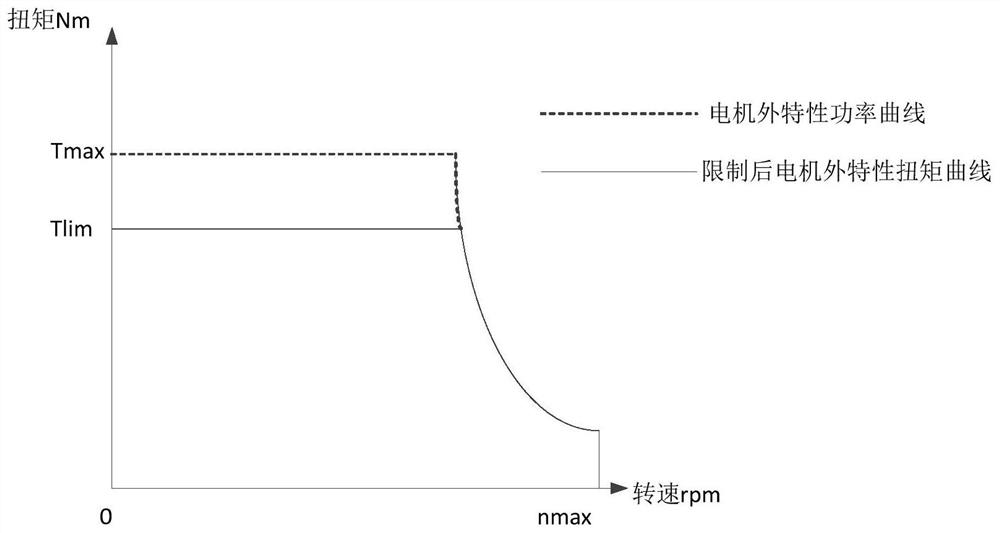

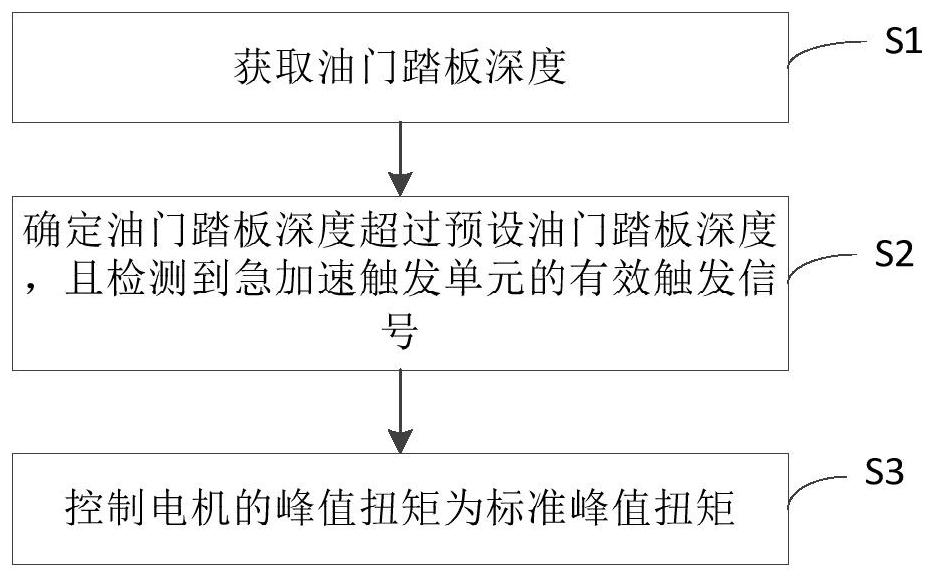

Method for controlling rapid acceleration of vehicle, storage medium and vehicle

PendingCN113928128AMeet power requirementsAvoid power requirementsSpeed controllerDriver interactionsElectrical batteryElectric machinery

The invention provides a method for controlling rapid acceleration of a vehicle, a computer storage medium and the vehicle. The method for controlling rapid acceleration of the vehicle comprises steps of the depth of an accelerator pedal being obtained; determining that the depth of the accelerator pedal exceeds a preset depth of the accelerator pedal, and detecting an effective trigger signal of the rapid acceleration trigger unit; and controlling the peak torque of the motor to be the standard peak torque. According to the method for controlling rapid acceleration of the vehicle, driving safety is improved while the power requirement is met, the service life of a motor, an electric controller and a battery is prolonged to a certain degree, a user can trigger the rapid acceleration function through a switch, and the user experience is improved.

Owner:BYD CO LTD

Anti-slip control method and system

The invention discloses an anti-slip control method which is applied to an anti-slip control system. The system comprises a vehicle body electronic stabilization system and an active anti-slip controlsystem, and the method comprises the following steps: acquiring state information of the vehicle body electronic stabilization system; comparing the state information of the vehicle body electronic stabilization system with first preset condition and second preset condition information; when the first preset condition is met, using an active anti-slip control system for carrying out anti-slip control; and when the second preset condition is met, using the vehicle body electronic stabilization system for anti-slip control. The anti-slip control method of the active anti-slip control system comprises the steps of: obtaining the slip vehicle speed difference; comparing the slip vehicle speed difference with a preset value; and when the preset value is not met, adjusting the actual torque according to the slip vehicle speed difference. The ESP is not affected, the active anti-slip control system is added, and driving is safer. The active anti-slip control system directly calculates the torque and distributes the torque, and the response is faster. Mode compensation is added, so that slipping speed calculation is more accurate. The invention discloses an anti-slip control system.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

Underground signal receiving and transmitting device

ActiveCN113482606AQuality improvementImprove decoding performanceSurveyTransmissionThermodynamicsWell drilling

Owner:SOUTHWEST PETROLEUM UNIV +1

Driving device and injection molding machine with the driving device

The invention provides a driving device and an injection molding machine provided with the driving device. The driving device comprises a speed reducer and a plurality of servo motors. The speed reducer is provided with a plurality of input shafts, an output shaft and a gear set. The gear set is connected between the input shafts and the output shaft and used for decelerating and synthesizing movement input of the input shafts and transmitting the movement input of the input shafts to the output shaft for single-shaft output. Output shafts of the servo motors are connected with the input shafts of the speed reducer correspondingly, so that movement input to the input shafts of the speed reducer is achieved. The driving device is used for driving a screw in a charge pipe assembly in the injection molding machine. According to the driving device and the injection molding machine provided with the driving device, the effect that input of the relatively-small-torque servo motors forms single large-torque output is achieved, and the torque requirement for screw driving of the large injection molding machine is met.

Owner:震雄机械(深圳)有限公司

Split weld cage nut assembly

Owner:ACUMENT INTPROP LLC

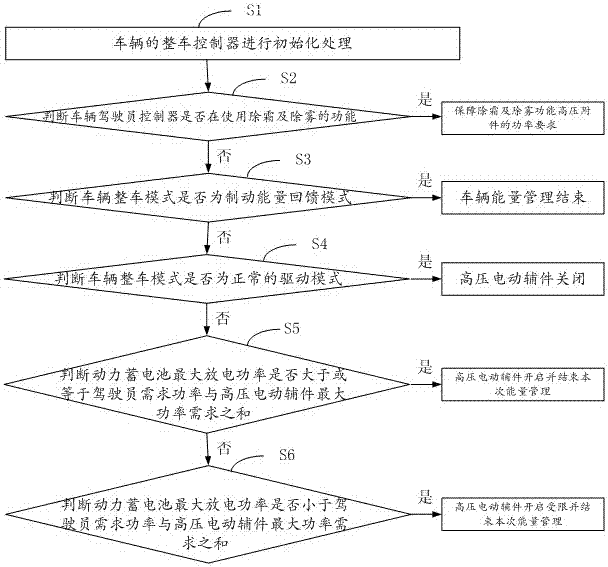

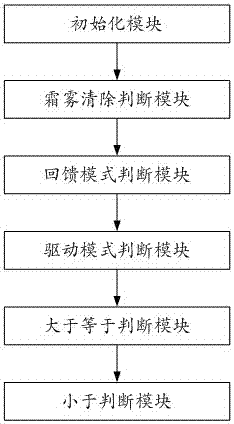

Energy management method and system for a pure electric vehicle

ActiveCN104842796BMeet Torque DemandsEffective protectionElectric powerVehicular energy storageEngineeringHigh pressure

The invention relates to an energy management method of a BEV (Blade Electric Vehicles). The method comprises the steps: A, judging whether a driver of a vehicle uses the functions of defrosting and defogging of a vehicle control unit; B, judging whether the vehicle control unit is in a brake energy feedback mode; C, judging whether the vehicle control unit is in a normal drive mode; D, judging whether the maximum discharge power of a power storage battery is greater than or equal to the sum of the demanding power of the driver and the maximum power demand of a high voltage electric accessory; E, judging whether the maximum discharge power of the power storage battery is less than the sum of the demand power of the driver and the maximum power demand of the high voltage electric accessory. The torque demand of the driver can be optimally met by judging the power demand of the driver, the existing state of the power storage battery and other information under the precondition that the vehicle safety cannot be affected, the normal driving of the vehicle can be ensured, and the brake energy feedback can be limited to effectively protect the power storage battery; furthermore, the high-efficiency energy use can be realized, and the power storage battery can be effectively protected at the same time.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com